Page 1

July 2000

ML4900*

High Current Synchronous Buck Controller

GENERAL DESCRIPTION

The ML4900 high current synchronous buck controller has

been designed to provide high efficiency DC/DC

conversion for next generation processors such as the

Pentium® Pro from Intel®.

The ML4900 controller, when combined with two

N-channel MOSFETs, generates output voltages between

2.1V and 3.5V from a 5V supply. The output voltage is

selected via an internal 4-bit DAC. Output currents in

excess of 14A can be attained at efficiencies greater than

90%.

The ML4900 can be enabled/disabled via the SHDN pin.

While disabled, the output of the regulator is completely

isolated from the circuit’s input supply. The ML4900

employs fixed-frequency PWM control combined with a

dual mode control loop to provide excellent load transient

response.

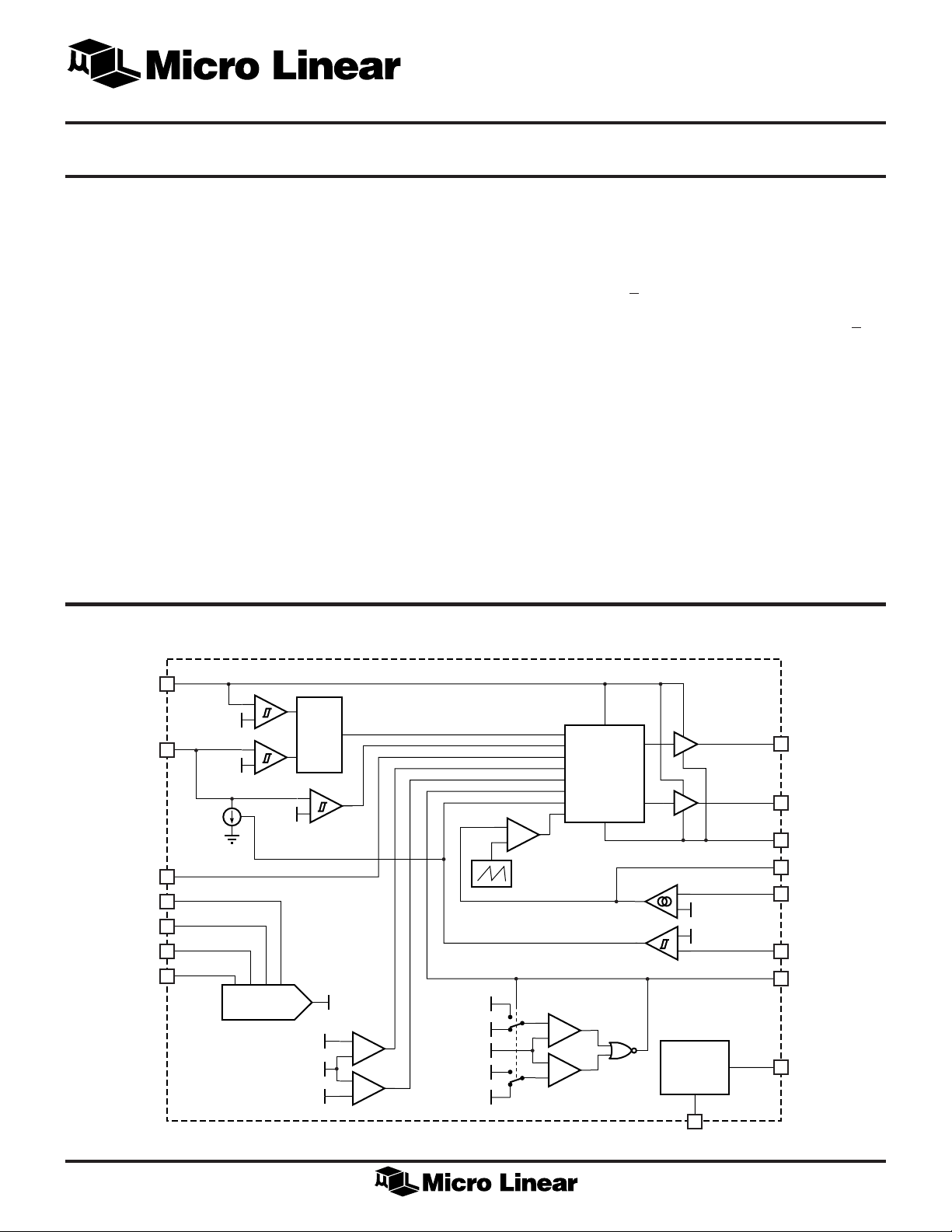

BLOCK DIAGRAM

(Pin Configuration Shown for 16-Pin SOIC Version)

FEATURES

■ Designed to meet Pentium

requirements

■ DC regulation to +1% maximum

■ Proprietary circuitry provides transient response of +5%

maximum over 300mA to 14A load range

■ Programmable output voltage (2.1V to 3.5V) is set by

an onboard 4-bit DAC

■ Synchronous N-channel buck topology for maximum

power conversion efficiency

■ Fixed frequency operation for easier system integration

■ Integrated antishoot-through logic, short circuit

protection, and UV lockout

■ Shutdown control provides load isolation

(* Indicates Part is End of Life as of July 1, 2000)

®

Pro power supply

V

DD

15

PROTECT

16

SHDN

5

D0

1

D1

2

D2

3

D3

4

10.5V

35µA

4.4V

+

–

+

–

4 BIT DAC

V

DAC

V

DAC

4V

UVLO

+ 3%

V

- 3%

N DRV H

CONTROL

LOGIC

+

–

V

DAC

+

–

FB

+

–

V

V

DAC

V

DAC

DAC

V

DAC

+ 10%

+ 3%

- 10%

- 3%

+

–

200kHz

+

V

FB

–

+

–

REFERENCE

+

–

+

–

3.5V

PWR GND

V

DAC

-73mV

PWR GOOD

GND

8

N DRV L

COMP

V

I

SENSE

V

REF

14

13

12

11

FB

9

10

6

7

1

Page 2

ML4900

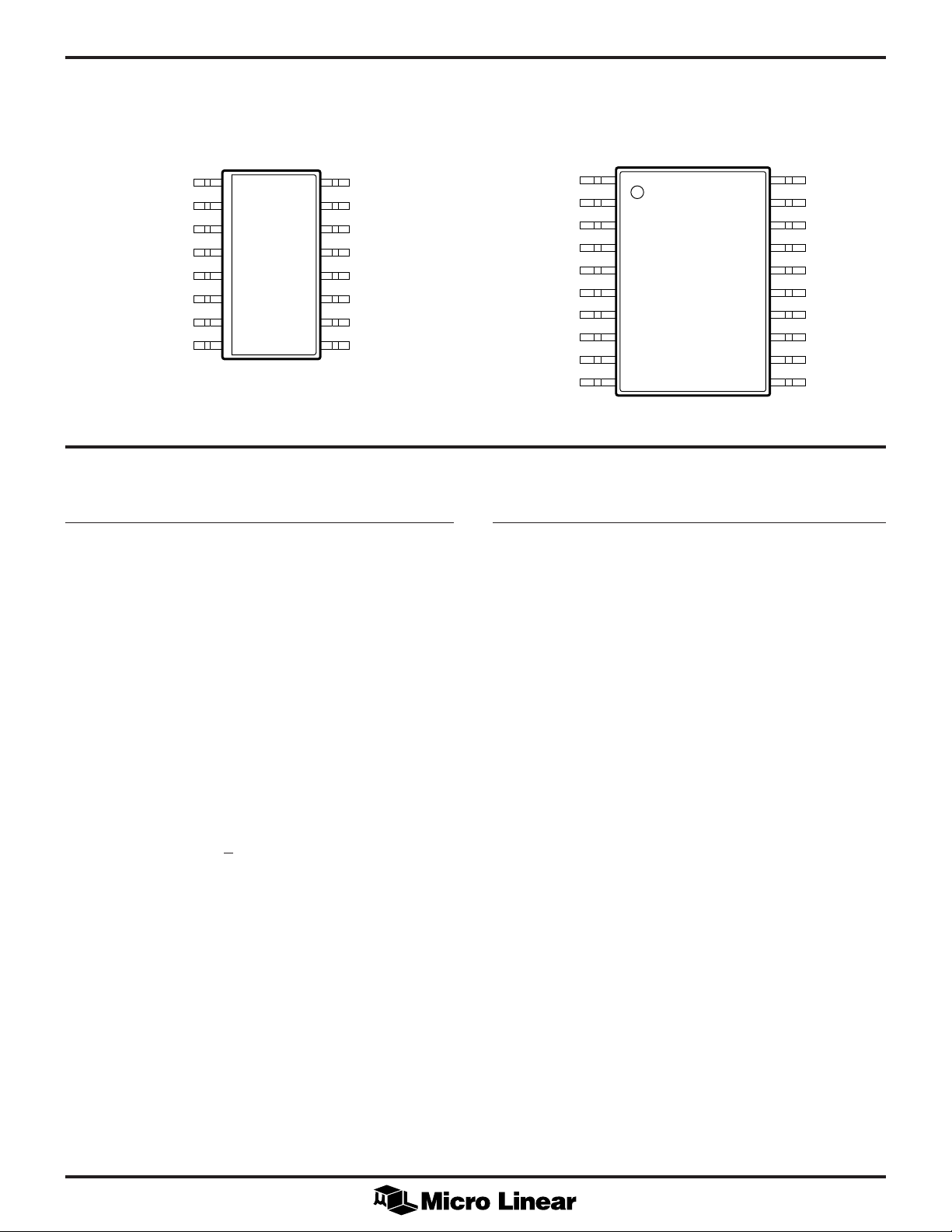

PIN CONFIGURATION

ML4900

16-Pin Narrow SOIC (S16N)

D0

D1

D2

D3

SHDN

PWR GOOD

V

REF

GND

PIN DESCRIPTION

1

2

3

4

5

6

7

8

TOP VIEW

(Pin Number in Parentheses is for TSSOP Version)

PIN NAME FUNCTION

16

15

14

13

12

11

10

PROTECT

V

DD

N DRV H

N DRV L

PWR GND

COMP

ISENSE

9

V

FB

1 (1) D0 LSB input to the DAC which sets

the output voltage

2 (2) D1 Input to the DAC which sets the

output voltage

ML4900

20-Pin TSSOP (T20)

D0

D1

D2

D3

NC

SHDN

NC

PWR GOOD

V

REF

GND

1

2

3

4

5

6

7

8

9

10

TOP VIEW

PIN NAME FUNCTION

20

19

18

17

16

15

14

13

12

11

8 (10) GND Analog signal ground

9 (11) V

10 (12) I

FB

SENSE

Output voltage feedback pin

Current sense input

PROTECT

V

DD

NC

N DRV H

N DRV L

PWR GND

NC

COMP

I

SENSE

V

FB

3 (3) D2 Input to the DAC which sets the

output voltage

4 (4) D3 MSB input to the DAC which sets

the output voltage

5 (6) SHDN Grounding this pin shuts down the

regulator

6 (8) PWR GOOD This open collector output goes

low whenever SHDN goes low or

when the output is not within

+10% of its nominal value

7 (9) V

REF

Bypass connection for the internal

3.5V reference

11 (13) COMP Connection for the compensation

and optional soft-start delay

network

12 (15) PWR GND Power ground

13 (16) N DRV L Synchronous rectifier driver output

14 (17) N DRV H Buck switch driver output

15 (19) V

DD

12V power supply input

16 (20) PROTECT Connection for the integrating

current limit network and the

UVLO monitor for the 5V supply

2

Page 3

ABSOLUTE MAXIMUM RATINGS

ML4900

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

V

.......................................................................................... 13.5V

DD

Lead Temperature (Soldering, 10 sec) ......................260ºC

Thermal Resistance (qJA)

16-Pin Narrow SOIC ...................................... 100ºC/W

20-Pin TSSOP ................................................. 143ºC/W

Peak Driver Output Current .......................................±2A

VFB Voltage....................................... GND - 0.3V to 5.5V

I

Voltage ................................... GND - 0.5V to 5.5V

SENSE

All Other Analog Inputs ..........GND - 0.3V to VDD + 0.3V

SHDN Input Current .............................................. 100mA

Junction Temperature .............................................. 150ºC

OPERATING CONDITIONS

Temperature Range........................................ 0ºC to 70ºC

VDD Range ...............................................11.4V to 12.6V

PROTECT (5V Supply) Range .................... 4.75V to 5.25V

Storage Temperature Range ...................... –65ºC to 150ºC

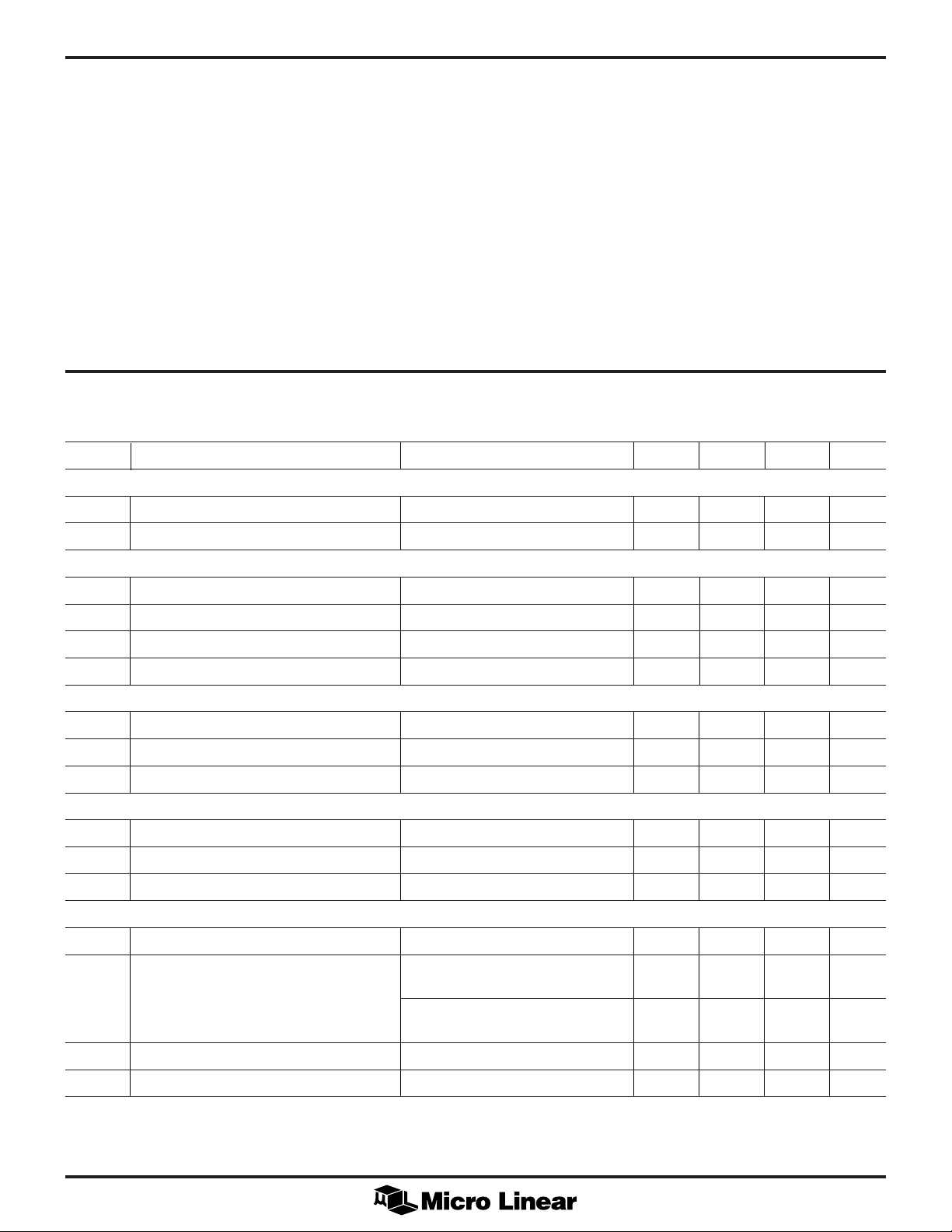

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, VDD = 12V, PROTECT = SHDN = 5V, TA = Operating Temperature Range (Note 1)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

REFERENCE

V

UV LOCKOUT

Output Voltage 3.51 3.535 3.56 V

REF

Line Regulation 11V < VDD < 13V 0.5 mV/V

VDD Start-up Threshold 10.2 10.5 10.8 V

VDD Hysteresis 300 450 600 mV

PROTECT (5V) Start-up Threshold 4.25 4.4 4.5 V

PROTECT (5V) Hysteresis 400 450 500 mV

SHUTDOWN

Input Low Voltage 0.8 V

Input High Voltage 2.0 V

Delay to Output 50 ns

POWER GOOD COMPARATOR

Output Voltage in Regulation 5kW pull-up to 5V 4.8 V

Output Voltage out of Regulation VFB < 90% V

Output Voltage in Shutdown SHDN = 0V, 5kW pull-up to 5V 0.4 V

BUCK REGULATOR

Oscillator Frequency 160 200 230 kHz

Duty Cycle Ratio DAC (D3-D0) Code = 0100, 85 95 %

or >110% V

DAC

VFB = 0V

DAC (D3-D0) Code = 0100, 0 %

VFB > 3.193V

DAC

0.4 V

DAC (D3-D0) Input Low Voltage 0.8 V

DAC (D3-D0) Input High Voltage 2.0 V

3

Page 4

ML4900

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

BUCK REGULATOR (continued)

VFB Threshold Voltage DAC (D3-D0) Code = 0000 3.495 3.535 3.575 V

(Continued)

DAC (D3-D0) Code = 0001 3.400 3.434 3.468 V

DAC (D3-D0) Code = 0010 3.300 3.333 3.366 V

DAC (D3-D0) Code = 0011 3.200 3.232 3.264 V

DAC (D3-D0) Code = 0100 3.100 3.131 3.162 V

DAC (D3-D0) Code = 0101 3.000 3.03 3.060 V

DAC (D3-D0) Code = 0110 2.900 2.929 2.958 V

DAC (D3-D0) Code = 0111 2.800 2.828 2.856 V

DAC (D3-D0) Code = 1000 2.700 2.727 2.754 V

DAC (D3-D0) Code = 1001 2.600 2.626 2.652 V

DAC (D3-D0) Code = 1010 2.500 2.525 2.550 V

DAC (D3-D0) Code = 1011 2.400 2.424 2.448 V

DAC (D3-D0) Code = 1100 2.299 2.323 2.347 V

DAC (D3-D0) Code = 1101 2.198 2.222 2.246 V

SUPPLY

Note 1:

DAC (D3-D0) Code = 1110 2.097 2.121 2.145 V

DAC (D3-D0) Code = 1111 0.8 V

I

Threshold Voltage -66 -73 -80 mV

SENSE

I

Hysteresis 3mV

SENSE

PROTECT Discharge Current V(I

PROTECT Leakage Current +100 nA

Transition Time, N DRV H and N DRV L CL = 5000pF, 10-90% 40 ns

VDD Current SHDN = 0V 300 450 µA

DAC (D3-D0) Code = 0000

SHDN = 5V, VFB = 5V 1 2 mA

SHDN = 5V, VFB = 0V, CL = 5000pF 30 mA

Limits are guaranteed by 100% testing, sampling, or correlation with worst case test conditions.

) = -100mV 35 mA

SENSE

4

Page 5

FUNCTIONAL DESCRIPTION

ML4900

The ML4900 PWM controller permits the construction of a

simple yet sophisticated power supply for Intel’s Pentium

Pro microprocessor which meets the guidelines of Intel’s

Application Note AP-523. This can be built either as a

Voltage Regulator Module (VRM) or as dedicated

motherboard circuitry. The ML4900 controls two Nchannel MOSFETs in a synchronous buck regulator circuit,

to convert a 5V input to the voltage required by the

microprocessor. The output voltage can be any set to any

one of 15 output voltages from 2.1V to 3.5V, in steps of

100mV, as selected by an onboard DAC. Other features

which facilitate the design of DC-DC converters for any

type of processor include a trimmed 1% reference, special

transient-response optimization in the feedback paths, a

shutdown input, input and output power good monitors,

and overcurrent protection.

4-BIT DAC

The inputs of the internal 4-bit DAC come from open

collector signals provided by the Pentium Pro. These

signals specify what supply voltage the microprocessor

requires. The output voltage of the buck converter is

compared directly with the DAC voltage to maintain

regulation. D3 is the MSB input and D0 is the LSB input of

the DAC. The output voltage set by the DAC is 1% above

the Pentium Pro's nominal operating voltage to counteract

the effects of connector and PC trace resistance, and of the

instantaneous output voltage droop which occurs when a

transient load is applied. The output of the DAC therefore

ranges from 2.121V to 3.535V in 100mV steps. For code

1111, the N DRV H output is disabled, and the output

voltage is zero.

VOLTAGE FEEDBACK LOOP

The ML4900 contains two control loops to improve the

load transient response. The output voltage is directly

monitored via the VFB pin and compared to the desired

output voltage set by the internal 4-bit DAC. When the

output voltage is within +3% of the DAC voltage, the

proportional control loop (closed by the voltage error

amplifier) keeps the output voltage at the correct value. If

the output falls below the DAC voltage by more than 3%,

one side of the transient loop is activated, forcing the

output of the ML4900 to maximum duty cycle until the

output comes back within the +3% limit. If the output

voltage rises above the DAC voltage by more than 3%, the

other side of the transient loop is activated, and the upper

MOSFET drive is disabled until the output comes back

within the +3% limit. During start-up, the transient loop is

disabled until the output voltage is within -3% of the DAC

voltage.

POWER GOOD (PWR GOOD)

An open drain signal is provided by the ML4900 which

tells the microprocessor when the entire power system is

functioning within the expected limits. PWR GOOD will

be false (low) if either the 5V or 12V supply is not in

regulation, when the SHDN pin is pulled low, or when the

output is not within +10% of the nominal output voltage

selected by the internal DAC.

When PWR GOOD is false, the PWR GOOD voltage

window is held to +3%; when PWR GOOD is true (high),

the window is expanded to +10%. Using different

windows for coming into and going out of regulation

makes sure that PWR GOOD does not oscillate during the

start-up of the microprocessor.

INTERNAL REFERENCE

The ML4900 contains a 3.535V, temperature

compensated, precision band-gap reference. The V

is connected to the output of this reference, and should be

bypassed with a 100nF to 220nF ceramic capacitor for

proper operation.

REF

pin

OVERCURRENT PROTECTION

When the output of the buck converter sees an overcurrent

condition (I

the ML4900 will operate in a “hiccup” mode until the

overcurrent condition has been removed.

During an overcurrent condition, a current sink within the

ML4900 draws a small current (35µA) out of the PROTECT

pin for the time during which I

sink is activated over a number of cycles, the voltage on

the PROTECT pin will drop below 4V, signalling a

sustained overcurrent or short circuit at the load. This will

cause the N DRV H output to turn off. The converter will

remain in an off state until the capacitor attached to the

PROTECT pin has charged back to 4.4V, at which time the

converter is re-enabled and tries to resume normal

operation. If the fault causing the overcurrent condition

has not been cleared, the overcurrent protection cycle will

repeat.

exceeds the current limit set point I

OUT

> I

OUT

. If this current

SET

SET

),

UNDERVOLTAGE LOCKOUT

The ML4900 has undervoltage lockout protection circuits

for both the 12V (VDD) and 5V (PROTECT) supplies. The

hysteresis voltage is typically 400mV for each supply.

During an input undervoltage condition, the internal

reference and voltage monitor circuits remain in

operation, but N DRV H and N DRV L are disabled and

the PWR GOOD output will be false (low).

COMPENSATION/SOFT-START

This pin connects to the output of the transconductance

amplifier which forms the gain block for the ML4900’s

proportional control loop. An RC network from this pin to

GND is used to compensate the amplifier.

5

Page 6

ML4900

DESIGN CONSIDERATIONS

This section is a quick-check guide for getting ML4900

circuits up and running, with a special emphasis on

Pentium Pro applications. All component designators refer

to the circuit shown in Figure 1.

COMPENSATION

The R and C values connected to the COMP pin for loop

compensation are 330kW and 33pF, respectively. These

values yield stable operation and rapid transient response

for a most values of L and C

10,000µF), and will generally not need to be altered. If

changes do need to be made, note that the drive capability

of the transconductance error amplifier is typically 10µA,

its Z

approximately 10 MHz.

is 10 MW, and its unity-gain frequency is

OUT

(1µH to 5µH, 1200µF to

OUT

INPUT AND OUTPUT CAPACITORS

The input and output capacitors used in conjunction with

the ML4900, especially in Pentium Pro VRM applications,

must be able to meet several criteria:

1. The input capacitors must be able to handle a relatively

high ripple current

2. The output capacitors must have a low Equivalent Series

Resistance (ESR) and Equivalent Series Inductance (ESL)

3. The output capacitors must be able to hold up the

output during the time that the current through the buck

inductor is slewing to meet a transient load step.

The circuit’s input bypass capacitance should be able to

handle a ripple current equal to 0.5 x I

converter sees load peaks only occasionally, and for less

than 30 seconds at a time during those intervals, then

aluminum electrolytic or OS-Con input capacitors need

only be sized to accommodate the average output load.

Note that tantalum input capacitors have much less

thermal mass than aluminum electrolytics, so this

relaxation of ripple current requirements may not apply to

them.

During a 30A/µs load transient, it is not possible for a buck

converter to slew the output current fast enough to

regulate the voltage in this application. During this

interval, the output capacitance of the converter must act

as passive energy storage. In delivering its energy to the

load, the output capacitance must not introduce any

considerable impedance, or its purpose will be defeated. A

total voltage aberration during load transients of ±5% is

allowed (see Intel AP-523). The voltage transient due to

ESL and ESR is:

For example, assume that a 3.3V output has 3% of the

output's DV contributed by ESR (100mV)and 2% by the

ESL (66mV). To meet this requirement, the output ESR

LOAD

. If the

(1)

should not exceed:

mV

ESR MAX)

With the effects of ESL limited to 2% of 3.3V, the

maximum ESL is:

Achieving these low a values of ESL and ESR is not trivial;

doing so typically requires using several high-quality

capacitors in parallel.

The output capacitance should have a value of > 2200µF

to hold the output voltage relatively constant (< 50mV of

sag) until the current in the buck inductor can catch up

with the change in output current. To meet the ESR and

ESL requirements, the actual output capacitance will

usually be significantly greater than this theoretical

minimum. These capacitors can be of all one type, or a

combination of aluminum electrolytic, OS-Con, and

tantalum devices.

100

==

137

.

73

Am(.

W

(2)

(3)

OVERCURRENT PROTECTION

Current sense resistor R1 is used to monitor the inductor

current during the off period, i.e., while current is flowing

through the synchronous rectifier (or Schottky diode, if no

synchronous rectifier MOSFET is used). The internal

current sense comparator has been designed to provide in

excess of 14A of output current when used with a 5mW

resistor. R1 must be a low inductance part such as Dale/

Vishay’s type WSL-2512-.005±2.5%. This is a 5mW surface

mount part rated at 1 Watt. Using a PCB trace as a current

sense element is not recommended due to the high

temperature coefficient of copper, and due to etching and

plating tolerances which can occur from board to board.

The R and C values connected to the PROTECT pin for

setting the current limit delay and the off-time of the

hiccup mode are 100kW and 1µF, respectively. These

values will protect most MOSFETs from overheating

during a short circuit condition. If it is necessary to change

the ratio of ON and OFF times during overcurrent

conditions, this can be done by selecting a different value

for C13. Larger values of C13 will increase the delay

between retry attempts (the length of the “hiccup”).

The voltage across current sense resistor R1 must be

Kelvin-sensed. This ensures that the ML4900 monitors only

the voltage across this resistor and not the voltage drops or

inductive transients in the PCB traces which carry current

into and out of this resistor. The two pins of the ML4900

which must be Kelvin-connected to the sense resistor are

I

and GND. There is no connection inside the

SENSE

ML4900 between GND (pin 8) and PWR GND (pin 12).

This is to facilitate the requisite Kelvin-sensing of the

voltage across R1. Because of this, there must be a good

electrical connection between the ML4900 PWR GND

6

Page 7

5V

IN

12V

OUTEN

UP#

VID0

VID1

VID2

VID3

PWRGD

C8

220nF

16V

ML4900

IN

D1

BAW56

C11

22µF

25V

1

D0

2

D1

3

D2

4

D3

5

SHDN

6

PWR GOOD

7

V

REF

8

GND

C10

220nF

16V

ML4900

PWR GND

PROTECT

V

DD

N DRV H

N DRV L

COMP

I

SENSE

V

FB

16

15

14

13

12

11

10

9

R3

330kΩ

C9

33pF

C13

1µF

16V

R5

100kΩ

1kΩ

C12

220nF

16V

R4

5m

Q1

Q2

R1

1W

3X

1800µF

10V

L2

1.4µH

C3C1 C2

VCCP

4X

C4 C5 C6 C7

1800µF

10V

V

Ω

SS

Figure 1. Pentium Pro VRM Circuit

and GND pins. At the same time, PWR GND must have a

low impedance connection to the ground plane used on

the board, as high instantaneous currents will flow in PWR

GND when N DRV L and N DRV H switch the capacitive

loads of the output MOSFET gates. A layout technique

which satisfies these requirements is to return PWR GND

to the grounded end of R1 using a high current Kelvin

connection. Figure 2 shows one successful

implementation of these PCB layout requirements.

I

is an input to a medium-speed, high-sensitivity

SENSE

comparator. It is often helpful to shield the trace running

from R1 to I

with a “guard trace” connected to circuit

SENSE

ground.

The compensation components R3 and C9 are highimpedance nodes connected to the output of the voltage

loop error amplifier. These components should be kept in

close proximity to the ML4900. C9 should be returned to

GND, not to PWR GND or the ground plane of the PC

board. It may be helpful to shield the trace running from

R3 to COMP with a “guard trace” connected to circuit

ground.

Keep the V

bypass capacitor C8 close to the ML4900.

REF

Ensure that its ground connection is to GND, not PWR

GND or the ground plane of the PCB.

The VDD bypass capacitors C10 and C11 should be

returned to PWR GND or to the PC board ground plane.

They should not be returned to GND due to high transient

currents which could interfere with the current sensing

function.

In order to reduce circuit size, complexity, and cost, direct

drive of all N-channel power MOSFETs in the output stage

is employed, derived from the 12V input bus. This delivers

at least 10V of VGS enhancement to the MOSFET(s)

performing the synchronous rectification function. The

power switching MOSFET(s), however, have a worst-case

VGS enhancement of about 6V, and must therefore be

logic-level parts.

If a given design uses power MOSFETs in an 8 pin SOIC

package style, keep in mind that the thermal dissipation

capability of these parts is largely dictated by the copper

area available to their drains. A good layout will maximize

this area.

TO

SYNCHRONOUS

RECTIFIER

MOSFET

SOURCE

SENSE

RESISTOR

POWER GROUND RETURN

(GROUND PLANE)

I

SENSE

TO

PWR GND

GND

TO

TO

Figure 2. Kelvin Sense Connections

7

Page 8

ML4900

PHYSICAL DIMENSIONS

16

0.017 - 0.027

(0.43 - 0.69)

(4 PLACES)

0.055 - 0.061

(1.40 - 1.55)

1

0.251 - 0.262

(6.38 - 6.65)

20

inches (millimeters)

Package: S16N

16-Pin Narrow SOIC

0.386 - 0.396

(9.80 - 10.06)

PIN 1 ID

0.050 BSC

(1.27 BSC)

0.012 - 0.020

(0.30 - 0.51)

0.059 - 0.069

(1.49 - 1.75)

SEATING PLANE

Package: T20

20-Pin TSSOP

0.148 - 0.158

(3.76 - 4.01)

0.004 - 0.010

(0.10 - 0.26)

0.228 - 0.244

(5.79 - 6.20)

0º - 8º

0.015 - 0.035

(0.38 - 0.89)

0.006 - 0.010

(0.15 - 0.26)

0.033 - 0.037

(0.84 - 0.94)

1

0.008 - 0.012

PIN 1 ID

(0.20 - 0.30)

0.026 BSC

(0.65 BSC)

0.169 - 0.177

(4.29 - 4.50)

0.043 MAX

(1.10 MAX)

SEATING PLANE

0.246 - 0.258

(6.25 - 6.55)

0.002 - 0.006

(0.05 - 0.15)

0º - 8º

0.020 - 0.028

(0.51 - 0.71)

0.004 - 0.008

(0.10 - 0.20)

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML4900CS (End Of Life) 0ºC to 70ºC 16-Pin Narrow SOIC (S16N)

ML4900CT (Obsolete) 0ºC to 70ºC 20-Pin TSSOP (T20)

© Micro Linear 1997 is a registered trademark of Micro Linear Corporation. Pentium is a registered trademark of Intel Corporation.

Products described herein may be covered by one or more of the following patents: 4,897,611; 4,964,026; 5,027,116; 5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940; 5,546,017;

5,559,470; 5,565,761; 5,594,376. Other patents are pending.

Micro Linear reserves the right to make changes to any product herein to improve reliability, function or design.

Micro Linear does not assume any liability arising out of the application or use of any product described herein,

neither does it convey any license under its patent right nor the rights of others. The circuits contained in this

data sheet are offered as possible applications only. Micro Linear makes no warranties or representations as to

whether the illustrated circuits infringe any intellectual property rights of others, and will accept no

responsibility or liability for use of any application herein. The customer is urged to consult with appropriate

legal counsel before deciding on a particular application.

8

2092 Concourse Drive

San Jose, CA 95131

Tel: 408/433-5200

Fax: 408/432-0295

DS4900-01

Loading...

Loading...