Page 1

MOS-TECH Semiconductor Co.,LTD

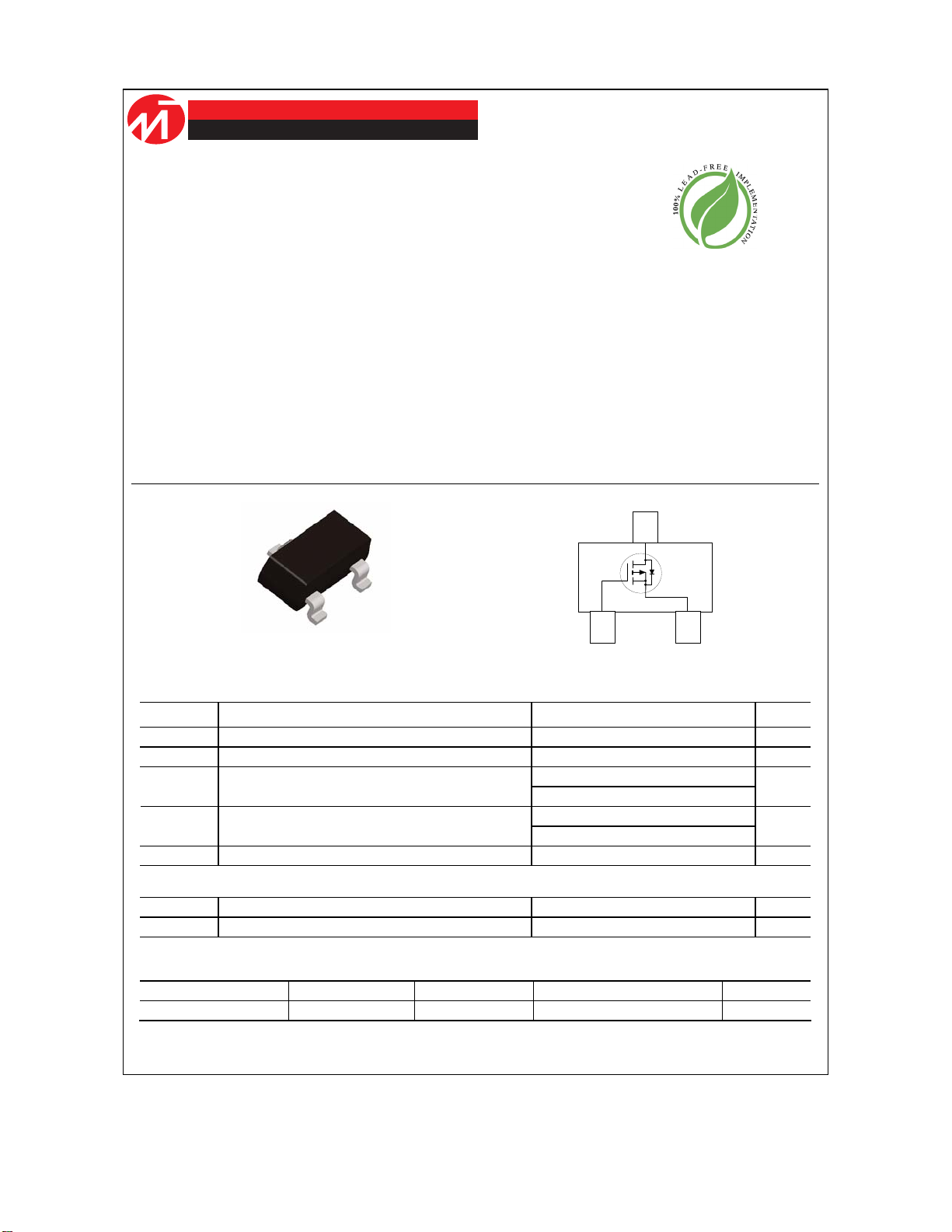

MT2301

Single P-Channel Power MOSFET

MT2301

General Description

This P-Channel Power MOSFET is pro duced

using MOS-TECH Semiconductor’s advanced

PowerTrench process that has b een especially tailored

to minimize the on-state r esistance and yet maintain

low gate charge for superior switching performance.

These devices a re well suit ed for portable electronics

applications: load s witching and power management,

battery charging circuits and DC/DC conversion.

D

Features

• –3.3 A, –20 V. R

R

• Low gate charge (3.6 nC typical)

• High performance trench technology for extremely

low R

• SuperSOT

higher power handling capability than SOT23 in

the same footprint

DS(ON)

TM

-23 provides low R

= 0.072 Ω @ VGS = –4.5 V

DS(ON)

= 0.096Ω @ VGS = –2.5 V

DS(ON)

DS(ON)

D

and 30%

S

G

SOT -23

TM

Absolute Maximum Ratings T

G

o

=25

C unless otherwise noted

A

Symbol Parameter Ratings Units

V

Drain-Source Voltage –20 V

DSS

V

Gate-Source Voltage

GSS

ID Drain Current – Continuous (Note 1a)

– Pulsed –10

Maximum Power Dissipation (Note 1a) 0.5 PD

TJ, T

Operating and Storage Junction Temperature Range –55 to +150

STG

(Note 1b)

±12

3.3

–

0.46

S

V

A

W

°C

Thermal Characteristics

R

θJA

R

θJC

Thermal Resistance, Junction-to-Ambient

Thermal Resistance, Junction-to-Case

(Note 1a) 250

(Note 1) 75

°C/W

°C/W

Package Marking and Ordering Information

Device Marking Device Reel Size Tape width Quantity

010X MT2301 7’’ 8mm 3000 units

©2010 MOS-TECH Semiconductor Corporation www.mtsemi.com Rev.D

Page 2

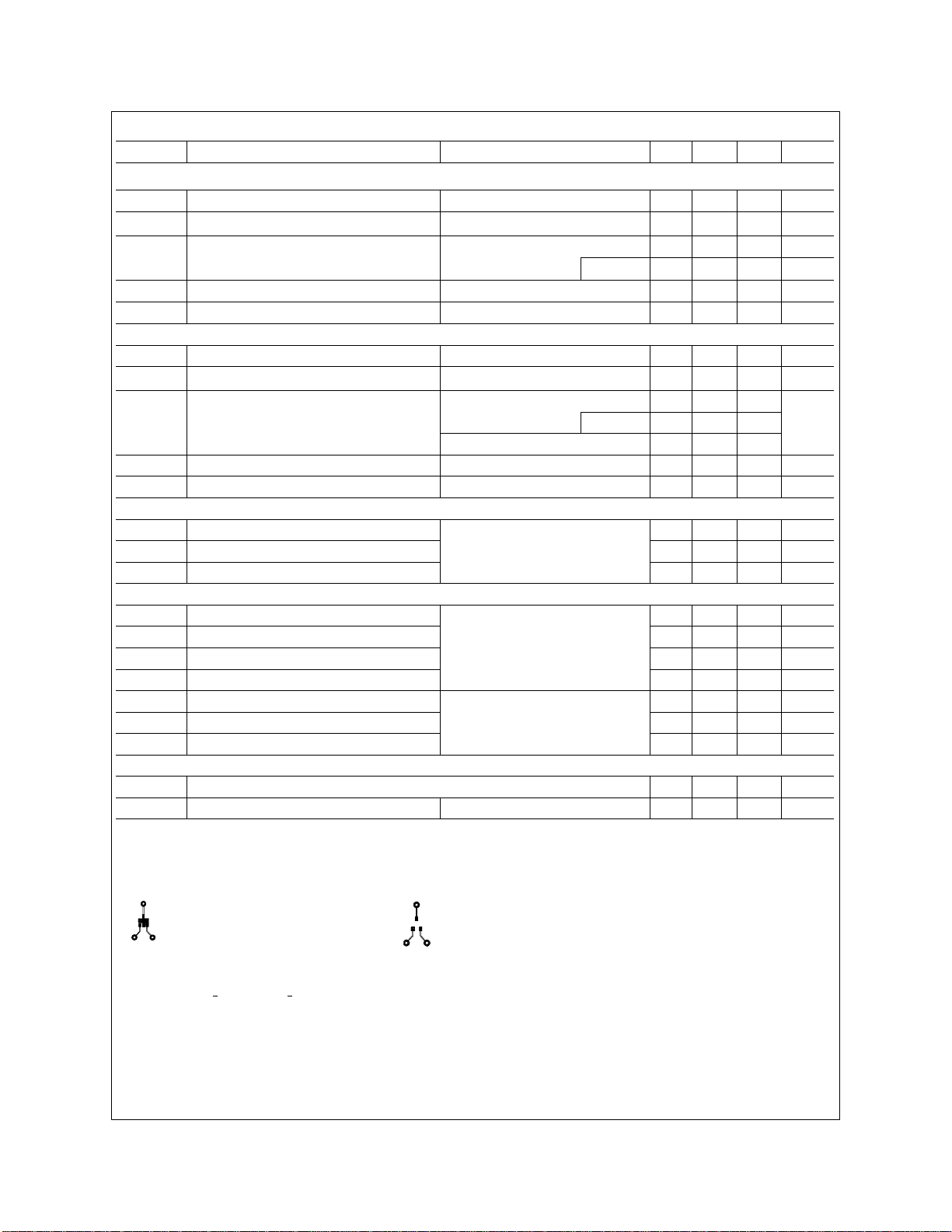

Electrical Characteristics (T

= 25 OC unless otherwise noted )

A

Symbol Parameter Conditions Min Typ Max Units

OFF CHARACTERISTICS

BV

∆BV

I

DSS

DSS

DSS

Drain-Source Breakdown Voltage VGS = 0 V, ID = -250 µA -20 V

Breakdown Voltage Temp. Coefficient

/∆T

J

Zero Gate Voltage Drain Current

ID = -250 µA, Referenced to 25 oC

VDS = -16 V, V

GS

= 0 V

-1 µA

TJ = 55°C

I

GSSF

I

GSSR

Gate - Body Leakage, Forward VGS = 8 V, VDS = 0 V 100 nA

Gate - Body Leakage, Reverse

VGS = -8 V, V

DS

= 0 V

ON CHARACTERISTICS (Note 2)

V

∆V

R

GS(th)

GS(th)

DS(ON)

Gate Threshold Voltage VDS = VGS, ID = -250 µA -0.8 -1.5 V

Gate Threshold Voltage Temp. Coefficient

/∆T

J

Static Drain-Source On-Resistance

ID = -250 µA, Referenced to 25 oC

VGS = -4.5 V, ID = -1.3 A

TJ =125°C 0.12 0.15

VGS = -2.5 V, I D = -1.1 A

I

g

D(ON)

FS

On-State Drain Current VGS = -4.5 V, VDS = -5 V -3.3 A

Forward Transconductance

VDS = -4.5 V, ID = -2 A

DYNAMIC CHARACTERISTICS

C

iss

C

oss

C

rss

Input Capacitance VDS = -10 V, VGS = 0 V,

Output Capacitance 80 pF

f = 1.0 MHz

Reverse Transfer Capacitance 35 pF

SWITCHING CHARACTERISTICS (Note 2)

t

t

t

t

Q

Q

Q

D(on)

r

D(off)

f

g

gs

gd

Turn - On Delay Time

Turn - On Rise Time 12 22 ns

VDD = -5 V, ID = -0.5 A,

VGS = -4.5 V, R

GEN

= 6 Ω

Turn - Off Delay Time 16 26 ns

Turn - Off Fall Time 5 12 ns

Total Gate Charge

Gate-Source Charge 0.8 nC

VDS = -10 V, ID = - 2 A,

VGS = -4.5 V

Gate-Drain Charge 0.7 nC

DRAIN-SOURCE DIODE CHARACTERISTICS AND MAXIMUM RATINGS

I

S

V

SD

Note:

1. R

is the sum of the junction-to-case and case-to-ambient thermal resistance where the case thermal reference is defined as the s older mounting surface of the drain pins. R

JA

θ

design while R

Maximum Continuous Drain-Source Diode Forward Current -0.42 A

Drain-Source Diode Forward Voltage VGS = 0 V, IS = -0.42 A

is determined by the user's board design.

CA

θ

(Note) -0.7 -1.2 V

-16

mV /o C

-10 µA

-100 nA

3

mV /oC

0.072 0.08

0.096 0.15

4 S

330 pF

7 15 ns

3.6 5 nC

is guaranteed by

JC

θ

Ω

o

a. 250

C/W when mounted on

a 0.02 in2 pad of 2oz Cu.

Scale 1 : 1 on letter size paper

2. Pulse Test: Pulse Width < 300µs, Duty Cycle < 2.0%.

o

b. 270

C/W when mounted on

2

a 0.001 in

pad of 2oz Cu.

Rev.D

Page 3

Typical Electrical Characteristics

10

V = -4.5V

GS

8

-3.5V

-3.0V

6

-2.5V

4

2

D

- I , DRAIN-SOURCE CURRENT (A)

0

0 1 2 3 4 5

-V , DRAIN-SOURCE VOLTAGE (V)

DS

-2.0V

Figure 1. On-Region Characteristics.

1.6

I = -1.3A

D

V = -4.5V

GS

1.4

1.2

1

DS(ON)

R , NORMALIZED

0.8

DRAIN-SOURCE ON-RESISTANCE

0.6

-50 -25 0 25 50 75 100 125 150

T , JUNCTION TEMPERATURE (°C)

J

2

1.8

V = -2.5 V

GS

1.6

1.4

1.2

DS(on)

R , NORMALIZED

1

DRAIN-SOURCE ON-RESISTANCE

0.8

0 2 4 6 8 10

-3.0V

-3.5V

- I , DRAIN CURRENT (A)

D

-4.0V

Figure 2. On-Resistance Variation with

Drain Current and Gate

0.5

0.4

0.3

0.2

0.1

DS(ON)

R , ON-RESISTANCE (OHM)

0

0 2 4 6 8 10

- V , GATE TO SOURCE VOLTAGE (V)

GS

T = 125°C

A

25°C

I = -0.6A

D

-4.5V

Figure 3. On-Resistance Variation

with Temperature.

4

V = -5V

DS

3

2

D

1

- I , DRAIN CURRENT (A)

0

0.5 1 1.5 2 2.5

-V , GATE TO SOURCE VOLTAGE (V)

GS

T = -55°C

J

25°C

125°C

Figure 5. Transfer Characteristics.

Figure 4. On-Resistance Variation with

Gate-to-Source Voltage.

10

V = 0V

GS

T = 125°C

1

J

25°C

0.1

0.01

S

- I , REVERSE DRAIN CURRENT (A)

0.001

0.2 0.4 0.6 0.8 1 1.2 1.4

-V , BODY DIODE FORWARD VOLTAGE (V)

SD

-55°C

Figure 6. Body Diode Forward Voltage

Variation with Source

Current

and Temperature.

Rev.D

Page 4

Typical Electrical Characteristics (continued)

5

I = -1.3A

D

4

V = -5V

DS

-10V

3

2

1

GS

-V , GATE-SOURCE VOLTAGE (V)

0

0 1 2 3 4

Q , GATE CHARGE (nC)

g

-15V

Figure 7. Gate Charge Characteristics.

30

10

DC

10ms

100ms

1s

10s

RDS(ON) LIMIT

3

1

0.3

V = -4.5V

GS

0.1

D

SINGLE PULSE

-I , DRAIN CURRENT (A)

R = 270°C/W

JA

θ

0.03

0.01

T = 25°C

A

0.2 0.5 1 3 5 10 30

-V , DRAIN-SOURCE VOLTAGE (V)

DS

1ms

700

400

200

100

CAPACITANCE (pF)

40

f = 1 MHz

V = 0 V

GS

0.1 0.2 0.5 1 2 5 10 20

-V , DRAIN TO SOURCE VOLTAGE (V)

DS

Figure 8. Capacitance Characteristics.

50

40

30

20

POWER (W)

10

0

0.0001 0.001 0.01 0.1 1 10 100 300

SINGLE PULSE TIME (SEC)

SINGLE PULSE

JA

R =270°C/W

θ

T = 25°C

A

C

C

C

iss

oss

rss

Figure 9. Maximum Safe Operating Area.

1

D = 0.5

0.5

0.2

0.2

0.1

0.05

0.02

0.01

0.005

r(t), NORMALIZED EFFECTIVE

0.002

TRANSIENT THERMAL RESISTANCE

0.001

0.0001 0.001 0.01 0.1 1 10 100 300

0.1

0.05

0.02

0.01

Single Pulse

Figure 11. Transient Thermal Response Curve.

Thermal characterization performed using the conditions described in Note 1b.

Transient thermal response will change depending on the circuit board design.

t , TIME (sec)

1

Figure 10. Single Pulse Maximum Power

Dissipation.

R (t) = r(t) * R

JA

θ

R = 270 °C/W

JA

θ

P(pk)

t

1

t

T - T = P * R (t)

J

A

Duty Cycle, D = t /t

JA

θ

2

JA

θ

1 2

Rev.D

Page 5

SOT-23 Std Tape and Reel Data

SOT23-3L Packaging

Configuration: F igure 1.0

PartNO.Label

Antistatic Cover Tape

Embossed

Carrier Tape

Packaging Description:

S OT23- 3L parts are s hipped in tape. T he c arrier tape is

made from a dis sipative (carbon filled) polycarbonate

res in. T he cove r tape i s a m ultilayer film (H eat Ac tiva ted

Adhes ive in nat ure) primarily c omposed o f polyester film,

adhes ive l ayer, seal ant, and ant i-static s prayed ag ent.

Thes e re eled pa rts in s tandard option ar e s hipped with

3,000 units per 7" or 177mm diamete r reel. The r eels ar e

dark blue in color and is made o f polystyrene p las tic (antistatic coated) . O ther option come s in 10, 000 units per 13"

or 330c m diameter reel. T his and s ome other options ar e

desc ribed in the P a cka ging Information table.

Thes e f ull reels are i ndividually labeled and placed inside

a s tandard imme diate box made o f r ecyclable corrugated

brown paper with a F airchild logo printing. One box

contains five r eels maxim um. And these immediate boxes

are placed ins ide a labe led s hipping box which c omes in

different s izes depending on the number of pa rts s hipped.

SOT23-3L Packaging Information

Packaging Option

Packaging type

Qty per Reel/Tube/Bag 3, 000 10,000

Reel Size

Box Dimension (mm) 193x 183x8 0 355x 333x4 0

Max qty per Box 15,000 30, 000

Weight per unit (gm ) 0. 0082 0.0082

Weight per Reel (kg) 0.1175 0. 4006

Note/Comments

S tandard

(no flow code)

TN R

7" D ia

D87Z

TN R

13"

B arcode L a bel s ample

XH1 MT2301ACTR

XH2 C97I27K1-018I-K133 M13274DSPEC :

D

MOS-TECH SEMICONDUCTOR LTD (ACTR)

QT Y: 3000

SOT23-3L Tape Leader and Trailer

Configuration: F igure 2.0

01 X X

018I

018I 018I 018I

SOT23-3L Unit Orientation

MARKING DIAGRAM

X:MonthCode

X:YearCode

01:Manufacturer ID

B

L

Pizza Box for Stan dard Option

B arcode

Lab el

193m m x 183m m x 80mm

C arrier Tape

C over T ape

Tra iler Ta pe

300mm mi nimum or

75 em pty pock ets

C omponents

Leade r T ape

500mm mi nimum or

125 empty pockets

©2010 MOS-TECH Semiconductor Corporation Rev. D

Page 6

SOT-23 Std Tape and Reel Data, continued

SOT23-3L Embossed Carrier Tape

Configuration: Figure 3.0

T

B0

Wc

D0P0 P2

D1

E1

W

F

E2

Tc

K0

P1

A0

User Direction of Feed

Dimensions are in millimeter

Pkg type

SOT-23

(8mm)

Notes: A0, B0, and K0 dimensions are determined with respect to the EIA/Jedec RS-481

rotational and lateral movem ent requirements (see sketches A, B, and C).

SOT23-3L Reel Configuration: Figure 4.0

A0 B0 W D0 D1 E1 E2 F P1 P0 K0 T Wc Tc

3.15

2.77

8.0

1.55

1.125

1.75

6.25

+/-0.10

+/-0.10

20 deg maximum component rotation

Sketch A (Side or Front Sectional View)

Component Rotation

+/-0.3

+/-0.05

+/-0.125

+/-0.10

B0

3.50

min

+/-0.05

20 deg maximum

A0

Sketch B (T op View)

Component Rotation

W1 Measured at Hub

4.0

+/-0.1

Typical

component

cavity

center line

Typical

component

center line

Dim A

Max

4.0

+/-0.1

1.30

0.228

+/-0.013

5.2

+/-0.3

0.5mm

maximum

+/-0.10

0.5mm

maximum

Sketch C (Top View)

Component la teral movement

0.06

+/-0.02

Dim A

max

Tape Size

8mm 7" Dia

8mm 13" Dia

Option

Dim N

7" Diameter Option

See detail AA

13" Diameter Option

W2 max Measured at Hub

Dimensions are in inches and millimeters

Reel

Dim A Dim B Dim C Dim D Dim N Dim W1 Dim W2 Dim W3 (LSL-USL)

7.00

0.059

177.8

13.00

330

1.5

0.059

1.5

512 +0.020/-0.008

13 +0.5/-0.2

512 +0.020/-0.008

13 +0.5/-0.2

0.795

2.165550.331 +0.059/-0.000

20.2

0.795

4.00

20.2

100

W3

Dim D

min

8.4 +1.5/0

0.331 +0.059/-0.000

8.4 +1.5/0

DETAIL AA

0.567

14.4

0.567

14.4

See detail AA

B Min

Dim C

0.311 - 0.429

7.9 - 10. 9

0.311 - 0.429

7.9 - 10. 9

October 2010, Rev. D

Page 7

MOS-TECH Semiconductor Co.,LTD

Notes regarding these materials

1. This document is provided for reference purposes only so that Mos-tech customers may select the appropriate

Mos-tech products for their use. Mos-tech neither makes warranties or representations with respect to the

accuracy or completeness of the information contained in this document nor grants any license to any

intellectual property rights or any other rights of Mos-tech or any third party with respect to the information in

this document.

2. Mos-tech shall have no liability for damages or infringement of any intellectual property or other rights arising

out of the use of any information in this document, including, but not limited to, product data, diagrams, charts,

programs, algorithms, and application circuit examples.

3. You should not use the products or the technology described in this document for the purpose of military

applications such as the development of weapons of mass destruction or for the purpose of any other military

use. When exporting the products or technology described herein, you should follow the applicable export

control laws and regulations, and procedures required by such laws and regulations.

4. All information included in this document such as product data, diagrams, charts, programs, algorithms, and

application circuit examples, is current as of the date this document is issued. Such information, however, is

subject to change without any prior notice. Before purchasing or using any Mos-tech products listed in this

document, please confirm the latest product information with a Mos-tech sales office. Also, please pay regular

and careful attention to additional and different information to be disclosed by Mos-tech such as that disclosed

through our website. (http://www.mtsemi.com )

5. Mos-tech has used reasonable care in compiling the information included in this document, but Mos-tech

assumes no liability whatsoever for any damages incurred as a result of errors or omissions in the information

included in this document.

6. When using or otherwise relying on the information in this document, you should evaluate the information in

light of the total system before deciding about the applicability of such information to the intended application.

Mos-tech makes no representations, warranties or guaranties regarding the suitability of its products for any

particular application and specifically disclaims any liability arising out of the application and use of the

information in this document or Mos-tech products.

7. With the exception of products specified by Mos-tech as suitable for automobile applications, Mos-tech

products are not designed, manufactured or tested for applications or otherwise in systems the failure or

malfunction of which may cause a direct threat to human life or create a risk of human injury or which require

especially high quality and reliability such as safety systems, or equipment or systems for transportation and

traffic, healthcare, combustion control, aerospace and aeronautics, nuclear power, or undersea communication

transmission. If you are considering the use of our products for such purposes, please contact a Mos-tech

sales office beforehand. Mos-tech shall have no liability for damages arising out of the uses set forth above.

8. Notwithstanding the preceding paragraph, you should not use Mos-tech products for the purposes listed below:

(1) artificial life support devices or systems

(2) surgical implantations

(3) healthcare intervention (e.g., excision, administration of medication, etc.)

(4) any other purposes that pose a direct threat to human life

Mos-tech shall have no liability for damages arising out of the uses set forth in the above and purchasers who

elect to use Mos-tech products in any of the foregoing applications shall indemnify and hold harmless Mos-tech

Technology Corp., its affiliated companies and their officers, directors, and employees against any and all

damages arising out of such applications.

9. You should use the products described herein within the range specified by Mos-tech, especially with respect

to the maximum rating, operating supply voltage range, movement power voltage range, heat radiation

characteristics, installation and other product characteristics. Mos-tech shall have no liability for malfunctions or

damages arising out of the use of Mos-tech products beyond such specified ranges.

10. Although Mos-tech endeavors to improve the quality and reliability of its products, IC products have specific

characteristics such as the occurrence of failure at a certain rate and malfunctions under certain use

conditions. Please be sure to implement safety measures to guard against the possibility of physical injury, and

injury or damage caused by fire in the event of the failure of a Mos-tech product, such as safety design for

hardware and software including but not limited to redundancy, fire control and malfunction prevention,

appropriate treatment for aging degradation or any other applicable measures. Among others, since the

evaluation of microcomputer software alone is very difficult, please evaluate the safety of the final products or

system manufactured by you.

11. In case Mos-tech products listed in this document are detached from the products to which the Mos-tech

products are attached or affixed, the risk of accident such as swallowing by infants and small children is very

high. You should implement safety measures so that Mos-tech products may not be easily detached from your

products. Mos-techshall have no liability for damages arising out of such detachment.

12. This document may not be reproduced or duplicated, in any form, in whole or in part, without prior written

approval from Mos-tech.

13. Please contact a Mos-tech sales office if you have any questions regarding the information contained in this

document, Mos-tech semiconductor products, or if you have any other inquiries.

©2010 MOS-TECH Semiconductor Corporation www.mtsemi.com

Page 8

Loading...

Loading...