Page 1

MLX10407

5-Channel Gauge Driver with Serial Link

Features and Benefits

Supply voltage up to 12 V

Interface directly with 5 V CMOS logic MCUs

Serial link

Can drive two 360° actuators & three 90° actuators simultaneously

Open circuit / short -circuit detection of the drivers outputs

Small size (SO24 package)

Real Time Angle Tracking

Applications

Logometer Driver Dashboard

Industrial Metering

Ordering Information

Part No. Temperature Suffix Package Temperature Range

MLX11407CA N/A SO24 -40C to +85C Automotive

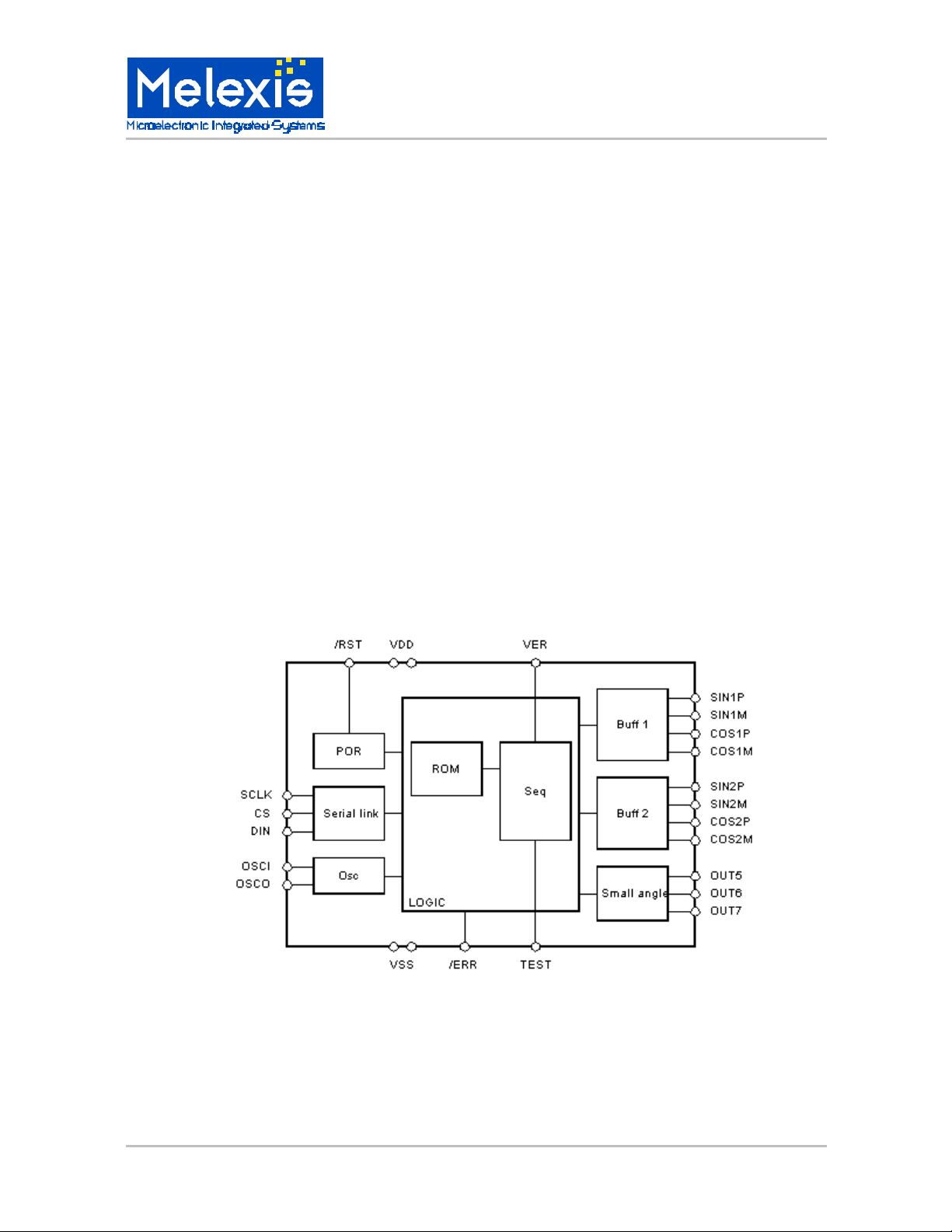

Functional Diagram

Description

The 10407 is a MCU peripheral for logometers control using SIN/COS PWM commands. The circuit controls two

independent sets of CMOS power bridges. A ten-bit angle is displayed with a 9 bit per quadrant resolution PWM whose

frequency is set by a crystal oscillator. A power-on self test detects open or short-circuit outputs for each logometer and

a real time angle tracking avoids display errors.

The 10407 can also drive three small angle logometers (90°). A three wire serial link allows bidirectional communication

with the MCU.

MLX902xx Name of Sensor Rev Y.X 22/Aug/98 Page 1

MLX10407 5-Channel Gauge Driver with Serial Link Page 1 Rev 1.1 28/Apr/01

Page 2

MLX10407

5-Channel Gauge Driver with Serial Link

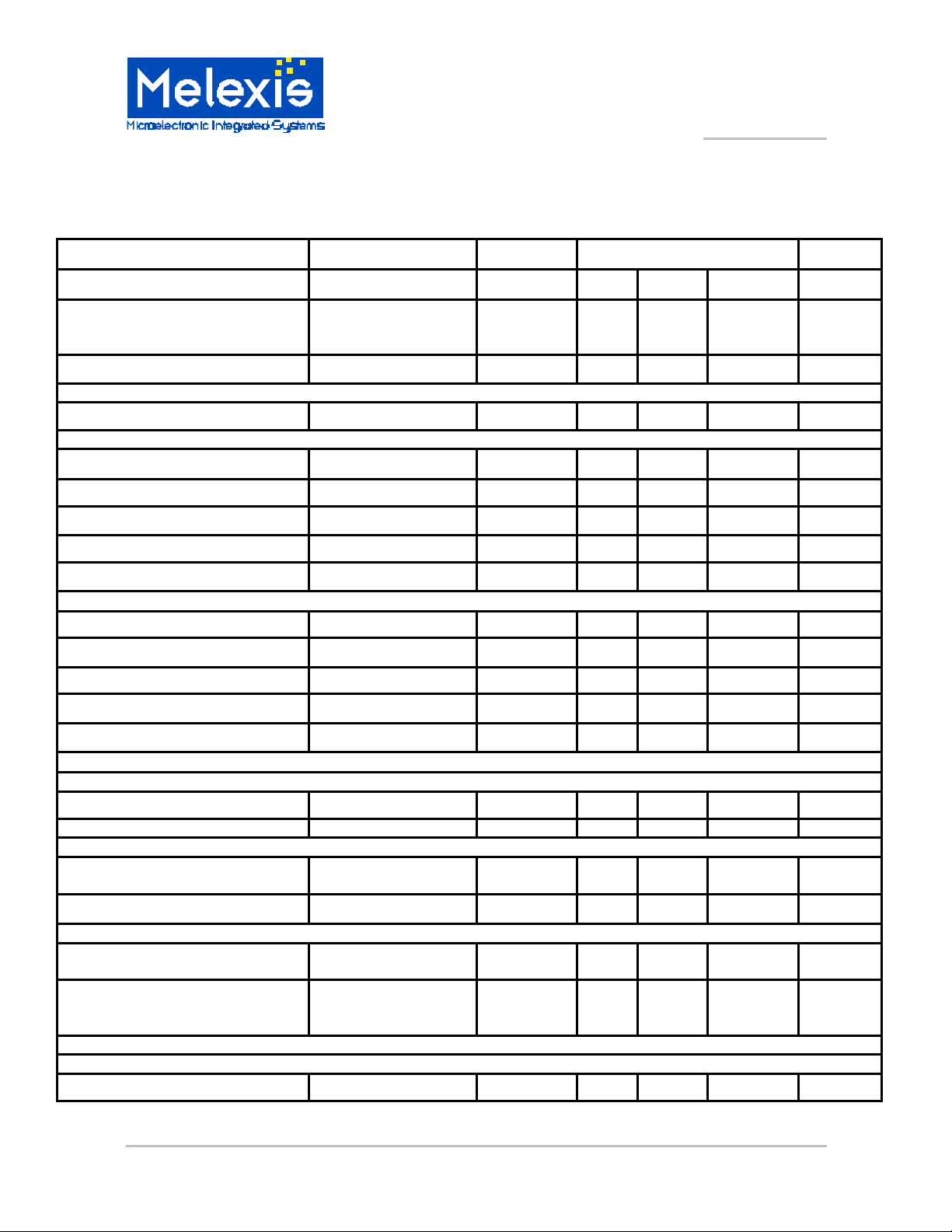

DC Electrical Characteristics

Tamb = -40 to 85°C, VDD = 4.5 V to 12 V unless otherwise specified.

Characteristics Test Conditions

Supply current Inputs at VDD or

VSS, No loads on

outputs

Maximum power dissipation

Inputs

Input capacitance

Pin 11

Pull-down resistance

Input voltage LOW

Input voltage HIGH

Hysteresis VDD = 8.5 V

Leakage current pin at VDD or VSS

Pin 12, 13, 14, 15, 17

Input voltage LOW

Input voltage HIGH

Hysteresis VDD = 8.5 V

Leakage current (pin 12, 15, 17) pin at VDD or VSS

Pull-down resistance (pin 14) Rpd 0.8 1.5 kOhm

Symbol Limits Unit

Min Typ Max

ICC

PDmax

Cin

Rpd 125

VIL -0.3

VIH 4

VHYS 0.5

IL -1

VIL -0.3

VIH 4

VHYS 0.5

IL -1

5.5 mA

620 mW

10 pF

750 kOhm

1 V

VDD+0.3 V

2.5 V

1 µA

1 V

VDD+0.3 V

2.5 V

1 µA

Outputs

Pin 16

Low level output voltage IOUT < 500 µA

High level output leakage current VOUT=VDD ILKG 10 µA

Pin 2, 3, 5, 6, 20, 21, 23, 24

Drop-out voltage for each pair of

buffers

Mismatch of drop -out voltage

Pin 7, 8, 9

Output voltage low VDD = 8.5V, Tamb=

Output voltage high VDD = 8.5V, Tamb=

Oscillator

Pin 18,19

Input pin capacitance

MLX10407 5-Channel Gauge Driver with Serial Link Page 2 Rev 1.1 27/Apr/01

VDD = 8.5V, Tamb =

25°C, Icoil = 30 mA

25°C, Isink = 40mA

25°C, Isource =

40mA

VOL

Vd

D Vd

VOL

VOH 6.8 7.8

Cin

0.3 V

1.6 V

± 50 mV

0.3 0.6 V

10 20 pF

V

Page 3

5-Channel Gauge Driver with Serial Link

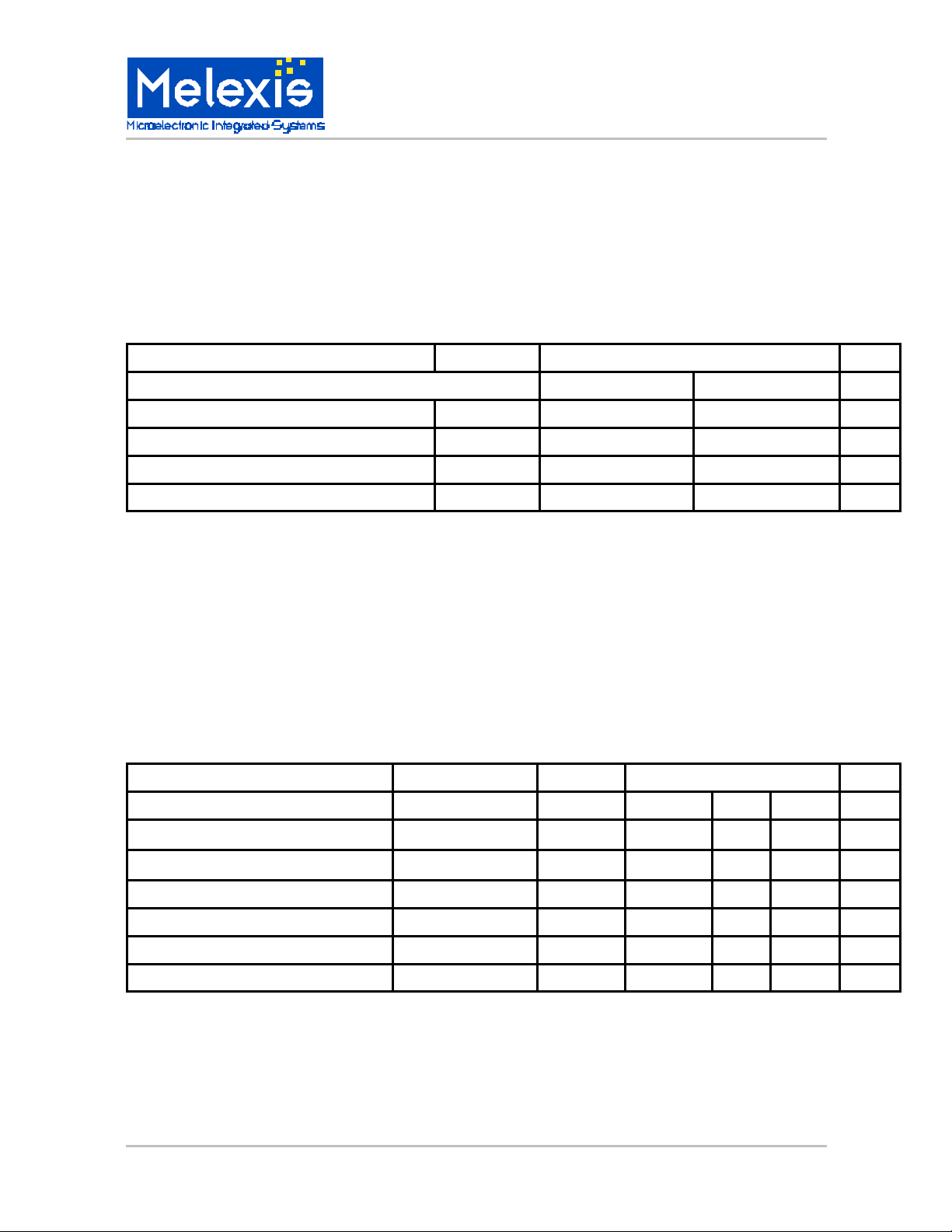

ABSOLUTE MAXIMUM RATINGS

MLX10407

Parameter Symbol

Min Max

Storage Temperature Range Tstg -40 +150 °C

Operating Temperature Range Tamb -40 +85 °C

Supply Voltage Range VDD -0.3 14.0 V

Input Voltage Range Vi -0.3 VDD +0.3 V

Value

AC Electrical Characteristics

Tamb = -40 to 85°C, VDD = 4.5 V to 12 V unless otherwise specified.

Characteristics Test Conditions

Symbol

Limits

Unit

Unit

Min Typ Max

Oscillator 0.95 8.4 MHz

Clock frequency Fclk 8 MHz

Serial communication

Serial data clock frequency Fsclk 500 kHz

Time for DIN stable to SCLK rise 100 ns

Hold time for DIN 100 ns

MLX902xx Name of Sensor Rev Y.X 22/Aug/98 Page 3

MLX10407 5-Channel Gauge Driver with Serial Link Page 3 Rev 1.1 28/Apr/01

Page 4

MLX10407

Typical application

5-Channel Gauge Driver with Serial Link

Notes

• The chip integrates its oscillator load capacitors.

• The quartz frequency is 8MHz

MLX10407 5-Channel Gauge Driver with Serial Link Page 4 Rev 1.1 27/Apr/01

Page 5

MLX10407

5-Channel Gauge Driver with Serial Link

Operation

1) 360° logometers

Immediately following a reset, the IC checks if there is any short -circuit or open circuit on each

buffer driver output (This test is not performed for outputs 5, 6 and 7). During this test, each buffer

is held in a high impedance state and large value internal resistors (100kOhm ) are sequentially

connected on each pair of buffers (note : actuator coils must be connected on bridges).

Three tests are performed according to the following figure and table.

Test for short and open circuits

Test 1 S1 closed, S2 open V1 = VSS

Test 2 S1 open, S2 closed V1 = VDD

Test 3 S1 and S2 closed V1 = VDD/2

During the tests the pin ERRB (16) is at logic level 0. After completing the tests, ERRB remains

low if one (or more) test failed.

ERRB returns to high impedance if everything is OK.

These tests last approximately 4 ms with an oscillator clock frequency of 8 MHz.

After testing, all buffers are at VSS. The chip then waits for the MCU to send an angle/quadrant

value to output the PWM signals for each buffer. Every logometer coil is connected in a bridge,

so the current Icoil can be either positive or negative.

Conditions Test for :

The total drop -out of a bridge is : Vd = | VCC - Vcoil |

One Bridge

MLX902xx Name of Sensor Rev Y.X 22/Aug/98 Page 5

MLX10407 5-Channel Gauge Driver with Serial Link Page 5 Rev 1.1 28/Apr/01

Page 6

MLX10407

5-Channel Gauge Driver with Serial Link

2) 90° logometers

In addition to driving (2) 360° logometers the MLX10407 has a push-pull stage so it Is possible to

drive (3) additional 90° coils connected to GND or VDD respectively.

Serial Link

The MCU outputs the serial communication clock SCLK, the chip select CS, the data DIP, and

reads the ERRB error stat us.

The data sent by the MCU is latched by the 10407 on the rising edge of SCLK.

The 10407 outputs the ERRB signal on the falling edge of SCLK

When CS = "0" the serial interface of the 10407 is inactive. When CS goes HIGH, the 10407

waits for a START BIT and then reads the following 15 bits transmitted by the MCU.

The START BIT (D0) must be "1".

D1 D2 D3 Instruction

0 0 0 Unused

0 0 1 Writing request LOGO1

0 1 0 Unused

0 1 1 Writing request LOGO2

1 0 0 Writing request LOGO3

1 0 1 Writing request LOGO5

1 1 0 Writing request LOGO4

1 1 1 Unused

The following 10 bits (D4, D5, D6, D7, D8, D9, D10, D11, D12, D13) set the angle value (D13

=lsb, D4 = msb).

The two remaining bits (D14D15) represent the quadrant (D14=msb). Note: for Logo1 & 2 only.

MLX10407 5-Channel Gauge Driver with Serial Link Page 6 Rev 1.1 27/Apr/01

Page 7

Serial Link

Sclk

CS

Din

ERRB

HiZ

MLX10407

5-Channel Gauge Driver with Serial Link

10 Bit AngleCODOP

MLX10407 Serial link Protocol

Quad

Error

The 10407 outputs an error status on pin ERRB on the falling edge of SCLK immediately

following the transmission of the quadrant lsb.

The pin 16 (ERRB) of the 10407 is driven low if there is no continuity between two consecutive

quadrant values sent (for logo1 or logo2). The data is valid till CS is high, then when CS goes low

ERRB returns to high impedance state and the error status is lost.

If the MCU has detected an error, it is possible to send data again : the first data bit set to "1" will

initiate a new transmission of 15 data bits.

On the HIGH to LOW transition of CS the angle and quadrant values are stored into the intern al

registers of the 10407 if the following conditions are met:

• The MCU sent the appropriate writing request

• No quadrant err or was detected by the 10407.

Otherwise new angle and quadrant values are discarded by the 10407 and the previous values

are kept. The MCU will have to initialize a new transmission to the 10407.

If VER (pin 17) is connected to VDD then the 10407 does not store values of angles and

quadrant in case of an error. It is however possible to make the 10407 store all angles and

quadrant values even if there is an error, by connecting VER (pin 17) to GND.

MLX902xx Name of Sensor Rev Y.X 22/Aug/98 Page 7

MLX10407 5-Channel Gauge Driver with Serial Link Page 7 Rev 1.1 28/Apr/01

Page 8

MLX10407

5-Channel Gauge Driver with Serial Link

PWM Generation

1) Logometers 360° ( Logo 1 and Logo 2 ):

From the angle value received from the MCU (range [0° - 89.8°]), the 10407 generates two PWM

signals (9 bit resolution) :

• The first one represents the sine PWMSIN,

• The second one is the cosine PWMCOS.

The 10407 uses a 512x9 ROM containing the sine of all angular values in the range [0° -89.8°]

(note that the lsb value of the angle is not used).

An angle value greater than 90° is obtained using different quadrant values :

• Q1 (D14D15 = 00) > 0° =< a < 90°

• Q2 (D14D15 = 01) > 90° =< a < 180°

• Q3 (D14D15 = 10) > 180° =< a < 270°

• Q4 (D14D15 = 11) > 270° =< a < 360°

a is the angle value

The PWM are switched to the outputs depending on the value of the quadrant :

• Logometer 1 is driven by outputs SIN1M/P COS1M/P,

• Logometer 2 is driven by outputs SIN2M/P COS2M/P.

The PWM frequency is given by :

F

= F

PWM

/ 512 (F

OSC

QUADRANT SIN1M SIN1P COS1M COS1P

D14 D15

0

0

1

1

= Crystal oscillator frequency)

OSC

0

1

0

1

0 PWMSIN 0 PWMCOS

0 PWMCOS PWMSIN 0

PWMSIN 0 PWMCOS 0

PWMCOS 0 0 PWMSIN

2) Logometers 90°

• There are three separate PWM outputs for Logo 3, Logo 4 and Logo 5.

MLX10407 5-Channel Gauge Driver with Serial Link Page 8 Rev 1.1 27/Apr/01

Page 9

Pin Out

5-Channel Gauge Driver with Serial Link

Pin Symbol Description

1 VDD

2 SIN1P Output buffer (coil 1 Logo1)

3 SIN1M Output buffer (coil 1 Logo1)

4 VSS

5 COS1P Output buffer (coil 2 Logo1)

6 COS1M Output buffer (coil 2 Logo1)

7 OUT5 Output buffer (Logo 3)

8 OUT6 Output buffer (Logo 4)

9 OUT7 Output buffer (Logo 5)

10 VDD

11 CS

12 SCLK Serial clock (Schmitt trigger)

13 DIN Data IN (Schmitt trigger)

14 TEST TEST input.(1K pull-down)

15 RSTB External reset (Schmitt trigger)

16 ERRB Quadrant error output (Open drain)

17 VER Quadrant verification inhibit

18 OSCO Crystal oscillator output

19 OSCI Crystal oscillator input

20 COS2M Output buffer (coil 2 Logo2)

21 COS2P Output buffer (coil 2 Logo2)

22 VSS

23 SIN2M Output buffer (coil 1 Logo2)

24 SIN2P Output buffer (coil 1 Logo2)

Chip select (Schmitt trigger with 300kOhm

pull-down)

MLX10407

For the latest version of this document,

Go to our website at:

www.melexis.com

Or for additional information

contact Melexis Di rect:

USA

Melexis Inc.

41 Locke Road, Concord, NH 03301

Phone: +1 603 223 2362 Fax: +1 603 223 9614

E-mail: sales_usa@melexis.com

United Kingdom

Silicon Concepts

PCB Lynchborough Road, Hampshire GU30 7SB, United Kingdom

Phone: +44 1428 751 617 Fax: +44 1428 751 603

E-mail: sales_uk@melexis.com

Germany

Am Seestern 8, 40547 Düsseldorf, Germany

Phone: +49 211 5360212 Fax: +49 211 5360250

E-mail: sales_de@melexis.com

MLX902xx Name of Sensor Rev Y.X 22/Aug/98 Page 9

MLX10407 5-Channel Gauge Driver with Serial Link Page 9 Rev 1.1 28/Apr/01

France

Melexis France

Tour Arago, 5 rue Bellini, 92806 Puteaux-La-Défense, France.

Phone: +33 1 47 78 11 34 Fax: +33 1 47 78 06 35

E-mail: sales_france@melexis.com

Italy

Dimacred IRL

Via Papa Giovanni XXIII no. 25, 20046 Biassono, Italy

Phone: +39 039 249 4856 Fax: +39 039 491773

E-mail: sales_italy@melexis.com

Japan

Satori Electric Co., LTD

1-14-10 Shiba, Minato -Ku, Tokyo, Japan

Phone: +81 3 3452 7171 Fax: +81 3 3769 2197

E-mail: sales_japan@melexis.com

Taiwan

Beechwood Int’l Taiwan Co.

Room 8, 17F, No. 189, Taipei, Taiwan

Phone: +886 2 2739 3322 Fax: +886 2 2739 3090

E-mail: sales_taiwan@melexis.com

Loading...

Loading...