Page 1

Inductive sensor NBN30-U1K-E2-3G-3D

Technical Data

General specifications

Switching function Normally open (NO)

Output type PNP

Rated operating distance sn30 mm

Installation non-flush

Output polarity DC

Model Number

NBN30-U1K-E2-3G-3D

Features

• Sensor head bidirectional and rotatable

• 4 LEDs indicator for 360° visibility

• 30 mm non-flush

• ATEX-approval for zone 2 and zone 22

Accessories

MHW 01

Modular mounting bracket

Assured operating distance s

Actual operating distance sr27 ... 33 mm typ. 30 mm

Reduction factor r

Reduction factor rCu 0.31

Reduction factor r

Reduction factor r

Output type 3-wire

Nominal ratings

Operating voltage UB10 ... 30 V

Switching frequency f 0 ... 150 Hz

Hysteresis H typ. 5 %

Reverse polarity protection reverse polarity protected

Short-circuit protection pulsing

Vol tag e d rop Ud≤ 2 V

Vol tag e d rop at I

Vol tage dro p IL = 1 mA, switching element

on U

d

Vol tag e dr op I

on U

d

Vol tag e dr op IL = 20 mA, switching element

on U

d

Vol tag e dr op I

on U

d

Vol tage dro p IL = 100 mA, switching element on U

Vol tage dro p I

ment on U

Operating current I

Off-state current I

Off-state current TU =40 °C, switching ele-

ment off

No-load supply current I

Time delay before availability t

Operating voltage indicator LED, green

Switching state indicator LED, yellow

Functional safety related parameters

MTTFd 1362 a

Mission Time (T

Diagnostic Coverage (DC) 0 %

Ambient conditions

Ambient temperature -25 ... 85 °C (-13 ... 185 °F)

Mechanical specifications

Connection type screw terminals

Information for connection A maximum of two conductors with the same core cross section

Core cross-section up to 2.5 mm

Minimum core cross-section

Maximum core cross-section

Housing material PA

Sensing face PA

Degree of protection IP68 / IP69K

Mass 225 g

Note Tightening torque: 1.8 Nm (housing)

General information

Use in the hazardous area see instruction manuals

Category

Compliance with standards and directives

Stan dard conf ormit y

Sta ndar ds

Approvals and certificates

FM approval hazardous (classified) location

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated ≤36 V

0.33

Al

0.74

304

0.38

Brass

L

= 10 mA, switching element

L

= 50 mA, switching element

L

d

= 200 mA, switching ele-

L

d

) 20 a

M

0 ... 24.3 mm

a

0.5 ... 2.3 V typ. 0.9 V

0.8 ... 2.2 V typ. 1.4 V

0.9 ... 2.3 V typ. 1.5 V

0.9 ... 2.5 V typ. 1.6 V

1 ... 2.6 V typ. 1.8 V

1.2 ... 2.8 V typ. 2 V

0 ... 200 mA

L

0 ... 0.5 mA typ. 0.01 mA

r

≤ 100 µA

≤ 20 mA

0

80 ms

v

may be mounted on one terminal connection!

tightening torque 1.2 Nm + 10 %

without wire end ferrule 0.5 mm

without wire end ferrule 2.5 mm2 , with connector sleeves 1.5 mm

3G; 3D

EN 60947-5-2:2007

EN 60947-5-2/A1:2012

IEC 60947-5-2:2007

IEC 60947-5-2 AMD 1:2012

Non-incendive

2

2

, with connector sleeves 0.34 mm

2

2

Release date: 2017-05-17 11:37 Date of issue: 2017-05-17 209263_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Page 2

Inductive sensor NBN30-U1K-E2-3G-3D

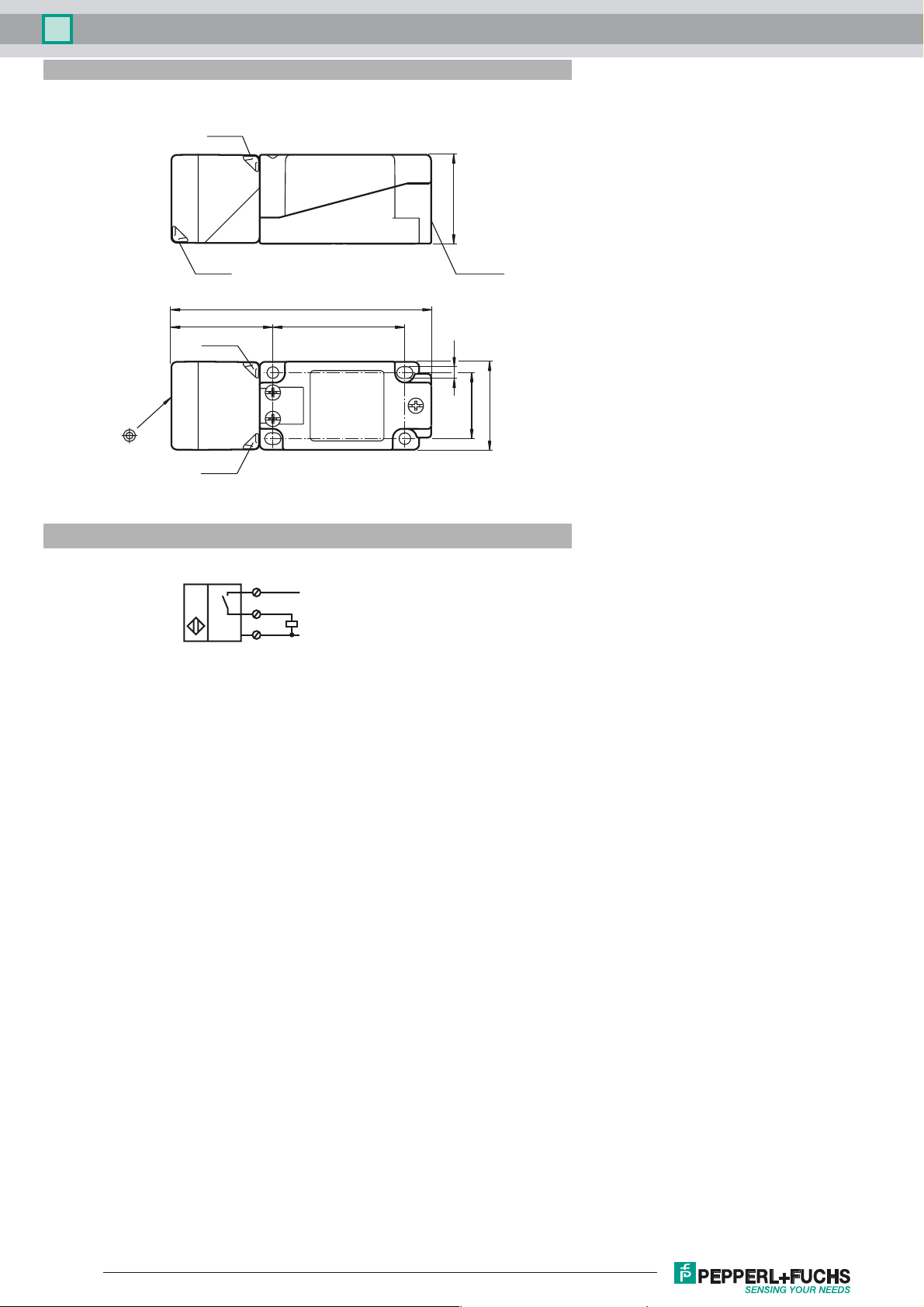

Dimensions

LED ye

40

LED gn

Electrical Connection

LED gn

LED ye

M20 x 1.5

118

6046

5.3

30

40

1

4

3

L+

L-

Release date: 2017-05-17 11:37 Date of issue: 2017-05-17 209263_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Page 3

Inductive sensor NBN30-U1K-E2-3G-3D

Equipment protection level Gc (nA)

Instruction Manual electrical apparatus for hazardous areas

Device category 3G (nA) for use in hazardous areas with gas, vapour and mist

Certificate PF 15CERT3754 X

CE marking

ATEX ma rk in g ¬ II 3G Ex nA IIC T6 Gc

Standards EN 60079-0:2012+A11:2013, EN 60079-15:2010

Ge n e r a l The apparatus has to be operated according to the appropriate data in the data sheet

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal must

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions

Maximum operating current I

Maximum operating voltage U

Maximum permissible ambient temperature T

at U

at U

at U

=30 V, IL=200 mA

Bmax

=30 V, IL=100 mA

Bmax

=30 V, IL=50 mA

Bmax

L

Bmax

Umax

Protection from mechanical danger

Protection from UV light

Protection against transients

Electrostatic charge

Lead insertion

Material selection accessories

Plug connector

The Ex-related marking can also be printed on the enclosed label.

Ignition protection category "n"

Use is restricted to the following stated conditions

and in this instruction manual. The data stated in the data sheet are restricted by this

operating instruction! The special conditions must be observed!

be observed. If the Ex-related marking is printed only on the supplied label, then this

must be attached in the immediate vicinity of the sensor. The sticking surface for the

label must be clean and free from grease. The attached label must be legible and indelible, including in the event of possible chemical corrosion. After opening the housing,

you should check that the seal is in the correct position and is clean and intact before

closing the housing again.

Repairs to these apparatus are not possible. After opening the housing, you should

check that the seal is in the correct position and is clean and intact before closing the

housing again.

The maximum permissible load current must be restricted to the values given in the following list. High load currents and load short-circuits are not permitted.

The maximum permissible operating voltage UB max is restricted to the values in the

following list. Tolerances are not permissible.

dependant of the load current I

Information can be taken from the following list.

and the max. operating voltage U

L

Bmax

50 °C (122 °F)

53 °C (127.4 °F)

54 °C (129.2 °F)

The sensor must not be exposed to ANY FORM of mechanical danger.

The sensor and the connection cable must be protected from damaging UV-radiation.

This can be achieved when the sensor is used in internal areas.

Ensure transient protection is provided and that the maximum value of the transient pro-

tection (140% of 85 V) is not exceeded.

When used in group IIC non-permissible electrostatic charges should be avoided on the

plastic housing parts. Avoid electrostatic charges that can cause electrostatic discharge

when installing or operating the device. Information on electrostatic hazards can be

found in the technical specification IEC/TS 60079-32-1.

If cable glands are required for the installation then the following points must be

observed: The cable glands must be certified in accordance with the application.

The temperature range of the cable glands must be selected according to the application. The degree of protection must not be reduced by the cable glands. Seal

the housing. Use a seal that meets the requirements of the application.

When selecting accessories, ensure that the material allows the temperature of the

enclosure to rise to up to 70 °C.

The plug connector must not be withdrawn under voltage. The proximity switch is identified as follows: "WARNING - DO NOT SEPARATE WHEN ENERGIZED". With the plug

connector disconnected, soiling of the internal area must be prevented.(i.e. the area that

is inaccessible when the connector is inserted)

Release date: 2017-05-17 11:37 Date of issue: 2017-05-17 209263_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Page 4

Inductive sensor NBN30-U1K-E2-3G-3D

Equipment protection level Dc (tD)

Note This instruction is only valid for products according to EN 61241-0:2006 and EN 61241-1:2004

Instruction Manual electrical apparatus for hazardous areas

Device category 3D for use in hazardous areas with combustible dust

CE marking

ATEX marking ¬ II 3D Ex tD A22 IP67 T80°C X

Standards EN 61241-0:2006, EN 61241-1:2004

General The apparatus has to be operated according to the appropriate data in the data sheet and in this instruction manual.

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal must be observed.

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions

Maximum operating current I

Maximum operating voltage U

Maximum permissible ambient temperature T

at U

at U

at U

Umax

=30 V, IL=200 mA

Bmax

=30 V, IL=100 mA

Bmax

=30 V, IL=50 mA

Bmax

L

Bmax

Protection from mechanical danger

Protection from UV light

Electrostatic charge

Connections for external wire

Lead insertion

Plug connector

Note the ex-marking on the sensor or on the enclosed adhesive label

Protection via housing "tD"

Use is restricted to the following stated conditions

The maximum surface temperature has been determined in accordance with method A without a dust layer on the equipment.

The data stated in the data sheet are restricted by this operating instruction!

The special conditions must be adhered to!

Repairs to these apparatus are not possible.

The maximum permissible load current must be restricted to the values given in the following list.

High load currents and load short-circuits are not permitted.

The maximum permissible operating voltage UBmax must be restricted to the values given in the following list. Tolerances are

not permitted.

dependant of the load current I

Information can be taken from the following list.

and the max. operating voltage U

L

Bmax

50 °C (122 °F)

53 °C (127.4 °F)

54 °C (129.2 °F)

The sensor must not be exposed to ANY FORM of mechanical danger.

The sensor and the connection cable must be protected from damaging UV-radiation. This can be achieved when the sensor is

used in internal areas.

Sliding contact discharges must be avoided.

Terminal connection: Minimum conductor cross-section: 0.5 mm

the conductor must be provided with cable sleeves.

The cable entry must be such, that no tension load or twist is applied to the cable

The protection category must be in accordance with EN 60529 and as stated in the data sheet.

The requirements of EN 61241-0 relating to the cable and lead entries are to be complied with. The special characteristics of

the ignition protection class "tD, method A" of the proximity switch must not be disregarded.

The plug connector must not be withdrawn under voltage. The proximity switch is identified as follows: "WARNING - DO NOT

SEPARATE WHEN ENERGIZED". With the plug connector disconnected, soiling of the internal area must be prevented.(i.e.

the area that is inaccessible when the connector is inserted)

2

, maximum conductor cross-section: 2.5 mm2. The ends of

Release date: 2017-05-17 11:37 Date of issue: 2017-05-17 209263_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Page 5

Inductive sensor NBN30-U1K-E2-3G-3D

Equipment protection level Dc (tc)

Instruction Manual electrical apparatus for hazardous areas

Device category 3D for use in hazardous areas with combustible dust

Certificate PF 15CERT3774 X

CE marking

ATEX ma rk in g ¬ II 3D Ex tc IIIC T80°C Dc

Standards EN 60079-0:2012+A11:2013, EN 60079-31:2014

Ge n e r a l The corresponding datasheets, declarations of conformity, EC-type examination certifi-

Installation, commissioning Laws and/or regulations and standards governing the use or intended usage goal must

Maintenance No changes can be made to apparatus, which are operated in hazardous areas.

Special conditions

Maximum operating current I

Maximum operating voltage U

Maximum permissible ambient temperature T

at U

at U

at U

=30 V, IL=200 mA

Bmax

=30 V, IL=100 mA

Bmax

=30 V, IL=50 mA

Bmax

L

Bmax

Umax

Protection from mechanical danger

Protection from UV light

Electrostatic charge

Lead insertion

Plug connector

The Ex-related marking can also be printed on the enclosed label.

Protection by enclosure "tc" Some of the information in this instruction manual is more

specific than the information provided in the datasheet.

cates, certifications, and control drawings, where applicable (see datasheets), form an

integral part of this document. These documents can be found at www.pepperlfuchs.com. The maximum surface temperature of the device was determined without a

layer of dust on the apparatus. Some of the information in this instruction manual is more

specific than the information provided in the datasheet.

be observed. If the Ex-relevant identification is printed exclusively on the adhesive label

provided, this label must be affixed in the immediate vicinity of the sensor! The background surface to which the adhesivelabel is to be applied must be clean and free from

grease! The applied label must be durable and remain legible, with due consideration of

the possibility of chemical corrosion! After opening the housing, you should check that

the seal is in the correct position and is clean and intact before closing the housing

again.

Repairs to these apparatus are not possible. After opening the housing, you should

check that the seal is in the correct position and is clean and intact before closing the

housing again.

The maximum permissible load current must be restricted to the values given in the following list.

High load currents and load short-circuits are not permitted.

The maximum permissible operating voltage UBmax must be restricted to the values

given in the following list. Tolerances are not permitted.

dependant of the load current I

Information can be taken from the following list.

and the max. operating voltage U

L

Bmax

50 °C (122 °F)

53 °C (127.4 °F)

54 °C (129.2 °F)

The sensor must not be exposed to ANY FORM of mechanical danger.

The sensor and the connection cable must be protected from damaging UV-radiation.

This can be achieved when the sensor is used in internal areas.

Sliding contact discharges must be avoided. Avoid electrostatic charges that can cause

electrostatic discharge when installing or operating the device. Information on electrostatic hazards can be found in the technical specification IEC/TS 60079-32-1. Do not

attach the nameplate provided in areas where electrostatic charge can build up.

If cable glands are required for the installation then the following points must be

observed: The cable glands must be certified in accordance with the application.

The temperature range of the cable glands must be selected according to the application. The degree of protection must not be reduced by the cable glands. Seal

the housing. Use a seal that meets the requirements of the application.

The plug connector must not be withdrawn under voltage. The proximity switch is identified as follows: "WARNING - DO NOT SEPARATE WHEN ENERGIZED". With the plug

connector disconnected, soiling of the internal area must be prevented.(i.e. the area that

is inaccessible when the connector is inserted)

Release date: 2017-05-17 11:37 Date of issue: 2017-05-17 209263_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

5

Loading...

Loading...