Page 1

NB670

The Future of Analog IC Technology

DESCRIPTION

The NB670 is a fully integrated high frequency

synchronous rectified step-down switch mode

converter with 3.3V fixed output voltage. It

offers very compact solution to achieve 6A

continuous output current and 9A peak output

current over a wide input supply range with

excellent load and line regulation. The NB670

operates at high efficiency over a wide output

current load range. Constant-On-Time (COT)

control mode provides fast transient response

and eases loop stabilization.

Under voltage lockout is internally set as 4.65 V.

An open drain power good signal indicates the

output is within its nominal voltage range.

NB670 also provides a 3.3V LDO, which can be

used to power the external peripheries, such as

the keyboard controller in the laptop computer.

A 300kHz CLK is also available; its output can

be used to drive an external charge pump,

generating gate drive voltage for the load

switches without reducing the main converter’s

efficiency.

Full protection features include OCP, OVP,

UVP and thermal shut down.

The converter requires minimum number of

external components and is available in QFN16

(3mmx3mm) package.

24V, High Current

Synchronous Buck Converter With LDO

FEATURES

• Wide 5V to 24V Operating Input Range

• 3.3V Fixed Output Voltage

• Built-in 3.3V, 100mA LDO with Switches

• 6A Continuous Output Current

• 9A Peak Output Current

• 300kHZ CLK for External Charge Pump

• Low R

(ON) Internal Power MOSFETs

DS

• Proprietary Switching Loss Reduction

Technique

• Internal Soft Start

• Output Discharge

• 500kHZ Switching Frequency

• OCP, OVP, UVP Protection and Thermal

Shutdown

APPLICATIONS

• Laptop Computer

• Tablet PC

• Networking Systems

• Personal Video Recorders

• Flat Panel Television and Monitors

• Distributed Power Systems

All MPS parts are lead-free and adhere to the RoHS directive. For MPS green

status, please visit MPS website under Products, Quality Assurance page.

“MPS” and “The Future of Analog IC Technology” are registered trademarks of

Monolithic Power Systems, Inc.

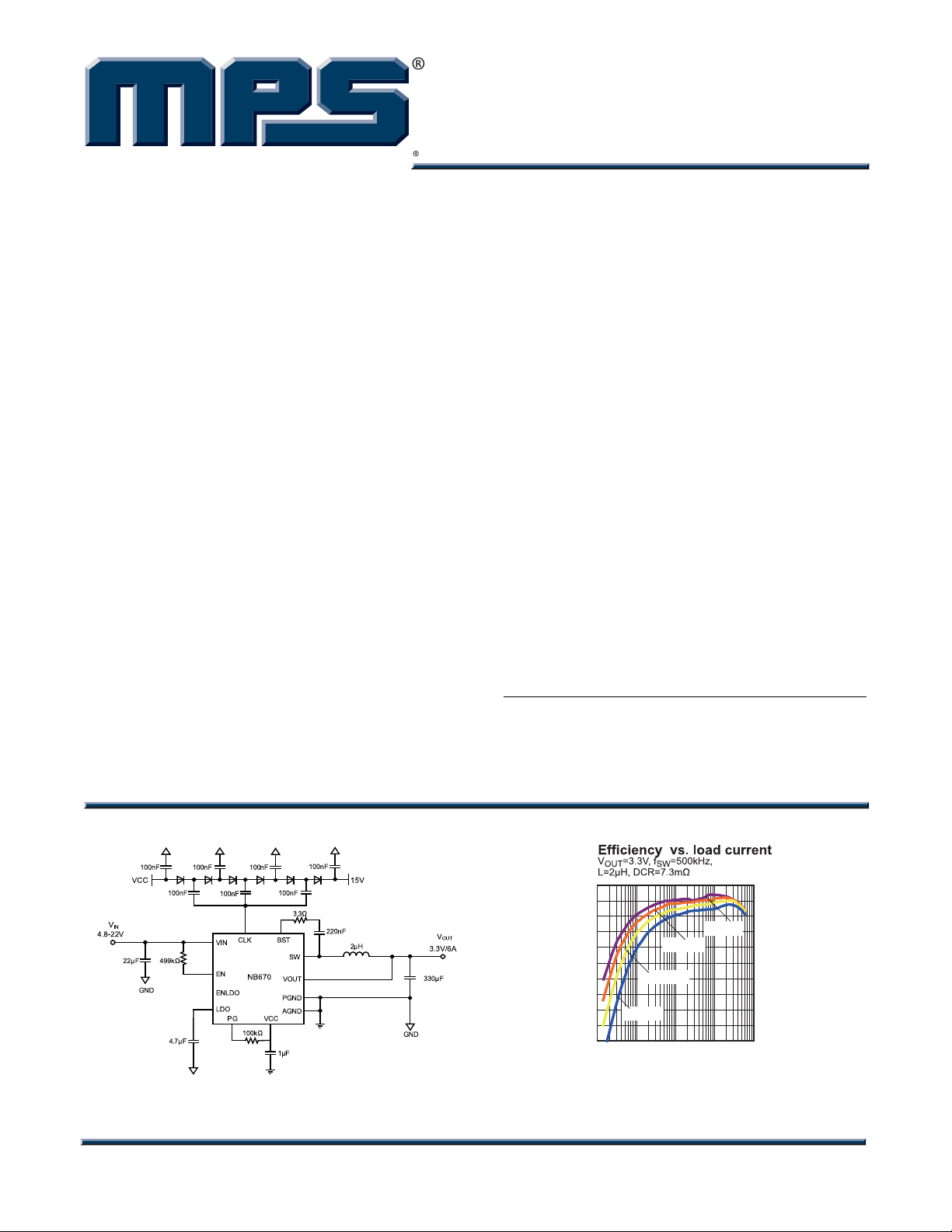

TYPICAL APPLICATION

100

95

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

NB670 Rev. 1.01 www.MonolithicPower.com 1

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

V

=12.6V

IN

VIN=19V

1 10 100 1000 10000

OUTPUT CURRENT (A)

V

=6V

IN

=8.4V

V

IN

Page 2

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

y

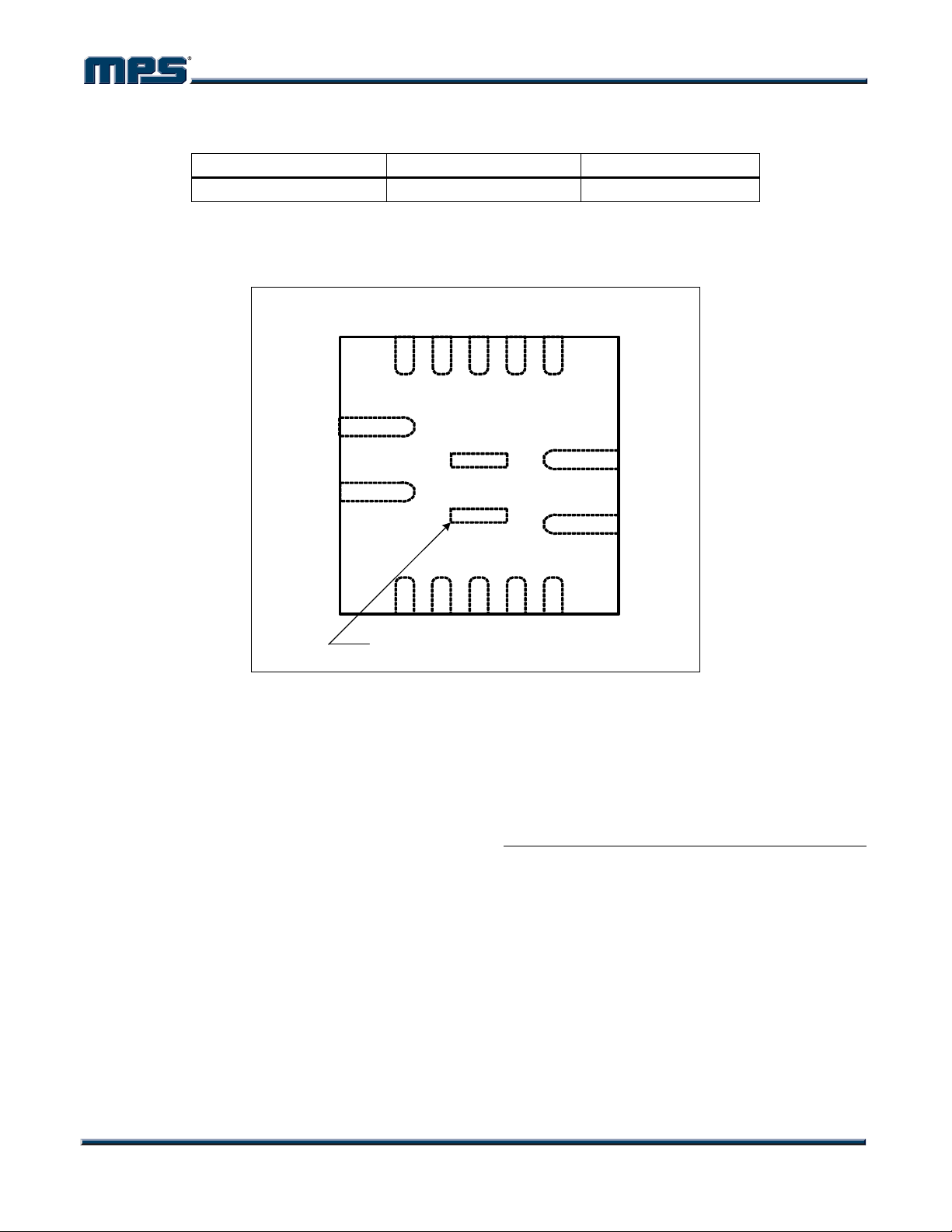

ORDERING INFORMATION

Part Number* Package Top Marking

NB670GQ QFN16 (3mmx3mm) ADZ

* For Tape & Reel, add suffix –Z (e.g. NB670GQ–Z)

PACKAGE REFERENCE

TOP VIEW

VCC

AGND EN

ENLDO

12 11

1314

BST

10

VIN

ABSOLUTE MAXIMUM RATINGS

1

2PGND

3

NC

EXPOSED PAD

ON BACKSIDE

(1)

Supply Voltage VIN....................................... 24V

V

...............................................-0.3V to 24.3V

SW

(30ns)..........................................-3V to 28V

V

SW

V

(5ns)............................................-6V to 28V

SW

V

................................................... VSW + 5.5V

BST

............................................................... 12V

V

EN

V

Enable Current I

........................................................... 12V

ENLDO

(2)

................................ 2.5mA

EN

All Other Pins...............................-0.3V to +5.5V

Continuous Power Dissipation (T

=+25°C)

A

(3)

QFN16……………………..….…..…………1.8W

Junction Temperature...............................150°C

Lead Temperature ....................................260°C

Storage Temperature............... -65°C to +150°C

15

SW

16

54 6 7

CLKPG VOUT

Recommended Operating Conditions

Supply Voltage VIN.............................. 5V to 22V

Output Voltage V

Enable Current I

Operating Junction Temp. (T

Thermal Resistance

QFN16 (3mmx3mm)............... 70...... 15... °C/W

Notes:

1) Exceeding these ratings may damage the device.

2) Refer to Page 19 of Configuring the EN Control.

3) The maximum allowable power dissipation is a function of the

4) The device is not guaranteed to function outside of its

5) Measured on JESD51-7, 4-layer PCB.

9

SWSW

SW

8

LDO

................................... 3.3V

OUT

...................................... 1mA

EN

)..-40°C to +125°C

J

(5)

θ

maximum junction temperature T

ambient thermal resistance

. The maximum allowable continuous power dissipation at

T

A

any ambient temperature is calculated by P

)/JA. Exceeding the maximum allowable power dissipation

T

A

will cause excessive die temperature, and the regulator will go

into thermal shutdown. Internal thermal shutdown circuitr

protects the device from permanent damage.

operating conditions.

(MAX), the junction-to-

J

, and the ambient temperature

JA

θJC

JA

(MAX)=(TJ(MAX)-

D

(4)

NB670 Rev. 1.01 www.MonolithicPower.com 2

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 3

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

ELECTRICAL CHARACTERISTICS

VIN = 12V, TJ = 25°C, unless otherwise noted.

Parameters Symbol Condition Min Typ Max Units

Supply Current

Supply Current (Shutdown) I

Supply Current (Quiescent) IIN

Supply Current (No load) IIN

Supply Current (Standby) I

MOSFET

High-side Switch On Resistance HS

Low-side Switch On Resistance LS

Switch Leakage SW

Current Limit

VEN = 0V 1 2 A

IN_Shtdn

V

= 2V, V

EN

V

= 3.5V

OUT

V

= 2V, V

EN

V

= 3.35V, Io=0A

OUT

V

= 0V, V

EN

IN_Stby

RDS-ON

RDS-ON

LKG

I

= 0A

LDO

30 m

15 m

VEN = 0V, VSW = 0V 0 1 A

ENLDO

ENLDO

ENLDO

= 2V ,

= 2V ,

= 2V ,

140 220 300 A

240 A

40 80 120 A

Low-side Valley Current Limit I

8 8.5 9.5 A

LIMIT

Switching frequency and minimum off timer

Switching Frequency FSW 400 500 600 kHz

Minimum Off Time

(6)

T

350 ns

OFF

Over-voltage and Under-voltage Protection

OVP Threshold V

OVP Delay

(6)

T

UVP Threshold V

UVP Delay

(6)

T

OVP

OVPDEL

UVP

UVPDEL

125 130 135

2.5 s

55 60 65

8 s

%

V

OUT_Ref

%

V

OUT_Ref

Vout_Ref And Soft Start

Vout Ref Voltage Vout_Ref 3.285 3.35 3.415 V

Soft Start Time TSS 1.5 1.8 1.95 ms

Enable And UVLO

Enable Input Low Voltage VILEN 1.15 1.25 1.35 V

Enable Hysteresis V

Enable Input Current IEN

Enable LDO Input Low Voltage V

Enable LDO Hysteresis V

VCC Under Voltage Lockout

Threshold Rising

VCC Under Voltage Lockout

Threshold Hysteresis

ENLDO-HYS

VCC

VCC

100 mV

EN-HYS

VEN = 2V 5

V

= 0V 0

EN

1.15 1.25 1.35 V

ENLDO

A

100 mV

4.65 4.85 V

Vth

500 mV

HYS

NB670 Rev. 1.01 www.MonolithicPower.com 3

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 4

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

ELECTRICAL CHARACTERISTICS (continued)

VIN = 12V, TJ = 25°C, unless otherwise noted.

Parameters Symbol Condition Min Typ Max Units

CLK Output

CLK Output High Level Voltage V

CLK Output Low Level Voltage V

CLK Frequency F

I

CLKH

I

CLKL

CLK

= -5mA 3.1 3.25 3.4 V

Vclk

= 5mA 0 0.05 0.1 V

Vclk

T

= 25°C

J

300 kHz

LDO Regulator

LDO Regulator V

LDO Load Regulation

LDO Load Capability

Switch Rdson R

3.25 3.35 3.45 V

LDO

I

Switch

=50mA 5 %

LDO

Before switch-over 70 90 120 mA

After switch-over 100 mA

I

=50mA 1.7 2.2

LDO

VCC Regulator

VCC Regulator V

VCC Load Regulation

CC

4.95 5.15 5.35 V

Icc=5mA 5 %

Power Good

PG Rising (Good) PG

PG Falling (Fault) PG

PG Rising (Fault) PG

PG Falling (Good) PG

95

Vth-Hi

85

Vth-Lo

115

Vth-Hi

105

Vth-Lo

%

V

OUT_Ref

Power Good Lower to High Delay PGTd 0.5 ms

Power Good Sink Current

Capability

Power Good Leakage Current I

Sink 4mA 0.4 V

V

PG

VPG = 3.3V 100 nA

PG_LEAK

Thermal Protection

Thermal Shutdown

(6)

T

150 °C

SD

Thermal Shutdown Hysteresis 25 °C

Note:

6) Guaranteed by design.

NB670 Rev. 1.01 www.MonolithicPower.com 4

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 5

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

PIN FUNCTIONS

PIN # Name Description

Supply Voltage. The VIN pin supplies power for internal MOSFET and regulator. The

1 VIN

2 PGND Power Ground. Use wide PCB traces and multiple vias to make the connection.

3 NC Not connected.

4 PG

5 CLK 300kHZ CLK output to drive the external charge pump

6 LDO

7 VOUT

8, 9

Exposed Pad

15, 16

10 BST

11 VCC

12 ENLDO

13 EN

14 AGND Analog ground. The internal reference is referred to AGND.

SW

NB670 operates from a +5V to +24V input rail. An input capacitor is needed to

decouple the input rail. Use wide PCB traces and multiple vias to make the

connection.

Power good output. The output of this pin is an open drain signal and is high if the

output voltage is higher than 95% of the nominal voltage. There is a delay from Vout

95% to PGOOD goes high.

Internal 3.3V LDO output. Decouple with a minimum 4.7µF ceramic capacitor as

close to the pin as possible. X7R or X5R grade dielectric ceramic capacitors are

recommended for their stable temperature characteristics.

Once the output voltage of the Buck regulator is ready, it will switch over the LDO

output to save the power loss.

Output voltage sense. For the NB670, the output of the Buck regulator is fixed to

3.3V. VOUT pin is used to sense the output voltage of the Buck regulator, connect

this pin to the output capacitor of the regulator directly. This pin also acts as the

input of the 3.3V LDO switch over power input.

Keep the VOUT sensing trace far away from the SW node. Vias should also be

avoided on the VOUT sensing trace.

Switch Output. Connect this pin to the inductor and bootstrap capacitor. This pin is

driven up to the VIN voltage by the high-side switch during the on-time of the PWM

duty cycle. The inductor current drives the SW pin negative during the off-time. The

on-resistance of the low-side switch and the internal diode fixes the negative

voltage. Use wide and short PCB traces to make the connection. Try to minimize the

area of the SW pattern.

Bootstrap. A capacitor connected between SW and BST pins is required to form a

floating supply across the high-side switch driver.

Internal 5V LDO output. The driver and control circuits are powered from this

voltage. Decouple with a minimum 1µF ceramic capacitor as close to the pin as

possible. X7R or X5R grade dielectric ceramic capacitors are recommended for their

stable temperature characteristics.

100mA LDO and VCC enable pin. ENLDO is internally pulled up to high. Leave this

pin open to enable the LDO. Drive it low to turn off all the regulators .

Buck regulator and charge pump clock enable pin. EN is a digital input that turns the

Buck regulator and CLK on or off. When the power supply of the control circuit is

ready, drive EN high to turn on the Buck regulator and charge pump clock, drive it

low to turn them off.

NB670 Rev. 1.01 www.MonolithicPower.com 5

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 6

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

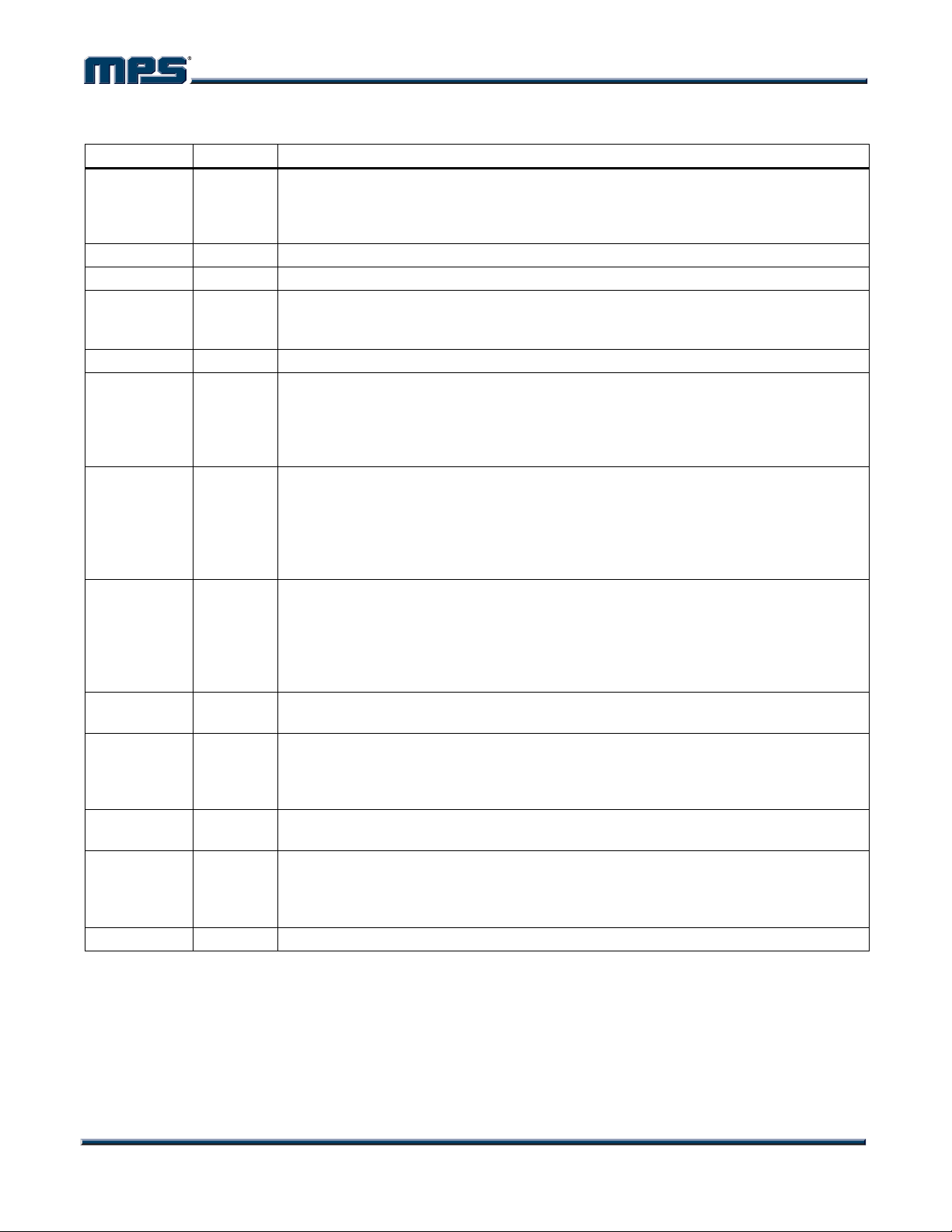

TYPICAL PERFORMANCE CHARACTERISTICS

Performance waveforms are tested on the evaluation board of the Design Example section.

=12V, V

V

IN

=3.3V, L=2µH, TJ=+25°C, unless otherwise noted.

OUT

100

95

90

85

80

75

70

65

EFFICIENCY (%)

60

VIN=19V

55

50

1 10 100 1000 10000

OUTPUT CURRENT (A) OUTPUT CURRENT (A)

2500

2000

1500

1000

POWER LOSS (mW)

500

0

01234567

OUTPUT CURRENT (A) OUTPUT CURRENT (A)

V

V

=12.6V

IN

V

=12.6V

IN

V

=19V

IN

V

IN

IN

=6V

=8.4V

VIN=6V

V

IN

=8.4V

2500

V

=6V

=19V

V

IN

VIN=8.4V

IN

2000

1500

1000

500

POWER LOSS (mW)

=12.6V

V

IN

0

0123456

100

VIN=6V

90

80

70

60

EFFICIENCY (%)

50

40

0.001 0.01 0.1 1 10

V

OUTPUT CURRENT (A)

Line Regulation Load Regulation

1

0.8

0.6

0.4

0.2

-0.2

-0.4

-0.6

LINE REGULATION (%)

-0.8

-1

I

=0A

OUT

I

=3A

OUT

0

=6A

I

OUT

5 7 9 11 13 15 17 19

INPUT VOLTAGE (V)

1

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

LOAD REGULATION (%)

-0.8

-1

VIN=8.4V

0123456

V

V

=12.6V

IN

=19V

IN

VIN=19V

IN

=8.4V

V

V

=12.6V

IN

=6V

IN

Supply Current(Shutdown)

vs. Input Voltage

2.5

2

1.5

1

0.5

0

5 7 9 111315171921

INPUT VOLTAGE (V) INPUT VOLTAGE (V)

Supply Current(Quiescent )

vs. Input Voltage

220

215

210

205

200

195

190

579111315171921

No Load Current vs.

Input Voltage

265

260

255

250

245

240

235

230

579111315171921

INPUT VOLTAGE (V)

NB670 Rev. 1.01 www.MonolithicPower.com 6

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 7

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

Performance waveforms are tested on the evaluation board of the Design Example section.

=12V, V

V

IN

=3.3V, L=2µH, TJ=+25°C, unless otherwise noted.

OUT

Input/Output Voltage Ripple

I

= 0A

OUT

Input/Output Voltage Ripple

I

= 6A

OUT

Power Good through VIN

Start-Up

I

= 6A

OUT

V

OUT(AC)

50mV/div.

V

IN(AC)

200mV/div.

V

SW

5V/div.

2A/div.

V

OUT

2V/div.

V

5V/div.

V

PG

5V/div.

5A/div.

I

L

Power Good through

VIN Shutdown

I

= 6A

OUT

IN

I

L

V

OUT(AC)

50mV/div.

V

IN(AC)

200mV/div.

V

SW

10V/div.

5A/div.

V

OUT

2V/div.

V

EN

5V/div.

V

PG

5V/div.

5A/div.

I

L

Power Good through

EN Start-Up

I

= 6A

OUT

I

L

V

OUT

2V/div.

V

5V/div.

V

5V/div.

5A/div.

V

OUT

2V/div.

V

5V/div.

V

5V/div.

10A/div.

IN

PG

I

L

Power Good through

EN Shut-Down

I

= 6A

OUT

EN

PG

I

L

Start-Up through VIN

I

= 0A

OUT

V

OUT

2V/div.

V

IN

5V/div.

V

SW

5V/div.

I

L

5A/div.

Start-Up through VIN

I

= 6A

OUT

V

OUT

2V/div.

V

IN

5V/div.

V

SW

10V/div.

I

L

5A/div.

Shut-Down through VIN

I

= 0A

OUT

V

OUT

2V/div.

V

IN

5V/div.

V

SW

5V/div.

I

L

5A/div.

NB670 Rev. 1.01 www.MonolithicPower.com 7

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 8

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

Performance waveforms are tested on the evaluation board of the Design Example section.

=12V, V

V

IN

=3.3V, L=2µH, TJ=+25°C, unless otherwise noted.

OUT

Shut-Down through Vin

I

= 6A

OUT

Start-Up through EN

I

= 0A

OUT

Start-Up through EN

I

= 6A

OUT

V

OUT

2V/div.

V

5V/div.

V

SW

10V/div.

5A/div.

V

OUT

2V/div.

V

EN

5V/div.

V

SW

10V/div.

5A/div.

IN

I

L

Shut-Down through EN

I

= 0A

OUT

I

L

V

OUT

2V/div.

V

EN

5V/div.

V

SW

10V/div.

5A/div.

V

OUT

2V/div.

V

EN

5V/div.

V

SW

10V/div.

5A/div.

I

L

Shut-Down through EN

I

= 6A

OUT

I

L

V

OUT

2V/div.

V

5V/div.

V

SW

10V/div.

5A/div.

V

OUT(AC)

50mV/div.

2A/div.

EN

I

L

I

L

V

OUT

2V/div.

V

SW

10V/div.

5A/div.

Short Circuit Protection

I

L

10V/div.

Thermal Shutdown

I

=6A

OUT

V

OUT

2V/div.

V

SW

I

L

5A/div.

V

OUT

2V/div.

V

SW

10V/div.

5A/div.

Thermal Recovery

I

=6A

OUT

I

L

NB670 Rev. 1.01 www.MonolithicPower.com 8

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 9

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

BLOCK DIAGRAM

VCC

VIN

VOUT

EN

Soft-

star t

0.6V V

BSTR EG

POR &

Reference

REF

V

FB

Min off time

On T ime

One Shot

Gate

control

VIN

BST

SW

Logic

VOUT

1V

130% V

REF

SW

95% V

OVP

REF

60% V

OCP

POK

REF

Fault

logic

UVP

PGND

PG

AGND

CLK

CLK

generator

Vcc

Vcc

Regulator

LDO

Swi tch-over

VIN

LDO

Control

ENLDO

LDO

Figure 1—Functional Block Diagram

VOUT

NB670 Rev. 1.01 www.MonolithicPower.com 9

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 10

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

OPERATION

PWM Operation

The NB670 is fully integrated synchronous

rectified step-down switch mode converter.

Constant-on-time (COT) control is employed to

provide fast transient response and easy loop

stabilization. At the beginning of each cycle, the

high-side MOSFET (HS-FET) is turned ON when

the feedback voltage (V

voltage (V

), which indicates insufficient output

REF

voltage. The ON period is determined by the

output voltage and input voltage to make the

switching frequency fairy constant over input

voltage range.

After the ON period elapses, the HS-FET is

turned off, or becomes OFF state. It is turned ON

again when V

drops below V

FB

operation this way, the converter regulates the

output voltage. The integrated low-side MOSFET

(LS-FET) is turned on when the HS-FET is in its

OFF state to minimize the conduction loss. There

will be a dead short between input and GND if

both HS-FET and LS-FET are turned on at the

same time. It’s called shoot-through. In order to

avoid shoot-through, a dead-time (DT) is

internally generated between HS-FET off and LSFET on, or LS-FET off and HS-FET on.

An internal compensation is applied for COT

control to make a more stable operation even

when ceramic capacitors are used as output

capacitors, this internal compensation will then

improve the jitter performance without affect the

line or load regulation.

Heavy-Load Operation

) is below the reference

FB

. By repeating

REF

When the output current is high and the inductor

current is always above zero amps, it is called

continuous-conduction-mode (CCM). The CCM

mode operation is shown in Figure 2 shown.

When V

is below V

FB

, HS-FET is turned on for

REF

a fixed interval. When the HS-FET is turned off,

the LS-FET is turned on until next period.

In CCM mode operation, the switching frequency

is fairly constant and it is called PWM mode.

Light-Load Operation

With the load decrease, the inductor current

decrease too. Once the inductor current touch

zero, the operation is transition from continuousconduction-mode (CCM) to discontinuousconduction-mode (DCM).

The light load operation is shown in Figure 3.

When V

is below V

FB

, HS-FET is turned on for

REF

a fixed interval which is determined by one- shot

on-timer as equation 1 shown. When the HS-FET

is turned off, the LS-FET is turned on until the

inductor current reaches zero. In DCM operation,

the V

does not reach V

FB

when the inductor

REF

current is approaching zero. The LS-FET driver

turns into tri-state (high Z) whenever the inductor

current reaches zero. A current modulator takes

over the control of LS-FET and limits the inductor

current to less than -1mA. Hence, the output

capacitors discharge slowly to GND through LSFET. As a result, the efficiency at light load

condition is greatly improved. At light load

condition, the HS-FET is not turned ON as

frequently as at heavy load condition. This is

called skip mode.

At light load or no load condition, the output

drops very slowly and the NB670 reduces the

switching frequency naturally and then high

efficiency is achieved at light load.

Figure 2—Heavy Load Operation

NB670 Rev. 1.01 www.MonolithicPower.com 10

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 11

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

V

V

NOISE

SLOPE2

V

FB

V

REF

HS D river

Figure 3—Light Load Operation

As the output current increases from the light

load condition, the time period within which the

current modulator regulates becomes shorter.

The HS-FET is turned ON more frequently.

Hence, the switching frequency increases

correspondingly. The output current reaches the

critical level when the current modulator time is

zero. The critical level of the output current is

determined as follows:

I

OUT

−×

=

2LF V

×× ×

SW IN

(1)

IN OUT OUT

(V V ) V

It turns into PWM mode once the output current

exceeds the critical level. After that, the switching

frequency stays fairly constant over the output

current range.

Jitter and FB Ramp Slope

Jitter occurs in both PWM and skip modes when

noise in the V

ripple propagates a delay to the

FB

HS-FET driver, as shown in Figures 4 and 5.

Jitter can affect system stability, with noise

immunity proportional to the steepness of V

downward slope. However, V

ripple does not

FB

FB

’s

directly affect noise immunity.

V

V

NOISE

S L OPE1

J itter

V

FB

V

HS Driver

RE

F

Figure 4—Jitter in PWM Mode

Jitter

Figure 5—Jitter in Skip Mode

Selecting the Output Capacitors

The traditional constant-on-time control scheme

is intrinsically unstable if output capacitor’s ESR

is not large enough as an effective current-sense

resistor. Ceramic capacitors usually can not be

used as output capacitor.

Figure 6 shows an equivalent circuit in PWM

mode with the HS-FET off. To realize the stability,

the ESR value should be chosen as follow:

TT

SW ON

R

≥

ESR

T

is the switching period.

SW

R

FB

R

0.7 2

SW

VOUT

×π

C

L

OUT

+

(2)

V

OUT

ESR

CAP

Figure 6—Simplified Circuit in PWM Mode

The NB670 has built in internal ramp

compensation to make sure the system is stable

even without the help of output capacitor’s ESR;

and thus the pure ceramic capacitor solution can

be applicant. The pure ceramic capacitor solution

can significantly reduce the output ripple, total

BOM cost and the board area.

Configuring the EN Control

The NB670 has two enable pins to control the

on/off of the internal regulators.

ENLDO is used to enable or disable the whole

NB670 Rev. 1.01 www.MonolithicPower.com 11

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 12

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

chip. Once ENLDO is off, all the regulators

include Vcc will be off. ENLDO is internally pulled

high so it can be floated in the normal operation.

When ENLDO is pulled high, Pull En high to turn

on the Buck regulator also the charge pump clk,

and pull EN low to turn them off. Do not float the

EN pin.

See Table1 for the logics to control the regulators

Table 1—ENLDO/EN Control

State ENLDO EN VCC VOUT/CLK LDO

S0 1 1 ON ON ON

S3 1 0 ON OFF ON

S4/S5 0 0 OFF OFF OFF

Others 0 1 OFF OFF OFF

For automatic start-up the EN pin can be pulled

up to input voltage through a resistive voltage

divider. Choose the values of the pull-up resistor

(R

from Vin pin to EN pin) and the pull-down

UP

resistor (R

from EN pin to GND) to

DOWN

determine the automatic start-up voltage:

+

RR

−

=×

V1.35 (V)

IN START

For example, for R

V is set at 5.32V.

the

−IN START

UP

UP DOW N

R

DOWN

=150k and R

(3)

DOWN

=51k,

To avoid noise, a 10nF ceramic capacitor from

EN to GND is recommended.

There is an internal Zener diode on the EN pin,

which clamps the EN pin voltage to prevent it

from running away. The maximum pull up current

assuming a worst case 12V internal Zener clamp

should be less than 1mA.

Therefore, when EN is driven by an external logic

signal, the EN voltage should be lower than 12V;

when EN is connected with VIN through a pull-up

resistor or a resistive voltage divider, the

resistance selection should ensure the maximum

pull up current less than 1mA.

If using a resistive voltage divider and VIN higher

than 12V, the allowed minimum pull-up resistor

R

should meet the following equation:

UP

V(V) 12

−

IN

R(k) R (k)

ΩΩ

UP DOWN

12

−<

1( m A )

(4)

Especially, just using the pull-up resistor R

UP

(the

pull-down resistor is not connected), the

V is determined by input UVLO, and the

IN-START

minimum resistor value is:

R(k)

Ω>

UP

IN

1( m A )

(5)

V(V) 12

−

A typical pull-up resistor is 499k.

Soft Start

The NB670 employs soft start (SS) mechanism

to ensure smooth output during power-up. When

the EN pin becomes high, the internal reference

voltage ramps up gradually; hence, the output

voltage ramps up smoothly, as well. Once the

reference voltage reaches the target value, the

soft start finishes and it enters into steady state

operation.

If the output is pre-biased to a certain voltage

during startup, the IC will disable the switching of

both high-side and low-side switches until the

voltage on the internal reference exceeds the

sensed output voltage at the internal FB node.

3.3V Linear Regulator

There is a built-in 100-mA standby linear

regulator which outputs 3.3V.The 3.3V LDO is

intended mainly for auxiliary 3.3V supply for the

notebook system during standby mode.

Add a ceramic capacitor with a value between

4.7F and 22uF placed close to the LDO pins to

stabilize LDOs.

3.3V LDO Switch Over

When the output voltage becomes higher than

3.15V and the power good flag is generated,

internal 3.3V LDO regulator is shut off and the

LDO output is connected to Vout pin by the

internal switch over MOSFET. The 20us power

good deglitch time helps a switch over without

glitch.

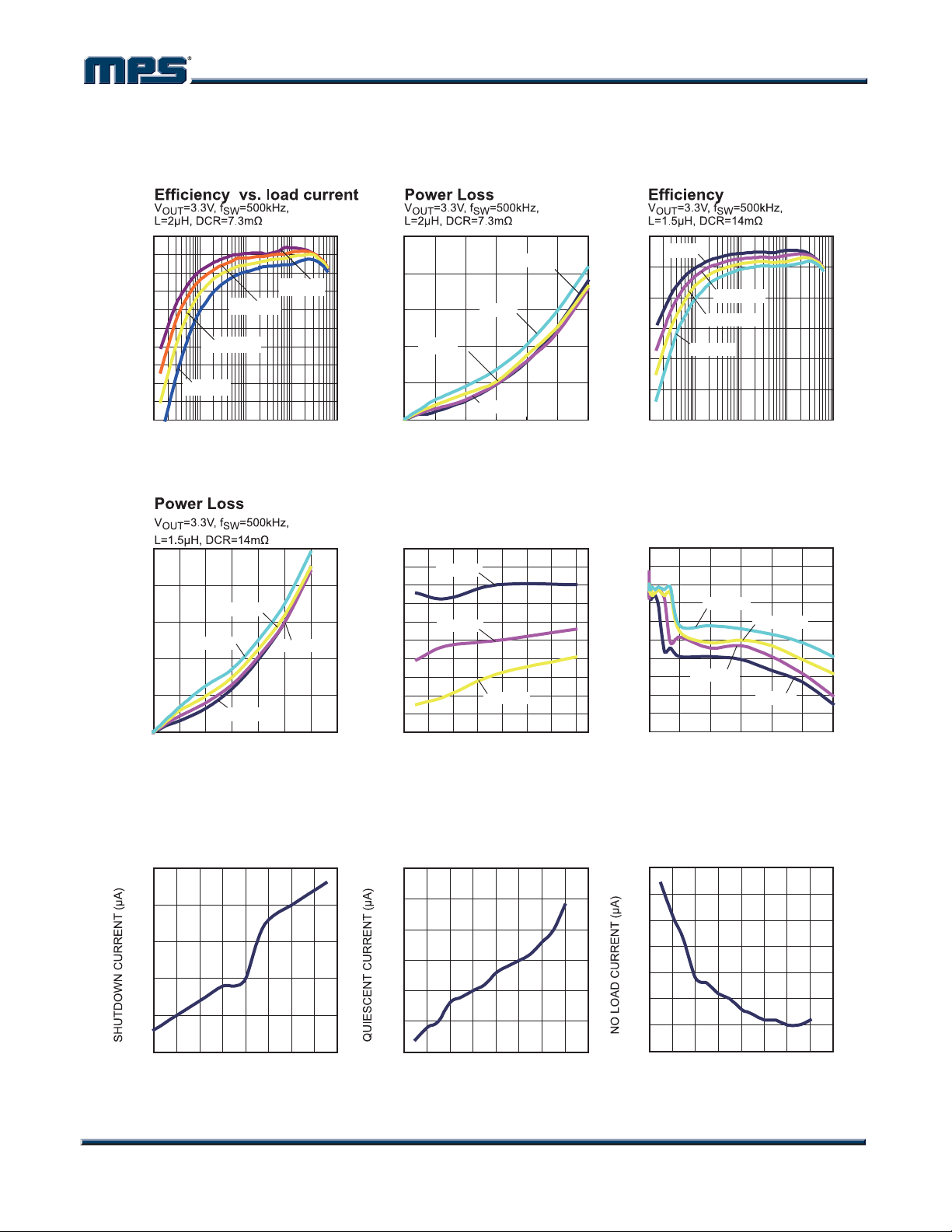

CLK for Charge Pump

The 300kHZ CLK signal can be used to drive an

external charge pump circuit to generate

approximately 12-15V DC voltage. The CLK

voltage becomes available once the VIN is higher

than UVLO threshold. Example of charge pump

control circuit is shown in Figure 7.

NB670 Rev. 1.01 www.MonolithicPower.com 12

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 13

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

CLK

100nF 100nF

5V 12V/100mA

100nF 100nF 100nF

PGND

PGND PGND

Figure 7—Charge Pump Circuit

Power Good (PG)

The NB670 has power-good (PG) output used to

indicate whether the output voltage of the Buck

regulator is ready or not. The PG pin is the open

drain of a MOSFET. It should be connected to

or other voltage source through a resistor

V

CC

(e.g. 100k). After the input voltage is applied, the

MOSFET is turned on so that the PG pin is pulled

to GND before SS is ready. After FB voltage

reaches 95% of REF voltage, the PG pin is

pulled high after a delay. The PG delay time is

0.5ms.

When the FB voltage drops to 85% of REF

voltage, the PG pin will be pulled low.

Over Current Protection

NB670 has cycle-by-cycle over current limiting

control. The current-limit circuit employs a

"valley" current-sensing algorithm. The part uses

the Rds(on) of the low side MOSFET as a

current-sensing element. If the magnitude of the

current-sense signal is above the current-limit

threshold, the PWM is not allowed to initiate a

new cycle.

The trip level is fixed internally. The inductor

current is monitored by the voltage between GND

pin and SW pin. GND is used as the positive

current sensing node so that GND should be

connected to the source terminal of the bottom

MOSFET.

Since the comparison is done during the high

side MOSFET OFF and low side MOSFET ON

state, the OC trip level sets the valley level of the

inductor current. Thus, the load current at overcurrent threshold, I

, can be calculated as

OC

follows:

In an over-current condition, the current to the

load exceeds the current to the output capacitor;

thus the output voltage tends to fall off.

Eventually, it will end up with crossing the under

voltage protection threshold and shutdown.

Over/Under-Voltage Protection (OVP/UVP)

NB670 monitors output voltage to detect over

and under voltage. When the feedback voltage

becomes higher than 115% of the target voltage,

the controller will enter Dynamic Regulation

Period. During this period, the LS will off when

the LS current goes to -1A, this will then

discharge the output and try to keep it within the

normal range. If the dynamic regulation can not

limit the increasing of the Vo, once the feedback

voltage becomes higher than 130% of the

feedback voltage, the OVP comparator output

goes high and the circuit latches as the high-side

MOSFET driver OFF and the low-side MOSFET

driver turn on acting as an -1A current source.

When the feedback voltage becomes lower than

60% of the target voltage, the UVP comparator

output goes high if the UV still occurs after 26us

delay; then the fault latch will be triggered--latches HS off and LS on; the LS FET keeps on

until the inductor current goes zero.

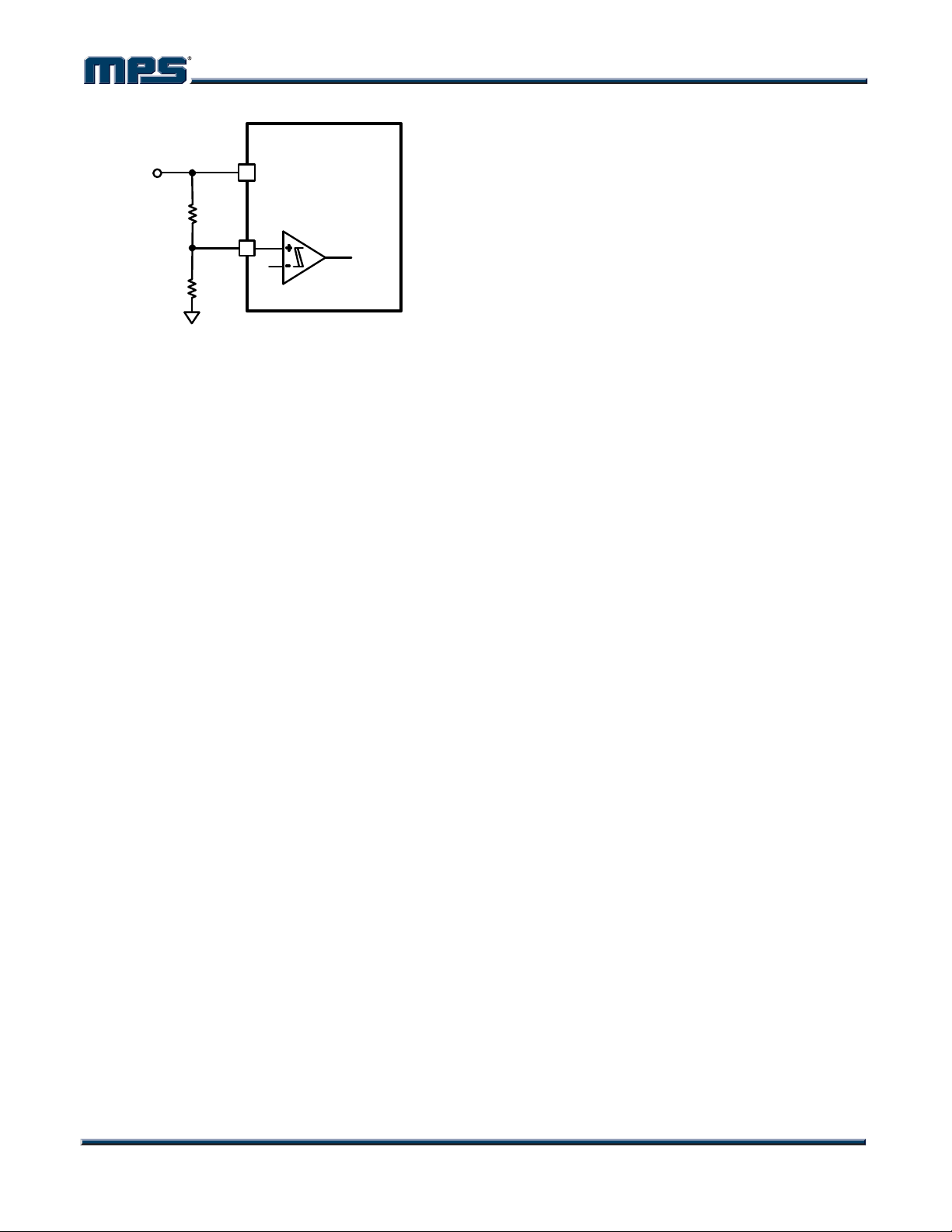

UVLO Protection

The NB670 has under-voltage lock-out protection

(UVLO). When the VCC voltage is higher than

the UVLO rising threshold voltage, the part will

be powered up. It shuts off when the VIN voltage

is lower than the UVLO falling threshold voltage.

This is non-latch protection. The part is disabled

when the VCC voltage falls below 4.65V. If an

application requires a higher under-voltage

lockout (UVLO), use the EN pin as shown in

Figure 8 to adjust the input voltage UVLO by

using two external resistors. It is recommended

to use the enable resistors to set the UVLO

falling threshold (VSTOP) above 4.65V. The

rising threshold (VSTART) should be set to

provide enough hysteresis to allow for any input

supply variations.

Δ

I

=+

I I_ limit

OC

NB670 Rev. 1.01 www.MonolithicPower.com 13

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

inductor

2

(6)

Page 14

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

R

R

UP

DOWN

VIN

EN Comparator

EN

NB670

Figure 8—Adjustable UVLO

Thermal Shutdown

Thermal shutdown is employed in the NB670.

The junction temperature of the IC is internally

monitored. If the junction temperature exceeds

the threshold value (typical 150ºC), the converter

shuts off. This is a non-latch protection. There is

about 25ºC hysteresis. Once the junction

temperature drops to about 125ºC, it initiates a

SS.

Output Discharge

NB670 discharges the output when EN is low, or

the controller is turned off by the protection

functions (UVP & OCP, OCP, OVP, UVLO, and

thermal shutdown). The part discharges outputs

using an internal 6 MOSFET.

NB670 Rev. 1.01 www.MonolithicPower.com 14

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 15

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

=

APPLICATION INFORMATION

Input Capacitor

The input current to the step-down converter is

discontinuous and therefore requires a capacitor

to supply the AC current to the step-down

converter while maintaining the DC input voltage.

Ceramic capacitors are recommended for best

performance and should be placed as close to

the VIN pin as possible. Capacitors with X5R and

X7R ceramic dielectrics are recommended

because they are fairly stable with temperature

fluctuations.

The capacitors must also have a ripple current

rating greater than the maximum input ripple

current of the converter. The input ripple current

can be estimated as follows:

VV

II (1 )

=× ×−

CIN OUT

OUT OUT

VV

IN IN

The worst-case condition occurs at V

where:

I

CIN

OUT

(8)

I2=

For simplification, choose the input capacitor with

an RMS current rating greater than half of the

maximum load current.

The input capacitance value determines the input

voltage ripple of the converter. If there is an input

voltage ripple requirement in the system, choose

the input capacitor that meets the specification.

The input voltage ripple can be estimated as

follows:

IV V

V(1)

Δ= × ×−

IN

OUT OUT OUT

FC V V

×

SW IN IN IN

Under worst-case conditions where V

1

V

Δ=×

IN

4F C

I

OUT

×

SW IN

Output Capacitor

The output capacitor is required to maintain the

DC output voltage. Ceramic or POSCAP

capacitors are recommended. The output voltage

ripple can be estimated as:

(7)

= 2V

IN

OUT

(9)

= 2V

IN

OUT

(10)

,

:

VV

V(1)(R )

Δ= ×− × +

OUT ESR

OUT OUT

FL V 8FC

×××

SW IN SW OUT

1

(11)

In the case of ceramic capacitors, the impedance

at the switching frequency is dominated by the

capacitance. The output voltage ripple is mainly

caused by the capacitance. For simplification, the

output voltage ripple can be estimated as:

VV

V(1)

Δ= ×−

OUT

8F LC V

OUT OUT

2

×××

SW OUT IN

(12)

In the case of POSCAP capacitors, the ESR

dominates the impedance at the switching

frequency. The ramp voltage generated from the

ESR is high enough to stabilize the system.

Therefore, an external ramp is not needed. A

minimum ESR value around 12m is required to

ensure stable operation of the converter. For

simplification, the output ripple can be

approximated as:

VV

V(1)R

Δ= ×− ×

OUT ESR

OUT OUT

FL V

×

SW IN

(13)

Maximum output capacitor limitation should be

also considered in design application. NB670 has

an around 1.8ms soft-start time period. If the

output capacitor value is too high, the output

voltage can’t reach the design value during the

soft-start time, and then it will fail to regulate. The

maximum output capacitor value C

O_MAX

can be

limited approximately by:

C(I I)T/V

O_MAX LIM_AVG OUT ss OUT

Where, I

LIM_AVG

is the average start-up current

during soft-start period. T

−× (14)

is the soft-start time.

ss

Inductor

The inductor is necessary to supply constant

current to the output load while being driven by

the switched input voltage. A larger-value

inductor will result in less ripple current that will

result in lower output ripple voltage. However, a

larger-value inductor will have a larger physical

footprint, higher series resistance, and/or lower

saturation current. A good rule for determining

the inductance value is to design the peak-topeak ripple current in the inductor to be in the

range of 30% to 40% of the maximum output

NB670 Rev. 1.01 www.MonolithicPower.com 15

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 16

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

current, and that the peak inductor current is

below the maximum switch current limit. The

inductance value can be calculated by:

VV

Where I

L(1)

is the peak-to-peak inductor ripple

L

OUT OUT

=×−

FI V

×Δ

SW L IN

(15)

current.

2. Put the input capacitors as close to the IN

and GND pins as possible.

3. Put the decoupling capacitor as close to the

VCC and AGND pins as possible. Place the

Cap close to AGND if the distance is long.

And place >3 Vias if via is required to reduce

the leakage inductance.

The inductor should not saturate under the

maximum inductor peak current, where the peak

inductor current can be calculated by:

VV

II (1 )

=+ ×−

LP OUT

OUT OUT

2F L V

×

SW IN

(16)

PCB Layout Guide

The following guidelines should be followed when

designing the PC board for the NB670:

1. The high current paths (GND, IN, and SW)

should be placed very close to the device

with short, direct and wide traces.

4. Keep the VOUT sensing trace far away from

the SW node.Vias should also be avoided on

the VOUT sensing trace.

5. Keep the BST voltage path (BST, C3, and

SW) as short as possible.

6. Keep the IN and GND pads connected with

large copper and use at least two layers for

IN and GND trace to achieve better thermal

performance. Also, add several Vias with

10mil_drill/18mil_copper_width close to the

IN and GND pads to help on thermal

dissipation.

7. AGND connects PGND with KELVIN

Connecting.

8. Four-layer layout is strongly recommended to

achieve better thermal performance.

Note:

Please refer to the PCB Layout Application Note

for more details.

NB670 Rev. 1.01 www.MonolithicPower.com 16

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 17

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

AGND KELVIN

CONNECT TO PGND

AGND

EN

ENLDO

VIN

1314 12 11

1

15

2

16

3

PG

CLK

54 6 7

LDO

10

SW

9

8

VOUT

VOUT

GND

DO NOT CONNECT

TO AGND HERE

Figure 9—Recommend Layout

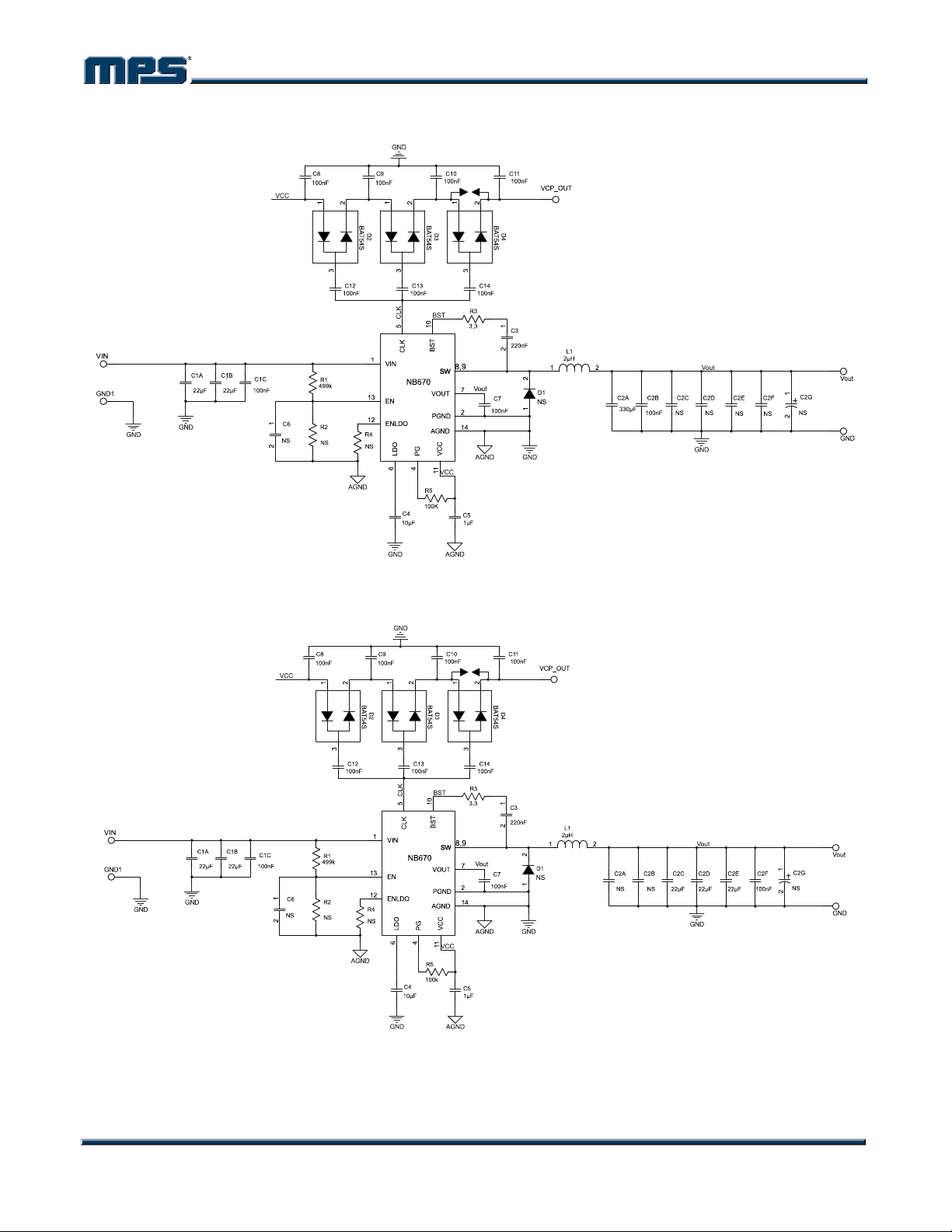

Recommend Design Example

A typical application schematic is shown in

Figure 10 when large ESR caps are used, and

Figure 11 shows the schematic when low ESR

caps are applied. The typical performance and

VOUT

circuit waveforms have been shown in the

Typical Performance Characteristics section. For

more possible applications of this device, please

refer to related Evaluation Board Datasheets.

NB670 Rev. 1.01 www.MonolithicPower.com 17

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 18

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

TYPICAL APPLICATION

Figure 10---Typical Application Circuit With Poscap

NB670 Vin=4.8-22V, Vout=3.3V, Iout=6A, Fsw=500kHz

Figure 11---Typical Application Circuit With Low ESR Ceramic Capacitor

NB670 Vin=4.8-22V, Vout=3.3V, Iout=6A, Fsw=500kHz

NB670 Rev. 1.01 www.MonolithicPower.com 18

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 19

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

PACKAGE INFORMATION

PIN 1 ID

MARKING

PIN 1 ID

INDEX AREA

QFN16 (3X3mm)

PIN 1 ID

0.10x45

癟 YP.

TOP VIEW

SIDE VIEW

0.10x45°

RECOMMENDED LAND PATTERN

BOTTOM VIEW

NOTE:

1) AL L DI ME NSI ONS ARE I N MI LL IM ETERS.

2) EXPOSED PADDLE SI ZE DOES NOT INCLUDE

MOLD FLASH.

3) L EAD COPLANARITY SHALL BE 0.10

MILLIMETERS MAX.

4) JEDEC REFERE NCE I S M O-220 .

5) DRAWING I S NOT TO SCALE .

NOTICE: The information in this document is subject to change without notice. Users should warrant and guarantee that third

party Intellectual Property rights are not infringed upon when integrating MPS products into any application. MPS will not

assume any legal responsibility for any said applications.

NB670 Rev. 1.01 www.MonolithicPower.com 19

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Page 20

Loading...

Loading...