Datasheet MX28F1000PRI-12, MX28F1000PRI-70, MX28F1000PRI-90, MX28F1000PTC-12C4, MX28F1000PTC-70C4 Datasheet (MXIC)

...Page 1

FEATURES

MX28F1000P

1M-BIT [128K x 8] CMOS FLASH MEMORY

• 131,072 bytes by 8-bit organization

• Fast access time: 70ns(Vcc:5V±5%; CL:35pF)

90/120ns(Vcc:5V±10%; CL:100pF)

• Low power consumption

– 50mA maximum active current

– 100uA maximum standby current

• Programming and erasing voltage 12V ± 5%

• Command register architecture

– Byte Programming (15us typical)

– Auto chip erase 5 seconds typical

(including preprogramming time)

– Block Erase

• Optimized high density blocked architecture

– Four 4-KB blocks

GENERAL DESCRIPTION

The MX28F1000P is a 1-mega bit Flash memory organized as 128K bytes of 8 bits each. MXIC's Flash

memories offer the most cost-effective and reliable

read/write non-volatile random access memory. The

MX28F1000P is packaged in 32-pin PDIP, PLCC

and TSOP. It is designed to be reprogrammed and

erased in-system or in-standard EPROM programmers.

– Seven 16-KB blocks

• Auto Erase (chip & block) and Auto Program

– DATA polling

– Toggle bit

• 10,000 minimum erase/program cycles

• Latch-up protected to 100mA from -1 to VCC+1V

• Advanced CMOS Flash memory technology

• Compatible with JEDEC-standard byte-wide 32-pin

EPROM pinouts

• Package type:

– 32-pin plastic DIP

– 32-pin PLCC

– 32-pin TSOP (Type 1)

MX28F1000P uses a 12.0V ± 5% VPP supply to

perform the Auto Program/Erase algorithms.

The highest degree of latch-up protection is

achieved with MXIC's proprietary non-epi process.

Latch-up protection is proved for stresses up to 100

milliamps on address and data pin from -1V to VCC

+ 1V.

The standard MX28F1000P offers access times as

fast as 70 ns, allowing operation of high-speed

microprocessors without wait states. To eliminate

bus contention, the MX28F1000P has separate chip

enable (CE) and output enable (OE ) controls.

MXIC's Flash memories augment EPROM functionality with in-circuit electrical erasure and

programming. The MX28F1000P uses a command

register to manage this functionality, while

maintaining a standard 32-pin pinout. The

command register allows for 100% TTL level control

inputs and fixed power supply levels during erase

and programming, while maintaining maximum

EPROM compatibility.

MXIC Flash technology reliably stores memory contents even after 10,000 erase and program cycles.

The MXIC cell is designed to optimize the erase and

programming mechanisms. In addition, the combination of advanced tunnel oxide processing and low

internal electric fields for erase and programming

operations produces reliable cycling. The

P/N: PM0340

1

REV. 1.6,JAN. 19, 1999

Page 2

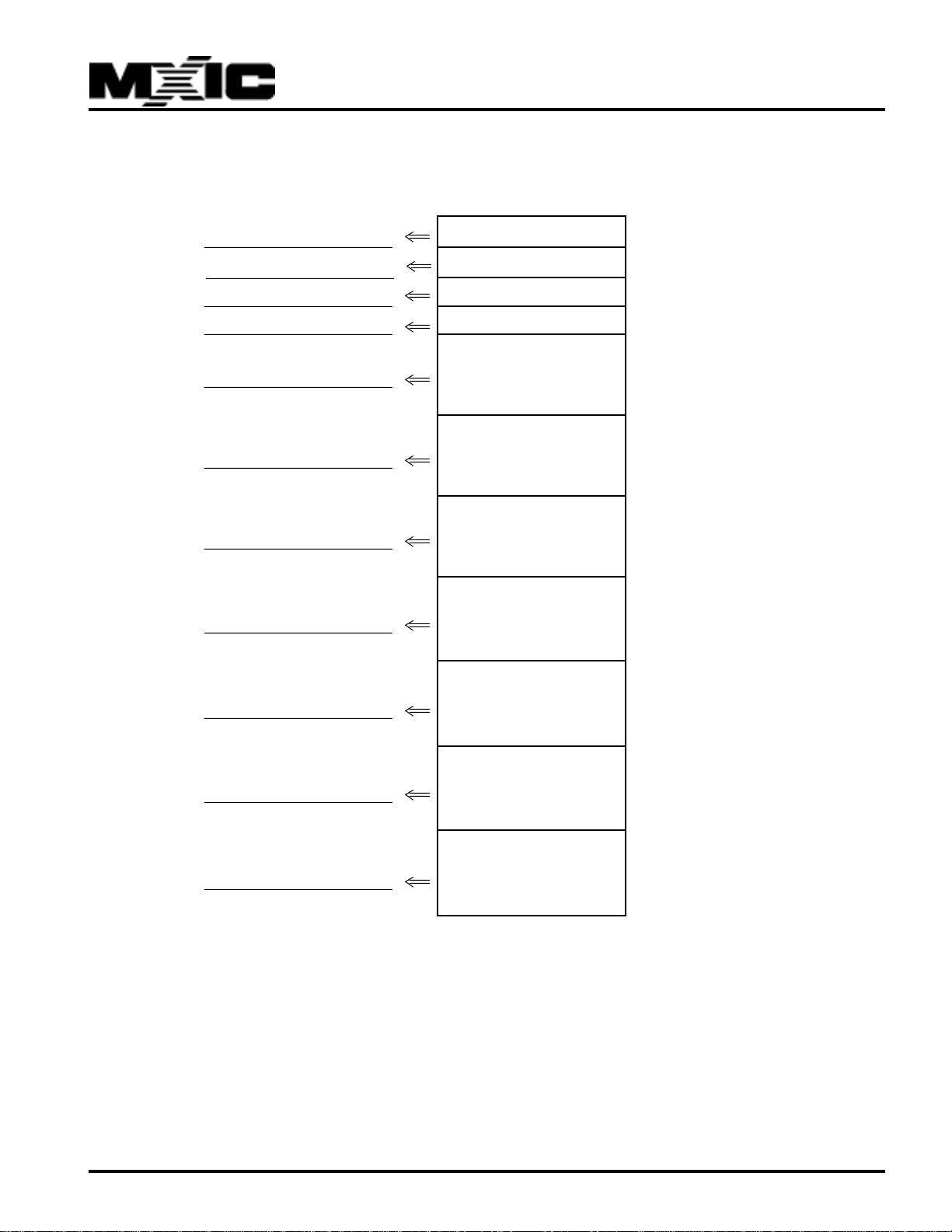

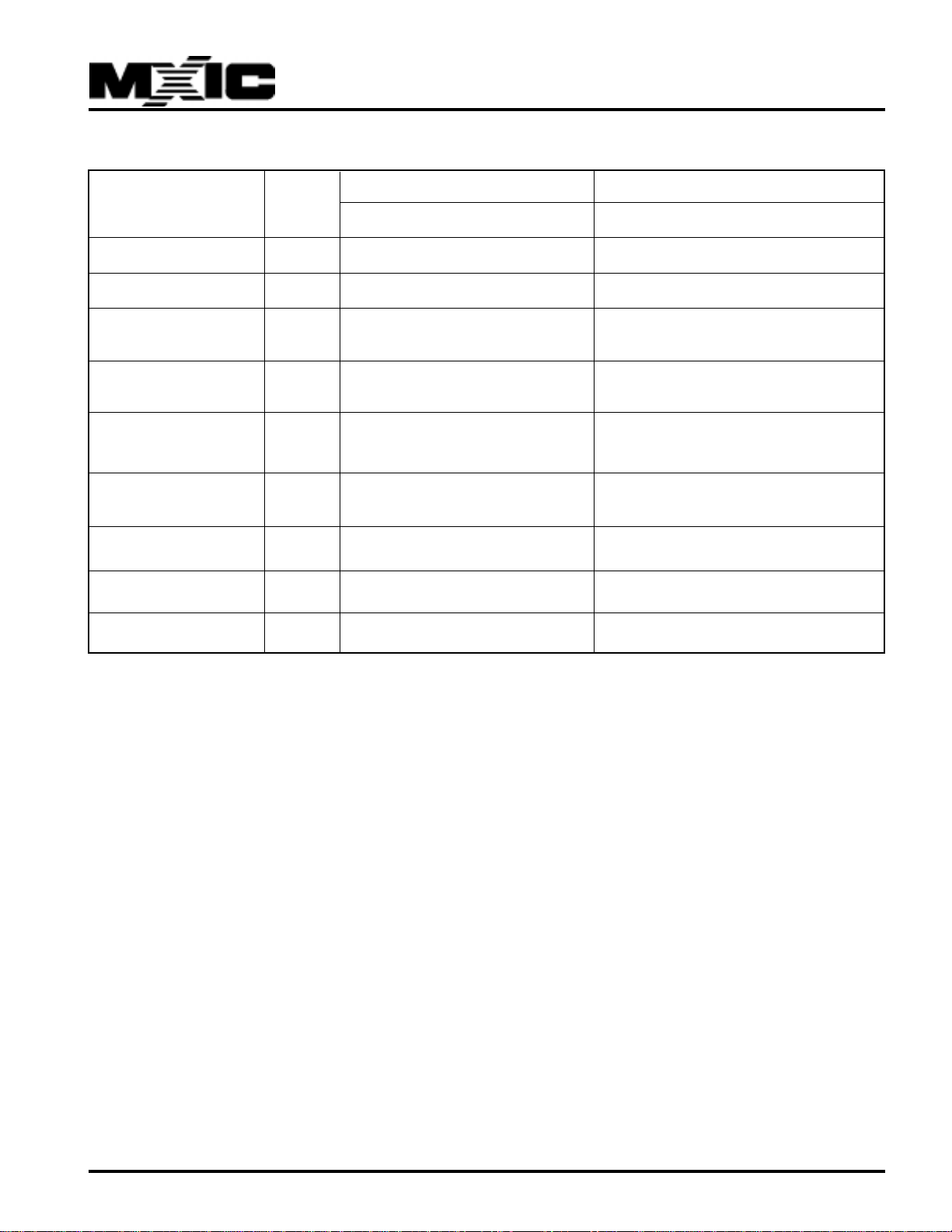

MX28F1000P Block Address and Block Structure

A16 A15 A14 A13 A12 A[16:0]

11111

11110

11101

11100

4k

4k

4k

4k

MX28F1000P

1FFFF

1F000

1EFFF

1E000

1DFFF

1D000

1CFFF

1C000

1BFFF

110XX

101XX

100XX

011XX

010XX

001XX

16k

18000

17FFF

16k

14000

13FFF

16k

10000

0FFFF

16k

0C000

0BFFF

16k

08000

07FFF

16k

04000

03FFF

P/N: PM0340

000XX

16k

00000

REV. 1.6, JAN. 19, 1999

2

Page 3

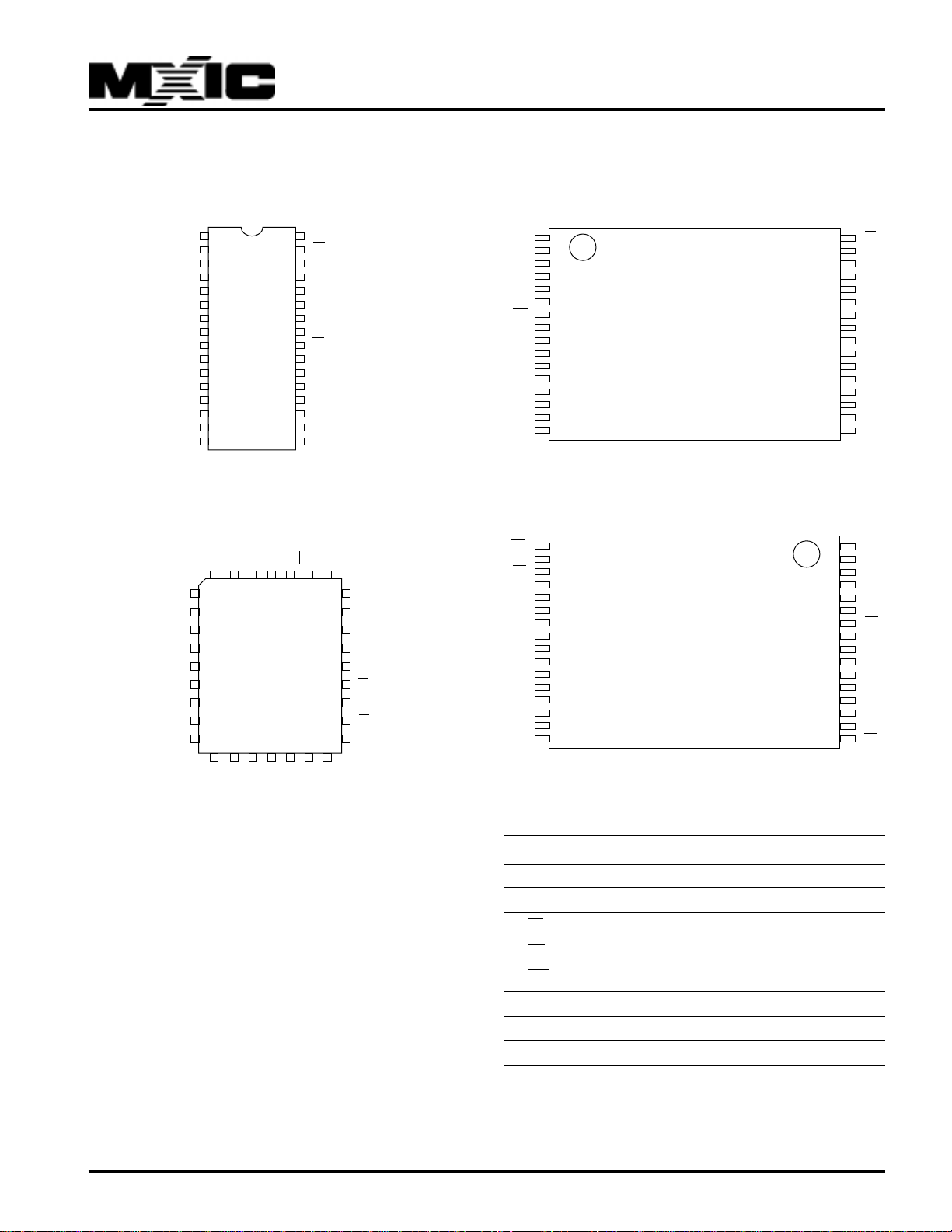

PIN CONFIGURATIONS

A11

A9

A8

A13

A14

NC

WE

VCC

VPP

A16

A15

A12

A7

A6

A5

A4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

OE

A10

CE

Q7

Q6

Q5

Q4

Q3

GND

Q2

Q1

Q0

A0

A1

A2

A3

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

MX28F1000P

MX28F1000P

32 PDIP

32 PLCC

VPP

1

A16

2

A15

3

A12

4

A7

5

A6

6

A5

7

A4

8

A3

9

A2

10

A1

11

A0

12

Q0

13

Q1

14

Q2

15

GND

16

A12

A15

4

5

A7

A6

A5

A4

MX28F1000P

9

A3

A2

A1

A0

13

Q0

14 17 20

Q1

Q2

VCC

32

WE

31

NC

30

A14

29

A13

28

A8

27

A9

26

A11

25

OE

24

A10

23

MX28F1000P

A16

VSS

22

21

20

19

18

17

VPP

VCCWENC

1

32

Q3Q4Q5

CE

Q7

Q6

Q5

Q4

Q3

TSOP (TYPE 1)

(NORMAL TYPE)

1

32

OE

CE

Q7

Q6

Q5

Q4

Q3

Q2

Q1

Q0

31

30

29

28

27

26

25

24

23

22

21

20

A0

19

A1

18

A2

17

A3

MX28F1000P

(REVERSE TYPE)

A10

30

29

A14

A13

A8

A9

25

A11

OE

A10

CE

21

Q7

Q6

GND

A11

2

A9

3

A8

4

A13

5

A14

6

NC

7

WE

8

VCC

9

VPP

10

A16

11

A15

12

A12

13

A7

14

A6

15

A5

16

A4

PIN DESCRIPTION:

SYMBOL PIN NAME

A0~A16 Address Input

Q0~Q7 Data Input/Output

CE Chip Enable Input

OE Output Enable Input

WE Write enable Pin

VPP Program Supply Voltage

P/N: PM0340

VCC Power Supply Pin (+5V)

GND Ground Pin

REV. 1.6, JAN. 19, 1999

3

Page 4

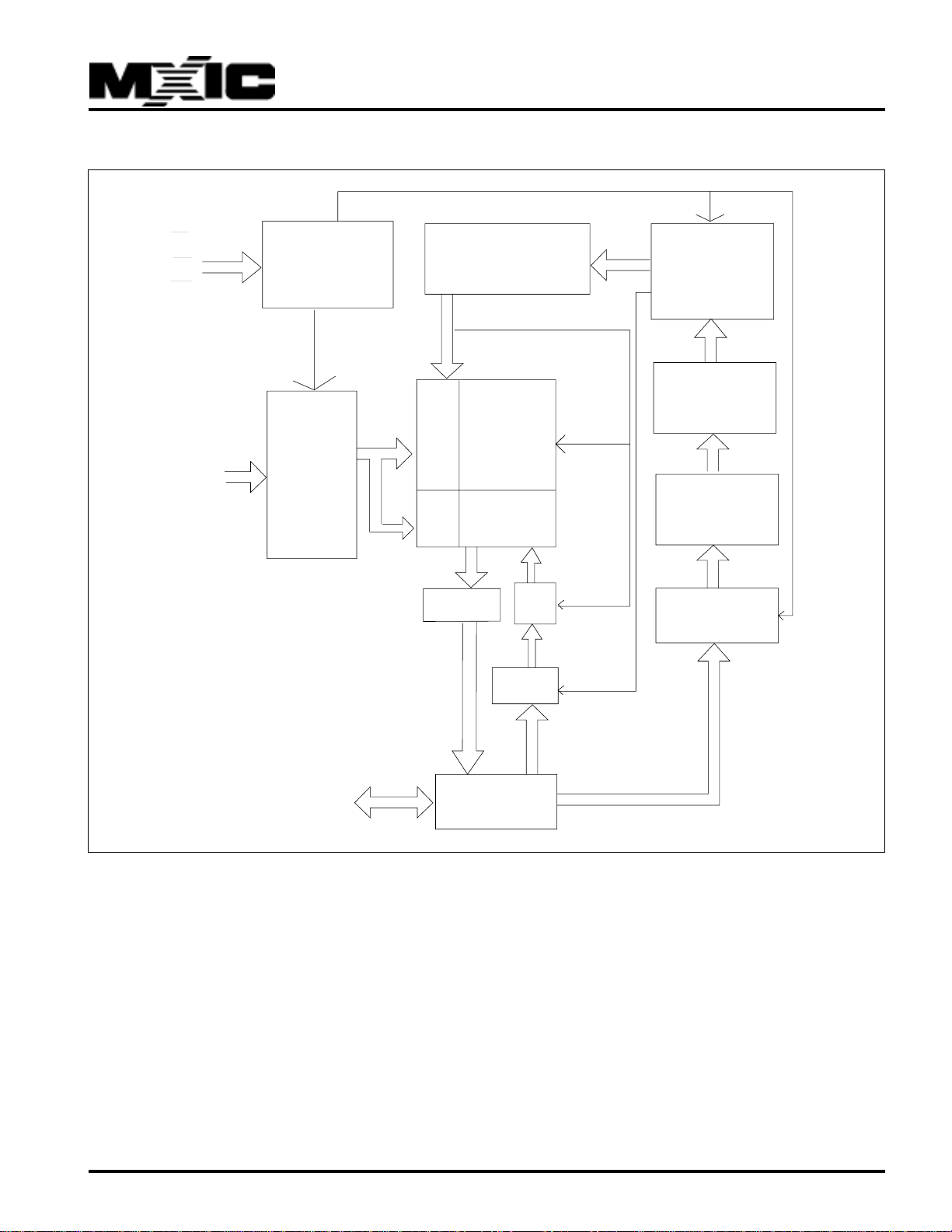

BLOCK DIAGRAM

MX28F1000P

CE

OE

WE

A0-A16

CONTROL

INPUT

LOGIC

ADDRESS

LATCH

AND

BUFFER

PROGRAM/ERASE

HIGH VOLTAGE

X-DECODER

MX28F1000P

FLASH

ARRA Y

Y-DECODER

Y-PASS GATE

SENSE

AMPLIFIER

PGM

DATA

HV

PROGRAM

DATA LATCH

ARRAY

SOURCE

HV

MODE

LOGIC

STATE

REGISTER

COMMAND

DATA

DECODER

COMMAND

DATA LATCH

P/N: PM0340

Q0-Q7

I/O BUFFER

REV. 1.6, JAN. 19, 1999

4

Page 5

MX28F1000P

AUTOMATIC PROGRAMMING

The MX28F1000P is byte programmable using the

Automatic Programming algorithm. The Automatic

Programming algorithm does not require the system to

time out or verify the data programmed. The typical

room temperature chip programming time of the

MX28F1000P is less than 5 seconds.

AUTOMATIC CHIP ERASE

The device may be erased using the Automatic Erase

algorithm. The Automatic Erase algorithm automatically programs the entire array prior to electrical erase.

The timing and verification of electrical erase are

controlled internal to the device.

AUTOMATIC BLOCK ERASE

The MX28F1000P is block(s) erasable using MXIC's

Auto Block Erase algorithm. Block erase modes allow

blocks of the array to be erased in one erase cycle.

The Automatic Block Erase algorithm automatically

programs the specified block(s) prior to electrical

erase. The timing and verification of electrical erase

are controlled internal to the device.

AUTOMATIC PROGRAMMING ALGORITHM

MXIC's Automatic Programming algorithm requires

the user to only write a program set-up command and

a program command (program data and address). The

device automatically times the programming pulse

width, provides the program verify, and counts the

number of sequences. A status bit similar to DATA

polling and a status bit toggling between consecutive

read cycles, provide feedback to the user as to the

status of the programming operation.

AUTOMATIC ERASE ALGORITHM

MXIC's Automatic Erase algorithm requires the user to

only write an erase set-up command and erase command. The device will automatically pre-program and

verify the entire array. Then the device automatically

times the erase pulse width, provides the erase verify,

and counts the number of sequences. A status bit

similar to DATA polling and a status bit toggling

between consecutive read cycles, provide feedback to

the user as to the status of the erase operation.

Commands are written to the command register using

standard microprocessor write timings. Register contents serve as inputs to an internal state-machine

which controls the erase and programming circuitry.

During write cycles, the command register internally

latches address and data needed for the programming

and erase operations. For system design simplification, the MX28F1000P is designed to support either

WE or CE controlled writes. During a system write

cycle, addresses are latched on the falling edge of WE

or CE whichever occurs last. Data is latched on the

rising edge of WE or CE whichever occur first. To

simplify the following discussion, the WE pin is used as

the write cycle control pin throughout the rest of this

text. All setup and hold times are with respect to the

WE signal.

MXIC's Flash technology combines years of EPROM

experience to produce the highest levels of quality, reliability, and cost effectiveness. The MX28F1000P electrically erases all bits simultaneously using Fowler-Nordheim tunneling. The bytes are programmed one byte at

a time using the EPROM programming mechanism of hot

electron injection.

P/N: PM0340

5

REV. 1.6, JAN. 19, 1999

Page 6

MX28F1000P

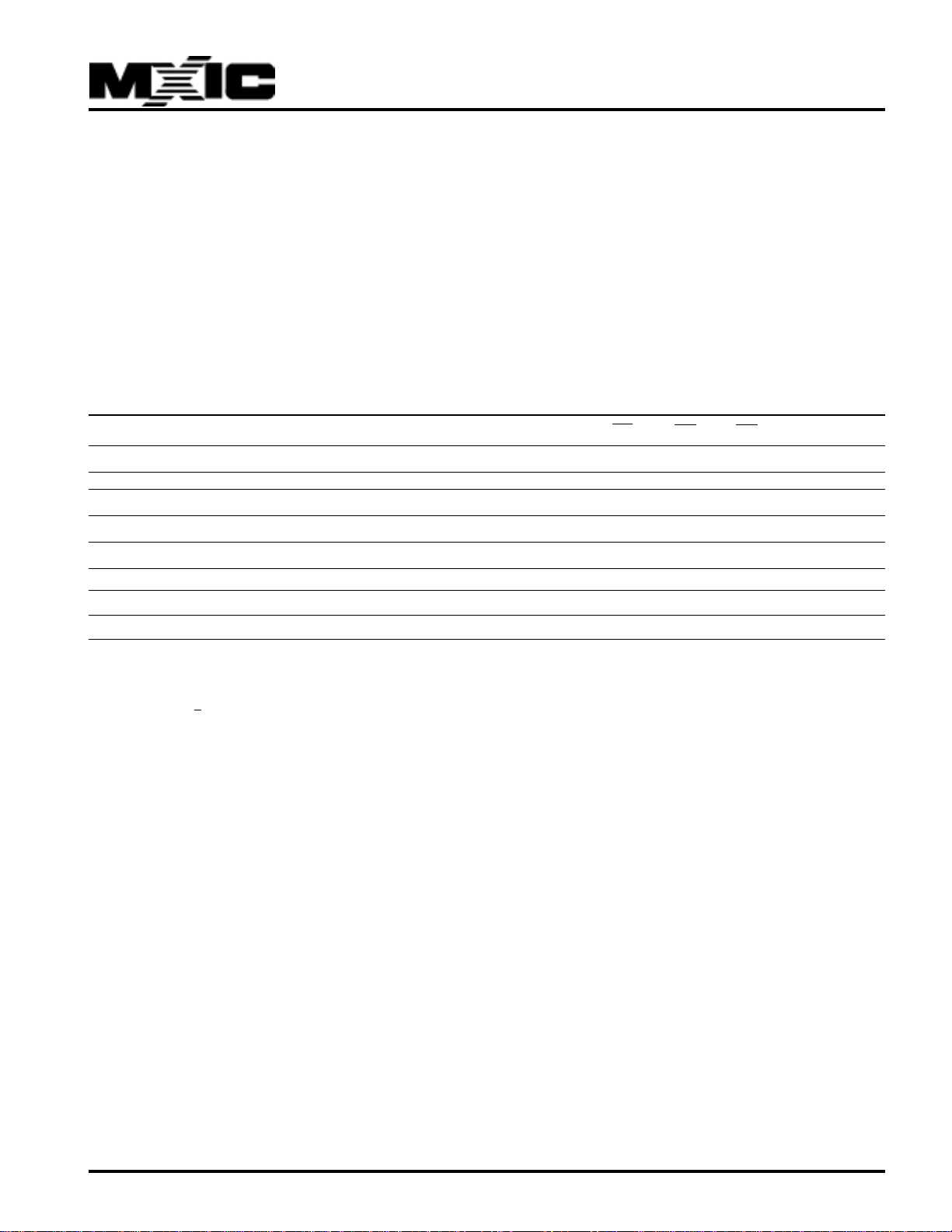

TABLE 1. COMMAND DEFINITIONS

COMMAND BUS FIRST BUS CYCLE SECOND BUS CYCLE

CYCLES OPERATION ADDRESS DATA OPERATION ADDRESS DATA

Read Memory 1 Write X 00H

Read Identified codes 2 Write X 90H Read IA ID

Setup auto erase/ 2 Write X 30H Write X 30H

auto erase (chip)

Setup auto erase/ 2 Write X 20H Write EA D0H

auto erase (block)

Setup auto program/ 2 Write X 40H Write PA PD

program

Setup Erase/ 2 Write X 20H Write X 20H

Erase (chip)

Setup Erase/ 2 Write X 60H Write EA 60H

Erase (block)

Erase verify 2 Write EVA A0H Read X EVD

Reset 2 Write X FFH Write X FFH

Note:

IA = Identifier address

EA = Block of memory location to be erased

PA = Address of memory location to be pro-

grammed

ID = Data read from location IA during device iden-

tification

PD = Data to be programmed at location PA

EVA = Address of memory location to be read during

erase verify.

EVD = Data read from location EVA during erase

verify.

Auto modes have the build-in enchanced features.

Please use the auto erase mode whenever it is.

P/N: PM0340

6

REV. 1.6, JAN. 19, 1999

Page 7

MX28F1000P

COMMAND DEFINITIONS

When low voltage is applied to the VPP pin, the contents of the command register default to 00H, enabling

read-only operation.

Placing high voltage on the VPP pin enables read/write

operations. Device operations are selected by writing

specific data patterns into the command register. Table 1 defines these MX28F1000P register commands.

Table 2 defines the bus operations of MX28F1000P.

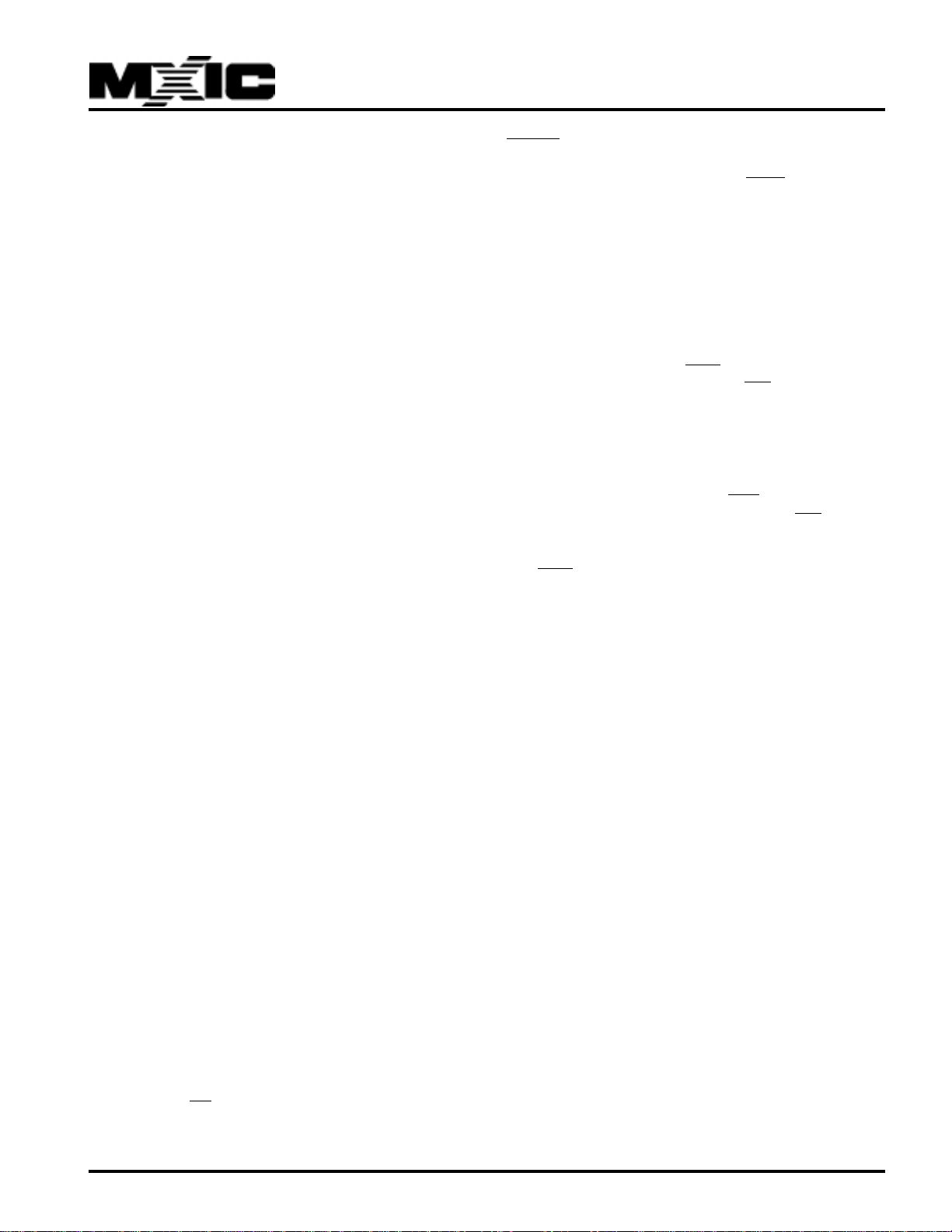

TABLE 2. MX28F1000P BUS OPERATIONS

OPERATION VPP(1) A0 A9 CE OE WE DQ0-DQ7

READ-ONLY Read VPPL A0 A9 VIL VIL VIH Data Out

Output Disable VPPL X X VIL VIH VIH Tri-State

Standby VPPL X X VIH X X Tri-State

Read Silicon ID (Mfr)(2) VPPL VIL VID(3) VIL VIL VIH Data = C2H

Read Silicon ID (Device)(2) VPPL VIH VID(3) VIL VIL VIH Data = 1AH

READ/WRITE Read VPPH A0 A9 VIL VIL VIH Data Out(4)

Standby(5) VPPH X X VIH X X Tri-State

Write VPPH A0 A9 VIL VIH VIL Data In(6)

NOTES:

1. VPPL may be grounded, a no-connect with a resistor tied

to ground, or < VCC + 2.0V. VPPH is the programming

voltage specified for the device. When VPP = VPPL,

memory contents can be read but not written or erased.

2. Manufacturer and device codes may also be accessed

via a command register write sequence. Refer to Table

1. All other addresses are don't care.

3. VID is the Silicon-ID-Read high voltage.(11.5V to 13v)

4. Read operations with VPP = VPPH may access array

data or Silicon ID codes.

5. With VPP at high voltage, the standby current equals ICC

+ IPP (standby).

6. Refer to Table 1 for valid Data-In during a write operation.

7. X can be VIL or VIH.

P/N: PM0340

7

REV. 1.6, JAN. 19, 1999

Page 8

MX28F1000P

READ COMMAND

While VPP is high, for erase and programming, memory contents can also be accessed via the read command. The read operation is initiated by writing 00H

into the command register. Microprocessor read

cycles retrieve array data. The device remains enabled for reads until the command register contents

are altered.

The default contents of the register upon VPP powerup is 00H. This default value ensures that no spurious

alteration of memory contents occurs during the VPP

power transition. Where the VPP supply is hard-wired

to the MX28F1000P, the device powers up and

remains enabled for reads until the command register

contents are changed.

SILICON-ID-READ COMMAND

Flash-memories are intended for use in applications

where the local CPU alters memory contents. As such,

manufacturer- and device-codes must be accessible

while the device resides in the target system. PROM

programmers typically access signature codes by raising A9 to a high voltage. However, multiplexing high

voltage onto address lines is not a desired systemdesign practice.

device returns to the Read mode. The system is not

required to provide any control or timing during these

operations.

When using the Automatic Chip Erase algorithm, note

that the erase automatically terminates when

adequate erase margin has been achieved for the

memory array(no erase verify command is required).

The margin voltages are internally generated in the

same manner as when the standard erase verify

command is used.

The Automatic set-up erase command is a commandonly operation that stages the device for automatic

electrical erasure of all bytes in the array. Automatic

set-up erase is performed by writing 30H to the

command register.

To command automatic chip erase, the command 30H

must be written again to the command register. The

automatic chip erase begins on the rising edge of the

WE and terminates when the data on DQ7 is "1" and

the data on DQ6 stops toggling for two consecutive

read cycles, at which time the device returns to the

Read mode.

SET-UP AUTOMATIC BLOCK ERASE/ERASE

COMMANDS

The MX28F1000P contains a Silicon-ID-Read

operation to supplement traditional PROMprogramming methodology. The operation is initiated

by writing 90H into the command register. Following

the command write, a read cycle from address 0000H

retrieves the manufacturer code of C2H. A read cycle

from address 0001H returns the device code of 1AH.

SET-UP AUTOMATIC CHIP ERASE/ERASE

COMMANDS

The automatic chip erase does not require the device

to be entirely pre-programmed prior to excuting the

Automatic set-up erase command and Automatic chip

erase command. Upon executing the Automatic chip

erase command, the device automatically will program

and verify the entire memory for an all-zero data

pattern. When the device is automatically verified to

contain an all-zero pattern, a self-timed chip erase and

verify begin. The erase and verify operations are

complete when the data on DQ7 is "1" at which time the

The automatic block erase does not require the device

to be entirely pre-programmed prior to executing the

Automatic set-up block erase command and

Automatic block erase command. Upon executing the

Automatic block erase command, the device automatically will program and verify the block(s) memory for an

all-zero data pattern. The system is not required to

provide any controls or timing during these operations.

When the block(s) is automatically verified to contain

an all-zero pattern, a self-timed block erase and verify

begin. The erase and verify operations are complete

when the data on DQ7 is "1" and the data on DQ6 stops

toggling for two consecutive read cycles, at which time

the device returns to the Read mode. The system is

not required to provide any control or timing during

these operations.

When using the Automatic Block Erase algorithm, note

that the erase automatically terminates when adequate

erase margin has been achieved for the memory array

(no erase verify command is required). The margin

P/N: PM0340

8

REV. 1.6, JAN. 19, 1999

Page 9

MX28F1000P

voltages are internally generated in the same manner

as when the standard erase verify command is used.

The Automatic set-up block erase command is a command only operation that stages the device for automatic electrical erasure of selected blocks in the array.

Automatic set-up block erase is performed by writing

20H to the command register.

To enter automatic block erase, the user must write

the command D0H to the command register. Block

addresses are loaded into internal register on the 2nd

falling edge of WE. Each successive block load cycles,

started by the falling edge of WE, must begin within

30ms from the rising edge of the preceding WE.

Otherwise, the loading period ends and internal auto

block erase cycle starts. When the data on DQ7 is "1"

and the data on DQ6 stops toggling for two

consecutive read cycles, at which time auto erase

ends and the device returns to the Read mode.

Refer to page 2 for detailed block address.

SET-UP AUTOMATIC PROGRAM/PROGRAM

COMMANDS

The Automatic Set-up Program is a command-only

operation that stages the device for automatic programming. Automatic Set-up Program is performed by

writing 40H to the command register.

Once the Automatic Set-up Program operation is performed, the next WE pulse causes a transition to an

active programming operation. Addresses are

internally latched on the falling edge of the WE pulse.

Data is internally latched on the rising edge of the WE

pulse. The rising edge of WE also begins the

programming operation. The system is not required to

provide further controls or timings. The device will

automatically provide an adequate internally

generated program pulse and verify margin. The

automatic programming operation is completed when

the data read on DQ6 stops toggling for two

consecutive read cycles and the data on DQ7 and

DQ6 are equivalent to data written to these two bits, at

which time the device returns to the Read mode (no

program verify command is required).

SET-UP CHIP ERASE/ERASE COMMANDS

Set-up Chip Erase is a command-only operation that

stages the device for electrical erasure of all bytes in

the array. The set-up erase operation is performed by

writing 20H to the command register.

To commence chip erasure, the erase command (20H)

must again be written to the register. The erase

operation begins with the rising edge of the WE pulse.

This two-step sequence of set-up followed by execution ensures that memory contents are not accidentally

erased. Also, chip-erasure can only occur when high

voltage is applied to the VPP pin. In the absence of this

high voltage, memory contents are protected against

erasure.

SET-UP BLOCK ERASE/ERASE COMMANDS

Set-up Block Erase is a command-only operation that

stages the device for electrical erasure of all selected

block(s) in the array. The set-up erase operation is

performed by writing 60H to the command register.

To enter block-erasure, the block erase command 60H

must be written again to the command register. The

block erase mode allows 1 to 8 blocks of the array to be

erased in one internal erase cycle. Internally, there are

8 registers (flags) addressed by A14 to A16. First block

address is loaded into internal registers on the 2-nd

falling of WE. Each successive block load cycles,

started by the falling edge of WE, must begin within

30ms from the rising edge of the preceding WE. Otherwise, the loading period ends and internal block erase

cycle starts. When the data on DQ7 is "1" at which time

auto erase ends and the device returns to the Read

mode.

ERASE-VERIFY COMMAND

After each erase operation, all bytes must be verified.

The erase verify operation is initiated by writing A0H

into the command register. The address for the byte to

be verified must be supplied as it is latched on the

falling edge of the WE pulse.

P/N: PM0340

9

REV. 1.6, JAN. 19, 1999

Page 10

MX28F1000P

The MX28F1000P applies an internally generated

margin voltage to the addressed byte. Reading FFH

from the addressed byte indicates that all bits in the

byte are erased.

The erase-verify command must be written to the

command register prior to each byte verification to

latch its address. The process continues for each byte

in the array until a byte does not return FFH data, or the

last address is accessed.

In the case where the data read is not FFH, another

erase operation is performed. (Refer to Set-up Erase/

Erase). Verification then resumes from the address of

the last-verified byte. Once all bytes in the array have

been verified, the erase step is complete. The device

can be programmed. At this point, the verify operation

is terminated by writing a valid command (e.g.

Program Set-up) to the command register. The High

Reliability Erase algorithm, illustrates how commands

and bus operations are combined to perform electrical

erasure of the MX28F1000P.

RESET COMMAND

DATA POLLING-DQ7

The MX28F1000P also features Data Polling as a

method to indicate to the host system that the

Automatic Program or Erase algorithms are either in

progress or completed.

While the Automatic Programming algorithm is in operation, an attempt to read the device will produce the

complement data of the data last written to DQ7. Upon

completion of the Automatic Program algorithm an

attempt to read the device will produce the true data

last written to DQ7. The Data Polling feature is valid

after the rising edge of the second WE pulse of the two

write pulse sequences.

While the Automatic Erase algorithm is in operation,

DQ7 will read "0" until the erase operation is completed. Upon completion of the erase operation, the

data on DQ7 will read "1". The Data Polling feature is

valid after the rising edge of the second WE pulse of

two write pulse sequences.

The Data Polling feature is active during Automatic

Program/Erase algorithms.

A reset command is provided as a means to safely

abort the erase- or program-command sequences.

Following either set-up command (erase or program)

with two consecutive writes of FFH will safely abort the

operation. Memory contents will not be altered.

Should program-fail or erase-fail happen, two

consecutive writes of FFH will reset the device to abort

the operation. A valid command must then be written

to place the device in the desired state.

WRITE OPERATON STATUS

TOGGLE BIT-DQ6

The MX28F1000P features a "Toggle Bit" as a method

to indicate to the host sytem that the Auto Program/

Erase algorithms are either in progress or completed.

While the Automatic Program or Erase algorithm is in

progress, successive attempts to read data from the

device will result in DQ6 toggling between one and

zero. Once the Automatic Program or Erase algorithm

is completed, DQ6 will stop toggling and valid data will

be read. The toggle bit is valid after the rising edge of

the second WE pulse of the two write pulse

sequences.

POWER-UP SEQUENCE

The MX28F1000P powers up in the Read only mode. In

addition, the memory contents may only be altered after

successful completion of a two-step command sequence.

Power up sequence is not required.

SYSTEM CONSIDERATIONS

During the switch between active and standby conditions, transient current peaks are produced on the

rising and falling edges of Chip Enable. The magnitude

of these transient current peaks is dependent on the

output capacitance loading of the device. At a

minimum, a 0.1uF ceramic capacitor (high frequency,

low inherent inductance) should be used on each

device between VCC and GND, and between VPP and

GND to minimize transient effects. In addition, to

overcome the voltage drop caused by the inductive

effects of the printed circuit board traces on FLASH

memory arrays, a 4.7uF bulk electrolytic capacitor

should be used between VCC and GND for each eight

devices. The location of the capacitor should be close

to where the power supply is connected to the array.

P/N: PM0340

10

REV. 1.6, JAN. 19, 1999

Page 11

MX28F1000P

ABSOLUTE MAXIMUM RATINGS

RATING VALUE

Ambient Operating Temperature -40

Storage Temperature -65

Applied Input Voltage -0.5V to 7.0V

Applied Output Voltage -0.5V to 7.0V

VCC to Ground Potential -0.5V to 7.0V

A9 & VPP -0.5V to 13.5V

o

C to 85oC

o

C to 125oC

NOTICE:

Stresses greater than those listed under ABSOLUTE MAXIMUM RATINGS may cause permanent damage to the device. This is stress rating only and functional operational

sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended period may

affect reliability.

NOTICE:

Specifications contained within the following tables are subject to change.

CAPACITANCE TA = 25oC, f = 1.0 MHz

SYMBOL PARAMETER MIN. TYP MAX. UNIT CONDITIONS

CIN Input Capacitance 14 pF VIN = 0V

COUT Output Capacitance 16 pF VOUT = 0V

READ OPERATION

DC CHARACTERISTICS

SYMBOL PARAMETER MIN. TYP MAX. UNIT CONDITIONS

ILI Input Leakage Current 10 uA VIN = GND to VCC

ILO Output Leakage Current 10 uA VOUT = GND to VCC

IPP1 VPP Current 1 100 uA VPP = 5.5V

ISB1 Standby VCC current 1 mA CE = VIH

ISB2 1 100 uA CE = VCC + 0.3V

ICC1 Operating VCC current 30(NOTE4) mA IOUT = 0mA, f=1MHz

ICC2 50 mA IOUT = 0mA, f=11MHz

VIL Input Low Voltage -0.3(NOTE 1) 0.8 V

VIH Input High Voltage 2.4 VCC + 0.3 V

VOL Output Low Voltage 0.45 V IOL = 2.1mA

VOH Output High Voltage 2.4 V IOH = -400uA

NOTES:

1. VIL min. = -1.0V for pulse width < 50 ns.

VIL min. = -2.0V for pulse width < 20 ns.

2. VIH max. = VCC + 1.5V for pulse width < 20 ns

If VIH is over the specified maximum value, read operation

cannot be guaranteed.

3. Test condition:

TA =-40°C to 85°C, Vcc = 5V±10%, Vpp = GND to Vcc, CL

= 100pF(for MX28F1000P-90/12)

TA = -40°C to 85°C, Vcc = 5V±10%, Vpp = GND to Vcc, CL

= 35pF(for MX28F1000P-70)

4.ICC1=35mA for TA=-40°C to 85°C

P/N: PM0340

11

REV. 1.6, JAN. 19, 1999

Page 12

MX28F1000P

AC CHARACTERISTICS

28F1000P-70 28F1000P-90 28F1000P-12

SYMBOL PARAMETER MIN. MAX. MIN. MAX. MIN. MAX. UNIT CONDITIONS

tACC Address to Output Delay 70 90 120 ns CE=OE=VIL

tCE CE to Output Delay 70 90 120 ns OE=VIL

tOE OE to Output Delay 30 35 50 ns CE=VIL

tDF OE High to Output Float (Note1) 0 15 0 20 0 30 ns CE=VIL

tOH Address to Output hold 0 0 0 0 ns CE=OE=VIL

TEST CONDITIONS:

• Input pulse levels: 0.45V/2.4V

• Input rise and fall times: < 10ns

• Reference levels for measuring timing: 0.8V, 2.0V

• 28F1000P-70:Vcc = 5V ± 5%, CL: 1TTL gate +

35pF(including scope and jig)

• 28F1000P-70:Vcc = 5V ± 5%, CL: 1TTL gate +

35pF(including scope and jig)

• Vpp = GND to Vcc

READ TIMING WAVEFORMS

ADDRESS

WE

CE

NOTE:

1. tDF is defined as the time at which the output achieves the

open circuit condition and data is no longer driven.

ACTIVE MODE

tCE

STANDBY MODESTANDBY MODE

DATA OUT

P/N: PM0340

OE

tACC

12

tOE

tDF

tOH

DATA OUT VALID

REV. 1.6, JAN. 19, 1999

Page 13

MX28F1000P

COMMAND PROGRAMMING/DATA PROGRAMMING/ERASE OPERATION

DC CHARACTERISTICS

SYMBOL PARAMETER MIN. TYP MAX. UNIT CONDITIONS

ILI Input Leakage Current 10 uA VIN=GND to VCC

ILO Output Leakage Current 10 uA VOUT=GND to VCC

ISB1 Standby VCC current 1 mA CE=VIH

ISB2 1 100 uA CE=VCC ± 0.3V

ICC1 (Read) Operating VCC Current 30 mA IOUT=0mA, f=1MHz

ICC2 50 mA IOUT=0mA, F=11MHz

ICC3 (Program) 50 mA In Programming

ICC4 (Erase) 50 mA In Erase

ICC5 (Program Verify) 50 mA In Program Verify

ICC6 (Erase Verify) 50 mA In Erase Verify

IPP1 (Read) VPP Current 100 uA VPP=12.6V

IPP2 (Program) 50 mA In Programming

IPP3 (Erase) 50 mA In Erase

IPP4 (Program Verify) 50 mA In Program Verify

IPP5 (Erase Verify) 50 mA In Erase Verify

VIL Input Voltage -0.3 (Note 5) 0.8 V

VIH 2.4 VCC+0.3V V

(Note 6)

VOL Output Voltage 0.45 V IOL=2.1mA

VOH 2.4 V IOH=-400uA

NOTES:

1. VCC must be applied before VPP and removed after VPP.

2. VPP must not exceed 14V including overshoot.

3. An influence may be had upon device reliability if the device

is installed or removed while VPP=12V.

4. Do not alter VPP either VIL to 12V or 12V to VIL when

CE=VIL.

5. VIL min. = -0.6V for pulse width < 20ns.

6. If VIH is over the specified maximum value, programming

operation cannot be guranteed.

7. All currents are in RMS unless otherwise noted.(Sampled, not

100% tested.)

8. For 28F1000P-70, Vcc = 5V ±5%, CL = 35pF; for 28F1000P90/12, Vcc = 5V ± 10%, CL = 100pF.

P/N: PM0340

13

REV. 1.6, JAN. 19, 1999

Page 14

MX28F1000P

AC CHARACTERISTICS TA = -40

o

C to 85oC, VCC = 5V ± 10%, VPP =12V ± 5%

28F1000-70 28F1000P-90 28F1000P-12

SYMBOL PARAMETER MIN. MAX. MIN. MAX. MIN. MAX. UNIT CONTIONS

tVPS VPP setup time 100 100 100 ns

tOES OE setup time 100 100 100 ns

tCWC Command programming cycle 70 90 120 ns

tCEP WE programming pulse width 40 45 50 ns

tCEPH1 WE programming pluse width High 20 20 20 ns

tCEPH2 WE programming pluse width High 100 100 100 ns

tAS Address setup time 0 0 0 ns

tAH Address hold time 40 45 50 ns

tAH1 Address hold time for DATA POLLING 0 0 0 ns

tDS Data setup time 40 45 50 ns

tDH Data hold time 10 10 10 ns

tCESP CE setup time before DATA polling/toggle bit 100 100 100 ns

tCES CE setup time 0 0 0 ns

tCESC CE setup time before command write 100 100 100 ns

tCESV CE setup time before verify 6 6 6 us

tVPH VPP hold time 100 100 100 ns

tDF Output disable time (Note 3) 15 20 30 ns

tDPA DATA polling/toggle bit access time 70 90 120 ns

tAETC Total erase time in auto chip erase 5(TYP.) 5(TYP.) 5(TYP.) s

tAETB Total erase time in auto block erase 5TYP.) 5(TYP.) 5(TYP.) s

tAVT Total programming time in auto verify 15 300 15 300 15 300 us

tBALC Block address load cycle 0.3 30 0.3 30 0.3 30 us

tBAL Block address load time 200 200 200 us

tCH CE Hold Time 0 0 0 ns

tCS CE setup to WE going low 0 0 0 ns

NOTES:

1. CE and OE must be fixed high during VPP transition from 5V

to 12V or from 12V to 5V.

2. Refer to read operation when VPP=VCC about read operation while VPP 12V.

3. tDF defined as the time at which the output achieves the open

circuit condition and data is no longer driven.

P/N: PM0340

14

REV. 1.6, JAN. 19, 1999

Page 15

SWITCHING TEST CIRCUITS

MX28F1000P

DEVICE

UNDER

TEST

CL = 100 pF including jig capacitance(35pF for 70 ns parts)

SWITCHING TEST WAVEFORMS

2.4 V

0.45 V

AC TESTING: Inputs are driven at 2.4V for a logic "1" and 0.45V for a logic "0".

CL

6.2K ohm

2.0V

TEST POINTS

0.8V

INPUT

Input pulse rise and fall times are <20ns.

1.8K ohm

DIODES = IN3064

OR EQUIVALENT

2.0V

0.8V

OUTPUT

+5V

P/N: PM0340

15

REV. 1.6, JAN. 19, 1999

Page 16

AUTOMATIC PROGRAMMING TIMING WAVEFORM

MX28F1000P

One byte data is programmed. Verify in fast algorithm

and additional programming by external control are not

required because these operations are excuted automatically by internal control circuit. Programming

completion can be verified by DATA polling and toggle bit

Setup auto program/

program command

Vcc 5V

12V

Vpp

0V

A0 ~ A16

WE

CE

OE

Q7

tOES

tVPS

tAS

tCWC

tCEPH1

tCEP

tDS tDH tDHtDS

checking after automatic verify starts. Device outputs

DATA during programming and DATA after programming

on Q7. Q0 to Q5 (Q6 is for toggle bit; see toggle bit, DATA

polling, timing waveform) are in high impedance.

Auto program & DATA polling

tVPH

Address

valid

tAH1

tAVT

tCEP tCESP

Data inCommand in

tCES

tDPA

DATA

tCESC

tDF

DATA

Q0~Q5

Command #40H

Data inCommand in

DATA polling

DATA

P/N: PM0340

16

REV. 1.6, JAN. 19, 1999

Page 17

AUTOMATIC PROGRAMMING ALGORITHM FLOWCHART

START

Apply VppH

Write Set up auto program Command (40H)

Write Auto program Command(A/D)

MX28F1000P

Toggle Bit Checking

DQ6 not Toggled

Verify Byte Ok

NO

Auto Program Completed

Last Byte

NO

YES

NO

YES

Reset

YES

Auto Program Failed

P/N: PM0340

17

REV. 1.6, JAN. 19, 1999

Page 18

AUTOMATIC CHIP ERASE TIMING WAVEFORM

MX28F1000P

All data in chip are erased. External erase verify is not

required because data is erased automatically by internal

control circuit. Erasure completion can be verified by

DATA polling and toggle bit checking after automatic

Setup auto chip erase/

erase command

Vcc 5V

12V

Vpp

0V

A0 ~ A16

WE

CE

OE

Q7

tOES

tVPS

tCWC

tCEP

tCEPH1

tDS tDH tDHtDS

Command in

erase starts. Device outputs 0 during erasure and 1 after

erasure on Q7. Q0 to Q5 (Q6 is for toggle bit; see toggle

bit, DATA polling, timing waveform) are in high impedance.

Auto chip erase & DATA polling

tVPH

tAETC

tCEP tCESP

Command in

tCES

tDPA

tCESC

tDF

Q0~Q5

Command in

Command #30H Command #30H

Command in

DATA polling

P/N: PM0340

18

REV. 1.6, JAN. 19, 1999

Page 19

AUTOMATIC CHIP ERASE ALGORITHM FLOWCHART

START

Apply VppH

Write Set up auto chip Erase Command (30H)

Write Auto chip Erase Command(30H)

MX28F1000P

Toggle Bit Checking

DQ6 not Toggled

YES

DATA Polling

DQ7 = 1

YES

Auto Chip Erase Completed

No

No

Reset

Auto Chip Erase Failed

P/N: PM0340

19

REV. 1.6, JAN. 19, 1999

Page 20

AUTOMATIC BLOCK ERASE TIMING WAVEFORM

MX28F1000P

Block data indicated by A12 to A16 are erased. External

erase verify is not required because data are erased

automatically by internal control circuit. Erasure completion can be verified by DATA polling and toggle bit

Setup auto block erase/erase command

Vcc 5V

12V

Vpp

0V

A0 ~ A11

A12 ~ A16

CE

WE

tVPS

tCS

tCH

tAS tAH

tCWC

tCEPH1

tCEPtOES

Block

address 0

tCEP

address 1

tBALC

tCEPH2

Block

checking after automatic erase starts. Device outputs 0

during erasure and 1 after erasure on Q7. Q0 to Q5 (Q6

is for toggle bit; see toggle bit, DATA polling, timing

waveform) are in high impedance.

Auto block erase & DATA polling

tVPH

Block

address #

tAH1

tBAL

tAETB

tCESC

tDS tDH tDS tDH

Q7

Q0~Q5

Command inOECommand in

Command in Command in

Command #20H Command #D0H

*Refer to page 2 for detailed block address.

tDPA

DATA polling

tDF

P/N: PM0340

20

REV. 1.6, JAN. 19, 1999

Page 21

AUTOMATIC BLOCK ERASE ALGORITHM FLOWCHART

ST ART

Apply VppH

Write Set up auto block Erase Command (20H)

Write Auto block Erase Command(D0H)

to Load Block Address

Load Block Address

MX28F1000P

Last Block

to Erase

YES

Wait 200us

Toggle Bit Checking

DQ6 not Toggled

YES

DATA Polling

DQ7 = 1

YES

Auto Block Erase Completed

NO

NO

NO

Reset

Auto Block Erase Failed

P/N: PM0340

21

REV. 1.6, JAN. 19, 1999

Page 22

COMPATIBLE CHIP ERASE TIMING WAVEFORM

All data in chip are erased. Control verification and

additional erasure externally according tocompatible chip

erase flowchart.

MX28F1000P

Vcc 5V

12V

Vpp

0V

A0 ~ A16

WE

CE

OE

Q7

Q0~Q6

Setup chip erase/

erase command

tVPS

Verify

Address

tAH

tAS

tCWC

tCEPtOES

tDS tDH tDS tDH

Command in

Command in

Command #20H Command #20H Command #A0H

tCEPH1

tCEP

Command in

Command in

tET

tCEP

tCESV

tDH

tDS

Command in

Command in

Erase VerifyChip erase

tCES

tVA

tVPH

tCESC

tDF

Data valid

Data valid

P/N: PM0340

22

REV. 1.6, JAN. 19, 1999

Page 23

COMPATIBLE BLOCK ERASE

MX28F1000P

This device can be applied to the compatible block erase

algorithm shown in the following flowchart. This algorithm

allows to obtain faster erase time by the block (16K byte

COMPATIBLE BLOCK ERASE FLOWCHART

START

For selected block(s),

All bits PGM"0"

N = 0

BLOCK ERASE FLOW

FAIL

ERSVFY FLOW

ALL BITS VERIFIED

APPLY

VPP = VCC

x 8 block) without any voltage stress to the device nor

deterioration in reliability of data.

N = N+1

N = 1024?

BLOCK ERASE FAIL

END

NO

YES

BLOCK ERASE FLOW

P/N: PM0340

BLOCK ERASE

COMPLETE

WRITE SETUP BLOCK ERASE COMMAND

( LOAD FIRST SECTOR ADDRESS , 60H )

START

Apply

VPP = VPPH

( 60H )

WRITE BLOCK ERASE COMMAND

LOAD OTHER SECTORS' ADDRESS

IF NECESSARY

( LOAD OTHER SECTOR ADDRESS )

WAIT

10 ms

END

23

REV. 1.6, JAN. 19, 1999

Page 24

ERASE VERIFY FLOW

MX28F1000P

START

APPLY

VPP = VPPH

ADDRESS =

FIRST ADDRESS OF ERASED BLOCKS

OR LAST VERIFY FAILED ADDRESS

INCREMENT ADDRESS

WRITE ERASE VERIFY COMMAND

NO

( A0H )

WAIT 6 us

ERSVFY

FFH ?

YES

LAST ADDRESS ?

YES

ERASE VERIFY

COMPLETE

NO

GO TO ERASE FLOW

AGAIN OR ABORT

P/N: PM0340

24

REV. 1.6, JAN. 19, 1999

Page 25

COMPATIBLE BLOCK ERASE TIMING WAVEFORM

Indicated block data (16 Kbyte) are erased. Control

verification and additional erasure externally according to

compatible block erase flowchart.

MX28F1000P

Vcc 5V

12V

Vpp

0V

A0 ~ A13

A14 ~ A16

WE

CE

OE

Q0~Q6

tVPS

tOES tCEP tCEP

Q7

Command #60H Command #60H

Setup block erase/erase command

Block

address 0

tAS tAH

tCWC tBALC

tCEPH1

tDS tDH tDS tDH

Command in

Command in

Block

address 1

tCEPH2

Command in

Command in

tBAL

Block

address #

Block erase

tET

Verify

address

Verify

address

tAS

tAH

tCEP

tDS

Command in

Command in

Command #A0H

tCESV

tDH

Erase Verify

tCES

tVA

tVPH

tCESC

tDF

Data valid

Data valid

P/N: PM0340

25

REV. 1.6, JAN. 19, 1999

Page 26

VPP HIGH READ TIMING WAVEFORM

Vcc 5V

12V

Vpp

0V

tVPS

MX28F1000P

tVPH

A0 - A16

tCWC

WE

CE

tOES

tCEP

tCEPH1

OE

tDH

00H

Q0-Q7

tDS

Command in

VPP LOW ID CODE READ TIMING WAVEFORM

VID

VIH

A9

VIL

Address valid

tACC

tCE

tOE

tCESC

tOES

tDF

tOH

Data out valid

P/N: PM0340

A0

A1 - A8

A10-A16

WE

CE

OE

Q0 - Q7

VIH

tACC

tACC

tCE

tOE

Manufacturer code Device code

C2H

tOH

26

tDF

tOH

1AH

REV. 1.6, JAN. 19, 1999

Page 27

VPP HIGH ID CODE READ TIMING WAVEFORM

Vcc 5V

12V

Vpp

0V

tVPS

MX28F1000P

tVPH

A0

A1 - A16

WE

CE

tOES

OE

Q0-Q7

RESET TIMING WAVEFORM

Address Valid 0 or 1

tCWC

tACC

tCEP

tDS

Command in

tCEPH2

tDH

90H C2H or 1AH

tCE

tOE

Data out valid

tCESC

tOES

tDF

tOH

P/N: PM0340

Vcc 5V

12V

Vpp

0V

A0 - A16

WE

CE

OE

Q0-Q7

tVPS

tOES

tCWC

tCEP

Command in

tCEPH1

tDS tDH

FFH FFH

tCEP

tDS tDH

Command in

REV. 1.6, JAN. 19, 1999

27

Page 28

TOGGLE BIT, DATA POLLING TIMING WAVEFORM

Toggle bit appears in Q6, when program/erase is

opperating. DATA polling appears in Q7 during programming or erase.

HIGH

WE

Vpp 12V

CE

OE

MX28F1000P

DURING P/E

Q6

Q7

DURING P

Q7

DURING E

Q0~Q5

HIGH-Z

HIGH-Z

HIGH-Z

HIGH-Z

DATA POLLING

DATA

TOGGLE BIT

DATA

DATA DATA DATA

PROGRAM/ERASE COMPLETE

DATA POLLING

DATA

ERASE AND PROGRAMMING PERFORMANCE

LIMITS

PARAMETER MIN. TYP. MAX. UNITS

Chip/Sector Erase Time 1.5 20 sec

Chip Programming Time 2 13.8 sec

Erase/Program Cycles 10,000 cycles

Byte Program Time 15 642 us

P/N: PM0340

28

REV. 1.6, JAN. 19, 1999

Page 29

MX28F1000P

ORDERING INFORMATION PLASTIC PACKAGE

PART NO. ACCESS TIME OPERATING STANDBY PACKAGE ERASE/PROGRAM

CURRENT CURRENT CYCLE

(ns) MAX.(mA) MAX.(uA) MIN.(time)

MX28F1000PPC-70C4 70 50 100 32 Pin DIP 10,000

MX28F1000PPC-90C4 90 50 100 32 Pin DIP 10,000

MX28F1000PPC-12C4 120 50 100 32 Pin DIP 10,000

MX28F1000PQC-70C4 70 50 100 32 Pin PLCC 10,000

MX28F1000PQC-90C4 90 50 100 32 Pin PLCC 10,000

MX28F1000PQC-12C4 120 50 100 32 Pin PLCC 10,000

MX28F1000PTC-70C4 70 50 100 32 Pin TSOP 10,000

(Normal Type)

MX28F1000PTC-90C4 90 50 100 32 Pin TSOP 10,000

(Normal Type)

MX28F1000PTC-12C4 120 50 100 32 Pin TSOP 10,000

(Normal Type)

MX28F1000PRC-70C4 70 50 100 32 Pin TSOP 10,000

(Reverse Type)

MX28F1000PRC-90C4 90 50 100 32 Pin TSOP 10,000

(Reverse Type)

MX28F1000PRC-12C4 120 50 100 32 Pin TSOP 10,000

(Reverse Type)

MX28F1000PPI-70 70 50 100 32 Pin DIP 10,000

MX28F1000PPI-90 90 50 100 32 Pin DIP 10,000

MX28F1000PPI-12 120 50 100 32 Pin DIP 10,000

MX28F1000PQI-70 70 50 1 00 32 Pin PLCC 10,000

MX28F1000PQI-90 90 50 1 00 32 Pin PLCC 10,000

MX28F1000PQI-12 120 50 100 32 Pin PLCC 10,000

MX28F1000PTI-70 70 50 100 32 Pin TSOP 10,000

(Normal Type)

MX28F1000PTI-90 90 50 100 32 Pin TSOP 10,000

(Normal Type)

MX28F1000PTI-12 120 50 100 32 Pin TSOP 10,000

(Normal Type)

MX28F1000PRI-70 70 5 0 100 32 Pin TSOP 10,000

(Reverse Type)

MX28F1000PRI-90 90 5 0 100 32 Pin TSOP 10,000

(Reverse Type)

MX28F1000PRI-12 120 5 0 100 32 Pin TSOP 10,000

(Reverse Type)

P/N: PM0340

29

REV. 1.6, JAN. 19, 1999

Page 30

PACKAGE INFORMATION

32-PIN PLASTIC DIP

ITEM MILLIMETERS INCHES

A 42.13 max. 1.660 max.

B 1.90 [REF] .075 [REF]

C 2.54 [TP] .100 [TP]

D .46 [Typ.] .050 [Typ.]

E 38.07 1.500

F 1.27 [Typ.] .050 [Typ.]

G 3.30 ± .25 .130 ± .010

H .51 [REF] .020 [REF]

I 3.94 ± .25 1.55 ± .010

J 5.33 max. .210 max.

K 15.22 ± .25 .600 ± .101

L 13.97 ± .25 .550 ± .010

M .25 [Typ.] .010 [Typ.]

NOTE: Each lead certerline is located within

.25mm[.01 inch] of its true position [TP] at a

maximum at maximum material condition.

MX28F1000P

1732

1

A

F

D

E

16

K

L

IJ

H

G

C

B

M

0~15¡

32-PIN PLASTIC LEADED CHIP CARRIER (PLCC)

ITEM MILLIMETERS INCHES

A 12.44 ± .13 .490 ± .005

B 11.50 ± .13 .453 ± .005

C 14.04 ± .13 .553 ± .005

D 14.98 ± .13 .590 ± .005

E 1.93 .076

F 3.30 ± .25 .130 ± .010

G 2.03 ± .13 .080 ± .005

H .51 ± .13 .020 ± .005

I 1.27 [Typ.] .050 [Typ.]

J .71 [REF] .028 [REF]

K .46 [REF] .018 [REF]

L 10.40/12.94 .410/.510

(W) (L) (W) (L)

M .89R .035R

N .25[Typ.] .010[Typ.]

NOTE: Each lead certerline is located within

.25mm[.01 inch] of its true position [TP] at a

maximum at maximum material condition.

A

B

4

5

9

13

14

F

G

H

1

32

30

29

25

CD

21

17

I

K

L

20

E

N

M

J

P/N: PM0340

30

REV. 1.6, JAN. 19, 1999

Page 31

32-PIN PLASTIC TSOP

ITEM MILLIMETERS INCHES

A 20.0 ± .20 .078 ± .006

B 18.40 ± .10 .724 ± .004

C 8.20 max. .323 max.

D 0.15 [Typ.] .006 [Typ.]

E .80 [Typ.] .031 [Typ.]

F .20 ± .10 .008 ± .004

G .30 ± .10 .012 ± .004

H .50 [Typ.] .020 [Typ.]

I .45 max. .018 max.

J 0 ~ .20 0 ~ .008

K 1.00 ± .10 .039 ± .004

L 1.27 max. .050 max.

M .50 .020

N 0 ~5° .500

NOTE: Each lead certerline is located within

.25mm[.01 inch] of its true position [TP] at a

maximum at maximum material condition.

MX28F1000P

A

B

C

O

M

D

E

F

H

G

N

KL

J

I

P/N: PM0340

31

REV. 1.6, JAN. 19, 1999

Page 32

MX28F1000P

Note. Revision History

Revision # Description Page Date

1.4 Fast access time 150ns and 1,000 times erase cycles removed.

Tsop pin configuration diagram rotated 180°.

The flow chart of block erase corrected.

1.5 Fast access time 70ns added. Dec/26/1996

1.6 1)Absolute max. ratings:TA=-40°C to 85°C P11 JAN/19/1999

2)DC Characteristics:ICC1=35mA for TA=-40°C to 85°C

3)AC Characteristics:TA=-40°C to 85°C P14

4)Order Informance:Add Industrial Grade P29

5)Erase & Programming Performance:New in Creased table

P/N: PM0340

32

REV. 1.6, JAN. 19, 1999

Page 33

MX28F1000P

MACRONIX INTERNATIONAL CO., LTD.

HEADQUARTERS:

TEL:+886-3-578-8888

FAX:+886-3-578-8887

EUROPE OFFICE:

TEL:+32-2-456-8020

FAX:+32-2-456-8021

JAPAN OFFICE:

TEL:+81-44-246-9100

FAX:+81-44-246-9105

SINGAPORE OFFICE:

TEL:+65-747-2309

FAX:+65-748-4090

TAIPEI OFFICE:

TEL:+886-3-509-3300

FAX:+886-3-509-2200

MACRONIX AMERICA, INC.

TEL:+1-408-453-8088

FAX:+1-408-453-8488

CHICAGO OFFICE:

TEL:+1-847-963-1900

FAX:+1-847-963-1909

http : //www.macronix.com

MACRONIX INTERNATIONAL CO., LTD. reserves the rignt to change product and specifications without notice.

33

Loading...

Loading...