Datasheet NCP1402SN19T1, NCP1402SN27T1, NCP1402SN30T1, NCP1402SN33T1, NCP1402SN40T1 Datasheet (ON) [ru]

...Page 1

NCP1402

200 mA, PFM Step−Up

Micropower Switching

Regulator

The NCP1402 series are monolithic micropower step−up DC to DC

converter that are specially designed for powering portable equipment

from one or two cell battery packs.These devices are designed to

startup with a cell voltage of 0.8 V and operate down to less than

0.3 V. With only three external components, this series allow a simple

means to implement highly efficient converters that are capable of up

to 200 mA of output current at V

Each device consists of an on−chip PFM (Pulse Frequency

Modulation) oscillator, PFM controller, PFM comparator, soft−start,

voltage reference, feedback resistors, driver, and power MOSFET

switch with current limit protection. Additionally, a chip enable

feature is provided to power down the converter for extended battery

life.

The NCP1402 device series are available in the Thin SOT−23−5

package with five standard regulated output voltages. Additional

voltages that range from 1.8 V to 5.0 V in 100 mV steps can be

manufactured.

Features

• Pb−Free Packages are Available

• Extremely Low Startup Voltage of 0.8 V

• Operation Down to Less than 0.3 V

• High Efficiency 85% (V

• Low Operating Current of 30 A (V

• Output Voltage Accuracy ± 2.5%

• Low Converter Ripple with Typical 30 mV

• Only Three External Components Are Required

• Chip Enable Power Down Capability for Extended Battery Life

• Micro Miniature Thin SOT−23−5 Packages

in

= 2.0 V, V

in

= 2.0 V, V

OUT

= 1.9 V)

OUT

= 3.0 V.

OUT

= 3.0 V, 70 mA)

http://onsemi.com

5

1

SOT23−5

(TSOP−5, SC59−5)

SN SUFFIX

CASE 483

PIN CONNECTIONS AND

MARKING DIAGRAM

1

CE

2

OUT

3

NC

xxx = Marking

Y = Year

W = Work Week

(Top View)

ORDERING INFORMATION

See detailed ordering and shipping information in the ordering

information section on page 3 of this data sheet.

xxxYW

5

LX

GND

4

T ypical Applications

• Cellular Telephones

• Pagers

• Personal Digital Assistants (PDA)

• Electronic Games

• Portable Audio (MP3)

• Camcorders

• Digital Cameras

• Handheld Instruments

Semiconductor Components Industries, LLC, 2004

October, 2004 − Rev. 6

1 Publication Order Number:

NCP1402/D

Page 2

NCP1402

1

CE

Chi Enable in

() g q g

OUT

NC

GND

V

in

CE

OUT

NC

1

NCP1402

2

3

LX

5

GND

4

V

OUT

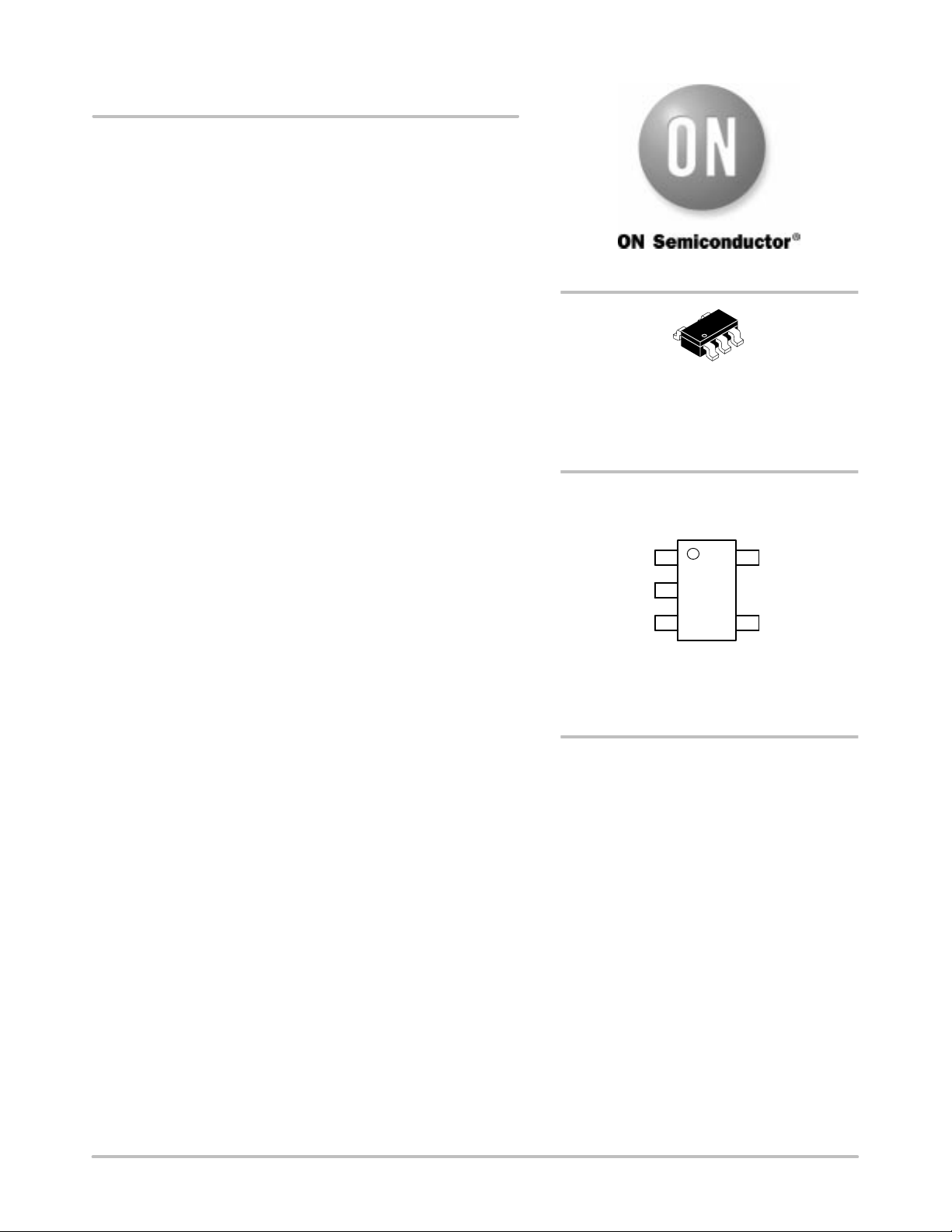

Figure 1. T ypical Step−Up Converter Application

2

PFM

COMPARATOR

−

3

REFERENCE

4

+

VOLTAGE

SOFT−START

VLX LIMITER

DRIVER

POWER

SWITCH

PFM

CONTROLLER

PFM

OSCILLATOR

LX

5

1 CE

Figure 2. Representative Block Diagram

PIN FUNCTION DESCRIPTIONS

Pin # Symbol Pin Description

1 CE Chip Enable pin

2 OUT Output voltage monitor pin, also the power supply pin of the device

3 NC No internal connection to this pin

4 GND Ground pin

5 LX External inductor connection pin to power switch drain

(1) The chip is enabled if a voltage which is equal to or greater than 0.9 V is applied

(2) The chip is disabled if a voltage which is less than 0.3 V is applied

(3) The chip will be enabled if it is left floating

http://onsemi.com

2

Page 3

NCP1402

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ORDERING INFORMATION

Device Output Voltage Device Marking Package Shipping

NCP1402SN19T1 1.9 V DAU

NCP1402SN27T1 2.7 V DAE

NCP1402SN30T1 3.0 V DAF

SOT23−5

NCP1402SN33T1 3.3 V DAG

NCP1402SN33T1G 3.3 V DAG SOT23−5

(Pb−Free)

3000 Units Per Reel

NCP1402SN40T1 4.0 V DCR

NCP1402SN50T1 5.0 V DAH

NCP1402SN50T1G 5.0 V DAH

SOT23−5

SOT23−5

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

NOTE: The ordering information lists five standard output voltage device options. Additional device with output voltage ranging from 1.8 V to

5.0 V in 100 mV increments can be manufactured. Contact your ON Semiconductor representative for availability.

ABSOLUTE MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage (Pin 2)

Input/Output Pins

БББББББББББББББББББББ

LX (Pin 5)

LX Peak Sink Current

БББББББББББББББББББББ

CE (Pin 1)

Input Voltage Range

БББББББББББББББББББББ

Input Current Range

Thermal Resistance, Junction−to−Air

Operating Ambient Temperature Range (Note 2)

Operating Junction Temperature Range

Storage Temperature Range

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously . If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

NOTES:

1. This device series contains ESD protection and exceeds the following tests:

Human Body Model (HBM) ±2.0 kV per JEDEC standard: JESD22−A114.

Machine Model (MM) ±200 V per JEDEC standard: JESD22−A115.

2. The maximum package power dissipation limit must not be exceeded.

T

P

D

J(max)

R

JA

T

A

3. Latchup Current Maximum Rating: ±150 mA per JEDEC standard: JESD78.

4. Moisture Sensitivity Level: MSL 1 per IPC/JEDEC standard: J−STD−020A.

V

OUT

ÁÁ

V

LX

I

LX

ÁÁ

V

CE

ÁÁ

I

CE

R

JA

T

A

T

J

T

stg

6.0

ÁÁÁÁ

−0.3 to 6.0

400

ÁÁÁÁ

−0.3 to 6.0

ÁÁÁÁ

−150 to 150

250

−40 to +85

−40 to +125

−55 to +150

†

Á

mA

Á

Á

mA

°C/W

°C

°C

°C

V

V

V

http://onsemi.com

3

Page 4

NCP1402

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

OSCILLATOR

Switch On Time (current limit not asserted)

Switch Minimum Off Time t

Maximum Duty Cycle D

Minimum Startup Voltage (IO = 0 mA) V

Minimum Startup Voltage Temperature Coefficient (TA = −40°C to 85°C) V

Minimum Operation Hold Voltage (IO = 0 mA) V

Soft−Start Time (V

0.8 V) t

OUT

LX (PIN 5)

Internal Switching N−Channel FET Drain Voltage

LX Pin On−State Sink Current (VLX = 0.4 V)

Device Suffix:

19T1

27T1

30T1

33T1

40T1

50T1

Voltage Limit V

Off−State Leakage Current (VLX = 6.0 V, TA = −40°C to 85°C) I

CE (PIN 1)

CE Input Voltage (V

OUT

= V

SET

x 0.96)

High State, Device Enabled

Low State, Device Disabled

CE Input Current (Note 6)

High State, Device Enabled (V

Low State, Device Disabled (V

= VCE = 6.0 V)

OUT

= 6.0 V, VCE = 0 V)

OUT

TOTAL DEVICE

Output Voltage

Device Suffix:

19T1

27T1

30T1

33T1

40T1

50T1

Output Voltage Temperature Coefficient (TA = −40°C to +85°C)

Device Suffix:

19T1

27T1

30T1

33T1

40T1

50T1

Operating Current 2 (V

Off−State Current (V

Operating Current 1 (V

= VCE = V

OUT

= 5.0 V, VCE = 0 V, TA = −40°C to +85°C, Note 6) I

OUT

= VCE = V

OUT

+0.5 V, Note 5) I

SET

x 0.96)

SET

Device Suffix:

19T1

27T1

30T1

33T1

40T1

50T1

5. V

means setting of output voltage.

SET

6. CE pin is integrated with an internal 10 M pullup resistor.

Symbol Min Typ Max Unit

t

on

off

MAX

start

start

hold

SS

V

LX

I

LX

LXLIM

LKG

3.6 5.5 7.6 s

1.0 1.45 1.9 s

70 78 85 %

− 0.8 0.95 V

− −1.6 − mV/°C

0.3 − − V

0.3 2.0 − ms

− − 6.0 V

mA

110

130

130

130

130

130

145

180

190

200

210

215

−

−

−

−

−

−

0.45 0.65 0.9 V

− 0.5 1.0 A

V

V

CE(high)

V

CE(low)

0.9

−

−

−

−

0.3

A

I

CE(high)

I

CE(low)

V

OUT

V

OUT

DD2

OFF

I

DD1

−0.5

−0.5

1.853

2.632

2.925

3.218

3.900

4.875

−

−

−

−

−

−

0

0.15

1.9

2.7

3.0

3.3

4.0

5.0

150

150

150

150

150

150

0.5

0.5

1.948

2.768

3.075

3.383

4.100

5.125

−

−

−

−

−

−

− 13 15 A

− 0.6 1.0 A

−

−

−

−

−

−

30

39

42

45

55

70

50

60

60

60

100

100

V

ppm/°C

A

http://onsemi.com

4

Page 5

NCP1402

2.1

2.0

1.9

1.8

, OUTPUT VOLTAGE (V)

1.7

OUT

V

1.6

0

Vin = 0.9 V

I

O

Vin = 1.2 V

604020

80 100 120 140 160 180 200 0 604020 80 100 120 140 160 180 200

, OUTPUT CURRENT (mA)

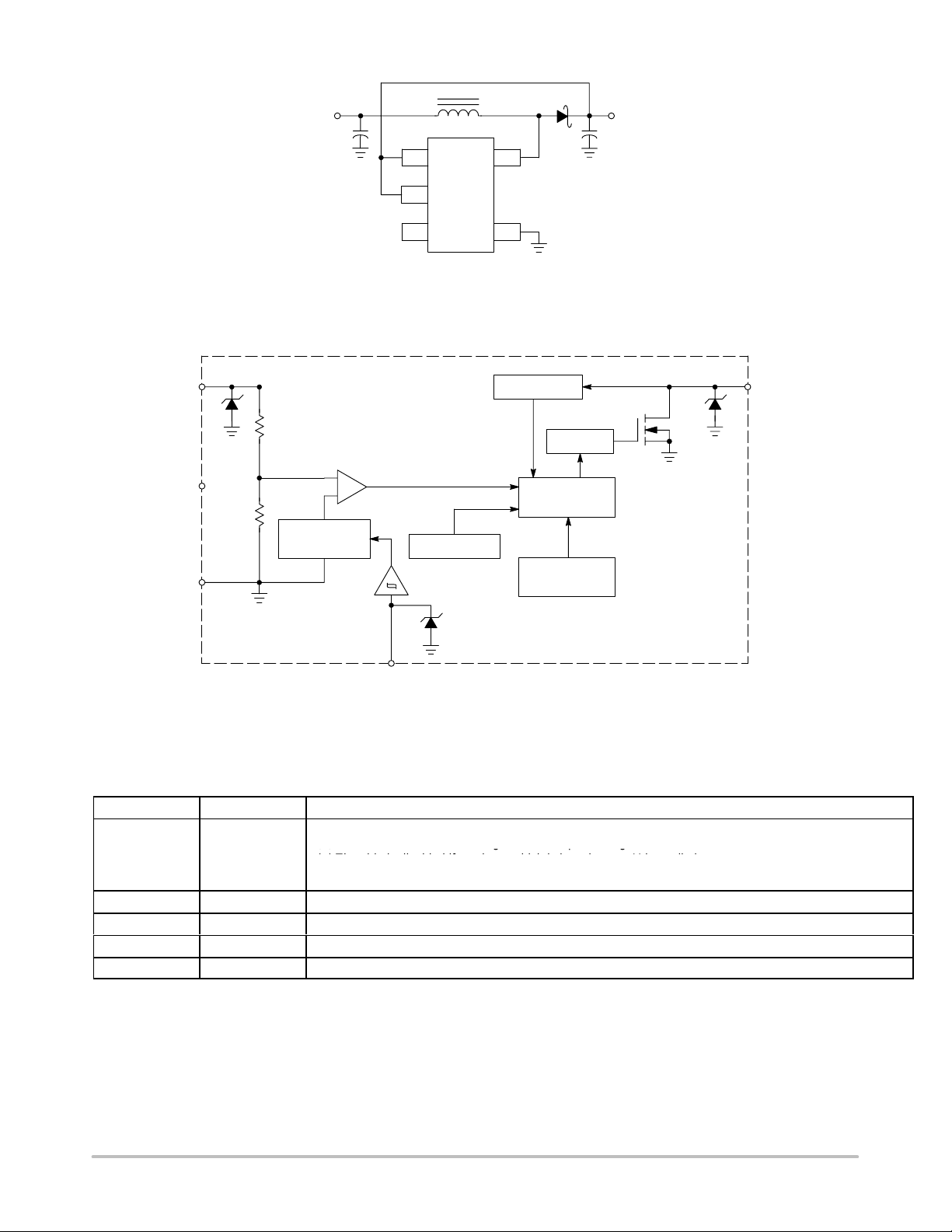

NCP1402SN19T1

L = 47 H

= 25°C

T

A

Vin = 1.5 V

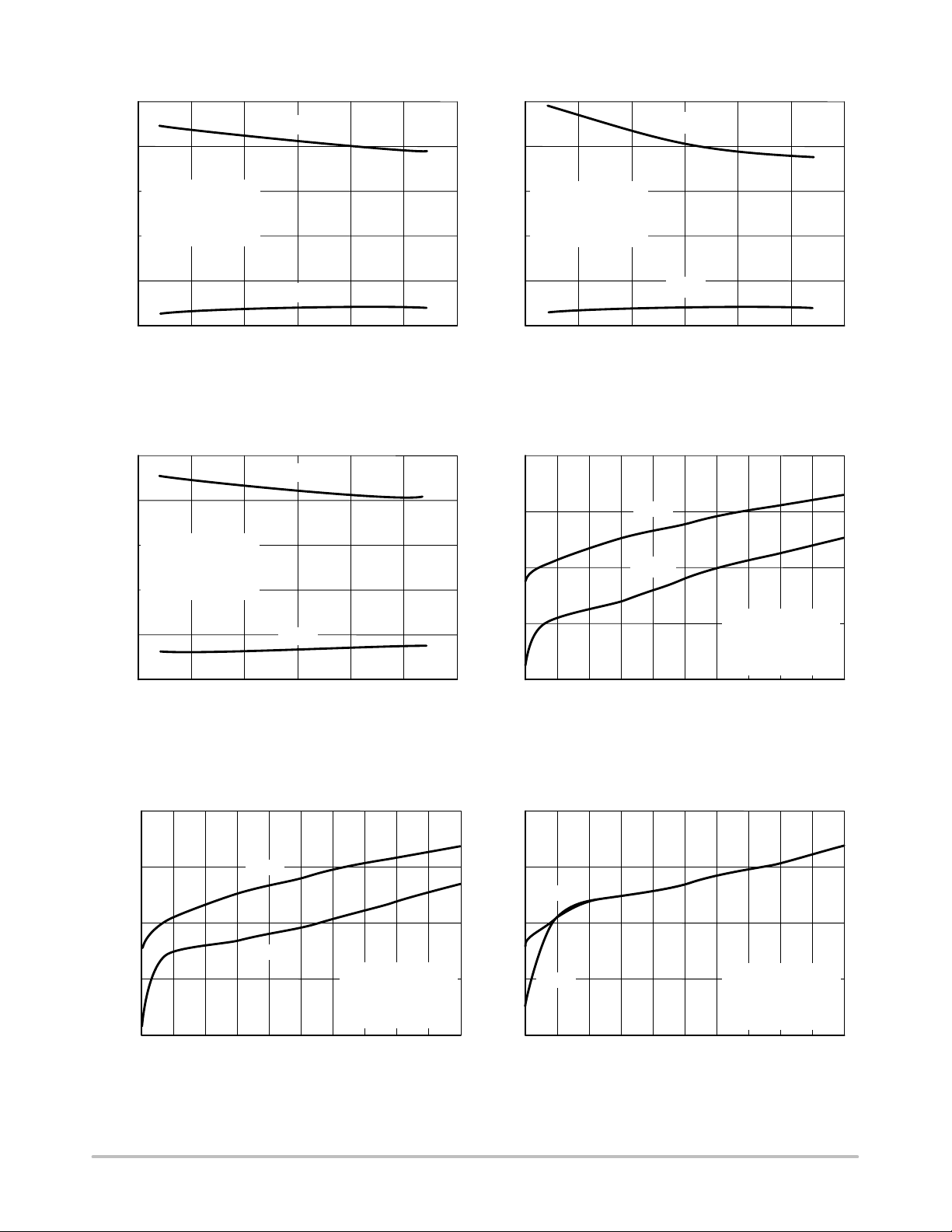

Figure 3. NCP1402SN19T1 Output Voltage vs.

Output Current

6.0

Vin = 4.0 V

5.0

4.0

3.0

, OUTPUT VOLTAGE (V)

2.0

OUT

V

1.0

Vin = 1.2 V

Vin = 0.9 V

NCP1402SN50T1

L = 47 H

T

= 25°C

A

0604020 80 100 120 140 160 180 200 0 604020 80 100 120 140 160 180 200

IO, OUTPUT CURRENT (mA)

Vin = 1.5 V

Vin = 2.0 V

Vin = 3.0 V

4.0

NCP1402SN30T1

L = 47 H

3.5

3.0

2.5

, OUTPUT VOLTAGE (V)

2.0

OUT

V

1.5

= 25°C

T

A

Vin = 0.9 V

Vin = 1.5 V

Vin = 1.2 V

I

, OUTPUT CURRENT (mA)

O

Figure 4. NCP1402SN30T1 Output Voltage vs.

Output Current

100

80

60

40

EFFICIENCY (%)

20

Vin = 0.9 V Vin = 1.2 V

NCP1402SN19T1

L = 47 H

T

= 25°C

A

0

IO, OUTPUT CURRENT (mA)

Vin = 1.5 V

Vin = 2.5 V

Vin = 2.0 V

Figure 5. NCP1402SN50T1 Output Voltage vs.

Output Current

100

Vin = 2.5 V

80

Vin = 2.0 V

60

Vin = 0.9 V Vin = 1.2 V Vin = 1.5 V

40

EFFICIENCY (%)

NCP1402SN30T1

20

L = 47 H

= 25°C

T

A

0

0604020 80 100 120 140 160 180 200

IO, OUTPUT CURRENT (mA)

Figure 7. NCP1402SN30T1 Efficiency vs.

Output Current

100

80

60

40

EFFICIENCY (%)

20

0

http://onsemi.com

5

Figure 6. NCP1402SN19T1 Efficiency vs.

Output Current

Vin = 4.0 V

Vin = 3.0 V

Vin = 1.2 V

Vin = 0.9 V

NCP1402SN50T1

L = 47 H

= 25°C

T

A

0604020 80 100 120 140 160 180 200

IO, OUTPUT CURRENT (mA)

Vin = 1.5 V

Vin = 2.0 V

Figure 8. NCP1402SN50T1 Efficiency vs.

Output Current

Page 6

NCP1402

0

0

2.1

2.0

1.9

1.8

, OUTPUT VOLTAGE (V)

1.7

NCP1402SN19T1

OUT

V

V

= 1.9 V x 0.96

OUT

Open−Loop Test

1.6

−50

250−25

50 75 100 −50 250−25 50 75 10

TEMPERATURE (°C)

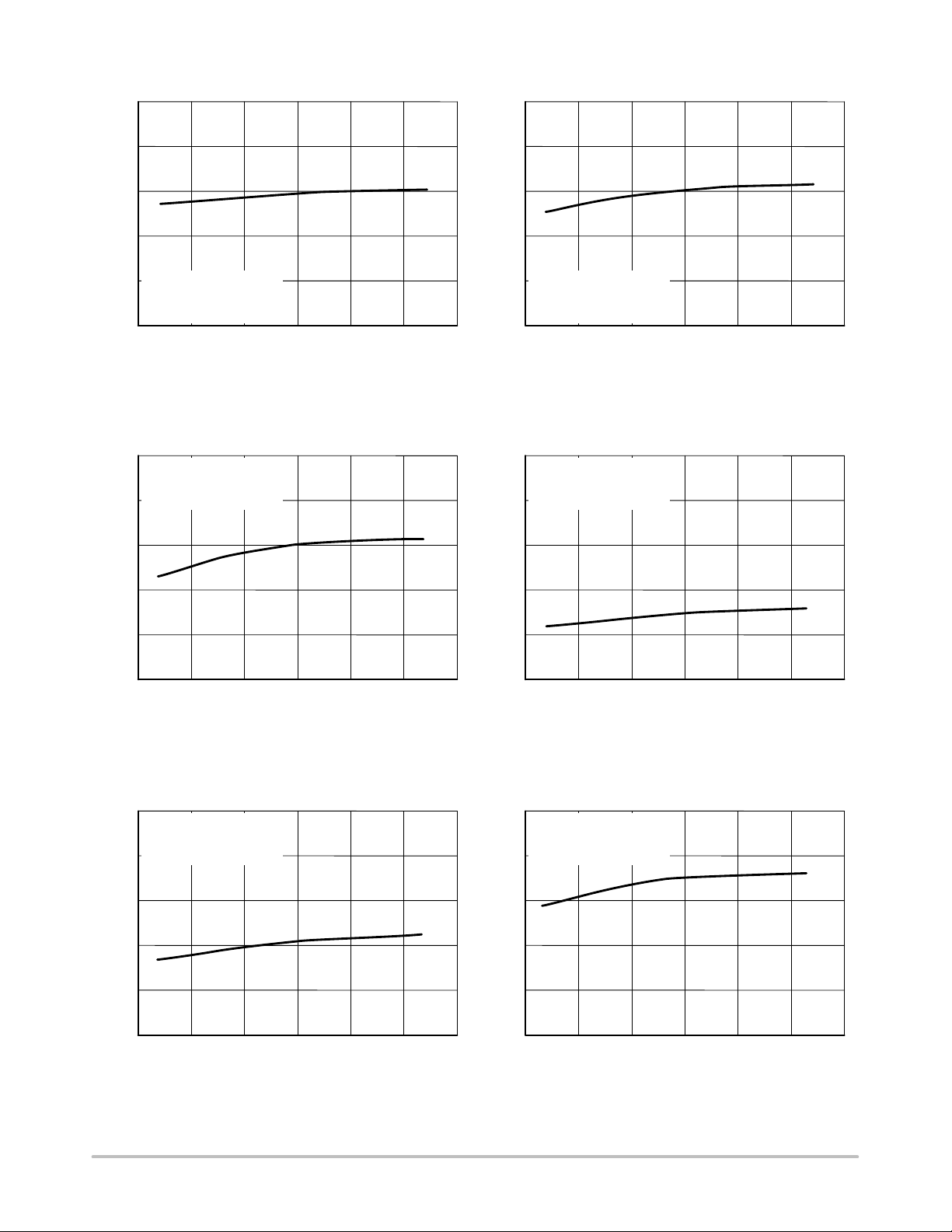

Figure 9. NCP1402SN19T1 Output Voltage vs.

Temperature

5.2

NCP1402SN50T1

V

= 5.0 V x 0.96

OUT

Open−Loop Test

5.1

5.0

3.2

3.1

3.0

2.9

, OUTPUT VOLTAGE (V)

2.8

NCP1402SN30T1

OUT

V

V

= 3.0 V x 0.96

OUT

Open−Loop Test

2.7

TEMPERATURE (°C)

Figure 10. NCP1402SN30T1 Output Voltage vs.

Temperature

100

NCP1402SN19T1

V

= 1.9 V x 0.96

OUT

Open−Loop Test

80

60

4.9

40

, OUTPUT VOLTAGE (V)

4.8

OUT

V

4.7

−50 250−25 50 75 100 −50 250−25 50 75 10

TEMPERATURE (°C)

Figure 11. NCP1402SN50T1 Output Voltage vs.

Temperature

20

, OPERATING CURRENT 1 (mA)

DD1

I

0

Figure 12. NCP1402SN19T1 Operating

Current 1 vs. Temperature

TEMPERATURE (°C)

100

NCP1402SN30T1

V

= 3.0 V x 0.96

OUT

Open−Loop Test

80

60

40

20

, OPERATING CURRENT 1 (mA)

DD1

I

0

100

NCP1402SN50T1

V

= 5.0 V x 0.96

OUT

Open−Loop Test

80

60

40

20

, OPERATING CURRENT 1 (mA)

DD1

I

0

−50 250−25 50 75 100 −50 250−25 50 75 100

TEMPERATURE (°C)

TEMPERATURE (°C)

Figure 13. NCP1402SN30T1 Operating

Current 1 vs. Temperature

Figure 14. NCP1402SN50T1 Operating

Current 1 vs. Temperature

http://onsemi.com

6

Page 7

NCP1402

7.5

7.0

6.5

6.0

, SWITCH ON TIME (s)

NCP1402SN19T1

5.5

on

t

V

= 1.9 V x 0.96

OUT

Open−Loop Test

5.0

−50

0−25

25

TEMPERATURE (°C)

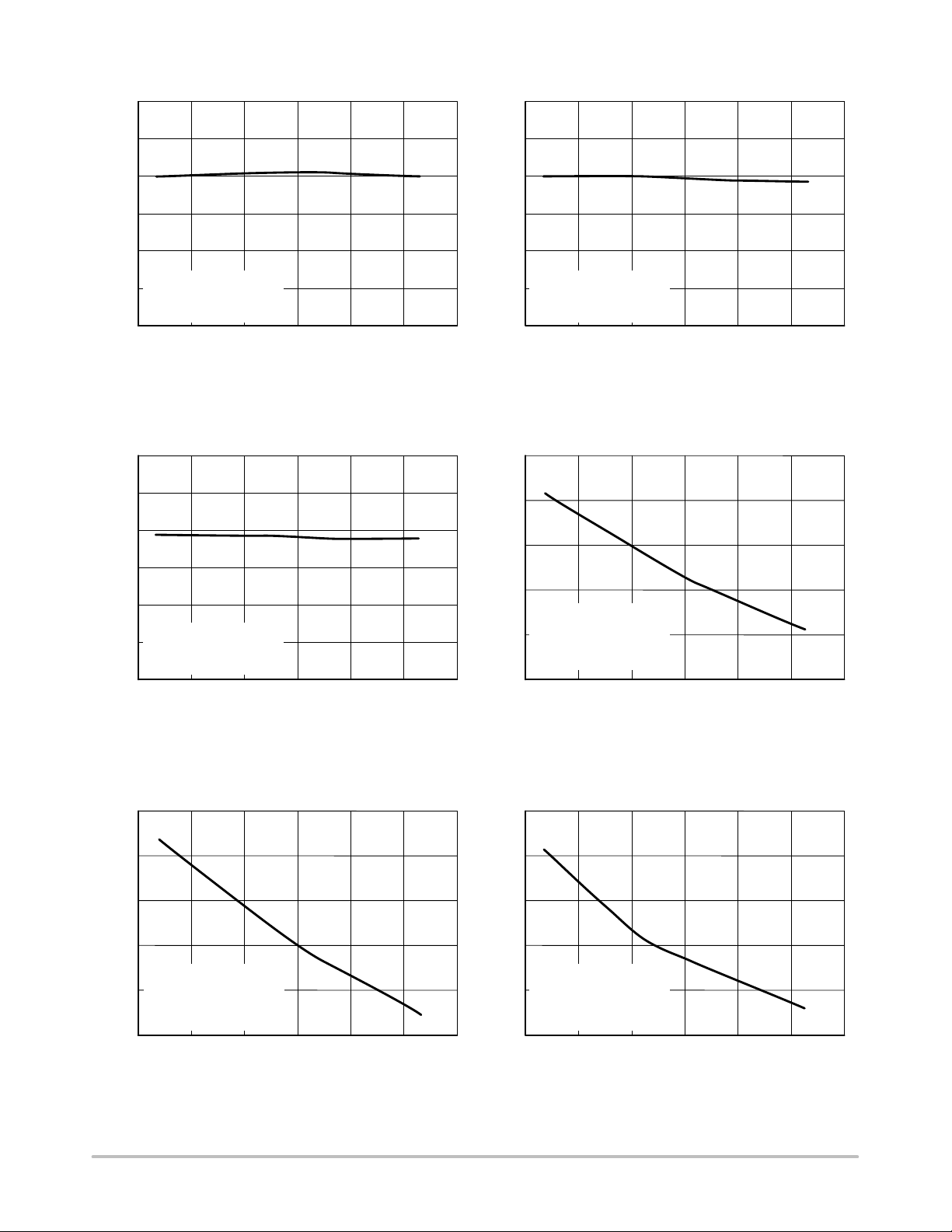

Figure 15. NCP1402SN19T1 Switch On Time

vs. Temperature

7.0

6.5

6.0

50 75 100

7.5

7.0

6.5

6.0

, SWITCH ON TIME (s)

on

t

NCP1402SN30T1

5.5

V

OUT

= 3.0 V x 0.96

Open−Loop Test

5.0

−50 250−25 50 75 100

TEMPERATURE (°C)

Figure 16. NCP1402SN30T1 Switch On Time

vs. Temperature

1.9

1.8

1.7

5.5

, SWITCH ON TIME (s)

on

5.0

t

NCP1402SN50T1

V

= 5.0 V x 0.96

OUT

Open−Loop Test

4.5

−50 250−25 50 75 100

TEMPERATURE (°C)

Figure 17. NCP1402SN50T1 Switch On Time

vs. Temperature

1.8

1.7

1.6

1.5

NCP1402SN30T1

1.4

V

= 3.0 V x 0.96

, MINIMUM SWITCH OFF TIME (s)

off

t

OUT

Open−Loop Test

1.3

1.6

NCP1402SN19T1

1.5

V

= 1.9 V x 0.96

, MINIMUM SWITCH OFF TIME (s)

off

t

Open−Loop Test

1.4

OUT

−50 250−25 50 75 100

TEMPERATURE (°C)

Figure 18. NCP1402SN19T1 Minimum Switch

Off Time vs. Temperature

1.8

1.7

1.6

1.5

NCP1402SN50T1

1.4

V

= 5.0 V x 0.96

, MINIMUM SWITCH OFF TIME (s)

off

t

OUT

Open−Loop Test

1.3

−50 250−25 50 75 100 −50 250−25 50 75 100

TEMPERATURE (°C)

TEMPERATURE (°C)

Figure 19. NCP1402SN30T1 Minimum Switch

Off Time vs. Temperature

http://onsemi.com

Figure 20. NCP1402SN50T1 Minimum Switch

Off Time vs. Temperature

7

Page 8

NCP1402

100

90

80

70

60

, MAXIMUM DUTY CYCLE (%)

D

NCP1402SN19T1

50

MAX

40

−50 250−25 50 75 100 −50 250−25 50 75 100

= 1.9 V x 0.96

V

OUT

Open−Loop Test

TEMPERATURE (°C)

Figure 21. NCP1402SN19T1 Maximum Duty

Cycle vs. T emperature

100

90

100

90

80

70

60

, MAXIMUM DUTY CYCLE (%)

D

50

MAX

40

NCP1402SN30T1

= 3.0 V x 0.96

V

OUT

Open−Loop Test

TEMPERATURE (°C)

Figure 22. NCP1402SN30T1 Maximum Duty

Cycle vs. T emperature

200

180

80

160

70

140

60

, MAXIMUM DUTY CYCLE (%)

D

MAX

50

40

NCP1402SN50T1

V

= 5.0 V x 0.96

OUT

Open−Loop Test

TEMPERATURE (°C)

, LX PIN ON−STATE CURRENT (mA)

LX

I

NCP1402SN19T1

V

V

OUT

LX

120

Open−Loop Test

100

−50 250−25 50 75 100−50 250−25 50 75 100

= 1.9 V x 0.96

= 0.4 V

TEMPERATURE (°C)

Figure 23. NCP1402SN50T1 Maximum Duty

250

230

210

190

NCP1402SN30T1

170

V

= 3.0 V x 0.96

OUT

= 0.4 V

V

, LX PIN ON−STATE CURRENT (mA)

LX

I

150

LX

Open−Loop Test

Cycle vs. T emperature

Figure 24. NCP1402SN19T1 LX Pin On−State

Current vs. Temperature

300

275

250

225

NCP1402SN50T1

200

V

= 5.0 V x 0.96

OUT

= 0.4 V

V

, LX PIN ON−STATE CURRENT (mA)

LX

I

175

LX

Open−Loop Test

−50 250−25 50 75 100 −50 250−25 50 75 100

TEMPERATURE (°C)

Figure 25. NCP1402SN30T1 LX Pin On−State

Current vs. Temperature

Figure 26. NCP1402SN50T1 LX Pin On−State

TEMPERATURE (°C)

Current vs. Temperature

http://onsemi.com

8

Page 9

NCP1402

1.0

0.8

0.6

VOLTAGE LIMIT (V)

0.4

LX

, V

0.2

LXLIM

NCP1402SN19T1

V

Open−Loop Test

0.0

−50 250−25 50 75 100

TEMPERATURE (°C)

Figure 27. NCP1402SN19T1 VLX Voltage Limit

vs. Temperature

1.0

0.8

1.0

0.8

0.6

VOLTAGE LIMIT (V)

0.4

LX

, V

0.2

LXLIM

V

NCP1402SN30T1

Open−Loop Test

0.0

−50 250−25 50 75 100

TEMPERATURE (°C)

Figure 28. NCP1402SN30T1 VLX Voltage Limit

vs. Temperature

4.0

3.5

3.0

0.6

2.5

VOLTAGE LIMIT (V)

0.4

LX

, V

0.2

LXLIM

V

NCP1402SN50T1

Open−Loop Test

0.0

−50 250−25 50 75 100 −50 250−25 50 75 100

TEMPERATURE (°C)

2.0

, SWITCH−ON RESISTANCE ()

1.5

DS(on)

1.0

NCP1402SN19T1

V

= 1.9 V x 0.96

OUT

= 0.4 V

V

LX

Open−Loop Test

TEMPERATURE (°C)

Figure 29. NCP1402SN50T1 VLX Voltage Limit

vs. Temperature

3.0

2.5

2.0

1.5

1.0

NCP1402SN30T1

V

, SWITCH−ON RESISTANCE ()

0.5

DS(on)

R

0.0

= 3.0 V x 0.96

OUT

= 0.4 V

V

LX

Open−Loop Test

3.0

2.5

2.0

1.5

1.0

, SWITCH−ON RESISTANCE ()R

0.5

DS(on)

R

0.0

Figure 30. NCP1402SN19T1 Switch−on

Resistance vs. T emperature

NCP1402SN50T1

V

= 5.0 V x 0.96

OUT

= 0.4 V

V

LX

Open−Loop Test

−50 250−25 50 75 100 −50 250−25 50 75 100

TEMPERATURE (°C)

Figure 31. NCP1402SN30T1 Switch−on

Resistance vs. T emperature

Figure 32. NCP1402SN50T1 Switch−on

TEMPERATURE (°C)

Resistance vs. T emperature

http://onsemi.com

9

Page 10

NCP1402

1.0

0.8

0.6

0.4

, STARTUP/HOLD VOLTAGE (V)

0.2

hold

/V

0.0

start

V

−50

1.0

0.8

0.6

0.4

, STARTUP/HOLD VOLTAGE (V)

0.2

hold

/V

start

0.0

V

−50

V

start

NCP1402SN19T1

L = 22 H

= 10 F

C

OUT

I

= 0 mA

O

V

hold

0

25−25

50

TEMPERATURE (°C)

Figure 33. NCP1402SN19T1 Startup/Hold

Voltage vs. Temperature

V

start

NCP1402SN50T1

L = 22 H

= 10 F

C

OUT

I

= 0 mA

O

V

hold

25−25

TEMPERATURE (°C)

50

75 100

75 1000

1.0

V

0.8

NCP1402SN30T1

0.6

L = 22 H

= 10 F

C

OUT

0.4

I

= 0 mA

O

, STARTUP/HOLD VOLTAGE (V)

0.2

hold

/V

0.0

start

V

−50 5025−25

V

TEMPERATURE (°C)

Figure 34. NCP1402SN30T1 Startup/Hold

Voltage vs. Temperature

2.0

1.5

1.0

0.5

, STARTUP/HOLD VOLTAGE (V)

hold

/V

0.0

start

V

040503020 6010 70

V

start

V

hold

IO, OUTPUT CURRENT (mA)

start

hold

75 1000

NCP1402SN19T1

L = 47 H

= 68 F

C

OUT

T

= 25°C

A

80 90 100

Figure 35. NCP1402SN50T1 Startup/Hold

Voltage vs. Temperature

2.0

1.5

V

start

1.0

V

hold

, STARTUP/HOLD VOLTAGE (V)

0.5

hold

/V

start

0.0

V

040503020 6010 70

I

, OUTPUT CURRENT (mA)

O

Figure 37. NCP1402SN30T1 Startup/Hold

Voltage vs. Output Current

NCP1402SN30T1

L = 47 H

= 68 F

C

OUT

T

= 25°C

A

80 90 100

http://onsemi.com

10

Figure 36. NCP1402SN19T1 Startup/Hold

Voltage vs. Output Current

2.0

1.5

V

start

1.0

, STARTUP/HOLD VOLTAGE (V)

0.5

V

hold

/V

start

V

0.0

hold

040503020 6010 70

I

, OUTPUT CURRENT (mA)

O

Figure 38. NCP1402SN50T1 Startup/Hold

Voltage vs. Output Current

NCP1402SN50T1

L = 47 H

= 68 F

C

OUT

T

= 25°C

A

80 90 100

Page 11

NCP1402

5 s/div

V

= 1.9 V, Vin = 1.2 V, IO = 30 mA, L = 47 H, C

OUT

1. V

, 1.0 V/div

LX

2. V

3. I

, 20 mV/div, AC coupled

OUT

, 100 mA/div

L

Figure 39. NCP1402SN19T1 Operating

Waveforms (Medium Load)

2 s/div

= 3.0 V, Vin = 1.2 V, IO = 30 mA, L = 47 H, C

V

OUT

1. V

, 2.0 V/div

LX

2. V

3. I

, 20 mV/div, AC coupled

OUT

, 100 mA/div

L

Figure 41. NCP1402SN30T1 Operating

Waveforms (Medium Load)

OUT

OUT

= 68 F

= 68 F

5 s/div

V

= 1.9 V, Vin = 1.2 V, IO = 70 mA, L = 47 H, C

OUT

1. V

, 1.0 V/div

LX

2. V

3. I

, 20 mV/div, AC coupled

OUT

, 100 mA/div

L

Figure 40. NCP1402SN19T1 Operating

Waveforms (Heavy Load)

2 s/div

V

= 3.0 V, Vin = 1.2 V, IO = 70 mA, L = 47 H, C

OUT

1. V

, 2.0 V/div

LX

2. V

3. I

, 20 mV/div, AC coupled

OUT

, 100 mA/div

L

Figure 42. NCP1402SN30T1 Operating

Waveforms (Heavy Load)

OUT

OUT

= 68 F

= 68 F

2 s/div

= 5.0 V, Vin = 1.5 V, IO = 30 mA, L = 47 H, C

V

OUT

1. V

, 2.0 V/div

LX

2. V

3. I

, 20 mV/div, AC coupled

OUT

, 100 mA/div

L

Figure 43. NCP1402SN50T1 Operating

Waveforms (Medium Load)

= 68 F

OUT

http://onsemi.com

2 s/div

= 5.0 V, Vin = 1.5 V, IO = 60 mA, L = 47 H, C

V

OUT

1. V

, 2.0 V/div

LX

2. V

3. I

, 20 mV/div, AC coupled

OUT

, 100 mA/div

L

OUT

= 68 F

Figure 44. NCP1402SN50T1 Operating

Waveforms (Heavy Load)

11

Page 12

NCP1402

Vin = 1.2 V, L = 47 H, C

1. V

2. I

= 1.9 V (AC coupled), 100 mV/div

OUT

= 0.1 mA to 80 mA

O

OUT

= 68 F

Figure 45. NCP1402SN19T1 Load Transient

Response

V

= 1.5 V, L = 47 H, C

in

1. V

2. I

= 3.0 V (AC coupled), 100 mV/div

OUT

= 0.1 mA to 80 mA

O

OUT

= 68 F

Figure 47. NCP1402SN30T1 Load Transient

Response

V

= 1.2 V, L = 47 H, C

in

1. V

2. I

= 1.9 V (AC coupled), 100 mV/div

OUT

= 80 mA to 0.1 mA

O

OUT

= 68 F

Figure 46. NCP1402SN19T1 Load Transient

Response

V

= 1.5 V, L = 47 H, C

in

1. V

2. I

= 3.0 V (AC coupled), 100 mV/div

OUT

= 80 mA to 0.1 mA

O

OUT

= 68 F

Figure 48. NCP1402SN30T1 Load Transient

Response

V

= 2.4 V, L = 47 H, C

in

1. V

2. I

= 5.0 V (AC coupled), 100 mV/div

OUT

= 0.1 mA to 80 mA

O

OUT

= 68 F

Figure 49. NCP1402SN50T1 Load Transient

Response

http://onsemi.com

12

V

= 2.4 V, L = 47 H, C

in

1. V

2. I

= 5.0 V (AC coupled), 100 mV/div

OUT

= 80 mA to 0.1 mA

O

OUT

= 68 F

Figure 50. NCP1402SN50T1 Load Transient

Response

Page 13

NCP1402

0

100

NCP1402SN19T1

L = 47 H

= 68 F

C

80

OUT

= 25°C

T

A

60

40

Vin = 1.2 V

Vin = 1.5 V

, RIPPLE VOLTAGE (mV)

20

ripple

V

Vin = 0.9 V

0

0

604020

80 100 120 140 160 180 200

I

, OUTPUT CURRENT (mA)

O

Figure 51. NCP1402SN19T1 Ripple Voltage vs.

Output Current

100

80

60

40

, RIPPLE VOLTAGE (mV)

20

ripple

V

0

0

Vin = 1.5 V

Vin = 1.2 V

Vin = 0.9 V

80 100 120 140 160 180 200

604020

IO, OUTPUT CURRENT (mA)

Vin = 4.0 V

Vin = 2.0 V

NCP1402SN50T1

L = 47 H

C

OUT

T

= 25°C

A

Vin = 3.0 V

= 68 F

100

NCP1402SN30T1

L = 47 H

= 68 F

C

80

OUT

T

= 25°C

60

40

A

Vin = 0.9 V

Vin = 1.2 V

Vin = 1.5 V

Vin = 2.0 V

Vin = 2.5 V

, RIPPLE VOLTAGE (mV)

20

ripple

V

0

0

604020

80 100 120 140 160 180 20

I

, OUTPUT CURRENT (mA)

O

Figure 52. NCP1402SN30T1 Ripple Voltage vs.

Output Current

100

80

85°C

60

−40°C

40

20

, OPERATING CURRENT 1 (mA)

DD1

I

0

NCP1402SNXXT1

V

= V

OUT

Open−loop Test

13425

V

, OUTPUT VOLTAGE (V)

OUT

SET

25°C

x 0.96

6

Figure 53. NCP1402SN50T1 Ripple Voltage vs.

Output Current

300

−40°C

260

220

180

25°C

85°C

NCP1402SNXXT1

140

, LX PIN ON−STATE CURRENT (mA)

LX

I

100

V

= V

V

OUT

LX

= 0.4 V

SET

x 0.96

Open−loop Test

13425

V

, OUTPUT VOLTAGE (V)

OUT

, SWITCH−ON RESISTANCE ()

DS(ON)

R

6

Figure 55. NCP1402SNXXT1 Pin On−state

Current vs. Output Voltage

http://onsemi.com

13

Figure 54. NCP1402SNXXT1 Operating

Current 1 vs. Output Voltage

3.5

3.0

2.5

2.0

1.5

1.0

13425

V

, OUTPUT VOLTAGE (V)

OUT

NCP1402SNXXT1

V

= V

V

OUT

LX

= 0.4 V

SET

x 0.96

Open−loop Test

25°C

−40°C

85°C

6

Figure 56. NCP1402SNXXT1 Switch−On

Resistance vs. Output Voltage

Page 14

NCP1402

400

300

200

100

, MAX. OUTPUT CURRENT (mA)

O(max)

I

0

0

3.0 V

2.7 V

1.9 V

12345

V

in

3.3 V 5.0 V

NCP1402SNXXT1

L = 47 H

T

, INPUT VOLTAGE (V)

Figure 58. NCP1402SNXXT1 Maximum Output

Current vs. Input Voltage

= 25°C

A

, NO LOAD INPUT CURRENT (A)

load)

in(no

I

150

125

100

75

50

25

5.0 V

3.3 V

3.0 V

2.7 V

1.9 V

0

0

, INPUT VOLTAGE (V)

V

in

321

NCP1402SNXXT1

L = 47 H

I

T

Figure 57. NCP1402SNXXT1 No Load Input

Current vs. Input Voltage

= 0 mA

O

= 25°C

A

45

6

DETAILED OPERATING DESCRIPTION

Operation

The NCP1402 series are monolithic power switching

regulators optimized for applications where power drain

must be minimized. These devices operate as variable

frequency, voltage mode boost regulators and designed to

operate in continuous conduction mode. Potential

Soft−Start

There is a Soft−Start circuit in NCP1402. When power is

applied to the device, the Soft−Start circuit pumps up the

output voltage to a pproximately 1 .5 V a t a f ixed d uty cycle, t he

level at which the converter can operate normally. What is

more, the startup capability w ith heavy loads is also i mproved.

applications include low powered consumer products and

battery powered portable products.

The NCP1402 series are low noise variable frequency

voltage−mode DC−DC converters, and consist of Soft−Start

circuit, feedback resistor, reference voltage, oscillator, PFM

comparator, PFM control circuit, current limit circuit and

power switch. Due to the on−chip feedback resistor network,

the system designer can get the regulated output voltage

from 1.8 V to 5 V with a small number of external

components. The operating current is typically 30 A

(V

= 1.9 V), and can be further reduced to about 0.6 A

OUT

when the chip is disabled (VCE < 0.3 V).

The NCP1402 operation can be best understood by

examining the block diagram in Figure 2. PFM comparator

monitors the output voltage via the feedback resistor. When

the feedback voltage is higher than the reference voltage, the

power switch is turned off. As the feedback voltage is lower

than reference voltage and the power switch has been off for

at least a period of minimum off−time decided by PFM

oscillator, the power switch is then cycled on for a period of

on−time also decided by PFM oscillator, or until current

limit signal is asserted. When the power switch is on, current

ramps up in the inductor, storing energy in the magnetic

field. When the power switch is off, the energy in the

magnetic field is transferred to output filter capacitor and the

load. The output filter capacitor stores the charge while the

inductor current is high, then holds up the output voltage

until next switching cycle.

Regulated Converter Voltage (V

The V

is set by an internal feedback resistor network.

OUT

This is trimmed to a selected voltage from 1.8 to 5.0 V range

in 100 mV steps with an accuracy of 2.5%.

Current Limit

The NCP1402 series utilizes cycle−by−cycle current

limiting as a means of protecting the output switch

MOSFET from overstress and preventing the small value

inductor from saturation. Current limiting is implemented

by monitoring the output MOSFET current build−up during

conduction, and upon sensing an overcurrent conduction

immediately turning off the switch for the duration of the

oscillator cycle.

The voltage across the output MOSFET is monitored and

compared against a reference by the VLX limiter. When the

threshold is reached, a signal is sent to the PFM controller

block to terminate the power switch conduction. The current

limit threshold is typically set at 350 mA.

Enable / Disable Operation

The NCP1402 series offer IC shut−down mode by chip

enable pin (CE pin) to reduce current consumption. An

internal pullup resistor tied the CE pin to OUT pin by default

i.e. user can float the pin CE for permanent “On”. When

voltage at pin CE is equal or greater than 0.9 V, the chip will

be enabled, which means the regulator is in normal

operation. When voltage at pin CE is less than 0.3 V, the chip

OUT

)

is disabled, which means IC is shutdown.

Impor tant: DO NOT apply a voltage between 0.3 V and 0.9 V to pin CE as this is the CE pin’s hyteresis voltage

range. Clearly defined output states can only be obtained by applying voltage out of this range.

http://onsemi.com

14

Page 15

NCP1402

APPLICATIONS CIRCUIT INFORMATION

V

in

C1

10 F

CE

OUT

NC

47 H

1

NCP1402

2

3

Figure 59. Typical Application Circuit

Step−up Converter Design Equations

NCP1402 step−up DC−DC converter designed to operate

in continuous conduction mode can be defined by:

Calculation Equation

2

V

L

I

PK

I

min

t

off

Q

V

ripple

*NOTES:

− Peak inductor current

I

PK

I

− Minimum inductor current

min

− Desired dc output current

I

O

− Desired maximum dc output current

I

Omax

I

− Average inductor current

L

− Nominal operating dc input voltage

V

in

V

− Desired dc output voltage

OUT

− Diode forward voltage

V

F

− Saturation voltage of the internal FET switch

V

S

Q − Charge stores in the C

− Output ripple voltage

V

ripple

ESR − Equivalent series resistance of the output capacitor

M − An empirical factor, when V

M = 8 x 10

M

(Vin Vs)t

(ton t

t

off

off)IO

(V

OUT

(IL IO)t

Q

C

OUT

OUT

−6

, otherwise M = 5.3 x 10−6.

in

V

OUTIOmax

on

I

L

(Vin Vs)t

min

(Vin VS)t

2L

on

VF Vin)

off

(IL IO)ESR

during charging up

≥ 3.0 V,

OUT

on

EXTERNAL COMPONENT SELECTION

Inductor

The NCP1402 is designed to work well with a 47 H

inductor in most applications. 47 H is a sufficiently low

value to allow the use of a small surface mount coil, but large

L1

LX

5

GND

4

D1

V

C2

68 F

OUT

enough to maintain low ripple. Low inductance values

supply higher output current, but also increase the ripple and

reduce efficiency. Note that values below 27 H is not

recommended due to NCP1402 switch limitations. Higher

inductor values reduce ripple and improve efficiency, but

also limit output current.

The inductor should have small DCR, usually less than 1

to m inimize l oss. I t i s n ecessary t o c hoose a n i nductor w ith

saturation current greater than the peak current which the

inductor will encounter in the application.

Diode

The diode is the main source of loss in DC−DC converters.

The most importance parameters which affect their

efficiency are the forward voltage drop, VF, and the reverse

recovery time, trr. The forward voltage drop creates a loss

just by having a voltage across the device while a current

flowing through it. The reverse recovery time generates a

loss when the diode is reverse biased, and the current appears

to actually flow backwards through the diode due to the

minority carriers being swept from the P−N junction. A

Schottky diode with the following characteristics is

recommended:

Small forward voltage, V

< 0.3 V

F

Small reverse leakage current

Fast reverse recovery time/ switching speed

Rated current larger than peak inductor current,

I

> I

rated

PK

Reverse voltage larger than output voltage,

V

> V

reverse

OUT

Input Capacitor

The input capacitor can stabilize the input voltage and

minimize peak current ripple from the source. The value of

the capacitor depends on the impedance of the input source

used. Small Equivalent Series Resistance ( ESR) Tantalum or

ceramic capacitor with value of 10 F should be suitable.

http://onsemi.com

15

Page 16

NCP1402

Output Capacitor

The output capacitor is used for sustaining the output

voltage when the internal MOSFET is switched on and

smoothing the ripple voltage. Low ESR capacitor should be

used to reduce output ripple voltage. In general, a 47 uF to

68 uF low ESR (0.15 to 0.30 ) Tantalum capacitor

should be appropriate. For applications where space is a

critical factor, two parallel 22 uF low profile SMD ceramic

capacitors can be used.

An evaluation board of NCP1402 has been made in the

size of 2 3 m m x 2 0 m m only, as shown in Figures 60 and 61.

Please contact your ON Semiconductor representative for

availability. The evaluation board schematic diagram, the

artwork and the silkscreen of the surface mount PCB are

shown below:

20 mm

23 mm

Figure 60. NCP1402 PFM Step−Up DC−DC Converter Evaluation Board Silkscreen

20 mm

23 mm

Figure 61. NCP1402 PFM Step−Up DC−DC Converter Evaluation Board Artwork (Component Side)

http://onsemi.com

16

Page 17

NCP1402

Components Supplier

Parts Supplier Part Number Description Phone

Inductor, L1 Sumida Electric Co. Ltd. CD54−470L Inductor 47 H / 0.72 A (852)−2880−6688

Schottky Diode, D1 ON Semiconductor Corp. MBR0520LT1 Schottky Power Rectifier (852)−2689−0088

Output Capacitor, C2 KEMET Electronics Corp. T494D686K010AS

Input Capacitor, C1 KEMET Electronics Corp. T491C106K016AS

PCB Layout Hints

Low ESR Tantalum Capacitor

68 F / 10 V

Low Profile Tantalum Capacitor

10 F / 16 V

(852)−2305−1168

(852)−2305−1168

Grounding

One point grounding should be used for the output power

return ground, the input power return g round, a nd t he d evice

switch ground to reduce noise as shown in Figure 62, e.g.:

C2 GND, C1 GND, and U1 GND are connected at one point

in the evaluation board. The input ground and output ground

traces must be thick enough for current to flow through and

for reducing ground bounce.

Power Signal Traces

Low resistance conducting paths should be used for the

power carrying traces to reduce power loss so as to improve

TP1

V

in

CE

1

OUT

2

NC

3

10 F/16 V

TP4

GND

++

C1

JP1

Enable

On

Off

efficiency (short and thick traces for connecting the inductor

L can also reduce stray inductance), e.g.: short and thick

traces listed below are used in the evaluation board:

1. Trace from TP1 to L1

2. Trace from L1 to Lx pin of U1

3. Trace from L1 to anode pin of D1

4. Trace from cathode pin of D1 to TP2

Output Capacitor

The output capacitor should be placed close to the output

terminals to obtain better smoothing effect on the output

ripple.

L1

47 H

NCP1402

D1

MBR0520LT1

LX

5

GND

6

TP2

V

C2

68 F/10 V

TP3

GND

out

Figure 62. NCP1402 Evaluation Board Schematic Diagram

http://onsemi.com

17

Page 18

0.05 (0.002)

S

H

D

54

123

L

G

A

NCP1402

PACKAGE DIMENSIONS

SOT23−5

(TSOP−5, SC59−5)

SN SUFFIX

CASE 483−02

ISSUE C

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. MAXIMUM LEAD THICKNESS INCLUDES

B

J

C

K

M

LEAD FINISH THICKNESS. MINIMUM LEAD

THICKNESS IS THE MINIMUM THICKNESS

OF BASE MATERIAL.

4. A AND B DIMENSIONS DO NOT INCLUDE

MOLD FLASH, PROTRUSIONS, OR GATE

BURRS.

DIM MIN MAX MIN MAX

A 2.90 3.10 0.1142 0.1220

B 1.30 1.70 0.0512 0.0669

C 0.90 1.10 0.0354 0.0433

D 0.25 0.50 0.0098 0.0197

G 0.85 1.05 0.0335 0.0413

H 0.013 0.100 0.0005 0.0040

J 0.10 0.26 0.0040 0.0102

K 0.20 0.60 0.0079 0.0236

L 1.25 1.55 0.0493 0.0610

M 0 10 0 10

___ _

S 2.50 3.00 0.0985 0.1181

INCHESMILLIMETERS

SOLDERING FOOTPRINT*

1.9

0.95

0.037

1.0

0.039

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

0.074

0.7

0.028

2.4

0.094

SCALE 10:1

inches

mm

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

18

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

NCP1402/D

Page 19

Loading...

Loading...