Page 1

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

N6200

SOT-25

Lead-Free

GENERAL DESCRIPTION

N6200 is a 1.5Mhz constant frequency, slope compensated current mode PWM step-down converter. The

device integrates a main switch and a synchronous rectifier for high efficiency without an external Schottky

diode. It is ideal for powering portable equipment that runs from a single cell lithium-Ion (Li+) battery. The

N6200 can supply 600mA of load current from a 2.5V to 5.5V input voltage. The output voltage can be

regulated as low as 0.6V. The N6200 can also run at 100% duty cycle for low dropout operation, extending

battery life in portable system. Idle mode operation at light loads provides very low output ripple voltage for

noise sensitive applications.

The N6200 is offered in a low profile (1mm) 5-pin, thin SOT package, and is available in an adjustable

version and fixed output voltage of 1.2V, 1.5V and 1.8V.

APPLICATIONS

‧ Cellular and Smart Phones

‧ Microprocessors and DSP Core Supplies

‧ Wireless and DSL Modems

‧ PDAs

FEATURES

‧ High Efficiency: Up to 92%

‧ 1.5Mhz Constant Switching Frequency

‧ 600mA Output Current at V

‧ Integrated Main switch and synchronous

rectifier. No Schottky Diode Required

‧ 2.5V to 5.5V Input Voltage Range

‧ Output Voltage as Low as 0.6V

‧ 100% Duty Cycle in Dropout

IN

= 3V

‧ MP3 Player

‧ Digital Still and Video Cameras

‧ Portable Instruments

‧ Low Quiescent Current : 300µA

Slope Compensated ‧ Current Mode Control for

Excellent Line and Load Transient Response

Short Circuit Protection‧

Thermal Fault Protection‧

‧ <1uA Shutdown Current

‧Space Saving 5-Pin SOT-25 package

1

May-8-2006

Page 2

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

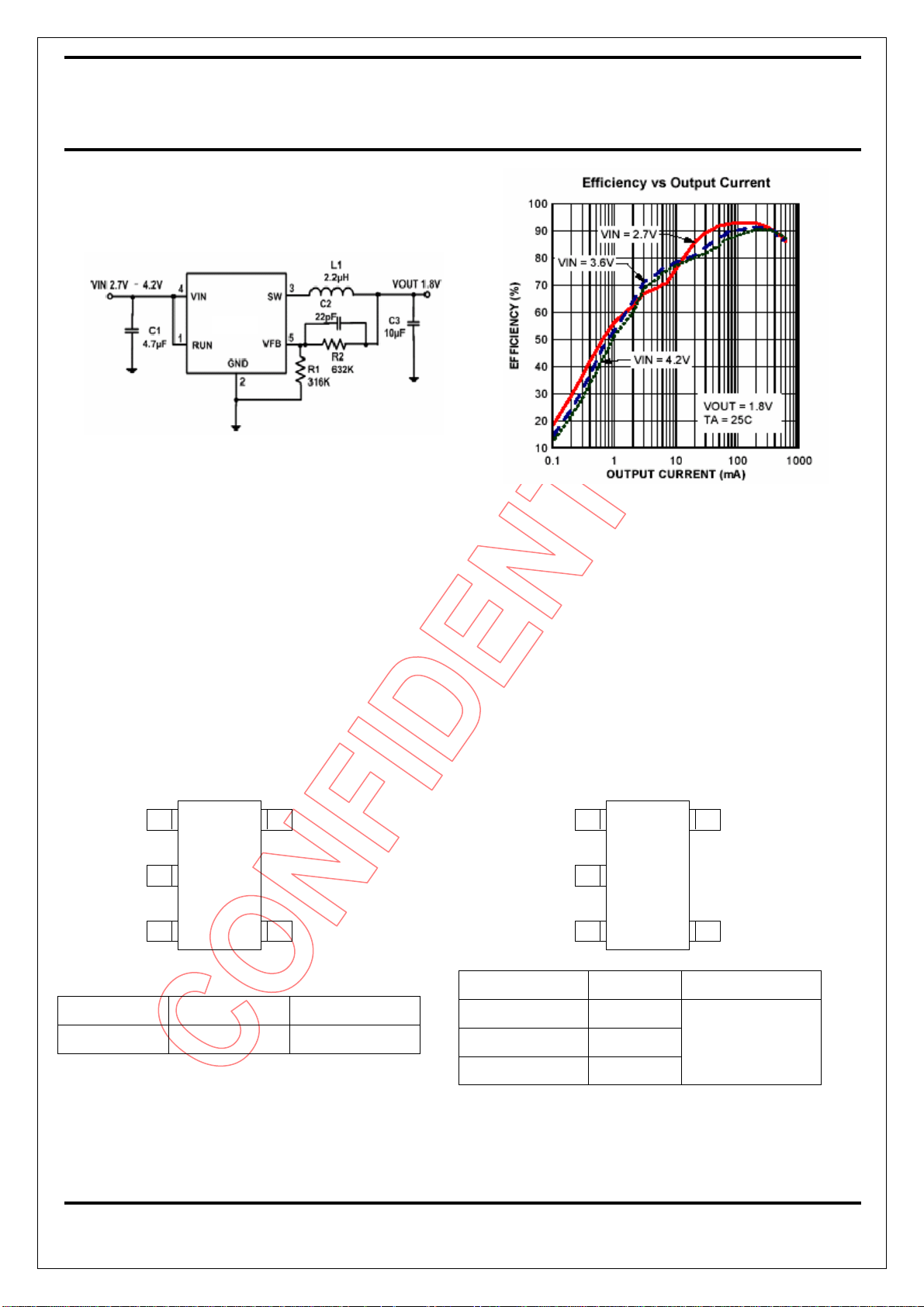

Typical Application

N6200

Figure 1 Basic Application Circuit with N6200

adjustable version, Vout = 1.8V

N6200

SOT-25

Lead-Free

Absolute Maximum Rating

Input Supply Voltage............................ -0.3V to +6V

RUN, V

SW, V

Peak SW Sink and Source Current ......................1.5A

Voltages ............................ -0.3V to VIN+0.3V

FB

Voltages...............................-0.3V to VIN+0.3V

OUT

(Note 1)

Operating Temperature Range........... ...0°C to +85°C

Junction Temperature

Storage Temperature Range ............ -40°C to +150°C

Lead Temperature (Soldering, 10s) ................+300°C

(Note2)

............................+125°C

Package/Order Information

Adjustable Output Version: Fixed Output Versions:

Run

GND

SW

Part Number Top Mark Temp range

N6200M5G A1XY

(note4)

V

VIN

FB

0°C to +85°C

Run

GND

SW

Part Number Top Mark Temp Range

N6200M5G-1.5 A2XY

N6200M5G-1.8 A3XY

N6200M5G-1.2 A4XYB

IN

V

VFB

0°C to +85°C

2

May-8-2006

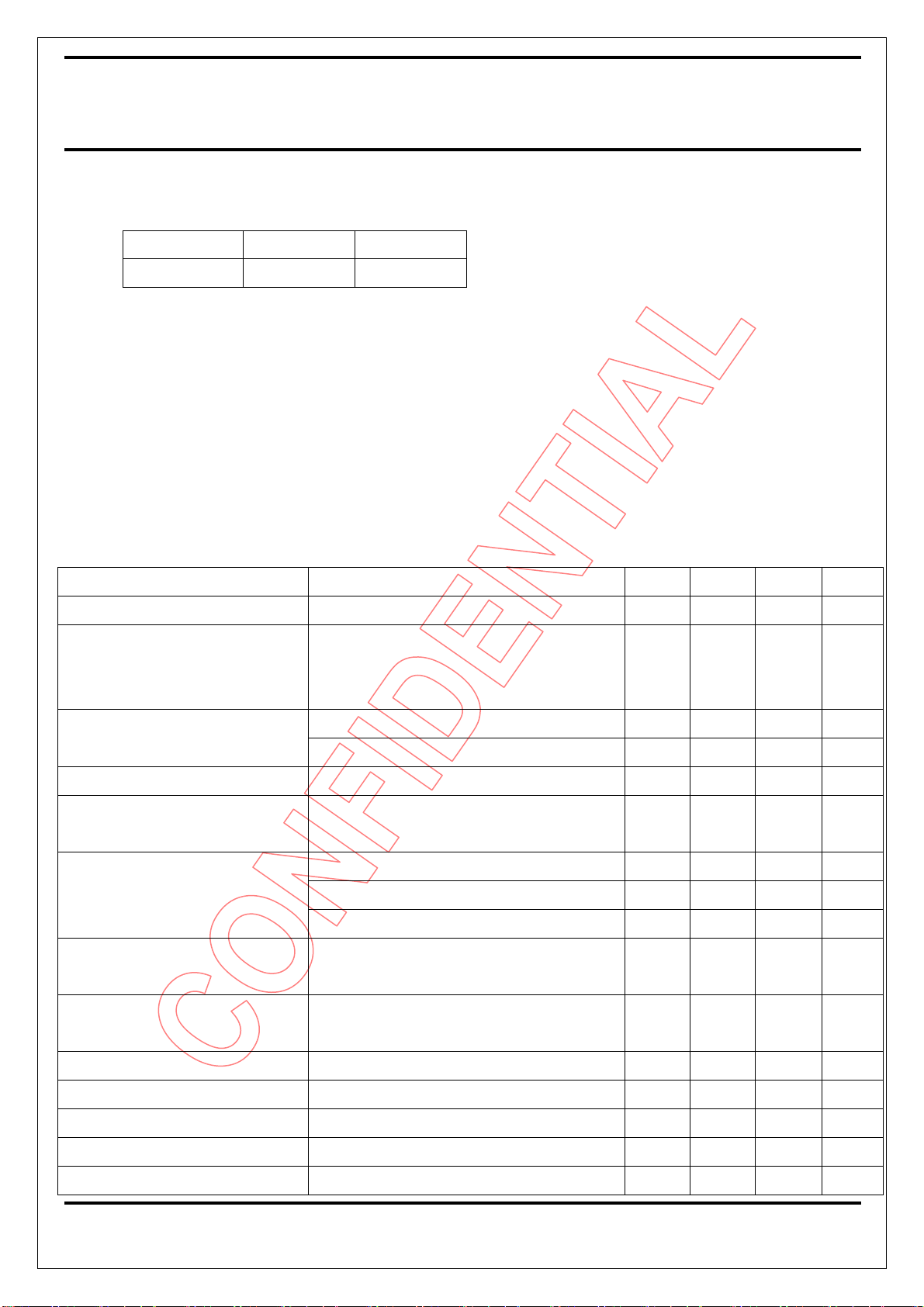

Page 3

NIKO-SEM

Thermal Resistance

(Note 3)

1.5 MHz, 600mA Synchronous

Step-Down Converter

:

N6200

SOT-25

Lead-Free

Package

SOT-25

θ

θ

JA

220℃/W 110℃/W

JC

Note 1: Absolute Maximum Ratings are those values beyond which the life of a device may be impaired.

Note 2: T

is calculated from the ambient temperature TA and power dissipation PD according to the

J

following formula:

TJ = T

+ PD x θJA

A

Note 3: Thermal Resistance is specified with approximately 1 square of 1 oz copper.

Note 4: XY = Manufacturing Date Code

Electrical Characteristics

(Note 5)

:

(VIN =V

= 3.6V, TA = 25°C, Test Circuit Figure 1, unless otherwise noted.)

RUN

Parameter Conditions MIN TYP MAX unit

Input Voltage Range 2.5 5.5 V

Input DC Supply Current

Active Mode

Shutdown Mode

V

= 0.5V

FB

V

= 0V, VIN = 4.2V

FB

270

0.08

400

1.0

µA

µA

TA = +25°C 0.5880 0.6000 0.6120 V Regulated Feedback Voltage

= 0°C T≦A 85°C≦ 0.5865 0.6000 0.6135 V

T

A

VFB Input Bias Current VFB = 0.65V ±30 nA

Reference Voltage Line

VIN = 2.5V to 5.5V, V

OUT

= V

(R2=0)

FB

0.11 0.40 %/V

Regulation

Regulated Output Voltage

APS1006ET5-1.2, 0°C T≦A 85°C≦ 1.164 1.200 1.236 V

APS1006ET5-1.5, 0°C T≦A 85°C≦ 1.455 1.500 1.545 V

APS1006ET5-1.8, 0°C T≦

Output Voltage Line Regulation VIN = 2.5V to 5.5V, I

OUT

85°C≦ 1.746 1.800 1.854 V

A

= 10mA

0.40 %/V

0.11

Output Voltage Load Regulation I

from 0 to 600mA

OUT

0.0015

%/mA

Maximum Output Current VIN = 3.0V 600 mA

Oscillator Frequency VFB = 0.6V or V

R

R

of P-CH MOSFET ISW = 300mA 0.30 0.50 .Ω

DS(ON)

of N-CH MOSFET ISW = -300mA 0.20 0.45 Ω

DS(ON)

Peak Inductor Current VIN = 3V, VFB = 0.5V or V

= 100% 1.2 1.5 1.8 MHz

OUT

= 90% 1.20 A

OUT

3

May-8-2006

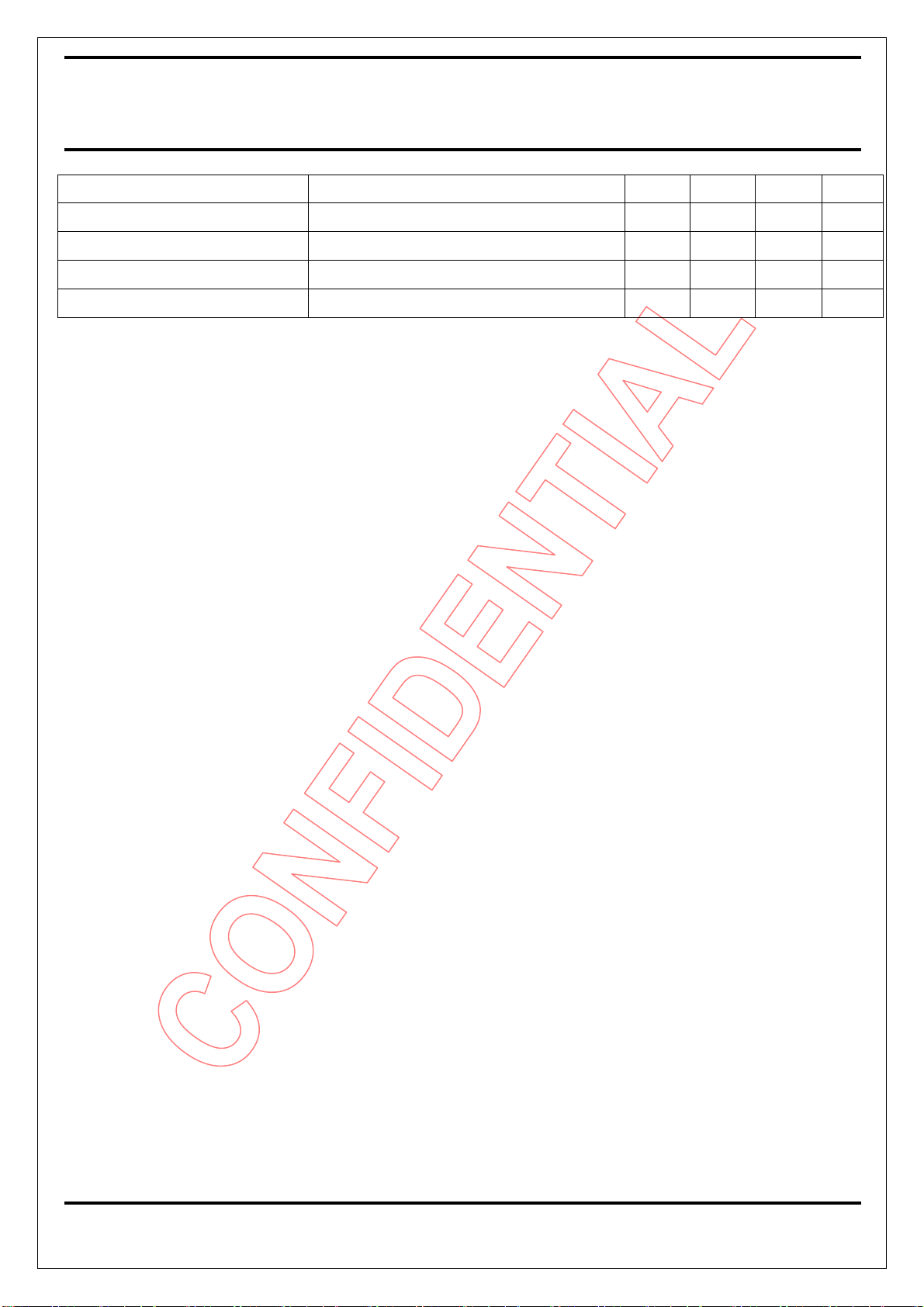

Page 4

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

Duty Cycle < 35%

N6200

SOT-25

Lead-Free

SW Leakage V

Output over voltage lockout ∆V

=0V, VSW = 0V or 5V, VIN = 5V ±0.01 ±1 µA

RUN

OVL

= V

- VFB 60 mV

OVL

RUN Threshold 0°C T≦A 85°C≦ 0.3 0.45 1.30 V

RUN Leakage Current ±0.1 ±1 µA

Note 5: 100% production test at +25°C. Specifications over the temperature range are guaranteed by

design and characterization.

4

May-8-2006

Page 5

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

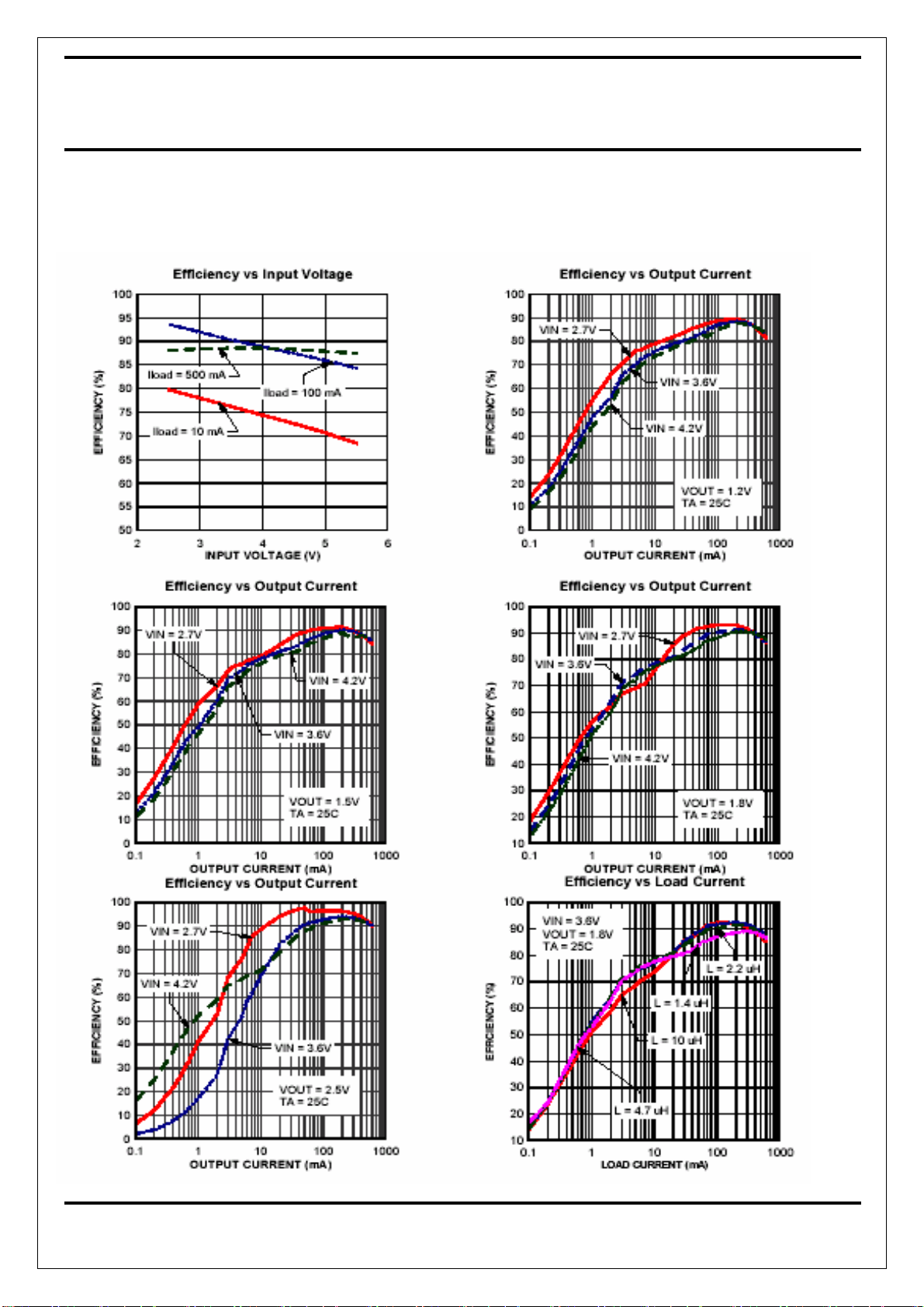

Typical Performance Characteristics

(Test Figure 1 above unless otherwise specified)

N6200

SOT-25

Lead-Free

5

May-8-2006

Page 6

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

N6200

SOT-25

Lead-Free

6

May-8-2006

Page 7

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

N6200

SOT-25

Lead-Free

Pin Description

7

May-8-2006

Page 8

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

PIN NAME FUNCTION

N6200

SOT-25

Lead-Free

1

2 GND Ground

3

4

5

RUN Regulator Enable control input. Drive RUN above 1.5V to turn on the part. Drive RUN below 0.3V to turn

it off. In shutdown, all functions are disabled drawing <1µA supply current. Do not leave RUN floating.

SW

IN

FB/VOU

T

Power Switch Output. It is the Switch note connection to Inductor. This pin connects to the drains of the

internal P-CH and N-CH MOSFET switches.

Supply Input Pin. Must be closely decoupled to GND, Pin 2, with a 2.2µF or greater ceramic capacitor.

VFB (N6200): Feedback Input Pin. Connect FB to the center point of the external resistor divider. The

feedback threshold voltage is 0.6V.

VOUT (N6200-1.2/N6200-1.5/N6200-1.8): Output Voltage Feedback Pin. An internal resistive divider

divides the output voltage down for comparison to the internal reference voltage.

Functional Block Diagram

Figure 2 N6200 Block Diagram

8

May-8-2006

Page 9

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

N6200

SOT-25

Lead-Free

Operation

N6200 is a monolithic switching mode Step-Down DC-DC converter. It utilizes internal MOSFETs to

achieve high efficiency and can generate very low output voltage by using internal reference at 0.6V. It

operates at a fixed switching frequency, and uses the slope compensated current mode architecture. This

Step-Down DC-DC Converter supplies 600mA output current at VIN = 3V with input voltage range from

2.5V to 5.5V.

Current Mode PWM Control

Slope compensated current mode PWM control provides stable switching and cycle-by-cycle current limit

for excellent load and line responses and protection of the internal main switch (P-Ch MOSFET) and

synchronous rectifier (N-CH MOSFET). During normal operation, the internal PCH MOSFET is turned on

for a certain time to ramp the inductor current at each rising edge of the internal oscillator, and switched

off when the peak inductor current is above the error voltage. The current comparator, ICOMP, limits the

peak inductor current. When the main switch is off, the synchronous rectifier will be turned on

immediately and stay on until either the inductor current starts to reverse, as indicated by the current

reversal comparator, I

, or the beginning of the next clock cycle. The OVDET comparator controls

ZERO

output transient overshoots by turning the main switch off and keeping it off until the fault is no longer

present.

Idle Mode Operation

At very light loads, the N6200 automatically enters Idle Mode. In the Idle Mode, the inductor current may

reach zero or reverse on each pulse. The PWM control loop will automatically skip pulses to maintain

output regulation. The bottom MOSFET is turned off by the current reversal comparator, I

ZERO

, and the

switch voltage will ring. This is discontinuous mode operation, and is normal behavior for the switching

regulator.

Dropout Operation

When the input voltage decreases toward the value of the output voltage, the N6200 allows the main

switch to remain on for more than one switching cycle and increases the duty cycle

(Note 5)

until it reaches

100%. The output voltage then is the input voltage minus the voltage drop across the main switch and the

inductor. At low input supply voltage, the R

of the P-Channel MOSFET increases, and the efficiency

DS(ON)

of the converter decreases. Caution must be exercised to ensure the heat dissipated not to exceed the

maximum junction temperature of the IC.

Note 5: The duty cycle D of a step-down converter is defined as:

Where TON is the main switch on time, and f

is the oscillator frequency (1.5Mhz).

OSC

9

May-8-2006

Page 10

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

N6200

SOT-25

Lead-Free

Maximum Load Current

The N6200 will operate with input supply voltage as low as 2.5V, however, the maximum load current

decreases at lower input due to large IR drop on the main switch and synchronous rectifier. The slope

compensation signal reduces the peak inductor current as a function of the duty cycle to prevent

sub-harmonic oscillations at duty cycles greater than 50%. Conversely the current limit increases as the

duty cycle decreases.

Layout Guidance

When laying out the PC board, the following suggestions should be taken to ensure proper operation of the

N6200. These items are also illustrated graphically in Figure 3.

1. The power traces, including the GND trace, the SW trace and the VIN trace should be kept short,

direct and wide.

2. The VFB pin should be connected directly to the feedback resistor. The resistive divider R1/R2 must

be connected between the (+) plate of C3 and ground.

3. Connect the (+) plate of C1 to the VIN pin as closely as possible. This capacitor provides the AC

current to internal power MOSFET.

4. Keep the switching node, SW, away from the sensitive VFB node.

5. Keep the (-) plates of C1 and C3 as close as possible.

N6200

Figure 3. N6200 Layout Example

10

May-8-2006

Page 11

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

APPLICATIONS INFORMATION

Figure 4 below shows the basic application circuit with N6200 fixed output versions.

N6200

Figure 4. Basic Application Circuit with fixed output versions

Setting the Output Voltage

N6200

SOT-25

Lead-Free

Figure 1 above shows the basic application circuit with N6200 adjustable output version. The external

resistor sets the output voltage according to the following equation:

R1=316kΩ for all outputs;

R2= 316kΩ for Vout=1.2V;

R2= 474kΩ for Vout=1.5V;

R2= 634kΩ for Vout=1.8V;

R2= 1MΩ for Vout=2.5V;

Inductor Selection

For most designs, the N6200 operates with inductors of 1µH to 4.7µH. Low inductance values are

physically smaller but require faster switching, which results in some efficiency loss. The inductor value

can be derived from the following equation:

Where ∆I

is inductor Ripple Current. Large value inductors lower ripple current and small value inductors

L

result in high ripple currents. Choose inductor ripple current approximately 35% of the maximum load

current 600mA, or ∆IL = 210mA.

11

May-8-2006

Page 12

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

N6200

SOT-25

Lead-Free

For output voltages above 2.0V, when light-load efficiency is important, the minimum recommended

inductor is 2.2µH. For optimum voltage-positioning load transients, choose an inductor with DC series

resistance in the 50mΩ to 150mΩ range. For higher efficiency at heavy loads (above 200mA), or minimal

load regulation (but some transient overshoot), the resistance should be kept below 100mΩ. The DC

current rating of the inductor should be at least equal to the maximum load current plus half the ripple

current to prevent core saturation (600mA+105mA). Table 1 lists some typical surface mount inductors

that meet target applications for the N6200.

Part # L (µH) Max DCR (m.) Rated D.C. Current (A) Size W x L x H (mm)

Sumida

1.4

2.2

56.2

71.2

2.52

1.75

4.5x4.0x3.5

CR43

3.3

4.7

1.5

86.2

108.7

1.44

1.15

Sumida

2.2

75

1.32

4.7x4.7x2.0

CDRH4D18

3.3

110

1.04

4.7

1.5

162

120

0.84

1.29

Toko

2.2

140

1.14

3.6x3.6x1.2

D312C

3.3

180

0.98

4.7

240

0.79

Table 1 Typical Surface Mount Inductors

Input Capacitor Selection

The input capacitor reduces the surge current drawn from the input and switching noise from the device.

The input capacitor impedance at the switching frequency shall be less than input source impedance to

prevent high frequency switching current passing to the input. A low ESR input capacitor sized for

maximum RMS current must be used. Ceramic capacitors with X5R or X7R dielectrics are highly

recommended because of their low ESR and small temperature coefficients. A 4.7µF ceramic capacitor for

most applications is sufficient.

Output Capacitor Selection

The output capacitor is required to keep the output voltage ripple small and to ensure regulation loop stability. The output

capacitor must have low impedance at the switching frequency. Ceramic capacitors with X5R or X7R dielectrics are

recommended due to their low ESR and high ripple current. The output ripple V

12

is determined by:

OUT

May-8-2006

Page 13

NIKO-SEM

1.5 MHz, 600mA Synchronous

Step-Down Converter

N6200

SOT-25

Lead-Free

SOT-25 (M5) MECHANICAL DATA

mm mm

Dimension

Min. Typ. Max.

A 0.9 1.1 e 1.9

A1 0.01 0.13 H 2.5 3.1

A2 L 0.35 0.8

b 0.3 0.5

C 0.09 0.2

Dimension

Min. Typ. Max.

D 2.8 3.0

E 1.5 1.7

D

C

L

HE

e

A

13

A1A2

May-8-2006

b

Page 14

Loading...

Loading...