Page 1

H-BRIDGE

ISO 9001 CERTIFIED BY DSCC

M.S. KENNEDY CORP.

4707 Dey Road Liverpool, N.Y. 13088 (315) 701-6751

FEATURES:

• Pin Compatible with MPM3002 and MPM3010

• P and N Channel MOSFETs for Ease of Drive

• N Channel Current Sensing MOSFET for Low Loss Sensing

• Isolated Package for Direct Heat Sinking, Excellent Thermal Conductivity

• Avalanche Rated Devices

• 55 Volt, 10 Amp Full H-Bridge

DESCRIPTION:

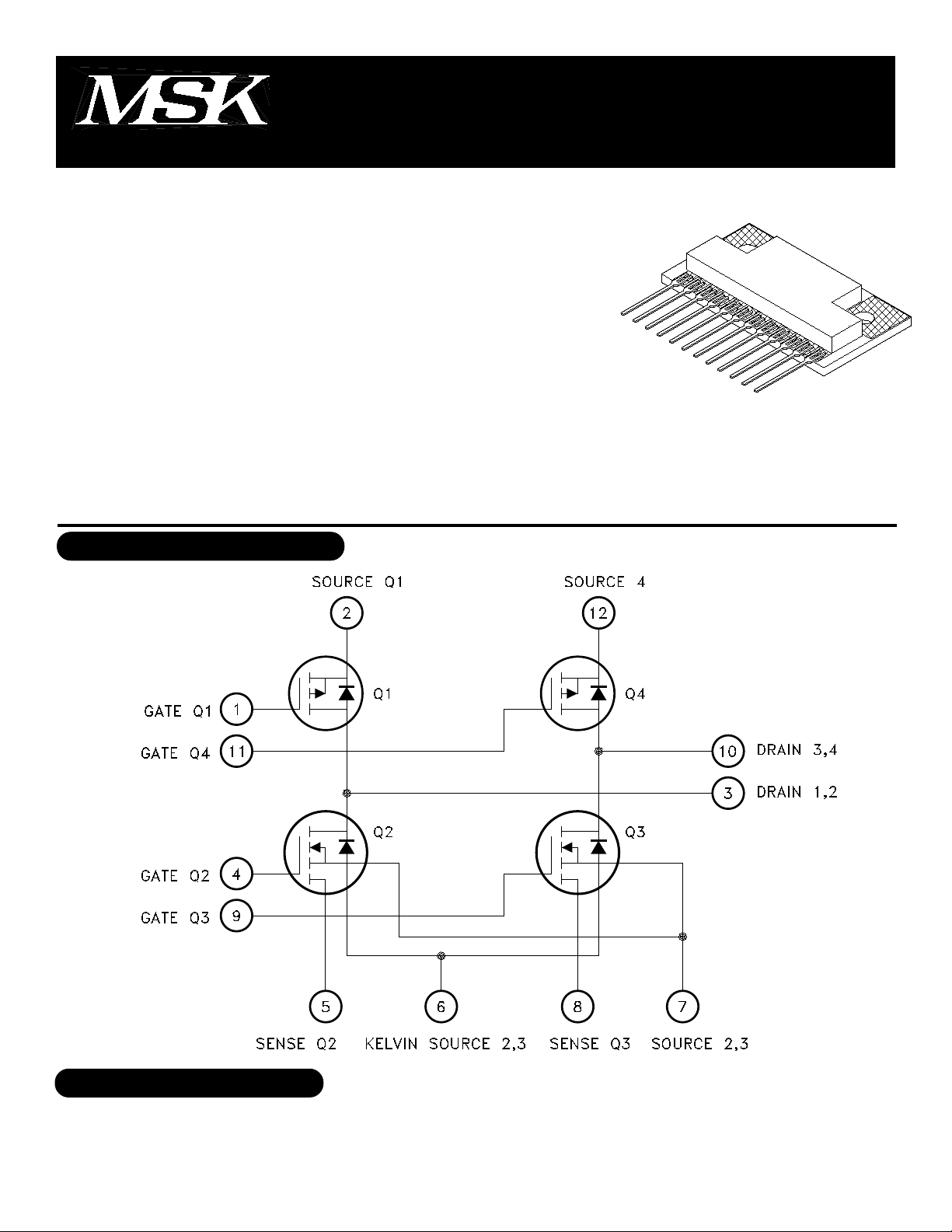

The MSK 3002 is an H-bridge power circuit packaged in a space efficient isolated ceramic tab power SIP package.

The MSK 3002 consists of P-Channel MOSFETs for the top transistors and N-Channel MOSFETs for the bottom

transistors. The N Channel MOSFETS are current sensing to allow for low loss current sensing for current controlled

applications. The MSK 3002 uses M.S. Kennedy's proven power hybrid technology to bring a cost effective high

performance circuit for use in today's sophisticated servo motor and disk drive systems. The MSK 3002 is pin

compatible with the MPM3002 and MPM3010 with some differences in specifications.

EQUIVALENT SCHEMATIC

MOSFET POWER MODULE

3002

TYPICAL APPLICATIONS

• Stepper Motor Servo Control

• Disk Drive Head Control

• X-Y Table Control

• Az-El Antenna Control

1

Rev. C 7/00

Page 2

ABSOLUTE MAXIMUM RATINGS

VDSS Drain to Source Voltage 55V MAX

○○○○○○

VDGDR Drain to Gate Voltage

(RGS = 1 MΩ) 55V MAX

○○○○○○○○○○○

VGS Gate to Source Voltage

(Continuous) ±20V MAX

ID Continuous Current 10A MAX

IDM Pulsed Current 25A MAX

○○○○○○○○○○○

○○○○○○○○

○○○○○○○○○○○

RTH-JC Thermal Resistance

(Junction to Case) 7.9°C/W

IM Sense Current - Continuou 13 mA MAX

IMM Sense Current Peak 33 mA MAX

○○○○○○○○○

○○

○○○○○○

Single Pulse Avalanche Energy

(Q1,Q4) 6.0J

(Q2,Q3) 71 mJ

TJ JunctionTemperature +175°CMAX

TST Storage Temperature -55°C to +150°C

TC Case Operating Temperature Range -55°C to +125°C

○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○

○○○○○○○○○○○○

○○○

TLD Lead Temperature Range

(10Seconds) 300°C MAX

○○○○○○○○○○○○○○○○○○○

ELECTRICAL SPECIFICATIONS

Parameter Test Conditions 4

Drain-Source Breakdown Voltage

Drain-Mirror Breakdown Voltage

Drain-Source Leakage Current

Gate-Source Leakage Current

Gate-Source Threshold Voltage

Drain-Source on Resistance 2

Drain-Source on Resistance 3

Forward Transconductance 1

N-CHANNEL (Q2, Q3)

Total Gate Charge 1

Gate-Source Charge 1

Gate-Drain Charge 1

Turn-On Delay Time 1

Rise Time 1

Turn-Off Delay Time 1

Fall Time 1

Input Capacitance 1

Output Capacitance 1

Reverse Transfer Capacitance 1

Output Capacitance of Sensing Cells 1

Current Sensing Ratio 1

P-CHANNEL (Q1, Q4)

Total Gate Charge 1

Gate-Source Charge 1

Gate-Drain Charge 1

Turn-On Delay Time 1

Rise Time 1

Turn-Off Delay Time 1

Fall Time 1

Input Capacitance 1

Output Capacitance 1

Reverse Transfer Capacitance 1

BODY DIODE

Forward on Voltage 1

Reverse Recovery Time 1

Reverse Recovery Charge 1

VGS = 0 ID = 0.25 mA (All Transistors)

GS = 0 VDS = 55V, (Q2, Q3)

V

VDS = 55V VGS = 0V, (Q2, Q3)

DS = -55V VGS = 0V, (Q1, Q4)

V

VGS = ±20V VDS = 0V (All Transistors)

V

DS = VGS ID = 250 µA (Q2, Q3)

VDS = VGS ID = 250 µA (Q1, Q4)

V

GS = 10V ID = 10A (Q2, Q3)

VGS = -10V ID = -7.2A (Q1, Q4)

V

GS = 10V ID = 10A (Q2, Q3)

VGS = -10V ID = -7.2A (Q1, Q4)

V

DS = 25V ID = 10A (Q2, Q3)

VDS = -25V ID = -7.2A (Q1, Q4)

I

D = 17A

DS = 48V

V

VGS = 10V

VDD = 30V

ID = 17A

G = 18Ω

R

D = 1.7Ω

R

V

GS = 0V

V

DS = 25V

f = 1 MHz

I

D = 17A

ID = -7.2A

VDS = -44V

VGS = -10V

V

DD = -28V

ID = -7.2A

R

G = 24Ω

RD = 3.7Ω

GS = 0V

V

VDS = -25V

f = 1 MHz

S = 17A VGS = 0V (Q2, Q3)

I

I

S = -7.2A VGS = 0V (Q1, Q4)

IS = 17A di/dt = 100A/µS (Q2, Q3)

IS = -7.2A di/dt = 100A/µS (Q1, Q4)

I

S = 17A di/dt = 100A/µS (Q2, Q3)

I

S = -7.2A di/dt = 100A/µS (Q1, Q4)

-2.0

740

NOTES:

1 This parameter is guaranteed by design but need not be tested. Typical parameters are representative of actual device performance but

are for reference only.

2 Resistance as seen at package pins.

3 Resistance for die only; use for thermal calculations.

4TA = 25°C unless otherwise specified.

2

Min.

55

55

-

-

-

2.0

-

-

-

-

5.8

2.5

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

MSK 3002

Typ.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

12

59

25

38

720

360

75

14

-

-

-

-

13

55

23

37

350

170

92

1.5

-1.6

87

47

0.29

0.084

Max.

-

-

25

-25

±100

4.5

-4.5

0.20

0.28

0.10

0.175

-

-

24

6.3

9

-

-

-

-

-

-

-

-

820

19

5.1

10

-

-

-

-

-

-

-

-

-

180

71

0.60

0.13

Rev. C 7/00

Units

V

V

µA

µA

nA

V

V

Ω

Ω

Ω

Ω

S

S

nC

nC

nC

nS

nS

nS

nS

pF

pF

pF

pF

r

nC

nC

nC

nS

nS

nS

nS

pF

pF

pF

V

V

nS

nS

µC

µC

Page 3

APPLICATION NOTES

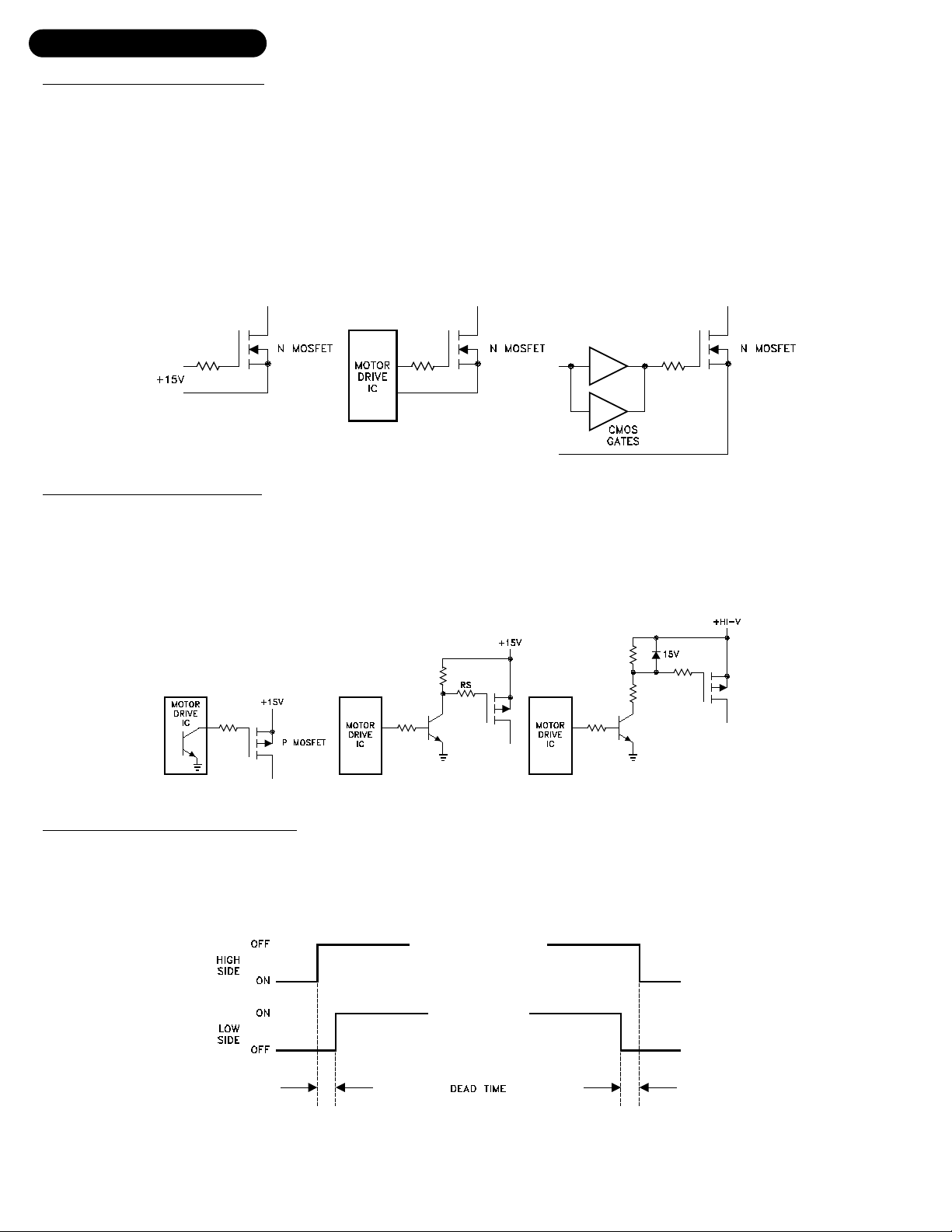

N-CHANNEL GATES (Q2, Q3):

For driving the N-Channel gates, it is important to keep in mind that it is essentially like driving a capacitance to a sufficient

voltage to get the channel fully on. Driving the gates to +15 volts with respect to their sources assures that the transistors

are on. This will keep the dissipation down to a minimum level. How quickly the gate gets turned ON and OFF will

determine the dissipation of the transistor while it is transitioning from OFF to ON and vice-versa. Turning the gate ON and

OFF too slow will cause excessive dissipation, while turning it ON and OFF too fast will cause excessive switching noise in

the system. It is important to have as low a driving impedance as practical for the size of the transistor. Many motor drive

IC's have sufficient gate drive capability for the MSK 3002. If not, paralleled CMOS standard gates will usually be

sufficient. A series resistor in the gate circuit slows it down, but also suppresses any ringing caused by stray iductances

in the MOSFET circuit. The selection of the resistor is determined by how fast the MOSFET wants to be switched. See

Figure 1 for circuit details.

FIGURE 1

P-CHANNEL GATES (Q1, Q4):

Most everything applies to driving the P-Channel gates as the N-Channel gates. The only difference is that the P-Channel

gate to source voltage needs to be negative. Most motor drive IC's are set up with an open collector or drain output for

directly interfacing with the P-Channel gates. If not, an external common emitter switching transistor configuration (see

Figure 2) will turn the P-Channel MOSFET on. All the other rules of MOSFET gate drive apply here. For high supply

voltages, additional circuitry must be used to protect the P-Channel gate from excessive voltages.

FIGURE 2

BRIDGE DRIVE CONSIDERATIONS:

It is important that the logic used to turn ON and OFF the various transistors allow sufficient "dead time" between a high

side transistor and its low side transistor to make sure that at no time are they both ON. When they are, this is called

"shoot-through" and it places a momentary short across the power supply. This overly stresses the transistors and causes

excessive noise as well. See Figure 3.

FIGURE 3

This deadtime should allow for the turn on and turn off time of the transistors, especially when slowing them down with

gate resistors. This situation will be present when switching motor direction, or when sophisticated timing schemes are

used for servo systems such as locked antiphase PWM'ing for high bandwidth operation.

3

Rev. C 7/00

Page 4

APPLICATION NOTES, CONT.

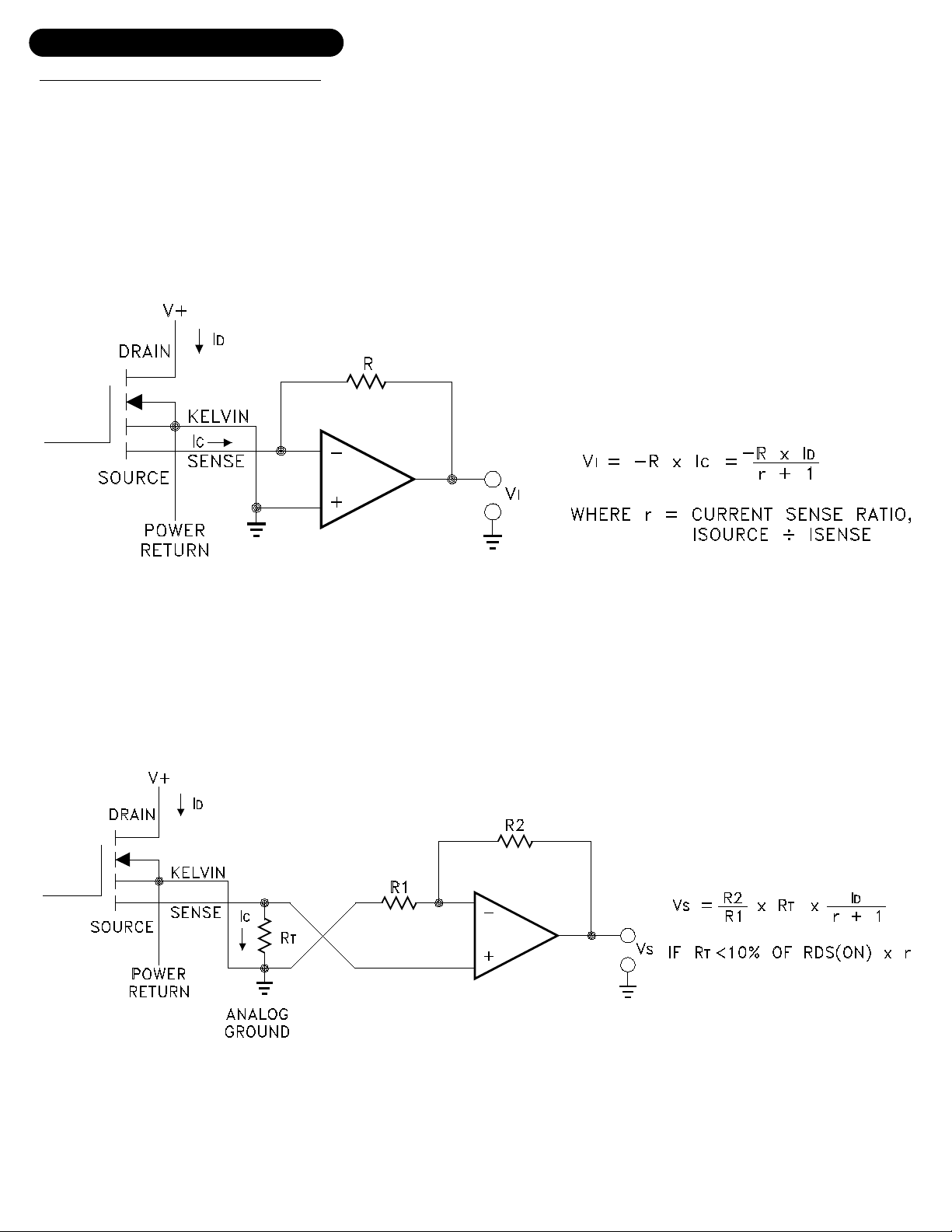

USING CURRENT SENSING MOSFETS:

A MOSFET transistor is constructed of many individual MOSFET cells connected in parallel. They share the current total

very evenly. If one of these cells are brought out to a pin, that cell will pass an accurate proportional amount of the total

current. This current can be used as a low power sense of the whole current without passing that whole current through a

sensing device like a resistor. This small current multiplied by the ratio specified on the data sheet equals the whole current.

There are several methods of working with the sense function to obtain the actual current.

1. Virtual Earth Sensing

The disadvantage is amplifying a current swing of 10 amps in 100 nSec to produce a 5V output means the op amp has to

slew 50V/µSec. This is beyond the capabilities of a lot of op amps.

2. Resistor Sensing

The disadvantage is RT voltage must be above the offset voltage of the op amp and RT must be much less than RDS(ON) of

the sensing cell or temperature shifts will affect accuracy.

4

Rev. C 7/00

Page 5

TYPICAL PERFORMANCE CURVES

5

Rev. C 7/00

Page 6

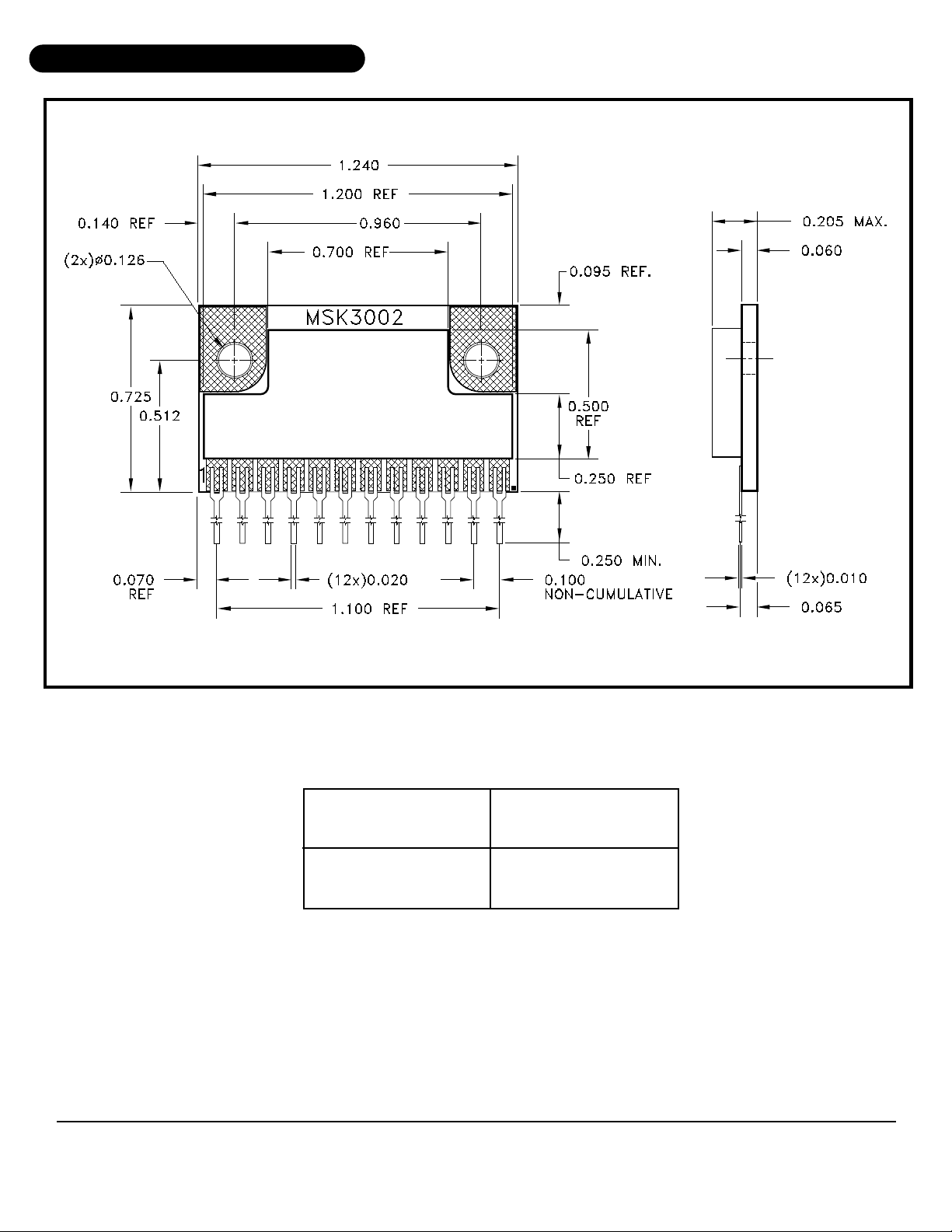

MECHANICAL SPECIFICATIONS

TORQUE SPECIFICATION 3 TO 5 IN/LBS. NYLON SCREWS OR WASHERS ARE RECOMMENDED.

ALL DIMENSIONS ARE ±0.010 INCHES UNLESS OTHERWISE SPECIFIED.

ORDERING INFORMATION

PART

NUMBER

MSK 3002

M.S. Kennedy Corp.

4707 Dey Road, Liverpool, New York 13088

Phone (315) 701-6751

FAX (315) 701-6752

www.mskennedy.com

SCREENING LEVEL

Industrial

The information contained herein is believed to be accurate at the time of printing. MSK reserves the right to make

changes to its products or specifications without notice, however, and assumes no liability for the use of its products.

6

Rev. C 7/00

Loading...

Loading...