Page 1

NCP1232

Microprocessor Monitor

The NCP1232 is a fully–integrated processor supervisor. It provides

three important functions to safeguard processor functionality:

precision power on/off reset control, watchdog timer and external

reset override.

On power–up, the NCP1232 holds the processor in the reset state for

a minimum of 250 msec after VCC is within tolerance to ensure a

stable system start–up.

Microprocessor functionality is monitored by the on–board

watchdog circuit. The microprocessor must provide a periodic

low–going signal on the ST

this signal within the selected time–out period (150 msec, 600 msec or

1200 msec), an out–of–control processor is indicated and the

NCP1232 issues a processor reset as a result.

The outputs of the NCP1232 are immediately driven active when

the PB input is brought low by an external push–button switch or other

electronic signal. When connected to a push–button switch, the

NCP1232 provides contact debounce.

The NCP1232 is packaged in a space–saving 8–pin plastic SOIC

package and requires no external components.

input. Should the processor fail to supply

http://onsemi.com

SO–8

8

1

YY, Y = Year

WW = Work Week

X = Assembly ID Code

Z = Subcontractor ID Code

D SUFFIX

CASE 751

MARKING

DIAGRAM

8

NCP

1232

YWWXZ

1

Features

• Precision Voltage Monitor

(Adjustable +4.5 V or +4.75 V)

• Reset Pulse Width (250 msec Min)

• No External Components

• Adjustable Watchdog Timer

(150 msec, 600 msec or 1.2 sec)

• Debounced Manual Reset Input for External Override

Applications

• Computers

• Controllers

• Intelligent Instruments

• Automotive Systems

• Critical µP Power Monitoring

PIN CONNECTIONS

8–Pin SOIC

TD

TOL

1

2

3

4

(Top View)

PB RST

ORDERING INFORMATION

Device Package Shipping

NCP1232DR2 SO–8 2500 Tape & Reel

8

V

CC

7

ST

6

RST

NCP1232D

5

RSTGND

Semiconductor Components Industries, LLC, 2000

May, 2000 – Rev. 0

1 Publication Order Number:

NCP1232/D

Page 2

NCP1232

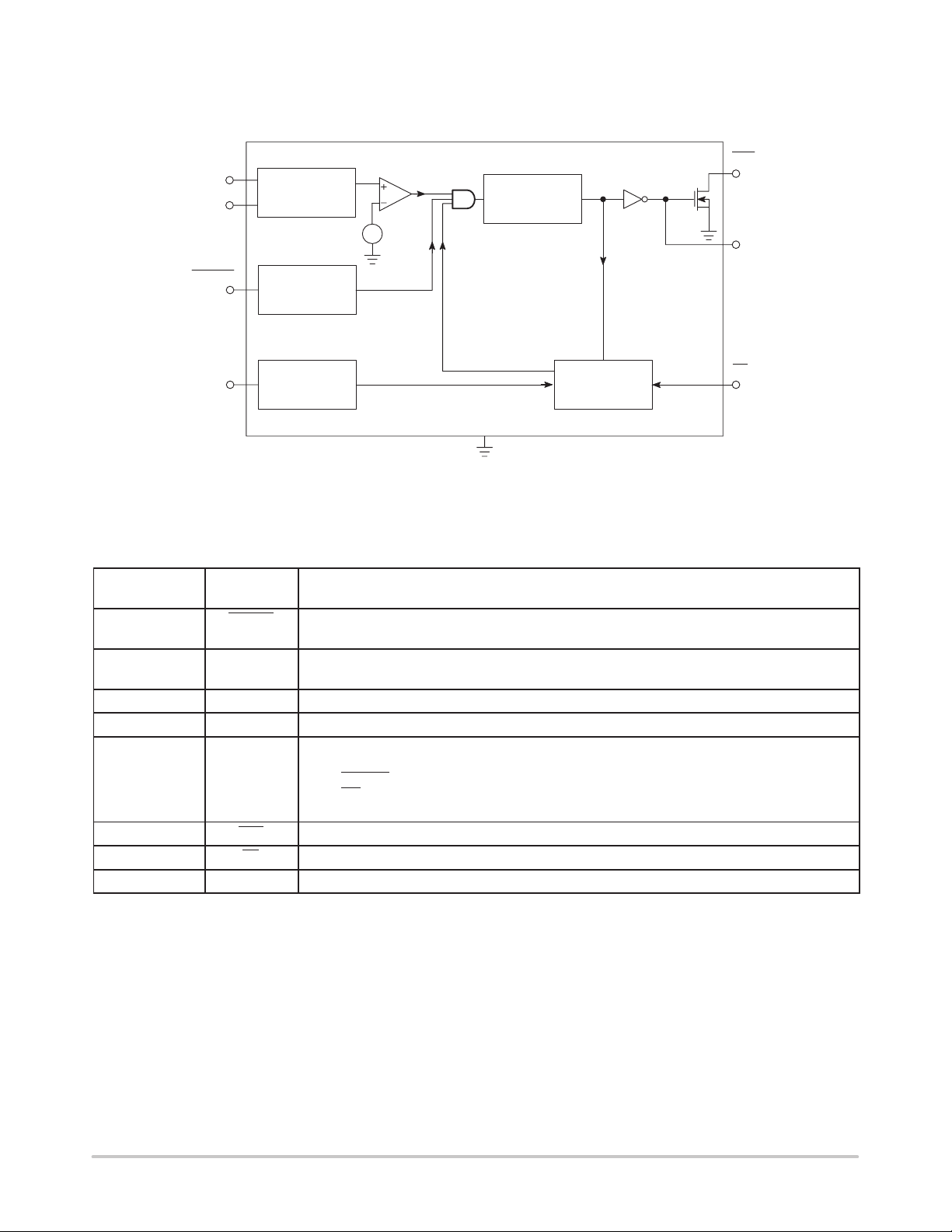

FUNCTIONAL BLOCK DIAGRAM

VD

CC

TOL

PB RST

TD

5%/10%

TOLERANCE

SELECT

DEBOUNCE

WATCHDOG

TIMEBASE

SELECT

REF

GND

RESET

GENERATOR

NCP1232

WATCHDOG

TIMER

RST

RST

ST

PIN DESCRIPTION

Pin No.

(8–Pin SOIC)

1 PB RST Push–button Reset Input. A debounced active–low input that ignores pulses less than 1 msec in

2 TD Time Delay Set. The watchdog time–out select input (tTD = 150 msec for

3 TOL Tolerance Input. Connect to GND for 5% tolerance or to VCC for 10% tolerance.

4 GND Ground.

5 RST Reset Output (Active High) – goes active:

6 RST Reset Output (Active Low, Open Drain) – see RST.

7 ST Strobe Input. Input for watchdog timer.

8 V

Symbol Description

duration and is guaranteed to recognize inputs of 20 msec or greater.

TD = 0 V, tTD = 600 msec for TD = open, tTD = 1.2 sec for TD = VCC.)

CC

1. If VCC falls below the selected reset voltage threshold

2. If PB RST

3. If ST

4. During power–up

The +5 V Power Supply Input.

is forced low

is not strobed within the minimum time–out period

http://onsemi.com

2

Page 3

NCP1232

ABSOLUTE MAXIMUM RATINGS* Voltage on any pin (with respect to GND) –0.3 V to +5.8 V

Rating

Operating Temperature Range –40 to +85 °C

Storage Temperature Range, T

Lead Temperature (Soldering, 10 sec) +300 °C

*Stresses beyond those listed under “Absolute Maximum Ratings’’ may cause permanent damage to the device. These are stress ratings only ,

and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications

is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability .

stg

Value Unit

–65 to +150

°C

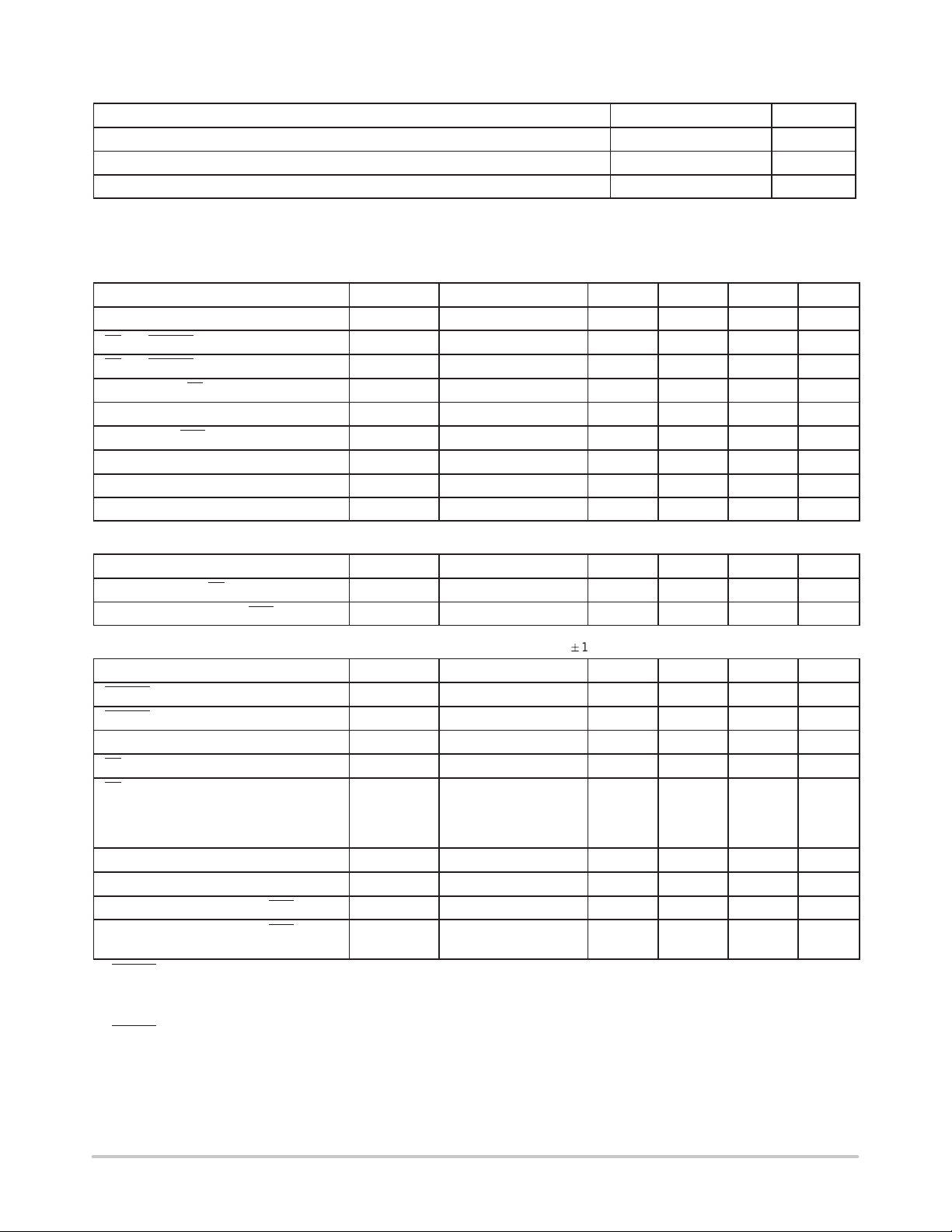

DC ELECTRICAL CHARACTERISTICS (T

Characteristic

Supply Voltage V

ST and PB RST Input High Level V

ST and PB RST Input Low Level V

Input Leakage ST, TOL I

Output Current RST I

Current RST, RST I

Operating Current I

VCC 5% Trip Point (Note 3.) V

VCC 10% Trip Point (Note 3.) V

CAPACITANCE (Note 4.) (T

Characteristic

Input Capacitance ST, TOL C

Output Capacitance RST, RST C

= +25°C)

A

AC ELECTRICAL CHARACTERISTICS (T

Characteristic

PB RST (Note 5.) t

PB RST Delay t

Reset Active Time t

ST Pulse Width t

ST Time–out Period t

VCC Fall Time (Note 4.) t

VCC Rise Time (Note 4.) t

VCC Detect to RST High and RST Low t

VCC Detect to RST High and RST Open

(Note 6.)

1. PB RST is internally pulled up to VCC with an internal impedance of typically 40 kΩ.

2. Measured with outputs open.

3. All voltages references to GND.

4. Guaranteed by design.

5. PB RST

6. tR = 5 µsec.

must be held low for a minimum of 20 msec to guarantee a reset.

= T

A

A

to T

MIN

Symbol Test Conditions Min Typ Max Unit

CC

IH

IL

L

OH

OL

CC

CCTP

CCTP

Symbol Test Conditions Min Typ Max Unit

IN

OUT

= T

to T

MIN

Symbol Test Conditions Min Typ Max Unit

PB

PBD

RST

ST

TD

F

R

RPD

t

RPU

; VCC = +4.5 V to 5.5 V, unless otherwise specified.)

MAX

– 4.5 5.0 5.5 V

Note 1. 2.0 – VCC +0.3 V

– –0.3 – +0.8 V

– –1.0 – +1.0 µA

VOH = 2.4 V –1.0 –12 – mA

VOL = 0.4 V 2.0 10 – mA

Note 2. – 50 200 µA

TOL = GND 4.50 4.62 4.74 V

TOL = V

; VCC = +5.0 V to "10%, unless otherwise specified.)

MAX

TD Pin = 0 V

TD Pin = Open

TD Pin = V

Figure 7, VCC Falling – – 100 nsec

Figure 8, VCC Rising 250 610 1000 msec

CC

– – – 5.0 pF

– – – 7.0 pF

Figure 3 20 – – msec

Figure 3 1.0 4.0 20 msec

– 250 610 1000 msec

Figure 4 20 – – nsec

Figure 4

CC

Figure 5 10 – – µsec

Figure 6 0 – – µsec

4.25 4.37 4.49 V

62.5

250

500

150

600

1200

250

1000

2000

msec

http://onsemi.com

3

Page 4

NCP1232

Power Monitor

The NCP1232 detects out–of–tolerance power supply

conditions and warns a processor–based system of an

impending power failure. When VCC is detected as below

the preset level defined by TOL, the VCC comparator

outputs the signals RST and RST

. If TOL is connected to

ground, the RST and RST signals become active as VCC falls

below 4.75 volts. If TOL is connected to VCC, the RST and

RST

become active as VCC falls below 4.5 volts. Because

the processing is stopped at the last possible moment of valid

VCC, the RST and RST are excellent control signals for a µP.

The reset outputs will remain in their active states until V

CC

has been continuously in–tolerance for a minimum of 250

msec allowing the power supply and µP to stabilize before

RST

is released.

Push–button Reset Input

The debounced manual reset input (PB RST) manually

forces the reset outputs into their active states. Once PB RST

has been low for a time, t

, the push–button delay time,

PBD

the reset outputs go active. The reset outputs remain in their

active states for a minimum of 250 msec after PB RST

rises

above VIH (Figure 3).

A mechanical push–button or active logic signal can drive

the PB RST input. The debounced input ignores input pulses

less than 1 msec and is guaranteed to recognize pulses of

20 msec or greater. No external pull–up resistor is required

because the PB RST

input has an internal pull–up to VCC of

approximately 100 µA.

Watchdog Timer

When the ST input is not stimulated for a preset time

period, the watchdog timer function forces RST and RST

signals to the active state. The preset time period is

determined by the TD inputs to be 150 msec with TD

connected to ground, 600 msec with TD open, or 1200 msec

with TD connected to VCC, typical. The watchdog timer

starts timing out from the set time period as soon as RST and

RST

are inactive. If a high–to–low transition occurs on the

ST input pin prior to time–out, the watchdog timer is reset

and begins to time–out again. If the watchdog timer is

allowed to time–out, then the RST and RST signals are

driven to the active state for 250 msec minimum (Figure 2).

The software routine that strobes ST

is critical. The code

must be in a section of software that is executed regularly so

the time between toggles is less than the watchdog time–out

period. One common technique controls the µP I/O line

from two sections of the program. The software might set the

I/O line high while operating in the foreground mode and set

it low while in the background or interrupt mode. If both

modes do not execute correctly, the watchdog timer issues

reset pulses.

Supply Monitor Noise Sensitivity

The NCP1232 is optimized for fast response to

negative–going changes in VDD. Systems with an inordinate

amount of electrical noise on VDD (such as systems using

relays), may require a 0.01 µF or 0.1 µF bypass capacitor to

reduce detection sensitivity. This capacitor should be

installed as close to the NCP1232 as possible to keep the

capacitor lead length short.

+5 V

3–TERMINAL

REGULATOR

V

CC

PB RST

GND

Figure 1. Push–button Reset

+5 V

0.1 µF

Figure 2. Watchdog Timer

NCP1232

TOL

V

CC

NCP1232

TD

TD

ST

RST

TOL

I/O

MICRO–

PROCESSOR

RESET

+5 V

RST

ST

GND

10 KΩ

RESET

MICRO–

PROCESSOR

I/O

http://onsemi.com

4

Page 5

NCP1232

t

PB

PB RST

RST

RST

t

PBD

V

IH

V

IL

t

RST

Figure 3. Push–button Reset. The debounced PB RST

input ignores input pulses less than 1 msec and is

guaranteed to recognized pulses of 20 msec or greater

PUSH–BUTTON RESET

t

ST

ST

t

TD

Figure 4. Strobe Input

NOTE: tTD is the maximum elapsed time between ST

transistions (ST is activated by falling edges only) which will

keep the watchdog timer from forcing the reset outputs active

for a time of t

as tabulated below.

CONDITION MIN TYP

TD PIN = 0 V 62.5 msec 150 msec 250 msec

TD PIN = OPEN 250 msec 600 msec 1000 msec

TD PIN = V

CC

. tTD is a function of the voltage at the TD pin,

RST

t

500 msec 1200 msec 2000 msec

high–to–low

TD

MAX

http://onsemi.com

5

Page 6

NCP1232

t

F

V

CC

+4.75 V

+4.25 V

V

CC

t

R

+4.25 V

+4.75 V

Figure 5. Power–Down Slew Rate

VCC = 5 V

+4.5 V (5% TRIP POINT)

+4.25 V (10% TRIP POINT)

t

RPD

RST

V

OH

RST

VCC, SLEW RATE = 1.66mV/µsec (0.5 V/300 µsec)

V

OL

Figure 6. Power–Down Slew Rate

4.5 V (10% TRIP POINT)

V

CC

RST

RST

4.6 V (5% TRIP POINT)

t

RPU

V

OH

V

OL

Figure 7. VCC Detect Reset Output Delay

(Power–Down)

Figure 8. VCC Detect Reset Output Delay

(Power–Up)

http://onsemi.com

6

Page 7

NCP1232

P ACKAGE DIMENSIONS

SO–8

D SUFFIX

CASE 751–06

ISSUE T

C

A

A1

D

58

0.25MB

E

1

B

e

H

4

M

h

X 45

_

q

C

A

SEATING

PLANE

0.10

L

B

SS

A0.25MCB

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. DIMENSIONS ARE IN MILLIMETER.

3. DIMENSION D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 1.35 1.75

A1 0.10 0.25

B 0.35 0.49

C 0.19 0.25

D 4.80 5.00

E

3.80 4.00

1.27 BSCe

H 5.80 6.20

h

0.25 0.50

L 0.40 1.25

0 7

q

__

http://onsemi.com

7

Page 8

NCP1232

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone : (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich T ime)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse Time)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong T ime)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–0031

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

8

NCP1232/D

Loading...

Loading...