Page 1

E2B0051-19-22

Prelim

This version: Feb. 1999

ML9060¡ Semiconductor

¡ Semiconductor

ML9060

1/2 DUTY, 160-OUTPUT STATIC LCD DRIVER

GENERAL DESCRIPTION

The ML9060 consists of a 320-bit shift register, a 320-bit data latch, 160 sets of LCD drivers, and

a common signal generator circuit.

The LCD display data is input serially to the shift register from the DATA IN pin in

synchronization with the CLOCK IN signal, and is stored in the data latch by the LOAD IN

signal.

The LCD display data stored in the data latch is output via the LCD drivers.

A maximum of 160 segments of LCD can be driven in static display mode and a maximum of

320 segments can be driven directly in the 1/2 duty display mode.

It is possible to select the mode of using the internal oscillator circuit or the mode of using an

external clock for the common signal generator circuit. The ML9060 also outputs the sync signal

during the 1/2 duty display mode.

inary

FEATURES

• Logic power supply : 2.7 to 5.5V

• LCD Driving voltage : 4.5 to 16V

• Maximum number of segments that can be driven:

Static display mode : 160 segments

1/2 Duty display mode : 320 segments

• Serial transfer clock : 1 MHz max.

• The microcontroller interface consists of the three signals DATA IN, CLOCK IN, and LOAD

IN.

• An RC oscillator circuit is built in which can use either an external resistor or the internal

resistor.

• Cascade connection of several ICs is possible.

• Built-in common signal generator circuit.

• Built-in common output mid-level voltage generator circuit.

• Input for turning all segments ON is available (SEG-TEST IN).

• Input for turning all segments OFF is available (BLANK IN).

• Gold bump chip Product name: ML9060DVWA

1/17

Page 2

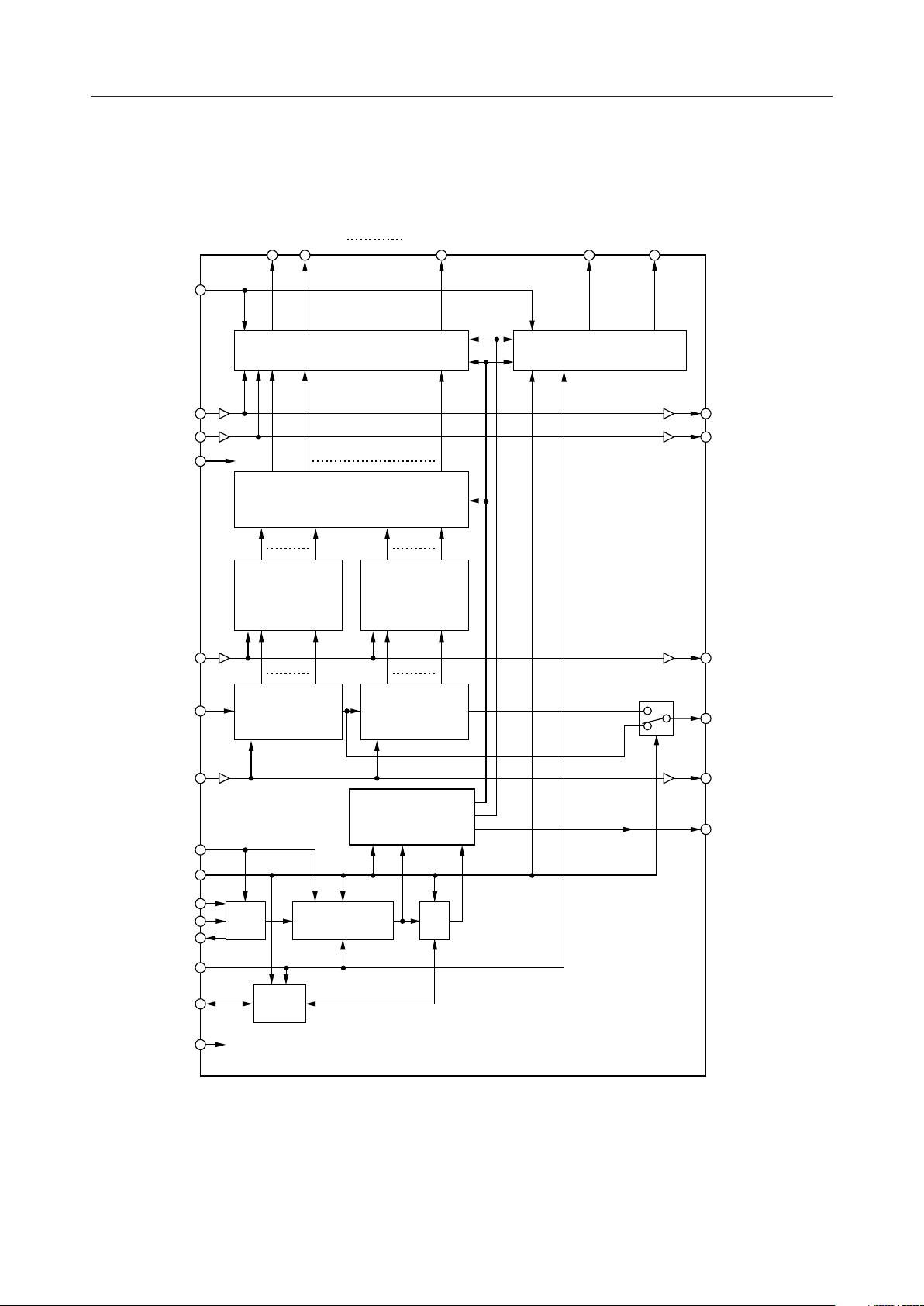

BLOCK DIAGRAM

ML9060¡ Semiconductor

SEG160SEG2SEG1

V

LCD

Segment Drivers

1/2VLCD Generator

& Common Drivers

COM BCOM A

SEG-TEST IN SEG-TEST OUT

BLANK IN BLANK OUT

V

DD

DS0160DS02DS01

Data Selector

DSI160bDSI1bDSI160aDSI1a

L0160aL01a

Data Latch A

LI160aLI1a

Data Latch B

L0160bL01b

LI160bLI1b

LOAD IN LOAD OUT

P0160bP01b

DATA OUT

DATA IN

P0160aP01a

SIa SOa

Shift Register A

SIb SOb

Shift Register B

CLOCK IN CLOCK OUT

Timing Generator

COM OUT

OSC I/E

D/S

OSC1

OSCR

1/64 or 1/128OSC 1/2

OSC2

M/S

SYNC

SYNC

GND

2/17

Page 3

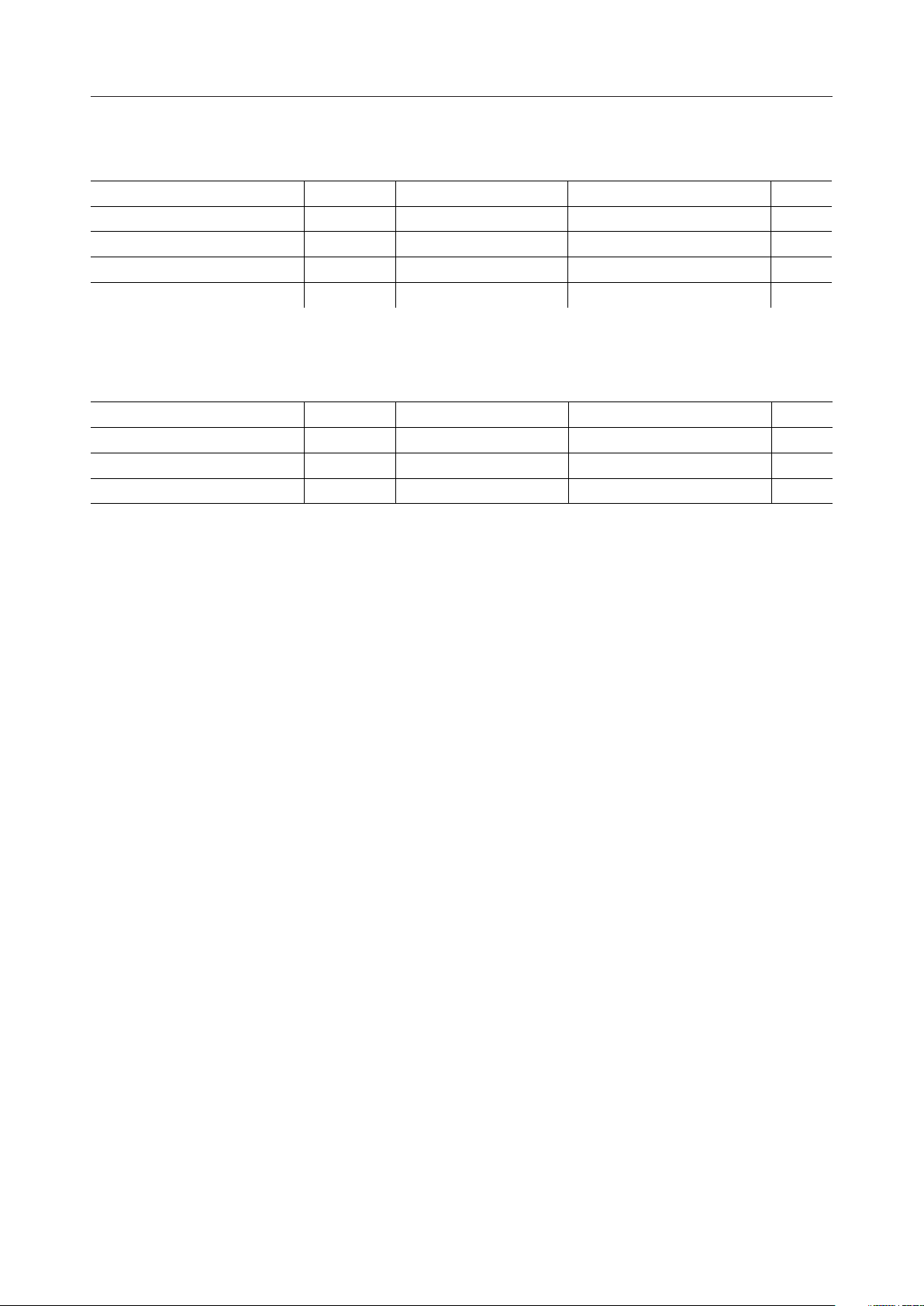

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Condition Rating Unit

Logic power supply voltage V

LCD Driving voltage V

Input voltage V

Storage temperature T

DD

LCD

I

STG

Ta = 25°C

Ta = 25°C

Ta = 25°C

— –55 to +150 °C

–0.3 to +6.5

0 to 18

GND–0.3 to VDD+0.3

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Condition Range Unit

Logic power supply voltage VDD* 2.7 to 5.5

LCD Driving voltage V

Operating temperature T

* 4.5 to 16

LCD

op

—

—

— –40 to +85 °C

ML9060¡ Semiconductor

V

V

V

V

V

*: Use with V

DD

≤ V

LCD

Note: Never place a short between an output pin and another output pin or between an output

pin and other pins (input pins, I/O pins, or power supply pins).

3/17

Page 4

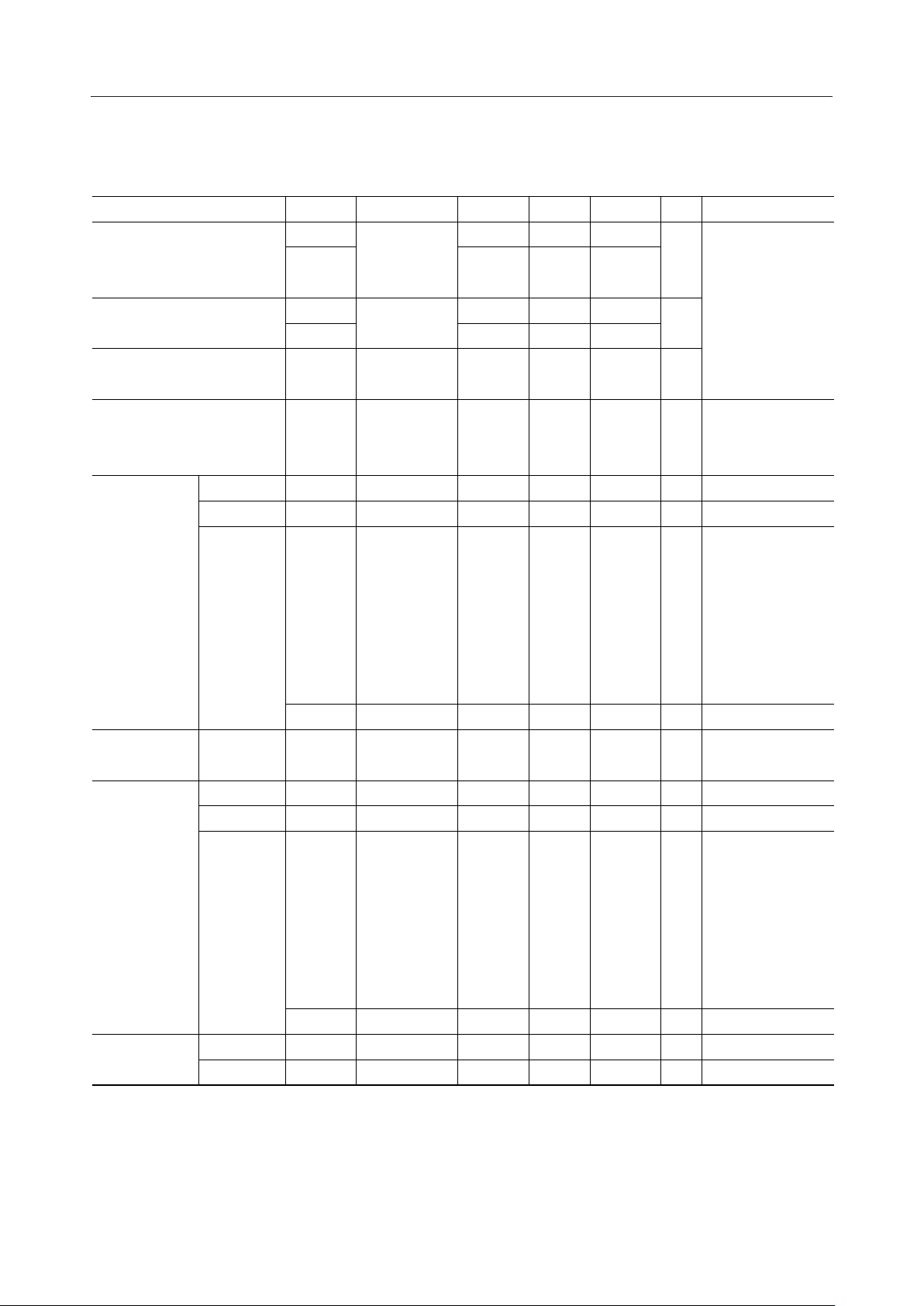

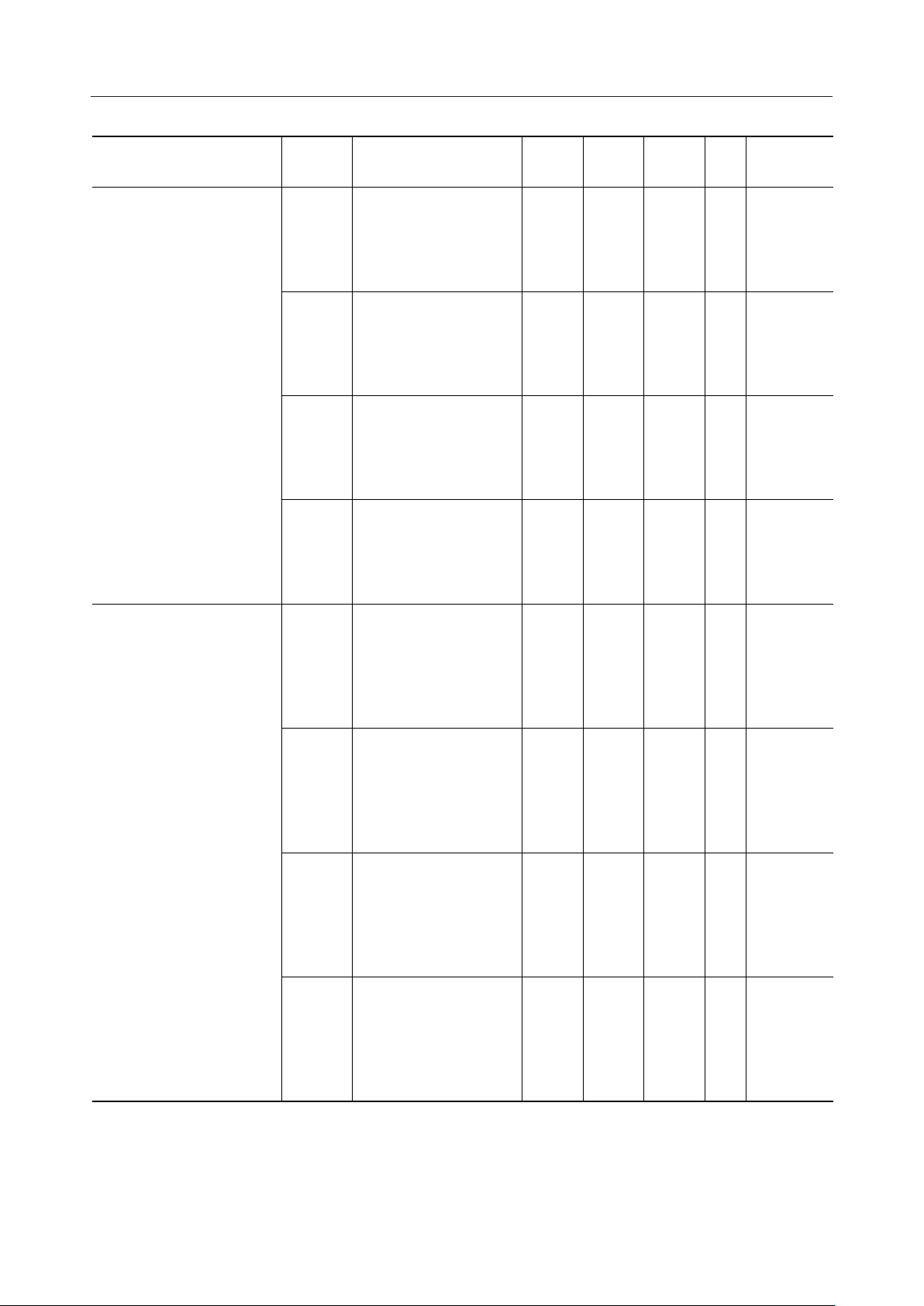

ELECTRICAL CHARACTERISTICS

DC Characteristics

Parameter Symbol Condition Min. Typ. Max. Unit Applicable pin

V

*1 0.7V

IH1

"H" Input voltage

"L" Input voltage

Input leakage current 1 I

Input leakage current 2 I

Segment

Common

"H" Output

voltage

Logic

*2

V

IH2

V

*1

IL1

*2 GND — 0.2V

V

IL2

VI = VDD or 0V

L1

VI = VDD or 0V

D/S = "H"

L2

M/S = "L"

V

OHSIO

*3 IO = –150mAV

V

OHC

V

OHL1IO

= –30mAV

= –100mA 0.9V

—

—

(VDD = 2.7 to 5.5V, V

—V

—V

0.8V

DD

DD

GND — 0.3V

= 4.5 to 16V, Ta = –40 to +85°C)

LCD

DD

DD

DD

DD

DATA IN

CLOCK IN

V

LOAD IN

SEG-TEST IN

V

BLANK IN

M/S, D/S

——±1.0

±10

–0.2 — — V SEG1 to SEG160

LCD

–0.2 — — V COM A, COM B

LCD

m

A

OSC1, OSC I/E

m

A SYNC——

DATA OUT

CLOCK OUT

LOAD OUT

SEG-TEST OUT

DD

——

V

BLANK OUT

COM OUT

SYNC

ML9060¡ Semiconductor

"M" Output

voltage

Common

Segment

Common

"L" Output

voltage

Output

resistance

Logic

Segment

Common

"M": Middle level

V

OHL2IO

*3 I

V

OMC

V

OLS

V

*3 IO = 150mA — — 0.2 V

OLC

V

OLL1IO

V

OLL2IO

R

SEG

R

COM

= –200mA 0.9V

= ±150

m

O

A

1/2V

–0.15

DD

LCD

IO = 30mA — — 0.2 V

= 100mA — — 0.1V

= 200mA — — 0.1V

— — 10 kW SEG1 to SEG160

— — 1.5 kW COM A, COM B

— — V OSC2

1/2V

1/2V

LCD

+0.15

LCD

DD

DD

V COM A, COM B

SEG1 to SEG160

COM A, COM B

DATA OUT

CLOCK OUT

LOAD OUT

SEG-TEST OUT

V

BLANK OUT

COM OUT

SYNC

V OSC2

4/17

Page 5

ML9060¡ Semiconductor

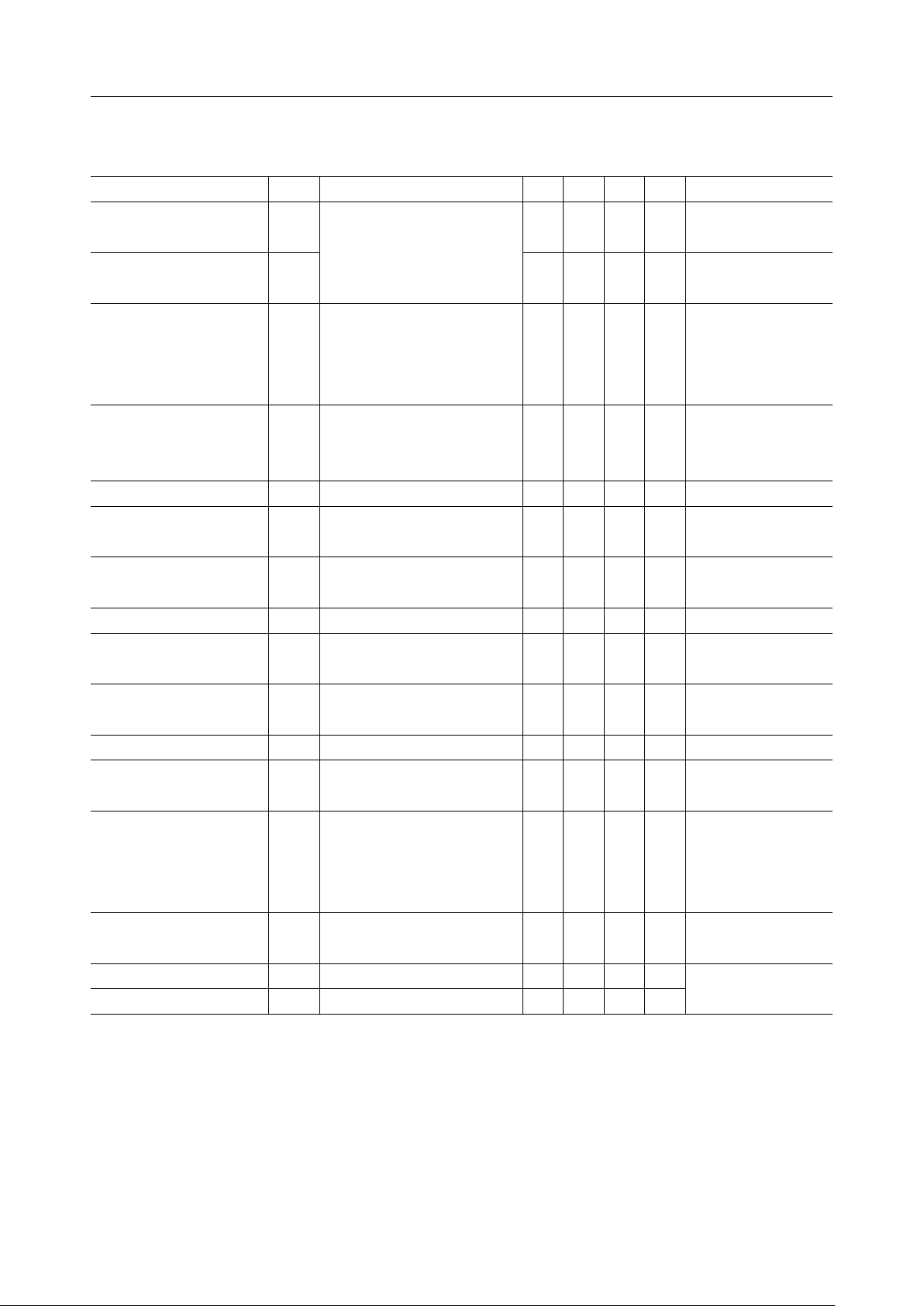

Parameter Symbol Condition Min. Typ. Max. Unit

Static supply current *4

Dynamic supply current *4

I

DDS1

I

DDS2

I

LCDS1

I

LCDS2

I

DD1

I

DD2

I

LCD1

I

LCD2

D/S = "L" (Static)

Fix other input levels

at either "H" or "L"

Oscillator stopped

No load

D/S = "H" (1/2duty)

Fix other input levels

at either "H" or "L"

Oscillator stopped

No load

D/S = "L" (Static)

Fix other input levels

at either "H" or "L"

Oscillator stopped

No load

D/S = "H" (1/2duty)

Fix other input levels

at either "H" or "L"

Oscillator stopped

No load

= 5.5V

V

DD

D/S = "L" (Static)

OSC1 is Open

OSC2 is connected to OSCR

Other inputs are "H" or "L"

No load

= 5.5V

V

DD

D/S = "H" (1/2duty)

OSC1 is Open

OSC2 is connected to OSCR

Other inputs are "H" or "L"

No load

= 5.5V

V

DD

D/S = "L" (Static)

OSC1 is Open

OSC2 is connected to OSCR

Other inputs are "H" or "L"

No load

V

= 5.5V

DD

D/S = "H" (1/2duty)

OSC1 is Open

OSC2 is connected to OSCR

Other inputs are "H" or "L"

No load

——

——

——

——

——

——

——

——

TBD

TBD

TBD

TBD

TBD

TBD

TBD

TBD

Applicable

m

A

m

A

m

A

m

A

mA

mA

m

A

m

A

pin

V

DD

V

DD

V

LCD

V

LCD

V

DD

V

DD

V

LCD

V

LCD

*1: Applicable to the DATA IN, LOAD IN, SEG-TEST IN, M/S, D/S, and OSC I/E pins.

*2: Applicable to the CLOCK IN, OSC1, and BLANK IN pins.

*3: Applicable to the voltage drop when the current flows into or out of one COM pin.

*4: The power supply current consumption will be determined finally at the end of sample

evaluations.

The LCD display data of “0” and “1” are input alternately.

5/17

Page 6

Switching Characteristics

Parameter

OSC IN Clock frequency

(external input)

Clock pulse width

(external input)

External Rf clock

frequency

(internal oscillations)

Internal Rf clock frequency

(with the built-in oscillator)

Data clock pulse width

Symbol

f

CP1

t

WCP1

f

OSC1

f

OSC2

f

CP2

t

WCP2

(VDD = 2.7 to 5.5V, V

Condition Min. Typ. Max. Unit Applicable pin

The clock is input to the

OSC1 pin. The pins OSC2

and OSCR are left open.

OSC I/E = "L"

An Rf of 120k W ±2% is

connected between OSC1

and OSC2. OSCR is left

open. OSC I/E = 'H"

OSC1 open. OSC2 and

OSCR shorted. OSC I/E

tied to V

or any "H" level.

DD

= 4.5 to 16V, Ta = –40 to +85°C)

LCD

— — 25.6 kHz

50——µs

7.7 12.8 20.5 kHz

OSC1

OSC1

OSC1, OSC2

OSC1, OSCR,

7.7 12.8 20.5 kHz

OSC2

— — 1 MHzData clock frequency CLOCK IN

100 — — ns

CLOCK IN

ML9060¡ Semiconductor

Data setup time

CLOCK to LOAD

Period

LOAD to CLOCK

Period

CLOCK IN to

DATA OUT delay time

COM OUT to SYNC

delay time

Input signal rise time

Input signal fall time

t

t

t

t

t

WLD

t

PLH

t

PHL

t

DIO

t

DCS

SU

HD

CL

LC

t

t

R

F

CL=15pF

CL=15pF

50——ns

DATA IN

50——nsData hold time CLOCK IN

100 — — ns

100 — — ns

CLOCK IN

LOAD IN

100 — — nsLOAD Pulse width LOAD IN

CLOCK IN

——50ns

DATA OUT

CLOCK IN/OUT

LOAD IN/OUT

——20nsIN to OUT delay time No load

SEG-TEST IN/OUT

BLANK IN/OUT

COM OUT

——40ns

——50ns

——50ns

SYNC

All inputs other than

the OSCR input

* : The specifications of the internal Rf clock frequency and the external Rf clock frequency will

be determined finally at the end of sample evaluations.

6/17

Page 7

TIMING DIAGRAM

t

WCP1

1/f

CP1

t

WCP1

ML9060¡ Semiconductor

OSC1

(External clock)

DATA IN

CLOCK IN

LOAD IN

DATA OUT

V

IH

V

IH

V

IL

t

SU

t

WCP2

V

V

IL

1/f

IL

CP2

V

IH

V

IL

V

IH

V

IL

t

HD

t

WCP2

V

IH

V

IH

V

IL

t

CL

t

t

PLH

PHL

V

VIHV

V

IL

V

IH

IL

V

IL

t

WLD

IH

V

IL

V

OH

V

OL

t

LC

CLOCK IN

LOAD IN

SEG-TEST IN

BLANK IN

CLOCK OUT

LOAD OUT

SEG-TEST OUT

BLANK OUT

All input signals

COM OUT

SYNC

V

IH

V

IL

t

DIO

V

OH

t

R

V

IH

V

IL

1/2V

DD

t

DCS

1/2V

t

DIO

V

OL

t

F

V

IH

V

IL

1/2V

DD

t

DCS

DD

1/2V

DD

7/17

Page 8

ML9060¡ Semiconductor

FUNCTIONAL DESCRIPTION

The ML9060 is an LCD driver LSI with an internal shift register and a set of internal data latches

and is capable of driving LCD displays of up to 320 segments either in the static mode or in the

1/2 duty mode. The display data is read into the shift register serially from the DATA IN pin

at the rising edge of the CLOCK IN input signal. The display data is transferred internally to

the data latches at the High level of the LOAD IN input signal and is output to the segments

via the segment drivers in this IC. The display data in the shift register is output via the DATA

OUT pin in synchronization with the falling edge of the CLOCK IN input signal. The display

data should be input in the sequence of SEG160, SEG159, ... , SEG2, SEG1 for proper display of

data.

Description of Pin Functions

• M/S

This is the input pin for selecting either the Master mode or the Slave mode. This LSI goes into

the master mode when this pin is High and enters the Slave mode when this pin is Low.

• D/S

This input pin is for selecting either the dynamic display mode at 1/2 duty (D mode - “H” input)

or the static display mode (S mode - “L” input).

Note that the internal bias resistor is made ON in the dynamic (D) mode and is turned OFF in

the static mode (S).

• OSC I/E

This is the input pin for selecting whether to use the external clock input mode, or the internal

Rf oscillation mode or the external Rf oscillation mode.

When this pin is tied to the “H” level, the internal Rf oscillation mode or the external Rf

oscillation is used. When this pin is tied to the “L” level, the external clock input is used for the

operation of the LSI.

In the slave mode of operation of this LSI, any input to this pin will be ignored. Hence, tie this

pin to VDD or GND in the slave mode.

• OSC1, OSCR, OSC2

These are the pins for the oscillator for generating the common signal.

In the Master mode (M/S pin = “H”):

It is possible to select from among the three modes - internal Rf oscillation mode, external Rf

oscillation mode, and the external clock input mode. During the static display operation mode,

a common signal with 1/128th the frequency of the clock oscillator is output via the COM OUT

pin.

During the 1/2 duty dynamic display operation mode, a common signal with 1/64th the

frequency of the clock oscillator is output via the COM OUT pin.

• Internal Rf oscillation mode: Tie the OSC I/E pin to “H”, short the pins OSCR and OSC2, and

leave the pin OSC1 open.

• External Rf oscillation mode: Tie the OSC I/E pin to “L”, connect an external resistor Rf

between the pins OSC1 and OSC2, and leave the pin OSCR open.

• External clock input mode: Tie the OSC I/E pin to “L”, leave open the pins OSCR and OSC2,

and input the external clock signal to the pin OSC1.

8/17

Page 9

ML9060¡ Semiconductor

In the Slave mode (M/S pin = “L”):

Leave open the pins OSCR and OSC2 and connect the pin OSC1 to the COM OUT pin of the

ML9060 which has been set in the master mode. The common signal that is input to the pin OSC1

will be used as the internal common signal and is also output via a buffer from the COM OUT

pin.

• COM OUT

This is the common signal output pin. Connect this pin to the OSC1 pin of the ML9060 that is

set in the slave mode.

During operation in the master mode (M/S pin = “H”) for static display, a common signal with

1/128th the frequency of the oscillator is output.

During operation in the master mode (M/S pin = “H”) for 1/2 duty dynamic display, a common

signal with 1/64th the frequency of the oscillator is output.

During operation in the slave mode (M/S pin = “L”), the common signal that is input at the pin

OSC1 is output from this pin via a buffer.

• SYNC

This is the I/O pin for common signal synchronization.

This pin becomes the synchronization signal output pin during operation in the master mode

(M/S pin = “H”) for 1/2 duty dynamic display.

This pin becomes the synchronization signal input pin during operation in the slave mode (M/

S pin = “H”) for 1/2 duty dynamic display.

For cascade operation in the 1/2 duty display mode, connect the SYNC pins of all ML9060 ICs

used together.

During operation in the static display mode, this pin is tied to the “L” level inside the IC.

Connect this pin either to GND or leave it open.

• DATA IN

This is the display data input pin. Input the display data in the sequence of SEG160, SEG159,

... , SEG2, SEG1. The segment is turned ON when the display data is “H” and OFF when “L”.

• DATA OUT

This is the display data output pin. During the static display mode of operation, the data of the

160th stage of the shift register is output from this pin. During the 1/2 duty dynamic display

mode, the data of the 320th stage of the shift register is output from this pin.

• CLOCK IN

This is the input pin for the shift clock of the display data. The display data that is input at the

DATA IN pin is input serially to the shift register at the rising edge of the CLOCK IN signal.

Also, the display data in the shift register is output from the DATA OUT pin at the falling edge

of the CLOCK IN signal.

• CLOCK OUT

This is the output pin for the shift clock of the display data. The shift clock signal that is input

to the CLOCK IN pin is output via a buffer from this pin.

• LOAD IN

This is the input pin for the display data load signal.

The display data in the shift register is output as such to the segment driver when this signal is

at the “H” level. When this signal is made “L”, the shift register is isolated from the segment

drivers, and the display data of the shift register just before this pin goes “L” is retained in the

data latches and transfered to the segment drivers.

9/17

Page 10

ML9060¡ Semiconductor

• LOAD OUT

This is the output pin for the display data load signal. The load signal that is input to the LOAD

IN pin is output from this pin via a buffer.

• SEG-TEST IN

This is the input pin for making all segments ON. When this pin is “H”, all segment outputs

(SEG1 to SEG160) become ON irrespective of the display data and the Blank signal. When this

pin is made “L”, each of the segment outputs (SEG1 to SEG160) become ON or OFF according

to the display data.

• SEG-TEST OUT

This is the output pin for making all segments ON. The segment ON signal that is input to at

the SEG-TEST IN pin is output via a buffer.

• BLANK IN

This is the input pin for making all segments OFF. When this pin is “H”, all segment outputs

(SEG1 to SEG160) become OFF irrespective of the display data. When this pin is made “L”, each

of the segment outputs (SEG1 to SEG160) becomes ON or OFF according to the display data. The

BLANK IN is valid when the segment ON signal is "L".

• BLANK OUT

This is the output pin for making all segments OFF. The segment OFF signal that is input to the

BLANK IN pin is output via a buffer.

• SEG1 to SEG160

These are the signal outputs for driving the LCD segments and are connected to the corresponding

segment pins of the LCD panel.

During the Static mode of operation:

The SEGn output corresponds to bit n of the display data in the data latch A. The display data

in the data latch B becomes invalid. In the segment ON condition, a signal with a phase opposite

to that of the COM OUT signal is output from these pins. In the segment OFF condition, a signal

with a phase identical to that of the COM OUT signal is output from these pins.

During the 1/2 duty dynamic display mode of operation:

The SEGn output corresponds to bit n of the display data in the data latch A when COM A has

been selected and to bin n of the display data in the data latch B when COM B has been selected.

In the segment display ON condition, a signal opposite in phase to that of the selected COM

output is output from these pins. In the segment display OFF condition, a signal identical in

phase to that of the selected COM output is output from these pins.

• COM A, COM B

These are the outputs for LCD display and are connected to the common pins of the LCD panel.

During the Static mode of operation:

COM A and COM B both output a signal with the same phase as that of the COM OUT signal.

10/17

Page 11

ML9060¡ Semiconductor

During the 1/2 duty dynamic display mode of operation:

COM A and COM B change their states at every cycle of the COM OUT signal and repeat the

selected and non-selected modes always opposing each other in phase. A signal with the same

phase as that of the COM OUT signal is output in the selected mode. A voltage equal to 1/2V

LCD

is output in the non-selected mode.

When COM A is in the selected mode (that is, COM B is in the non-selected mode), the segment

outputs (SEG1 to SEG160) output signals corresponding to the display data in the data latch A.

When COM B is in the selected mode (that is, COM A is in the non-selected mode), the segment

outputs (SEG1 to SEG160) output signals corresponding to the display data in the data latch B.

• V

DD

This is the power supply input pin for the logic circuits.

• V

LCD

This is the power supply input pin for the LCD drivers.

• GND

This is the ground pin for all circuits.

11/17

Page 12

Segment Output and Common Output Waveforms

During the 1/2 duty display operation mode:

COM OUT

SYNC

COM A

Selected

COM A

COM B

COM B

Selected

COM A

Selected

COM B

Selected

V

DD

GND

V

DD

GND

V

LCD

1/2V

GND

V

LCD

1/2V

GND

V

LCD

ML9060¡ Semiconductor

LCD

LCD

OFF OFF OFF OFF

SEGn

OFF ON OFF ON

ON OFF ON OFF

ON ON ON ON

Data latch A Data latch B Data latch A Data latch B

During the static display operation mode:

COM OUT

COM A

COM B

GND

V

LCD

GND

V

LCD

GND

V

LCD

GND

V

DD

GND

V

LCD

GND

V

LCD

GND

V

LCD

SEGn

OFF OFF OFF OFF

ON ON ON ON

GND

V

LCD

GND

12/17

Page 13

ML9060¡ Semiconductor

APPLICATION CIRCUIT EXAMPLES

When a single ML9060 is used - Static display mode (internal Rf oscillation mode)

From the controller

LCD Panel 160 segments,

static display

SEG160SEG1

SEG-TEST IN

BLANK IN

LOAD IN

DATA IN

CLOCK IN

D/S M/S OSC1 OSC2 OSCR OSC I/E

ML9060

open

COM

COM A

SYNC

openCOM B

GND

or

open

V

DD

When a single ML9060 is used - 1/2 duty dynamic display mode (external Rf oscillation

mode)

COM A

COM B

SEG160SEG1

COM A

COM B

SYNC

open

V

DD

From the controller

LCD Panel 320 segments,

1/2 Duty dynamic display

SEG-TEST IN

BLANK IN

LOAD IN

DATA IN

CLOCK IN

D/S M/S OSC1 OSC2 OSCR OSC I/E

ML9060

Rf

open

13/17

Page 14

Cascade Connection - Static display mode (external clock input mode)

LCD Panel (160 x n segments)

COM Static

ML9060¡ Semiconductor

From the controller

V

DD

External clock

160

COM A COM A

COM B COM B

SEG-TEST IN

BLANK IN

LOAD IN

DATA IN

CLOCK IN

D/S M/S OSC1 OSC2 OSCR OSC I/E

ML9060

SEG-TEST OUT

BLANK OUT

LOAD OUT

DATA OUT

CLOCK OUT

COM OUT

SYNC

open open

SEG-TEST IN

BLANK IN

LOAD IN

DATA IN

CLOCK IN

D/S M/S OSC1 OSC2 OSCR OSC I/E

160

ML9060

open open

SEG-TEST OUT

BLANK OUT

LOAD OUT

DATA OUT

CLOCK OUT

COM OUT

SYNC

V

DD

or

GND

open

openopen

open

Note: Take care about the resistance and capacitance of wiring for cascade connection.

Cascade Connection - 1/2 duty dynamic display mode (internal Rf oscillation mode)

LCD Panel (320 x n segments)

From the controller

V

DD

160

COM A COM A

COM B COM B

SEG-TEST IN

BLANK IN

LOAD IN

DATA IN

CLOCK IN

D/S M/S OSC1 OSC2 OSCR OSC I/E

ML9060

open

SEG-TEST OUT

BLANK OUT

LOAD OUT

DATA OUT

CLOCK OUT

COM OUT

SYNC

COM A

COM B 1/2 duty dynamic display

160

SEG-TEST IN

BLANK IN

LOAD IN

DATA IN

CLOCK IN

D/S M/S OSC1 OSC2 OSCR OSC I/E

ML9060

SEG-TEST OUT

BLANK OUT

CLOCK OUT

open open

LOAD OUT

DATA OUT

COM OUT

SYNC

V

DD

or

GND

Note: Take care about the resistance and capacitance of wiring for cascade connection.

open

open

open

14/17

Page 15

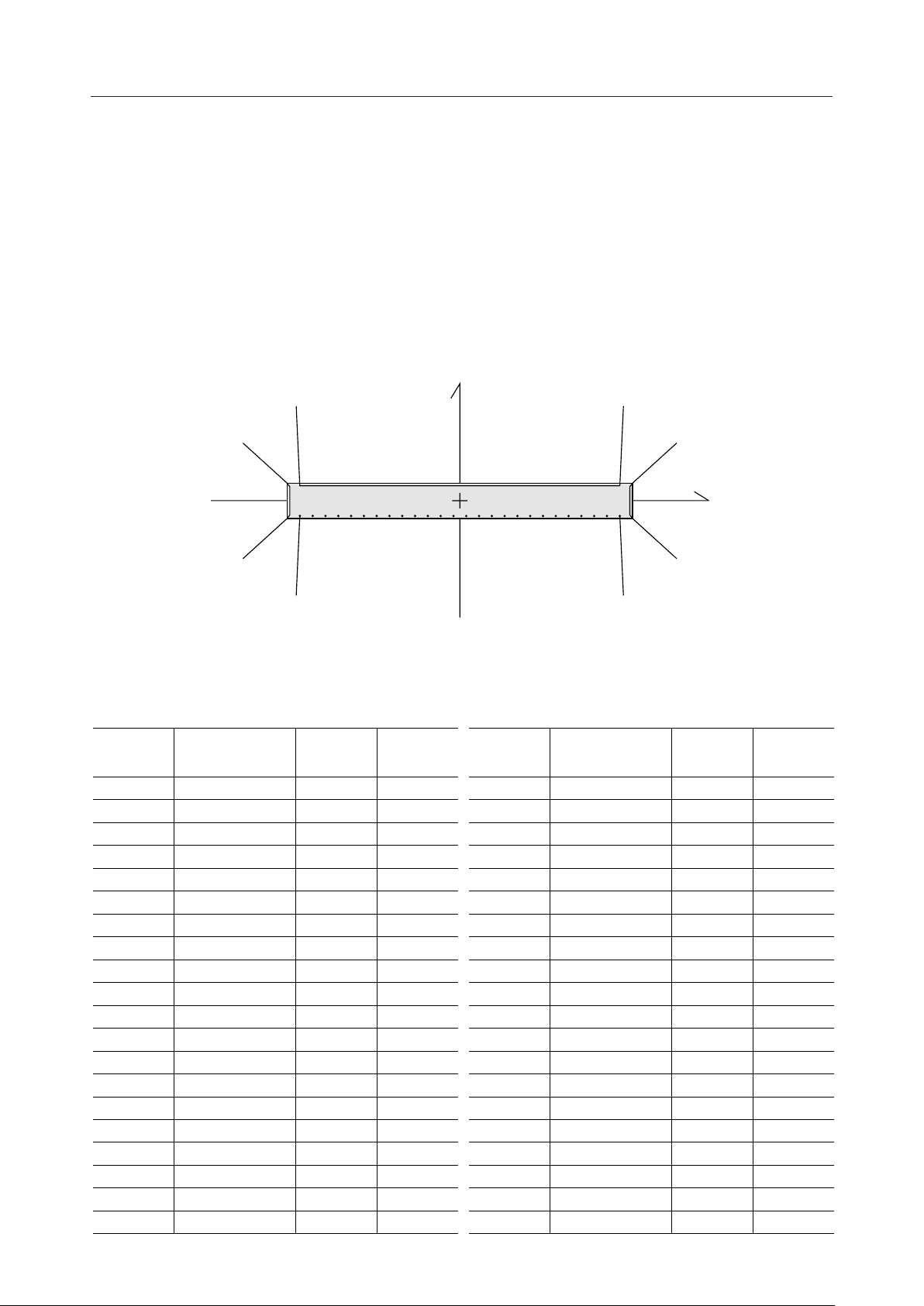

PAD CONFIGURATION

Pad layout (Pattern side)

Chip size : 14.50 ¥ 1.48mm

Chip thickness : 625mm ± 30mm

Minimum bump pitch : 80mm

Bump size : 50 ¥ 80µm

Bump height : 15mm ± 5µm

Bump height inside the chip: max. – min. ≤ 4µm

Bump hardness : max. 100 (HV: 25 g LOAD)

Y

204 37

205 36

ML9060¡ Semiconductor

X

214 27

126

* : The substrate of the chip should either be connected to the GND level or be left open.

Pad Coordinates

267

802

Y-coordinate

(mm)

Pad No.

Pad name

X-coordinate

21 –5614008OSC2

–561 4542

–561 5077

–561 5611

–561 6146

–561 6680

–561 7121

–561 7121

–561 7121

–561 7121

–561 7121

–561 7121

–561 7121

–561 7121

–561 7121

–561 7121

–561 6680

–561 6600

–561 6520

–561 6440

22 OSCR

23 OSC1

24

25

26

NC

NC

NC

27

28

29

30

31

32

33

34

35

36

NC

DATA IN

NC

CLOCK IN

LOAD IN

SEG-TEST IN

BLANK IN

NC

NC

37 NC

38 NC

39 NC

40 COMA

(mm)

Y-coordinate

(mm)

–561

–561

–561

–561

–561

–360NC

–280

–200

–120

Pad No.

1 –561–6680NC

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Pad name

NC

SYNC

NC

COMOUT

NC

V

LCD

V

LCD

V

LCD

NC

GND

GND

GND

D/S

OSC I/E

M/S

V

DD

V

DD

V

DD

NC

X-coordinate

(mm)

–6146

–5611

–5077

–4542

–4008

–3474

–2939

–2405

–1870

–1336

–802

–267

1336

1870

2405

2939

3474

–40

40

120

200

280

360

561

561

561

561

NC: No Connection

15/17

Page 16

ML9060¡ Semiconductor

Pad No.

Pad name

41 5616360COM B

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

X-coordinate

(mm)

6280

6200

6120

6040

5960

5880

5800

5720

5640

5560

5480

5400

5320

5240

5160

5080

5000

4920

4840

4760

4680

4600

4520

4440

4280

4200

4120

4040

3960

3880

3800

3720

3640

3560

3480

3400

3320

3240

3080

3000

2920

2840

Y-coordinate

(mm)

Pad No.

86 5612760SEG45

561SEG1 561SEG46

561SEG2 561SEG47

561SEG3 561SEG48

561SEG4 561SEG49

561SEG5 561SEG50

561SEG6 561SEG51

561SEG7 561SEG52

561SEG8 561SEG53

561SEG9 561SEG54

561SEG10 561SEG55

561SEG11 561SEG56

561SEG12 561SEG57

561SEG13 561SEG58

561SEG14 561SEG59

561SEG15 561SEG60

561SEG16 561SEG61

561SEG17 561SEG62

561SEG18 561SEG63

561SEG19 561SEG64

561SEG20 561SEG65

561SEG21 561SEG66

561SEG22 561SEG67

561SEG23 561SEG68

561SEG24 561SEG69

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

1114360 760561SEG25 561SEG70

561SEG26 561SEG71

561SEG27 561SEG72

561SEG28 561SEG73

561SEG29 561SEG74

561SEG30 561SEG75

561SEG31 561SEG76

561SEG32 561SEG77

561SEG33 561SEG78

561SEG34 561SEG79

561SEG35 561SEG80

561SEG36 561SEG81

561SEG37 561SEG82

561SEG38 561SEG83

561SEG39 561SEG84

561SEG40 561SEG85

561SEG41 561SEG86

561SEG42 561SEG87

561SEG43 561SEG88

561SEG44 561SEG89

112

113

114

115

116

117

118

119

120

121

122

123

124

125

1263160

127

128

129

130

Pad name

X-coordinate

(mm)

2680

2600

2520

2440

2360

2280

2200

2120

2040

1960

1880

1800

1720

1640

1560

1480

1400

1320

1240

1160

1080

1000

920

840

680

600

520

440

360

280

200

120

40

–40

–120

–200

–280

–360

–440

–520

–600

–680

–760

Y-coordinate

(mm)

16/17

Page 17

ML9060¡ Semiconductor

Pad No.

Pad name

131 561–840SEG90

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

X-coordinate

(mm)

–920

–1000

–1080

–1160

–1240

–1320

–1400

–1480

–1560

–1640

–1720

–1800

–1880

–1960

–2040

–2120

–2200

–2280

–2360

–2440

–2520

–2600

–2680

–2760

–2920

–3000

–3080

–3160

–3240

–3320

–3400

–3480

–3560

–3640

–3720

–3800

–3880

–3960

–4040

–4120

–4200

–4280

–4360

Y-coordinate

(mm)

Pad No.

Pad name

176 561–4440SEG135

561SEG91 561SEG136

561SEG92 561SEG137

561SEG93 561SEG138

561SEG94 561SEG139

561SEG95 561SEG140

561SEG96 561SEG141

561SEG97 561SEG142

561SEG98 561SEG143

561SEG99 561SEG144

561SEG100 561SEG145

561SEG101 561SEG146

561SEG102 561SEG147

561SEG103 561SEG148

561SEG104 561SEG149

561SEG105 561SEG150

561SEG106 561SEG151

561SEG107 561SEG152

561SEG108 561SEG153

561SEG109 561SEG154

561SEG110 561SEG155

561SEG111 561SEG156

561SEG112 561SEG157

561SEG113 561SEG158

561SEG114 561SEG159

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201–2840 –6440561SEG115 561SEG160

561SEG116 561NC

561SEG117 561NC

561SEG118 561NC

561SEG119 360NC

561SEG120 280NC

561SEG121 200BLANKOUT

561SEG122 120SEG-TESTOUT

561SEG123 40LOADOUT

561SEG124 –40CLOCKOUT

561SEG125 –120NC

561SEG126 –200DATAOUT

561SEG127 –280NC

561SEG128 –360NC

202

203

204

205

206

207

208

209

210

211

212

213

214

561SEG129

561SEG130

561SEG131

561SEG132

561SEG133

561SEG134

X-coordinate

(mm)

–4520

–4600

–4680

–4760

–4840

–4920

–5000

–5080

–5160

–5240

–5320

–5400

–5480

–5560

–5640

–5720

–5800

–5880

–5960

–6040

–6120

–6200

–6280

–6360

–6520

–6600

–6680

–7121

–7121

–7121

–7121

–7121

–7121

–7121

–7121

–7121

–7121

Y-coordinate

(mm)

17/17

Page 18

E2Y0002-29-11

NOTICE

1. The information contained herein can change without notice owing to product and/or

technical improvements. Before using the product, please make sure that the information

being referred to is up-to-date.

2. The outline of action and examples for application circuits described herein have been

chosen as an explanation for the standard action and performance of the product. When

planning to use the product, please ensure that the external conditions are reflected in the

actual circuit, assembly, and program designs.

3. When designing your product, please use our product below the specified maximum

ratings and within the specified operating ranges including, but not limited to, operating

voltage, power dissipation, and operating temperature.

4. Oki assumes no responsibility or liability whatsoever for any failure or unusual or

unexpected operation resulting from misuse, neglect, improper installation, repair, alteration

or accident, improper handling, or unusual physical or electrical stress including, but not

limited to, exposure to parameters beyond the specified maximum ratings or operation

outside the specified operating range.

5. Neither indemnity against nor license of a third party’s industrial and intellectual property

right, etc. is granted by us in connection with the use of the product and/or the information

and drawings contained herein. No responsibility is assumed by us for any infringement

of a third party’s right which may result from the use thereof.

6. The products listed in this document are intended for use in general electronics equipment

for commercial applications (e.g., office automation, communication equipment,

measurement equipment, consumer electronics, etc.). These products are not authorized

for use in any system or application that requires special or enhanced quality and reliability

characteristics nor in any system or application where the failure of such system or

application may result in the loss or damage of property, or death or injury to humans.

Such applications include, but are not limited to, traffic and automotive equipment, safety

devices, aerospace equipment, nuclear power control, medical equipment, and life-support

systems.

7. Certain products in this document may need government approval before they can be

exported to particular countries. The purchaser assumes the responsibility of determining

the legality of export of these products and will take appropriate and necessary steps at their

own expense for these.

8. No part of the contents cotained herein may be reprinted or reproduced without our prior

permission.

9. MS-DOS is a registered trademark of Microsoft Corporation.

Copyright 1999 Oki Electric Industry Co., Ltd.

Printed in Japan

Loading...

Loading...