Page 1

D

ATA SHEET

O K I N E T W O R K P R O D U C T S

ML53812-2

H.100/H.110 CT Bus System Interface and

Time-Slot Interchange

January 2000

Page 2

Revision History

September 1999 320101-005 Previous Release

January 2000 320101-006 Timing tables altered on page 50:

“Local Clock and Frame Synchronization Timing”,

“Local Clock to CT Bus Clock Skew”, and

“Local Serial Stream Timing”

Timing diagram (Figure 11) atered on page 51:

“Local Clock and Frame Synchronization Timing”

Oki Semiconductor

Page 3

Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ML53812-2 176-Pin LQFP Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Signal descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Local Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CT Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Test Access Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pin Continuity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Analog PLL Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Microprocessor Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Analog PLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Slave PLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Master PLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reference Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Local Clock and Frame Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Local Streams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CT Bus Streams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CT_D disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

GPIO Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Message Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Microprocessor Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Command/Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Internal Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Device ID Registers (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Stream Switch Routing Registers, AR = 1007h:1000h (Ch. 7:0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Stream Switch Connection Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Transmit Switch Routing Registers, AR = 20ffh:2000h (Ch. 255:0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Receive Switch Routing Registers, AR = 30ffh:3000h (Ch. 255:0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Indirect Transmit Switch Parallel Access Registers, AR = 40ffh:4000h (Ch. 255:0) . . . . . . . . . . . . . . . . . . . 45

Indirect Receive Switch Parallel Access Registers, AR = 50ffh:5000h (Ch. 255:0) . . . . . . . . . . . . . . . . . . . . 45

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DC Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

AC Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

H.100/H.110 Bus Timing Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Clock Skew Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ML53812-2 Package specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

LQFP176 Package Outlines and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

LQFP176 Mounting Pad Reference Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Oki Semiconductor

Page 4

■ ■

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Oki Semiconductor

Page 5

ML53812-2

H.100/H.110CT Bus System Interface and Time Slot Interchange

1.0 DESCRIPTION

The ML53812-2 is a complete CT Bus system interface and time slot interchange device that provides a

cost-effective connection between a computer board’s telephony interfaces or signal processing resources

and the CT Bus. The ML53812-2 is an evolution of existing time-slot interchange ICs which offers seam-

less interoperability with SCbus devices.

A key element in computer telephony (CT) equipment is the auxiliary telecom bus. Most manufacturers

of high-capacity CT equipment have used one or more types of telecom buses to transport and switch

low-latency communications traffic between boards within the computer, bypassing the computer’s

main I/O and memory buses. To simplify the integration of devices that incorporate a telecom bus, the

Enterprise Computer Telephony Forum (ECTF) developed a standard bus (H.100/H.110 CT Bus™) that

provides compatibility modes with the most prevalent telecom buses today (SCbus™ and MVIP-90™),

as well as the capacity and feature set needed to support the next generation of high capacity CT servers.

The new CT Bus is embraced by Dialogic under the Signal Computing System Architecture™ (SCSA™)

umbrella of open standards for building interoperable CT systems.

The ML53812-2 runs in both 4 MHz and 8 MHz SCbus modes and supports the switching features

needed to integrate CT Bus devices with 4 MHz SCbus, 8 MHz SCbus, and 2 MHz MVIP-90 devices.

Because the H.100/H.110 CT Bus uses an identical switching model and clock speeds to that used for the

SCbus, developers have unparalleled flexibility in integrating these two types of devices, or in transition-

ing from one type to the other.

The ML53812-2 takes full advantage of the mandatory and optional features defined in the ECTF H.100

and H.110 interoperability specifications. It is a non-blocking 512 x 4096 time slot switch, interfacing up

to 512 ports on its parent device to any of the 4096 time slots on the new CT Bus. The high number of local

time slots available makes it easier to design high-density CT hardware, supporting as many as eight net-

work interfaces or 256 voice processing ports per chip.

This powerful chip is offered in an ultra slim profile (176-pin LQFP package, with a 24 mm x 24 mm x 1.4

mm body size) that makes it possible to mount the chip on either side of the board. The chip is fully soft-

ware programmable, and can be controlled by a variety of microprocessors, including Intel and Motorola

in both multiplexed and nonmultiplexed modes.

1Oki Semiconductor

Page 6

■

ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

2.0 FEATURES

• High functionality, low cost implementation of

the ECTF H.100/H.110 interoperability

specifications.

• Simple to connect PCI and cPCI™ board-level

circuitry to the universally accepted CT Bus™.

• Ultra slim profiling (176-pin LQFP package).

• Up to 512 programmable connections (256

transmit and 256 receive) to any of the 4096

time slots on the H.100/H.110 CT Bus.

• 8-channel stream-to-stream switching for data

stream connections at variable rates.

• Implementation of all compatibility signals for

complete interoperability with existing 4 MHz

SCbus™, 8 MHz SCbus, 2 MHz MVIP-90™

devices, and H-MVIP™.

• Provides reliable clock synchronization for

network-grade connection to digital network

interfaces.

2.1 Applications

• Supports all H.100/H.110 CT Bus clock fallback

features.

• Choice of constant or minimum switching

delay on a per time slot basis.

• 3.3 V I/O with 5 V tolerant input.

• Supports multiplexed and nonmultiplexed

address/data bus modes for both Intel and

Motorola microprocessors.

• Supports CT Bus optional message channel

interface, for both H.100 (PCI) and H.110 (cPCI)

applications.

• Supports a variety of framing formats via a

configurable local bus.

• Efficient microprocessor interface access to

Local and CT Bus data streams through direct

parallel access to/from transmit and receive

switch.

• Low and high-density computer telephony hardware (PCI and cPCI platforms)

• Enhanced service platforms

• Private branch exchanges (PBXs)

• Wireless base stations

• Internet telephony systems

• Digital trunking equipment

2 Oki Semiconductor

Page 7

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2

3.0 PIN CONFIGURATION

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

■

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

123456789

1011121314151617181920212223242526272829303132333435363738394041424344

Figure 1. ML53812-2 176-Pin LQFP Pin Configuration

3Oki Semiconductor

Page 8

■

ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

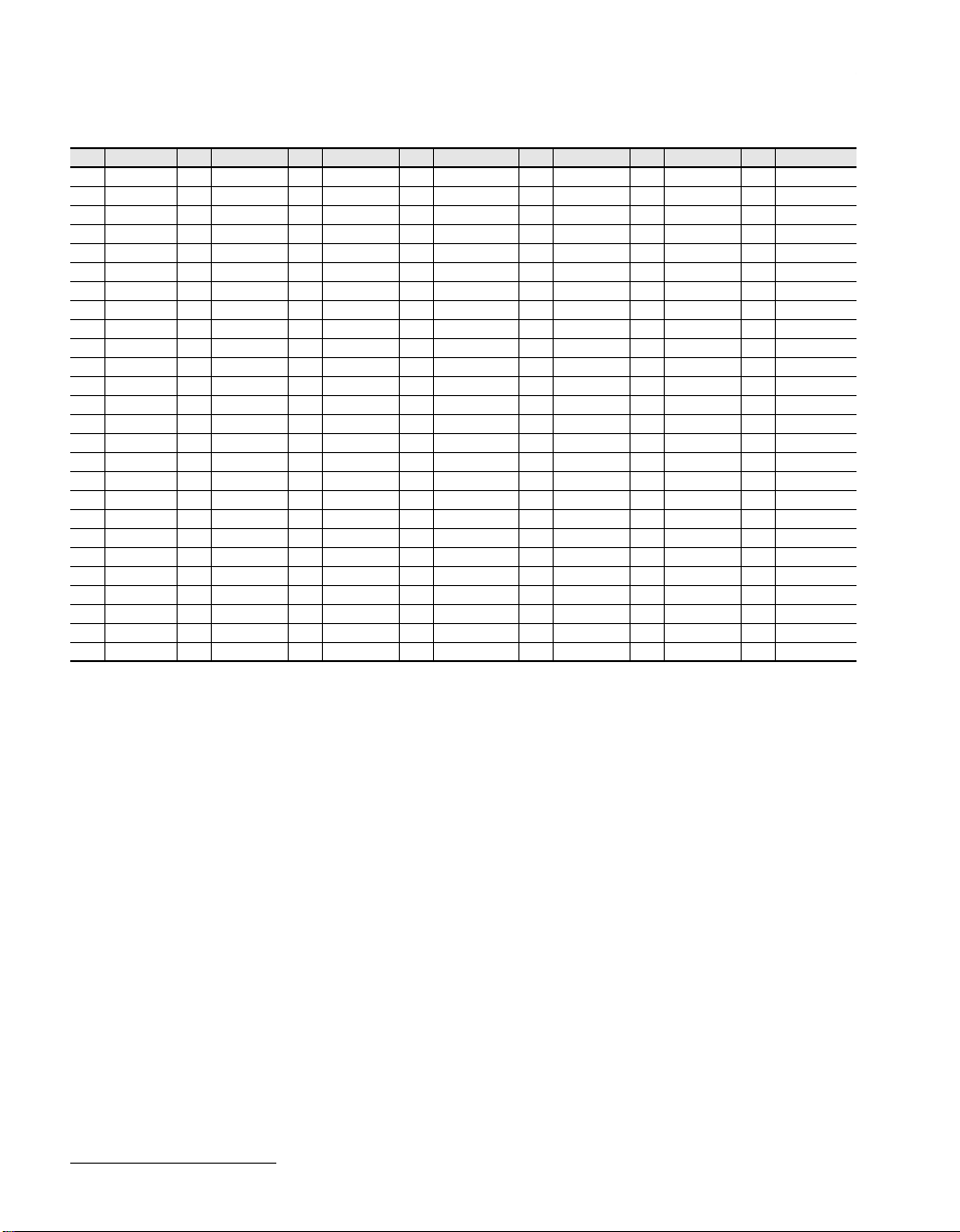

3.1 ML53812-2 176-Pin LQFP Pin Assignment

Pin Pin Name Pin Pin Name Pin Pin Name Pin Pin Name Pin Pin Name Pin Pin Name Pin Pin Name

1 VDDC 27 D_6 53 VSSO 79 VDDO 105 CT_D_9 131 CT_D_25 157 L_SI_6

2 ALE 28 A_6 54 APPL_CLKREF 80 CT_FRAME_B_N 106 CT_D_10 132 VSSC 158 L_SI_7

3 VDDO 29 D_7 55 APLL_TEST 81 VSSO 107 VDDO 133 VDDC 159 VSSO

4 CS_N 30 A_7 56 TMS 82 CT_NETREF_2 108 CT_D_11 134 CT_D_26 160 L_SO_0

5 RD_N 31 A_8 57 TCK 83 CT_NETREF_1 109 VSSO 135 VDDO 161 L_SO_1

6 WR_N 32 A_9 58 TRST_N 84 VDDO 110 CT_D_12 136 CT_D_27 162 L_SO_2

7 VSSO 33 NC 59 TDI 85 CT_C8_A 111 CT_D_13 137 VSSO 163 L_SO_3

8 RESET 34 VDDO 60 TDO 86 VSSO 112 VDDO 138 CT_D_28 164 VDDO

9 I_N 35 L_NETREF_0 61 VDDO 87 CT_FRAME_A_N 113 CT_D_14 139 CT_D_29 165 L_SO_4

10 INT 36 L_NETREF_1 62 MC_TXD 88 VSSC 114 VSSO 140 VDDO 166 L_SO_5

11 VDDO 37 L_NETREF_2 63 MC_RXD 89 VDDC 115 CT_D_15 141 CT_D_30 167 L_SO_6

12 D_0 38 L_NETREF_3 64 MC_CLK 90 CT_D_0 116 CT_D_16 142 CT_D_31 168 L_SO_7

13 A_0 39 VSSO 65 VSSO 91 VDDO 117 VDDO 143 VSSO 169 VSSO

14 D_1 40 L_NETREF_4 66 C16_NEG_N 92 CT_D_1 118 CT_D_17 144 GPIO_0 170 L_CLK_0

15 A_1 41 L_NETREF_5 67 C16_POS_N 93 CT_D_2 119 CT_D_18 145 GPIO_1 171 L_FS_0

16 VSSO 42 L_NETREF_6 68 VDDO 94 VSSO 120 VSSO 146 VDDO 172 L_CLK_1

17 D_2 43 L_NETREF_7 69 C4_N 95 CT_D_3 121 CT_D_19 147 GPIO_2 173 L_FS_1

18 A_2 44 VSSC 70 C2 96 CT_D_4 122 VDDO 148 GPIO_3 174 CT_D_DISABLE

19 D_3 45 VDDC 71 VSSO 97 VDDO 123 CT_D_20 149 VSSO 175 TEST

20 A_3 46 VDDO 72 SCLKX2_N 98 CT_D_5 124 VSSO 150 L_SI_0 176 VSSC

21 VDDO 47 APLL_VDDO 73 SCLK 99 VSSO 125 CT_D_21 151 L_SI_1

22 D_4 48 APLL_VDDC 74 VDDO 100 CT_D_6 126 CT_D_22 152 L_SI_2

23 A_4 49 APPL_PC 75 FR_COMP_N 101 VDDO 127 VDDO 153 L_SI_3

24 D_5 50 APPL_VCO 76 CT_MC 102 CT_D_7 128 CT_D_23 154 VDDO

25 A_5 51 APPL_VSSC 77 VSSO 103 CT_D_8 129 CT_D_24 155 L_SI_4

26 VSSO 52 APLL_VSSO 78 CT_C8_B 104 VSSO 130 VSSO 156 L_SI_5

[1]

1. In this document, signals ending with “_N” are “active low” (eg. CS_N). Note that in the H.100/H110 specification, active low is indicated with a

preceding forward slash (eg. /CS).

4 Oki Semiconductor

Page 9

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2

4.0 SIGNAL DESCRIPTIONS

Signal Description

Name

D_[7:0] Microprocessor Data Bus. (I/O, TTL Schmitt, 8 mA, 5V tolerant)

A_ [9:0] Microprocessor Address Bus. (Input, TTL Schmitt, 5V tolerant)

ALE (AS) Intel Bus Mode - Address Latch Enable. Motorola Bus Mode - Address Strobe. The Microprocessor Address Bus A[9:0] is latched

CS_N Chip Select. This active low signal selects the ML53812-2 for a microprocessor read or write operation. (Input, TTL Schmitt, 5V

RD_N (STRB_N) Intel Bus Mode - Microprocessor Bus Read. Motorola Bus Mode - Microprocessor Bus Strobe. (Input, TTL Schmitt, 5V tolerant)

WR_N (R/W_N) Intel Bus Mode - Microprocessor Bus Write. Motorola Bus Mode - Microprocessor Bus Read/Write signal.

RESET Reset. This active high input signal initializes the microprocessor interface, configuration, and routing registers. (Input, TTL

I_N (M) Microprocessor Bus Mode. When this input is low, Intel Bus Mode is selected. When this input is high, Motorola Bus Mode is

CT_D_DISABLE CT_D Global disable. (I/O, TTL Schmitt, 8 mA, 50 k Pull Up, 5V tolerant)

L_NETREF_[7:0] Local Network Reference [7:0] Input. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

L_SI_[7:0] Local bus Serial Input Data Input. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

MC_TXD Message Channel Transmit Data Input. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

APLL_CLKREF Analog PLL Clock Reference Input. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

APLL_VDDO +3.3 Volt Analog PLL I/O Power Supply

APLL_VDDC +3.3 Volt Analog PLL Core Power Supply

APLL_PC Analog PLL Phase Comparator Analog Output

APLL_VCO Analog PLL VCO Analog Input

APLL_VSSC Analog PLL Core Ground

APLL_VSSO Analog PLL I/O Ground

APLL_TEST Analog PLL Test Enable Input. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

TEST Test Select. This input enables the pin continuity test. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

TMS Test Access Port Mode Select. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

TCK Test Access Port Clock. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

TRST_N Test Access Port Reset. (active low). (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

TDI Test Access Port Data Input. (Input, TTL Schmitt, 50 k Pull Up, 5V tolerant)

INT Interrupt Output. (I/O, TTL Schmitt, 50 k Pull Up, 8 mA, 5V tolerant)

CT_D_[31:0] CT Bus Serial Data Streams. (I/O, PCI, 5V tolerant)

CT_FRAME_A_N CT Bus "A" Frame Sync. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

CT_C8_A CT Bus "A" 8 MHz Clock. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

CT_NETREF_1 CT Bus Network Reference 1. (I/O, PCI, 5V tolerant)

CT_NETREF_2 CT Bus Network Reference 2. (I/O, PCI, 5V tolerant)

CT_FRAME_B_N CT Bus "B" Frame Sync. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

CT_C8_B CT Bus "B" 8 MHz Clock. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

CT_MC CT Bus Message Channel. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

[1]

Description

internally on the falling edge of this signal. (Input, TTL Schmitt, 5V tolerant)

tolerant)

(Input, TTL Schmitt, 5V tolerant)

Schmitt, 5V tolerant)

selected. (Input, TTL Schmitt, 5V tolerant)

■

5Oki Semiconductor

Page 10

■

ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Signal Description

Name

FR_COMP_N Compatibility frame sync used by SCbus, MVIP-90, and H-MVIP. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

SCLK SCbus Clock. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

SCLKX2_N SCbus X2 Clock. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

C2 MVIP-90 2.048 MHz Clock. (I/O, TTL Schmitt, 6 mA, 5V tolerant)

C4_N MVIP-90 4.096 MHz Clock. (I/O, TTL Schmitt, 6 mA, 5V tolerant)

C16_POS_N H-MVIP 16.384 MHz Positive active low Clock. High to low transition on frame boundary. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

C16_NEG_N H-MVIP 16.384 MHz Negative active low Clock. Low to high transition on frame boundary. (I/O, TTL Schmitt, 24 mA, 5V tolerant)

L_CLK_1 Local bus Clock 1. (I/O, TTL Schmitt, 24 mA, 50 k Pull Up, 5 V tolerant)

L_FS_1 Local bus Frame Sync 1. (I/O, TTL Schmitt, 24 mA, 50 k Pull Up, 5V tolerant)

L_CLK_0 Local bus Clock 0. (I/O, TTL Schmitt, 24 mA, 50 k Pull Up, 5 V tolerant)

L_FS_0 Local bus Frame Sync 0. (I/O, TTL Schmitt, 50 k Pull Up, 24 mA, 5V tolerant)

L_SO_[7:0] Local bus Serial Output Data Streams. (I/O, TTL Schmitt, 50 k Pull Up, 8 mA, 5V tolerant)

MC_CLK Message Channel Clock Output. (I/O, TTL Schmitt, 50 k Pull Up, 6 mA, 5V tolerant)

MC_RXD Message Channel Receive Data Output. (I/O, TTL Schmitt, 50 k Pull Up, 6 mA, 5V tolerant)

GPIO_[3:0] General Purpose I/O ports. (I/O, TTL Schmitt, 24 mA, 50 k Pull Up, 5V tolerant)

TDO Test Access Port Data Output. (Output, 6 mA, 5V tolerant)

NC No Connect

VDDO +3.3 Volt I/O Power Supply

VSSO I/O Ground

VDDC +3.3 Volt Core Power Supply

VSSC Core Ground

1. Signals ending in “_N” are active low.

[1]

Description

6 Oki Semiconductor

Page 11

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2

5.0 FUNCTIONAL DESCRIPTION

The ML53812-2 has the following interfaces:

■

• Microprocessor Interface

• Local Serial Data In

• Local Serial Data Out

• Local Timing

Microprocessor

Interface

Local Serial

Data In

Local Serial

Data Out

Local Timing

APLL

Reference Clock

Configuration &

Routing Register

Internal Control

• Analog PLL Reference Clock

• CT Bus Timing

• CT Bus Serial Data

8 Channel

Stream Switch

256 x 4096

Transmit Switch

Local

Connect

4352 x 256

Receive Switch

Internal Timing

Slave Digital

PLL

Master

Digital PLL

Analog

PLL

131.072 MHz

Figure 2. Block Diagram

CT Bus Serial Data

CT Bus Timing

5.1 Local Bus

The local bus consists of up to eight serial input ports and eight serial output ports, totalling 512 possible

local bus connections to the CT Bus. The input and output ports can be configured independently as two

groups of four 2 Mb/s streams, two 4 Mb/s streams, or one 8 Mb/s stream. The chip includes two independent, configurable local clock and frame synchronization signals. The local clocks have configurable

polarity and frequency that can be set to 2 MHz, 4 MHz, 8 MHz, or 16 MHz regardless of local stream

data rate. The local frame syncs also have a configurable polarity and can be set to use one of three framing formats (early, straddle, or late).

To transfer data to and from the local bus, the ML53812-2 allows the user to select a minimum delay or

constant delay buffer mode on a per channel basis. In the minimum delay mode, the input-output buffer

transfer occurs on the next 2 Mb/s time slot boundary, reducing any potential channel delay for classic

voice processing applications. In the constant delay mode, the buffer transfer occurs at the frame boundary for bundling and proper switching of wide-band data, for data sent on the ISDN H channel.

7Oki Semiconductor

Page 12

■

ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

5.2 CT Bus

The ML53812-2 provides access to all 4096 CT Bus time slots. The upper 16 data lines run at 8 Mb/s,

while the lower 16 data lines can be configured, in groups of four, to run at 8 Mb/s, 4 Mb/s, or 2 Mb/s

for compatibility with SCbus and MVIP-90 devices.

The chip uses an internal analog phase locked loop (PLL) as a rate multiplier to produce a 131.072 MHz

internal clock locked to a variety of reference frequencies. This high frequency internal clock provides

fine grained correction steps (7.6 nS) for the master and slave digital PLLs. The main CT Bus network reference signal can be configured to run at 8 kHz, 1.544 MHz, or 2048 MHz. The timing for the CT Bus can

be configured to be derived from the local clock and frame sync signals to allow multiple chips to be connected to the CT Bus without overloading the reference clock line.

The ML53812-2 incorporates internal master digital PLL circuitry that is designed to meet the jitter attenuation, holdover and Maximum Time Interval Error (MTIE) requirements of 62411 Stratum 3,4 and 4E.

This enables the ML53812-2 to be well suited for developers of digital telephone network interfaces,

where reliable clock synchronization is critical. Because the circuitry is internal, board designers do not

have to add expensive or custom circuitry to support these types of environments.

The ML53812-2 also includes an 8-channel stream-to-stream switch to connect one CT Bus data stream to

another at the same or different data rates. This type of connection makes it possible for CT Bus compatible devices (such as SCbus and MVIP-90) to efficiently exchange data even though they operate at different rates. This stream switch enables switching between any of the 32 CT Bus data streams operating at

2, 4, or 8 Mb/s. Depending upon the data stream rates, the stream switch provides a minimum of 256 and

a maximum of 1024 unidirectional time slot connections. Stream switches in other ML53812-2 devices,

within a system, may be used simultaneously to increase switching capability.

5.3 Test Access Port

The current version of the ML53812-2 does not support IEEE 1149.1 Boundary Scan. The Test Access Port

on the ML53812-2 passes TDI through to TDO when TMS and TRST_N are both high which simplifiers

the transition to eventual Boundary Scan support. Drive TMS and TRST_N both low for normal operation.

5.4 Pin Continuity Test

For normal operation, the TEST pin is driven low. When the TEST pin is high, all pins except VDD, VSS,

NC, APLL_PC, APLL_VCO, TMS, TCK, TRST_N, TDI, TDO, TEST are sequentially "NAND’ed" with

ALE and output on TDO. This test allows each input pin to be toggled and a corresponding output to be

observed on the TDO pin to verify the proper connection of the ML53812-2 to a printed circuit board.

5.5 Analog PLL Test

For normal operation, the APLL_TEST pin is driven low.

5.6 Microprocessor Interface

Both Intel and Motorola microprocessor bus interfaces are supported. Drive I_N (M) low for Intel mode

and high for Motorola mode. Multiplexed addresses are latched on the falling edge of ALE (AS). If multiplexed address is not used, drive ALE (AS) high. Multiplexed address and data must be connected to

both A_ and D_ pins.

8 Oki Semiconductor

Page 13

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2

5.7 Analog PLL

The analog PLL is used to create an internal 131.072 MHz clock locked to one of several reference frequencies. The analog PLL reference signal is input on the APLL_CLKREF pin and should be a stable

clock typically

±

25 ppm. An external loop filter is required (see

Figure 3

).

■

0.01 µF

R2

100Ω

CI

R1

19 kΩ

APLL_PC

APLL_VCO

APLL_VSS

Figure 3. Analog PLL Loop Filter

5.8 Slave PLL

The slave PLL is used to generate all of the internal timing for the ML53812-2. Even when the ML538122 is enabled as master, the slave PLL is still in operation. The slave PLL is a fast tracking digital PLL operating at 131.072 MHz.

The slave PLL can be configured to lock to one of the following sources:

• CT_C8_A and CT_FRAME_A

• CT_C8_B and CT_FRAME_B

• SCLK and FR_COMP

• C2 and FR_COMP

• L_CLK_0 and L_FS_0

• L_CLK_1 and L_FS_1

5.9 Master PLL

The master PLL is used to generate timing for the CT Bus. The master PLL is a digital PLL operating at

131.072 MHz. When operating as primary master the PLL can lock to one of eight local network references, or one of two CT Bus network references. These reference signals may be 8 kHz, 1.536 MHz, 1.544

MHz or 2.048 MHz. When operating as secondary master the PLL locks to the primary CT Bus master.

The master PLL can be configured to automatically switch from secondary to primary in the event of a

CT Bus timing error.

The master PLL can be configured to drive either the CT Bus "A" or "B" signals as well as all of the compatibility clocks defined in the H.100/H.110 Specifications.

When operating as the primary master, the PLL provides jitter attenuation with a cut-off frequency of

1.25 Hz and a roll-off of 20dB per decade. When operating as the secondary master, the PLL is fast tracking.

When operating as the primary master, the PLL has a lock range of ±488 ppm (minus the tolerance of

APLL_CLKREF source). The maximum lock time is 3s. Holdover stability is 0.06 ppm, resulting in a

frame slip rate of 42/day, assuming no drift in APLL_CLKREF source, exceeding the 62411 Stratum 3

requirement of 255/day. During normal operation new holdover values are updated at 128ms intervals.

9Oki Semiconductor

Page 14

■

ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

To make an MTIE compliant reference switch, enable "Condition Master PLL reference", select the "Master PLL Reference", and configure the "Master PLL Mode " to normal.The master PLL will be locked to

the selected reference.

The following sequence will produce an MTIE-compliant reference switch:

1. Change the "Master PLL Mode" from Normal to Holdover. The master PLL can also be configured to

make this change automatically in the event of a master PLL error.

2. Change the "Master PLL Reference Select" to the new reference, or change the reference source of

CT_NETREF.

3. Change the "Master PLL Mode" back to Normal.

MTIE Specifications

ML53812-2

MTIE during rearrangement 100 ns 1 µs

Phase change slope 81 ns / 1.326 ms 81 ns / 1.326 ms

62411 Stratum 3 and 4E

5.10 Reference Master

CT_NETREF_1 and CT_NETREF_2 can be independently configured to output a reference signal to the

CT Bus selected from one of eight local network reference inputs. The local network references can be

passed through or divided by 192, 193, or 256.

5.11 Local Clock and Frame Sync

Two sets of local clock and frame sync are provided. A variety of clock frequencies, polarities, and framing formats may be selected to allow "glue less" local port interfacing. Each set of local clock and frame

sync may be configured separately. The frequency selection is independent of the local stream rate.

5.12 Local Streams

The local streams consist of up to eight serial input ports and eight serial output ports, defined as two

groups of 128 time-slots. Each group can be independently configured to operate as four 2 Mb/s streams,

two 4 Mb/s streams, or one 8 Mb/s stream.

Local Stream Time Slot to Channel Mapping

Local stream 8Mb/s stream rate time slot 127:0 4Mb/s stream rate time slot 63:0 2Mb/s stream rate time slot 31:0

L_SI_0,L_SO_0 channel 127:0 channel 63:0 channel 31:0

L_SI_1,L_SO_1 - channel 127:64 channel 63:32

L_SI_2,L_SO_2 - - channel 95:64

L_SI_3,L_SO_3 - - channel 127:96

L_SI_4,L_SO_4 channel 255:128 channel 191:128 channel 159:128

L_SI_5,L_SO_5 - channel 255:192 channel 191:160

L_SI_6,L_SO_6 - - channel 223:192

L_SI_7,L_SO_7 - - channel 255:224

10 Oki Semiconductor

Page 15

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2

5.13 CT Bus Streams

Connection to all 32 CT Bus streams is supported without restriction. The upper 16 streams run at 8Mb/s

while the lower 16 may be configured, in groups of four, to operate at 8Mb/s, 4Mb/s, or 2Mb/s.

5.14 CT_D disable

The user may disable all CT_D output streams in the event of a bus timing error. When enabled, an error

on the slave PLL reference source causes the CT_D streams to be tri-stated until an entire frame time

without errors has passed. The CT_D_DISABLE signal is provided to link multiple ML53812-2 devices.

5.15 Diagnostic Mode

Diagnostic mode tri-states all CT Bus signals while internally looping-back CT Bus outputs to inputs.

This mode allows a printed circuit board containing the ML53812-2 to be thoroughly tested without

causing CT Bus errors.

5.16 Interrupts

The ML53812-2 supports the following interrupt sources:

• CT Bus A Error

• CT Bus B Error

CT Bus A (CT Bus B) error is detected when CT_C8_A (CT_C8_B) rising edge does not occur within

35 ns of the expected time, relative to the previous period (see

Figure 4

) or when CT_FRAME_A_N

(CT_FRAME_B_N) low does not occur when expected. (See ECTF H.100/H.110 Specifications for

details on CT_C8_(A/B) and CT_FRAME_(A/B)_N signal timing.)

• SCbus Error

SCbus error is detected when SCLK does not transition at close to the expected frequency (C_[25:24]

determines the expected frequency) or FR_COMP_N low does not occur when expected. (See ECTF

H.100/H.110 Specifications for details on SCLK, SCLKx2, and FR_COMP_N signal timing.)

• MVIP Error

MVIP error is detected when C2 does not transition at close to 2 MHz, or FR_COMP_N low does not

occur when expected. (See ECTF H.100/H.110 Specifications for details on C2 and FR_COMP_N signal timing).

• Master PLL Out of Lock Error

Master PLL error is detected when the master PLL is not locked to the selected Reference defined by

C_[43:40].

• Frame Boundary

Frame Boundary interrupt is not an error condition, and occurs when the internal state machine

crosses a frame boundary.

• GPIO

GPIO interrupt occurs when one or more of the GPIO inputs match the programmed latch polarity,

defined by C_[167:136].

■

11Oki Semiconductor

Page 16

■

ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

The interrupts are both globally and individually maskable, and are signaled to the processor via the INT

pin (pin 10). The INT pin can be configured to operate as either push-pull or open drain, and its polarity

(active high or active low) is also selectable.

All of these interrupt latches have an individual enable/clear register and an individual interrupt mask

register associated with them.

Rising edge of CT_C8 occurring

after this limit will trigger an

interrupt (if enabled).

CT_C8_(A/B)

Expected Delay (Approx. 125 ns) Late Allowance (35 ns)

Figure 4. CT_C8_A and CT_C8_B Error Detection

5.17 GPIO Ports

Four general purpose input/output ports are provided. The ports may be individually configured to a

variety of modes and can also be used as interrupt sources. Possible uses of the GPIO ports would be controlling H.100/H.110 termination switches or implementing the SCbus CLKFAIL signal.

5.18 Message Channel

The ML53812-2 provides a complete interface between the CT_MC CT Bus signal and a local HDLC controller. This includes generation of MC_CLK as well as buffering of MC_TXD and MC_RXD.

12 Oki Semiconductor

Page 17

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2

6.0 REGISTERS

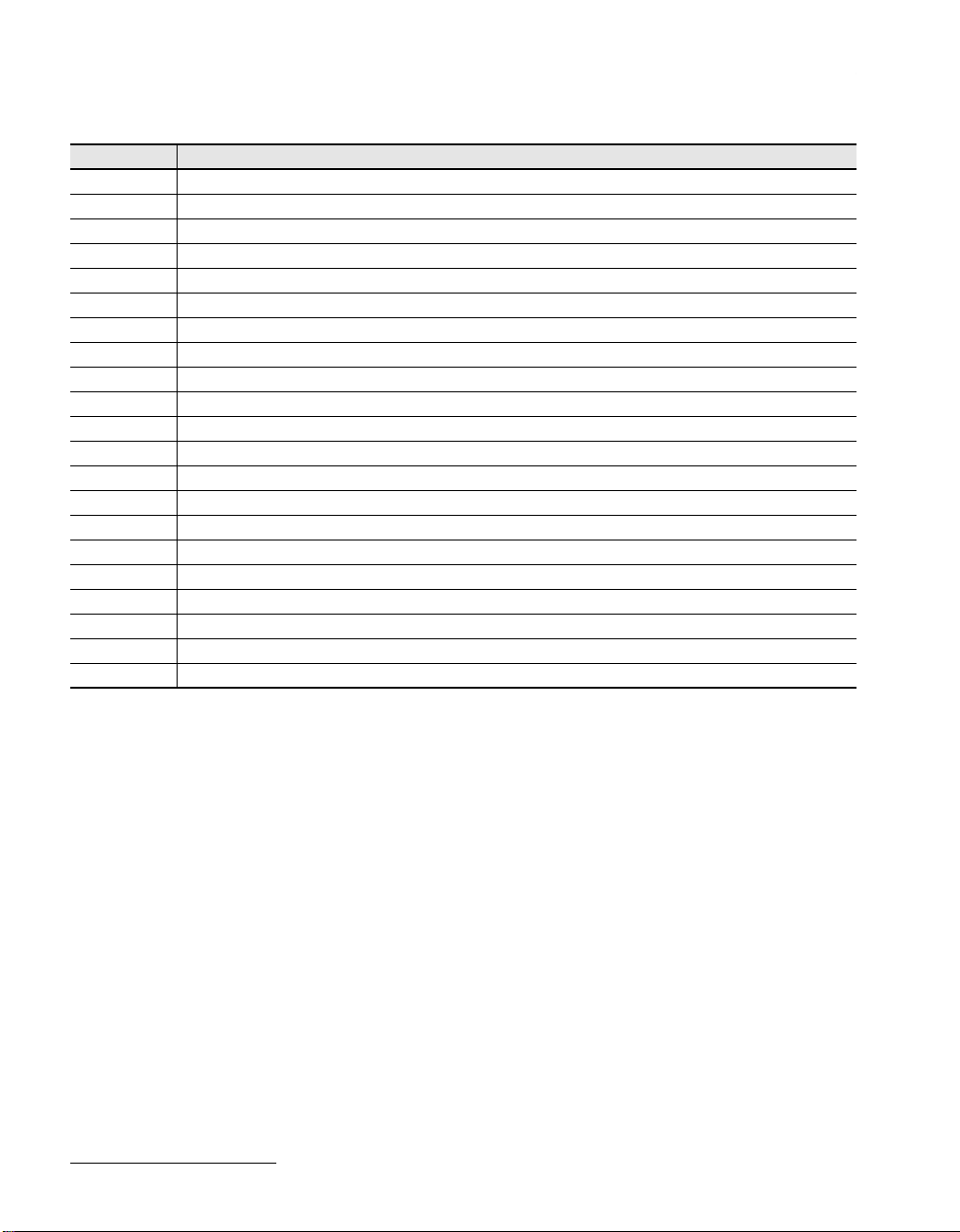

6.1 Microprocessor Address Map

With Direct Parallel Access Disabled (C_[96] = 0) (Default)

A_[2:0]

7h Reserved

6h Data Register 2 (DR_2)

5h Data Register 1 (DR_1)

4h Data Register 0 (DR_0)

3h Reserved

2h Address Register 1 (AR_1)

1h Address Register 0 (AR_0)

0h Command/Status Register

With Direct Parallel Access Enabled (C_[96] = 1)

A_[9:0]

3FFh:300h Direct Receive Switch Parallel Access Ch. 255:0

2FFh:200h Direct Transmit Switch Parallel Access Ch. 255:0

1FFh:008h Reserved

007h Reserved

006h Data Register 2 (DR_2)

005h Data Register 1 (DR_1)

004h Data Register 0 (DR_0)

003h Reserved

002h Address Register 1 (AR_1)

001h Address Register 0 (AR_0)

000h Command/Status Register

Register

Register

■

13Oki Semiconductor

Page 18

■

ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6.2 Command/Status Register

D_[7:0]

0 Busy (Read Only)

1 Read Command (Write Only)

2 Write Command (Write Only)

3 Terminate Command (Write Only)

4 Reserved

5 Reserved

6 Reserved

7 Reset (Read/Write)

Definition

Busy (D_0) (Read Only)

This bit is set ("1") when a Command that requires synchronization with the ML53812-2's internal state machine has been initiated, and cleared ("0")

when the command has been completed.

For Commands that do not require synchronization this bit is always clear ("0").

The following commands require synchronization:

• Routing Memory Write command

• In-Direct Parallel Access Read or Write command

Read (D_1) (Write Only)

Setting this bit ("1") initiates a synchronized read of the register pointed to by the Address Register. When the Busy bit is clear ("0"), the contents of

the register to be read are available by reading the Data Register. It is NOT necessary to clear ("0") this bit after it has been set ("1").

Note: For "Reads" that do not require synchronization (all "Reads" except In-Direct Parallel Access Read) it is

not necessary to set this bit. The Data Registers can be read immediately after writing the Address Register.

Write (D_2) (Write Only)

Setting this bit ("1") initiates a write of the register pointed to by the Address Register. It is NOT necessary to clear ("0") this bit after it has been set ("1").

Terminate (D_3) (Write Only)

Setting this bit ("1") terminates a command that requires synchronization with the ML53812-2's internal state machine. The command in process is

completed asynchronously and the Busy bit is cleared. It is NOT necessary to clear ("0") this bit after it has been set ("1").

Reset (D_7) (Read/Write)

Setting this bit ("1") resets the ML53812-2 and initializes the Configuration and Routing Registers. This command is analogous to the function of the

RESET pin. Clearing this bit ("0") returns the ML53812-2 to normal operation, ready to be configured.

14 Oki Semiconductor

Page 19

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2

■

6.3 Internal Address Map

AR

0014h:0000h Configuration

00ffh:00fch Device ID

1007h:1000h Stream Switch Routing Ch. 7:0

20ffh:2000h Transmit Switch Routing Ch. 255:0

30ffh:3000h Receive Switch Routing Ch. 255:0

40ffh:4000h Indirect Transmit Switch Parallel Access Ch. 255:0

50ffh:5000h Indirect Receive Switch Parallel Access Ch. 255:0

1. AR is the concatenation of AR_1 and AR_0.

2. All other locations reserved (Read-back = 00, Write has no effect).

[1] [2]

Register

15Oki Semiconductor

Page 20

■

ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6.4 Configuration Registers

Note: All "Reserved" configuration registers should be written "0".

Configuration Register Byte 0, AR = 0000h

DR_0

0 0 Diagnostic Mode

1 1 Test Mode

2 2 APLL Power-down Mode

3 3 APLL Bypass Mode

[7:4] [7:4] APLL CLKREF Frequency [3:0]

C Definition

Diagnostic Mode (C_ [0]) (Read/Write)

Set to 0 for normal operation

0

→

Diagnostic Mode Disabled

1

→

Diagnostic Mode Enabled (Default)

Test Mode (C_ [1]) (Read/Write)

Enables testing with the slave DPLL bypassed. Set to 0 for normal operation.

0

→

Test Mode Disabled (Default)

1

→

Test Mode Enabled

APLL Power-down Mode (C_ [2]) (Read/Write)

Powers down analog PLL, resets APLL charge pump. Set to 0 for normal operation.

0

→

APLL Power-down Mode Disabled

1

→

APLL Power-down Mode Enabled (Default)

APLL Bypass Mode (C_ [3]) (Read/Write)

APLL Bypass used during simulation and testing. Set to 0 for normal operation.

0 → APLL Bypass Mode Disabled

1 → APLL Bypass Mode Enabled (Default)

APLL CLKREF Frequency [3:0] (C_ [7:4]) (Read/Write)

Put APLL in Power-down (C_[2] = 1) when changing APLL CLKREF Frequency.

0h → 65.536 MHz (32 X 2.048 MHz) (Default)

1h → 49.152 MHz (24 X 2.048 MHz)

2h → 32.768 MHz (16 X 2.048 MHz)

3h → 16.384 MHz (8 X 2.048 MHz)

4h → 8.192 MHz (4 X 2.048 MHz)

5h → 4.096 MHz (2 X 2.048 MHz)

6h → 2.048 MHz

7h - fh → Reserved

16 Oki Semiconductor

Page 21

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 1, AR = 0001h

DR_0 C Definition

[1:0] [9:8] Slave Bus Mode [1:0]

2 10 Slave Local Timing Source Select

3 11 Advance Slave PLL Timing

4 12 Slave CT Manual/Auto Mode

5 13 Slave CT A/B Select

6 14 Slave CT A/B Read-back

7 15 Reserved

Slave Bus Mode [1:0] (C_ [9:8]) (Read/Write)

00 → CT Bus - Slave to CT_C8 & CT_FRAME (see Slave CT A/B Select) (Default)

01 → SCbus - Slave to SCLK & FR_COMP

10 → MVIP - Slave to C2 & FR_COMP

11 → Local - Slave to L_CLK & L_FS (see Slave Local Timing Source Select)

1. When local slave mode is selected, L_CLK frequency, polarity and output enable, and L_FS polarity, position and output enable must be configured

accordingly.

[1]

Slave Local Timing Source Select (C_ [10]) (Read/Write)

0 → L_CLK_0, L_FS_0 (Default)

1 → L_CLK_1, L_FS_1

Advance Slave PLL Timing (C_ [11]) (Read/Write)

The slave PLL timing may be advanced one 7.6 ns period to compensate for delay. Set to 0 for normal operation.

0 → Advance Slave PLL Timing Disabled (Default)

1 → Advance Slave PLL Timing Enabled

Slave CT Manual/Auto Mode (C_ [12]) (Read/Write)

0 → Slave CT Manual Mode (Default)

1 → Slave CT Auto Mode

1. In auto mode, slave will only switch when an error exists on the current signal set and NOT on the other signal set.

[1]

Slave CT A/B Select (C_ [13]) (Read/Write)

Select signal set in manual mode then switch to auto.

0 → CT A Select (Default)

1 → CT B Select

Slave CT A/B Read-back (C_ [14]) (Read Only)

0 → CT A Selected

1 → CT B Selected

17Oki Semiconductor

Page 22

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 2, AR = 0002h

DR_0 C Definition

0 16 Master CT Enable

1 17 Master CT A/B Select

2 18 Reserved

3 19 Advance Master PLL Timing

4 20 Master Manual/Auto Mode

5 21 Master Primary/Secondary Select

6 22 Master Primary/Secondary Read-back

7 23 Reserved

Master CT Enable (C_ [16]) (Read/Write)

Enables the Master PLL to drive the CT Bus.

0 → Master Disabled (Default)

1 → Master Enabled

Master CT A/B Select (C_ [17]) (Read/Write)

Selects the signal set driven by the Master PLL.

0 → CT_C8_A & CT_FRAME_A (Default)

1 → CT_C8_B & CT_FRAME_B

1. When in Secondary Master mode, the signal set (A or B) NOT selected here is used as the reference.

[1]

Advance Master PLL Timing (C_ [19]) (Read/Write)

When operating as secondary master, the master PLL timing may be advanced one 7.6 ns clock period to compensate for delay.

Set to 0 for normal operation.

0 → Advance Master PLL Timing Disabled (Default)

1 → Advance Master PLL Timing Enabled

Master Manual/Auto Mode (C_ [20]) (Read/Write)

0 → Master Manual Mode (Default)

1 → Master Auto Mode

1. Master Auto mode allows Secondary Master to become Primary if an error occurs on the reference signal set. To switch back to Secondary Master

it is necessary to go into manual mode.

[1]

Master Primary/Secondary Select (C_ [21]) (Read/Write)

0 → Primary Master Select (Default)

1 → Secondary Master Select

Master Primary/Secondary Read-back (C_ [22]) (Read Only)

0 → Primary Master Selected

1 → Secondary Master Selected

18 Oki Semiconductor

Page 23

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 3, AR = 0003h

DR_0 C Definition

[1:0] [25:24] SCbus SCLK Frequency [1:0]

2 26 SCbus Master Enable - SCLK, SCLKX2 & FR_COMP

3 27 Reserved

4 28 MVIP-90 Master Enable - C2, C4 & FR_COMP

5 29 H-MVIP Master Enable - C2, C4, C16 & FR_COMP

6 30 Reserved

7 31 Reserved

SCbus SCLK Frequency [1:0] (C_ [25:24]) (Read/Write)

00 → 2.048 MHz (Default)

01 → 4.096 MHz

10 → 8.192 MHz

11 → Reserved

SCbus Master Enable (C_ [26]) (Read/Write)

When enabled as Primary Master, this register enables the SCLK, SCLKX2 & FR_COMP signals to be driven.

0 → SCbus Master Disabled (Default)

1 → SCbus Master Enabled

MVIP-90 Master Enable (C_ [28]) (Read/Write)

When enabled as Primary Master, this register enables the C2, C4 & FR_COMP signals to be driven.

0 → MVIP-90 Master Disabled (Default)

1 → MVIP-90 Master Enabled

H-MVIP Master Enable (C_ [29]) (Read/Write)

When enabled as Primary Master, this register enables the C2, C4, C16 & FR_COMP signals to be driven.

0 → H-MVIP Master Disabled (Default)

1 → H-MVIP Master Enabled

19Oki Semiconductor

Page 24

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 4, AR = 0004h

DR_0 C Definition

[2:0] [34:32] Master PLL Mode [2:0]

3 35 Reserved

[5:4] [37:36] Master PLL Mode Read-back [1:0]

6 38 Condition Master PLL Reference

7 39 Reserved

Master PLL Mode [2:0] (C_ [34:32]) (Read/Write)

000 → Normal (Default)

001 → Reserved

010 → Holdover

011 → Free Run

100 → Reserved

101 → Reserved

110 → Auto Normal to Holdover switch on Master PLL error

111 → Auto Normal to Free Run switch on Master PLL error

1. Master PLL error occurs when the Master PLL is out of lock with its reference signal. It is necessary to manually select "Normal" to go back to

normal operation after an auto switch has occurred.

[1]

Master PLL Mode Read-back [1:0] (C_ [37:36]) (Read Only)

00 → Normal

01 → Reserved

10 → Holdover

11 → Free Run

Condition Master PLL Reference (C_ [38]) (Read/Write)

When enabled, conditions a change in references for MTIE compatibility.

0 → Condition Master PLL Reference Disabled (Default)

1 → Condition Master PLL Reference Enabled

20 Oki Semiconductor

Page 25

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 5, AR = 0005h

DR_0 C Definition

[3:0] [43:40] Master PLL Reference Select [3:0]

4 44 Reserved

[6:5] [46:45] Master PLL Reference Frequency [1:0]

7 47 Reserved

Master PLL Reference Select [3:0] (C_ [43:40]) (Read/Write)

0h → None (Default)

1h → Reserved

2h → Reserved

3h → Reserved

4h → Reserved

5h → Reserved

6h → CT_NETREF_1

7h → CT_NETREF_2

8h → L_NETREF_0

9h → L_NETREF_1

ah → L_NETREF_2

bh → L_NETREF_3

ch → L_NETREF_4

dh → L_NETREF_5

eh → L_NETREF_6

fh → L_NETREF_7

Master PLL Reference Frequency [1:0] (C_ [46:45]) (Read/Write)

00 → 8 kHz (Default)

01 → 1.536 MHz

10 → 1.544 MHz

11 → 2.048 MHz

21Oki Semiconductor

Page 26

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 6, AR = 0006h

DR_0 C Definition

[3:0] [51:48] CT_NETREF_1 Source Select [3:0]

4 52 Reserved

[6:5] [54:53] CT_NETREF_1 Divider [1:0]

7 55 CT_NETREF_1 Output Enable

CT_NETREF_1 Source Select [3:0] (C_ [51:48]) (Read/Write)

0h → None (Default)

1h → Reserved

2h → Reserved

3h → Reserved

4h → Reserved

5h → Reserved

6h → Reserved

7h → Reserved

8h → L_NETREF_0

9h → L_NETREF_1

ah → L_NETREF_2

bh → L_NETREF_3

ch → L_NETREF_4

dh → L_NETREF_5

eh → L_NETREF_6

fh → L_NETREF_7

CT_NETREF_1 Divider [1:0] (C_ [54:53]) (Read/Write)

00 → Divide source by 1 (Default)

01 → Divide source by 192

10 → Divide source by 193

11 → Divide source by 256

CT_NETREF_1 Output Enable (C_ [55]) (Read/Write)

0 → CT_NETREF_1 Output Tri-stated (Default)

1 → CT_NETREF_1 Output Enabled

22 Oki Semiconductor

Page 27

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 7, AR = 0007h

DR_0 C Definition

[3:0] [59:56] CT_NETREF_2 Source Select [3:0]

4 60 Reserved

[6:5] [62:61] CT_NETREF_2 Divider [1:0]

7 63 CT_NETREF_2 Output Enable

CT_NETREF_2 Source Select [3:0] (C_ [59:56]) (Read/Write)

0h → None (Default)

1h → Reserved

2h → Reserved

3h → Reserved

4h → Reserved

5h → Reserved

6h → Reserved

7h → Reserved

8h → L_NETREF_0

9h → L_NETREF_1

ah → L_NETREF_2

bh → L_NETREF_3

ch → L_NETREF_4

dh → L_NETREF_5

eh → L_NETREF_6

fh → L_NETREF_7

CT_NETREF_2 Divider [1:0] (C_ [62:61]) (Read/Write)

00 → Divide source by 1 (Default)

01 → Divide source by 192

10 → Divide source by 193

11 → Divide source by 256

CT_NETREF_2 Output Enable (C_ [63]) (Read/Write)

0 → CT_NETREF_2 Output Tri-stated (Default)

1 → CT_NETREF_2 Output Enabled

23Oki Semiconductor

Page 28

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 8, AR = 0008h

DR_0 C Definition

0 64 L_CLK_0, L_FS_0 Output Enable

1 65 L_CLK_1, L_FS_1 Output Enable

2 66 CT_D_ Output Enable Mode

3 67 CT_D_DISABLE Output Enable

4 68 CT_D_DISABLE

5 69 CT_D_DISABLE On Input

6 70 CT_D_DISABLE On Error

7 71 CT_D_DISABLE Read-back

L_CLK_0, L_FS_0 Output Enable (C_ [64]) (Read/Write)

0 → L_CLK_0, L_FS_0 Output Tri-stated (Default)

1 → L_CLK_0, L_FS_0 Output Enabled

L_CLK_1, L_FS_1 Output Enable (C_ [65]) (Read/Write)

0 → L_CLK_1, L_FS_1 Output Tri-stated (Default)

1 → L_CLK_1, L_FS_1 Output Enabled

CT_D_ Output Enable Mode (C_ [66]) (Read/Write)

0 → CT_D_[31:0] Output Tri-stated before bit cell boundary - Based on H.100/H.110 (Default)

1 → CT_D_[31:0] Output Tri-stated at bit cell boundary

CT_D_DISABLE Output Enable (C_ [67]) (Read/Write)

0 → CT_D_DISABLE pin Output Tri-stated (Default)

1 → CT_D_DISABLE pin Output Enabled

CT_D_DISABLE (C_ [68]) (Read/Write)

0 → CT_D_ Outputs Enabled (Default)

1 → CT_D_ Outputs Disabled

CT_D_DISABLE On Input (C_ [69]) (Read/Write)

0 → CT_D_DISABLE On Input Disabled (Default)

1 → CT_D_DISABLE On Input Enabled

CT_D_DISABLE On Error (C_ [70]) (Read/Write)

0 → CT_D_DISABLE On Error Disabled (Default)

1 → CT_D_DISABLE On Error Enabled

CT_D_DISABLE Read-back (C_ [71]) (Read Only)

0 → CT_D_ Outputs Enabled

1 → CT_D_ Outputs Disabled

24 Oki Semiconductor

Page 29

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 9, AR = 0009h

DR_0 C Definition

[1:0] [73:72] L_SI_[3:0], L_SO_[3:0] Stream Rate [1:0]

[3:2] [75:74] L_CLK_0 Frequency [1:0]

4 76 L_CLK_0 Polarity

5 77 L_FS_0 Polarity

[7:6] [79:78] L_FS_0 Position [1:0]

L_SI_[3:0], L_SO_[3:0] Stream Rate [1:0] (C_ [73:72]) (Read/Write)

00 → 2.048 Mb/s (L_SI_[3:0], L_SO_[3:0]) (Default)

01 → 4.096 Mb/s (L_SI_[1:0], L_SO_[1:0])

10 → 8.192 Mb/s (L_SI_[0], L_SO_[0])

11 → Reserved

L_CLK_0 Frequency [1:0] (C_ [75:74]) (Read/Write)

00 → 2.048 MHz (Default)

01 → 4.096 MHz

10 → 8.192 MHz

11 → 16.384 MHz

1. Note: the L_CLK_0 frequency need not match the L_SI and L_SO stream frequencies, neither need it match the CT_C8 frequency when configured

as slave-to-CT.

[1]

L_CLK_0 Polarity (C_ [76]) (Read/Write)

0 → L_CLK_0 Non-Inverted (Default)

1 → L_CLK_0 Inverted

L_FS_0 Polarity (C_ [77]) (Read/Write)

0 → L_FS_0 Non-Inverted (Default)

1 → L_FS_0 Inverted

L_FS_0 Position [1:0] (C_ [79:78]) (Read/Write)

00 → Early - L_FS_0 occurs during the last L_CLK_0 period of the frame (Default)

01 → Straddle - L_FS_0 straddles the frame boundary

10 → Late - L_FS_0 occurs during the first L_CLK_0 period of the frame

11 → Reserved

25Oki Semiconductor

Page 30

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 10, AR = 000ah

DR_0 C Definition

[1:0] [81:80] L_SI_[7:4], L_SO_[7:4] Stream Rate [1:0]

[3:2] [83:82] L_CLK_1 Frequency [1:0]

4 84 L_CLK_1 Polarity

5 85 L_FS_1 Polarity

[7:6] [87:86] L_FS_1 Position [1:0]

L_SI_[7:4], L_SO_[7:4] Stream Rate [1:0] (C_ [81:80]) (Read/Write)

00 → 2.048 Mb/s (L_SI_[7:4], L_SO_[7:4]) (Default)

01 → 4.096 Mb/s (L_SI_[5:4], L_SO_[5:4])

10 → 8.192 Mb/s (L_SI_[4], L_SO_[4])

11 → Reserved

L_CLK_1 Frequency [1:0] (C_ [83:82]) (Read/Write)

00 → 2.048 MHz (Default)

01 → 4.096 MHz

10 → 8.192 MHz

11 → 16.384 MHz

1. Note: the L_CLK_1 frequency need not match the L_SI and L_SO stream frequencies, neither need it match the CT_C8 frequency when configured

as slave-to-CT.

[1]

L_CLK_1 Polarity (C_ [84]) (Read/Write)

0 → L_CLK_1 Non-Inverted (Default)

1 → L_CLK_1 Inverted

L_FS_1 Polarity (C_ [85]) (Read/Write)

0 → L_FS_1 Non-Inverted (Default)

1 → L_FS_1 Inverted

L_FS_1 Position [1:0] (C_ [87:86]) (Read/Write)

00 → Early - L_FS_1 occurs during the last L_CLK_1 period of the frame (Default)

01 → Straddle - L_FS_1 straddles the frame boundary

10 → Late - L_FS_1 occurs during the first L_CLK_1 period of the frame

11 → Reserved

26 Oki Semiconductor

Page 31

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 11, AR = 000bh

DR_0 C Definition

[1:0] [89:88] CT_D_[3:0] Data Stream Rate [1:0]

[3:2] [91:90] CT_D_[7:4] Data Stream Rate [1:0]

[5:4] [93:92] CT_D_[11:8] Data Stream Rate [1:0]

[7:6] [95:94] CT_D_[15:12] Data Stream Rate [1:0]

CT_D_[3:0] Data Stream Rate [1:0] (C_ [89:88]) (Read/Write)

00 → 2.048 Mb/s

01 → 4.096 Mb/s

10 → 8.192 Mb/s (Default)

11 → Reserved

CT_D_[7:4] Data Stream Rate [1:0] (C_ [91:90]) (Read/Write)

00 → 2.048 Mb/s

01 → 4.096 Mb/s

10 → 8.192 Mb/s (Default)

11 → Reserved

CT_D_[11:8] Data Stream Rate [1:0] (C_ [93:92]) (Read/Write)

00 → 2.048 Mb/s

01 → 4.096 Mb/s

10 → 8.192 Mb/s (Default)

11 → Reserved

CT_D_[15:12] Data Stream Rate [1:0] (C_ [95:94]) (Read/Write)

00 → 2.048 Mb/s

01 → 4.096 Mb/s

10 → 8.192 Mb/s (Default)

11 → Reserved

27Oki Semiconductor

Page 32

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 12, AR = 000ch

DR_0 C Definition

0 96 Direct Parallel Access Enable

1 97 Microprocessor Watchdog Enable

2 98 APLL Clock Watchdog Enable

3 99 Reserved

4 100 Message Channel Registered TXD Enable

5 101 Message Channel Output Disable

6 102 Reserved

7 103 Reserved

Direct Parallel Access Enable (C_ [96]) (Read/Write)

0 → Direct Parallel Access disabled (Default)

1 → Direct Parallel Access enabled

Microprocessor Watchdog Enable (C_ [97]) (Read/Write)

When enabled, the ML53812-2 enters into reset after the Analog PLL clocks for 256mS (± 50%).

Each time C_[97] is cleared (0) and then set (1), the microprocessor watchdog count is reset.

0 → Microprocessor Watchdog disabled (Default)

1 → Microprocessor Watchdog enabled

APLL Clock Watchdog Enable (C_ [98]) (Read/Write)

When enabled, C_[98] will read back as being set (1) until the Analog PLL clocks for 125 µS (± 50%), then will read back as being cleared (0). Each

time C_[98] is cleared (0) and then set (1), the clock watchdog count is reset.

0 → APLL Clock Watchdog disabled (Default)

1 → APLL Clock Watchdog enabled

Message Channel Registered TXD Enable (C_ [100]) (Read/Write)

0 → MC_TXD passed though to CT_MC (Default)

1 → MC_TXD registered to CT_MC on rising edge of MC_CLK

Message Channel Output Disable with Loop-back (C_ [101]) (Read/Write)

When CT_MC output is disabled, the local message channel circuitry can be tested without disturbing the CT Bus.

0 → CT_MC Output enabled (Default)

1 → CT_MC Output Tri-stated, MC_TXD looped back to MC_RXD

28 Oki Semiconductor

Page 33

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 13, AR = 000dh

DR_0 C Definition

0 104 INT Polarity

1 105 INT Mask

2 106 INT Output Driver Configuration

3 107 INT

4 108 Reserved

5 109 Reserved

6 110 Reserved

7 111 Reserved

INT Polarity (C_ [104]) (Read/Write)

0 → INT Active Low (Default)

1 → INT Active High

INT Mask (C_ [105]) (Read/Write)

0 → INT Unmasked

1 → INT Masked (Default)

INT Output Driver Configuration (C_ [106]) (Read/Write)

0 → Open Drain (Default)

1 → Push-Pull

INT (C_ [107]) (Read Only)

This register is the logical or of all unmasked interrupt sources.

0 → All unmasked interrupts false

1 → Any unmasked interrupt true

29Oki Semiconductor

Page 34

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 14, AR = 000eh

DR_0 C Definition

0 112 CT Bus A Error Interrupt Mask

1 113 CT Bus B Error Interrupt Mask

2 114 SCbus Error Interrupt Mask

3 115 MVIP Error Interrupt Mask

4 116 Master PLL Error Interrupt Mask

5 117 Frame Boundary Interrupt Mask

6 118 Reserved

7 119 Reserved

1. Masking an interrupt disables that interrupt from being OR’ed together with other interrupts to the INT pin. The state of the latches are accessible

while masked (polling mode).

[1]

CT Bus A Error Interrupt Mask (C_ [112]) (Read/Write)

0 → CT Bus A Error Interrupt Unmasked

1 → CT Bus A Error Interrupt Masked (Default)

CT Bus B Error Interrupt Mask (C_ [113]) (Read/Write)

0 → CT Bus B Error Interrupt Unmasked

1 → CT Bus B Error Interrupt Masked (Default)

SCbus Error Interrupt Mask (C_ [114]) (Read/Write)

0 → SCbus Error Interrupt Unmasked

1 → SCbus Error Interrupt Masked (Default)

MVIP Error Interrupt Mask (C_ [115]) (Read/Write)

0 → MVIP Error Interrupt Unmasked

1 → MVIP Error Interrupt Masked (Default)

Master PLL Error Interrupt Mask (C_ [116]) (Read/Write)

0 → Master PLL Error Interrupt Unmasked

1 → Master PLL Error Interrupt Masked (Default)

Frame Boundary Interrupt Mask (C_ [117]) (Read/Write)

0 → Frame Boundary Interrupt Unmasked

1 → Frame Boundary Interrupt Masked (Default)

30 Oki Semiconductor

Page 35

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 15, AR = 000fh

DR_0 C Definition

0 120 CT Bus A Error Latch Clear

1 121 CT Bus B Error Latch Clear

2 122 SCbus Error Latch Clear

3 123 MVIP Error Latch Clear

4 124 Master PLL Error Latch Clear

5 125 Frame Boundary Latch Clear

6 126 Reserved

7 127 Reserved

CT Bus A Error Latch Clear (C_ [120]) (Read/Write)

0 → CT Bus A Error Latch Enabled

1 → CT Bus A Error Latch held clear (Default)

CT Bus B Error Latch Clear (C_ [121]) (Read/Write)

0 → CT Bus B Error Latch Enabled

1 → CT Bus B Error Latch held clear (Default)

SCbus Error Latch Clear (C_ [122]) (Read/Write)

0 → SCbus Error Latch Enabled

1 → SCbus Error Latch held clear (Default)

MVIP Error Latch Clear (C_ [123]) (Read/Write)

0 → MVIP Error Latch Enabled

1 → MVIP Error Latch held clear (Default)

Master PLL Error Latch Clear (C_ [124]) (Read/Write)

0 → Master PLL Error Latch Enabled

1 → Master PLL Error Latch held clear (Default)

Frame Boundary Latch Clear (C_ [125]) (Read/Write)

0 → Frame Boundary Latch Enabled

1 → Frame Boundary Latch held clear (Default)

31Oki Semiconductor

Page 36

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 16, AR = 0010h

DR_0 C Definition

0 128 CT Bus A Error Latch

1 129 CT Bus B Error Latch

2 130 SCbus Error Latch

3 131 MVIP Error Latch

4 132 Master PLL Error Latch

5 133 Frame Boundary Latch

6 134 Reserved

7 135 Reserved

CT Bus A Error Latch (C_ [128]) (Read Only)

0 → CT Bus A Error Latch False

1 → CT Bus A Error Latch True

CT Bus B Error Latch (C_ [129]) (Read Only)

0 → CT Bus B Error Latch False

1 → CT Bus B Error Latch True

SCbus Error Latch (C_ [130]) (Read Only)

0 → SCbus Error Latch False

1 → SCbus Error Latch True

MVIP Error Latch (C_ [131]) (Read Only)

0 → MVIP Error Latch False

1 → MVIP Error Latch True

Master PLL Error Latch (C_ [132]) (Read Only)

0 → Master PLL Error Latch False

1 → Master PLL Error Latch True

Frame Boundary Latch (C_ [133]) (Read Only)

0 → Frame Boundary Latch False

1 → Frame Boundary Latch True

32 Oki Semiconductor

Page 37

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 17, AR = 0011h

DR_0 C Definition

0 136 GPIO_0 Input

1 137 GPIO_0 Output

2 138 GPIO_0 Output Enable

3 139 GPIO_0 Output Driver Configuration

4 140 GPIO _0 Latch Polarity

5 141 GPIO _0 Interrupt Mask

6 142 GPIO _0 Latch Clear

7 143 GPIO _0 Latch

GPIO_0 Input (C_ [136]) (Read Only)

0 → GPIO_0 Input = 0

1 → GPIO_0 Input = 1

GPIO_0 Output (C_ [137]) (Read/Write)

0 → GPIO_0 Output = 0 (Default)

1 → GPIO_0 Output = 1

GPIO_0 Output Enable (C_ [138]) (Read/Write)

0 → GPIO_0 Output Tri-stated (Default)

1 → GPIO_0 Output Enabled

GPIO_0 Output Driver Configuration (C_ [139]) (Read/Write)

0 → Open Drain (Default)

1 → Push-Pull

GPIO _0 Latch Polarity (C_ [140]) (Read/Write)

0 → GPIO _0 Latch set when GPIO_0 input = 0 (Default)

1 → GPIO _0 Latch set when GPIO_0 input = 1

GPIO _0 Interrupt Mask (C_ [141]) (Read/Write)

0 → GPIO _0 Interrupt Unmasked

1 → GPIO _0 Interrupt Masked (Default)

GPIO _0 Latch Clear (C_ [142]) (Read/Write)

0 → GPIO _0 Latch Enabled

1 → GPIO _0 Latch held clear (Default)

GPIO _0 Latch (C_ [143]) (Read Only)

0 → GPIO _0 Latch False

1 → GPIO _0 Latch True

33Oki Semiconductor

Page 38

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 18, AR = 0012h

DR_0 C Definition

0 144 GPIO_1 Input

1 145 GPIO_1 Output

2 146 GPIO_1 Output Enable

3 147 GPIO_1 Output Driver Configuration

4 148 GPIO _1 Latch Polarity

5 149 GPIO _1 Interrupt Mask

6 150 GPIO _1 Latch Clear

7 151 GPIO _1 Latch

GPIO_1 Input (C_ [144]) (Read Only)

0 → GPIO_1 Input = 0

1 → GPIO_1 Input = 1

GPIO_1 Output (C_ [145]) (Read/Write)

0 → GPIO_1 Output = 0 (Default)

1 → GPIO_1 Output = 1

GPIO_1 Output Enable (C_ [146]) (Read/Write)

0 → GPIO_1 Output Tri-stated (Default)

1 → GPIO_1 Output Enabled

GPIO_1 Output Driver Configuration (C_ [147]) (Read/Write)

0 → Open Drain (Default)

1 → Push-Pull

GPIO _1 Latch Polarity (C_ [148]) (Read/Write)

0 → GPIO _1 Latch set when GPIO_1 input = 0 (Default)

1 → GPIO _1 Latch set when GPIO_1 input = 1

GPIO _1 Interrupt Mask (C_ [149]) (Read/Write)

0 → GPIO _1 Interrupt Unmasked

1 → GPIO _1 Interrupt Masked (Default)

GPIO _1 Latch Clear (C_ [150]) (Read/Write)

0 → GPIO _1 Latch Enabled

1 → GPIO _1 Latch held clear (Default)

GPIO _1 Latch (C_ [151]) (Read Only)

0 → GPIO _1 Latch False

1 → GPIO _1 Latch True

34 Oki Semiconductor

Page 39

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

Configuration Register Byte 19, AR = 0013h

DR_0 C Definition

0 152 GPIO_2 Input

1 153 GPIO_2 Output

2 154 GPIO_2 Output Enable

3 155 GPIO_2 Output Driver Configuration

4 156 GPIO _2 Latch Polarity

5 157 GPIO _2 Interrupt Mask

6 158 GPIO _2 Latch Clear

7 159 GPIO _2 Latch

GPIO_2 Input (C_ [152]) (Read Only)

0 → GPIO_2 Input = 0

1 → GPIO_2 Input = 1

GPIO_2 Output (C_ [153]) (Read/Write)

0 → GPIO_2 Output = 0 (Default)

1 → GPIO_2 Output = 1

GPIO_2 Output Enable (C_ [154]) (Read/Write)

0 → GPIO_2 Output Tri-stated (Default)

1 → GPIO_2 Output Enabled

GPIO_2 Output Driver Configuration (C_ [155]) (Read/Write)

0 → Open Drain (Default)

1 → Push-Pull

GPIO _2 Latch Polarity (C_ [156]) (Read/Write)

0 → GPIO _2 Latch set when GPIO_2 input = 0 (Default)

1 → GPIO _2 Latch set when GPIO_2 input = 1

GPIO _2 Interrupt Mask (C_ [157]) (Read/Write)

0 → GPIO _2 Interrupt Unmasked

1 → GPIO _2 Interrupt Masked (Default)

GPIO _2 Latch Clear (C_ [158]) (Read/Write)

0 → GPIO _2 Latch Enabled

1 → GPIO _2 Latch held clear (Default)

GPIO _2 Latch (C_ [159]) (Read Only)

0 → GPIO _2 Latch False

1 → GPIO _2 Latch True

35Oki Semiconductor

Page 40

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Configuration Register Byte 20, AR = 0014h

DR_0 C Definition

0 160 GPIO_3 Input

1 161 GPIO_3 Output

2 162 GPIO_3 Output Enable

3 163 GPIO_3 Output Driver Configuration

4 164 GPIO _3 Latch Polarity

5 165 GPIO _3 Interrupt Mask

6 166 GPIO _3 Latch Clear

7 167 GPIO _3 Latch

GPIO_3 Input (C_ [160]) (Read Only)

0 → GPIO_3 Input = 0

1 → GPIO_3 Input = 1

GPIO_3 Output (C_ [161]) (Read/Write)

0 → GPIO_3 Output = 0 (Default)

1 → GPIO_3 Output = 1

GPIO_3 Output Enable (C_ [162]) (Read/Write)

0 → GPIO_3 Output Tri-stated (Default)

1 → GPIO_3 Output Enabled

GPIO_3 Output Driver Configuration (C_ [163]) (Read/Write)

0 → Open Drain (Default)

1 → Push-Pull

GPIO _3 Latch Polarity (C_ [164]) (Read/Write)

0 → GPIO _3 Latch set when GPIO_3 input = 0 (Default)

1 → GPIO _3 Latch set when GPIO_3 input = 1

GPIO _3 Interrupt Mask (C_ [165]) (Read/Write)

0 → GPIO _3 Interrupt Unmasked

1 → GPIO _3 Interrupt Masked (Default)

GPIO _3 Latch Clear (C_ [166]) (Read/Write)

0 → GPIO _3 Latch Enabled

1 → GPIO _3 Latch held clear (Default)

GPIO _3 Latch (C_ [167]) (Read Only)

0 → GPIO _3 Latch False

1 → GPIO _3 Latch True

36 Oki Semiconductor

Page 41

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

6.5 Device ID Registers (Read Only)

Device ID byte 3, AR = 00ffh

DR_0 Definition

[7:4] Version [3:0]

[3:0] Part Number [15:12]

Device ID byte 2, AR = 00feh

DR_0 Definition

[7:0] Part Number [11:4]

Device ID byte 1, AR = 00fdh

DR_0 Definition

[7:4] Part Number [3:0]

[3:0] Manufacturer ID [10:7]

Device ID byte 0, AR = 00fch

DR_0 Definition

[7:1] Manufacturer ID [6:0]

0 0 = Device does not support Boundary Scan

1 = Device supports Boundary Scan

ML53812-2 Device ID byte [3:0] = 20 8c 00 00h

37Oki Semiconductor

Page 42

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

6.6 Stream Switch Routing Registers, AR = 1007h:1000h (Ch. 7:0)

Note: To ensure compatibility with possible future versions of this device, write “0” to all "Reserved" bits in the

routing registers. All "Reserved" routing registers read-back "0".

DR_0 Definition

[4:0] Input Data Stream [4:0]

[7:5] Reserved (write zero)

Input Data Stream [4:0] (Read/Write)

00h → CT_D_[0] (Default)

01h → CT_D_[1]

02h → CT_D_[2]

• •

• •

1eh → CT_D_[30]

1fh → CT_D_[31]

DR_1 Definition

[4:0] Output Data Stream [4:0]

[6:5] Reserved (write zero)

7 Output Enable

Output Data Stream [4:0] (Read/Write)

00h → CT_D_[0] (Default)

01h → CT_D_[1]

02h → CT_D_[2]

• •

• •

1eh → CT_D_[30]

1fh → CT_D_[31]

Output Enable (Read/Write)

0 → Output Disabled (Default)

1 → Output Enabled

DR_2 Definition

[1:0] Partition [1:0]

[7:2] Reserved (write zero)

Partition [1:0] (Read/Write)

Selects which time-slots are used when rate conversion is taking place. See the following table for a

description of the partition function.

38 Oki Semiconductor

Page 43

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

6.7 Stream Switch Connection Mapping

Input Data

Stream Rate

2 Mb/s 2 Mb/s 0 0 to 1, 1 to 2, 2 to 3, … , 31 to 0

4 Mb/s 2 Mb/s 0 0 to 1, 2 to 2, 4 to 3, … , 62 to 0

8 Mb/s 2 Mb/s 0 0 to 1, 4 to 2, 8 to 3, … , 124 to 0

Output Data

Stream Rate

4 Mb/s 0 0 to 2, 1 to 4, 2 to 6, … , 31 to 0

8 Mb/s 0 0 to 4, 1 to 8, 2 to 12, … , 31 to 0

4 Mb/s 0 0 to 1, 1 to 2, 2 to 3, … , 63 to 0

8 Mb/s 0 0 to 2, 1 to 4, 2 to 6, … , 63 to 0

4 Mb/s 0 0 to 1, 2 to 2, 4 to 3, … , 126 to 0

8 Mb/s 0 0 to 1, 1 to 2, 2 to 3, … , 127 to 0

Partition Timeslot Connection

1 0 to 3, 1 to 5, 2 to 7, … , 31 to 1

1 0 to 5, 1 to 9, 2 to 13, … , 31 to 1

2 0 to 6, 1 to 10, 2 to 14, … , 31 to 2

3 0 to 7, 1 to 11, 2 to 15, … , 31 to 3

1 1 to 1, 3 to 2, 5 to 3, … , 63 to 0

1 0 to 3, 1 to 5, 2 to 7, … , 63 to 1

1 1 to 1, 5 to 2, 9 to 3, … , 125 to 0

2 2 to 1, 6 to 2, 10 to 3, … , 126 to 0

3 3 to 1, 7 to 2, 11 to 3, … , 127 to 0

1 1 to 1, 3 to 2, 5 to 3, … , 127 to 0

Frame Boundary

CT_D time-slots @ 8mb/s

CT_D time-slots @ 4mb/s 123 62 63 0 1 2

CT_D time-slots @ 2mb/s 30 31 0 1

12312412512612701234

Figure 5. CT Bus Data Stream Switching

The Stream Switch provides a data stream-to-data stream connection capability. Switching between any

of the 32 CT Bus data streams operating at 2, 4, or 8 Mb/s is supported. Eight stream switch channels are

provided. Individual time-slots are not tri-state controlled. Buffering is done on single timeslots rather

than entire frames. This trade-off complicates the connection matrix, but without this compromise it

would not be practical to implement the Stream Switch.

Depending upon the data stream rates, the stream switch provides a minimum of 256 and a maximum of

1024 uni-directional timeslot connections. Stream switches in other ML53812-2 devices in a system may

be used simultaneously to increase switching capability. The output of the stream switch is multiplexed

with the output of the transmit switch, with the transmit switch having priority.

39Oki Semiconductor

Page 44

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

The main application of the Stream Switch is to provide an inter-rate exchange highway allowing legacy

Bus devices operating at different rates to exchange data.

A typical configuration of the Stream Switch using 2 switch channels and 3 streams to provide 32 full

duplex connections between SCbus (operating at 4 MHz) and MVIP is outlined below.

Example:

Stream switch channel 0 is configured with CT_D_0 as the input data stream and the even time-slots

(partition = 0) of CT_D_8 as the output data stream.

Stream switch channel 1 is configured with the odd timeslots (partition = 1) of CT_D_8 as the input data

stream and CT_D_1 as the output data stream.

CT_D _0 (MVIP) 1

CT_D _1 (MVIP)

CT_D _8 (SCbus) 63

31 0

012

01234

Figure 6. Data Stream Switching Example

40 Oki Semiconductor

Page 45

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– ■ ML53812-2 ■

6.8 Transmit Switch Routing Registers, AR = 20ffh:2000h (Ch. 255:0)

Note: To ensure compatibility with subsequent versions of this device, write “0” to all "Reserved" bits in the

routing registers. All "Reserved" routing registers read-back "0".

DR_0 Definition

[6:0] Output Time-slot

7 Reserved (write zero)

Output Time-slot [6:0] (Read/Write)

Selects the CT_D time-slot for transmit channel routing.

00h → Time-slot 0 (Default)

01h → Time-slot 1

02h → Time-slot 2

• •

• •

7eh → Time-slot 126

7fh → Time-slot 127

Note: Internally all time-slots run at 8Mb/s. To transmit on CT_D data streams running at a slower rate, use

the following conversion:

If CT_D data stream is operating at 4Mb/s, transmit switch output time-slot = CT_D time-slot X 2.

If CT_D data stream is operating at 2Mb/s, transmit switch output time-slot = CT_D time-slot X 4.

DR_1 Definition

[4:0] Output Data Stream

[6:5] Reserved (write zero)

7 Output Enable

Output Data Stream [4:0] (Read/Write)

Selects the CT_D Data stream for transmit channel routing.

00h → CT_D_[0] (Default)

01h → CT_D_[1]

02h → CT_D_[2]

• •

• •

1eh → CT_D_[30]

1fh → CT_D_[31]

Output Enable (Read/Write)

Controls the Output Enable for the selected CT Bus data stream and time-slot.

0 → Output Disabled (Default)

1 → Output Enabled

41Oki Semiconductor

Page 46

■ ML53812-2 ■ ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

DR_2 Definition

0 Delay

1 CT Bus Connect

2 Source

[7:3] Reserved (write zero)

Delay (Read/Write)

Selects the switching delay mode. When set to Constant, data is switched on frame boundaries resulting in a constant 1 frame delay and allowing

"bundling". When set to Minimum, data is switched on 2Mb/s timeslot boundaries reducing the delay through the switch for certain combinations of

input to output time-slots.

0 → Constant (Default)

1 → Minimum

Note: Do not use Minimum delay mode on channels using parallel data source.

CT Bus Connect Enable (Read/Write)

Enables the switch to be used for CT Bus to CT Bus connection without externally connecting L_SO to L_SI. When enabled, the L_SI input is replaced

by the corresponding L_SO output. CT Bus connect allows inter-operability switching to be provided by any unused transmit and receive switch pair.

0 → CT Bus Connect Disabled (Default)

1 → CT Bus Connect Enabled

Note: The receive switch output enable register does not have to be set to make this connection.

Source (Read/Write)

Selects the transmit channel data source. When set to 0, Serial TDM data from L_SI or L_SO (see CT Bus Connect Enable) is selected. When set to 1,