Datasheet MSM518222-40JS, MSM518222-25ZS, MSM518222-30GS-K, MSM518222-30JS, MSM518222-30ZS Datasheet (OKI)

...Page 1

E2L0033-17-Y1

¡ Semiconductor MSM518222

¡ Semiconductor

This version: Jan. 1998

Previous version: Dec. 1996

MSM518222

262,214-Word ¥ 8-Bit Field Memory

DESCRIPTION

The OKI MSM518222 is a high performance 2-Mbit, 256K ¥ 8-bit, Field Memory. It is designed for

high-speed serial access applications such as HDTVs, conventional NTSC TVs, VTRs, digital movies

and Multi-media systems. The 2-Mbit capacity fits one field of a conventional NTSC TV screen. Two

cascaded MSM518222s make one frame of the screen: two or more MSM518222s can be cascaded

directly without any delay devices between them. (Cascading provides larger storage depth or a

longer delay).

Each of the 8-bit planes has separate serial write and read ports. These employ independent control

clocks to support asynchronous read and write operations. Different clock rates are also supported,

which allow alternate data rates between write and read data streams.

The MSM518222 provides high speed FIFO, First-In First-Out, operation without external refreshing:

it refreshes its DRAM storage cells automatically, so that it appears fully static to the users.

Moreover, fully static type memory cells and decoders for serial access enable the refresh free serial

access operation, so that serial read and/or write control clock can be halted high or low for any

duration as long as the power is on. Internal conflicts of memory access and refreshing operations

are prevented by special arbitration logic.

The MSM518222's function is simple and similar to a digital delay device whose delay-bit-length is

easily set by reset timing. The delay length, and the number of read delay clocks between write and

read, is determined by externally controlled write and read reset timings.

Additional SRAM serial registers, or line buffers for the initial access of 256 ¥ 8-bit enable high speed

first-bit-access with no clock delay just after the write or read reset timings.

The MSM518222 is similar in operation and functionality to OKI 1-Mbit Field Memory MSM514221B,

with the addition of cascade capability. (As for MSM514221B operation compatible 2-Mbit Field

Memory, OKI has the MSM518221 which is a sister device of MSM518222).

Additionally, the MSM518222 has a write mask function or input enable function (IE), and read-data

skipping function or output enable function (OE). The differences between write enable (WE) and

input enable (IE), and between read enable (RE) and output enable (OE) are that WE and RE can stop

serial write/read address increments, but IE and OE cannot stop the increment, when write/read

clocking is continuously applied to MSM518222. The input enable (IE) function allows the user to

write into selected locations of the memory only, leaving the rest of the memory contents unchanged.

This facilitates data processing to display a "picture in picture" on a TV screen.

1/16

Page 2

¡ Semiconductor MSM518222

FEATURES

• Single power supply : 5 V ±10%

• 512 Rows ¥ 512 Columns ¥ 8 bits

• Fast FIFO (First-In First-Out) operation

• High speed asynchronous serial access

Read/write cycle time 25 ns/30 ns/40 ns

Access time 25 ns/25 ns/30 ns

• Direct cascading capability

• Write mask function (Input enable control)

• Data skipping function (Output enable control)

• Self refresh (No refresh control is required)

• Package options :

28-pin 400 mil plastic ZIP (ZIP28-P-400-1.27) (Product : MSM518222-xxZS)

28-pin 400 mil plastic SOJ (SOJ28-P-400-1.27) (Product : MSM518222-xxJS)

28-pin 430 mil plastic SOP (SOP28-P-430-1.27-K) (Product : MSM518222-xxGS-K)

xx indicates speed rank.

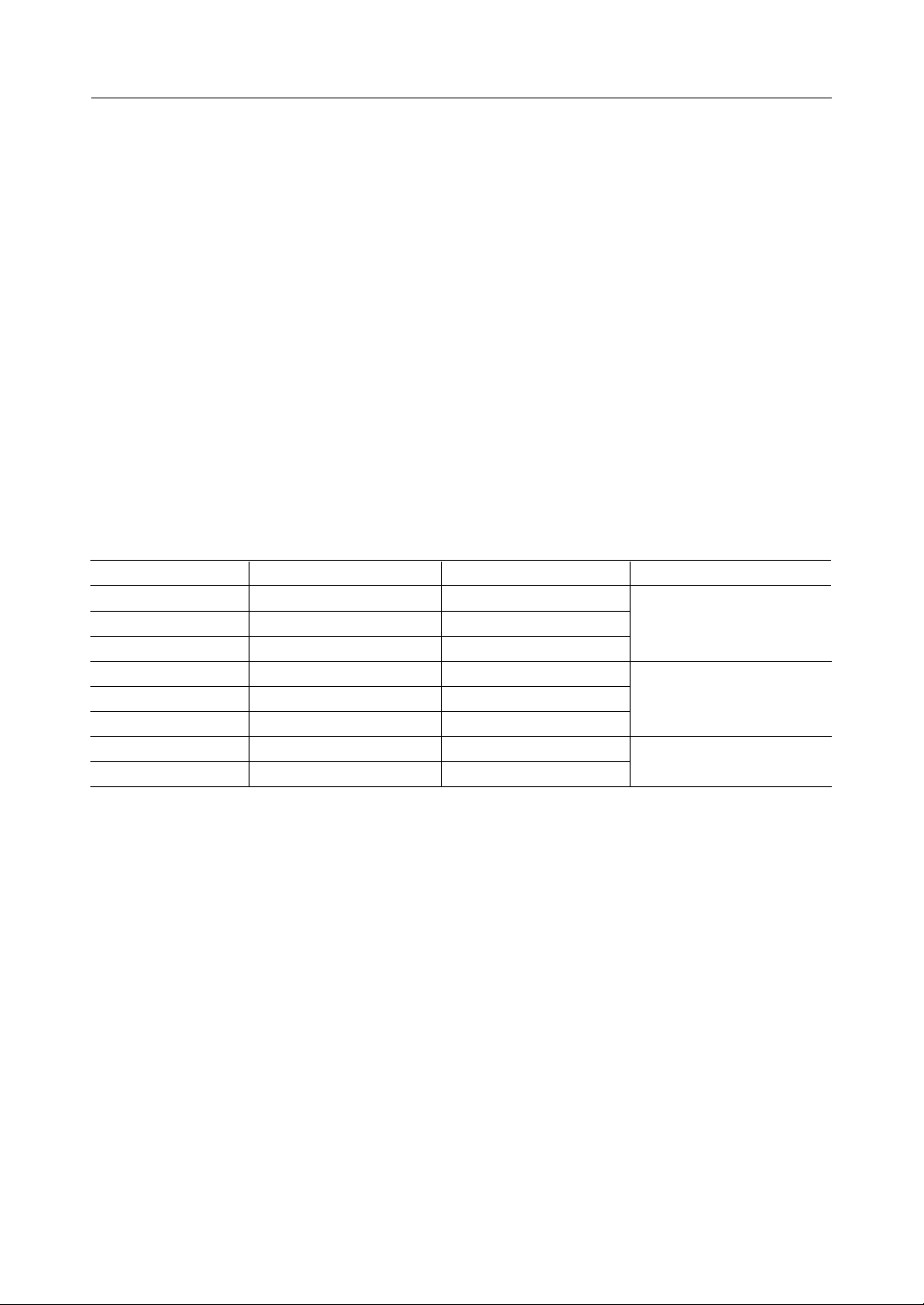

PRODUCT FAMILY

Family Access Time (Max.) Cycle Time (Min.) Package

MSM518222-25ZS 25 ns25 ns

MSM518222-30ZS 30 ns25 ns 400 mil 28-pin ZIP

MSM518222-40ZS 40 ns30 ns

MSM518222-25JS

MSM518222-30JS 30 ns25 ns 400 mil 28-pin SOJ

MSM518222-40JS 40 ns30 ns

MSM518222-30GS-K 30 ns25 ns

MSM518222-40GS-K 40 ns30 ns

25 ns25 ns

430 mil 28-pin SOP

2/16

Page 3

¡ Semiconductor MSM518222

PIN CONFIGURATION (TOP VIEW)

WE

D

IN

DIN2

V

DIN5

D

IN

SWCK

NC

OE

D

OUT

D

OUT

D

OUT

D

OUT

RSTR

1

3

0

5

7

CC

9

7

11

13

15

17

19

6

21

4

23

3

25

1

27

10

12

14

16

18

20

22

24

26

28

2

4

6

8

IE

1

D

IN

DIN3

4

D

IN

6

D

IN

RSTW

NC

RE

D

OUT

D

OUT

V

SS

D

OUT

D

OUT

SRCK

DIN4

1

D

5

2

IN

6

D

3

IN

D

7

4

IN

RSTW

5

623

SWCK

722

NC

RE

821

OE

9

D

10

7

OUT

11

D

6

OUT

7

5

12

5

D

OUT

13

D

4

OUT

14 15

V

SS

28

27

26

25

24

20

19

18

17

16

V

CC

DIN3

2

D

IN

D

1

IN

0

D

IN

IE

WE

NC

SRCK

RSTR

D

OUT

D

OUT

D

OUT

D

OUT

1

4

D

IN

5

D

2

IN

3

D

6

IN

7

4

D

IN

RSTW

5

SWCK

6

NC

RE

8

OE

9

D

10

7

OUT

0

1

2

3

11

D

6

OUT

12

D

5

OUT

13

4

D

OUT

V

14 15

SS

28

27

26

25

24

23

227

21

20

19

18

17

16

V

CC

DIN3

D

IN

D

IN

D

IN

IE

WE

NC

SRCK

RSTR

D

OUT

D

OUT

D

OUT

D

OUT

2

0

28-Pin Plastic SOJ

28-Pin Plastic SOP

2

1

0

0

1

2

3

28-Pin Plastic ZIP

Pin Name Function

SWCK

SRCK

RSTW

RSTR

D

IN

D

OUT

WE

RE

IE

OE

0 - 7

V

CC

V

SS

0 - 7

Serial Write Clock

Serial Read Clock

Write Enable

Read Enable

Input Enable

Output Enable

Write Reset Clock

Read Reset Clock

Data Input

Data Output

Power Supply (5 V)

Ground (0 V)

NC No Connection

3/16

Page 4

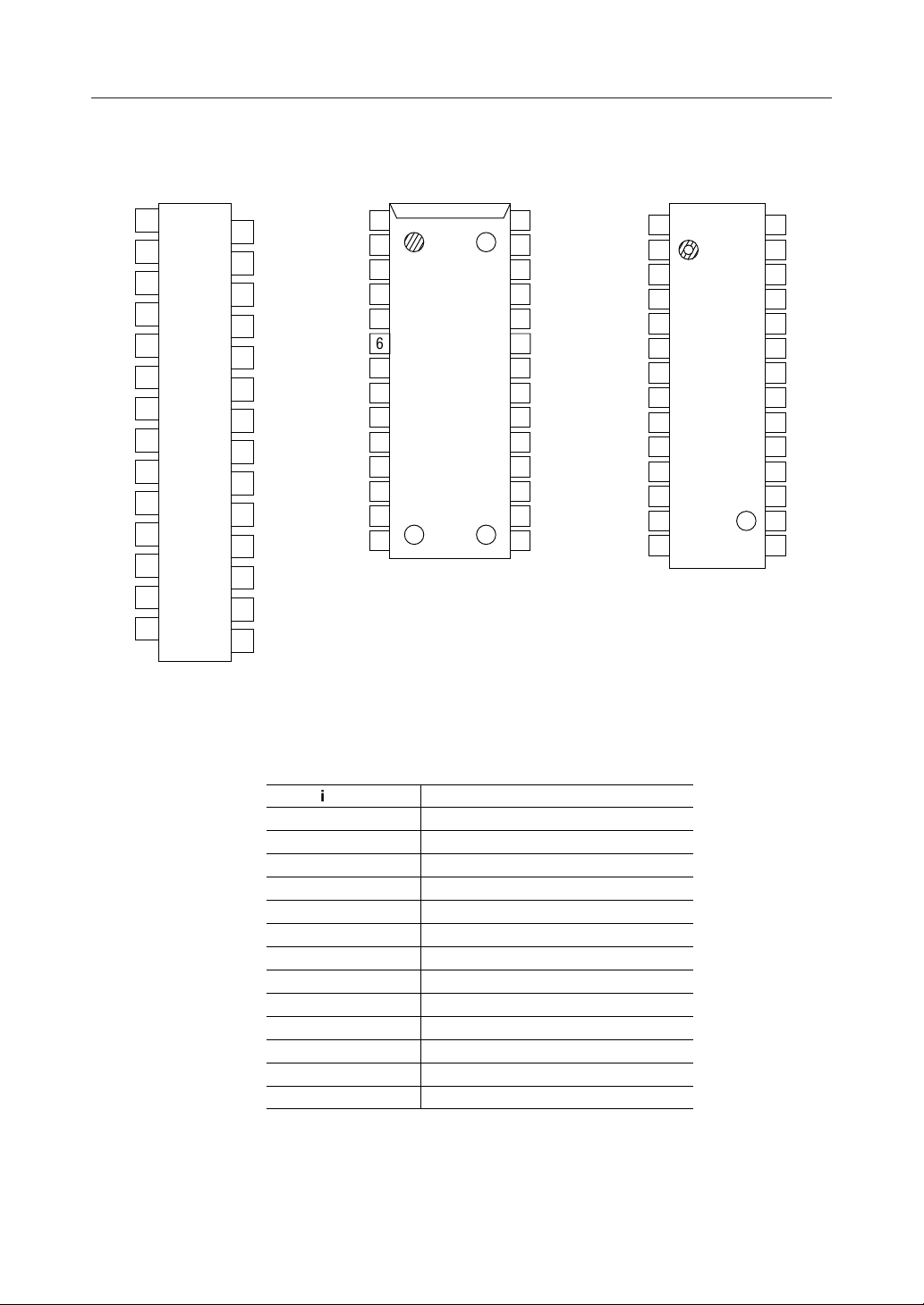

D

(¥ 8)

OUT

OE

RE

RSTR SRCK

BLOCK DIAGRAM

¡ Semiconductor MSM518222

Data-out

Buffer (¥ 8)

71 Word

Sub-Register (¥ 8)

71 Word

Sub-Register (¥ 8)

Data-in

Buffer (¥ 8)

Serial

Read

Controller

512 Word Serial Read Register (¥ 8)

Read Line Buffer

Low-Half (¥ 8)

Read Line Buffer

High-Half (¥ 8)

256 (¥ 8)

256K (¥ 8)

Memory

Array

256 (¥ 8)

Write Line Buffer

Low-Half (¥ 8)

Write Line Buffer

High-Half (¥ 8)

512 Word Serial Write Register (¥ 8)

Serial

Write

Controller

256 (¥ 8)

256 (¥ 8)

X

Decoder

Read/Write

and Refresh

Controller

Clock

Oscillator

V

Generator

BB

4/16

D

(¥ 8)

IN

IE WE RSTW SWCK

Page 5

¡ Semiconductor MSM518222

OPERATION

Write Operation

The write operation is controlled by three clocks, SWCK, RSTW, and WE. Write operation is

accomplished by cycling SWCK, and holding WE high after the write address pointer reset operation

or RSTW.

Each write operation, which begins after RSTW, must contain at least 80 active write cycles, i.e.

SWCK cycles while WE is high. To transfer the last data to the DRAM array, which at that time

is stored in the serial data registers attached to the DRAM array, an RSTW operation is required

after the last SWCK cycle.

Note that every write timing of MSM518222 is delayed by one clock compared with read timings for

easy cascading without any interface delay devices.

Write Reset : RSTW

The first positive transition of SWCK after RSTW becomes high resets the write address counters to

zero. RSTW setup and hold times are referenced to the rising edge of SWCK. Because the write reset

function is solely controlled by the SWCK rising edge after the high level of RSTW, the states of WE

and IE are ignored in the write reset cycle.

Before RSTW may be brought high again for a further reset operation, it must be low for at least two

SWCK cycles.

Data Inputs : DIN0 - 7

Write Clock : SWCK

The SWCK latches the input data on chip when WE is high, and also increments the internal write

address pointer. Data-in setup time tDS, and hold time tDH are referenced to the rising edge of SWCK.

Write Enable : WE

WE is used for data write enable/disable control. WE high level enables the input, and WE low level

disables the input and holds the internal write address pointer. There are no WE disable time (low)

and WE enable time (high) restrictions, because the MSM518222 is in fully static operation as long

as the power is on. Note that WE setup and hold times are referenced to the rising edge of SWCK.

Input Enable : IE

IE is used to enable/disable writing into memory. IE high level enables writing. The internal write

address pointer is always incremented by cycling SWCK regardless of the IE level. Note that IE setup

and hold times are referenced to the rising edge of SWCK.

5/16

Page 6

¡ Semiconductor MSM518222

Read Operation

The read operation is controlled by three clocks, SRCK, RSTR, and RE. Read operation is

accomplished by cycling SRCK, and holding RE high after the read address pointer reset operation

or RSTR.

Each read operation, which begins after RSTR, must contain at least 80 active read cycles, i.e.

SRCK cycles while RE is high.

Read Reset : RSTR

The first positive transition of SRCK after RSTR becomes high resets the read address counters to

zero. RSTR setup and hold times are referenced to the rising edge of SRCK. Because the read reset

function is solely controlled by the SRCK rising edge after the high level of RSTR, the states of RE and

OE are ignored in the read reset cycle.

Before RSTR may be brought high again for a further reset operation, it must be low for at least *two

SRCK cycles.

Data Out : D

OUT

0 - 7

Read Clock : SRCK

Data is shifted out of the data registers. It is triggered by the rising edge of SRCK when RE is high

during a read operation. The SRCK input increments the internal read address pointer when RE is

high.

The three-state output buffer provides direct TTL compatibility (no pullup resistor required). Data

out is the same polarity as data in. The output becomes valid after the access time interval tAC that

begins with the rising edge of SRCK. *There are no output valid time restrictions on MSM518222.

Read Enable : RE

The function of RE is to gate the SRCK clock for incrementing the read pointer. When RE is high

before the rising edge of SRCK, the read pointer is incremented. When RE is low, the read pointer

is not incremented. RE setup times (t

RENS

and t

) and RE hold times (t

RDSS

RENH

and t

RDSH

) are

referenced to the rising edge of the SRCK clock.

Output Enable : OE

OE is used to enable/disable the outputs. OE high level enables the outputs. The internal read

address pointer is always incremented by cycling SRCK regardless of the OE level. Note that OE

setup and hold times are referenced to the rising edge of SRCK.

6/16

Page 7

¡ Semiconductor MSM518222

Power-up and Initialization

On power-up, the device is designed to begin proper operation after at least 100 ms after VCC has

stabilized to a value within the range of recommended operating conditions. After this 100 ms

stabilization interval, the following initialization sequence must be performed.

Because the read and write address counters are not valid after power-up, a minimum of 80 dummy

write operations (SWCK cycles) and read operations (SRCK cycles) must be performed, followed by

an RSTW operation and an RSTR operation, to properly initialize the write and the read address

pointer. Dummy write cycles/RSTW and dummy read cycles/RSTR may occur simultaneously.

If these dummy read and write operations start while VCC and/or the substrate voltage has not

stabilized, it is necessary to perform an RSTR operation plus a minimum of 80 SRCK cycles plus

another RSTR operation, and an RSTW operation plus a minimum of 80 SRCK cycles plus another

RSTW operation to properly initialize read and write address pointers.

Old/New Data Access

There must be a minimum delay of 600 SWCK cycles between writing into memory and reading out

from memory. If reading from the first field starts with an RSTR operation, before the start of writing

the second field (before the next RSTW operation), then the data just written will be read out.

The start of reading out the first field of data may be delayed past the beginning of writing in the

second field of data for as many as 70 SWCK cycles. If the RSTR operation for the first field read-out

occurs less than 70 SWCK cycles after the RSTW operation for the second field write-in, then the

internal buffering of the device assures that the first field will still be read out. The first field of data

that is read out while the second field of data is written is called "old data".

In order to read out"new data", i.e., the second field written in, the delay between an RSTW operation

and an RSTR operation must be at least 600 SRCK cycles. If the delay between RSTW and RSTR

operations is more than 71 but less than 600 cycles, then the data read out will be undetermined. It

may be "old data" or "new" data, or a combination of old and new data. Such a timing should be

avoided.

Cascade Operation

The MSM518222 is designed to allow easy cascading of multiple memory devices. This provides

higher storage depth, or a longer delay than can be achieved with only one memory device.

7/16

Page 8

¡ Semiconductor MSM518222

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings

Parameter Symbol Condition Rating

Input Output Voltage

Output Current

Power Dissipation

Operating Temperature

Storage Temperature

V

T

I

OS

P

D

T

opr

T

stg

at Ta = 25°C, V

Ta = 25°C

Ta = 25°C

—

—

SS

Recommended Operating Conditions

Parameter Symbol Min. UnitTyp. Max.

Power Supply Voltage

Power Supply Voltage

Input High Voltage

Input Low Voltage

V

CC

V

SS

V

IH

V

IL

4.5

0

2.4

–1.0

5.0

V

0

CC

0

DC Characteristics

Parameter Symbol Condition Min.

Input Leakage Current

Output Leakage Current

Output "H" Level Voltage

Output "L" Level Voltage

Operating Current

Standby Current

I

0 < VI < V

LI

I

LO

V

OH

V

OL

I

1

Minimum Cycle Time, Output Open

CC

I

CC2

+ 1, Other Pins Tested at V = 0 V

CC

0 < VO < V

I

= –1 mA

OH

I

OL

Input Pin = V

= 2 mA

CC

-25

-30

-40

/ V

IH

IL

–1.0 to 7.0

0 to 70

–55 to 150

–10

–10

2.4

—

—

—

—

—

50

1

5.5

0

VCC + 1

0.8

Max. Unit

10

10

—

0.4

60

50

40

5

Unit

V

mA

W

°C

°C

V

V

V

V

mA

mA

V

V

mA

mA

Capacitance

Input Capacitance (D

Output Capacitance (D

Parameter Unit

, SWCK, SRCK, RSTW, RSTR, WE, RE, IE, OE)

IN

)

OUT

(Ta = 25°C, f = 1 MHz)

Symbol Max.

C

I

C

O

7

7

pF

pF

8/16

Page 9

¡ Semiconductor MSM518222

AC Characteristics

t

AC

DS

DH

SRC

t

T

MSM518222-25

—

6

6

9

9

5

6

0

5

0

5

0

5

0

5—

5

5—

5

5

0

10

9

9

0

5

0

5

0

5

0

5

5

5

5

5

0

10RSTR Hold Time 10 10 ns—

25SWCK Cycle Time 30 40 ns—

25SRCK Cycle Time 30 40 ns—

3

Parameter

Symbol Unit

Access Time from SRCK

D

Hold Time from SRCK

OUT

Enable Time from SRCK

D

OUT

SWCK "H" Pulse Width

SWCK "L" Pulse Width

Input Data Setup Time

Input Data Hold Time

WE Enable Setup Time

WE Enable Hold Time

WE Disable Setup Time

WE Disable Hold Time

IE Enable Setup Time

IE Enable Hold Time

IE Disable Setup Time

IE Disable Hold Time

WE "H" Pulse Width

WE "L" Pulse Width

IE "H" Pulse Width

IE "L" Pulse Width

RSTW Setup Time

RSTW Hold Time

SRCK "H" Pulse Width

SRCK "L" Pulse Width

RE Enable Setup Time

RE Enable Hold Time

RE Disable Setup Time

RE Disable Hold Time

OE Enable Setup Time

OE Enable Hold Time

OE Disable Setup Time

OE Disable Hold Time

RE "H" Pulse Width

RE "L" Pulse Width

OE "H" Pulse Width

OE "L" Pulse Width

RSTR Setup Time

t

DDCK

t

DECK

t

WSWH

t

WSWL

t

t

t

WENS

t

WENH

t

WDSS

t

WDSH

t

IENS

t

IENH

t

IDSS

t

IDSH

t

WWEH

t

WWEL

t

WIEH

t

WIEL

t

RSTWS

t

RSTWH

t

WSRH

t

WSRL

t

RENS

t

RENH

t

RDSS

t

RDSH

t

OENS

t

OENH

t

ODSS

t

ODSH

t

WREH

t

WREL

t

WOEH

t

WOEL

t

RSTRS

t

RSTRH

t

SWC

t

Transition Time (Rise and Fall) 3 3 ns30

(VCC = 5 V ±10%, Ta = 0°C to 70°C)

MSM518222-30 MSM518222-40

Max.Min.

25

—

25

—

—

—

—

—

—

—

—

—

—

—

—

12

12

25

6

6

—

25

—

—

5

6

0

5

0

5

0

5

0

—

—

—

—

—

—

—

—

—

—

6

6

17

17

5

6

0

5

0

5

0

5

0

Max.Min.Max.Min.

30

—

25

—

—

—

—

—

—

—

—

—

—

—

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

5—5—ns

—

10

—

10

—

ns

10 — 10 — ns

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

10

10

10

12

12

10

10

10

10

—

—

0

—

—

—

—

0

5

0

5

0

5

—

—

—

—

—

—

—

5

—

—

—

—

—

0

—

10

10

10

17

17

10

10

10

10

—

—

0

—

—

—

—

0

5

0

5

0

5

0

5

—

—

—

—

—

—

—

—

—

—

—

—

0

—

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns0

ns

ns

ns

ns

ns

ns

——

——

——

30 30

9/16

Page 10

¡ Semiconductor MSM518222

Notes: 1. Input signal reference levels for the parameter measurement are VIH = 3.0 V and V

= 0 V. The transition time tT is defined to be a transition time that signal transfers

between VIH = 3.0 V and VIL = 0 V.

2. AC measurements assume tT = 3 ns.

3. Read address must have more than a 600 address delay than write address in every

cycle when asynchronous read/write is performed.

4. Read must have more than a 600 address delay than write in order to read the data

written in a current series of write cycles which has been started at last write reset

cycle: this is called "new data read".

When read has less than a 70 address delay than write, the read data are the data

written in a previous series of write cycles which had been written before the last

write reset cycle: this is called "old data read".

5. When the read address delay is between more than 71 and less than 599, read data

will be undetermined. However, normal write is achieved in this address condition.

6. Outputs are measured with a load equivalent to 1 TTL load and 30 pF.

Output reference levels are VOH = 2.4 V and VOL = 0.8 V.

IL

10/16

Page 11

¡ Semiconductor MSM518222

TIMING WAVEFORM

Write Cycle Timing (Write Reset)

n cycle 0 cycle 1 cycle 2 cycle

V

SWCK

RSTW

D

IN

t

t

t

t

T

t

DS

RSTWS

t

DH

RSTWH

WSWH

t

SWC

t

WSWL

n-1 n 0 1 2

V

V

V

V

V

IH

IL

IH

IL

IH

IL

WE

IE

Write Cycle Timing (Write Enable)

n cycle Disable cycle Disable cycle n+1 cycle

SWCK

WE

D

t

WENH

t

WWEL

IN

n-1 n n+1

t

WDSH

t

WWEH

t

WDSS

t

WENS

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

IE

RSTW

V

V

V

V

11/16

IH

IL

IH

IL

Page 12

¡ Semiconductor MSM518222

Write Cycle Timing (Input Enable)

n cycle

n+1 cycle n+2 cycle n+3 cycle

SWCK

t

IENH

IE

t

WIEL

D

IN

n-1 n n+3

WE

RSTW

Read Cycle Timing (Read Reset)

t

IDSH

t

WIEH

t

IDSS

t

IENS

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

SRCK

RSTR

D

OUT

RE

OE

n cycle 0 cycle 1 cycle 2 cycle

t

t

t

t

T

RSTRS

t

AC

RSTRH

WSRH

t

DDCK

t

SRC

t

WSRL

n-1n012

V

IH

V

IL

V

IH

V

IL

V

OH

V

OL

V

IH

V

IL

V

IH

V

IL

12/16

Page 13

¡ Semiconductor MSM518222

Read Cycle Timing (Read Enable)

n cycle Disable cycle Disable cycle n+1 cycle

SRCK

V

V

IH

IL

t

RENH

t

RDSH

RE

t

t

WREL

D

OUT

n-1 n n+1

WREH

OE

RSTR

Read Cycle Timing (Output Enable)

n cycle n+1 cycle n+2 cycle n+3 cycle

SRCK

t

RDSS

t

RENS

V

IH

V

IL

V

OH

V

OL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

OE

D

OUT

RE

RSTR

t

OENH

t

WOEN

t

ODSH

t

WOEH

n-1 n n+3Hi-Z

t

ODSS

t

OENS

t

DECK

V

V

V

V

V

V

V

V

13/16

IH

IL

OH

OL

IH

IL

IH

IL

Page 14

¡ Semiconductor MSM518222

PACKAGE DIMENSIONS

(Unit : mm)

ZIP28-P-400-1.27

Mirror finish

Package material

Lead frame material

Pin treatment

Solder plate thickness

Package weight (g)

Epoxy resin

42 alloy

Solder plating

5 mm or more

1.85 TYP.

14/16

Page 15

¡ Semiconductor MSM518222

(Unit : mm)

SOJ28-P-400-1.27

Mirror finish

Package material

Lead frame material

Pin treatment

Solder plate thickness

Package weight (g)

Epoxy resin

42 alloy

Solder plating

5 mm or more

1.30 TYP.

Notes for Mounting the Surface Mount Type Package

The SOP, QFP, TSOP, SOJ, QFJ (PLCC), SHP and BGA are surface mount type packages, which

are very susceptible to heat in reflow mounting and humidity absorbed in storage.

Therefore, before you perform reflow mounting, contact Oki’s responsible sales person for the

product name, package name, pin number, package code and desired mounting conditions

(reflow method, temperature and times).

15/16

Page 16

¡ Semiconductor MSM518222

(Unit : mm)

SOP28-P-430-1.27-K

Mirror finish

Package material

Lead frame material

Pin treatment

Solder plate thickness

Package weight (g)

Epoxy resin

42 alloy

Solder plating

5 mm or more

0.75 TYP.

Notes for Mounting the Surface Mount Type Package

The SOP, QFP, TSOP, SOJ, QFJ (PLCC), SHP and BGA are surface mount type packages, which

are very susceptible to heat in reflow mounting and humidity absorbed in storage.

Therefore, before you perform reflow mounting, contact Oki’s responsible sales person for the

product name, package name, pin number, package code and desired mounting conditions

(reflow method, temperature and times).

16/16

Loading...

Loading...