Page 1

NCP1205

Single Ended PWM

Controller Featuring QR

Operation and Soft

Frequency Foldback

The NCP1205 combines a true Current Mode Control modulator

and a demagnetization detector to ensure full Discontinuous

Conduction Mode in any load/line conditions and minimum drain

voltage switching (Quasi–Resonant operation, also called critical

conduction operation). With its inherent Variable Frequency Mode

(VFM), the controller decreases its operating frequency at constant

peak current whenever the output power demand diminishes.

Associated with automatic multiple valley switching, this unique

architecture guarantees minimum switching losses and the lowest

power drawn from the mains when operating at no–load conditions.

Thus, the NCP1205 is optimal for applications targeting the newest

International Energy Agency (IEA) recommendations for standby

power.

The internal High–Voltage current source provides a reliable

charging path for the VCC capacitor and ensures a clean and short

start–up sequence without deteriorating the efficiency once off.

The continuous feedback signal monitoring implemented with an

Over–Current fault Protection circuitry (OCP) makes the final design

rugged and reliable. An internal Over Voltage Protection (OVP) circuit

continuously monitors the VCC pin and stops the IC whenever its level

exceeds 36 V. The DIP14 offers an adjustable version of the OVP

threshold via an external resistive network.

Features

• Natural Drain Valley Switching for Lower EMI and Quasi–Resonant

Operation (QR)

• Smooth Frequency Foldback for Low Standby and Minimum Ripple

at Light–Load

• Adjustable Maximum Switching Frequency

• Internal 200 ns Leading Edge Blanking on Current Sense

• 250 mA Sink and Source Driver

• Wide Operating Voltages: 8.0 to 36 V

• Wide UVLO Levels: 7.2 to 15 V Typical

• Auto–Recovery Internal Short–Circuit Protection (OCP)

• Integrated 3.0 mA Typ. Start–Up Source

• Current Mode Control

• Adjustable Over–Voltage Level

• Available in DIP8 and DIP14 Package

http://onsemi.com

MARKING

DIAGRAMS

8

1

1

14

NCP1205P2

1

NCP1205P

YYWW

AWLYYWW

PDIP–8

8

1

14

1

ORDERING INFORMATION

Device Package Shipping

NCP1205P PDIP–8 50 Units/Rail

NCP1205P2 PDIP–14 25 Units/Rail

N SUFFIX

CASE 626

PDIP–14

P SUFFIX

CASE 646

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

AWL

Applications

• High Power AC/DC Adapters for Notebooks, etc.

• Offline Battery Chargers

• Power Supplies for DVD, CD Players, TVs, Set–Top Boxes, etc.

• Auxiliary Power Supplies (USB, Appliances, etc.)

Semiconductor Components Industries, LLC, 2002

April, 2002 – Rev. 2

1 Publication Order Number:

NCP1205/D

Page 2

NCP1205

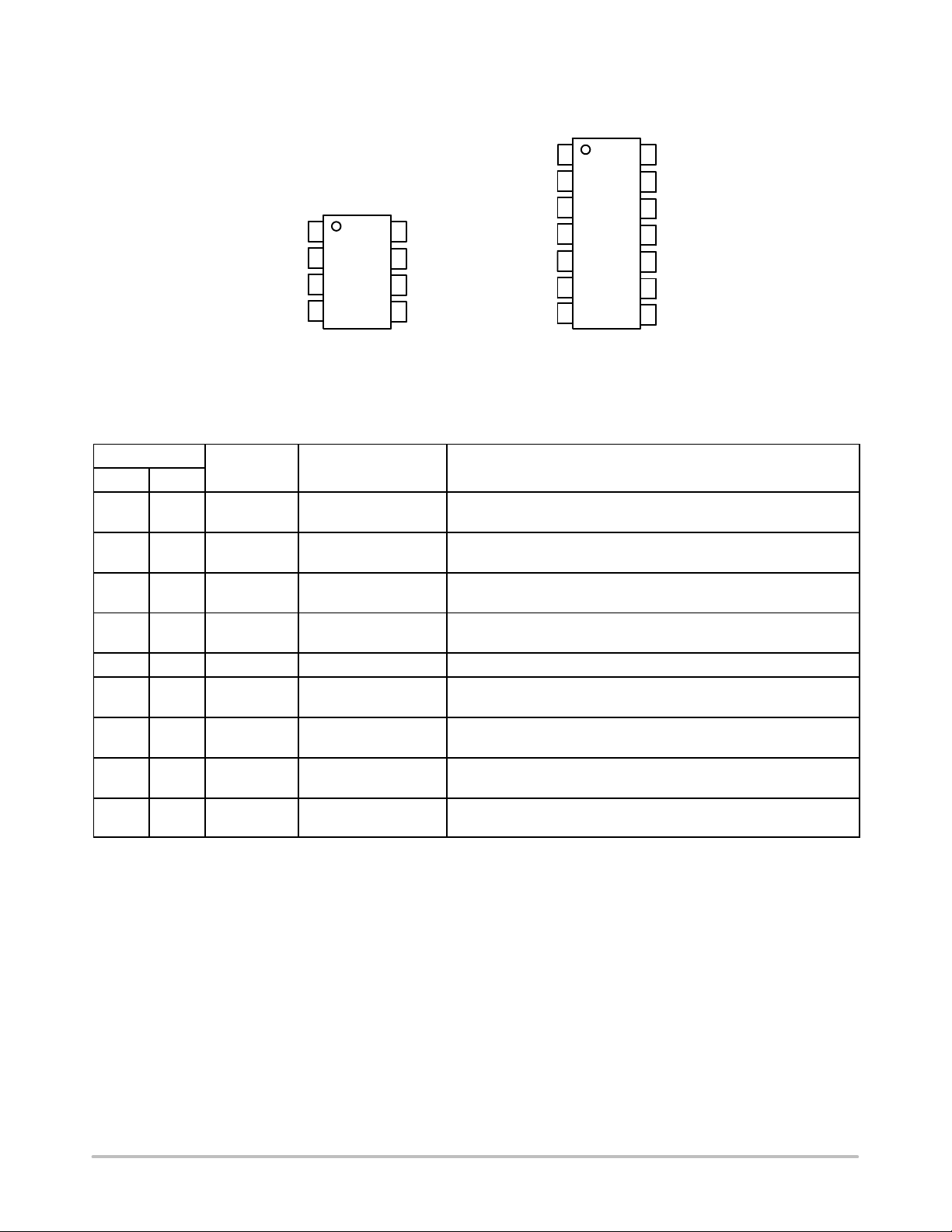

PIN CONNECTIONS

HV

Demag

FB

Ct

1

2

3

4

PDIP–8

8

7

6

5

V

CC

Drive

Isense

GND

HV

NC

Demag

FB

Ct

OVP

NC

1

2

3

4

5

6

7

PDIP–14

14

13

12

11

10

9

8

NC

V

CC

Drive

Isense

GND

NC

NC

PIN FUNCTION DESCRIPTION

Pin No.

DIP8 DIP14

1 1 HV Start–up rail Connected to the rectified HV rail, this pin provides a charging path to

2 3 Demag Zero primary–current

3 4 FB Feedback signal to

4 5 Ct Timing capacitor By adding a capacitor from Ct to the ground, the user selects the

5 10 Gnd The IC’s ground –

NA 6 OVP Overvoltage input By applying a 2.8 V typical level on this pin, the IC is permanently

6 11 Isense The primary–current

7 12 Drv This pin drives the

8 13 V

1. DIP14 has different pinouts. Please see Pin Connections.

2. Pin 2, 7, 8, 9 and 14 are nonconnected on DIP14.

Pin Name Function Description

V

bulk capacitor.

CC

This pin ensures the re–start of the main switcher when operating in

detection

free–run.

This level modulates the peak current level in free–running operation

control the PWM

and modulates the frequency in VFM operation.

minimum/maximum operating frequency.

latched–off until V

falls below UVLOL.

CC

This pin senses the primary current via an external shunt resistor.

sensing pin

The IC is able to deliver or absorb 250 mA peak currents while

CC

external switcher

Powers the IC A positive voltage up to 40 V

delivering a clamped driving signal.

typical

can be applied upon this pin

before the IC stops.

http://onsemi.com

2

Page 3

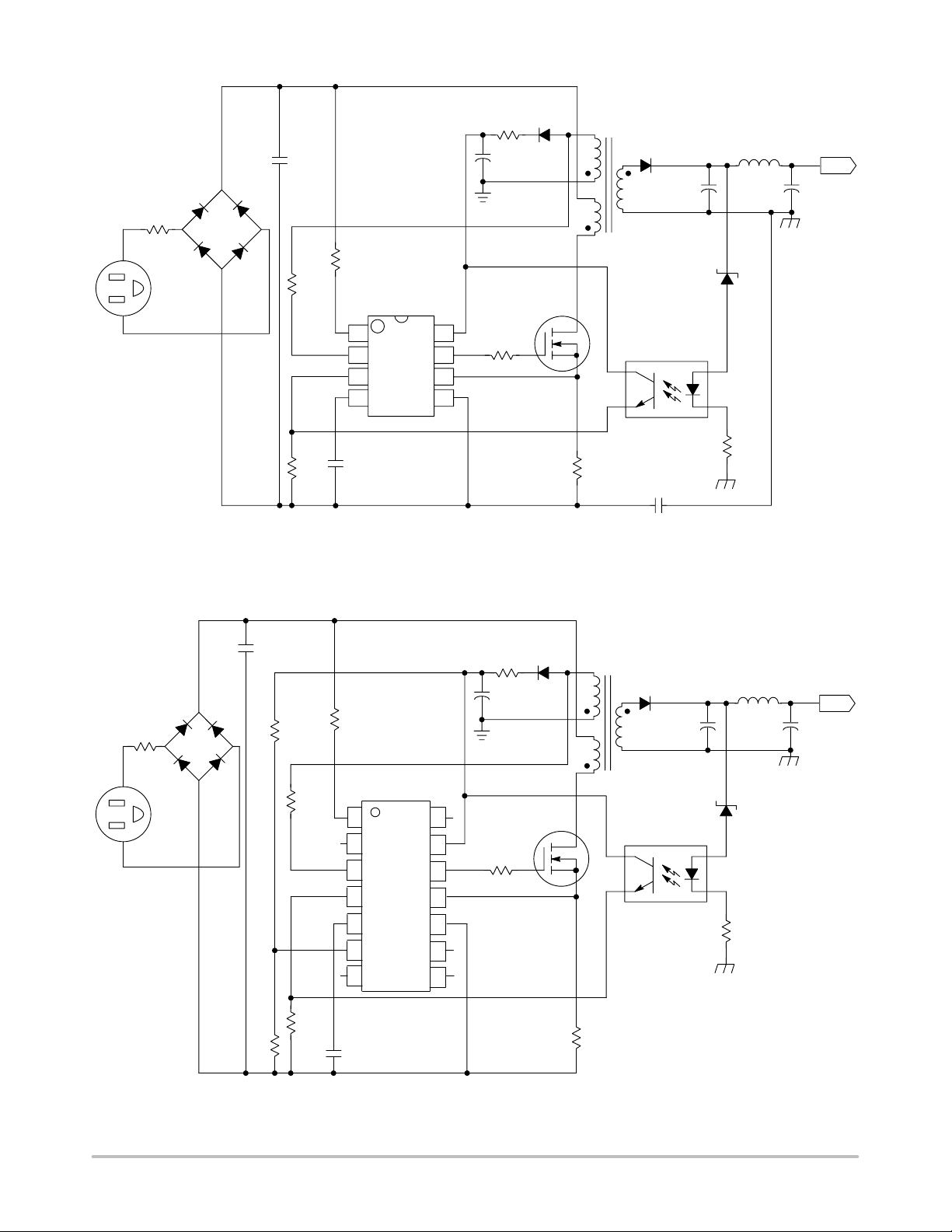

4x1N4007

R5

15

Universal Input

+

C1

10 µF

R8

22 k

* R10

15 k

1

2

NCP1205P

3

4

NCP1205

R2

150

+

C14

22 µF

8

7

6

5

R4

10

D2

1N4148

M2

MTD1N60E

D6

1N5819

IC4

C10

470 µF

10 V

D7

5.1 V

L2

10 µH

++

C11

100 µF

10 V

5 V

4x1N4007

R5

15

Universal Input

C12

R6

1 nF

4.7 k

* Please refer to the application information section regarding this element.

R3

3.3

Figure 1. Typical Application Example for DIP8 Version

+

C1

10 µF

R8

22 k

* R10

15 k

NCP1205P2

1 14

2

3

4

5

6

7

13

12

11

10

9

8

D2

R2

1N4148

15

+

C14

33 µF/35 V

M2

MTD1N60E

R4

6.8

SFH6156–2

C13

1.5 nF Y1

D6

1N5819

C10

470 µF

10 V

IC4

SFH6156–2

R1

560

L2

10 µH

D7

4.3 V

R1

560

++

C11

47 µF

10 V

5 V

R6

2.7 k

C12

ROVPL ROVPU

* Please refer to the application information section regarding this element.

1 nF

Figure 2. Typical Application Example for DIP14 Version

http://onsemi.com

3

R3

3.3

Page 4

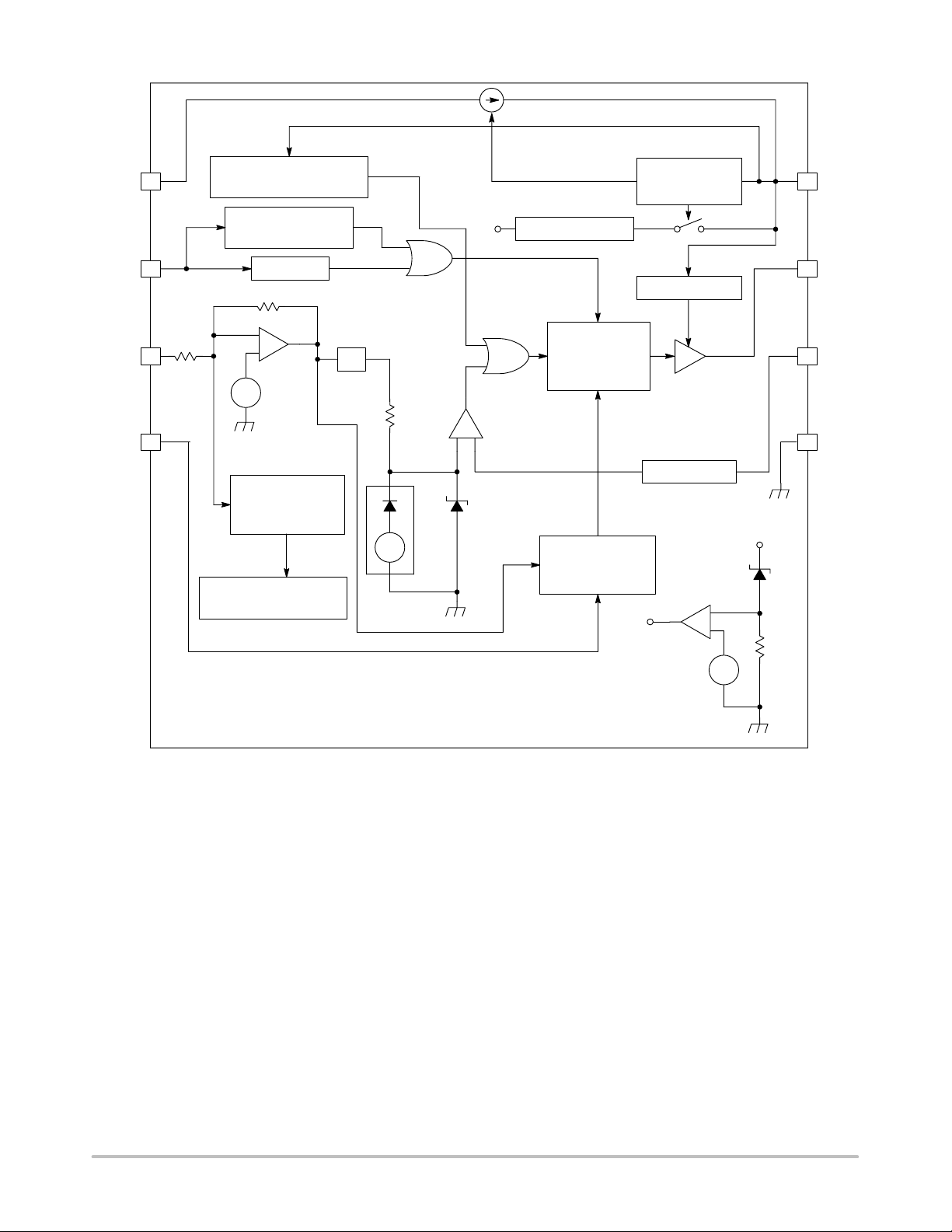

NCP1205

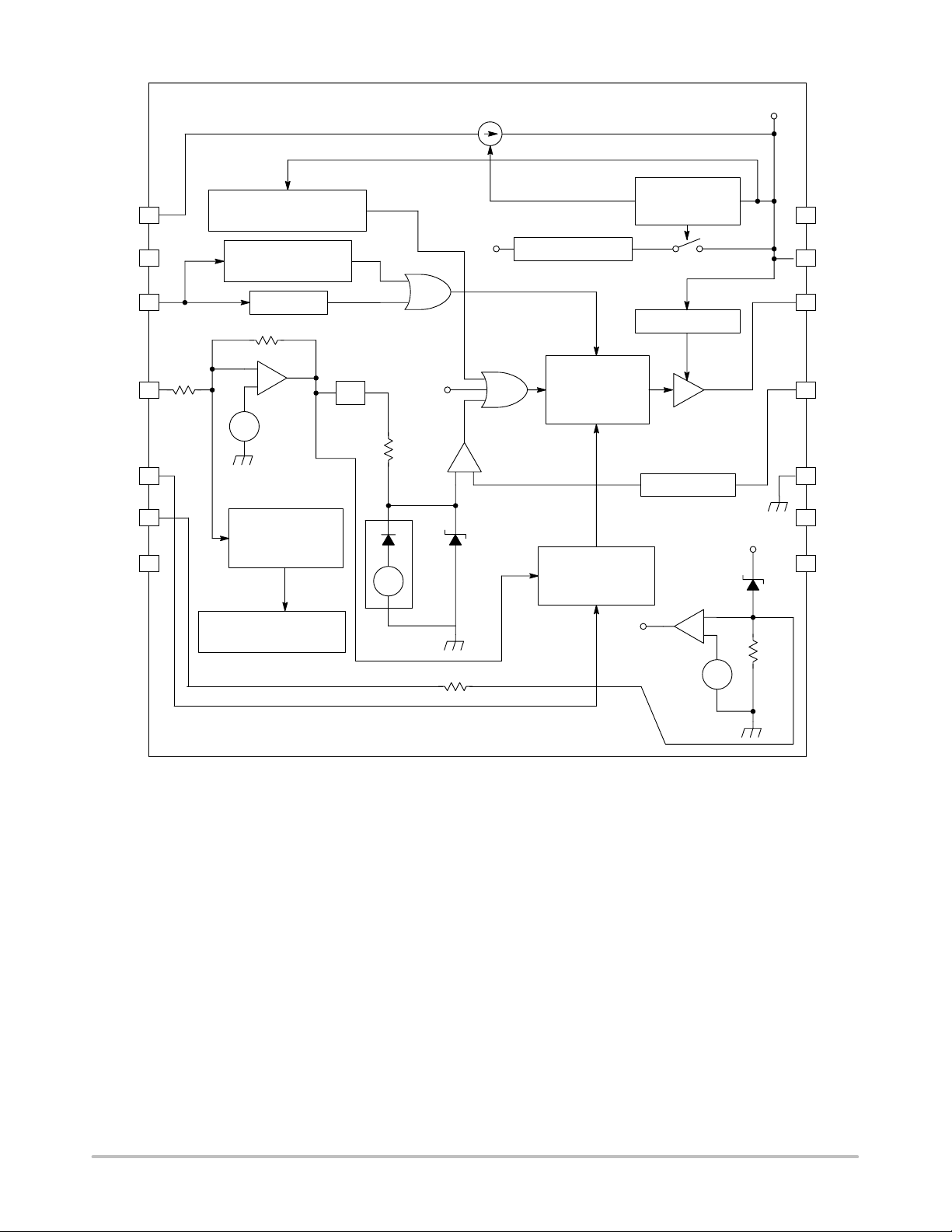

Startup

HV

Demag

FB

Ct

1

2

Protection (V

> 40 V)

CC

Last Pulse of Demag

after 4 µs

DEMAG ?

Internal V

CC

Internal Regulator

Rf

V

Max = 3 V

err

V

Min = 10 mV

Over Voltage

Ri

3

–

+

+

2.5 V

–

4 5

err

1/3

Current Comparator

–

+

250 mV – 1 V

Max Setpoint

Clock

Flip–Flop

RQ

D

UVLO

= 15 V

H

UVLO

= 7.2 V

L

Internal Clamp

Driver

200 ns L.E.B

Over Current

Protection (OCP)

V(–) < 1.5 V

+

–

Lasts more than 128 ms?

––> Protection Circuitry

1 V

250 mV Clamp

V

Pin 8

CC

err

VCO Feedback

T

= f (V

off

err

= f (Ct)

Max T

off

)

35 V Zener

V

+

OVP

–

18 k

+

2.8 V

–

8

V

CC

7

DRV

6

I

sense

Gnd

Figure 3. Internal Circuit Architecture for DIP8 Version

http://onsemi.com

4

Page 5

HV

NC

NCP1205

V

Pin 13

CC

Startup

UVLO

= 15 V

1

2

Protection (V

Last Pulse of Demag

after 4 µs

> 40 V)

CC

Internal V

CC

Internal Regulator

Over Voltage

UVLO

H

= 7.2 V

L

14

13

V

CC

Demag

FB

OVP

NC

Ct

3

Ri

4

5

6

7

Lasts more than 128 ms?

––> Protection Circuitry

DEMAG ?

Rf

–

+

+

2.5 V

–

Over Current

Protection (OCP)

V(–) < 1.5 V

Max = 3 V

V

err

V

Min = 10 mV

err

1/3

+

–

OVP

Current Comparator

–

+

250 mV – 1 V

Max Setpoint

1 V

250 mV Clamp

2.0 k

Internal Clamp

Clock

Flip–Flop

RQ

D

Driver

200 ns L.E.B

V

Pin 13

CC

err

VCO Feedback

T

= f (V

off

err

= f (Ct)

Max T

off

)

35 V Zener

V

+

OVP

–

18 k

+

2.8 V

–

12

11

10

DRV

I

sense

Gnd

NC

9

NC

8

Figure 4. Internal Circuit Architecture for DIP14 Version

http://onsemi.com

5

Page 6

NCP1205

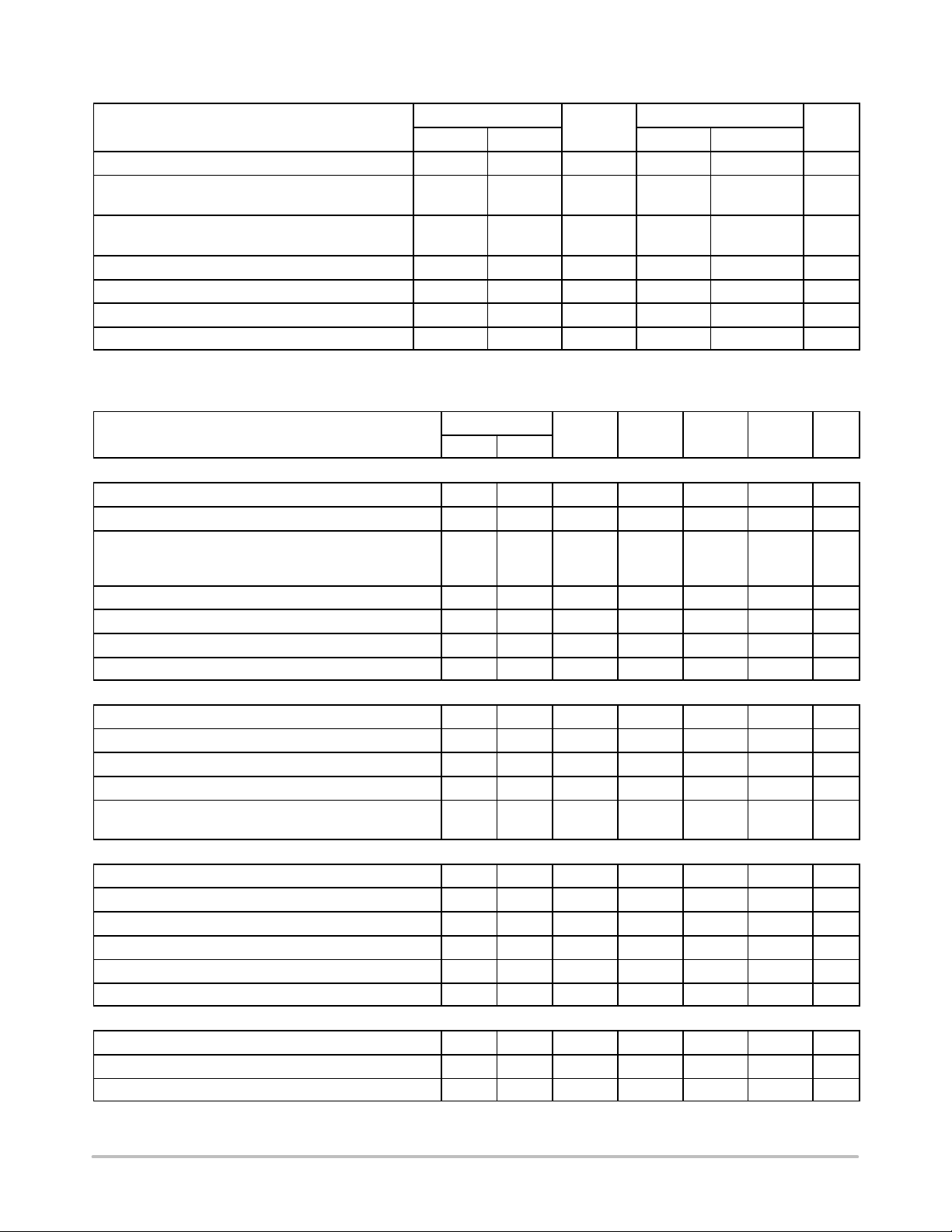

MAXIMUM RATINGS

Pin No.

Rating

Power Supply Voltage 8 13 V

Thermal Resistance Junction–to–Air DIP8

DIP14

Operating Junction Temperature Range

Maximum Junction Temperature

Storage Temperature Range – – T

ESD Capability, HBM Model All Pins All Pins

ESD Capability, Machine Model All Pins All Pins

DIP8 DIP14

–

–

–

–

–

–

–

–

Symbol

in

R

JA

T

J

T

Jmax

stg

–

–

Demagnetization Pin Current 3 3 – – 5.0 mA

Value

Min Max

– 45 V

–

–

–

–

100

100

–25 to +125

150

– –60 to +150 °C

– 2.0 kV

– 200 V

Unit

°C/W

°C

°C

ELECTRICAL CHARACTERISTICS (For typical values T

V

= 12 V unless otherwise noted.)

CC

= 25°C, for min/max values TJ = –25°C to +125°C, Max TJ = 150°C,

A

Pin No.

Characteristics

DIP8 DIP14

Symbol Min Typ Max Unit

Demagnetization Block

Input Threshold Voltage (V

Hysteresis (V

decreasing) 2 3 V

pin2

Input Clamp Voltage

High State (I

Low State (I

= 3.0 mA)

pin2

= –3.0 mA)

pin2

increasing) 2 3 Vth 50 65 85 mV

pin2

H

– 30 – mV

2 3

VC

VC

H

L

8.0

–0.9

10

–0.7

12

–0.5

Demag Propagation Delay – – – 100 300 350 ns

No Demag Signal Activation – – – – 4.0 8.0 µs

Internal Input Capacitance at 1.0 V 2 3 C

pin2

– 10 – pF

Demag Propagation Delay with 22 kΩ External Resistor 2 3 – 100 370 480 ns

Feedback Path

Input Impedance at V

Internal Error Amplifier Closed Loop Gain 3 4 AV

Internal Built–In Offset Voltage for Error Detection – – V

= 3.0 V 3 4 Zin – 50 – kΩ

FB

CL

ref

– –3.0 – –

2.2 2.5 2.8 V

Error Amplifier Level of VCO Take Over – – – – 1.0 – V

Internal Divider from Internal Error Amp, Pin to Current

– – – – 3.0 – –

Setpoint

V

Fault Detection Circuitry

Internal Over Current Level

– – WL

L

– 1.5 – V

Fault Time Duration to Latch Activation @ Ct = 1.0 ηF – – – – 128 – ms

Over Current Latch–Off Phase @ Ct = 1.0 ηF – – – – 1.0 – s

Hysteresis when VFB goes back into Regulation – – – – 100 – mV

VCC (Pin 8) Over Voltage Protection 8 13 OVP1 36 40 43 V

Over Voltage Protection Threshold for DIP14 Version 6 6 OVP2 2.5 2.8 3.1 V

Current Sense Comparator

Input Bias Current @ 1.0 V

Maximum Current Setpoint 6 11 V

Minimum Current Setpoint 6 11 V

6 11 I

IB

min

– 0.02 – µA

cl

0.9 1.0 1.1 V

225 250 285 mV

http://onsemi.com

6

Page 7

NCP1205

ELECTRICAL CHARACTERISTICS (continued) (For typical values T

Max T

= 150°C, VCC = 12 V unless otherwise noted.)

J

= 25°C, for min/max values TJ = 25°C to +125°C,

A

Pin No.

Characteristics

DIP8 DIP14

Symbol Min Typ Max Unit

Current Sense Comparator (continued)

Propagation Delay from Current Detection to Gate OFF

6 11 T

del

– 200 250 ns

State

Leading Edge Blanking (LEB) 6 11 T

leb

– 200 – ns

Frequency Modulator

Minimum Frequency Operation @ Ct = 1.0 ηF and

V

= 35 V

CC

Maximum Frequency Operation @ Ct = 1.0 ηF and

V

= 35 V

CC

4 5 F

4 5 F

min

max

– 0 – kHz

90 110 125 kHz

Minimum Ct Charging Current (Note 3) 4 5 ICtmin – 0 – µA

Maximum Ct Charging Current (Note 3) 4 5 ICtmax 280 350 420 µA

Discharge Time @ Ct = 1.0 ηF 4 5 – – 500 – ns

Drive Output

Output Voltage Rise Time @ C

Output Voltage Fall Time @ CL = 1.0 ηF (V = 10 V) 7 12 t

Clamped Output Voltage @ VCC = 35 V (Note 4) 7 12 V

Voltage Drop on the Stage @ VCC = 10 V (Note 4) 12 12 V

= 1.0 ηF (V = 10 V) 7 12 t

L

r

f

DRV

DRV

– 30 50 ns

– 30 50 ns

11 13 16 V

– – 0.5 V

Undervoltage Lockout

Startup Threshold (V

Minimum Operating Voltage (VCC Decreasing) 8 13 UVLO

Increasing) 8 13 UVLO

CC

13.5 15 16.5 V

H

6.5 7.2 8.0 V

L

Startup Current Source

Maximum Voltage, Pin 1 Grounded

1 1 – – 450 – V

Maximum Voltage, Pin 1 Decoupled (470 µF) 1 1 – – 500 – V

Startup Current Source Flowing through Pin 1 1 1 – 2.3 3.0 4.8 mA

Leakage Current in Offstate @ Vpin 1 = 500 V 1 1 – – 32 70 µA

Device Current Consumption

V

less than UVLO

CC

H

8 13 – – 1.5 1.8 mA

VCC = 35 V and Fsw = 2.0 kHz, CL = 1.0 ηF 8 13 – – 1.2 3.0 mA

VCC = 35 V and Fsw = 125 kHz, CL = 1.0 ηF 8 13 – – 3.0 4.0 mA

Startup Current to VCC Capacitor 8 13 – 1.4 – – mA

3. Typical capacitor swing is between 0.5 V and 3.5 V.

4. Guaranteed by design, T

= 25°C.

J

http://onsemi.com

7

Page 8

NCP1205

380

360

340

320

300

Ct CHARGING CURRENT (µA)

280

16.5

15.5

420

400

16

–50

0 50 100 –50 0 50 100150

TEMPERATURE (°C)

Figure 5. Ct Charging Current versus

Temperature

125

120

115

110

105

100

95

SWITCHING FREQUENCY (kHz)

90

TEMPERATURE (°C)

Figure 6. Switching Frequency @ Ct = 1 nF

versus Temperature

1100

1050

150

15

14.5

START–UP THRESHOLD (V)

14

13.5

–50 0 50 100 –50 0 50 100

TEMPERATURE (°C)

150

Figure 7. Start–up Threshold versus

Temperature

43

42

41

40

39

OVER VOLTAGE (V)

38

CC

V

37

36

–50 0 50 100 –50 0 50 100

TEMPERATURE (°C)

150

1000

950

MAXIMUM CURRENT SET POINT (mV)

900

TEMPERATURE (°C)

Figure 8. Maximum Current Set Point versus

Temperature

8

7.75

7.5

7.25

7

6.75

MINIMUM OPERATING VOLTAGE (V)

6.5

TEMPERATURE (°C)

150

150

Figure 9. VCC Over Voltage Protection versus

Temperature

http://onsemi.com

Figure 10. Minimum Operating Voltage versus

Temperature

8

Page 9

NCP1205

APPLICATION INFORMATION

Introduction

By implementing a unique smooth frequency reduction

technique, the NCP1205 represents a major leap toward

low–power Switch–Mode Power Supply (SMPS) integrated

management. The circuit combines free–running operation

with minimum drain–source switching (so–called valley

switching), which naturally reduces the peak current stress

as well as the ElectroMagnetic Interferences (EMI). At

I

L

Not 0 at

Turn ON

I

P

OFF

I

L(avg)

ON

nominal output power, the circuit implements a traditional

current–mode SMPS whose peak current setpoint is given

by the feedback signal. However, rather than keeping the

switching frequency constant, each cycle is initiated by the

end of the primary demagnetization. The system therefore

operates at the boundary between Discontinuous

Conduction Mode (DCM) and Continuous Conduction

Mode (CCM). Figure 11 details this terminology:

L > Lc

0

L = Lc

L < Lc

Borderline

D/Fs

Time

Figure 11. Defining the Conduction Mode, Discontinuous, Continuous and Borderline

When the output power demands decreases, the natural

switching frequency raises. As a natural result, switching

losses also increase and degrade the SMPS efficiency. To

overcome this problem, the maximum switching frequency

of the NCP1205 is clamped to typically 125 kHz. When the

free running mode (also called Borderline Control Mode,

BCM) reaches this clamp value, an internal

Voltage–Controlled Oscillator (VCO) takes over and starts

to decrease the switching frequency: we are in Variable

Frequency Mode (VFM). Please note that during this

transition phase, the peak current is not fixed but is still

decreasing because the output power demand does. At a

given state, the peak current reaches a minimum ceil

(typically 250 mV/Rsense), and cannot go further down: the

switching frequency continues its decrease down to a

possible minimum of 0 Hz (the IC simply stops switching).

During normal free–running operation and VFM, the

controller always ensures single or multiple drain–source

0 Before

Turn ON

0

Dead–Time

valley switching. We will see later on how this is internally

implemented.

The FLYBACK operation is mainly defined through a

simple formula:

Pout

1

·Lp·Ip2· Fsw (eq. 1)

2

With:

Lp the primary transformer inductance (also called the

magnetizing inductance)

Ip the peak current at which the MOSFET is turned off

Fsw the nominal switching frequency

To adjust the transmitted power, the PWM controller can

play on the switching frequency or the peak current setpoint.

To refine the control, the NCP1205 of fers the ability to play

on both parameters either altogether on an individual basis.

http://onsemi.com

9

Page 10

NCP1205

In order to clarify the device behavior, we can distinguish the

following simplified operating phases:

1. The load is at its nominal value. The SMPS operates in

borderline conduction mode and the switching

frequency is imposed by the external elements (Vin,

Lp, Ip, Vout). The MOSFET is turned on at the

minimum drain–source level.

2. The load starts to decrease and the free–running

frequency hits the internal clamp.

3. The frequency can no longer naturally increase

because of the clamp. The frequency is now controlled

by the internal VCO but remains constant. The peak

current finds no other option that diminishing to satisfy

equation (1).

4. The peak current has reached the internal minimum

ceiling level and is now frozen for the remaining

cycles.

5. To further reduce the transmitted power (V

the VCO decreases the switching frequency. In case of

output overshoot, the VCO could decrease the

frequency down to zero. When the overshoot has gone,

V

diminishes again and the IC smoothly resumes its

FB

operation.

Advantages of the Method

By implementing the aforementioned control scheme, the

NCP1205 brings the following advantages:

goes up),

FB

• Discontinuous only operation: in DCM, the Flyback is

a first order system (at low frequencies) and thus

naturally eases the feedback loop compensation.

• A low–cost secondary rectifier can be used due to

smooth turn–off conditions.

• Valley switching ensures minimum switching losses

brought by Coss and all the parasitic capacitances.

• By folding back the switching frequency, you turn the

system into Pulse Duration Modulation. This method

prevents from generating uncontrolled output ripple as

with hysteretic controllers.

• By letting you control the peak current value at which

the frequency goes down, you ensure that this level is

low enough to avoid transformer acoustic noise

generation even at audible frequencies.

Detailed Description

The following sections describe the internal behavior of

the NCP1205.

Free–Running Operation

As previously s aid, t he o perating f requency a t n ominal l oad

is dictated b y t he e xternal e lements. We can split the d if ferent

switching sections in t wo s eparated i nstants. I n t he following

text we use the internal error voltage, Verr. This level is

elaborated as F igure 1 4 p ortrays. Verr is linked t o V FB (pin 4)

by the following formula:

Verr 10 3·V

ON time: The ON time is given by the time it takes to

reach the peak current setpoint imposed by the level on FB

pin (pin 4). Since this level is internally divided by three, the

peak setpoint is simply:

Ipk

The rising slope of the peak current is also dependent on

the inductance value and the rectified DC input voltage by:

By combining both equations, we obtain the ON time

definition:

Vin

toff

·Ip

Verr · Lp

3 · Rsense

Lp

DC

Np

Ns

ton

OFF time: The time taken by the demagnetization of the

transformer depends on the reset voltage applied at the

switch opening. During the conduction time of the

secondary diode, the primary side of the transformer

undergoes a reflected voltage of: [Np/Ns . (Vf + Vout)]. This

voltage applied on the primary inductance dictates the time

needed to decrease from Ip down to zero:

By adding ton + toff, we obtain the natural switching

frequency of the SMPS operating in Borderline Conduction

Mode (BCM):

ton toff

1

3 · Rsense

dIL

Vin

dt

·Ip

Np

· (Vout Vf)

Ns

Lp · Verr

· (Vout Vf)·3·Rsense

·

Vin

FB

· Verr (eq. 3)

DC

Lp

Lp·V

ERR

VinDC·3·Rsense

Lp

1

DC

Np

· (Vout Vf)

Ns

(eq. 2)

(eq. 4)

(eq. 5)

(eq. 6)

1

(eq. 7)

http://onsemi.com

10

Page 11

NCP1205

If we now enter this formula into a spreadsheet, we can easily plot the switching frequency versus the output power demand:

250000

200000

150000

100000

50000

SWITCHING FREQUENCY (Hz)

Fmax Fmax

VCO Action

0

015105

OUTPUT POWER (W)

Figure 12. A Typical Behavior of Free Running Systems

with a Smooth Frequency Foldback with the NCP1205

The typical above diagram shows how the frequency

moves with the output power demand. The components used

for the simulation were: Vin = 300 V, Lp = 6.5 mH,

Vout = 10 V, Np/Ns = 12.

The red line indicates where the maximum frequency is

clamped. At this time, the VCO takes over and decreases the

switching frequency to the minimum value.

VCO Operation

The VCO is controlled from the Verr voltage. For Verr

levels above 1.0 V, the VCO frequency remains unchanged

at 125 kHz. As soon as Verr starts to decrease below 1.0 V,

Transition

BCM to VFM

20

the VCO frequency decreases with a typical small–signal

slope of –175 kHz/mV @ Verr = 500 mV down to

zero (typically at FB ≈ 3.3 V). The demagnetization

synchronization is however kept when the Toff expands.

The maximum switching frequency can be altered by

adjusting the Ct capacitor on pin 5. The 125 kHz maximum

operation ensures that the fundamental component stays

external from the international EMI CISPR–22

specification beginning.

The following drawing explains the philosophy behind

the idea:

Internal V

Frequency

V

CO

is Fixed at 130 kHz

VCO Frequency

can Decrease

Figure 13. When the Power Demand goes Low, the Peak Current is Frozen and the Frequency Decreases

Zero Crossing Detector

To detect the zero primary current, we make use of an

auxiliary winding. By coupling this winding to the primary,

we have a voltage image of the flux activity in the core.

Figure 13 details the shape of the signal in BCM.

The auxiliary winding for demagnetization needs to

be wired in Forward mode. However, the application

note describes a n alternative s olution showing h ow to wire

err

BCM Mode

Peak Current is Fixed

3 V

Peak current

can change

1 V

0.75 V

the MOSFET closes, the auxiliary winding delivers

(Naux/Np . Vin). At the switch opening, we couple the

auxiliary winding to the main output power winding and

thus deliver: (–Naux/Ns . Vout). When DCM occurs, the

ringing also takes place on the auxiliary winding. As soon

as the level crosses–up the internal reference level

(65 mV), a s ignal i s internally sent to re–start the M OSFET .

Three different conditions can occur:

the winding i n Flyback a s well. A s Figure 1 3 depicts, w hen

http://onsemi.com

11

Page 12

NCP1205

1. In BCM, every time the 65 mV line is crossed, the

switch is immediately turned–on. By accounting for

the internal Demag pin capacitance (10–15 pF

typical), you can introduce a fixed delay, which,

combined to the propagation delay, allows to precisely

re–start in the drain–source valley (minimum voltage

to reduce capacitive losses).

2. When the IC enters VFM, the VCO delivers a pulse

which is internally latched. As soon as the

demagnetization pulse appears, the logic re–starts the

MOSFET.

3. As can be seen from Figure 13, the parasitic

oscillations on the drain are subject to a natural

damping, mainly imputed to ohmic l osses. A t a g iven

point, the demag activity on the auxiliary winding

becomes too l ow to b e detected. To avoid a ny r e–start

problem, the TY72001 features an internal 4.0 µs

timeout delay. This timeout runs after each demag

pulse. If within 4.0 µs further to a demag pulse no

activity is detected, an internal signal is combined

with the VCO to actually re–start the MOSFET

(synchronized with Ct).

Error Amplifier and Fault Detection

The NCP1205 features an internal error amplifier solely

used to detect an overcurrent problem. The application

assumes that all the error gain associated with the precise

reference level is located on the secondary side of the SMPS.

Various solutions can be purposely implemented such as the

TL431 or a dedicated circuit like the MC33341. In the

NCP1205, the internal OPAMP is used to create a virtual

ground permanently biased at 2.5 V (Figure 14), an internal

reference level. By monitoring this virtual ground further

called V(–), we have the possibility to confirm the good

behavior of the loop. If by any mean the loop is broken

(shorted optocoupler, open LED etc.) or the regulation

cannot be reached (true output short–circuit), the OPAMP

network is adjusted in order to no longer be able to ensure

the 2.5 V virtual point V(–). If V(–) passes down the 1.5 V

level (e.g. output shorted) for a time longer than 128 ms, then

the pulses are stopped for 8 x 128 ms. The IC enters a kind

of burst mode with bunch of pulses lasting 128 ms and

repeating every 8 x 128 ms. If the loop is restored within the

8 x 128 ms period, then the pulses are back again on the

output drive (synchronized with UVLO

).

H

Drain Level

Valley

Switching

Possible Demag

65 mV

Auxiliary Level

IP = 0

Restart when Demag is too low

750.0 U 754.0 U 758.0 U 762.0 U 766.0 U

Figure 14. Core Reset Detection is done through

an Auxiliary Winding Operated in Forward

4 µs

0 V

2

http://onsemi.com

12

Page 13

NCP1205

Monitor

Rf

150 k

V

fb

Ri

50 k

V(–)

+

V

fb

V

V

HIGH

LOW

3

1

+

= 3 V

= 5 mV

–

+

V1

2.5 V

2R

2

6

R

Current

Setpoint

+

V

low

1.5 V

Figure 15. This Typical Arrangement Allows for an Easy Fault Detection Management

To illustrate how the system reacts to a variable FB level,

we have entered the above circuit into a SPICE simulator

and observed the output waveforms. When FB is within

regulation, the error flag is low. However, as soon as FB

leaves its normal operating area, the OPAMP can no longer

keep the V(–) point and either goes to the positive top or

down to zero: the error flag goes high.

Because of the large amount of delay necessary for this

128 ms operation, the capacitor used for the timing is Ct,

6.500

Regulation Area

4.500

+

–

5

7

OCP

Circuitry

connected from ground to pin 5. In normal VFM operation,

this timing capacitor serves as the VCO capacitor and the

error management circuit is transparent. As soon as an error

is detected (error flag goes high), an internal switch routes

Ct to the 128 ms generator. As a first effect, the switching

frequency is no longer controlled by the VCO (if the error

appears during VFM) and the system is relaxed to natural

BCM. The capacitor now ramps up and down to be further

divided and finally create the 128 ms delay.

FB

Virtual Point

2.500

500.0 M

1.5 V

OCP Condition

Error Flag

1.000 M 3.000 M 5.000 M 7.000 M 9.000 M

Figure 16. By Monitoring the Internal Virtual Ground, the System can Detect the Presence of a Fault

http://onsemi.com

13

Page 14

NCP1205

As soon as the system recovers from the error, e.g. FB is

back within its regulation area, the IC operation comes back

to normal.

To avoid any system thermal runaway, another internal

8 x 128 ms delay is combined with the previous 128 ms. It

works as follows: the 128 ms delay is provided to account for

any normal transients that engender a temporary loss of

feedback (FB goes toward ground). However, when the

128 ms period is actually over (the feedback is definitively

lost) the IC stops the output driving pulses for a typical

period of 8 x 128 ms. During this mode, the rest of the

functions are still activated. For instance, in lack of pulses,

the self–supplied being no longer provided, the start–up

source turns on and off (when reaching the corresponding

UVLO

and UVLO

L

levels), creating an hiccup waveform

H

on the Vcc line. As soon as the feedback condition is

restored, the 8 x 128 ms is interrupted and, in synchronism

with the Vcc line, the IC is back to normal. The following

diagrams show how this mechanism takes place when FB is

down to zero (optocoupler opened) or up to Vcc

(optocoupler shorted). If we assume that the error is

permanently present, then a burst mode takes place with a

128/8 x 128 = 12.5% duty–cycle. The real transmitted

power is thus:

Pout

BURST

1

·Lp·Ip2·Fsw·Duty

2

BURST

discharges toward ground. When the Vcc level crosses

UVLO

, a new startup sequence occurs. If the OVP has

L

gone, normal IC operation takes place. For different OVP

levels, the comparator input is accessible through pin 6 in the

DIP14 option.

V

CC

6

5 V

5

10 V

4

10 V

3

10 V

Latched

OVP

+

7

–

2

1

+

2.8 V

2 k

18 k

OVP

8

Overvoltage Detection (OVP)

OVP detection is done differently on the DIP8 and DIP14

versions. In the DIP8, because of available pin count, the

OVP is accomplished by monitoring the Vcc voltage. On the

DIP14, the device also monitors the Vcc level but in parallel,

the triggering point has been pin–out to allow precise OVP

selection. This pin can also be used to externally latch–off

the IC.

As mentioned, Over Voltage Conditions are detected by

monitoring the Vcc level. Figure 17 describes how three

10 V zener plus one 5.0 V zener are connected in series

together with a 18 kΩ to ground. As soon as Vcc exceeds

40 V typical, a current starts to flow in the 18 k resistor.

When the voltage developed across this element exceeds

2.8 V, an error is triggered and immediately latches the IC

off. In lack of switching pulses, the Vcc capacitor is no

longer refreshed by the auxiliary supply and slowly

Figure 17. In the DIP8 Version, the OVP Pad is not

Pinned Out and is Available with DIP14 Devices Only

Protecting Pin 1 Against Negative Spikes

As any CMOS controller, NCP1205 is sensitive to

negative voltages that could appear on it’s pins. To avoid any

adverse latch–up of the IC, we strongly recommend

inserting a 15 k resistor in series with pin 1 and the

high–voltage rail, as shown in Figures 18 and 19. This 15 k

resistor prevents from adversely latching the controller in

case of negative spikes appearing on the bulk capacitor

during the power–off sequence. Please note that this resistor

does not dissipate any continuous power and can therefore

be of low power type. Two 8.2 k can also be wired in series

to sustain the large DC voltage present on the bulk.

http://onsemi.com

14

Page 15

NCP1205

V

CC

Drive

OVP

Unit V

Reaches UVLO

CC

L

Figure 18. When the VCC Voltage Goes Above the

Maximum Value, the Device Enters Safe Burst Mode

40 V

UVLO

UVLO

H

L

V

CC

Drive

V(–)

Arbitrary V

Representation

CC

8 x 128 ms maximum if loop does not

recover

128 ms

Figure 19. When the Internal V(–) Passes Below 1.5 V, the IC

Senses a Short–Circuit Event

UVLO

UVLO

3.5 V

1.5 V

H

L

Loop Recovers

Here

http://onsemi.com

15

Page 16

NOTE 2

–T–

SEATING

PLANE

H

58

–B–

14

F

–A–

C

N

D

G

0.13 (0.005) B

NCP1205

PACKAGE DIMENSIONS

PDIP–8

N SUFFIX

CASE 626–05

ISSUE L

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

DIM MIN MAX MIN MAX

A 9.40 10.16 0.370 0.400

B 6.10 6.60 0.240 0.260

C 3.94 4.45 0.155 0.175

D 0.38 0.51 0.015 0.020

L

J

K

M

M

A

T

M

M

F 1.02 1.78 0.040 0.070

G 2.54 BSC 0.100 BSC

H 0.76 1.27 0.030 0.050

J 0.20 0.30 0.008 0.012

K 2.92 3.43 0.115 0.135

L 7.62 BSC 0.300 BSC

M --- 10 --- 10

N 0.76 1.01 0.030 0.040

INCHESMILLIMETERS

http://onsemi.com

16

Page 17

NCP1205

PACKAGE DIMENSIONS

PDIP–14

P SUFFIX

CASE 646–06

ISSUE M

14 8

B

17

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. ROUNDED CORNERS OPTIONAL.

–T–

SEATING

PLANE

N

HG

A

F

L

C

D

14 PL

0.13 (0.005)

K

J

M

M

DIM MIN MAX MIN MAX

A 0.715 0.770 18.16 18.80

B 0.240 0.260 6.10 6.60

C 0.145 0.185 3.69 4.69

D 0.015 0.021 0.38 0.53

F 0.040 0.070 1.02 1.78

G 0.100 BSC 2.54 BSC

H 0.052 0.095 1.32 2.41

J 0.008 0.015 0.20 0.38

K 0.115 0.135 2.92 3.43

0.290 0.310 7.37 7.87

L

M --- 10 --- 10

N 0.015 0.039 0.38 1.01

MILLIMETERSINCHES

http://onsemi.com

17

Page 18

Notes

NCP1205

http://onsemi.com

18

Page 19

Notes

NCP1205

http://onsemi.com

19

Page 20

NCP1205

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make

changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any

particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death

may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

NCP1205/D

20

Loading...

Loading...