Page 1

SEMICONDUCTOR TECHNICAL DATA

1

REV 0

Motorola, Inc. 1997

9/97

The MPC993 is a PLL clock driver designed specifically for redundant

clock tree designs. The device receives two differential LVPECL clock

signals from which it generates 5 new differential LVPECL clock outputs.

Two of the output pairs regenerate the input signals frequency and phase

while the other three pairs generate 2x, phase aligned clock outputs.

External PLL feedback is used to also provide zero delay buffer

performance.

• Fully Integrated PLL

• Intelligent Dynamic Clock Switch

• LVPECL Clock Outputs

• LVCMOS Control/Statis I/O

• 3.3V Operation

• 32–Lead TQFP Packaging

• ±50ps Cycle–Cycle Jitter

The MPC993 continuously monitors the two input signals to identify faulty reference clocks. Upon identification of a faulty

input clock (input clock stuck HIGH or LOW for at least 3 feedback clock edges), an input bad flag will be set and the device will

automatically switch from the bad reference clock input to the good one. During this dynamic switch of the input references, the

MPC993 outputs will slew, with minimal period disturbances to the new phase.

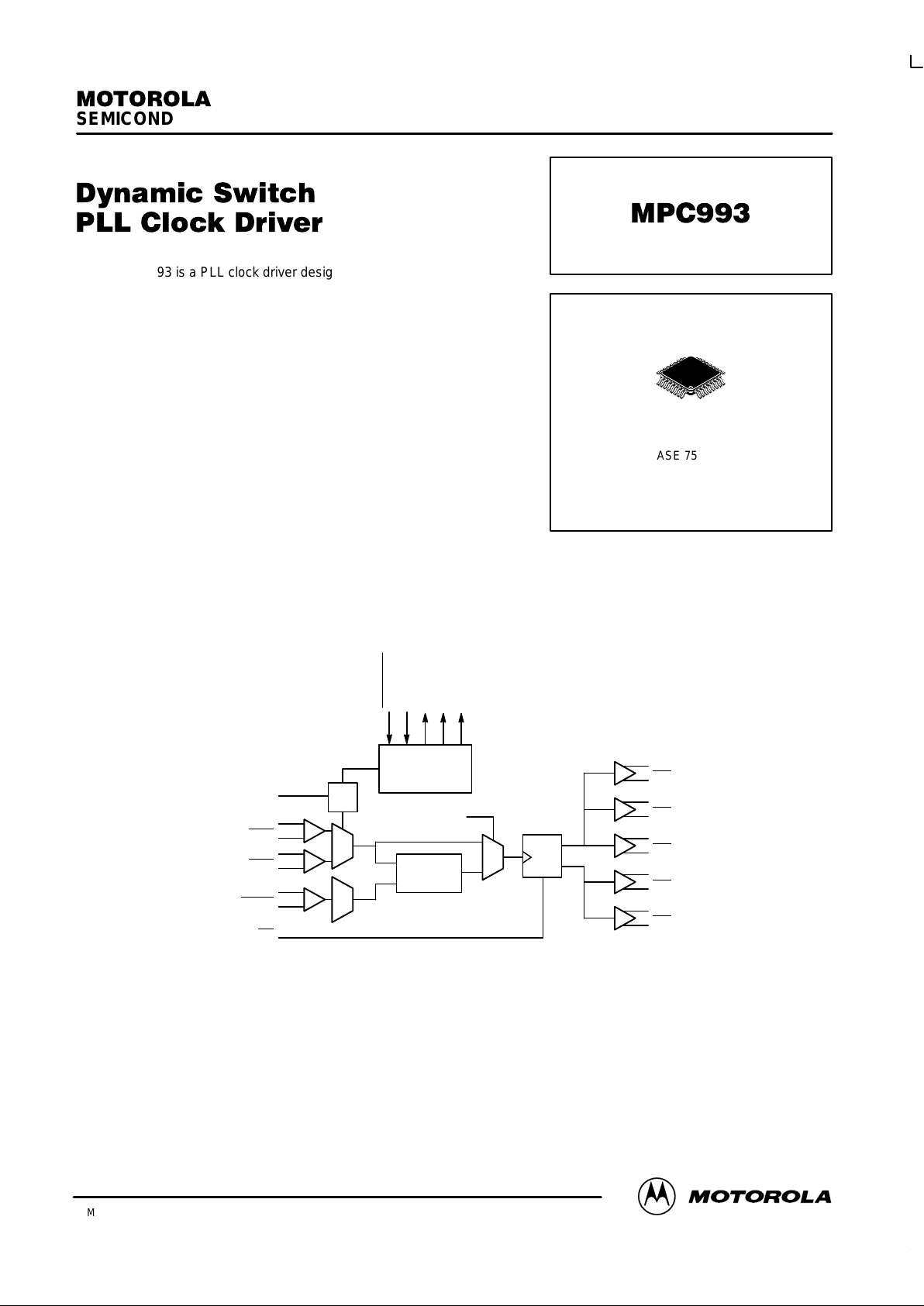

Figure 1. Block Diagram

CLK0

CLK0

CLK1

CLK1

Ext_FB

Ext_FB

OR

Sel_Clk

Dynamic Switch

Logic

PLL

PLL_En

÷

2

÷

4

Qb0

Qb0

Qb1

Qb1

Qb2

Qb2

Qa0

Qa0

Qa1

Qa1

MR

Man_OVerride

Alarm_Reset

Inp0bad

Inp1bad

Clk_Selected

FA SUFFIX

32–LEAD PLASTIC TQFP PACKAGE

CASE 751D–04

Page 2

MPC993

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

2

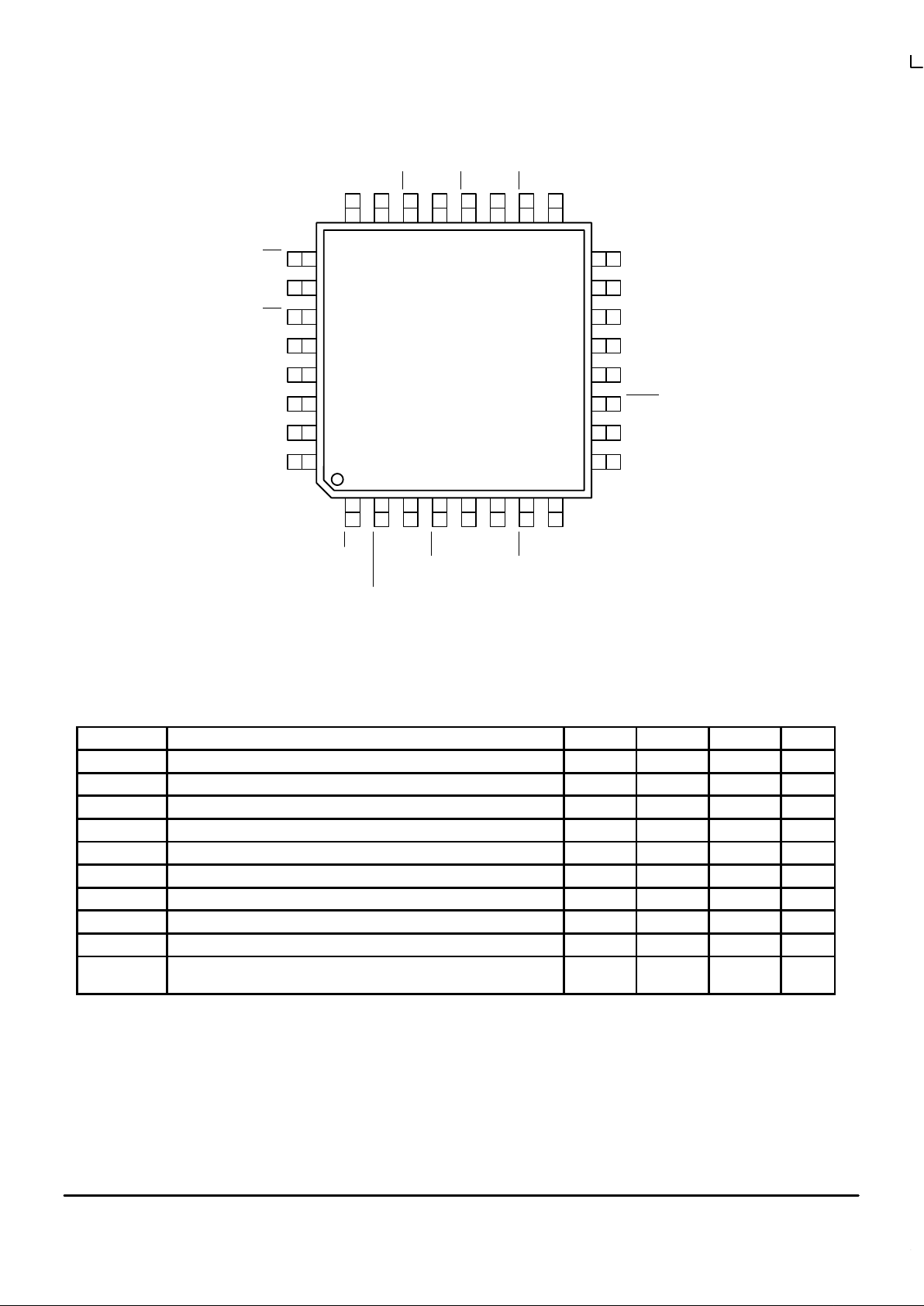

Figure 2. 32–Lead Pinout (Top View)

GND

VCC

Qb0

Qb0

Qb1

Qb1

Qb2

Qb2

VCC

MR

Alarm_Reset

CLK0

CLK0

Sel_Clk

CLK1

CLK1

GNDA

25

26

27

28

29

30

31

32

15

14

13

12

11

10

9

12345678

24 23 22 21 20 19 18 17

16

PRELIMINARY

MPC993

Ext_FB

Ext_FB

GND

Clk_Selected

Inp1bad

Inp0bad

VCC

PLL_En

Man_Override

VCCA

VCC

Qa0

Qa0

Qa1

Qa1

3.3V PECL DC Characteristics (TA = 0°C to 70°C)

Symbol Parameter Min Typ Max Unit

V

OH

Output HIGH Voltage (LVPECL Outputs) 2.275 2.345 2.420 V

V

OH

Output HIGH Voltage (LVCMOS Outputs) 2.4 V

V

OL

Output LOW Voltage (LVPECL Outputs) 1.490 1.595 1.680 V

V

OL

Output LOW Voltage (LVCMOS Outputs) 0.5 V

V

IH

Input HIGH Voltage (LVPECL Outputs) 2.135 2.420 V

V

IH

Input HIGH Voltage (LVCMOS Outputs) 2.0 3.3 V

V

IL

Input LOW Voltage (LVPECL Outputs) 1.490 1.825 V

V

IL

Input LOW Voltage (LVCMOS Outputs) 0.8 V

I

IL

Input LOW Current 0.5 µA

I

EE

Power Supply Current GNDA

GND

15

80

mA

Page 3

MPC993

3 MOTOROLAECLinPS and ECLinPS Lite

DL140 — Rev 3

3.3V PECL AC Characteristics (TA = 0°C to 85°C)

Symbol Parameter Min Typ Max Unit

f

VCO

Maximum VCO Frequency 480 MHz

t

pwi

25 75 %

t

pd

Propagation Delay (Note 1.) CLKn to Q (Bypass)

CLKn to Q (Locked (Note 2.))

X–500

Y–150

2000

0

X+500

Y+150

ps

tr/t

f

Output Rise/Fall Time 200 800 ps

t

skew

Output Skew Within Bank

All Outputs

50

100

ps

∆

pe

Maximum Phase Error Deviation TBD (Note 3.)

TBD (Note 4.)

ps

∆

per/cycle

Rate of Change of Periods 75MHz Output (Note 3.)

150MHz Output (Note 3.)

75MHz Output (Note 4.)

150MHz Output (Note 4.)

20

10

TBD

TBD

ps

t

pw

Output Duty Cycle 45 55 %

t

jitter

Cycle–to–Cycle Jitter 50 ps

t

lock

Maximum PLL Lock Time 10 ms

1. These values represent simulation results. Final values will be determined from silicon measurements and may be adjusted slightly.

2. Static phase offset between the selected reference clock and the feedback signal.

3. Specification holds for a clock switch between two signals no greater than 400ps out of phase. Delta period change per cycle is averaged over

the clock switch excursion. (See Applications Information section on page 4 for more detail)

4. Specification holds for a clock switch between two signals no greater than ±π out of phase. Delta period change per cycle is averaged over the

clock switch excursion.

PIN DESCRIPTIONS

Pin Name I/O Pin Definition

CLK0, CLK0

CLK1, CLK1

LVPECL Input

LVPECL Input

Differential PLL clock reference (CLK0 pulldown, CLK0 pullup)

Differential PLL clock reference (CLK1 pulldown, CLK1

pullup)

Ext_FB, Ext_FB LVPECL Input Differential PLL feedback clock (Ext_FB pulldown, Ext_FB pullup)

Qa0:1, Qa0:1 LVPECL Output Differential 1x output pairs

Qb0:2, Qb0:2 LVPECL Output Differential 2x output pairs

Inp0bad LVCMOS Output Indicates detection of a bad input reference clock 0 with respect to the feedback signal. The output

is active HIGH and will remain HIGH until the alarm reset is asserted

Inp1bad LVCMOS Output Indicates detection of a bad input reference clock 1 with respect to the feedback signal. The output

is active HIGH and will remain HIGH until the alarm reset is asserted

Clk_Selected LVCMOS Output ‘0’ if clock 0 is selected, ‘1’ if clock 1 is selected

Alarm_Reset LVCMOS Input ‘0’ will reset the input bad flags and align Clk_Selected with Sel_Clk. The input is “one–shotted”

(75Ω pullup)

Sel_Clk L VCMOS Input ‘0’ selects CLK0, ‘1’ selects CLK1 (75Ω pulldown)

Manual_Override L VCMOS Input ‘1’ disables internal clock switch circuitry (75Ω pulldown)

PLL_En LVCMOS Input ‘0’ bypasses selected input reference around the phase–locked loop (75Ω pulldown)

MR LVCMOS Input ‘0’ resets the internal dividers forcing Q outputs LOW. Asynchronous to the clock (75Ω pullup)

VCCA Power Supply PLL power supply

VCC Power Supply Digital power supply

GNDA Power Supply PLL ground

GND Power Supply Digital ground

Page 4

MPC993

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

4

The MPC993 is a single switch circuit. The device

continuously monitors the two input signals to identify faulty

reference clocks. A clock is considered faulty if it has been

stuck LOW or HIGH for 3 consecutive feedback clock edges

(rising or falling). Upon identifying a faulty reference clock, an

input bad flag (Inp0bad or Inp1bad) corresponding to the

faulty clock will be set. If the PLL was currently locked to the

input signal that goes bad, the MPC993 will automatically

switch to the other clock provided it is operational. The input

bad flags will remain set until an Alarm_Reset

is asserted.

The Alarm_Reset

input is an active LOW input that will reset

the input bad flag(s). Note that the Alarm_Reset

is one

shotted, thus if upon clearing the input bad flags the inputs

are still bad the flags will be reset without the Alarm_Reset

pin being negated.

If both of the input signals go bad simultaneously the

MPC993 PLL will lose lock and the VCO will drift to an

indeterminate frequency. Once the MPC993 switches from a

bad clock it will continue to use the new clock until the

Alarm_Reset

pin is asserted. The device will not switch back

to a “repaired” bad input clock until the Alarm_Reset

is

asserted. Asserting the Alarm_Reset

pin forces the

Clk_Selected output to match the Sel_Clk input. Users

identify their primary clock via the Sel_Clk input. If not faulty

the MPC993 will always lock to this clock source in the

normal mode of operation. The only time clock Clk_Selected

does not equal Sel_Clk is when the device is in automatic

switch mode and the primary clock source is faulty. In this

condition the MPC993 will have switched to the secondary

clock and Clk_Selected will be in the opposite state as

Sel_Clk. Note that when in manual override (Man_Override

input is asserted) Clk_Selected will always equal Sel_Clk

regardless of the condition of the input bad flags.

Upon detection and switch from a “bad” input to a “good”

one, the internal PLL of the MPC993 will ensure a smooth

phase transition from the original to the new reference clock

source. The magnitudes of the disturbances seen in the

output clocks are detailed in the AC tables of this data sheet.

The two datasheet specifications are the maximum phase

error deviation and the rate of change of the output periods

during a reference clock switch. The maximum phase error

deviation describes the change in the input/output phase

difference caused by a switch between two out–of–phase

references. The rate of change periods describes the

behavior of the output signals from the MPC993 as it requires

phase–lock to the new reference source. Two different

conditions are specified, one for a maximum phase deviation

of the two clock sources of ≤±400ps and the other for phase

deviations of ≤±π. Under these conditions the MPC993 will be

guaranteed to take the “shortest path” to regain phase lock.

That is for a phase difference of –300ps, the output phase will

slew 300ps to align to the new phase as opposed to travelling

one clock period minus 300ps in the other direction. This

guarantee will ensure phase coherency in a clocking scheme

in which multiple MPC993’s are synchronized in a clock tree

and a subset of the devices under go a dynamic switch. Note

if the phase of the two input clock sources differs by more

than ±π the direction of phase lock cannot be guaranteed.

To calculate the overall uncertainty between any clocks

from multiple MPC993’s the following procedure should be

followed. Assuming that the reference clocks to the multiple

MPC993’s are exactly in phase, the total uncertainty will be

the combination of the static phase offset uncertainty

between the reference and feedback clocks, plus the

uncertainty between the feedback clock and the other clock

outputs, plus the jitter between the reference clock and

feedback clock inputs to the PLL. Based on the preliminary

data sheet specifications on this data sheet the total

uncertainty between CPU clocks would be 300ps + 50ps +

200ps or 550ps. The numbers used to derive this are the

Tpd, Output Skew and I/O jitter numbers respectively. Any

uncertainty in the phase of the reference clocks between the

different MPC993’s will add directly to this calculated

uncertainty.

During a dynamic switch the part to part skew between

two devices may be increased for a short period of time. In

the condition that only a subset of a number of parallel

MPC993’s under go a dynamic switch an additional

component will need to be added to the part to part skew of

the device during this transient event. If the two reference

clocks are 400ps out of phase a dynamic switch of an

MPC993 will lead to an instantaneous change of the input

phase by 400ps without a corresponding change in the

output phase due to the limited bandwidth of the PLL. As a

result the delay through a device under going the above

described switch will change by 400ps until the PLL has an

opportunity to slew to its new phase. This transient timing

issue should be considered when analyzing the overall skew

budget of a system.

The MPC993 inputs are not designed for “hot insertion”

applications when the device is used in a PECL environment.

In an ECL environment the reference clock inputs to the

device are hot insertion compatible. However in a PECL

environment a powered down receiver will present a low

impedance connection to ground to a powered up driver. To

make the MPC993 hot insertion compatible in a PECL

environment series resistance needs to be added in front of

the input reference clock pins to limit the current in the above

mentioned case. For a 3.3V PECL environment a 100Ω

series resistor will be sufficient to limit the current to

acceptable levels for both the driver and the receiver. A 100Ω

series resistor on the reference clock inputs will have minimal

impact on the rise and fall times of the input signals.

Page 5

MPC993

5 MOTOROLAECLinPS and ECLinPS Lite

DL140 — Rev 3

OUTLINE DIMENSIONS

FA SUFFIX

PLASTIC TQFP PACKAGE

CASE 873A–02

ISSUE A

DETAIL Y

A

S1

VB

1

8

9

17

25

32

AE

AE

P

DETAIL Y

BASE

N

J

DF

METAL

SECTION AE–AE

G

SEATING

PLANE

R

Q

_

W

K

X

0.250 (0.010)

GAUGE PLANE

E

C

H

DETAIL AD

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DATUM PLANE –AB– IS LOCATED AT BOTTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY AT

THE BOTTOM OF THE PARTING LINE.

4. DATUMS –T–, –U–, AND –Z– TO BE DETERMINED

AT DATUM PLANE –AB–.

5. DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE –AC–.

6. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS

0.250 (0.010) PER SIDE. DIMENSIONS A AND B

DO INCLUDE MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE –AB–.

7. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

NOT CAUSE THE D DIMENSION TO EXCEED

0.520 (0.020).

8. MINIMUM SOLDER PLATE THICKNESS SHALL BE

0.0076 (0.0003).

9. EXACT SHAPE OF EACH CORNER MAY VARY

FROM DEPICTION.

DIMAMIN MAX MIN MAX

INCHES

7.000 BSC 0.276 BSC

MILLIMETERS

B 7.000 BSC 0.276 BSC

C 1.400 1.600 0.055 0.063

D 0.300 0.450 0.012 0.018

E 1.350 1.450 0.053 0.057

F 0.300 0.400 0.012 0.016

G 0.800 BSC 0.031 BSC

H 0.050 0.150 0.002 0.006

J 0.090 0.200 0.004 0.008

K 0.500 0.700 0.020 0.028

M 12 REF 12 REF

N 0.090 0.160 0.004 0.006

P 0.400 BSC 0.016 BSC

Q 1 5 1 5

R 0.150 0.250 0.006 0.010

V 9.000 BSC 0.354 BSC

V1 4.500 BSC 0.177 BSC

__

____

DETAIL AD

A1

B1

V1

4X

S

4X

B1 3.500 BSC 0.138 BSC

A1 3.500 BSC 0.138 BSC

S 9.000 BSC 0.354 BSC

S1 4.500 BSC 0.177 BSC

W 0.200 REF 0.008 REF

X 1.000 REF 0.039 REF

9

–T–

–Z–

–U–

T–U0.20 (0.008) ZAC

T–U0.20 (0.008) ZAB

0.10 (0.004) AC

–AC–

–AB–

M

_

8X

–T–, –U–, –Z–

T–U

M

0.20 (0.008) ZAC

Page 6

MPC993

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

6

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

MPC993/D

◊

Mfax is a trademark of Motorola, Inc.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.: SPD, Strategic Planning Office, 4–32–1,

P.O. Box 5405, Denver, Colorado 80217. 1–303–675–2140 or 1–800–441–2447 Nishi–Gotanda, Shinagawa–ku, Tokyo 141, Japan. 81–3–5487–8488

Customer Focus Center: 1–800–521–6274

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 1–602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

Moto rola Fax Back System – US & Canada ONLY 1–800–774–1848 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

– http://sps.motorola.com/mfax/

HOME PAGE: http://motorola.com/sps/

Loading...

Loading...