Page 1

FEATURING

Extended Commercial Temperature Range

–20°C to 70°C

for Portable Handheld Equipment

July 2000

ML4880*

Portable PC/PCMCIA Power Controller

GENERAL DESCRIPTION

The ML4880 Portable PC and PCMCIA Power Controller

is a complete solution for DC/DC power conversion for

portable computing systems with single or multiple

PCMCIA slots.

The device provides two synchronous buck controllers to

implement mixed voltage systems and a flyback controller

for 12V VPP generation for PCMCIA slots. The flyback

architecture enables generation of high currents (150mA

or more per slot) on the 12V bus for multiple slot PCMCIA

applications.

Each regulator can be independently switched off to fully

isolate the load from the power supply. The PFM

FEATURES

■Regulation to ±3% maximum: provides 2% PCMCIA

switch matrix margin

■ Two synchronous buck controllers for 3.3/3V, 5V

generation, and a flyback for high current, 12V

generation from 5.5V to 18V input

■ Regulator power conversion efficiencies > 90%

■ Pulse frequency modulation for high efficiency

operation

■ Independent regulator shutdown for full load isolation

■ Adjustable current limit

■ Wide input voltage range (5.5V to 18V)

architecture will automatically adjust switching frequency

at light loads in order to maintain power conversion

efficiencies in excess of 90% over a wide output power

range. (* Indicates Part is End Of Life as of July 1, 2000)

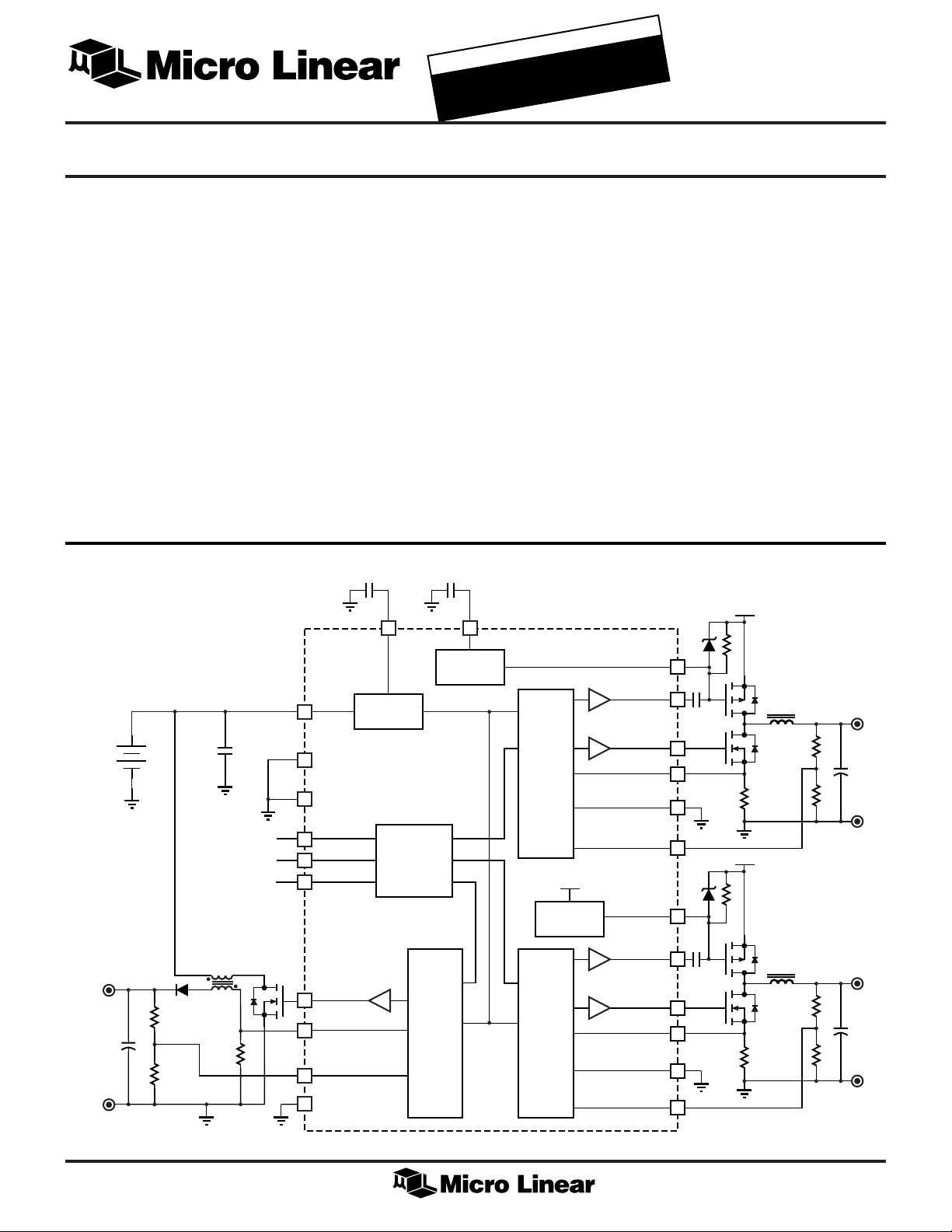

BLOCK DIAGRAM

V

IN

V

IN

5.5 – 18V

+

V

C

OUT

6V – 15V

–

TO SYSTEM

POWER

MANAGEMENT

V

IN

16

6

GND

7

GND

SHDN A

11

SHDN B

18

SHDN C

10

N DRV C

17

I

SENSE

3

V

FB

12

21

PWR GND C

C

C

15

V

BIAS

CIRCUITS

SHUTDOWN

LOGIC

REG

GATE

CLAMP

FLYBACK REGULATOR C

24

CLAMP

BUCK REGULATOR ABUCK REGULATOR B

CLAMP

GATE

CLAMP

CLAMP A

P DRV A

N DRV A

I

SENSE

PWR GND A

VFB A

CLAMP B

P DRV B

N DRV B

I

SENSE

PWR GND B

VFB B

2

13

14

A

4

23

9

1

19

20

B

5

22

8

V

IN

+

V

A

OUT

2.5 – 3.5V

–

+

V

B

OUT

4.5 – 5.0V

–

1

Page 2

ML4880

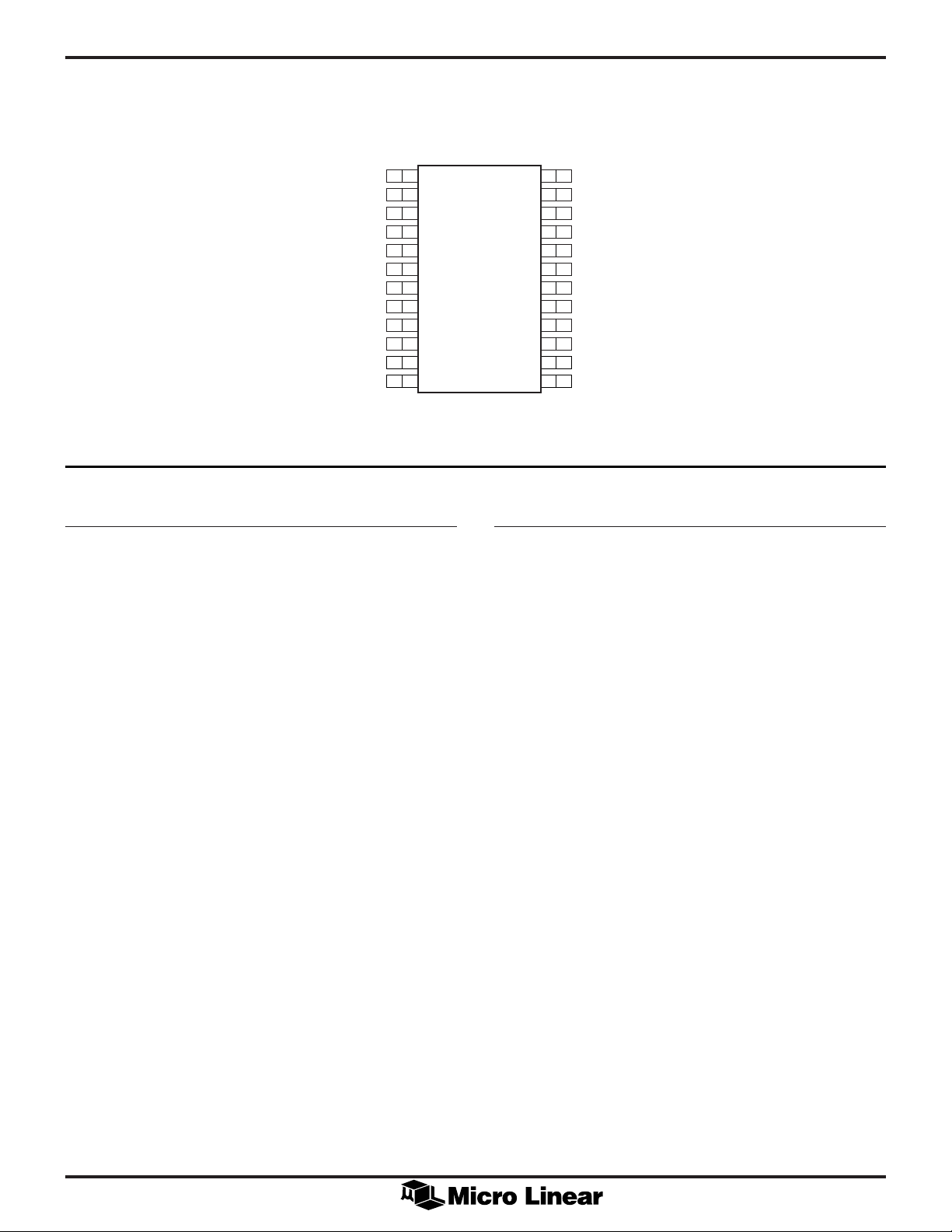

PIN CONFIGURATION

ML4880

24-Pin SOIC (S24)

CLAMP B

CLAMP A

I

SENSE

I

SENSE

I

SENSE

GND

GND

V

FB

V

FB

SHDN C

SHDN A

V

FB

1

2

C

A

B

B

A

C

3

4

5

6

7

8

9

10

11

12

TOP VIEW

24

23

22

21

20

19

18

17

16

15

14

13

CLAMP

PWR GND A

PWR GND B

PWR GND C

NDRV B

PDRV B

SHDN B

NDRV C

V

IN

V

REG

NDRV A

PDRV A

PIN DESCRIPTION

PIN# NAME FUNCTION PIN# NAME FUNCTION

1 CLAMP B Gate clamp, regulator B

2 CLAMP A Gate clamp, regulator A

3I

4I

5I

C Current sense, regulator C

SENSE

A Current sense, regulator A

SENSE

B Current sense, regulator B

SENSE

6 GND Ground

7 GND Ground

8VFB B Feedback node, buck regulator B

9VFB A Feedback node, buck regulator A

10 SHDN C Shutdown input, regulator C

11 SHDN A Shutdown input, regulator A

12 VFB C Feedback node, regulator C

13 PDRV A P-channel drive, regulator A

14 NDRV A N-channel drive, regulator A

15 V

16 V

REG

IN

Linear regulator output

Power supply input voltage

17 NDRV C N-channel drive, regulator C

18 SHDN B Shutdown input, regulator B

19 PDRV B P-channel drive, regulator B

20 NDRV B N-channel drive, regulator B

21 PWR GND C Power Ground, regulator C

22 PWR GND B Power Ground, regulator B

23 PWR GND A Power Ground, regulator A

24 CLAMP Charge pump capacitor input

2

Page 3

ML4880

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond

which the device could be permanently damaged.

Absolute maximum ratings are stress ratings only and

functional device operation is not implied.

V

............................................................................................... 20V

IN

OPERATING CONDITIONS

VIN Range ..................................................... 5.5V to 18V

Temperature Range

ML4880CS ................................................ 0°C to 70°C

ML4880ES ............................................. –20°C to 70°C

Peak Driver Output Current ........................................ 2A

VFB Voltage .........................................GND – 0.3V to 6V

I

Voltage..................................................... ±500mV

SENSE

All Other Analog Inputs ......... GND – 0.3V to VIN + 0.3V

All Digital Inputs .................. GND – 0.3V to V

REG

+ 0.3V

Junction Temperature ............................................. 150°C

Storage Temperature Range .................... –65°C to 150°C

Lead Temperature (Soldering, 10 sec) ..................... 150°C

Thermal Resistance (θJA)...................................... 80°C/W

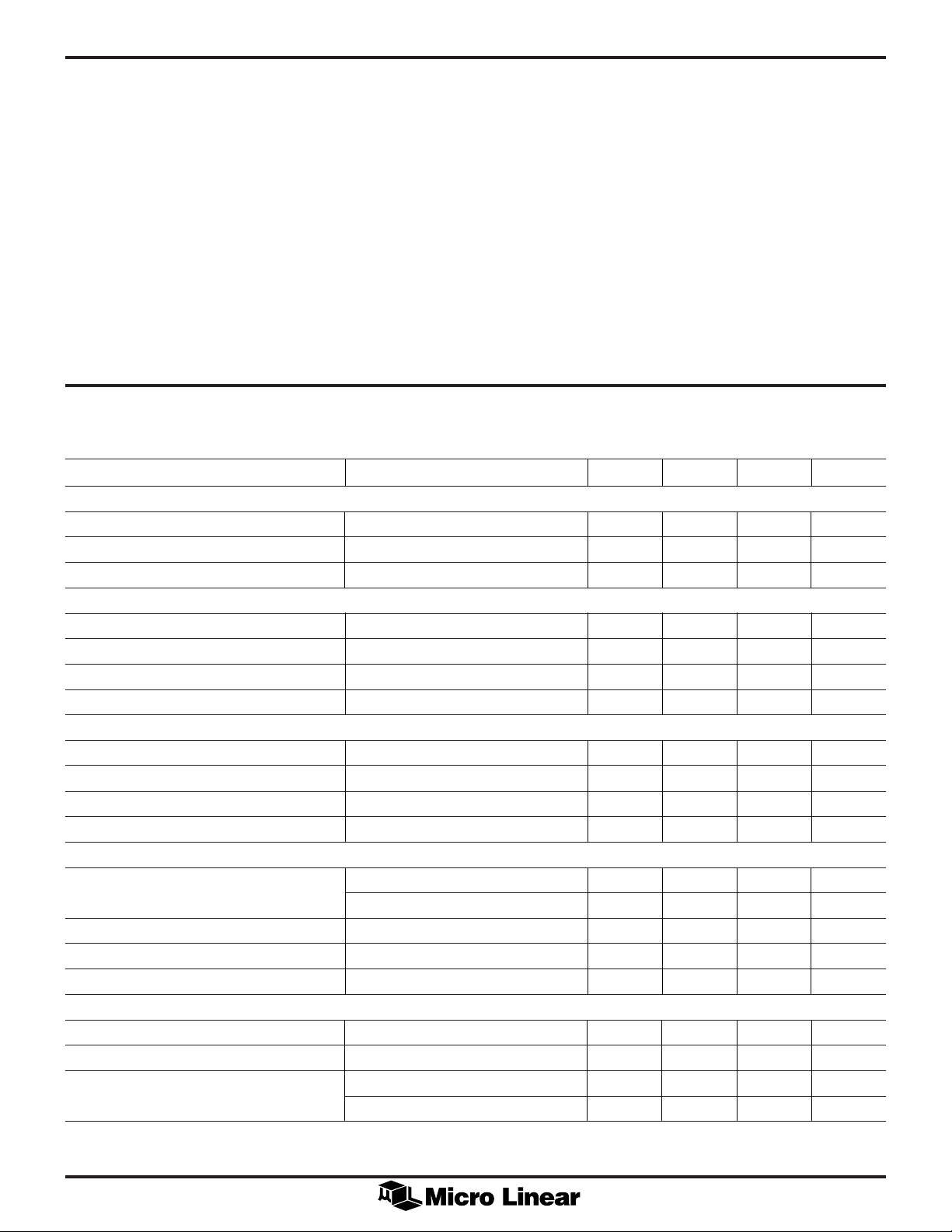

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Shutdown Inputs

Input Low Voltage 0.8 V

Input High Voltage 2.0 V

Input Bias Current –1 1 µA

Buck Regulator A

Duty Cycle Ratio VIN = 5.5V, I

VFB A Threshold Voltage 1.21 1.25 1.29 V

I

A Threshold Voltage –140 –200 –250 mV

SENSE

Transition Time CL = 1000pF, 0 to V

Buck Regulator B

Duty Cycle Ratio VIN = 5.5V, I

VFB B Threshold Voltage 1.21 1.25 1.29 V

I

B Threshold Voltage –140 –200 –250 mV

SENSE

Transition Time CL = 1000pF, 0 to V

Flyback Regulator C

Duty Cycle Ratio VIN = 5.5V, I

VFB C Threshold Voltage 1.21 1.25 1.29 V

I

C Threshold Voltage –140 –200 –250 mV

SENSE

Transition Time CL = 1000pF, 0 to V

Supply

Linear Regulator Output Voltage 7V ≤ VIN ≤ 18V 6.25 6.99 V

Linear Regulator Load Regulation I(V

VIN Current SHDN A/B/C = 5V 300 350 µA

= 14V, C(V

IN

) = 10µF, T

REG

VIN = 18V, I

) = 0 to 10mA 6.10 6.99 V

REG

SHDN A/B/C = 0V 350 400 µA

= Operating Temperature Range (Note 1)

A

A = VFB A = 0V 86 96 %

SENSE

REG

B = VFB B = 0V 92 98 %

SENSE

REG

C = VFBC = 0V 86 94 %

SENSE

C = VFBC = 0V 61 77 %

SENSE

REG

80 100 ns

80 100 ns

80 100 ns

Note 1: Limits are guaranteed by 100% testing, sampling or correlation with worst case test conditions.

3

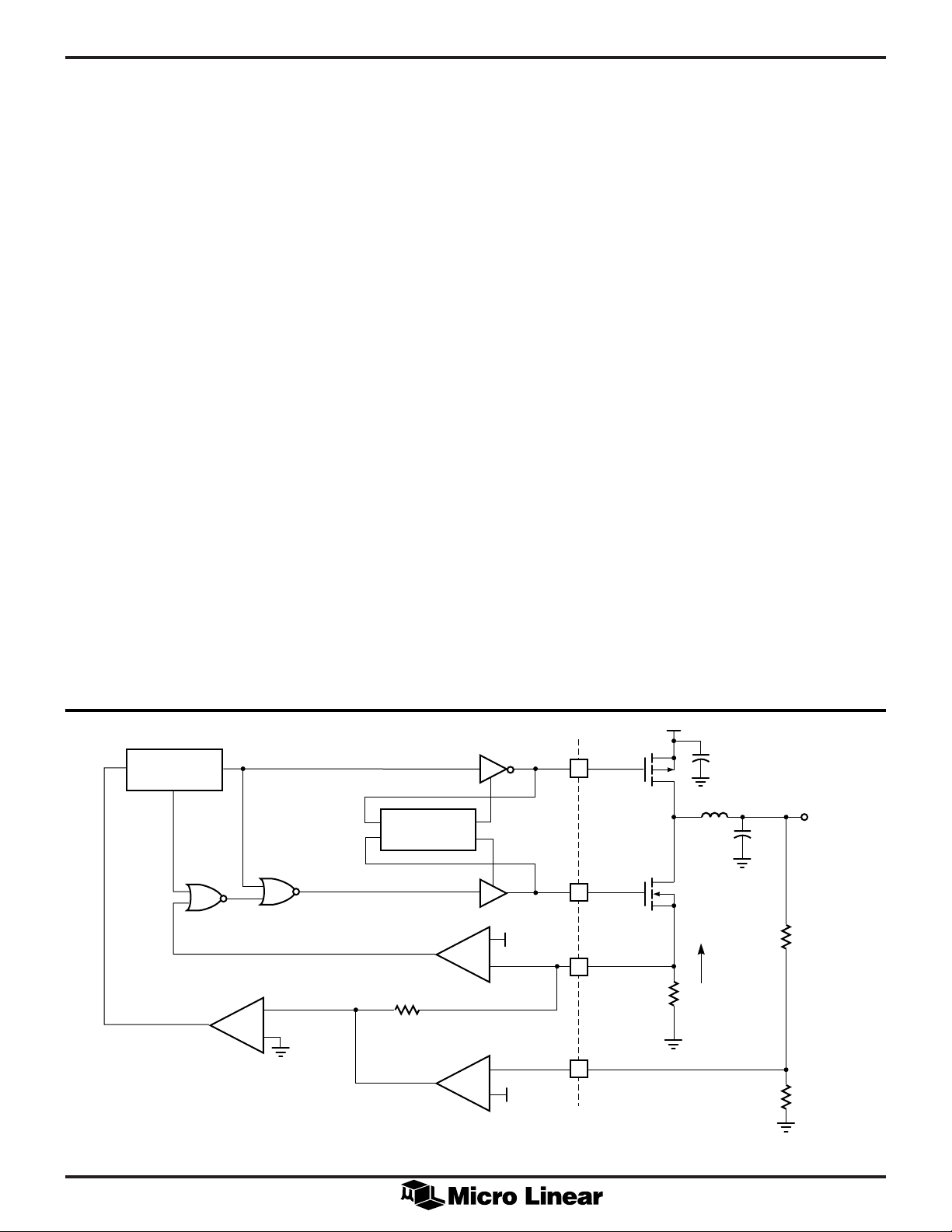

Page 4

ML4880

FUNCTIONAL DESCRIPTION

The ML4880 converts a 5.5V to 18V input to three outputs

via two synchronous buck controllers and a flyback

controller. The two buck controllers utilize a unique

current mode PFM control architecture that generate

output voltages in the range of 2.5V to 3.5V (output A),

and 4.5V to 5V (output B). The output current is set by

external components, and can exceed 2A on each supply.

The flyback controller also uses a current mode PFM

control scheme and can be used to generate a 6V to 15V

output. Again, the output current of the flyback is

dependent on external components, and output currents

of 500mA are obtainable. Even at light loads, the PFM

architecture maintains high conversion efficiencies over a

wide range of input voltages. If it is necessary to further

extend battery life, the user can shutdown and fully

disconnect each load from the input independently.

BIAS CIRCUITS

The bias circuits are comprised of a linear regulator and a

precision voltage reference. The linear regulator produces

a supply voltage (V

V

pin should be bypassed to GND with a 4.7µF to

REG

10µF capacitor. The precision voltage reference is used by

the feedback circuit of each controller to maintain an

accurate output voltage.

) used by the control circuits. The

REG

GATE CLAMP

The gate clamp circuit provides a method of preventing

the buck regulator P-channel MOSFET switches from

accidentally turning on when the input is suddenly

switched to a higher voltage. This condition can occur

during start-up or when an adapter voltage is applied. As

shown in the block diagram, the P DRV drivers are

capacitively coupled to the gates.

Assume that P DRV is in the OFF state, or at V

REG

, and the

gate voltage is held at VIN through the resistor. The gatesource voltage of the MOSFET is 0V and the switch stays

off. If a higher input voltage (VIN + 5V for example) is

suddenly applied with P DRV still in the OFF state, the

source voltage of the MOSFET would jump up to VIN +

5V, but the gate would still be at VIN. The gate-source

voltage becomes –5V and the P-channel MOSFET would

turn on even though P DRV is still in the OFF state. In

order to prevent the MOSFET from turning on, the gate

clamp circuit senses the increase in the input voltage and

pumps charge into the gate side of the coupling capacitor,

quickly charging the capacitor to the new input voltage

level.

The CLAMP pin requires a capacitor to GND in order for

the gate clamp circuit to function properly. The capacitor

value should be 1.5 to 2 times the value used for the

coupling capacitor.

SHUTDOWN LOGIC

Each controller has a separate shutdown pin. By applying

a logic high to the appropriate pin, the transconductance

amplifier and current comparator of each controller

(shown in Figures 1 and 3) can be disabled. This prevents

switching from occurring and disconnects the load from

the input. All other circuitry within the ML4880 remains

active during shutdown.

T

OSCILLATOR/

ONE SHOT

V

CURRENT

COMPARATOR

ON

SHOOT THRU

PROTECTION

SYNCHRONOUS

RECTIFIER

COMPARATOR

V

SR

Rgm

C

+

–

TRANSCONDUCTANCE

AMPLIFIER

BUCK CONTROLLERS

A block diagram of the buck controllers is shown in Figure

1. The circuit utilizes a constant ON-time PFM control

architecture. The circuit determines the OFF-time by

waiting for the inductor current to drop to a level set by

the feedback voltage (VFB).

V

IN

C

R

SENSE

IN

L

V

OUT

C

OUT

R1

I

L

P DRV

N DRV

–18mV

+

I

–

–

SENSE

V

FB

+

1.25V

R2

Figure 1. Buck Controller Functional Diagram

4

Page 5

ML4880

The oscillator/one shot block generates a constant ONtime and a minimum OFF-time. The OFF-time is extended

for as long as the output of the current comparator stays

low. Note that the inductor current flows in the current

sense resistor during the OFF-time. Therefore, a minimum

OFF-time is required to allow for the finite circuit delays

in sensing the inductor current. The ON-time is triggered

when the current comparator’s output goes high.

However, unlike conventional fixed ON-time controllers,

the ML4880’s one shot has an inverse relationship with

the input voltage as shown in Figure 4. Figure 5 plots the

inductor voltage-ON-time product. Note that the voltsecond product is nearly constant at voltages above 7V

input. This results in an inductor current ripple of:

TVV

×−()

ON IN OUT

∆I

=

L

L

(1)

It is important to note that the ripple current does not vary

in proportion with VIN, but remains nearly constant over a

wide input voltage range.

The transconductance amplifier generates a current from

the voltage difference between the reference and the

feedback voltage, VFB. This current produces a voltage

across Rgm that adds to the negative voltage that is

developed across the current sense resistor. When the

current level in the inductor drops low enough (a less

negative sense voltage) to cause the voltage at the noninverting input of the current comparator to go positive,

the comparator trips and starts a new ON cycle. In other

words, the current programming comparator controls the

length of the OFF-time by waiting until the inductor

current decreases to a value determined by the

transconductance amplifier.

This technique allows the feedback transconductance

amplifier’s output current to steer the current level in the

inductor. The higher the transconductance amplifier’s

output current, the higher the inductor current. For

example, when the output voltage drops due to a load

increase, the transconductance amplifier will increase its

output current and generate a larger voltage across Rgm,

which in turn raises the inductor current trip level,

shortening the OFF-time. At some level of increasing the

output load, the transconductance amplifier can no longer

continue to increase its output current. When this occurs,

the voltage across Rgm reaches a maximum and the

inductor current cannot increase. If the inductor current

tries to increase, the voltage developed across the current

sense resistor would become more negative, causing the

non-inverting input of the current comparator to be

negative, which extends the OFF-time and reduces the

inductor current.

When the output voltage is too high, the

transconductance amplifier’s output current will

eventually become negative. However, since the inductor

current flows in only one direction (assuming no shoot

through current) the non-inverting input of the current

comparator will also stay negative. This extends the OFFtime allowing the inductor current to decrease to zero and

causing the converter to stop operation until the output

voltage drops enough to increase the output current of the

transconductance amp above zero.

In summary, the three operation modes can be defined by

the voltage at the I

V

≥ 0V Discontinuous

SENSE

pin at the end of the OFF-time:

SENSE

current mode

0V > V

> –140mV Continuous

SENSE

current mode

–140mV > V

> –250mV Current limit

SENSE

The synchronous rectifier comparator and the two NOR

gates make up the synchronous rectifier control circuit.

The synchronous control does not influence the operation

of the main control loop, and operation with a Schottky

diode in place of the synchronous rectifier is possible, but

at a lower conversion efficiency. The synchronous rectifier

(N DRV) is turned on during the minimum OFF-time or

whenever the I

pin goes below –18mV. N DRV will

SENSE

remain on until a new ON-time is started or until the

I

pin goes above –18mV. When the ISENSE pin goes

SENSE

above –18mV, the current in the inductor has gone to zero

T

OFF(MIN)

V

C

T

ON

V

SR

I

L

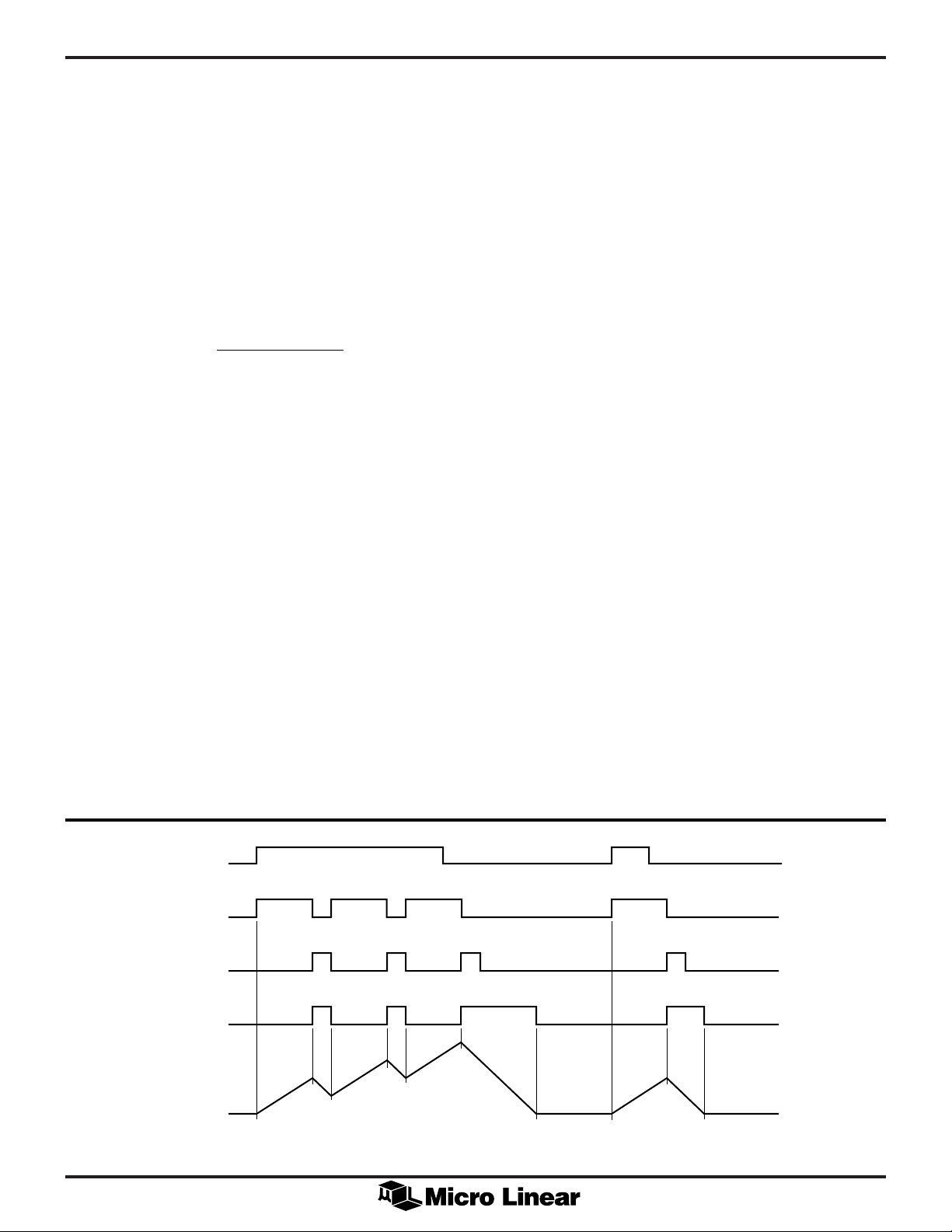

Figure 2. One Shot and Synchronous Rectifier Timing Diagram

5

Page 6

ML4880

or the buck regulator is operating in a discontinuous

current mode (DCM). Therefore, the synchronous rectifier

comparator is used only for DCM operation. A timing

diagram is shown in Figure 2.

FLYBACK CONTROLLER

A block diagram of the flyback regulator is shown in

Figure 3. The circuit also utilizes a constant ON-time PFM

control architecture. As with the buck controllers, the

flyback controller determines the OFF-time by waiting for

the inductor current to drop to a level set by the feedback

voltage VFB. As a result of the control scheme, the valley

of the inductor current ripple is programmed instead of

the peak, and features an automatic transition into and out

of burst mode which does not require additional control

circuitry.

The flyback controller’s oscillator/one shot block has a

constant ON-time and a minimum OFF-time similar to

that of the buck controllers. The OFF-time is extended for

as long as the current comparator’s output stays low.

Again, since the inductor current flows in the current

sense resistor during the OFF-time, a minimum OFF-time

is required to allow for the finite circuit delays in sensing

the inductor current. The ON-time is triggered when the

current comparator’s output goes high. However, unlike

conventional fixed ON-time controllers, the ML4880’s

one shot has an inverse relationship with the input voltage

as shown in Figure 4. Figure 5 plots the inductor voltageON-time product. Note that the volt-second product is

nearly constant over the input voltage range. This results

in an inductor current ripple of:

TV

×

ON IN

∆I

=

L

L

(2)

It is important to note that the ripple current does not vary

in proportion with VIN, but remains nearly constant over a

wide input voltage range.

The transconductance amplifier and current comparator

operate in the same manner as the buck regulator. The

current programming comparator controls the length of

the OFF-time by waiting until the inductor current

decreases to a value determined by the transconductance

amplifier before starting a new ON-time.

Like the buck controllers, when the flyback’s output

voltage drops due to a load increase, the

transconductance amplifier will increase its output current

and generate a larger voltage across Rgm, which in turn

causes the current comparator’s output to go positive

earlier or shortens the OFF-time. Conversely, when the

output voltage is too high, the transconductance

amplifier’s output current will eventually become

negative. This holds the current comparator’s output low

and extends the OFF-time causing the converter to stop

operation until the output voltage drops enough to

increase the output current of the transconductance amp

above zero.

In summary, the flyback has three operation modes that

can be defined by the voltage at the SENSE pin at the end

of the OFF-time:

V

≥ 0V Discontinuous

SENSE

current mode

0V > V

> –140mV Continuous

SENSE

current mode

–140mV > VSENSE > –250mV Current limit

OSCILLATOR/

ONE SHOT

V

CURRENT

COMPARATOR

V

IN

T

ON

Rgm

C

+

–

TRANSCONDUCTANCE

AMPLIFIER

–

+

1.25V

N DRV

I

SENSE

V

FB

Figure 3. Flyback Controller Functional Diagram

6

Page 7

ML4880

DESIGN CONSIDERATIONS

A typical design can be implemented by using the

following design procedure. Note that this procedure is

not intended to give final values, but to give a good

starting point, and provide the relationships necessary to

make trade-off decisions. Some experimentation will be

necessary to optimize values and to verify that the design

operates over worst case conditions.

DESIGN SPECIFICATIONS

It is important to start with a clear definition of the design

specifications. Make sure the specifications reflect worst

case conditions. Key specifications include the minimum

and maximum input voltage and the output voltage and

load current for each output.

BUCK REGULATORS - INDUCTOR AND SENSE

RESISTOR SELECTION

Figure 6 shows the inductor current of the step down

regulators. The inductor current is made up of two

components: the DC current level set by the

transconductance amplifier, I

current, ∆I

summation of I

II I

OUT SENSE L

. The figure also shows that I

L

SENSE

=+= +

1

∆

22

and

V

R

1

/2 ∆I

SENSE

SENSE

, and the inductor ripple

SENSE

:

L

TVV

×−

ON IN OUT

is the

OUT

()

L

×

(3)

Inductor ripple currents in the range of 30% to 70% of the

maximum output current are typical. As a good starting

point set the inductor ripple current to 50% of the

maximum output current:

TVV

×−

()

ON IN OUT

where F

∆I

=

L

= ratio of inductor ripple current to the

IRC

L

FI

=×

IRC OUT MAX

()

(4)

maximum output current, or:

TVV

×−

()

ON IN OUT

L

=

05

I

×

.

OUT MAX

()

(5)

Calculate the inductance using the volt-seconds value

given in Figure 5 at the maximum input voltage. Choose

the nearest standard value, realizing the trade-offs

mentioned before. Then, using the inductance value

chosen, determine the actual inductor ripple current at the

maximum and minimum input voltage using Equation 4

and Figure 5.

The sense resistor value can be determined using the

inductor ripple current value calculated above and

Equation 3 rearranged as follows:

R

SENSE

V

SENSE MIN

=

IIII

OUT MAX L MIN OUT MAX L MIN

()

1

−

() () () ()

∆∆

2

=

.

014

−

1

(6)

2

Therefore, the selection of the inductance value

determines how much of the output current is made up of

the ripple current. Higher inductor ripple current allows

smaller inductor values, but results in higher peak

currents, lower efficiency, and higher output voltage

ripple.

(µs)

T

ON

18

16

14

12

10

3.3V BUCK

8

12V FLYBACK

6

4

5V BUCK

45

40

35

30

25

20

VOLT-SECONDS (V-µs)

15

10

12V FLYBACK

3.3V BUCK

5V BUCK

2

0 5 10 15 20

VIN (V)

Figure 4. TON vs. V

IN

5

0510

V

(V)

IN

Figure 5. Volt-seconds vs V

15 20

IN

7

Page 8

ML4880

Having determined the values for the inductor and sense

resistor, we can now specify the inductor peak current

rating. This value is calculated at current limit and at the

maximum input voltage, and is given by:

II I

L PK MAX SENSE MAX L MAX

(@ ) ( ) ( )

V

SENSE MAX

R

=+=

()

+=+

∆∆

I

L MAX

SENSE

() ()

∆

025

V

.

R

SENSE

I

L MAX

(7)

For reliable operation, the inductor current rating should

exceed the value calculated by 10%-20%.

For future reference, determine the peak inductor current

at the minimum input voltage:

II I

L PK MIN SENSE MAX L MIN

(@ ) ( ) ( )

V

SENSE MAX

R

=+=

()

SENSE

I

+=+

∆∆

L MIN

() ()

∆

V

.

025

R

SENSE

I

L MIN

(8)

Now the sense resistor’s power rating can be determined.

The sense resistor must be able to carry the peak current

in the inductor during the OFF-time:

PI R

R RMS OFF SENSE

SENSE

where

2

I

RMS OFF

2

=×

()

,

()()()()

IIII

V

OUT

V

IN MAX

()

SENSE MAX

1

=−

()

22

++

()

SENSE MAX L PK MAX

(9)

()(@)

3

L PK MAX

(@ )

One final parameter should be specified: the winding

resistance of the inductor. In general the winding

resistance should be as low as possible, preferably in the

low mΩ range. Since the inductor is in series with the

load at all times, the copper losses can be approximated

by:

BUCK REGULATORS — MOSFET SELECTION

The switching MOSFETs must be logic level types with the

ON resistance specified at VGS = 4.5V. In general, the ON

resistance - gate charge product provides a good figure of

merit by which to compare various MOSFETs, the lower

the figure the better. The internal gate drivers of the

ML4880 can drive over 100nC of total gate charge, but

60nC to 70nC is a more practical limit to ensure good

switching times.

The drain-source breakdown voltage rating is determined

by the input voltage. For input voltages up to 12V, a drain

to source rating of 20V is acceptable. For input voltages

up to 18V, a drain to source rating of 30V is

recommended. For a more reliable design, look for

MOSFETs that are avalanche rated.

In high current applications, the MOSFET’s power

dissipation often becomes a major design factor. The I2R

losses generate the largest portion of heat in the MOSFET

package. Make sure that the MOSFETs are within their

rated junction temperature at the maximum ambient

temperature by calculating the temperature rise using the

thermal resistance specifications.

The worst case power dissipation for the P-MOS switch

occurs at the minimum input voltage and is determined as

follows:

PIR

P MOS RMS ON DS ON( ) () ()−

where

2

I

RMS ON

()

2

=×

()()()()

IIII

SENSE MAX SENSE MAX L PK MIN L PK MIN

V

OUT

=

V

IN MIN

()

22

++

() ()(@) (@)

3

The worst case power dissipation for the N-MOS switch

occurs at the maximum input voltage and is determined

using:

(11)

2

PI R

=×

CU OUT L

A good rule of thumb is to allow 2mΩ of winding

resistance per µH of inductance.

I

L

V

IN – VOUT

L

T

ON

V

T

OFF

Figure 6. Buck Regulator Inductor Current

8

OUT

L

(10)

∆I

I

LPK

L

I

SENSE

PIR

N MOS RMS OFF DS ON()()()−

I

= I

OUT

SENSE

V

SENSE

=

R

SENSE

2

=×

+ 1/2 ∆I

L

t

(12)

Page 9

ML4880

BUCK REGULATORS — INPUT CAPACITOR SELECTION

The choice of the input capacitor is based on it’s ripple

current and voltage ratings rather than its capacitance

value. The input capacitor should be a low ESR type and

located as close to the source of the P-MOS switch as

possible. The input capacitor’s ripple current is

determined by the load current and the input voltage, with

the worst case condition occurring at V

II I

RMS C SENSE MAX L MAX

≈+

() () ()

IN

1

∆

2

= 2 × V

IN

()

VVV

OUT IN OUT

V

OUT

−

IN

:

(13)

The capacitor’s voltage rating is based on the maximum

input voltage, V

. Capacitor manufacturers typically

IN(MAX)

recommend derating the capacitor voltage rating by 20%

to 50% for aluminum electrolytic types and 50% to 70%

for tantalum types.

In high current applications it may necessary to add a

10µF bulk capacitor and a small 0.1µF ceramic capacitor

to bypass VIN (pin 16) right at the ML4880.

BUCK REGULATORS — OUTPUT CAPACITOR

SELECTION

The output capacitors determine the loop stability and the

output ripple voltage. Use only low ESR capacitors

intended for switching power supply applications, such as

AVX TPS, Sprague 593D Sanyo OS-CON, or Nichicon PL

series. To ensure stability, the minimum capacitance value

is given by:

C

OUT

V

43.

OUT

T

ON MAX

R

≥

()

SENSE

(14)

The maximum ESR value can be estimated using:

V

∆

≤

∆

OUT

I

L MAX

()

(15)

ESR

The selected capacitor must meet both the capacitance

and ESR requirements. As a final check, make sure the

output capacitor can handle the ripple current,

I

RMS(C

OUT

:

)

I

∆

L MAX

I

RMS C

()

OUT

≈

()

12

(16)

BUCK REGULATORS - OUTPUT VOLTAGE

The output of buck regulator A is adjustable and can be

set to any voltage between 2.5V and 3.5V by connecting a

resistor divider to the feedback pin as shown in Figure 1.

Similarly, the output voltage of buck regulator B is

adjustable and has a usable range of 4.5V to 5.0V. The

resistor values R1 and R2 can be calculated using the

following equation:

.

VV

125

=×

OUT

RR

12

+

2

R

(17)

The value of R2 should be 125kΩ or less to minimize bias

current errors.

It is important to note that the accuracy of these resistors

directly affects the accuracy of the output. Use precision

resistors and set the nominal voltage approximately 1% to

2% high with no load in order to make up for the drops

that normally occur when supplying heavy loads. This

offset results in the best overall output accuracy over line

and load.

FLYBACK REGULATOR — INDUCTOR AND SENSE

RESISTOR SELECTION

Figure 7 shows the inductor current of the flyback

regulator. The inductor current is made up of two

components: the DC current level set by the

transconductance amplifier, I

current, ∆I

. Therefore, the selection of the inductance

L

, and the inductor ripple

SENSE

value determines how much of the output current is made

up of the inductor ripple current. Higher inductor ripple

current allows smaller inductor values, but results in

higher peak currents, lower efficiency, and higher output

voltage ripple.

I

L

V

IN

L

T

ON

V

OUT

L

T

OFF

I

OUT

∆I

∆IL =

I

SENSE

= (I

L(PEAK)

VIN T

SENSE

L

V

=

R

ON

SENSE

SENSE

+ 1/2 ∆IL)

V

VIN + V

t

IN

OUT

Figure 7. Flyback Regulator Inductor Current

9

Page 10

ML4880

The relationship of the inductor current to the output

current is given by the following equation:

+

IN OUT

(18)

II I

=+

OUT SENSE L

1

∆

22

VVVR

V

IN

+

IN OUT

=+

TVLV

SENSE

ON IN IN

SENSE

×

×

VV

The inductance value can be determined by setting the

ripple current portion of Equation 18 to some percentage

of the output current. Inductor ripple currents in the range

of 50% to 80% of the maximum output current are

typical. As a good starting point set the inductor ripple

current to 65% of the maximum output current:

IN

(19)

TV

∆I

=

L

where F

×

ON IN

L

= ratio of inductor ripple current to the

IRC

FI

=× ×

IRC OUT MAX

()

VV

IN OUT

+

V

maximum output current, or:

TV

ON IN MIN

L

=

.065

×

()

I

×+

OUT MAX

()

V

IN MIN

()

VV

IN MIN OUT

()

(20)

Calculate the inductance using the volt-seconds value

given in Figure 5 at the minimum input voltage. Choose

the nearest standard value, and determine the actual

inductor ripple current at the maximum and minimum

input voltage using Equation 19 and Figure 5.

Next, determine the sense resistor value using the inductor

ripple current value calculated above using:

The winding resistance and the turns ratio of the coupled

inductor need to be specified. In general the winding

resistance should be as low as possible, preferably in the

low milliohm range. A good rule of thumb is to allow 2

mW of winding resistance per mH of inductance. The

turns ratio is specified at 1:1 for simplicity and availability.

FLYBACK REGULATOR - MOSFET SELECTION

The internal gate drive of the ML4880 limits the selection

of the switching FET to logic level types with the ON

resistance specified at VGS = 4.5V. Also, look for a FET

with a maximum total gate charge of around 70nC.

The drain to source breakdown voltage rating is

determined as follows:

VV V F

=+×()

DS IN MAX OUT DS

()

(24)

A safety derating factor, FDS, in the range of 1.5 to 2.0 is

recommended due to the voltage spikes caused by the

leakage inductance of a transformer. For a more reliable

design, look for MOSFETs that are avalanche rated.

The maximum ON resistance of the MOSFET can be

determined using the worst case power dissipation for the

package type chosen. This assumes that the major portion

of heat generated in the package is due to I2R losses.

P

R

DS ON

()

=

2

I

RMS ON

PKG

(25)

()

V

()

R

SENSE

=

I

OUT MAX

=

I

()

OUT MAX

VV

()

IN MIN OUT

()

SENSE MIN

VV

+

()

IN MIN OUT

V

V

IN MIN

014

.

+

()

()

IN MIN

−

1

∆

I

2

1

−

2

()

L MIN

∆

I

()

L MIN

(21)

Having determined the values for the inductor and sense

resistor, the inductor peak current rating can now be

specified. This value is calculated at current limit and at

the maximum input voltage, and is given by:

II I

L PK MAX SENSE MAX L MAX

(@ ) ( ) ( )

V

=+=+

=+

SENSE MAX

()

R

SENSE

∆∆

∆

025

V

I

L MAX

() ()

.

R

SENSE

I

L MAX

(22)

For reliable operation, the inductor current rating should

exceed the value calculated by 10%-20%.

Now the sense resistor’s power rating can be determined.

The sense resistor must be able to carry the peak current

in the inductor, but only during the OFF-time:

PI R

R RMS OFF SENSE

2

=×

SENSE

()

(23)

where,

()()()()

IIII

2

I

()

RMS OFF

V

IN MAX

=

VV

()

IN MAX OUT

SENSE MAX

()

+

22

++

()(@) (@)

SENSE MAX L PK MAX L PK MAX

()

3

where,

2

I

RMS ON

()

V

OUT

=

+

VV

IN MIN OUT

()

()()()()

IIII

SENSE MAX

2

++

SENSE MAX L PK MAX

()

()(@)

3

FLYBACK REGULATOR — RECTIFIER SELECTION

The output diode must be able to carry the worst case

output current as well as withstand the worst case reverse

voltage. The worst case output current occurs at current

limit and at the maximum input voltage. Therefore, the

average forward current rating of the output diode can be

determined by the following:

I

I

D AVG

OUT MAX

==+

()

FR

025

() () ()

ID SENSE

.

TV

×

ON IN MAX IN MAX

2

L

×

VVF

IN MAX OUT ID

()

where,

F derating factor

=

ID

The derating factor is typically in the range of 0.5 to 0.9

depending on reliability goals. Typically a value of 0.8 is

used for most applications.

The reverse voltage rating is determined by the sum of the

output voltage and the maximum input voltage:

V

+

L PK MAX

(@ )

(26)

2

1

10

Page 11

ML4880

VV

+

()

F

VR

(27)

where,

OUT IN MAX

V

=

R

F derating factor

=

VR

Again a derating factor of 0.8 is typical for most

applications.

FLYBACK REGULATOR - INPUT CAPACITOR

SELECTION

The input capacitor should be a low ESR type and located

as close to the primary winding of the transformer as

possible. The capacitor’s ability to handle ripple current is

the selection criteria used. The input capacitor’s ripple

current is determined by the load current and the input

voltage, with the worst case condition occurring at

VIN = V

II I

RMS C SENSE MAX L MAX

() () ()

.

OUT

≈+

IN

1

∆

2

×

VV

OUT IN

+

VV

OUT IN

(28)

The capacitor must also be able to handle the maximum

input voltage. For reliable operation derate the capacitor

voltage rating by 20% to 50% for aluminum electrolytic

types and 50% to 70% for tantalum types.

FLYBACK REGULATOR - OUTPUT CAPACITOR

SELECTION

The output capacitors determine the flyback regulator’s

loop stability and the output ripple voltage. Use only low

ESR capacitors intended for switching power supply

applications. To ensure stability, the minimum capacitance

value is given by:

L MIN

()

(29)

C

OUT

V

86.

OUT

T

ON MAX

R

SENSE

≥

I

() ()

OUT MAX

∆

I

The maximum ESR value can be estimated using:

V

∆

≤

∆

OUT

I

L MAX

()

(30)

ESR

The selected capacitor must meet both the capacitance

and ESR requirements. As a final check, make sure the

output capacitor can handle the ripple current,

I

RMS(C

OUT

.

)

II

RMS C RMS C

≈

() ()

OUT IN

(31)

FLYBACK REGULATOR - OUTPUT VOLTAGE

The output of the flyback regulator is adjustable and can

be set to any voltage between 6.0V and 15.0V by

connecting a resistor divider to the feedback pin as shown

in Figure 3. The resistor values R1 and R2 can be

calculated using the following equation:

125

VV

OUT

.

=×

RR

12

+

2

R

(32)

The value of R2 should be 125kΩ or less to minimize bias

current errors.

It is important to note that the accuracy of these resistors

directly affects the accuracy of the output. Use precision

resistors and set the nominal voltage approximately 1% to

2% high in order to make up for the ML4880’s load

regulation. This offset results in the best overall output

accuracy over line and load.

LAYOUT

Proximity of passive devices and adequate power and

ground planes are critical for reliable operation of the

circuit. In general, use the top layer for the high current

connections and the bottom layer for the quiet

connections such as GND, feedback and current sense.

Some more specific guidelines follow.

1. The connection from the current sense resistor to the

I

pin should be made by a separate trace and

SENSE

located as close to the lead of the resistor as

possible. The trace length from the sense resistor to

the ML4880 should be kept as short as possible and

away from switching components and their traces.

2. The trace lengths from the buck regulator’s input

capacitor to the switching MOSFET, from the

MOSFETs to the inductor, from the synchronous

rectifier MOSFET to the SENSE resistor, and from the

inductor to the output capacitor should all be as

short as possible. The flyback regulator’s trace length

from the input capacitor to the inductor, from the

inductor to the MOSFET, from the sense resistor to

the inductor, and from the diode to the output

capacitor should also be kept short to minimize

noise and ground bounce.

3. The high current ground paths need to be kept

separate from the signal ground paths. The GND

connection should be made at a single-point star

ground. It is very important that the ground for the

ML4880 ground pins (pins 6 and 7) be made using a

separate trace.

4. Note: Concentrating on keeping the current sense

and high current connections short as well as

keeping the switching components and traces away

from the sensitive analog components and traces

during layout will eliminate the majority of problems

created by a poor layout.

5. The VIN and V

located close to the ML4880 for adequate filtering of

the IC’s internal bias voltage.

6. Remote sensing the output for improved load

regulation can be implemented with the ML4880.

Any output can be remote sensed by using the top of

the external resistor divider as the remote sense

point.

bypass capacitors need to be

REG

11

Page 12

ML4880

ML4480

16

V

IN

11

SHDN A

18

SHDN B

10

SHDN C

17

N DRV C

3

I

SENSE

C

21

PWR GND C

12

V

FB

C

GND

GND

V

REG

CLAMP

5.5V to 18V

C1

33µF

25V

C2

33µF

25V

C3

33µF

25V

C4

10µF

35V

C5

0.1µF

C8

68µF

20V

C9

68µF

20V

C10

10nF

R4

887k

1%

R5

100k

1%

D1

MBRS340T3

T1

39µH

V

IN

Q1 A&B

Si9955

R6

0.12

C6

0.1µF

C7

10µF

35V

15 24

67

R12

80m

R14

124k

1%

D5*

L2

33µH

C17

10nF

R13

383k

1%

C18

100µF

10V

C19

100µF

10V

*Optional

Q5

IRF7403

Q4

IRF7406

R11

100k

D4

IN4148

C16

47nF

R8

80m

C12

47nF

Q3

IRF7403

Q2

IRF7406

R7

100k

D2

IN4148

C11

68nF

D3*

C13

10nF

R9

205k

1%

R10

124k

1%

L1

33µH

C14

100µF

10V

C15

100µF

10V

3.3V, 2A

5.0V, 2A

12V, 0.5A

3.3 SHDN

5.0 SHDN

12 SHDN

V

IN

V

IN

V

IN

CLAMP A

P DRV A

N DRV A

I

SENSE

A

PWR GND A

V

FB

A

CLAMP B

P DRV B

N DRV B

I

SENSE

B

PWR GND B

V

FB

B

21314423

9

11920522

8

12

Figure 8. Typical Application Circuit

Page 13

SUGGESTED VENDORS

See Table 1 for a list of suggested component manufacturers.

TABLE 1: COMPONENT SUPPLIERS

COMPONENT MANUFACTURER PART NUMBER PHONE

SENSE RESISTORS Dale WSL Series (402) 563-6506

IRC LRC Series (512) 992-7900

INDUCTORS Coilcraft DO/DT Series (708) 639-6400

Coiltronics OCTA-PAC Series (305) 781-8900

Dale LPE-6562 Series (605) 665-9301

LPT-4545 Series

Premier Magnetics VTK & HTK Series (714) 362-4211

Pulse Engineering LCI & HCI Series (619) 674-8100

Sumida CD & CDR Series (708) 956-0666

XFMRS, Inc. Surface Mt Series (317) 834-1066

CAPACITORS AVX TPS Series (207) 282-5111

Sprague 593D Series (708) 956-0667

Sanyo SC & SA Series (619) 661-6835

Nichicon PL Series (708) 843-7500

Panasonic HFQ Series (201) 348-5227

ML4880

SEMICONDUCTORS Diodes, Inc. SK Series (805) 446-4800

International Rectifier IRF7XXX Series (310) 322-3331

Motorola MMSF Series (602) 302-8056

MMDF Series

National Semiconductor NDS94XX (800) 272-9959

NDS99XX

Siliconix Littlefoot Series (408) 970-5700

Litefoot Series

13

Page 14

ML4880

PHYSICAL DIMENSIONS

0.600 - 0.614

(15.24 - 15.60)

0.050 BSC

(1.27 BSC)

0.024 - 0.034

(0.61 - 0.86)

(4 PLACES)

24

PIN 1 ID

1

inches (millimeters)

Package: S24

24-Pin SOIC

0.291 - 0.301

(7.39 - 7.65)

0.095 - 0.107

(2.41 - 2.72)

0.398 - 0.412

(10.11 - 10.47)

0º - 8º

0.090 - 0.094

(2.28 - 2.39)

0.012 - 0.020

(0.30 - 0.51)

SEATING PLANE

0.005 - 0.013

(0.13 - 0.33)

0.022 - 0.042

(0.56 - 1.07)

0.009 - 0.013

(0.22 - 0.33)

14

Page 15

ML4880

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML4880CS0°C to 70°C24-PIN SOIC (S24) (End Of Life)

ML4880ES–20°C to 70°C24-PIN SOIC (S24) (Obsolete)

© Micro Linear 1997 is a registered trademark of Micro Linear Corporation

Products described in this document may be covered by one or more of the following patents, U.S.: 4,897,611; 4,964,026; 5,027,116; 5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940;

5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376; Japan: 2598946; 2619299. Other patents are pending.

Micro Linear reserves the right to make changes to any product herein to improve reliability, function or design.

Micro Linear does not assume any liability arising out of the application or use of any product described herein,

neither does it convey any license under its patent right nor the rights of others. The circuits contained in this

data sheet are offered as possible applications only. Micro Linear makes no warranties or representations as to

whether the illustrated circuits infringe any intellectual property rights of others, and will accept no responsibility

or liability for use of any application herein. The customer is urged to consult with appropriate legal counsel

before deciding on a particular application. DS4880-01

16

2092 Concourse Drive

San Jose, CA 95131

Tel: 408/433-5200

Fax: 408/432-0295

04/28/97 Printed in U.S.A.

Loading...

Loading...