Page 1

1

MOTOROLA

MMQA5V6T1 MMQA20VT1

Transient Voltage Suppressor

for ESD Protection

This quad monolithic silicon voltage suppressor is designed for applications

requiring transient overvoltage protection capability. It is intended for use in

voltage and ESD sensitive equipment such as computers, printers, business

machines, communication systems, medical equipment, and other applications. Its quad junction common anode design protects four separate lines

using only one package. These devices are ideal for situations where board

space is at a premium.

Specification Features:

• SC-59 Package Allows Four Separate Unidirectional Configurations

• Peak Power — 24 Watts @ 1.0 ms (Unidirectional), per Figure 7 Waveform

• Maximum Clamping Voltage @ Peak Pulse Current

• Low Leakage < 2.0 µA

• ESD Rating of Class N (exceeding 16 kV) per the Human Body Model

Mechanical Characteristics:

• Void Free, Transfer-Molded, Thermosetting Plastic Case

• Corrosion Resistant Finish, Easily Solderable

• Package Designed for Optimal Automated Board Assembly

• Small Package Size for High Density Applications

• Available in 8 mm Tape and Reel

Use the Device Number to order the 7 inch/3,000 unit reel. Replace

with “T3” in the Device Number to order the 13 inch/10,000 unit reel.

THERMAL CHARACTERISTICS

(TA = 25°C unless otherwise noted)

Characteristic

Symbol Value Unit

Peak Power Dissipation @ 1.0 ms (1)

@ TA ≤ 25°C

P

pk

24 Watts

Total Power Dissipation on FR-5 Board (2) @ TA = 25°C

Derate above 25°C

°PD° °225

1.8

°mW°

mW/°C

Thermal Resistance Junction to Ambient R

θJA

556 °C/W

Total Power Dissipation on Alumina Substrate (3) @ TA = 25°C

Derate above 25°C

°PD° °300

2.4

°mW

mW/°C

Thermal Resistance Junction to Ambient R

θJA

417 °C/W

Junction and Storage Temperature Range T

J

T

stg

°– 55 to +150° °C

Lead Solder Temperature — Maximum (10 Second Duration) T

L

260 °C

1. Non-repetitive current pulse per Figure 7 and derate above TA = 25°C per Figure 8.

2. FR-5 = 1.0 x 0.75 x 0.62 in.

3. Alumina = 0.4 x 0.3 x 0.024 in., 99.5% alumina

4. Other voltages are available

Thermal Clad is a trademark of the Bergquist Company

Preferred devices are Motorola recommended choices for future use and best overall value.

SEMICONDUCTOR TECHNICAL DATA

Order this document

by MMQA5V6T1/D

Motorola, Inc. 1996

Rev 3

SC-59 QUAD

TRANSIENT VOLTAGE

SUPPRESSOR

5.6 VOLTS (4)

24 WATTS PEAK POWER

CASE 318F-01

STYLE 1

SC-59 PLASTIC

4 5

6

Motorola Preferred Devices

PIN 1. CATHODE

2. ANODE

3. CATHODE

4. CATHODE

5. ANODE

6. CATHODE

1

2

3

1

2

3

4

5

6

Page 2

MOTOROLA

2

MMQA5V6T1 MMQA20VT1

ELECTRICAL CHARACTERISTICS (T

A

= 25°C unless otherwise noted)

UNIDIRECTIONAL (Circuit tied to pins 1, 2, and 5; Pins 2, 3, and 5; Pins 2, 4, and 5; or Pins 2, 5, and 6) (V

F

= 0.9 V Max @ IF = 10 mA)

Breakdown Voltage

Max Reverse

Leakage Current

Max Zener Impedance (5)

Max

Reverse

Max Reverse

Voltage @

Maximum

VZT(3)

(V)

@ I

ZT

IR @ VR

ZZT @ IZT

Surge

Current

I

RSM(4)

I

RSM

(4)

(Clamping

Voltage)

Temperature

Coefficient of

V

Z

Min Nom Max

(mA)

1

(µA) (V)

(Ω) (mA)

I

RSM(4)

(A)

V

RSM

(V)

(mV/°C)

5.32 5.6 5.88 1.0 2.0 3.0 400 3.0 8.0 1.26

19 20 21 1.0 0.1 15 125 0.84 28.6 20.07

(3) VZ measured at pulse test current IT at an ambient temperature of 25°C.

(4) Surge current waveform per Figure 5 and derate per Figure 6.

(5) ZZT is measured by dividing the AC voltage drop across the device by the AC current supplied. The specfied limits are I

Z(AC)

= 0.1 I

Z(DC)

, with AC frequency = 1 kHz.

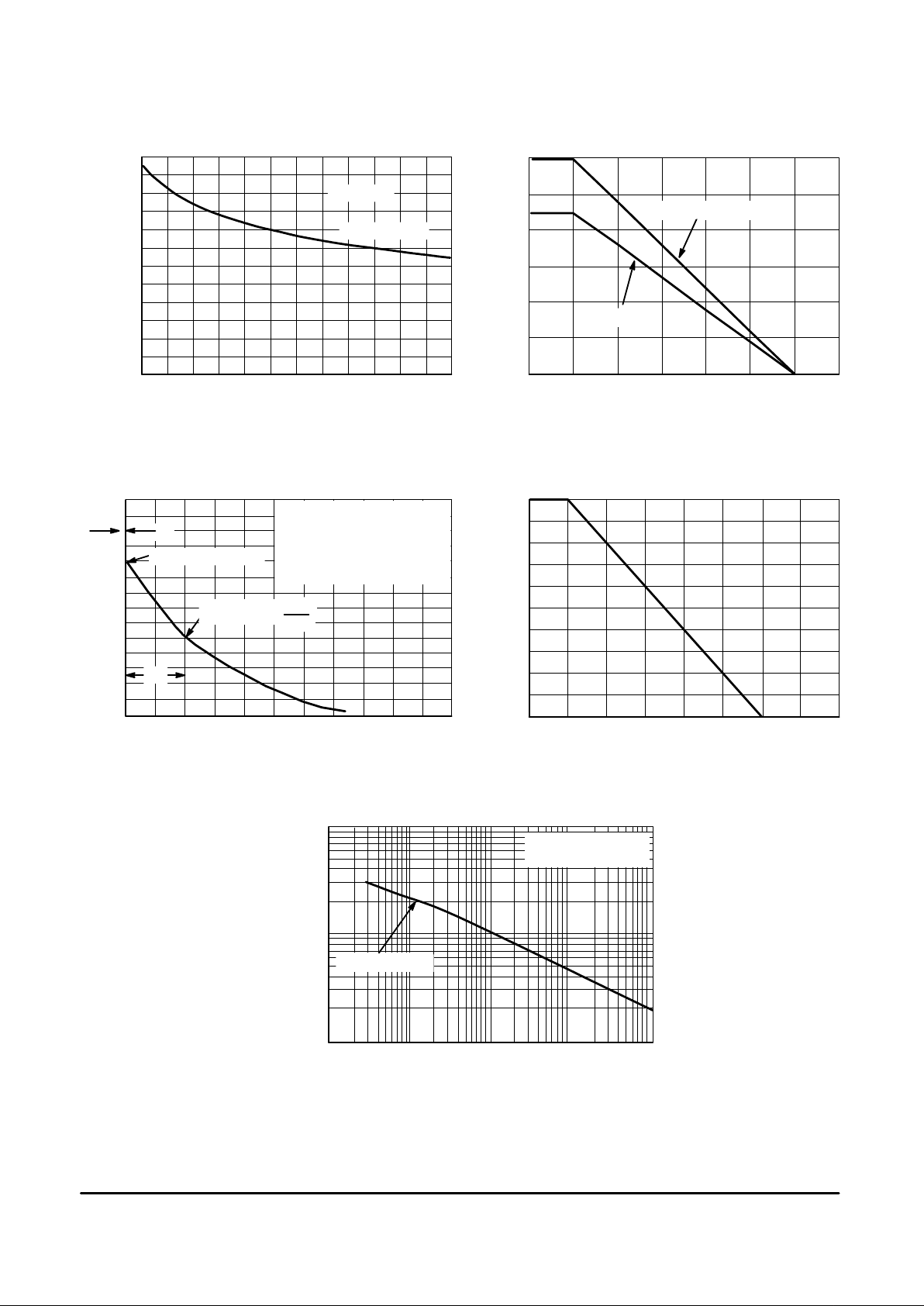

Typical Characteristics

– 50 50 100 150

8

7

6

5

4

V ,

Z

BREAKDOWN VOLTAGE (VOLTS)

23

17

TA, AMBIENT TEMPERATURE (

°

C)

Figure 1. Typical Breakdown Voltage

versus Temperature

Figure 2. Typical Breakdown Voltage

versus Temperature

0 2 4 6 8 10 14 16

70

60

50

40

30

20

0

C, CAPACITANCE (pF)

0 – 40 25 150

TA, AMBIENT TEMPERATURE (

°

C)

REVERSE VOLTAGE (V)

VZ @ I

T

MMQA5V6T1

22

21

20

19

18

MMQA20VT1

10000

1000

100

TA, AMBIENT TEMPERATURE (

°

C)

I

R,

REVERSE LEAKAGE CURRENT (nA)

– 50 50 100 1500

Figure 3. Typical Leakage Current

versus Temperature

Figure 4. Typical Capacitance versus

Reverse Voltage

10

12

MMQA20VT1

UNIDIRECTIONAL

V ,

Z

BREAKDOWN VOLTAGE (VOLTS)

0

UNIDIRECTIONAL

Page 3

3

MOTOROLA

MMQA5V6T1 MMQA20VT1

Typical Characteristics

0 1 1.5 3

300

Figure 5. Typical Capacitance versus

Reverse Voltage

0 25 50 75 100 125 150 175

300

250

200

150

100

50

0

Figure 6. Steady State Power Derating Curve

P

D

, POWER DISSIPATION (mW)

0.5

REVERSE VOLTAGE (V)

TA, AMBIENT TEMPERATURE (

°

C)

FR-5 BOARD

ALUMINA SUBSTRATE

C, CAPACITANCE (pF)

2 2.5

275

250

225

200

175

150

125

100

75

50

25

0

UNIDIRECTIONAL

MMQA5V6T1

VALUE (%)

100

50

0

0 1 2 3 4

t, TIME (ms)

Figure 7. Pulse Waveform

t

r

t

P

100

90

80

70

60

50

40

30

20

10

0

0 25 50 75 100 125 150 175 200

TA, AMBIENT TEMPERATURE (

°

C)

Figure 8. Pulse Derating Curve

PEAK PULSE DERATING IN % OF PEAK POWER

OR CURRENT @ T

A

= 25

C

°

Figure 9. Maximum Non-repetitive Surge

Power, Ppk versus PW

Ppk PEAK SURGE POWER (W)

0.1 1.0 10 100 1000

1.0

10

100

Power is defined as V

RSM

x IZ(pk) where V

RSM

is the clamping voltage at IZ(pk).

PW, PULSE WIDTH (ms)

PULSE WIDTH (tP) IS DEFINED

AS THAT POINT WHERE THE

PEAK CURRENT DECAYS TO 50%

OF I

RSM

.

tr

≤

10 µs

HALF VALUE—

I

RSM

2

PEAK VALUE—I

RSM

UNIDIRECTIONAL

RECTANGULAR

WAVEFORM, TA = 25

°

C

Page 4

MOTOROLA

4

MMQA5V6T1 MMQA20VT1

TYPICAL COMMON ANODE APPLICATIONS

A quad junction common anode design in a SC-59 package protects four separate lines using only one package.

This adds flexibility and creativity to PCB design especially

when board space is at a premium. Two simplified examples

of MMQA5V6T1 and MMQA20VT1 applications are illustrated below.

MMQA5V6T1

MMQA20VT1

KEYBOARD

TERMINAL

PRINTER

ETC.

FUNCTIONAL

DECODER

I/O

A

MMQA5V6T1

MMQA20VT1

GND

Computer Interface Protection

B

C

D

Microprocessor Protection

I/O

RAM ROM

CLOCK

CPU

CONTROL BUS

ADDRESS BUS

DATA BUS

GND

V

GG

V

DD

Page 5

5

MOTOROLA

MMQA5V6T1 MMQA20VT1

INFORMATION FOR USING THE SC-59 6 LEAD SURFACE MOUNT PACKAGE

MINIMUM RECOMMENDED FOOTPRINT FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the total

design. The footprint for the semiconductor packages must

be the correct size to ensure proper solder connection inter-

face between the board and the package. With the correct

pad geometry, the packages will self-align when subjected to

a solder reflow process.

inches

mm

SC-59 6 LEAD

0.028

0.7

0.074

1.9

0.037

0.95

0.037

0.95

0.094

2.4

0.039

1.0

SC-59 6 LEAD POWER DISSIPATION

The power dissipation of the SC-59 6 Lead is a function of

the pad size. This can vary from the minimum pad size for

soldering to a pad size given for maximum power dissipation.

Power dissipation for a surface mount device is determined

by T

J(max)

, the maximum rated junction temperature of the

die, R

θJA

, the thermal resistance from the device junction to

ambient, and the operating t emperature, TA. Using t he

values provided o n the data sheet for the SC-59 6 Lead

package, PD can be calculated as follows:

PD =

T

J(max)

– T

A

R

θJA

The values for the equation are found in the maximum

ratings table on the data sheet. Substituting these values into

the equation for an ambient temperature TA of 25°C, one can

calculate the power dissipation of the device which in this

case is 225 milliwatts.

PD =

150°C – 25°C

556°C/W

= 225 milliwatts

The 556°C/W for the SC-59 6 Lead package assumes the

use of the recommended footprint on a glass epoxy printed

circuit board to achieve a power dissipation of 225 milliwatts.

There a re other alternatives t o achieving higher power

dissipation from the SC-59 6 Lead package. Another alternative would be to use a ceramic substrate or an aluminum

core board such as Thermal Clad. Using a board material

such as Thermal Clad, an aluminum core board, the power

dissipation can be doubled using the same footprint.

SOLDER STENCIL GUIDELINES

Prior to placing surface mount components onto a printed

circuit board, solder paste must be a pplied to t he pads.

Solder stencils are used to screen the optimum amount.

These stencils are typically 0.008 inches thick and may be

made of brass or stainless steel. For packages such as the

SC-59, SC-59 6 Lead, SC-70/SOT-323, SOD-123, SOT-23,

SOT-143, SOT-223, SO-8, SO-14, SO-16, and SMB/SMC

diode packages, the stencil opening should be the same as

the pad size or a 1:1 registration.

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within a

short t ime could result i n device f ailure. Therefore, the

following items should always be observed in order to minimize the thermal stress to which the devices are subjected.

• Always preheat the device.

• The delta temperature between the preheat and

soldering should be 100°C or less.*

• When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering method,

the difference should be a maximum of 10°C.

* Soldering a device without preheating can cause excessive

thermal shock and stress which can result in damage to the

device.

Page 6

MOTOROLA

6

MMQA5V6T1 MMQA20VT1

• The soldering temperature and time should not exceed

260°C for more than 10 seconds.

• When shifting from preheating to soldering, the

maximum temperature gradient should be 5°C or less.

• After soldering has been completed, the device should

be allowed to cool naturally for at least three minutes.

Gradual cooling should be used since the use of forced

cooling will increase the temperature gradient and will

result in latent failure due to mechanical stress.

• Mechanical stress or shock should not be applied during

cooling.

TYPICAL SOLDER HEATING PROFILE

For any given circuit board, there will be a group of control

settings that will give the desired heat pattern. The operator

must set temperatures for several heating zones and a figure

for belt speed. Taken together, these control settings make

up a heating “profile” for that particular circuit board. On

machines controlled by a computer, the computer remembers these profiles from one operating session to the next.

Figure 8 s hows a t ypical h eating profile f or use w hen

soldering a surface mount device to a printed circuit board.

This profile will vary among soldering systems, but it is a

good starting point. Factors that can affect the profile include

the type of soldering system in use, density and types of

components on the board, type of solder used, and the type

of board or substrate material being used. This profile shows

temperature versus time. The line on the graph shows the

actual temperature that might be experienced on the surface

of a test board at or near a central solder joint. The two

profiles are based on a high density and a low density board.

The Vitronics SMD310 convection/infrared reflow soldering

system was used to generate this profile. The type of solder

used w as 62/36/2 Tin Lead Silver with a m elting p oint

between 177 –189°C. When this type of furnace is used for

solder reflow work, the circuit boards and solder joints tend to

heat first. The components on the board are then heated by

conduction. The circuit board, because it has a large surface

area, absorbs the thermal energy more efficiently, then

distributes this energy to the components. Because of this

effect, the m ain body of a component may be u p to 30

degrees cooler than the adjacent solder joints.

STEP 1

PREHEAT

ZONE 1

“RAMP”

STEP 2

VENT

“SOAK”

STEP 3

HEATING

ZONES 2 & 5

“RAMP”

STEP 4

HEATING

ZONES 3 & 6

“SOAK”

STEP 5

HEATING

ZONES 4 & 7

“SPIKE”

STEP 6

VENT

STEP 7

COOLING

200

°

C

150

°

C

100

°

C

50°C

TIME (3 TO 7 MINUTES TOTAL)

T

MAX

SOLDER IS LIQUID FOR

40 TO 80 SECONDS

(DEPENDING ON

MASS OF ASSEMBLY)

205

°

TO 219°C

PEAK AT

SOLDER JOINT

DESIRED CURVE FOR LOW

MASS ASSEMBLIES

100°C

150°C

160

°

C

170°C

140

°

C

Figure 10. Typical Solder Heating Profile

DESIRED CURVE FOR HIGH

MASS ASSEMBLIES

Page 7

7

MOTOROLA

MMQA5V6T1 MMQA20VT1

OUTLINE DIMENSIONS

CASE 318F-01

ISSUE A

SC-59 6 LEAD

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. MAXIMUM LEAD THICKNESS INCLUDES LEAD

FINISH THICKNESS. MINIMUM LEAD THICKNESS

IS THE MINIMUM THICKNESS OF BASE

MATERIAL.

STYLE 1:

PIN 1. CATHODE

2. ANODE

3. CATHODE

4. CATHODE

5. ANODE

6. CATHODE

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

A

B

C

D

G

H

J

K

L

M

S

2.70

1.30

1.00

0.35

0.85

0.013

0.10

0.20

1.25

0

_

2.50

3.10

1.70

1.30

0.50

1.05

0.100

0.26

0.60

1.65

10

_

3.00

0.1063

0.0512

0.0394

0.0138

0.0335

0.0005

0.0040

0.0079

0.0493

0

_

0.0985

0.1220

0.0669

0.0511

0.0196

0.0413

0.0040

0.0102

0.0236

0.0649

10

_

0.1181

A

G

S

L

D

H

C

K

J

B

0.05 (0.002)

M

1 2 3

456

Page 8

MOTOROLA

8

MMQA5V6T1 MMQA20VT1

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit,

and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters can and do vary in different

applications. All operating parameters, including “T ypicals” must be validated for each customer application by customer’s technical experts. Motorola does

not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of

the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such

unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

How to reach us:

USA /EUROPE: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, Toshikatsu Otsuki,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 6F Seibu–Butsuryu–Center, 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–3521–8315

MFAX: RMFAX0@email.sps.mot.com – TOUCHTONE (602) 244–6609 HONG KONG: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

MMQA5V6T1/D

*MMQA5V6T1/D*

◊

Loading...

Loading...