Page 1

ISO 9001 CERTIFIED BY DSCC

HIGH SPEED, BUFFER

AMPLIFIER AMP

0002

M.S.KENNEDY CORP.

4707 Dey Road Liverpool, N.Y. 13088

FEATURES:

Industry Wide LH0002 Replacement

High Input Impedance-180KΩ Min

Low Output Impedance-10Ω Max

Low Harmonic Distortion

DC to 30 MHz Bandwidth

Slew Rate is Typically 400 V/µS

Operating Range from±5V to ±20V

Available to DSCC SMD5962-7801301XC

MIL-PRF-38534 CERTIFIED

(315) 701-6751

DESCRIPTION:

The MSK 0002 is a general purpose current amplifier. It is the industry wide replacement for the LH0002. The

device is ideal for use with an operational amplifier in a closed loop configuration to increase current output. The MSK

0002 is designed with a symmetrical output stage that provides low output impedances to both the positive and

negative portions of output pulses. The MSK 0002 is packaged in a hermetic 8 lead low profile T0-5 header and is

specified over the full military temperature range.

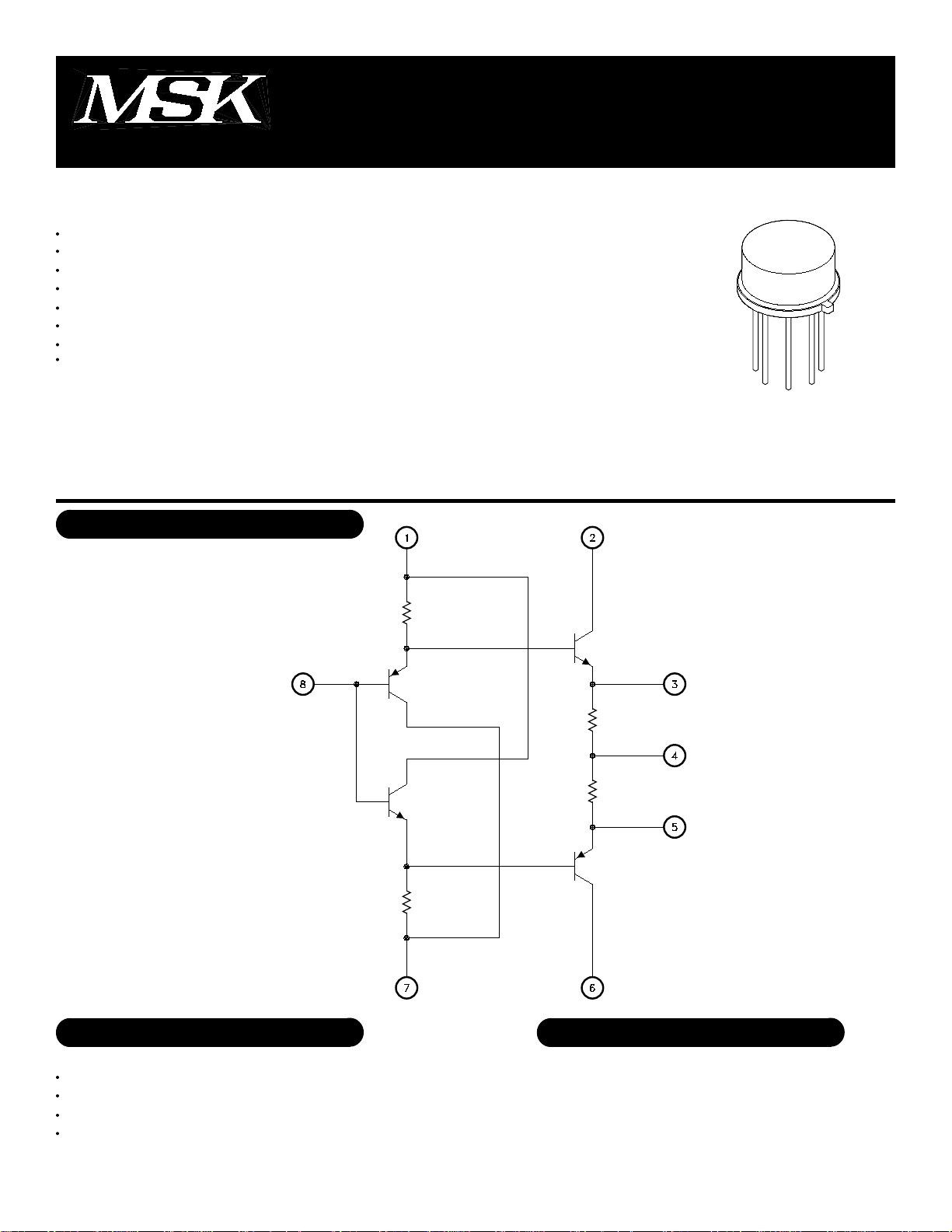

EQUIVALENT SCHEMATIC

TYPICAL APPLICATIONS

High Speed D/A Conversion

30MHz Buffer

Line Driver

Precision Current Source

PIN-OUT INFORMATION

V1+

1

V2+

2

E3

3

Output

4

1

5

E4

6

V2-

7

V1-

8

Input

Rev. - 10/00

Page 2

ABSOLUTE MAXIMUM RATINGS

Supply Voltage

±VCC

Input Voltage

VIN

Power Dissipation

Pd

Case Operating Temperature

Tc

(MSK 0002H)

(MSK 0002)

○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○

○○○○○○○○○○

○○○○○○○○○○

ELECTRICAL SPECIFICATIONS

±22V

±22V

600mW

-55°C to +125°C

-40°C to +85°C

TST

Storage Temperature Range

TLD

Lead Temperature Range

(10 Seconds)

TJ

Junction Temperature

θjC

Thermal Resistance

-65°C to +150°C

○○○○○○○○○○

○○○○○○○○○○○○

○○○○○○○○○○○○○

+300°C

+175°C

40°C/W

Parameter

Quiescent Current

Input Offset Current

Input Offset Voltage

Input Impedance

Output Impedance

3

3

Output Voltage Swing

Voltage Gain

2

Rise Time

Test Conditions

1

VIN=0V

RS=10KΩ RL=1.0KΩ

RS=10KΩ RL=1.0KΩ

RS=300Ω RL=1.0KΩ

VIN=1.0VRMS RS=200KΩ

RL=1KΩ f=1.0KHz

VIN=1.0VRMS Rs=10KΩ

RL=50Ω f=1.0KHz

VIN=±12Vp RL=1.0KΩ

f=1.0KHz

VIN=±10Vp RL=100Ω

+VCC=±15V f=1.0KHz

VIN=3.0VPP f=1.0KHz

RS=10KΩ RL=1.0KΩ

VOUT=2.5VPP f=10KHz

RS=100Ω RL=50Ω

Group A

Subgroup

1

1

2,3

1

2,3

4

4

4

4

4

5,6

4

MSK 0002H

Min. Typ. Max.

±6.3

±2

±2

±6

±10

-

-

±11

-

0.97

-

8

±10

±10

±10

±30

±30

10

12

-

-

-

-

-

180

-

±10

±9.5

0.95

0.95

-

4

MSK 0002

Min. Typ. Max.

-

-

-

-

-

-

180

-

-

±10

-

±9.5

0.95

-

-

-

-

±6.3

±2

-

±6

-

-

-

±11

-

0.97

-

8

±10

±10

-

±30

-

-

10

-

-

-

-

12

Units

mA

µA

µA

mV

mV

KΩ

Ω

Vp

Vp

V/V

V/V

nS

NOTES:

1

Unless otherwise specified ±V

2

Subgroups 5 & 6 shall be tested as part of device initial characterization and after design

and process changes. Parameter shall be guaranteed to the limits specified for subgroups

5 & 6 for all lots not specifically tested.

3

Devices shall be capable of meeting the parameter, but need not be tested.

4

Subgroup 1,4 TA=TC=+25°C

Subgroup 2,5 TA=TC=+125°C

Subgroup 3,6 TA=TC=-55°C

CC=±12VDC

Rev. - 10/002

Page 3

APPLICATION NOTES

HEAT SINKING

To determine if a heat sink is necessary for your application

and if so, what type, refer to the thermal model and governing

equation below.

Thermal Model:

R

ΘSA = ((TJ - TA)/PD) - (RΘJC) - (RΘCS)

= ((125°C - 80°C) / 0.36W) - 40°C/W - 0.15°C/W

= 125 - 40.15

= 84.9°C/W

This heat sink in this example must have a thermal resistance

of no more than 84.9°C/W to maintain a junction temperature

of no more than +125°C.

Typical Applications:

Governing Equation:

TJ=PD X (RΘJC +RΘCS +RΘSA) +TA

Where

TJ=Junction Temperature

PD=Total Power Dissipation

RΘJC=Junction to Case Thermal Resistance

RΘCS=Heat Sink to Ambient Thermal Resistance

TC=Case Temperature

TA=Ambient Temperature

TS=Sink Temperature

Example:

This example demonstrates a worst case analysis for the buffer

output stage. This occurs when the output voltage is 1/2 the

power supply voltage. Under this condition, maximum power

transfer occurs and the output is under maximum stress.

Conditions:

VCC= ±12VDC

Vo= ±6Vp Sine Wave, Freq. = 1KHz

RL= 100Ω

For a worst case analysis we will treat the ±6Vp sine wave as

an 6 VDC output voltage.

1.) Find Driver Power Dissipation

PD= (Vcc-Vo) (Vo/RL)

= (12V-6V) (6V/100Ω)

= 360mW

2.) For conservative design, set TJ=+125°C Max.

3.) For this example, worst case TA=+80°C

4.) RΘJC = 40° C/W from MSK 0002H Data Sheet

5.) RΘCS = 0.15° C/W for most thermal greases

6.) Rearrange governing equation to solve for RΘSA

Rev. - 10/003

Page 4

TYPICAL PERFORMANCE CURVES

4

Rev. - 10/00

Page 5

MECHANICAL SPECIFICATIONS

ALL DIMENSIONS ARE ±0.010 INCHES UNLESS OTHERWISE LABELED

ORDERING INFORMATION

Part

Number

MSK0002

MSK0002H

7801-301XC

M.S. Kennedy Corp.

4707 Dey Road, Liverpool, New York 13088

Phone (315) 701-6751

FAX (315) 701-6752

www.mskennedy.com

The information contained herein is believed to be accurate at the time of printing. MSK reserves the right to make

changes to its products or specifications without notice, however, and assumes no liability for the use of its products.

Screening Level

Industrial

Military-Mil-PRF-38534

DSCC-SMD

Rev. - 10/005

Loading...

Loading...