Page 1

SEMICONDUCTOR TECHNICAL DATA

1

REV 3

Motorola, Inc. 1996

10/96

! !

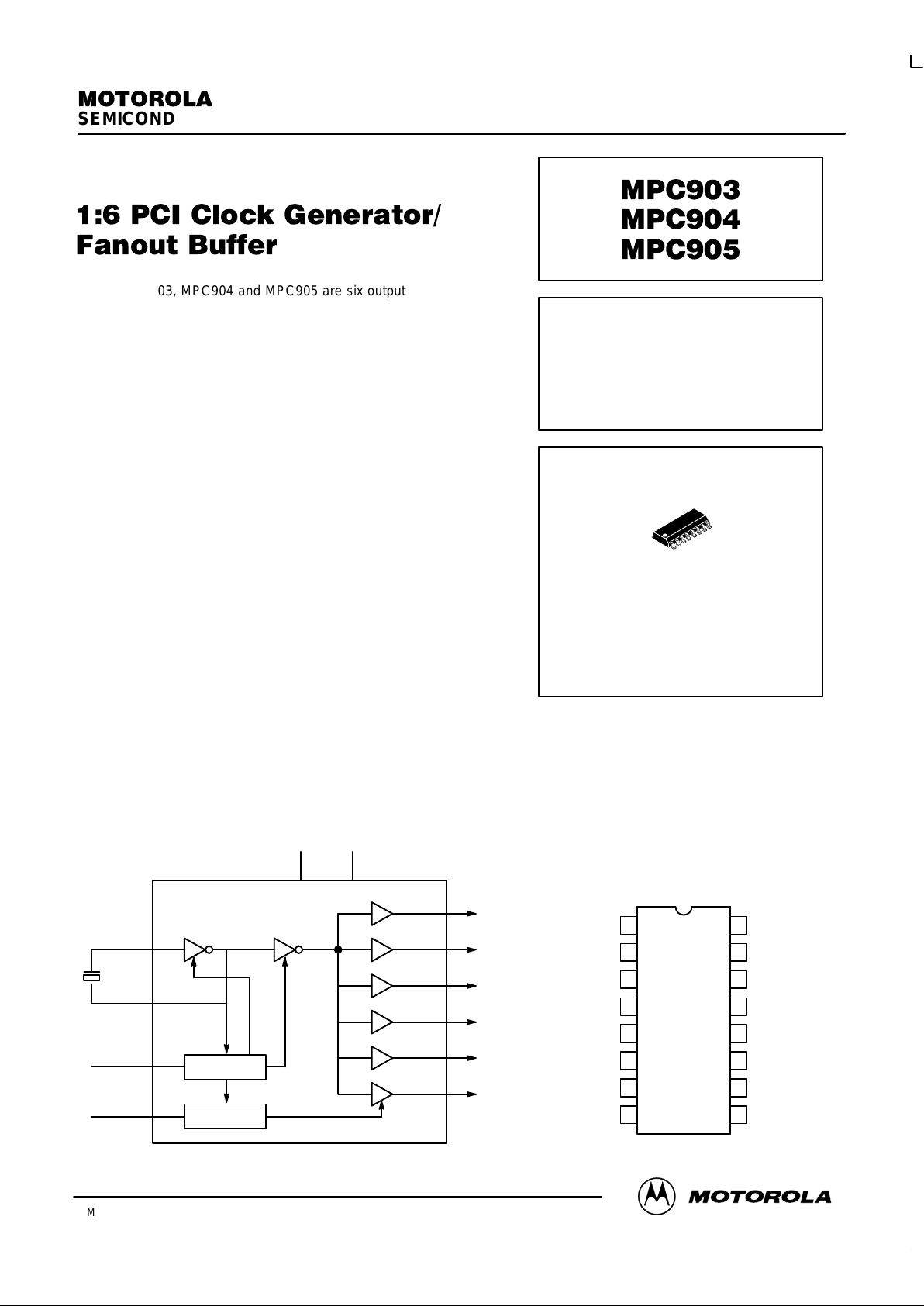

The MPC903, MPC904 and MPC905 are six output clock generation

devices targeted to provide the clocks required in a 3.3V or 5.0V PCI

environment. The device operates from a 3.3V supply and can interface

to either a TTL input or an external crystal. The inputs to the device can be

driven with 5.0V when the VCC is at 3.3V. The outputs of the

MPC903/904/905 meet all of the specifications of the PCI standard. The

three devices are identical except in the function of the Output Enables.

• Six Low Skew Outputs

• Synchronous Output Enables for Power Management

• Low Voltage Operation

• XTAL Oscillator Interface

• 16-Lead SOIC Package

• 5.0V Tolerant Enable Inputs

The MPC903/904/905 device is targeted for PCI bus or processor bus

environments with up to 12 clock loads. Each of the six outputs on the

MPC903/904/905 can drive two series terminated 50Ω transmission

lines. This capability effectively makes the MPC903/904/905 a 1:12

fanout buffer.

The MPC903 offers two synchronous enable inputs to allow users

flexibility in developing power management features for their designs.

Both enable signals are active HIGH inputs. A logic ‘0’ on the Enable1

input will pull all of the outputs into the logic ‘0’ state and shut down the

internal oscillator for a zero power sleep state. A logic ‘0’ on the Enable2

input will disable only the BCLK5 output. The Enable2 input can be used to disable any high power device for system power

savings during periods of inactivity. Both enable inputs are synchronized internal to the chip so that the output disabling will

happen only when the outputs are already LOW. This feature guarantees no runt pulses will be generated during enabling and

disabling. Note that when the MPC903 is re-enabled via the Enable1 pin, the user must allow for the oscillator to regain stability .

Thus, the re-enabling of the chip cannot occur instantaneously. The MPC904 and MPC905 Enable functions are slightly dif ferent

than the 903 and are outlined in the function tables on the following page.

BCLK0

BCLK1

BCLK2

BCLK3

BCLK4

BCLK5

XTAL_IN

XTAL_OUT

Enable1

Enable2

GND (3)VDD (3)

Pinout: 16-Lead Plastic Package (Top View)

161

152

143

134

XTAL_IN

Enable1

BCLK5

V

DD3

XTAL_OUT

Enable2

GND1

BCLK0

125

116

107

98

BCLK4

GND3

BCLK3

V

DD2

V

DD1

BCLK1

GND2

BCLK2

SYNCHRONIZE

SYNCHRONIZE

1:6 PCI

CLOCK GENERATOR/

FANOUT BUFFER

D SUFFIX

PLASTIC SOIC PACKAGE

CASE 751B-05

1

16

Page 2

MPC903 MPC904 MPC905

MOTOROLA TIMING SOLUTIONS

BR1333 — REV 5

2

FUNCTION TABLE

Outputs 0 to 4 Output 5 OSC (On/Off)

ENABLE1 ENABLE2 MPC903 MPC904 MPC905 MPC903 MPC904 MPC905 MPC903 MPC904 MPC905

0

0

1

1

0

1

0

1

Low

Low

Toggling

Toggling

Low

Low

Toggling

Toggling

Low

Low

Toggling

Toggling

Low

Low

Low

Toggling

Low

Toggling

Low

Toggling

Low

Toggling

Low

Toggling

OFF

OFF

ON

ON

OFF

ON

ON

ON

ON

ON

ON

ON

ABSOLUTE MAXIMUM RATINGS*

Symbol Parameter Min Max Unit

V

DD

Supply Voltage –0.5 4.6 V

V

IN

Input Voltage –0.5 VCC + 0.5 V

T

oper

Operating Temperature Range 0 +70 °C

T

stg

Storage Temperature Range –65 +150 °C

T

sol

Soldering Temperature Range (10 Sec) +260 °C

T

j

Junction Temperature Range +125 °C

P(E1=1) Power Dissipation TBD mW

P(E1=0) Power Dissipation 40 µW

ESD Static Discharge Voltage 2000 V

I

Latch

Latch Up Current 50 mA

* Absolute Maximum Ratings are those values beyond which damage to the device may occur. Functional operation should be restricted to the

Recommended Operating Conditions.

RECOMMENDED OPERATING CONDITIONS

Symbol Parameter Min Max Unit

T

A

Ambient Temperature Range 0 70 °C

V

DD

Positive Supply Voltage (Functional Range) 3.0 3.6 V

tDCin T

high

(at XTAL_IN Input)

T

low

(at XTAL_IN Input)

0.44T

1

0.44T

1

0.56T

1

0.56T

1

T = Period

1. When using External Source for reference, requirement to meet PCI clock duty cycle requirement on the output.

DC CHARACTERISTICS (TA = 0–70°C; VDD = 3.3V ±0.3V)

Symbol Characteristic Min Typ Max Unit Condition

V

IH

High Level Input Voltage 2.0 5.5

2

V

V

IL

Low Level Input Voltage 0.8 V

V

OH

High Level Output Voltage 2.4 V IOH = –36mA

1

V

OL

Low Level Output Voltage 0.4 V IOL = 36mA

1

I

IH

Input High Current 2.5

2

µA

I

IL

Input Low Current 2.5 µA

I

CC

Power Supply Current DC

33MHz

66MHz

20

37

78

45

95

µA

mA

mA

C

IN

Input Capacitance XTAL_IN

Others

9.0

4.5

pF

1. The MPC903/904/905 outputs can drive series terminated or parallel terminated 50Ω (or 50Ω to VCC/2) transmission lines on the incident edge

(see Applications Info).

2. XTAL_IN input will sink up to 10mA when driven to 5.5V . There are no reliability concerns associated with the condition. Note that the Enable1

input must be a logic HIGH. Do not take the Enable1 input to a logic LOW with >VCC volts on the XTAL_IN input.

Page 3

MPC903 MPC904 MPC905

TIMING SOLUTIONS

BR1333 — REV 5

3 MOTOROLA

AC CHARACTERISTICS (TA = 0–70°C; VDD = 3.3V ±0.3V)

Symbol Characteristic Min Typ Max Unit Condition

F

max

Maximum Operating Using External Crystal

Frequency Using External Clock Source

TBD

DC

50

100

MHz

t

pw

Output Pulse Width HIGH (Above 2.0V)

LOW (Below 0.8V)

HIGH (Above 2.0V)

LOW (Below 0.8V)

0.40T

1

0.40T

1

0.45T

2

0.45T

2

0.60T

1

0.60T

1

0.55T

2

0.55T

2

T = Periods

t

per

Output Period T – 400ps T = Desired Period

t

os

Output-to-Output Skew Rising Edges

Falling Edges

400

500

ps

tr, t

f

Rise/Fall Times (Slew Rate) 1 4 V/ns Series Terminated

Transmission Lines

t

EN

Enable Time Enable1

Enable2

5

4

ms

Cycles

t

DIS

Disable Time Enable1

Enable2

4

4

Cycles

A

osc

XTAL_IN to XTAL_OUT Oscillator Gain 6 db

Phase Loop Phase Shift Modulo 360° + 30 Degrees

1. Assuming input duty cycle specs from Recommended Operationg Conditions table are met.

2. Assuming external crystal or 50% duty cycle external reference is used.

Figure 1. Crystal Oscillator Interface

(Fundamental)

100

Ω

Pin 1Pin 16

Y1

33.3333MHz

16pF10pFC1 C3

Figure 2. Crystal Oscillator Interface

(3rd Overtone)

C

TRAP

Pin 1Pin 16

Y1

11.1111MHz

16pF10pFC1 C3

L

TRAP

f

FUND

+

1

2pL

TRAPCTRAP

Ǹ

Table 1. Crystal Specifications

Parameter Value

Crystal Cut Fundamental AT Cut

Resonance Parallel Resonance*

Frequency Tolerance ±75ppm at 25°C

Frequency/Temperature Stability ±150pm 0 to 70°C

Operating Range 0 to 70°C

Shunt Capacitance 5–7pF

Equivalent Series Resistance (ESR) 50 to 80Ω

Correlation Drive Level 100µW

Aging 5ppm/Yr (First 3 Y ears)

Page 4

MPC903 MPC904 MPC905

MOTOROLA TIMING SOLUTIONS

BR1333 — REV 5

4

BCLK0–4

BCLK5

ENABLE2

ENABLE1

Figure 3. Enable Timing Diagram

APPLICATIONS INFORMATION

Driving Transmission Lines

The MPC903/904/905 clock driver was designed to drive

high speed signals in a terminated transmission line

environment. T o provide the optimum flexibility to the user the

output drivers were designed to exhibit the lowest impedance

possible. With an output impedance of less than 10Ω the

drivers can drive either parallel or series terminated

transmission lines. For more information on transmission

lines the reader is referred to application note AN1091 in the

Timing Solutions brochure (BR1333/D).

In most high performance clock networks point–to–point

distribution of signals is the method of choice. In a

point–to–point scheme either series terminated or parallel

terminated transmission lines can be used. The parallel

technique terminates the signal at the end of the line with a

50Ω resistance to VCC/2. This technique draws a fairly high

level of DC current and thus only a single terminated line can

be driven by each output of the MPC903/904/905 clock

driver. For the series terminated case however there is no DC

current draw, thus the outputs can drive multiple series

terminated lines. Figure 4 illustrates an output driving a

single series terminated line vs two series terminated lines in

parallel. When taken to its extreme the fanout of the

MPC903/904/905 clock driver is effectively doubled due to its

capability to drive multiple lines.

Figure 4. Single versus Dual Transmission Lines

7

Ω

IN

MPC903

OUTPUT

BUFFER

RS = 43

Ω

ZO = 50

Ω

OutA

7

Ω

IN

MPC903

OUTPUT

BUFFER

RS = 43

Ω

ZO = 50

Ω

OutB0

RS = 43

Ω

ZO = 50

Ω

OutB1

The waveform plots of Figure 5 show the simulation

results of an output driving a single line vs two lines. In both

cases the drive capability of the MPC903/904/905 output

buffers is more than sufficient to drive 50Ω transmission lines

on the incident edge. Note from the delay measurements in

the simulations a delta of only 43ps exists between the two

differently loaded outputs. This suggests that the dual line

Page 5

MPC903 MPC904 MPC905

TIMING SOLUTIONS

BR1333 — REV 5

5 MOTOROLA

driving need not be used exclusively to maintain the tight

output–to–output skew of the MPC903. The output waveform

in Figure 5 shows a step in the waveform, this step is caused

by the impedance mismatch seen looking into the driver. The

parallel combination of the 43Ω series resistor plus the output

impedance does not match the parallel combination of the

line impedances. The voltage wave launched down the two

lines will equal:

VL = VS ( Zo / Rs + Ro +Zo) = 3.0 (25/53.5) = 1.40V

At the load end the voltage will double, due to the near

unity reflection coefficient, to 2.8V. It will then increment

towards the quiescent 3.0V in steps separated by one round

trip delay (in this case 4.0ns).

Figure 5. Single versus Dual Waveforms

TIME (nS)

VOLTAGE (V)

3.0

2.5

2.0

1.5

1.0

0.5

0

2 4 6 8 10 12 14

OutB

tD = 3.9386

OutA

tD = 3.8956

In

Since this step is well above the threshold region it will not

cause any false clock triggering, however designers may be

uncomfortable with unwanted reflections on the line. To

better match the impedances when driving multiple lines the

situation in Figure 6 should be used. In this case the series

terminating resistors are reduced such that when the parallel

combination is added to the output buffer impedance the line

impedance is perfectly matched.

Figure 6. Optimized Dual Line Termination

7

Ω

MPC903

OUTPUT

BUFFER

RS = 36

Ω

ZO = 50

Ω

RS = 36

Ω

ZO = 50

Ω

7Ω + 36Ω k 36Ω = 50Ω k 50Ω

25Ω = 25Ω

SPICE level output buffer models are available for

engineers who want to simulate their specific interconnect

schemes. In addition IV characteristics are in the process of

being generated to support the other board level simulators in

general use.

Page 6

MPC903 MPC904 MPC905

MOTOROLA TIMING SOLUTIONS

BR1333 — REV 5

6

OUTLINE DIMENSIONS

D SUFFIX

PLASTIC SOIC PACKAGE

CASE 751B-05

ISSUE J

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

18

16 9

SEATING

PLANE

F

J

M

R

X 45

_

G

8 PLP

–B–

–A–

M

0.25 (0.010) B

S

–T–

D

K

C

16 PL

S

B

M

0.25 (0.010) A

S

T

DIM MIN MAX MIN MAX

INCHESMILLIMETERS

A 9.80 10.00 0.386 0.393

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

____

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE /Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 or 602–303–5454 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–81–3521–8315

MFAX: RMF AX0@email.sps.mot.com – T OUCHTONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

MPC903/D

*MPC903/D*

◊

Loading...

Loading...