Page 1

JULY 2000

NEW!

30W CCFL Inverter Design

ML4877*

LCD Desktop Backlight Lamp Driver

GENERAL DESCRIPTION

The ML4877 is an ideal solution for driving multiple cold

cathode fluorescent tubes (CCFL) used in liquid crystal

display (LCD) backlight applications. It provides dimming

ballast control for the LCD display.

By utilizing differential drive the ML4877 can deliver the

same light output with significantly less input power

compared to existing single ended drive schemes.

Improvements as high as 30% can be realized when using

low power lamps and advanced LCD screen housings. This

increased light output is achieved because the differential

drive configuration is much less sensitive, and therefore

less power is wasted in the capacitive parasitics that exist

in the backlight housing. An additional benefit of this

configuration is an even distribution of light.

The IC includes an adjustable lamp out detect circuit that

latches the IC off when a lamp fault is detected. Also, the

unique architecture of the ML4877 allows the

development of a backlight system that will inherently

meet the UL requirements for safety.

The ML4877 is optimized for large LCD applications

applications where high efficiency is critical to maximize

battery life. The high efficiency is achieved by a resonant

scheme with zero voltage switching.

FEATURES

■ Ideal for 30W inverter designs, 1 to 8 lamp design

■ PWM dimming capability

■ Backlight lamp driver with differential drive

■ Up to 30% lower power for same light output

■ Low standby current (<10µA)

■ Improved efficiency (»95%)

■ Allows all N-channel MOSFET drive

■ Adjustable lamp out detect with latch

■ Resonant threshold detection and synchronous

rectification

■ Positive input for dimming control

* THIS PART IS END OF LIFE AS OF JULY 1, 2000

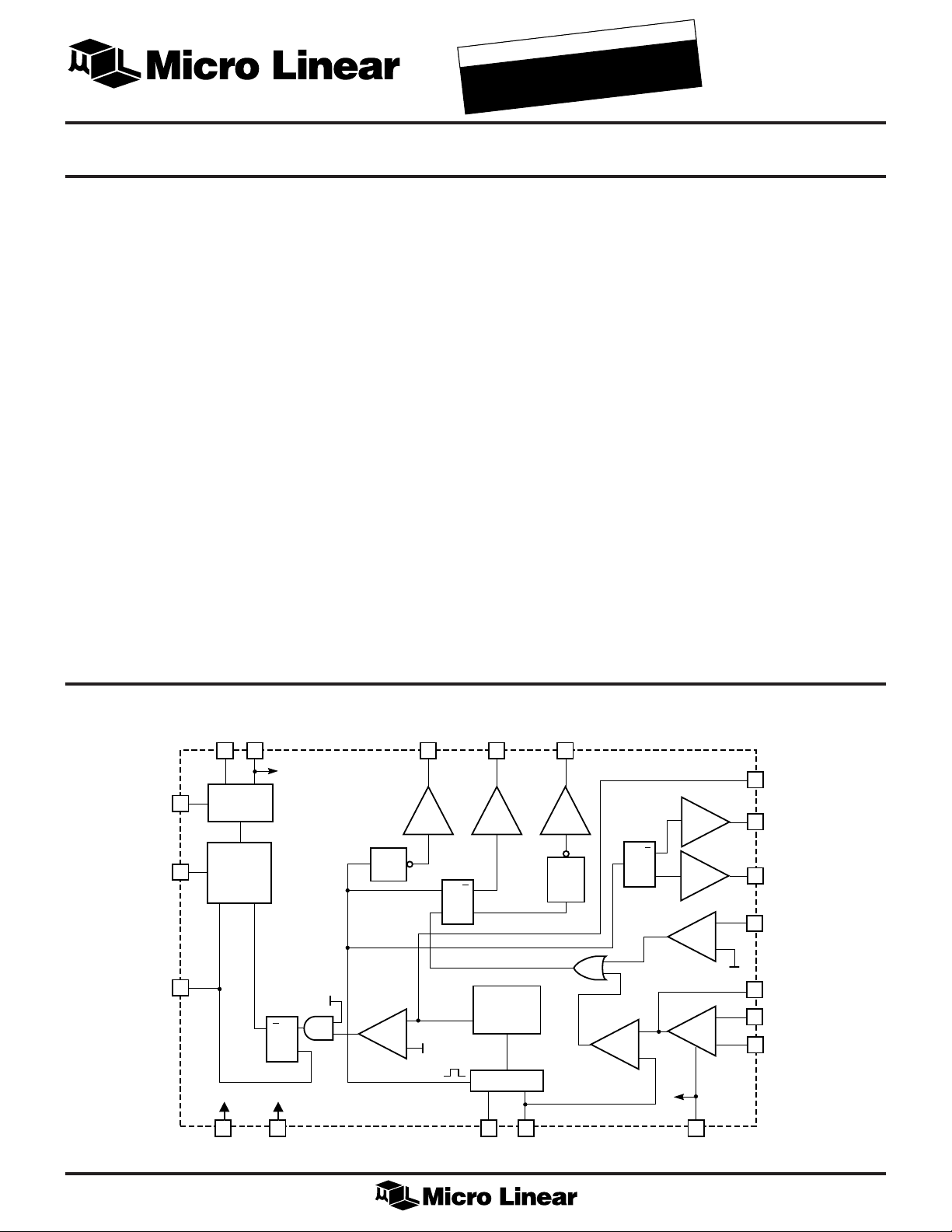

BLOCK DIAGRAM

AZR

2

REGULATOR

5

PGND18GND

LINEAR

MASTER

BIAS

&

UVLO

17

ON/OFF

HVDD

VREF

12

15

VDD

13

VDD

Q

S

QR

B ON

19

DR3 DR1 DR1

ONE

SHOT

SS

+

–

VDD

CLK

S

Q

RQ

B OFF

RESONANT

THRESHOLD

DETECTOR

OSCILLATOR

4

R

T

B SYNC OUT

20

11

L RTD

10

L GATE 1

DR2

Q

NEG

EDGE

DELAY

9

T

T

Q

DR2

–

+

SS

3

SS CAPC

14

L GATE 2

16

6

+

–

–

+

0.5V

8

7

1

L ILIM

LEA OUT

LEA–

LEA+

1

Page 2

ML4877

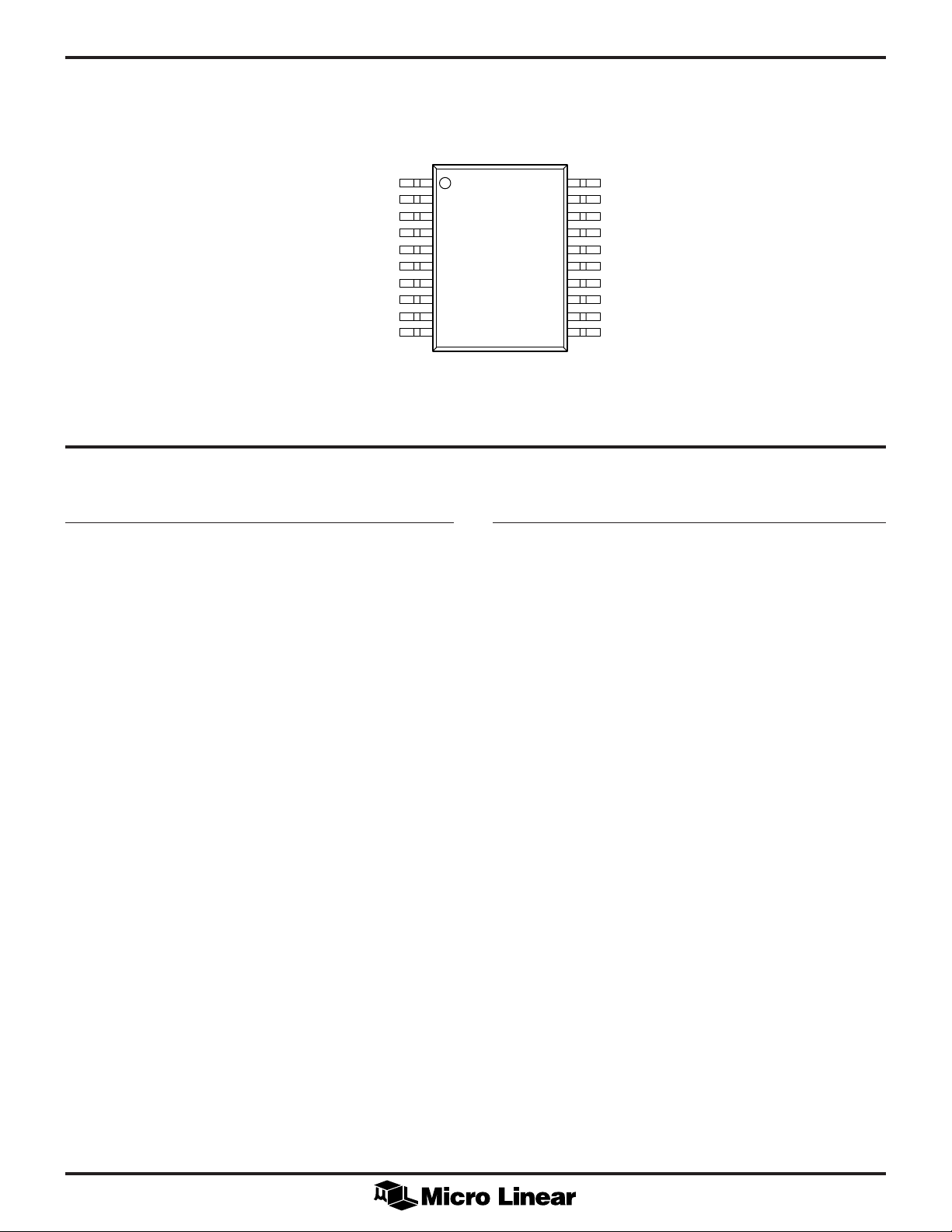

PIN CONFIGURATION

PIN DESCRIPTION

LEA+

AZR

SS CAP

R

VREF

L ILIM

LEA–

LEA OUT

C

L RTD

ML4877

20-Pin SSOP (R20)

1

2

3

T

T

4

5

6

7

8

9

10

TOP VIEW

20

19

18

17

16

15

14

13

12

11

B OFF

B ON

GND

PGND

L GATE 2

ON/OFF

L GATE 1

VDD

HVDD

B SYNC OUT

PIN NAME FUNCTION

1 LEA+ Positive input for lamp error amp

2 AZR Connection to gate of external FET for

high voltage regulator. Internally a

zener diode to ground.

3 SS CAP Connection of optional external soft

start capacitor

4R

T

Oscillator timing resistor

5 VREF Voltage reference output

6 L ILIM Input to current limit amplifier

7 LEA- Negative input for lamp error

amplifier

8 LEA OUT Output of lamp error amplifier.

External compensation capacitor

connects between this pin and LEA.

9C

T

Oscillator timing capacitor

10 L RTD Input to resonant threshold detector

PIN NAME FUNCTION

11 B SYNC Output of MOSFET driver to gate of

OUT synchronous FET catch diode.

12 HVDD Battery power input to linear regulator

13 VDD Output of linear regulator. Positive

power for IC.

14 L GATE1 Output of MOSFET driver. Connection

to gate of one side of inverter FET

drive pair.

15 ON/OFF Logic input for chip

16 L GATE2 Output of MOSFET driver. Connection

to gate of one side of inverter FET

drive pair.

17 PGND Power ground

18 GND Signal ground

19 B ON Connection to primary side of gate

pulse transformer

20 B OFF Output of MOSFET driver. Connection

to gate of FET that disables the input

power.

2

Page 3

ABSOLUTE MAXIMUM RATINGS

ML4877

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

Voltage on HVIDD .................................................... 20V

Current into L RTD ............................................... ±10mA

Junction Temperature.............................................. 150ºC

Storage Temperature Range .......................-65ºC to 150ºC

Lead Temperature (Soldering 10 sec.) ..................... 260ºC

Supply Current (ICC) ............................................... 75mA

Thermal Resistance (qJA).................................... 100ºC/W

Output Current, Source or Sink ............................. 250mA

Voltage on Pins LEA+, AZR, SS CAP, RT, VREF,

OPERATING CONDITIONS

L ILIM, LEA-, LEA OUT, CT, B SYNC OUT, VDD,

L GATE 1, ON/OFF, L GATE 2, PGND, GND,

B ON, B OFF ............................... –0.3V to VDD +0.3V

Temperature Range

ML4877C ................................................... 0ºC to 70ºC

ML4877E...............................................–20ºC to 70ºC

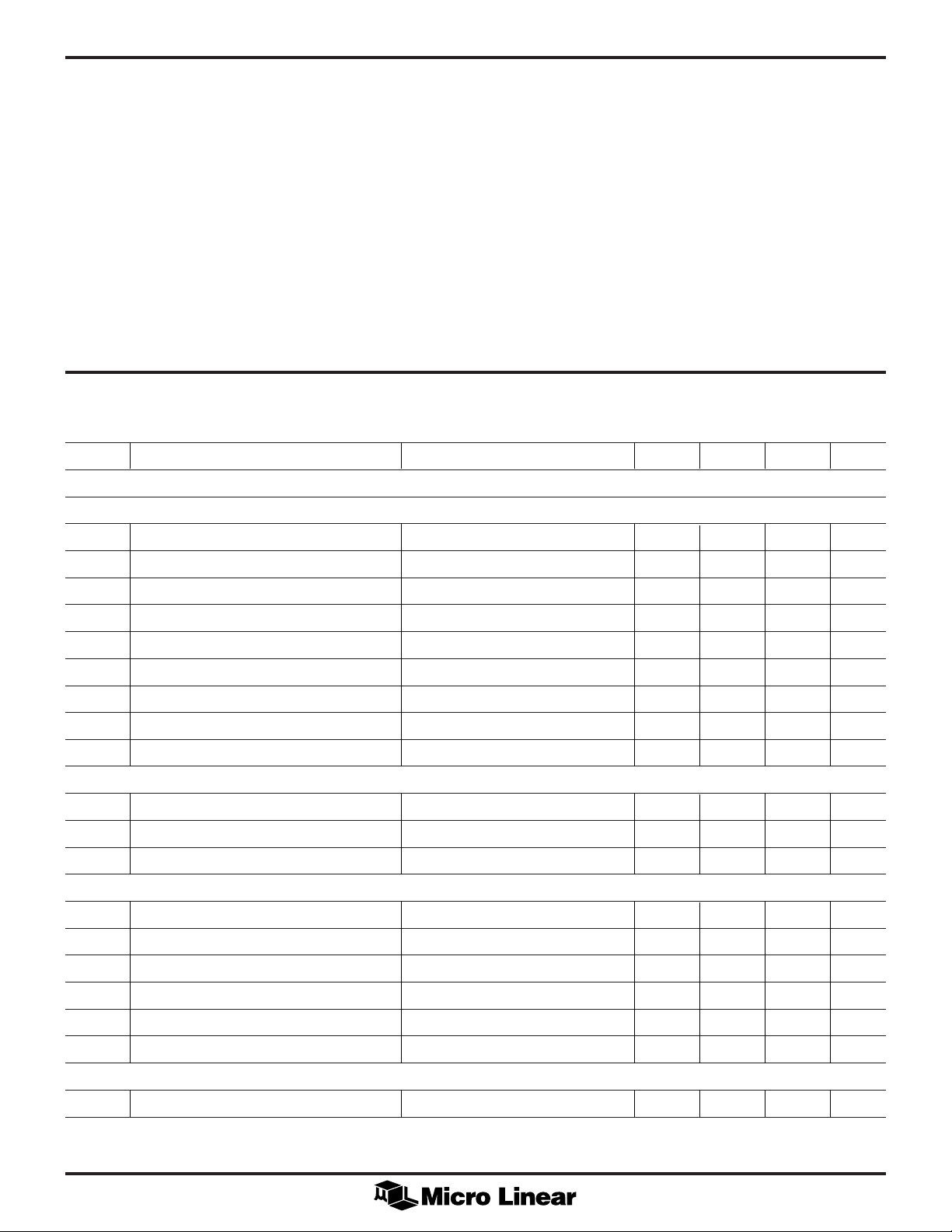

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, VDD = 5V ±5%, TA= Operating Temperature Range, CT = 47pF, RT = 82kW (Note 1)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

CURRENT REGULATOR

ERROR AMPLIFIER

Open Loop Gain 60 70 dB

Output High I

Output Low I

Bandwidth (-3dB) 1 MHz

= 5µA 2.8 3.0 V

LOAD

= 25µA 0.4 0.7 V

LOAD

Common Mode Voltage Range 0 1.0 V

Input Bias Current 50 100 nA

Input Offset Voltage -5 0 5 mv

Soft Start Charge Current V

Soft Start Threshold (LEA OUT) V

CURRENT LIMIT COMPARATOR

Current Threshold 450 500 550 mV

Input Bias Current V

Propagation Delay (Note 2) 150 250 ns

OUTPUT DRIVERS

Output High - B SYNC OUT, B OFF VDD 5V, I

Output Low - B SYNC OUT, B OFF I

Rise & Fall time - B SYNC OUT, B OFF C

Output High - B ON VDD 5V, I

Output Low - B ON I

Fall Time - B ON C

ONE SHOT

= 1V 550 750 950 nA

SSCAP

= 1V 2 2.5 V

SSCAP

= 0.1V 50 100 nA

ILIM

= 12mA 4.625 4.8 V

LOAD

12mA 0.2 0.375 V

LOAD

=100pF 20 50 ns

LOAD

= 12mA 4.625 4.8 V

LOAD

50mA 0.2 0.375 V

LOAD

= 2400pF (Note 2) 45 80 ns

LOAD

Pulse Width 100 150 200 ns

3

Page 4

ML4877

ELECTRICAL CHARACTERISTICS (Continued)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

DELAY TIMER

Delay Time 20 35 55 ns

HIGH VOLTAGE INVERTER

Oscillator

Nominal Frequency 68 80 92 kHz

Discharge Current VCT = 2V 500 700 900 µA

Peak Voltage 2.3 2.5 2.7 V

Valley Voltage 0.8 1 1.2 V

Output Drivers

Output High - L GATE 1, 2 VDD = 5V, I

Output Low - L GATE 1, 2 I

Rise & Fall Time - L GATE 1, 2 C

Resonant Threshold Detector

Threshold 0.45 0.8 1.15 V

Hysteresis 0.15 03 0.45 mV

Lamp Out Detect

Threshold -2 VDD 2 %

Latch Inhibit Threshold (SSCAP) LRTD > VDD + 0.1V 2.5 V

Under Voltage Detector

Start Up Threshold 3.8 4.1 4.4 V

Hysteresis 150 300 450 mV

Logic Interface (ON/OFF)

V

IH

V

IL

Input Bias Current ON/OFF = 3V 10 25 µA

Linear Regulator

12mA 4.625 4.8 V

LOAD

= 50mA 0.2 0.375 V

LOAD

=1000pF 20 50 ns

LOAD

2.5 V

0.5 V

Aux Zener Reference Voltage (AZR) I

Regulator Voltage (VDD) HVDD = 12V 4.75 5.0 5.35 V

Regulator Source Current External to device 10 mA

Drop Out Voltage I

Drop Out Voltage l

HVDD Input Voltage Range 5 18 V

= 10µA 12.3 13.5 14.7 V

AZR

= 1mA 30 90 mA

HVDD

= 5mA 125 275 mA

HVDD

4

Page 5

ML4877

ELECTRICAL CHARACTERISTICS (Continued)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

BIAS

VDD Supply Current ON/OFF = “I”, no load 375 450 µA

VDD Supply Current ON/OFF = “0”, HVDD = 12V 1 10 µA

VREF Load Regulation I

VREF Output Voltage TA = 25ºC 2.47 2.5 2.53 V

VREF Line Regulation 20 30 mV

VREF Line, Load, Temp 2.465 2.5 2.535 V

Note 1: Limits are guaranteed by 100% testing, sampling, or correlation with worst case test conditions.

Note 2: Actual load is 1200pF. The 2:1 transformer reflects an effective 2400pF.

= 25µA 10 20 mV

LOAD

5

Page 6

ML4877

5 TO 18V

U2-A

IN

C7

C8

Q1

HVDD

12

VREF

5

C3

1.0µF

ON/OFF

15

R1

AZR

2

LINEAR

REGULATOR

MASTER

BIAS

& UVLO

Q S

QR

*OPTIONAL

SEE NOTE

VDD

13

SS

C1

VDD

D1

T2

C9

B ON B ON B SYNC

DR3 DR1

ONE

SHOT

+

–

VDD

CLK

Q2

2019

DR1

S Q

SQ

RESONANT

THRESHOLD

DETECTOR

OSCILLATOR

11

NEG

EDGE

DELAY

R7

10k

100µh

C6

0.1µF

R6

100k

1.6MΩ

L1

C11

T1

39pF

LAMP

Q4

R6

O.5Ω

R4

OPTIONALORU2-B

L RTD

10

GATE1

DR2

Q

T

–

+

DR2

Q

SS

14

GATE2

16

L ILIM

6

+

–

0.5V

LEA OUT

8

C4

LEA–

7

1

0.047µF

R5

100kΩ

–

+

82kΩ

4 9 317 18

R

T

R2

C

C5

47pF

T

SS CAP

C2

0.1µF

PGND

GND

Figure 1. Typical Application Schematic for the ML4877

6

Page 7

FUNCTIONAL DESCRIPTION

ML4877

The ML4877 consists of a PWM regulator, a lamp driver/

inverter, a linear regulator and control circuits. This IC, in

conjunction with external components, converts a DC

battery voltage into the high voltage and high frequency

AC signal required to start and drive miniature cold

cathode fluorescent lamps. Typical application circuits

are shown in Figure 1 and Figure 5. Note: Please read the

Power Sequencing section below prior to using the

ML4877.

LAMP DRIVER

The lamp driver, sometimes referred to as a lamp inverter,

is comprised of a PWM regulator and a Royer type

inverter circuit to drive the lamp. The PWM regulator, in a

buck configuration, controls the magnitude of the lamp

current to provide the dimming capability. Figure 2 shows

a simplified circuit to more easily illustrate the operation

of the circuit.

Due to the presence of the buck inductor, L1, the circuit

shown in Figure 2 is essentially a current fed parallel

loaded resonant circuit. Lm is the primary inductance of

the output transformer, T1, which tunes with the resonant

capacitor CR to set the resonant frequency of the inverter.

The oscillator frequency is always set lower than the natural

resonant frequency to ensure synchronization. The current

source IC models the current through the buck inductor L1.

The MOSFETs, (Q3 and Q4) are alternately turned on with

a constant 50% duty cycle signal (L GATE1, L GATE2) at

one-half the frequency of the oscillator. In this way each

transistor pulses, or excites, the resonant tank on each

half cycle. The combination of these two signals appear

across the primary winding of the output transformer as a

sinusoidal waveform. This voltage is multiplied by the

step-up turns ratio of the output transformer and impressed

across the lamp.

The output transitions are controlled by feedback through

the L RTD pin by sensing the voltage at the center tap of

the output transformer. Each time this signal reaches the

minimum resonant threshold detection point an internal

clock pulse is generated to keep the system synchronized.

Figure 3 shows some of these representative waveforms at

the important nodes of the circuit.

The PWM regulator is comprised of a MOSFET (U2-A),

inductor L1, and the gate control and drive circuitry as

shown in Figure 1. A signal with a constant pulse width of

I 50ns is applied to the primary of the 2:1 pulse

transformer T2, rectified by diode D1, and used to charge

the gate capacitance of U2-A, thereby turning it on. The

turn off is controlled by discharging this capacitance

through MOSFET Q2. The pulse width of the signal on the

gate of Q2 (B OFF) varies according to the difference of

the amplitude of the feedback signal on LEA+, and LEA–.

The signal on LEA– is proportional to the AC current

flowing in the lamp, while the signal on LEA+ is a

function of the brightness control setting. The AC lamp

current feedback signal is developed by monitoring the

current through resistor R6 in the common source

connection of the inverter MOSFETs, Q3 and Q4. The

lamp current, and therefore brightness, is adjusted by

varying the voltage applied to R4, at the brightness adjust

control point. Increasing this voltage increases the brightness.

OSCILLATOR

The frequency of the oscillator in the ML4877 is set by

selecting the values Of CT and RT. Figure 4 shows the

I

C

➞

T1

LmLm

C

R

Q3 Q4

T1

1:N

Figure 2. Kelvin Sense Connections

C

OUT

LAMP

C

T

CLOCK

L GATE1

DRAIN-Q4

L GATE2

DRAIN-Q3

T1-CNTR-PRI

SOURCE OF

U2-A

Figure 3. Operating Waveforms

of the Lamp Driver Section

7

Page 8

ML4877

FUNCTIONAL DESCRIPTION (Continued)

oscillator frequency versus the value of RT for different

values Of CT. This nomograph may be used to select the

appropriate value of RT and CT to achieve the desired

oscillator frequency for the ML4877.

LINEAR REGULATOR

A linear voltage regulator is provided to power the low

voltage and low current control circuitry on the ML4877.

This is typically used when there is no separate 5V supply

available at the inverter board. For operation up to 18V,

the linear regulator is used by connecting the HVDD pin

to the input battery voltage. For operation over 18V, a

MOSFET, and a resistor (Q and R1, Figure 1) are

connected as shown. The MOSFET is required to stand off

the high voltage. The AZR pin is just a zener diode to

ground used to bias the gate of Q1.

LAMP OUT DETECT

In those cases when there is no lamp connected, or the

connection is faulty, the output voltage of the lamp driver

circuit will tend to rise to a high level in an attempt to

start the nonexistent lamp. The lamp out detect circuit on

the ML4877 will detect this condition by sensing a

voltage proportional to the center tap voltage on the

primary of the output transformer, T1 on the L RTD pin.

The ration of resistors R7 and R8 sets the lamp out detect

threshold. When the voltage on the L RTD pin exceeds

VDD, an internal latch is set and the lamp driver goes

into a shutdown mode. The logic control pin ON/OFF

must be cycled low, then high to reset the latch and

return the lamp driver to the normal state. The input to the

lamp out latch is inhibited by the signal on the soft start

pin. The latch will not be set until the voltage on SS CAP

(pin 3) rises to more than 4.2V nominally.

By selecting the appropriate value the AC lamp current

can be set to slowly increase with a controlled time

constant. The capacitor value can be calculated

according to the following formula.

C = (3 X 10-7)TS (1)

Where TS = Duration of the soft start sequence in seconds

LOGIC CONTROL

The ML4877 is controlled by a single logic input, ON/

OFF. A logic level high on this pin enables the lamp

driver. A logic zero puts the circuit into a very low power

state.

POWER SEQUENCING

It is important to observe correct power and logic input

sequencing when powering up the ML4877. The following

procedure must be observed to avoid damaging the

device.

1. Apply the battery power to HVDD, or

2. If HVDD is not used. Apply the VDD voltage. With

HVDD connected the VDD voltage is supplied by the

internal regulator on the ML4877.

3. Apply a logic high to the ON/OFF input.

Please refer to Application Note 32 for detailed

application information beyond what is presented here.

APPLICATIONS SECTION

SOFT START

The capability to control the start up behavior is achieved

by setting the value of a single capacitor, C2 in Figure 1.

1000

C = 30pF

C = 46pF

100

FRQUENCY (kHz)

10

10 100 1000

C = 81pF

C = 120pF

RESISTANCE (kΩ)

Figure 4. Oscillator Frequency Nomograph

8

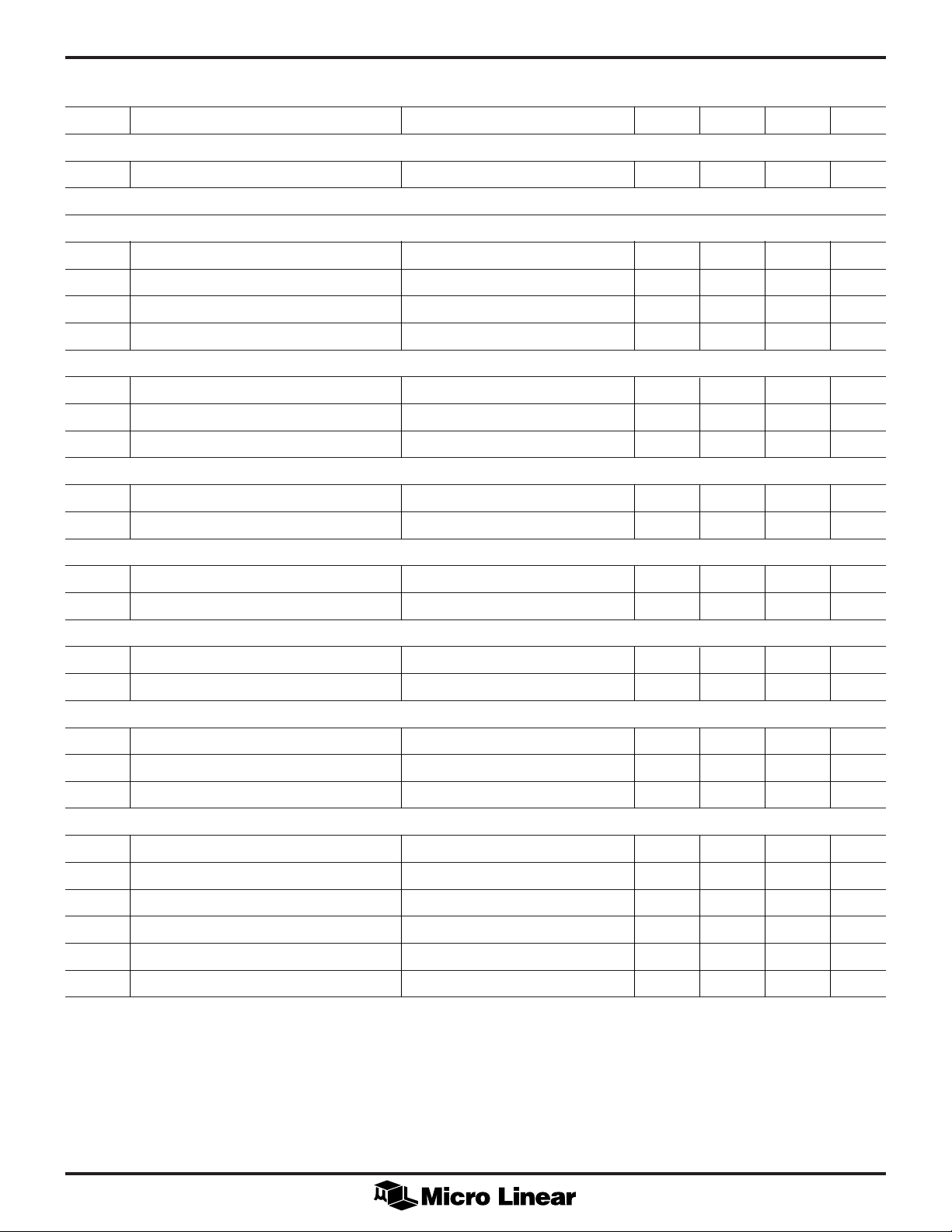

HIGH POWER INVERTER

The ML4877 is easily adapted to high power CCFL

inverter designs. Figure 5 displays a schematic of a 30W

ML4877 application. This particular design employs PWM

dimming in order to extend dimming range.

The 30W inverter design is ideal for applications between

the 20W and 30W range. Deep dimming capability is

achieved via PWM technique with no flicker and no popon effects. Uniform intensity can be maintained across 1

to 8 lamps to well below 5%.

Figure 6 provides a top view of an example of a ML4877

30W design. This design can be modified for 1 to 8 lamps

and contains a PWM dimming interface using standard

low cost components.

For the latest application notes and other information,

visit the Micro Linear website at www.microlinear.com.

Page 9

ML4877

GND

V

DD

DIMMING

F1 4A

C24

220µF

R7

10kΩ

C22

220µF

J1

1

2

3

C21

1nF

R13

10kΩ

C19

4.7nF

R8

91kΩ

C18

1nF

Q5

2N3904

C20

0.1µF

C13

1µF

R15

1kΩ

R14

1kΩ

Q4

IRF7416

C23

1nF

2N3904

C17

4.7nF

R4

6.2kΩ

R18

200Ω

Q6

1

2

3

4

5

6

7

8

9

10

C16

47pF

Q7

2N3904

R16

20Ω

2N3906

LEA+

AZR

SS CAP

R

T

VREF

L ILIM

LEA–

LEA OUT

C

T

L RTD

R17

20Ω

Q8

ML4877

U2

B SYNC OUT

B OFF

B ON

GND

PGND

L GATE 2

ON/OFF

L GATE 1

VDD

HVDD

L1

22µH

CR6

SK34MSCT

20

19

18

17

16

15

14

13

12

11

R5

30kΩ

CR5

R6

7.5kΩ

IRLR2905

R9

143kΩ

C14

1µF

Q1

R11

0.2Ω

1W

R3

10kΩ

C12

1µF

C1

0.22µF

MKS-10

63V

4, 10

9

Q2

IRLR2905

R12

0.2Ω

1W

T1

CR1

5.1V

J2

C2

13

5

8

12

68pF

C3

68pF

C4

68pF

C5

68pF

C6

68pF

C7

68pF

C8

68pF

C9

68pF

1kV

1kV

1kV

1kV

1kV

1kV

1kV

1kV

1

2

3

4

5

6

7

8

9

10

11

J3

1

2

3

4

5

6

7

8

9

10

11

R1

10kΩ

2

3

1N4148

1

–

+

CR3

U1B

J1

2

CR4

1N4148

J2

1

2

R2

10kΩ

CR2

1N4148

1

Q3

2N3906

R6

390kΩ

0.033µF

PWM Control

C10

C15

1µF

R10

10kΩ

8

5

+

6

–

U1A

4

7

C11

1µF

Figure 5. 30W Backlight CCFL Inverter with PWM Dimming

9

Page 10

ML4877

Figure 6. 30W CCFL Inverter Board, 1 to 8 Lamps

10

Page 11

PHYSICAL DIMENSIONS inches (millimeters)

Package: R20

20-Pin SSOP

0.279 - 0.289

(7.08 - 7.34)

20

ML4877

PIN 1 ID

1

0.026 BSC

(0.65 BSC)

0.066 - 0.070

(1.68 - 1.78)

0.009 - 0.015

(0.23 - 0.38)

SEATING PLANE

ORDERING INFORMATION

0.205 - 0.213

(5.20 - 5.40)

0.068 - 0.078

(1.73 - 1.98)

0.301 - 0.313

(7.65 - 7.95)

0.002 - 0.008

(0.05 - 0.20)

0º - 8º

0.022 - 0.038

(0.55 - 0.95)

0.004 - 0.008

(0.10 - 0.20)

PART NUMBER TEMPERATURE RANGE PACKAGE

ML4877CR (END OF LIFE) 0°C to 70°C Molded SSOP (R20)

ML4877ER (OBSOLETE) –20ºC to 70ºC Molded SSOP (R20)

© Micro Linear 1998. is a registered trademark of Micro Linear Corporation. All other trademarks are the property of their respective owners.

Products described herein may be covered by one or more of the following U.S. patents: 4,897,611; 4,964,026; 5,027,116; 5,281,862; 5,283,483; 5,418,502;

5,508,570; 5,510,727; 5,523,940; 5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376; 5,652,479; 5,661,427; 5,663,874; 5,672,959; 5,689,167; 5,714,897;

5,717,798; 5,742,151; 5,747,977; 5,754,012; 5,757,174; 5,767,653; 5,777,514; 5,793,168; 5,798,635; 5,804,950; 5,808,455; 5,811,999; 5,818,207; 5,818,669;

5,825,165; 5,825,223. Japan: 2,598,946; 2,619,299; 2,704,176; 2,821,714. Other patents are pending.

Micro Linear reserves the right to make changes to any product herein to improve reliability, function or design. Micro Linear does not assume any liability

arising out of the application or use of any product described herein, neither does it convey any license under its patent right nor the rights of others. The circuits

contained in this data sheet are offered as possible applications only. Micro Linear makes no warranties or representations as to whether the illustrated circuits

infringe any intellectual property rights of others, and will accept no responsibility or liability for use of any application herein. The customer is urged to consult

with appropriate legal counsel before deciding on a particular application.

10/29/98Printed in U.S.A.

DS4877-01

2092 Concourse Drive

San Jose, CA 95131

Tel: (408) 433-5200

Fax: (408) 432-0295

www.microlinear.com

11

Loading...

Loading...