Datasheet MT58V512V36DT-7.5, MT58V1MV18DT-6, MT58V1MV18DT-7.5, MT58V1MV18DF-7.5, MT58L512Y36DT-10 Datasheet (MICRON)

...Page 1

1

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

16Mb SYNCBURST

™

SRAM

FEATURES

• Fast clock and OE# access times

• Single +3.3V ±0.165Vor 2.5V ±0.125V power supply

(VDD)

• Separate +3.3V or 2.5V isolated output buffer

supply (VDDQ)

• SNOOZE MODE for reduced-power standby

• Common data inputs and data outputs

• Individual BYTE WRITE control and GLOBAL

WRITE

• Three chip enables for simple depth expansion and

address pipelining

• Clock-controlled and registered addresses, data I/Os

and control signals

• Internally self-timed WRITE cycle

• Burst control (interleaved or linear burst)

• Automatic power-down

• 100-pin TQFP package

• 165-pin FBGA package

• Low capacitive bus loading

• x18, x32, and x36 versions available

OPTIONS TQFP MARKING*

• Timing (Access/Cycle/MHz)

3.5ns/6ns/166 MHz -6

4.0ns/7.5ns/133 MHz -7.5

5ns/10ns/100 MHz -10

• Configurations

3.3V VDD, 3.3V or 2.5V I/O

1 Meg x 18 MT58L1MY18D

512K x 32 MT58L512Y32D

512K x 36 MT58L512Y36D

2.5V VDD, 2.5V I/O

1 Meg x 18 MT58V1MV18D

512K x 32 MT58V512V32D

512K x 36 MT58V512V36D

• Packages

100-pin TQFP (3-chip enable) T

165-pin FBGA F

• Operating Temperature Range

Commercial (0ºC to +70ºC) None

*See page 34 for FBGA package marking guide.

Part Number Example:

MT58L1MY18DT-7.5

MT58L1MY18D, MT58V1MV18D,

MT58L512Y32D, MT58V512V32D,

MT58L512Y36D, MT58V512V36D

3.3V VDD, 3.3V or 2.5V I/O; 2.5V VDD, 2.5V

I/O, Pipelined, Double-Cycle Deselect

GENERAL DESCRIPTION

The Micron® SyncBurst™ SRAM family employs highspeed, low-power CMOS designs that are fabricated

using an advanced CMOS process.

Micron’s 16Mb SyncBurst SRAMs integrate a 1 Meg x

18, 512K x 32, or 512K x 36 SRAM core with advanced

synchronous peripheral circuitry and a 2-bit burst

counter. All synchronous inputs pass through registers

controlled by a positive-edge-triggered single-clock input (CLK). The synchronous inputs include all addresses,

all data inputs, active LOW chip enable (CE#), two

additional chip enables for easy depth expansion (CE2,

CE2#), burst control inputs (ADSC#, ADSP#, ADV#),

byte write enables (BWx#) and global write (GW#). Note

that CE2# is not available on the T Version.

Asynchronous inputs include the output enable

(OE#), clock (CLK) and snooze enable (ZZ). There is also

100-Pin TQFP

1

NOTE: 1. JEDEC-standard MS-026 BHA (LQFP).

165-Pin FBGA

(Preliminary Package Data)

Page 2

2

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

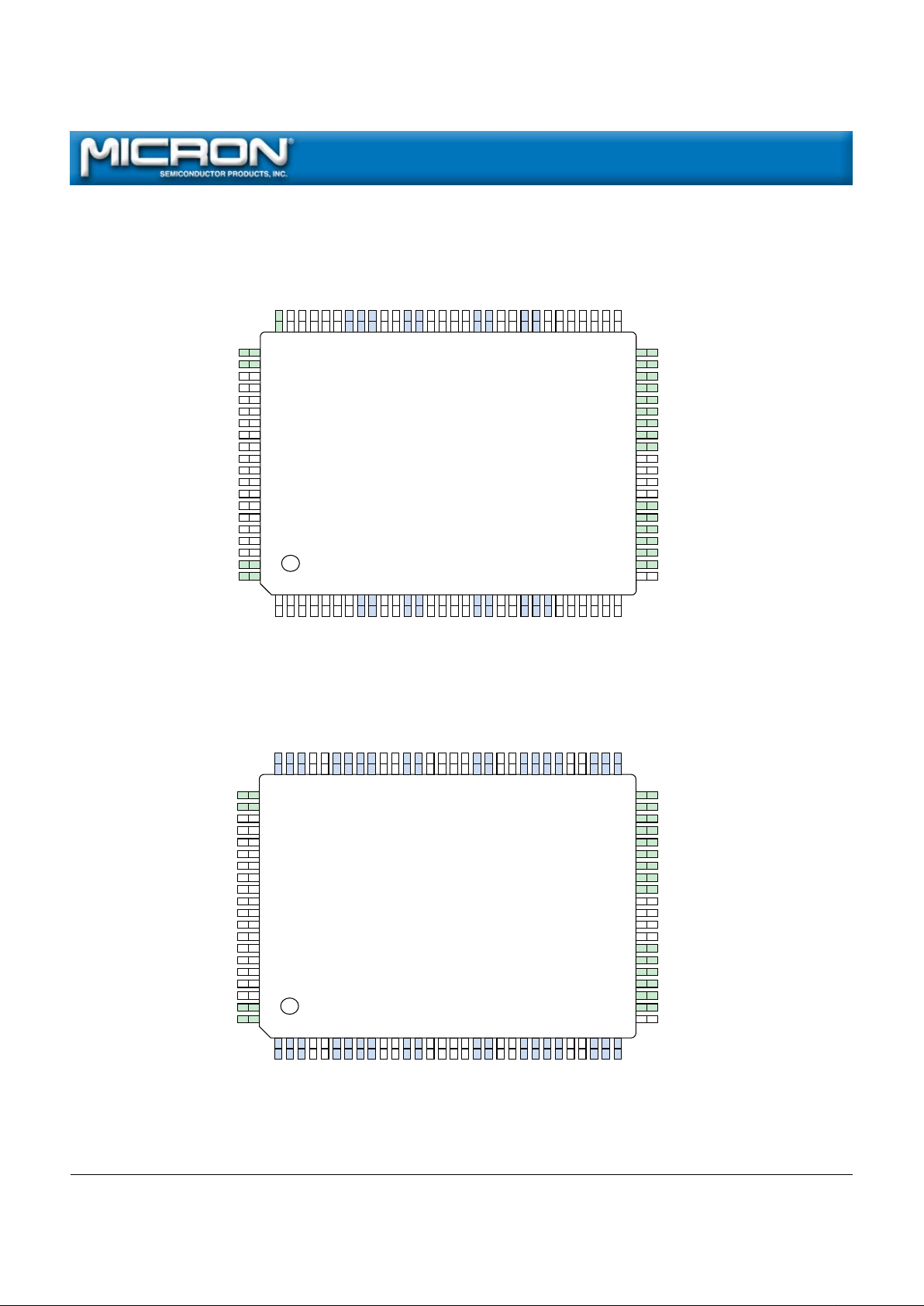

FUNCTIONAL BLOCK DIAGRAM

1 MEG x 18

SA0, SA1, SAs

ADDRESS

REGISTER

ADV#

CLK

BINARY

COUNTER AND

LOGIC

CLR

Q1

Q0

ADSC#

20

20

18 20

BWb#

BWa#

CE#

BYTE “b”

WRITE REGISTER

BYTE “a”

WRITE REGISTER

ENABLE

REGISTER

SA0'

SA1'

OE#

SENSE

AMPS

1 Meg x 9 x 2

MEMORY

ARRAY

ADSP#

2

SA0-SA1

MODE

CE2

CE2#

GW#

BWE#

PIPELINED

ENABLE

DQs

DQPa

DQPb

2

OUTPUT

REGISTERS

INPUT

REGISTERS

E

BYTE “b”

WRITE DRIVER

BYTE “a”

WRITE DRIVER

OUTPUT

BUFFERS

9

9

9

9

18 18 18 18

18

NOTE: Functional block diagrams illustrate simplified device operation. See truth table, pin descriptions and timing diagrams for

detailed information.

FUNCTIONAL BLOCK DIAGRAM

512K x 32/36

ADDRESS

REGISTER

ADV#

CLK

BINARY

COUNTER

CLR

Q1

Q0

ADSP#

ADSC#

MODE

19

19

17 19

BWd#

BWc#

BWb#

BWa#

BWE#

GW#

CE#

CE2

CE2#

OE#

BYTE “d”

WRITE REGISTER

BYTE “c”

WRITE REGISTER

BYTE “b”

WRITE REGISTER

BYTE “a”

WRITE REGISTER

ENABLE

REGISTER

PIPELINED

ENABLE

DQs

DQPa

DQPb

DQPc

DQPd

4

OUTPUT

REGISTERS

SENSE

AMPS

512K x 8 x 4

(x32)

512K x 9 x 4

(x36)

MEMORY

ARRAY

OUTPUT

BUFFERS

E

BYTE “a”

WRITE DRIVER

BYTE “b”

WRITE DRIVER

BYTE “c”

WRITE DRIVER

BYTE “d”

WRITE DRIVER

INPUT

REGISTERS

SA0, SA1, SAs

SA0'

9

9

9

9

9

9

36 36 36 36

36

9

9

SA1'

SA0-SA1

Page 3

3

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

GENERAL DESCRIPTION (continued)

NOTE: 1. No Connect (NC) is used on the x32 version. Parity (DQPx) is used on the x36 version.

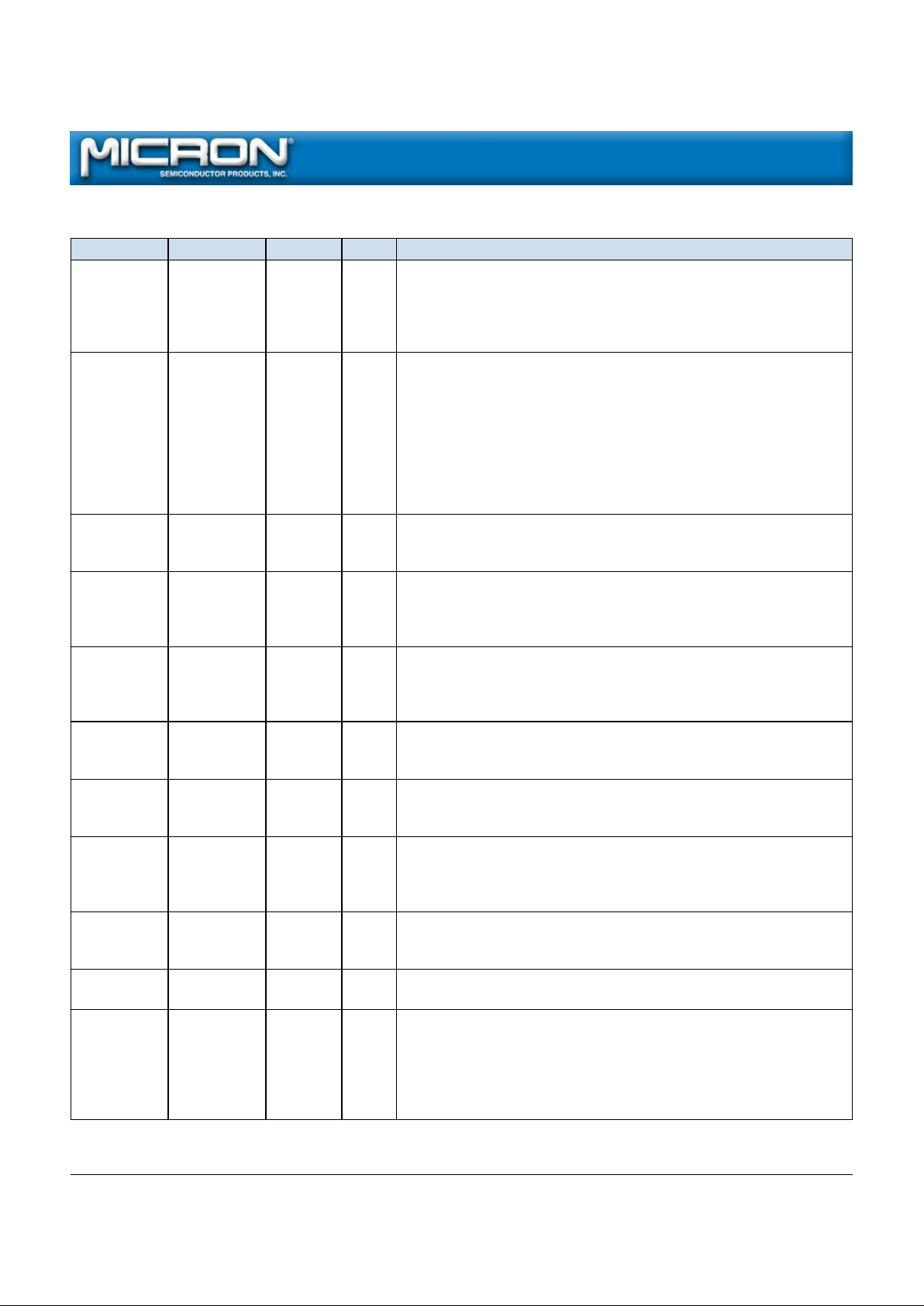

TQFP PIN ASSIGNMENT TABLE

PIN # x18 x32/x36

1 NC NC/DQPc

1

2NC DQc

3NC DQc

4VDDQ

5VSS

6NC DQc

7NC DQc

8 DQb DQc

9 DQb DQc

10 VSS

11 VDDQ

12 DQb DQc

13 DQb DQc

14 NC

15 VDD

16 NC

17 VSS

18 DQb DQd

19 DQb DQd

20 VDDQ

21 VSS

22 DQb DQd

23 DQb DQd

24 DQPb DQd

25 NC DQd

PIN # x18 x32/x36 PIN # x18 x32/x36 PIN # x18 x32/x36

51 NC NC/DQPa

1

52 NC DQa

53 NC DQa

54 VDDQ

55 VSS

56 NC DQa

57 NC DQa

58 DQa

59 DQa

60 VSS

61 VDDQ

62 DQa

63 DQa

64 ZZ

65 VDD

66 NC

67 VSS

68 DQa DQb

69 DQa DQb

70 VDDQ

71 VSS

72 DQa DQb

73 DQa DQb

74 DQPa DQb

75 NC DQb

26 VSS

27 VDDQ

28 NC DQd

29 NC DQd

30 NC NC/DQPd

1

31 MODE (LBO#)

32 SA

33 SA

34 SA

35 SA

36 SA1

37 SA0

38 DNU

39 DNU

40 VSS

41 VDD

42 SA

43 SA

44 SA

45 SA

46 SA

47 SA

48 SA

49 SA

50 SA

a burst mode input (MODE) that selects between interleaved and linear burst modes. The data-out (Q), enabled by OE#, is also asynchronous. WRITE cycles can be

from one to two bytes wide (x18) or from one to four

bytes wide (x32/x36), as controlled by the write control

inputs.

Burst operation can be initiated with either address

status processor (ADSP#) or address status controller

(ADSC#) inputs. Subsequent burst addresses can be internally generated as controlled by the burst advance

input (ADV#).

Address and write control are registered on-chip to

simplify WRITE cycles. This allows self-timed WRITE

cycles. Individual byte enables allow individual bytes to

be written. During WRITE cycles on the x18 device,

BWa# controls DQas and DQPa; BWb# controls DQbs

and DQPb. During WRITE cycles on the x32 and x36

devices, BWa# controls DQas and DQPa; BWb# controls

DQbs and DQPb; BWc# controls DQcs and DQPc; BWd#

controls DQds and DQPd. GW# LOW causes all bytes to

be written. Parity bits are only available on the x18 and

x36 versions.

This device incorporates an additional pipelined

enable register which delays turning off the output

buffer an additional cycle when a deselect is executed.

This feature allows depth expansion without penalizing

system performance.

Micron’s 16Mb SyncBurst SRAMs operate from a

+3.3V or +2.5V power supply, and all inputs and outputs

are TTL-compatible. Users can implement either a 3.3V

or 2.5V I/O for the +3.3V VDD or a 2.5V I/O for the +2.5V

VDD. The device is ideally suited for Pentium® and

PowerPC pipelined systems and systems that benefit

from a very wide, high-speed data bus. The device is also

ideal in generic 16-, 18-, 32-, 36-, 64-, and 72-bit-wide

applications.

Please refer to the Micron Web site

(www.micronsemi.com/en/products/sram/) for the latest data sheet.

76 VSS

77 VDDQ

78 NC DQb

79 NC DQb

80 SA NC/DQPb

1

81 SA

82 SA

83 ADV#

84 ADSP#

85 ADSC#

86 OE# (G#)

87 BWE#

88 GW#

89 CLK

90 VSS

91 VDD

92 CE2#

93 BWa#

94 BWb#

95 NC BWc#

96 NC BWd#

97 CE2

98 CE#

99 SA

100 SA

Page 4

4

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

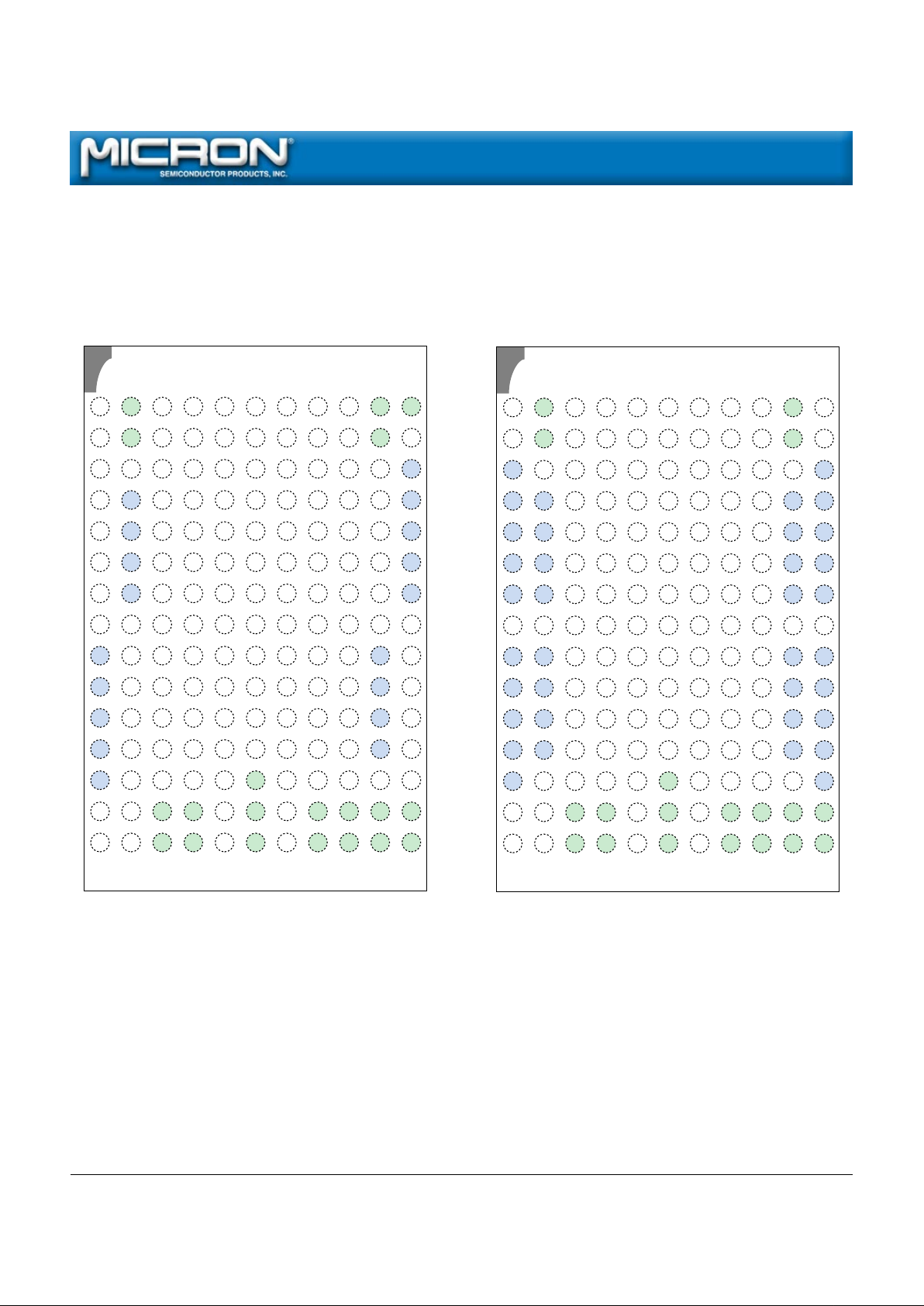

PIN ASSIGNMENT (TOP VIEW)

100-PIN TQFP

NOTE: 1. No Connect (NC) is used on the x32 version. Parity (DQPx) is used on the x36 version.

SA

SA

ADV#

ADSP#

ADSC#

OE# (G#)

BWE#

GW#

CLK

V

SS

V

DD

CE2#

BWa#

BWb#

NC

NC

CE2

CE#

SA

SA

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52 51

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

SANCNC

V

DD

Q

V

SS

NC

DQPa

DQa

DQa

VSSV

DD

Q

DQa

DQa

V

SS

NC

VDDZZ

DQa

DQa

V

DD

Q

V

SS

DQa

DQaNCNC

VSSV

DD

Q

NCNCNC

SA

SA

SA

SA

SA

SA

SA

SA

SA

V

DD

V

SS

DNU

DNU

SA0

SA1

SA

SA

SA

SA

MODE (LBO#)

NCNCNC

V

DD

Q

V

SS

NC

NC

DQb

DQb

V

SS

V

DD

Q

DQb

DQb

NC

V

DD

NC

V

SS

DQb

DQb

V

DD

Q

V

SS

DQb

DQb

DQPb

NC

V

SS

V

DD

Q

NCNCNC

x18

SA

SA

ADV#

ADSP#

ADSC#

OE# (G#)

BWE#

GW#

CLK

V

SS

V

DD

CE2#

BWa#

BWb#

BWc#

BWd#

CE2

CE#

SA

SA

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52 51

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

NC/DQPb1DQb

DQb

V

DD

Q

V

SS

DQb

DQb

DQb

DQb

VSSV

DD

Q

DQb

DQb

V

SS

NC

VDDZZ

DQa

DQa

V

DD

Q

V

SS

DQa

DQa

DQa

DQa

VSSV

DD

Q

DQa

DQa

NC/DQPa

1

SA

SA

SA

SA

SA

SA

SA

SA

SA

V

DD

V

SS

DNU

DNU

SA0

SA1

SA

SA

SA

SA

MODE (LBO#)

NC/DQPc

1

DQc

DQc

V

DD

Q

V

SS

DQc

DQc

DQc

DQc

V

SS

V

DD

Q

DQc

DQc

NC

V

DD

NC

V

SS

DQd

DQd

V

DD

Q

V

SS

DQd

DQd

DQd

DQd

V

SS

V

DD

Q

DQd

DQd

NC/DQPd

1

x32/x36

Page 5

5

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

TQFP PIN DESCRIPTIONS

x18 x32/x36 SYMBOL TYPE DESCRIPTION

37 37 S A 0 Input Synchronous Address Inputs: These inputs are registered and must

36 36 SA1 meet the setup and hold times around the rising edge of CLK.

32-35, 42-50, 32-35, 42-50, SA

80-82, 99, 81, 82, 99,

100 100

93 93 BWa# Input Synchronous Byte Write Enables: These active LOW inputs allow

94 94 BWb# individual bytes to be written and must meet the setup and hold

– 95 BWc# times around the rising edge of CLK. A byte write enable is LOW

– 96 BWd# for a WRITE cycle and HIGH for a READ cycle. For the x18 version,

BWa# controls DQa pins and DQPa; BWb# controls DQb pins and

DQPb. For the x32 and x36 versions, BWa# controls DQa pins and

DQPa; BWb# controls DQb pins and DQPb; BWc# controls DQc pins

and DQPc; BWd# controls DQd pins and DQPd. Parity is only

available on the x18 and x36 versions.

87 87 BWE# Input Byte Write Enable: This active LOW input permits BYTE WRITE

operations and must meet the setup and hold times around the

rising edge of CLK.

88 8 8 GW# Input Global Write: This active LOW input allows a full 18-, 32-, or 36-bit

WRITE to occur independent of the BWE# and BWx# lines and

must meet the setup and hold times around the rising edge of

CLK.

89 8 9 CLK Input Clock: This signal registers the address, data, chip enable, byte

write enables and burst control inputs on its rising edge. All

synchronous inputs must meet setup and hold times around the

clock’s rising edge.

98 98 CE# Input Synchronous Chip Enable: This active LOW input is used to enable

the device and conditions the internal use of ADSP#. CE# is

sampled only when a new external address is loaded.

92 92 CE2# Input Synchronous Chip Enable: This active LOW input is used to enable

the device and is sampled only when a new external address is

loaded.

64 64 ZZ Input Snooze Enable: This active HIGH, asynchronous input causes the

device to enter a low-power standby mode in which all data in the

memory array is retained. When ZZ is active, all other inputs are

ignored.

This pin has an internal pull-down and can be floating.

97 97 CE2 Input Synchronous Chip Enable: This active HIGH input is used to enable

the device and is sampled only when a new external address is

loaded.

86 86 OE# Input Output Enable: This active LOW, asynchronous input enables the

(G#) data I/O output drivers.

G# is the JEDEC-standard term for OE#.

83 83 ADV# Input Synchronous Address Advance: This active LOW input is used to

advance the internal burst counter, controlling burst access after

the external address is loaded. A HIGH on this pin effectively

causes wait states to be generated (no address advance). To ensure

use of correct address during a WRITE cycle, ADV# must be HIGH at

the rising edge of the first clock after an ADSP# cycle is initiated.

(continued on next page)

Page 6

6

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

TQFP PIN DESCRIPTIONS (continued)

x18 x32/x36 SYMBOL TYPE DESCRIPTION

84 84 ADSP# Input Synchronous Address Status Processor: This active LOW input

interrupts any ongoing burst, causing a new external address to be

registered. A READ is performed using the new address,

independent of the byte write enables and ADSC#, but dependent

upon CE#, CE2, and CE2#. ADSP# is ignored if CE# is HIGH. Powerdown state is entered if CE2 is LOW or CE2# is HIGH.

85 85 ADSC# Input Synchronous Address Status Controller: This active LOW input

interrupts any ongoing burst, causing a new external address to be

registered. A READ or WRITE is performed using the new address if

CE# is LOW. ADSC# is also used to place the chip into power-down

state when CE# is HIGH.

31 31 MODE Input Mode: This input selects the burst sequence. A LOW on this pin

(LBO#) selects “linear burst.” NC or HIGH on this pin selects “interleaved

burst.” Do not alter input state while device is operating.

LBO# is

the JEDEC-standard term for MODE.

(a) 58, 59, (a) 52, 53, DQa Input/ SRAM Data I/Os: For the x18 version, Byte “a” is

associated with

62, 63, 68, 69, 56-59, 62, 63 Output DQa pins; Byte “b” is

associated with

DQb pins. For the x32 and

72, 73 x36 versions, Byte “a” is

associated with

DQa pins; Byte “b” is

(b) 8, 9, 12, (b) 68, 69 DQb

associated with

DQb pins; Byte “c” is

associated with

DQc pins;

13, 18, 19, 22, 72-75, 78, 79 Byte “d” is

associated with

DQd pins. Input data must meet setup

23 and hold times around the rising edge of CLK.

(c) 2, 3, 6-9, DQc

12, 13

(d) 18, 19, DQd

22-25, 28, 29

74 51 NC/DQPa NC/ No Connect/Parity Data I/Os: On the x32 version, these pins are No

24 80 NC/DQPb I/O Connect (NC). On the x18 version, Byte “a” parity is DQPa; Byte

– 1 NC/DQPc “b” parity is DQPb. On the x36 version, Byte “a” parity is DQPa;

– 30 NC/DQPd Byte “b” parity is DQPb; Byte “c” parity is DQPc; Byte “d” parity is

DQPd.

15, 41, 65, 15, 41, 65, VDD Supply Power Supply: See DC Electrical Characteristics and Operating

91 91 Conditions for range.

4, 11, 20, 27, 4, 11, 20, 27, VDDQ Supply Isolated Output Buffer Supply: See DC Electrical Characteristics and

54, 61, 70, 77 54, 61, 70, 77 Operating Conditions for range.

5, 10, 17, 21, 5, 10, 17, 21, VSS Supply Ground: GND.

26, 40, 55, 60, 26, 40, 55, 60,

67, 71, 76, 90 67, 71, 76, 90

38, 39 38, 39 DNU – Do Not Use: These signals may either be unconnected or wired to

GND to improve package heat dissipation.

1-3, 6, 7, 14 14, 16, 66 NC – No Connect: These signals are not internally connected and may be

16, 25, 28-30, connected to ground to improve package heat dissipation.

51-53, 56, 57,

66, 75, 78, 79,

95, 96

NA NA NF – No Function: These pins are internally connected to the die and

have the capacitance of an input pin. It is allowable to leave these

pins unconnected or driven by signals.

Page 7

7

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

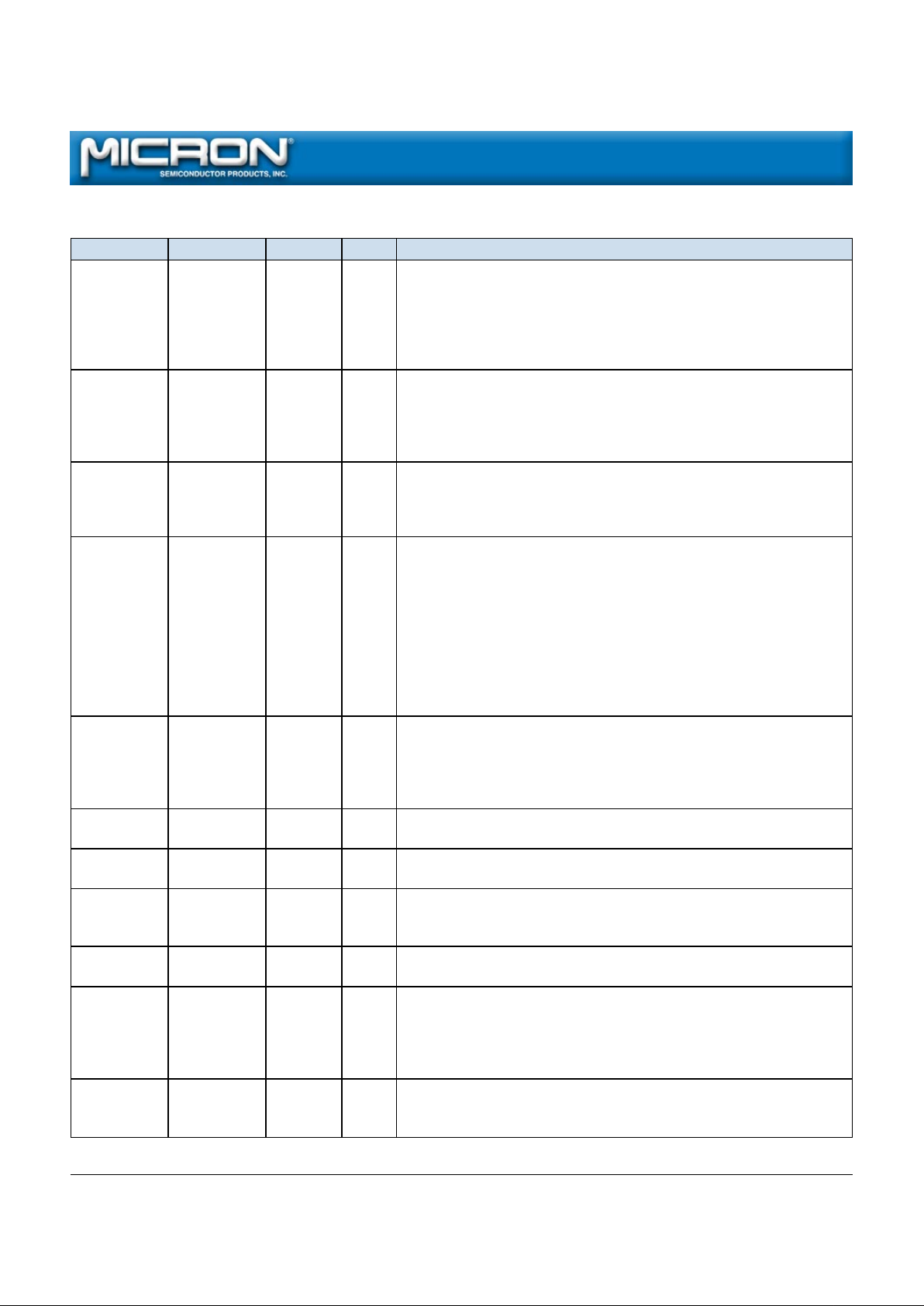

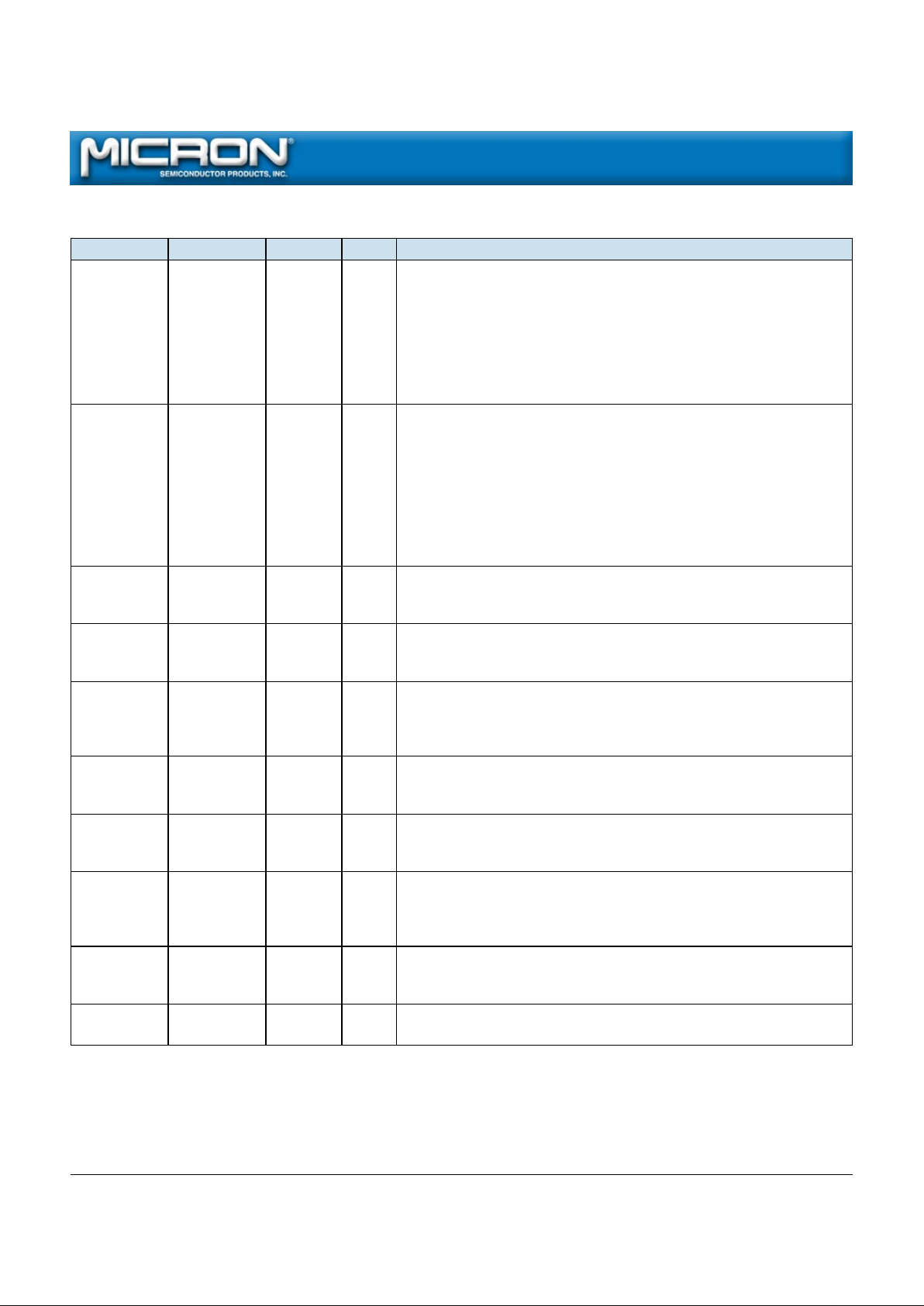

PIN LAYOUT (TOP VIEW)

165-PIN FBGA

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

2

CE#

CE2

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

NC

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

SA

SA

SA

SA

NC

DQb

DQb

DQb

DQb

V

SS

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

V

DD

DQb

DQb

DQb

DQb

DQPb

NC

MODE

(LBO#)

BWb#

NC

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

SA

SA

NC

BWa#

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

NC

DNU

DNU

CE2#

CLK

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

SA

SA1

SA0

BWE#

GW#

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

DNU

DNU

ADSC#

OE# (G#)

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

SA

SA

ADV#

ADSP#

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

NC

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

SA

SA

SA

SA

NC

NC

NC

NC

NC

NC

DQa

DQa

DQa

DQa

NC

SA

SA

SA

NC

DQPa

DQa

DQa

DQa

DQa

ZZ

NC

NC

NC

NC

NC

SA

SA

TOP VIEW

3456789

10 11

1

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

2

CE#

CE2

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

NC

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

SA

SA

SA

SA

NC

DQc

DQc

DQc

DQc

V

SS

DQd

DQd

DQd

DQd

NC

NC

NC

NC

NC

NC/DQPc

DQc

DQc

DQc

DQc

V

DD

DQd

DQd

DQd

DQd

NC/DQPd

NC

MODE

(LBO#)

BWc#

BWd#

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

SA

SA

BWb#

BWa#

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

NC

DNU

DNU

CE2#

CLK

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

SA

SA1

SA0

BWE#

GW#

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

DNU

DNU

ADSC#

OE# (G#)

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

SA

SA

ADV#

ADSP#

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

NC

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

V

DD

Q

SA

SA

SA

SA

NC

DQb

DQb

DQb

DQb

NC

DQa

DQa

DQa

DQa

NC

SA

SA

NC

NC

NC/DQPb

DQb

DQb

DQb

DQb

ZZ

DQa

DQa

DQa

DQa

NC/DQPa

SA

SA

TOP VIEW

3456789

10 11

1

x18

x32/x36

*No Connect (NC) is used on the x32 version. Parity (DQPx) is used on the x36 version.

Page 8

8

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

FBGA PIN DESCRIPTIONS

x18 x32/x36 SYMBOL TYPE DESCRIPTION

6R 6R SA0 Input Synchronous Address Inputs: These inputs are registered and must

6P 6P SA1 meet the setup and hold times around the rising edge of CLK.

2A, 2B, 3P, 2A, 2B, 3P, SA

3R, 4P, 4R, 6N, 3R, 4P, 4R, 6N,

8P, 8R, 9P, 9R, 8P, 8R, 9P,

10A, 10B, 10P, 9R, 10A, 10B,

10R, 11A, 11P, 10P, 10R, 11P,

11R 11R

5B 5B BWa# Input Synchronous Byte Write Enables: These active LOW inputs allow

4A 5A BWb# individual bytes to be written and must meet the setup and hold

– 4A B Wc# times around the rising edge of CLK. A byte write enable is LOW

– 4B BWd# for a WRITE cycle and HIGH for a READ cycle. For the x18 version,

BWa# controls DQa’s and DQPa; BWb# controls DQb’s and DQPb.

For the x32 and x36 versions, BWa# controls DQa’s and DQPa; BWb#

controls DQb’s and DQPb; BWc# controls DQc’s and DQPc; BWd#

controls DQd’s and DQPd. Parity is only available on the x18 and

x36 versions.

7A 7A BWE# Input Byte Write Enable: This active LOW input permits BYTE WRITE

operations and must meet the setup and hold times around the

rising edge of CLK.

7B 7B GW# Input Global Write: This active LOW input allows a full 18-, 32- or 36-bit

WRITE to occur independent of the BWE# and BWx# lines and must

meet the setup and hold times around the rising edge of CLK.

6B 6B CLK Input Clock: This signal registers the address, data, chip enable, byte write

enables, and burst control inputs on its rising edge. All synchronous

inputs must meet setup and hold times around the clock’s rising

edge.

3A 3A CE# Input Synchronous Chip Enable: This active LOW input is used to enable

the device and conditions the internal use of ADSP#. CE# is sampled

only when a new external address is loaded.

6A 6A CE2# Input Synchronous Chip Enable: This active LOW input is used to enable

the device and is sampled only when a new external address is

loaded.

11H 11H ZZ Input Snooze Enable: This active HIGH, asynchronous input causes the

device to enter a low-power standby mode in which all data in the

memory array is retained. When ZZ is active, all other inputs are

ignored.

3B 3B CE2 Input Synchronous Chip Enable: This active HIGH input is used to enable

the device and is sampled only when a new external address is

loaded.

8B 8B OE#(G#) Input Output Enable: This active LOW, asynchronous input enables the

data I/O output drivers.

(continued on next page)

Page 9

9

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

FBGA PIN DESCRIPTIONS (continued)

x18 x32/x36 SYMBOL TYPE DESCRIPTION

9A 9A ADV# Input Synchronous Address Advance: This active LOW input is used to

advance the internal burst counter, controlling burst access after the

external address is loaded. A HIGH on ADV# effectively causes wait

states to be generated (no address advance). To ensure use of

correct address during a WRITE cycle, ADV# must be HIGH at the

rising edge of the first clock after an ADSP# cycle is initiated.

9B 9B ADSP# Input Synchronous Address Status Processor: This active LOW input

interrupts any ongoing burst, causing a new external address to be

registered. A READ is performed using the new address,

independent of the byte write enables and ADSC#, but dependent

upon CE#, CE2, and CE2#. ADSP# is ignored if CE# is HIGH. Powerdown state is entered if CE2 is LOW or CE2# is HIGH.

8A 8A ADSC# Input Synchronous Address Status Controller: This active LOW input

interrupts any ongoing burst, causing a new external address to be

registered. A READ or WRITE is performed using the new address if

CE# is LOW. ADSC# is also used to place the chip into power-down

state when CE# is HIGH.

1R 1R MODE Input Mode: This input selects the burst sequence. A LOW on this

(LB0#) input selects “linear burst.” NC or HIGH on this input selects

“interleaved burst.” Do not alter input state while device is

operating.

(a) 10J, 10K, (a) 10J, 10K, DQa Input/ SRAM Data I/Os: For the x18 version, Byte “a” is associated DQas;

10L, 10M, 11D, 10L, 10M, 11J, Output Byte “b” is associated with DQbs. For the x32 and x36 versions,

11E, 11F, 11G 11K, 11L, 11M Byte “a” is associated with DQas; Byte “b” is associated with DQbs;

(b) 1J, 1K, (b) 10D, 10E, DQb Byte “c” is associated with DQcs; Byte “d” is associated with DQds.

1L, 1M, 2D, 10F, 10G, 11D, Input data must meet setup and hold times around the rising edge

2E, 2F, 2G 11E, 11F, 11G of CLK.

(c) 1D, 1E, DQc

1F, 1G, 2D,

2E, 2F, 2G

(d) 1J, 1K, 1L, D Qd

1M, 2J, 2K,

2L, 2M

11C 11N NC/DQPa NC / No Connect/Parity Data I/Os: On the x32 version, these are No

1N 11C NC/DQPb I/O Connect (NC). On the x18 version, Byte “a” parity is DQPa; Byte “b”

– 1C NC/DQPc parity is DQPb. On the x36 version, Byte “a” parity is DQPa; Byte

– 1N NC/DQPd “b” parity is DQPb; Byte “c” parity is DQPc; Byte “d” parity is DQPd.

1H, 4D, 4E, 4F, 1H, 4D, 4E, 4F, V

DD

Supply Power Supply: See DC Electrical Characteristics and Operating

4G, 4H, 4J, 4G, 4H, 4J, Conditions for range.

4K, 4L, 4M, 4K, 4L, 4M,

8D, 8E, 8F, 8D, 8E, 8F,

8G, 8H, 8J, 8G, 8H, 8J,

8K, 8L, 8M 8K, 8L, 8M

(continued on next page)

Page 10

10

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

FBGA PIN DESCRIPTIONS (continued)

x18 x32/x36 SYMBOL TYPE DESCRIPTION

3C, 3D, 3E, 3C, 3D, 3E, VDDQ Supply Isolated Output Buffer Supply: See DC Electrical Characteristics and

3F, 3G, 3J, 3F, 3G, 3J, Operating Conditions for range.

3K, 3L, 3M, 3K, 3L, 3M,

3N, 9C, 9D, 3N, 9C, 9D,

9E, 9F, 9G, 9E, 9F, 9G,

9J, 9K, 9L, 9J, 9K, 9L,

9M, 9N 9M, 9N

2H, 4C, 4N, 5C, 2H, 4C, 4N, 5C, V

SS

Supply Ground: GND.

5D, 5E 5F, 5D, 5E 5F,

5G, 5H, 5J, 5G, 5H, 5J,

5K, 5L, 5M, 5K, 5L, 5M,

6C, 6D, 6E, 6F, 6C, 6D, 6E, 6F,

6G, 6H, 6J, 6G, 6H, 6J,

6K, 6L, 6M, 6K, 6L, 6M,

7C, 7D, 7E, 7C, 7D, 7E,

7F, 7G, 7H, 7F, 7G, 7H,

7J, 7K, 7L, 7J, 7K, 7L,

7M, 7N, 8C, 8N 7M, 7N, 8C, 8N

5P, 5R, 7P, 7R 5P, 5R, 7P, 7R DNU – Do Not Use: These signals may either be unconnected or wired to

GND to improve package heat dissipation.

1A, 1B, 1C, 1A, 1B, 1P, NC – No Connect: These signals are not internally connected and

1D, 1E, 1F, 2C, 2N, 2P, may be connected to ground to improve package heat

1G, 1P, 2C, 2R, 3H, 5N, dissipation.

2J, 2K, 2L, 9H, 10C, 10H,

2M, 2N, 2P, 10N, 11A, 11B

2R, 3H, 4B,

5A, 5N, 9H,

10C, 10D, 10E,

10F, 10G, 10H,

10N, 11B, 11J,

11K, 11L,

11M, 11N

Page 11

11

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

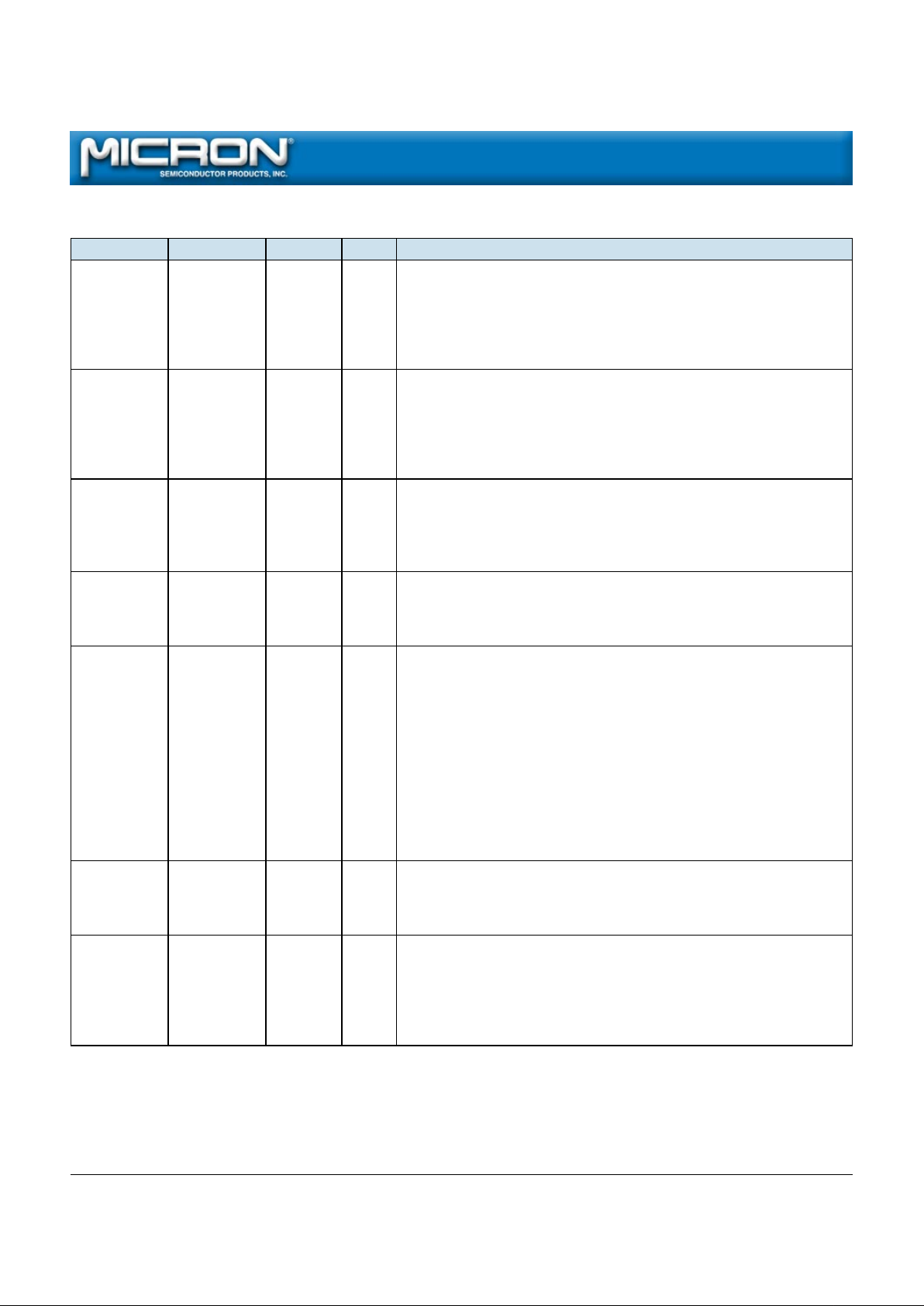

INTERLEAVED BURST ADDRESS TABLE (MODE = NC OR HIGH)

FIRST ADDRESS (EXTERNAL) SECOND ADDRESS (INTERNAL) THIRD ADDRESS (INTERNAL) FOURTH ADDRESS (INTERNAL)

X...X00 X...X01 X...X10 X...X11

X...X01 X...X00 X...X11 X...X10

X...X10 X...X11 X...X00 X...X01

X...X11 X...X10 X...X01 X...X00

LINEAR BURST ADDRESS TABLE (MODE = LOW)

FIRST ADDRESS (EXTERNAL) SECOND ADDRESS (INTERNAL) THIRD ADDRESS (INTERNAL) FOURTH ADDRESS (INTERNAL)

X...X00 X...X01 X...X10 X...X11

X...X01 X...X10 X...X11 X...X00

X...X10 X...X11 X...X00 X...X01

X...X11 X...X00 X...X01 X...X10

PARTIAL TRUTH TABLE FOR WRITE COMMANDS (x18)

FUNCTION GW# BWE# BWa# BWb#

READ H H X X

READ H L H H

WRITE Byte “a” H L L H

WRITE Byte “b” H L H L

WRITE All Bytes H L L L

WRITE All Bytes L X X X

PARTIAL TRUTH TABLE FOR WRITE COMMANDS (x32/x36)

FUNCTION GW# BWE# BWa# BWb# BWc# BWd#

READ H H X X X X

READ H L H H H H

WRITE Byte “a” H L L H H H

WRITE All Bytes H L L L L L

WRITE All Bytes L X X X X X

NOTE: Using BWE# and BWa# through BWd#, any one or more bytes may be written.

Page 12

12

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

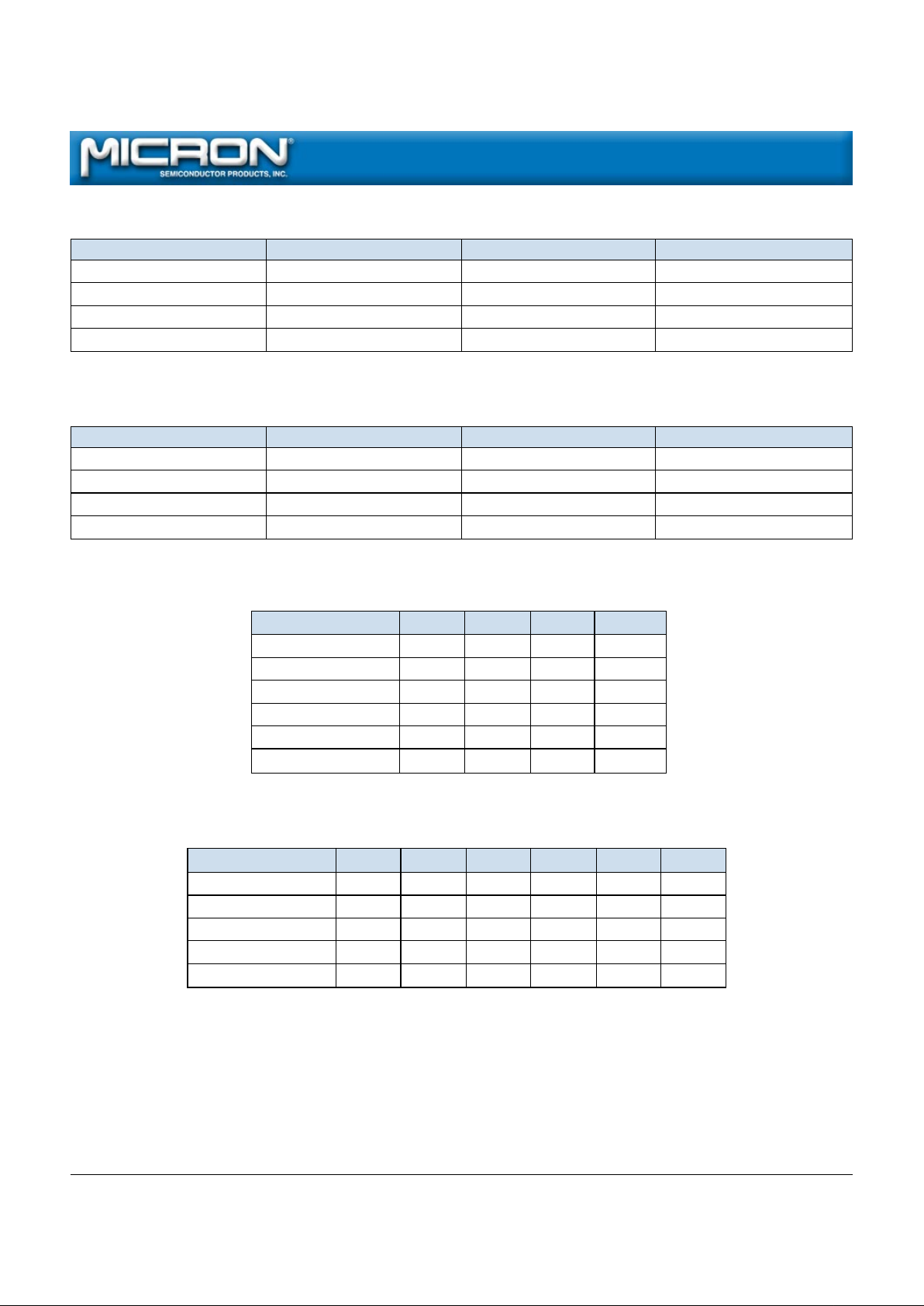

TRUTH TABLE

(Notes 1-8)

ADDRESS

OPERATION USED CE# CE2# CE2 ZZ ADSP# ADSC# ADV# WRITE# OE# CLK DQ

DESELECT Cycle, Power-Down None H X X L X L X X X L-H High-Z

DESELECT Cycle, Power-Down None L X L L L X X X X L-H High-Z

DESELECT Cycle, Power-Down None L H X L L X X X X L-H High-Z

DESELECT Cycle, Power-Down None L X L L H L X X X L-H High-Z

DESELECT Cycle, Power-Down None L H X L H L X X X L-H High-Z

SNOOZE MODE, Power-Down None X X X H XXXXXXHigh-Z

READ Cycle, Begin Burst External L L H L L X X X L L-H Q

READ Cycle, Begin Burst External L L H L L X X X H L-H High-Z

WRITE Cycle, Begin Burst External L L H L H L X L X L-H D

READ Cycle, Begin Burst External L L H L H L X H L L-H Q

READ Cycle, Begin Burst External L L H L H L X H H L-H High-Z

READ Cycle, Continue Burst Next X X X L H H L H L L-H Q

READ Cycle, Continue Burst Next X X X L H H L H H L-H High-Z

READ Cycle, Continue Burst Next H X X L X H L H L L-H Q

READ Cycle, Continue Burst Next H X X L X H L H H L-H High-Z

WRITE Cycle, Continue Burst Next X X X L H H L L X L-H D

WRITE Cycle, Continue Burst Next H X X L X H L L X L-H D

READ Cycle, Suspend Burst Current X X X L HHHHLL-HQ

READ Cycle, Suspend Burst Current X X X L HHHHHL-HHigh-Z

READ Cycle, Suspend Burst Current H X X L X H H H L L-H Q

READ Cycle, Suspend Burst Current H X X L X H H H H L-H High-Z

WRITE Cycle, Suspend Burst Current X X X L H H H L X L-H D

WRITE Cycle, Suspend Burst Current H X X L X H H L X L-H D

NOTE: 1. X means “Don’t Care.” # means active LOW. H means logic HIGH. L means logic LOW.

2. For WRITE#, L means any one or more byte write enable signals (BWa#, BWb#, BWc# or BWd#) and BWE# are LOW or

GW# is LOW. WRITE# = H for all BWx#, BWE#, GW# HIGH.

3. BWa# enables WRITEs to DQa’s and DQPa. BWb# enables WRITEs to DQb’s and DQPb. BWc# enables WRITEs to DQc’s

and DQPc. BWd# enables WRITEs to DQd’s and DQPd. DQPa and DQPb are only available on the x18 and x36 versions.

DQPc and DQPd are only available on the x36 version.

4. All inputs except OE# and ZZ must meet setup and hold times around the rising edge (LOW to HIGH) of CLK.

5. Wait states are inserted by suspending burst.

6. For a WRITE operation following a READ operation, OE# must be HIGH before the input data setup time and held

HIGH throughout the input data hold time.

7. This device contains circuitry that will ensure the outputs will be in High-Z during power-up.

8. ADSP# LOW always initiates an internal READ at the L-H edge of CLK. A WRITE is performed by setting one or more

byte write enable signals and BWE# LOW or GW# LOW for the subsequent L-H edge of CLK. Refer to WRITE timing

diagram for clarification.

Page 13

13

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

3.3V VDD, ABSOLUTE MAXIMUM

RATINGS*

Voltage on VDD Supply

Relative to VSS ................................-0.5V to +4.6V

Voltage on VDDQ Supply

Relative to VSS ................................-0.5V to +4.6V

VIN (DQx)....................................-0.5V to VDDQ + 0.5V

VIN (inputs) ................................... -0.5V to VDD + 0.5V

Storage Temperature (TQFP) .............. -55ºC to +150ºC

Storage Temperature (FBGA).............. -55ºC to +125ºC

Junction Temperature** ................................... +150ºC

Short Circuit Output Current............................100mA

2.5V VDD, ABSOLUTE MAXIMUM

RATINGS*

Voltage on VDD Supply

Relative to VSS ................................-0.3V to +3.6V

Voltage on VDDQ Supply

Relative to VSS ................................-0.3V to +3.6V

VIN (DQx)....................................-0.3V to VDDQ + 0.3V

VIN (inputs) ................................... -0.3V to VDD + 0.3V

Storage Temperature (TQFP) .............. -55ºC to +150ºC

Storage Temperature (FBGA).............. -55ºC to +125ºC

Junction Temperature** ................................... +150ºC

Short Circuit Output Current............................100mA

*Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only, and functional operation of the device at these or any other conditions above

those indicated in the operational sections of this specification is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect reliability.

**Maximum junction temperature depends upon package type, cycle time, loading, ambient temperature and

airflow. See Micron Technical Note TN-05-14 for more

information.

3.3V VDD, 3.3V I/O DC ELECTRICAL CHARACTERISTICS AND OPERATING CONDITIONS

(0ºC £ TA £ +70ºC; VDD = +3.3V ±0.165V; VDDQ = +3.3V ±0.165V unless otherwise noted)

DESCRIPTION CONDITIONS SYMBOL MIN MAX UNITS NOTES

Input High (Logic 1) Voltage VIH 2.0 VDD + 0.3 V 1, 2

Input Low (Logic 0) Voltage VIL -0.3 0.8 V 1, 2

Input Leakage Current 0V £ VIN £ VDD ILI -1.0 1.0 µA 3

Output Leakage Current Output(s) disabled, ILO -1.0 1.0 µA

0V £ VIN £ VDD

Output High Voltage IOH = -4.0mA VOH 2.4 – V 1, 4

Output Low Voltage IOL = 8.0mA VOL – 0.4 V 1, 4

Supply Voltage VDD 3.135 3.465 V 1

Isolated Output Buffer Supply VDDQ 3.135 3.465 V 1, 5

NOTE: 1. All voltages referenced to VSS (GND).

2. For 3.3V VDD:

Overshoot: VIH £ +4.6V for t £ tKC/2 for I £ 20mA

Undershoot: VIL ³ -0.7V for t £ tKC/2 for I £ 20mA

Power-up: VIH £ +3.6V and VDD £ 3.135V for t £ 200ms

For 2.5V VDD:

Overshoot: VIH £ +3.6V for t £ tKC/2 for I £ 20mA

Undershoot: VIL ³ -0.5V for t £ tKC/2 for I £ 20mA

Power-up: VIH £ +2.65V and VDD £ 2.375V for t £ 200ms

3. MODE has an internal pull-up, and input leakage = ±10µA.

4. The load used for VOH, VOL testing is shown in Figure 2. AC load current is higher than the stated DC values. AC I/O

curves are available upon request.

5. VDDQ should never exceed VDD. VDD and VDDQ can be connected together.

Page 14

14

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

3.3V VDD, 2.5V I/O DC ELECTRICAL CHARACTERISTICS AND OPERATING CONDITIONS

(0ºC £ TA £ +70ºC; VDD = +3.3V ±0.165V; VDDQ = +2.5V ±0.125V unless otherwise noted)

DESCRIPTION CONDITIONS SYMBOL MIN MAX UNITS NOTES

Input High (Logic 1) Voltage Data bus (DQx) VIHQ 1.7 VDDQ + 0.3 V 1, 2

Inputs VIH 1.7 VDD + 0.3 V 1, 2

Input Low (Logic 0) Voltage VIL -0.3 0.7 V 1, 2

Input Leakage Current 0V £ VIN £ VDD ILI -1.0 1.0 µA 3

Output Leakage Current Output(s) disabled, ILO -1.0 1.0 µA

0V £ VIN £ VDDQ (DQx)

Output High Voltage IOH = -2.0mA VOH 1.7 – V 1, 4

IOH = -1.0mA VOH 2.0 – V 1, 4

Output Low Voltage IOL = 2.0mA VOL – 0.7 V 1, 4

IOL = 1.0mA VOL – 0.4 V 1, 4

Supply Voltage VDD 3.135 3.6 V 1

Isolated Output Buffer Supply VDDQ 2.375 2.625 V 1

2.5V VDD, 2.5V I/O DC ELECTRICAL CHARACTERISTICS AND OPERATING CONDITIONS

(0ºC £ TA £ +70ºC; VDD = +2.5V ±0.125V; VDDQ = +2.5V ±0.125V unless otherwise noted)

DESCRIPTION CONDITIONS SYMBOL MIN MAX UNITS NOTES

Input High (Logic 1) Voltage Data bus (DQx) VIHQ 1.7 VDDQ + 0.3 V 1, 2

Inputs VIH 1.7 VDD + 0.3 V 1, 2

Input Low (Logic 0) Voltage VIL -0.3 0.7 V 1, 2

Input Leakage Current 0V £ VIN £ VDD ILI -1.0 1.0 µA 3

Output Leakage Current Output(s) disabled, ILO -1.0 1.0 µA

0V £ VIN £ VDDQ (DQx)

Output High Voltage IOH = -2.0mA VOH 1.7 – V 1, 4

IOH = -1.0mA VOH 2.0 – V 1, 4

Output Low Voltage IOL = 2.0mA VOL – 0.7 V 1, 4

IOL = 1.0mA VOL – 0.4 V 1, 4

Supply Voltage VDD 2.375 2.625 V 1

Isolated Output Buffer Supply VDDQ 2.375 2.625 V 1

NOTE: 1. All voltages referenced to VSS (GND).

2. For 3.3V VDD:

Overshoot: VIH £ +4.6V for t £ tKC/2 for I £ 20mA

Undershoot: VIL ³ -0.7V for t £ tKC/2 for I £ 20mA

Power-up: VIH £ +3.6V and VDD £ 3.135V for t £ 200ms

For 2.5V VDD:

Overshoot: VIH £ +3.6V for t £ tKC/2 for I £ 20mA

Undershoot: VIL ³ -0.5V for t £ tKC/2 for I £ 20mA

Power-up: VIH £ +2.65V and VDD £ 2.375V for t £ 200ms

3. MODE has an internal pull-up, and input leakage = ±10µA.

4. The load used for VOH, VOL testing is shown in Figure 4 for 2.5V I/O. AC load current is higher than the shown DC

values. AC I/O curves are available upon request.

5. This parameter is sampled.

Page 15

15

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

TQFP THERMAL RESISTANCE

DESCRIPTION CONDITIONS SYMBOL TYP UNITS NOTES

Thermal Resistance Test conditions follow standard test methods θ

JA

46 ºC/W 1

(Junction to Ambient) and procedures for measuring thermal

Thermal Resistance

impedance, per EIA/JESD51.

θ

JC

2.8 ºC/W 1

(Junction to Top of Case)

NOTE: 1. This parameter is sampled.

TQFP CAPACITANCE

DESCRIPTION CONDITIONS SYMBOL TYP MAX UNITS NOTES

Control Input Capacitance TA = 25ºC; f = 1 MHz; CI 34pF1

Input/Output Capacitance (DQ) VDD = 3.3V CO 45pF1

Address Capacitance CA 3 3.5 pF 1

Clock Capacitance CCK 3 3.5 pF 1

FBGA THERMAL RESISTANCE

DESCRIPTION CONDITIONS SYMBOL TYP UNITS NOTES

Junction to Ambient Test conditions follow standard test methods q

JA

40 ºC/W 1

(Airflow of 1m/s) and procedures for measuring thermal

Junction to Case (Top)

impedance, per EIA/JESD51.

q

JC

9 ºC/W 1

Junction to Pins q

JB

17 ºC/W 1

(Bottom)

FBGA CAPACITANCE

DESCRIPTION CONDITIONS SYMBOL TYP MAX UNITS NOTES

Address/Control Input Capacitance CI 2.5 3.5 pF 1

Output Capacitance (Q) TA = 25ºC; f = 1 MHz CO 45pF1

Clock Capacitance CCK 2.5 3.5 pF 1

Page 16

16

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

NOTE: 1. If VDD = +3.3V, then VDDQ = +3.3V or +2.5V. If VDD = +2.5V, then VDDQ = +2.5V.

Voltage tolerances: +3.3V ±0.165 or +2.5V ±0.125V for all values of VDD and VDDQ.

2. IDD is specified with no output current and increases with faster cycle times. IDDQ increases with faster cycle times and

greater output loading.

3. “Device deselected” means device is in power-down mode as defined in the truth table. “Device selected” means

device is active (not in power-down mode).

4. Typical values are measured at 3.3V, 25ºC, and 10ns cycle time.

IDD OPERATING CONDITIONS AND MAXIMUM LIMITS

(Note 1, unless otherwise noted)(0ºC £ TA £ +70ºC)

DESCRIPTION CONDITIONS SYMBOL TYP -6 -7.5 -10 UNITS NOTES

Power Supply Device selected; All inputs £ VIL

Current: or ³ VIH; Cycle time ³ tKC (MIN); IDD 225 475 425 325 mA 2, 3, 4

Operating VDD = MAX; Outputs open

Power Supply Device selected; VDD = MAX;

Current: Idle ADSC#, ADSP#, GW#, BWx#, ADV# ³ IDD1 55 110 100 85 mA 2, 3, 4

VIH; All inputs £ VSS + 0.2 or ³ VDD - 0.2;

Cycle time ³ tKC (MIN)

CMOS Standby Device deselected; VDD = MAX;

All inputs £ VSS + 0.2 or ³ VDD - 0.2; ISB2 0.4 10 10 10 mA 3, 4

All inputs static; CLK frequency = 0

TTL Standby Device deselected; VDD = MAX;

All inputs £ VIL or ³ VIH;ISB3 8 252525mA3, 4

All inputs static; CLK frequency = 0

Clock Running Device deselected; VDD = MAX;

ADSC#, ADSP#, GW#, BWx#, ADV# ³ ISB4 55 110 90 85 mA 3, 4

VIH; All inputs £ VSS + 0.2 or ³ VDD - 0.2;

Cycle time ³ tKC (MIN)

MAX

Page 17

17

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

NOTE: 1. Test conditions as specified with the output loading shown in Figure 1 for +3.3V I/O (VDDQ = +3.3V ±0.165V) and Figure

3 for 2.5V I/O (VDDQ = +2.5V ±0.125V) unless otherwise noted.

2. Measured as HIGH above VIH and LOW below VIL.

3. This parameter is measured with the output loading shown in Figure 2.

4. This parameter is sampled.

5. Transition is measured ±500mV from steady state voltage.

6. Refer to Technical Note TN-58-09, “Synchronous SRAM Bus Contention Design Considerations,” for a more thorough

discussion on these parameters.

7. OE# is a “Don’t Care” when a byte write enable is sampled LOW.

8. A WRITE cycle is defined by at least one byte write enable LOW and ADSP# HIGH for the required setup and hold

times. A READ cycle is defined by all byte write enables HIGH and ADSC# or ADV# LOW or ADSP# LOW for the

required setup and hold times.

9. This is a synchronous device. All addresses must meet the specified setup and hold times for all rising edges of CLK

when either ADSP# or ADSC# is LOW and chip enabled. All other synchronous inputs must meet the setup and hold

times with stable logic levels for all rising edges of clock (CLK) when the chip is enabled. Chip enable must be valid at

each rising edge of CLK when either ADSP# or ADSC# is LOW to remain enabled.

10. If VDD = +3.3V, then VDDQ = +3.3V or +2.5V. If VDD = +2.5V, then VDDQ = +2.5V.

Voltage tolerances: +3.3V ±0.165 or +2.5V ±0.125V for all values of VDD and VDDQ.

AC ELECTRICAL CHARACTERISTICS AND RECOMMENDED OPERATING CONDITIONS

(Notes 1, 10 unless otherwise noted) (0ºC £ TA £ +70ºC)

-6 -7.5 -10

DESCRIPTION SYMBOL MIN MAX MIN MAX MIN MAX UNITS NOTES

Clock

Clock cycle time

t

KC 6.0 7.5 10 ns

Clock frequency

f

KF 166 133 100 MHz

Clock HIGH time

t

KH 2.3 2.5 3.0 ns 2

Clock LOW time

t

KL 2.3 2.5 3.0 ns 2

Output Times

Clock to output valid

t

KQ 3.5 4.0 5.0 ns

Clock to output invalid

t

KQX 1.5 1.5 1.5 ns 3

Clock to output in Low-Z

t

KQLZ 0 0 0 ns 3, 4, 5, 6

Clock to output in High-Z

t

KQHZ 3.5 4.2 5.0 ns 3, 4, 5, 6

OE# to output valid

t

OEQ 3.5 4.2 5.0 ns 7

OE# to output in Low-Z

t

OELZ 0 0 0 ns 3, 4, 5, 6

OE# to output in High-Z

t

OEHZ 3.5 4.2 4.5 ns 3, 4, 5, 6

Setup Times

Address

t

AS 1.5 1.5 2.0 ns 8, 9

Address status (ADSC#, ADSP#)

t

ADSS 1.5 1.5 2.0 ns 8, 9

Address advance (ADV#)

t

AAS 1.5 1.5 2.0 ns 8, 9

Write signals

t

WS 1.5 1.5 2.0 ns 8, 9

(BWa#-BWd#, BWE#, GW#)

Data-in

t

DS 1.5 1.5 2.0 ns 8, 9

Chip enables (CE#, CE2#, CE2)

t

CES 1.5 1.5 2.0 ns 8, 9

Hold Times

Address

t

AH 0.5 0.5 0.5 ns 8, 9

Address status (ADSC#, ADSP#)

t

ADSH 0.5 0.5 0.5 ns 8, 9

Address advance (ADV#)

t

AAH 0.5 0.5 0.5 ns 8, 9

Write signals

t

WH 0.5 0.5 0.5 ns 8, 9

(BWa#-BWd#, BWE#, GW#)

Data-in

t

DH 0.5 0.5 0.5 ns 8, 9

Chip enables (CE#, CE2#, CE2)

t

CEH 0.5 0.5 0.5 ns 8, 9

Page 18

18

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

Q

50

V = 1.5V

Z = 50

O

T

Figure 1

Q

351

317

5pF

+3.3V

Figure 2

3.3V VDD, 3.3V I/O AC TEST CONDITIONS

Input pulse levels ................... VIH = (VDD/2.2) + 1.5V

.................... VIL = (VDD/2.2) - 1.5V

Input rise and fall times ...................................... 1ns

Input timing reference levels ....................... VDD/2.2

Output reference levels............................. VDDQ/2.2

Output load ..............................See Figures 1 and 2

LOAD DERATING CURVES

Micron 1 Meg x 18, 512K x 32 and 512K x 36

SyncBurst SRAM timing is dependent upon the capacitive loading on the outputs.

Consult the factory for copies of I/O current versus

voltage curves.

3.3V I/O Output Load Equivalents

3.3V VDD, 2.5V I/O AC TEST CONDITIONS

Input pulse levels ............... VIH = (VDD/2.64) + 1.25V

................ VIL = (VDD/2.64) - 1.25V

Input rise and fall times ...................................... 1ns

Input timing reference levels ..................... VDD/2.64

Output reference levels................................ VDDQ/2

Output load ..............................See Figures 3 and 4

2.5V VDD, 2.5V I/O AC TEST CONDITIONS

Input pulse levels .................... VIH = (VDD/2) + 1.25V

..................... VIL = (VDD/2) - 1.25V

Input rise and fall times ...................................... 1ns

Input timing reference levels ..........................VDD/2

Output reference levels................................ VDDQ/2

Output load ..............................See Figures 3 and 4

Q

50Ω

V = 1.25V

Z = 50Ω

O

T

Figure 3

Q

351

317

5pF

+3.3V

Figure 4

2.5V I/O Output Load Equivalents

Page 19

19

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

SNOOZE MODE

SNOOZE MODE is a low-current, “power-down”

mode in which the device is deselected and current is

reduced to ISB2Z. The duration of SNOOZE MODE is

dictated by the length of time ZZ is in a HIGH state. After

the device enters SNOOZE MODE, all inputs except ZZ

become gated inputs and are ignored.

ZZ is an asynchronous, active HIGH input that causes

the device to enter SNOOZE MODE. When ZZ becomes

a logic HIGH, ISB2Z is guaranteed after the setup time tZZ

is met. Any READ or WRITE operation pending when

the device enters SNOOZE MODE is not guaranteed to

complete successfully. Therefore, SNOOZE MODE must

not be initiated until valid pending operations are

completed.

SNOOZE MODE ELECTRICAL CHARACTERISTICS

DESCRIPTION CONDITIONS SYMBOL MIN MAX UNITS NOTES

Current during SNOOZE MODE ZZ ³ VIH ISB2Z 10 mA

ZZ active to input ignored

t

ZZ 2(tKC) ns 1

ZZ inactive to input sampled

t

RZZ 2(tKC) ns 1

ZZ active to snooze current

t

ZZI 2(tKC) ns 1

ZZ inactive to exit snooze current

t

RZZI 0 ns 1

NOTE: 1. This parameter is sampled.

SNOOZE MODE WAVEFORM

t

ZZ

I

SUPPLY

CLK

ZZ

t

RZZ

ALL INPUTS

(except ZZ)

DON’T CARE

I

ISB2Z

t

ZZI

t

RZZI

Outputs (Q) High-Z

DESELECT or READ Only

Page 20

20

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

READ TIMING

3

t

KC

t

KL

CLK

ADSP#

t

ADSH

t

ADSS

ADDRESS

t

KH

OE#

ADSC#

CE#

(NOTE 2)

t

AH

t

AS

A1

t

CEH

t

CES

GW#, BWE#,

BWa#-BWd#

Q

High-Z

t

KQLZ

t

KQX

t

KQ

ADV#

t

OEHZ

t

KQ

Single READ BURST READ

t

OEQ

t

OELZ

t

KQHZ

Burst wraps around

to its initial state.

t

AAH

t

AAS

t

WH

t

WS

t

ADSH

t

ADSS

Q(A2) Q(A2 + 1) Q(A2 + 2)

Q(A1)

Q(A2) Q(A2 + 1) Q(A3)Q(A2 + 3)

A2 A3

(NOTE 1)

Deselect

cycle.

(NOTE 3)

Burst continued with

new base address.

(NOTE 4)

ADV# suspends burst.

DON’T CARE UNDEFINED

NOTE: 1. Q(A2) refers to output from address A2. Q(A2 + 1) refers to output from the next internal burst address following A2.

2. CE2# and CE2 have timing identical to CE#. On this diagram, when CE# is LOW, CE2# is LOW and CE2 is HIGH. When

CE# is HIGH, CE2# is HIGH and CE2 is LOW.

3. Timing is shown assuming that the device was not enabled before entering into this sequence. OE# does not cause Q

to be driven until after the following clock rising edge.

4. Outputs are disabled within two clock cycles after deselect.

-6 -7.5 -10

SYM MIN MAX MIN MAX MIN MAX UNITS

t

AS 1.5 1.5 2.0 ns

t

ADSS 1.5 1.5 2.0 ns

t

AAS 1.5 1.5 2.0 ns

t

WS 1.5 1.5 2.0 ns

t

CES 1.5 1.5 2.0 ns

t

AH 0.5 0.5 0.5 ns

t

ADSH 0.5 0.5 0.5 ns

t

AAH 0.5 0.5 0.5 ns

t

WH 0.5 0.5 0.5 ns

t

CEH 0.5 0.5 0.5 ns

READ TIMING PARAMETERS

-6 -7.5 -10

SYM MIN MAX MIN MAX MIN MAX UNITS

t

KC 6.0 7.5 10 ns

f

KF 166 133 100 MHz

t

KH 2.3 2.5 3.0 ns

t

KL 2.3 2.5 3.0 ns

t

KQ 3.5 4.0 5.0 ns

t

KQX 1.5 1.5 1.5 ns

t

KQLZ 0 0 1.0 ns

t

KQHZ 3.5 4.2 5.0 ns

t

OEQ 3.5 4.2 5.0 ns

t

OELZ 0 0 0 ns

t

OEHZ 3.5 4.2 4.5 ns

Page 21

21

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

WRITE TIMING

t

KC

t

KL

CLK

ADSP#

t

ADSH

t

ADSS

ADDRESS

t

KH

OE#

ADSC#

CE#

(NOTE 2)

t

AH

t

AS

A1

t

CEH

t

CES

BWE#,

BWa#-BWd#

Q

High-Z

ADV#

BURST READ BURST WRITE

D(A2) D(A2 + 1) D(A2 + 1) D(A3) D(A3 + 1) D(A3 + 2)D(A2 + 3)

A2 A3

D

Extended BURST WRITE

D(A2 + 2)

Single WRITE

t

ADSH

t

ADSS

t

ADSH

t

ADSS

t

OEHZ

t

AAH

t

AAS

t

WH

t

WS

t

DH

t

DS

(NOTE 3)

(NOTE 1)

(NOTE 4)

GW#

t

WH

t

WS

(NOTE 5)

Byte write signals are ignored for first cycle when

ADSP# initiates burst.

ADSC# extends burst.

ADV# suspends burst.

DON’T CARE UNDEFINED

D(A1)

NOTE: 1. D(A2) refers to input for address A2. D(A2 + 1) refers to input for the next internal burst address following A2.

2. CE2# and CE2 have timing identical to CE#. On this diagram, when CE# is LOW, CE2# is LOW and CE2 is HIGH. When

CE# is HIGH, CE2# is HIGH and CE2 is LOW.

3. OE# must be HIGH before the input data setup and held HIGH throughout the data hold time. This prevents input/

output data contention for the time period prior to the byte write enable inputs being sampled.

4. ADV# must be HIGH to permit a WRITE to the loaded address.

5. Full-width WRITE can be initiated by GW# LOW; or by GW# HIGH, BWE# LOW and BWa#-BWb# LOW for x18 device; or

GW# HIGH, BWE# LOW and BWa#-BWd# LOW for x32 and x36 devices.

-6 -7.5 -10

SYM MIN MAX MIN MAX MIN MAX UNITS

t

DS 1.5 1.5 2.0 ns

t

CES 1.5 1.5 2.0 ns

t

AH 0.5 0.5 0.5 ns

t

ADSH 0.5 0.5 0.5 ns

t

AAH 0.5 0.5 0.5 ns

t

WH 0.5 0.5 0.5 ns

t

DH 0.5 0.5 0.5 ns

t

CEH 0.5 0.5 0.5 ns

WRITE TIMING PARAMETERS

-6 -7.5 -10

SYM MIN MAX MIN MAX MIN MAX UNITS

t

KC 6.0 7.5 10 ns

f

KF 166 133 100 MHz

t

KH 2.3 2.5 3.0 ns

t

KL 2.3 2.5 3.0 ns

t

OEHZ 3.5 4.2 4.5 ns

t

AS 1.5 1.5 2.0 ns

t

ADSS 1.5 1.5 2.0 ns

t

AAS 1.5 1.5 2.0 ns

t

WS 1.5 1.5 2.0 ns

Page 22

22

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

READ/WRITE TIMING

3

t

KC

t

KL

CLK

ADSP#

t

ADSH

t

ADSS

ADDRESS

t

KH

OE#

ADSC#

CE#

(NOTE 2)

t

AH

t

AS

A2

t

CEH

t

CES

Q

High-Z

ADV#

Single WRITE

D(A3)

A4 A5 A6

D(A5) D(A6)

D

BURST READBack-to-Back READs

High-Z

Q(A2)Q(A1)

Q(A4) Q(A4+1) Q(A4+2)

t

WH

t

WS

Q(A4+3)

t

OEHZ

t

DH

t

DS

t

OELZ

(NOTE 5)

t

KQLZ

t

KQ

Back-to-Back

WRITEs

A1

BWE#,

BWa#-BWd#

(NOTE 4)

A3

DON’T CARE UNDEFINED

NOTE: 1. Q(A4) refers to output from address A4. Q(A4 + 1) refers to output from the next internal burst address following A4.

2. CE2# and CE2 have timing identical to CE#. On this diagram, when CE# is LOW, CE2# is LOW and CE2 is HIGH. When

CE# is HIGH, CE2# is HIGH and CE2 is LOW.

3. The data bus (Q) remains in High-Z following a WRITE cycle unless an ADSP#, ADSC# or ADV# cycle is performed.

4. GW# is HIGH.

5. Back-to-back READs may be controlled by either ADSP# or ADSC#.

-6 -7.5 -10

SYM MIN MAX MIN MAX MIN MAX UNITS

t

ADSS 1.5 1.5 2.0 ns

t

WS 1.5 1.5 2.0 ns

t

DS 1.5 1.5 2.0 ns

t

CES 1.5 1.5 2.0 ns

t

AH 0.5 0.5 0.5 ns

t

ADSH 0.5 0.5 0.5 ns

t

WH 0.5 0.5 0.5 ns

t

DH 0.5 0.5 0.5 ns

t

CEH 0.5 0.5 0.5 ns

READ/WRITE TIMING PARAMETERS

-6 -7.5 -10

SYM MIN MAX MIN MAX MIN MAX UNITS

t

KC 6.0 7.5 10 ns

f

KF 166 133 100 MHz

t

KH 2.3 2.5 3.0 ns

t

KL 2.3 2.5 3.0 ns

t

KQ 3.5 4.0 5.0 ns

t

KQLZ 0 0 1.0 ns

t

OELZ 0 0 0 ns

t

OEHZ 3.5 4.2 4.5 ns

t

AS 1.5 1.5 2.0 ns

Page 23

23

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

IEEE 1149.1 SERIAL BOUNDARY SCAN

(JTAG)

The SRAM incorporates a serial boundary scan test

access port (TAP). This port operates in accordance with

IEEE Standard 1149.1-1990 but does not have the set of

functions required for full 1149.1 compliance. These

functions from the IEEE specification are excluded because their inclusion places an added delay in the critical

speed path of the SRAM. Note that the TAP controller

functions in a manner that does not conflict with the

operation of other devices using 1149.1 fully compliant

TAPs. The TAP operates using JEDEC-standard 2.5V I/O

logic levels.

The SRAM contains a TAP controller, instruction

register, boundary scan register, bypass register and ID

register.

DISABLING THE JTAG FEATURE

These pins can be left floating (unconnected), if the

JTAG function is not to be implemented. Upon powerup, the device will come up in a reset state which will not

interfere with the operation of the device.

TEST ACCESS PORT (TAP)

TEST CLOCK (TCK)

The test clock is used only with the TAP controller.

All inputs are captured on the rising edge of TCK. All

outputs are driven from the falling edge of TCK.

TEST MODE SELECT (TMS)

The TMS input is used to give commands to the TAP

controller and is sampled on the rising edge of TCK. It is

allowable to leave this pin unconnected if the TAP is not

used. The pin is pulled up internally, resulting in a logic

HIGH level.

TEST DATA-IN (TDI)

The TDI pin is used to serially input information into

the registers and can be connected to the input of any of

the registers. The register between TDI and TDO is

chosen by the instruction that is loaded into the TAP

instruction register. For information on loading the

instruction register, see Figure 5. TDI is internally pulled

up and can be unconnected if the TAP is unused in an

application. TDI is connected to the most significant bit

(MSB) of any register. (See Figure 6.)

Figure 5

TAP Controller State Diagram

NOTE: The 0/1 next to each state represents the value of TMS at the rising edge of TCK.

TEST-LOGIC

RESET

RUN-TEST/

IDLE

SELECT

DR-SCAN

SELECT

IR-SCAN

CAPTURE-DR

SHIFT-DR

CAPTURE-IR

SHIFT-IR

EXIT1-DR

PAUSE-DR

EXIT1-IR

PAUSE-IR

EXIT2-DR

UPDATE-DR

EXIT2-IR

UPDATE-IR

1

1

1

0

1 1

0 0

1 1

1

0

0

0

0 0

0

0

0 0

1

0

1

1

0

1

0

1

1

1

1 0

Page 24

24

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

TEST DATA-OUT (TDO)

The TDO output pin is used to serially clock data-out

from the registers. The output is active depending upon

the current state of the TAP state machine. (See Figure 5.)

The output changes on the falling edge of TCK. TDO is

connected to the least significant bit (LSB) of any register. (See Figure 6.)

PERFORMING A TAP RESET

A RESET is performed by forcing TMS HIGH (VDD) for

five rising edges of TCK. This RESET does not affect the

operation of the SRAM and may be performed while the

SRAM is operating.

At power-up, the TAP is reset internally to ensure that

TDO comes up in a High-Z state.

TAP REGISTERS

Registers are connected between the TDI and TDO

pins and allow data to be scanned into and out of the

SRAM test circuitry. Only one register can be selected at

a time through the instruction register. Data is serially

loaded into the TDI pin on the rising edge of TCK. Data

is output on the TDO pin on the falling edge of TCK.

INSTRUCTION REGISTER

Three-bit instructions can be serially loaded into the

instruction register. This register is loaded when it is

placed between the TDI and TDO pins as shown in

Figure 5. Upon power-up, the instruction register is

loaded with the IDCODE instruction. It is also loaded

with the IDCODE instruction if the controller is placed

in a reset state as described in the previous section.

When the TAP controller is in the Capture-IR state,

the two least significant bits are loaded with a binary

“01” pattern to allow for fault isolation of the boardlevel serial test data path.

BYPASS REGISTER

To save time when serially shifting data through

registers, it is sometimes advantageous to skip certain

chips. The bypass register is a single-bit register that can

be placed between the TDI and TDO pins. This allows

data to be shifted through the SRAM with minimal

delay. The bypass register is set LOW (VSS) when the

BYPASS instruction is executed.

BOUNDARY SCAN REGISTER

The boundary scan register is connected to all the

input and bidirectional pins on the SRAM. Several no

connect (NC) pins are also included in the scan register

to reserve pins for 9Mb and 18Mb Claymore SRAMs. The

x36 configuration has a 68-bit-long register, and the x18

configuration has a 49-bit-long register.

The boundary scan register is loaded with the contents of the RAM I/O ring when the TAP controller is in

the Capture-DR state and is then placed between the TDI

and TDO pins when the controller is moved to the ShiftDR state. The EXTEST, SAMPLE/PRELOAD and SAMPLE

Z instructions can be used to capture the contents of the

I/O ring.

The Boundary Scan Order tables show the order in

which the bits are connected. Each bit corresponds to

one of the bumps on the SRAM package. The MSB of the

Bypass Register

0

Instruction Register

012

Identification Register

012293031 ...

Boundary Scan Register*

012..x ...

Selection

Circuitry

Selection

Circuitry

TCK

TMS

TAP CONTROLLER

TDI TDO

*x = 49 for the x18 configuration, x = 68 for the x36 configuration.

Figure 6

TAP Controller Block Diagram

Page 25

25

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

register is connected to TDI, and the LSB is connected to

TDO.

IDENTIFICATION (ID) REGISTER

The ID register is loaded with a vendor-specific, 32bit code during the Capture-DR state when the IDCODE

command is loaded in the instruction register. The

IDCODE is hardwired into the SRAM and can be shifted

out when the TAP controller is in the Shift-DR state. The

ID register has a vendor code and other information

described in the Identification Register Definitions table.

TAP INSTRUCTION SET

OVERVIEW

Eight different instructions are possible with the

three-bit instruction register. All combinations are listed

in the Instruction Codes table. Three of these instructions are listed as RESERVED and should not be used.

The other five instructions are described in detail below.

The TAP controller used in this SRAM is not fully

compliant to the 1149.1 convention because some of

the mandatory 1149.1 instructions are not fully implemented. The TAP controller cannot be used to load

address, data or control signals into the SRAM and

cannot preload the I/O buffers. The SRAM does not

implement the 1149.1 commands EXTEST or INTEST or

the PRELOAD portion of SAMPLE/PRELOAD; rather it

performs a capture of the I/O ring when these instructions are executed.

Instructions are loaded into the TAP controller during the Shift-IR state when the instruction register is

placed between TDI and TDO. During this state, instructions are shifted through the instruction register through

the TDI and TDO pins. To execute the instruction once

it is shifted in, the TAP controller needs to be moved into

the Update-IR state.

EXTEST

EXTEST is a mandatory 1149.1 instruction which is

to be executed whenever the instruction register is loaded

with all 0s. EXTEST is not implemented in this SRAM

TAP controller, and therefore this device is not compliant to 1149.1.

The TAP controller does recognize an all-0 instruction. When an EXTEST instruction is loaded into the

instruction register, the SRAM responds as if a SAMPLE/

PRELOAD instruction has been loaded. There is one

difference between the two instructions. Unlike the

SAMPLE/PRELOAD instruction, EXTEST places the SRAM

outputs in a High-Z state.

IDCODE

The IDCODE instruction causes a vendor-specific,

32-bit code to be loaded into the instruction register. It

also places the instruction register between the TDI and

TDO pins and allows the IDCODE to be shifted out of the

device when the TAP controller enters the Shift-DR

state. The IDCODE instruction is loaded into the instruction register upon power-up or whenever the TAP

controller is given a test logic reset state.

SAMPLE Z

The SAMPLE Z instruction causes the boundary scan

register to be connected between the TDI and TDO pins

when the TAP controller is in a Shift-DR state. It also

places all SRAM outputs into a High-Z state.

SAMPLE/PRELOAD

SAMPLE/PRELOAD is a 1149.1 mandatory instruction. The PRELOAD portion of this instruction is not

implemented, so the device TAP controller is not fully

1149.1-compliant.

When the SAMPLE/PRELOAD instruction is loaded

into the instruction register and the TAP controller is in

the Capture-DR state, a snapshot of data on the inputs

and bi-directional pins is captured in the boundary scan

register.

The user must be aware that the TAP controller clock

can only operate at a frequency up to 10 MHz, while the

SRAM clock operates more than an order of magnitude

faster. Because there is a large difference in the clock

frequencies, it is possible that during the Capture-DR

state, an input or output will undergo a transition. The

TAP may then try to capture a signal while in transition

(metastable state). This will not harm the device, but

there is no guarantee as to the value that will be captured. Repeatable results may not be possible.

To guarantee that the boundary scan register will

capture the correct value of a signal, the SRAM signal

must be stabilized long enough to meet the TAP

controller’s capture setup plus hold time (tCS plus tCH).

The SRAM clock input might not be captured correctly

if there is no way in a design to stop (or slow) the clock

during a SAMPLE/PRELOAD instruction. If this is an

issue, it is still possible to capture all other signals and

simply ignore the value of the CK and CK# captured in

the boundary scan register.

Once the data is captured, it is possible to shift out the

data by putting the TAP into the Shift-DR state. This

places the boundary scan register between the TDI and

TDO pins.

Note that since the PRELOAD part of the command

is not implemented, putting the TAP to the Update-DR

state while performing a SAMPLE/PRELOAD instruction

will have the same effect as the Pause-DR command.

Page 26

26

16Mb: 1 Meg x 18, 512K x 32/36 Pipelined, DCD SyncBurst SRAM Micron Technology, Inc., reserves the right to change products or specifications without notice.

MT58L1MY18D_2.p65 – Rev 7/00 ©2000, Micron Technology, Inc.

16Mb: 1 MEG x 18, 512K x 32/36

PIPELINED, DCD SYNCBURST SRAM

ADVANCE

BYPASS

When the BYPASS instruction is loaded in the instruction register and the TAP is placed in a Shift-DR

state, the bypass register is placed between TDI and TDO.

The advantage of the BYPASS instruction is that it

shortens the boundary scan path when multiple devices

are connected together on a board.

RESERVED

These instruction are not implemented but are re-

served for future use. Do not use these instructions.

t

TLTH

Test Clock

(TCK)

123456

Test Mode Select

(TMS)

t

THTL

Test Data-Out

(TDO)

t

THTH

Test Data-In

(TDI)

t

THMX

t

MVTH

t

THDX

t

DVTH

t

TLOX

t

TLOV