Page 1

July 2000

ML4866*

3.3V Output DC–DC Step-Down Converter

GENERAL DESCRIPTION

The ML4866 is a high efficiency pulse width modulated

(PWM) buck regulator designed for use in 5V systems or

portable equipment that need a compact, efficienct 3.3V

supply. It has a switching frequency of 120kHz and uses

synchronous rectification to optimize power conversion

efficiency. Unlike other solutions, the ML4866 requires no

external diodes or FETs.

The ML4866 can provide up to 500mA of output current,

and operates over an input voltage range of 3.5V to 6.5V

(3 to 4 cells or a 5 VDC supply). A complete switched

mode power converter can be quickly and easily

implemented with few external components. Thanks to a

built-in autoburst mode, power conversion efficiency of

this DC–DC converter can exceed 90% over more than 2

decades of output load current.

Stability and fast loop response are provided by current

programming and a current sense circuit. The ML4866

also has a SHDN pin for use in systems which have power

management control. Undervoltage lockout and soft start

are also built in.

FEATURES

■ High power conversion efficiency over 2 decades of

load current

■ No external FETs or diodes; minimum external

components

■ 3.5V to 6.5V input voltage range

■ Significantly extends battery life over linear regulator

based solutions

■ Micropower operation

■ Low shutdown mode quiescent current

(* Indicates Part is End Of Life as of July 1, 2000)

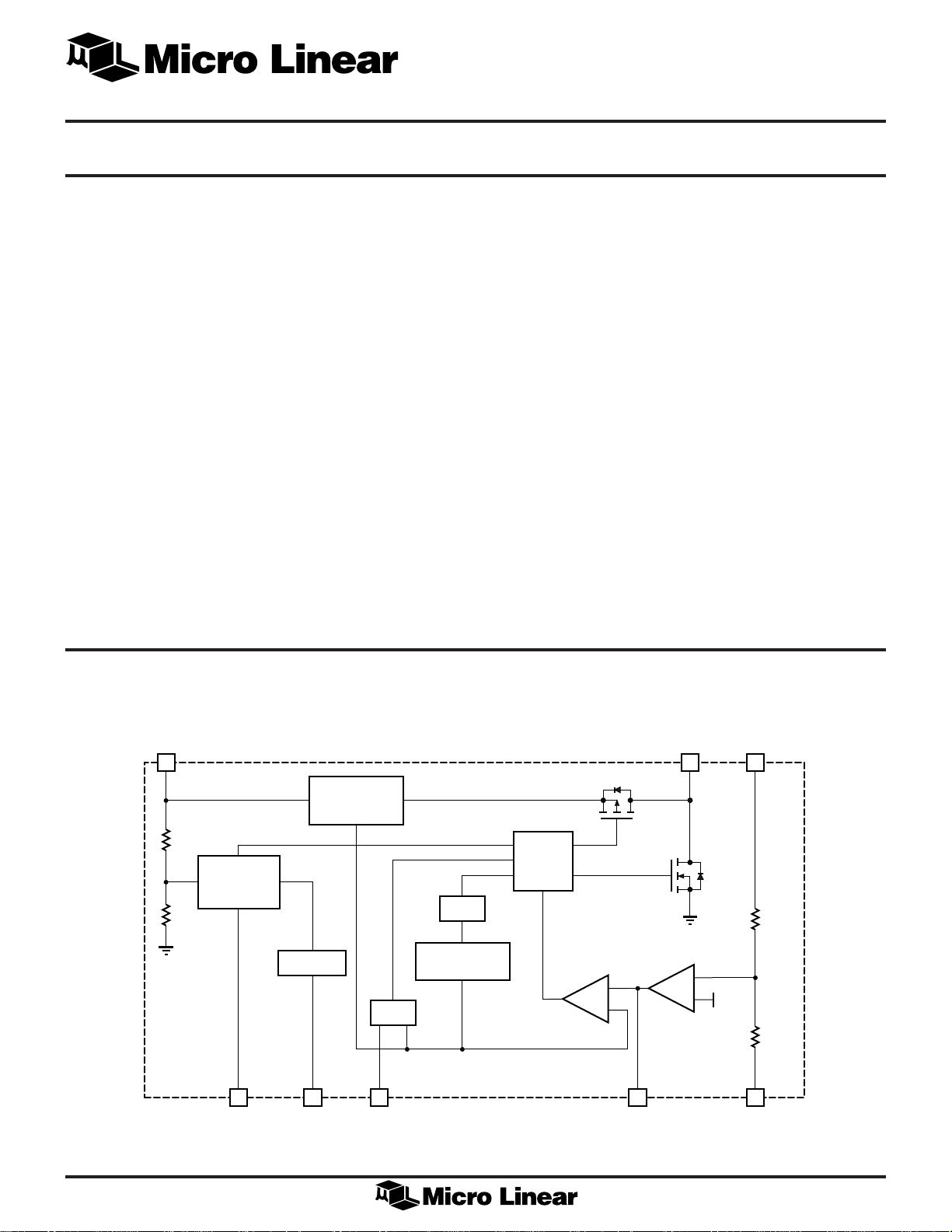

BLOCK DIAGRAM

5

V

IN

UVLO/

SHUTDOWN

6

SHDN

REFERENCE

V

3

CURRENT

SENSE

REF

BURST

BURST

4

OSC

SLOPE

COMPENSATION

BUCK

CONTROL

–

+

ERROR

AMPLIFIER

COMP

2

7

V

–

+

1

V

L

V

REF

OUT

GND

8

1

Page 2

ML4866

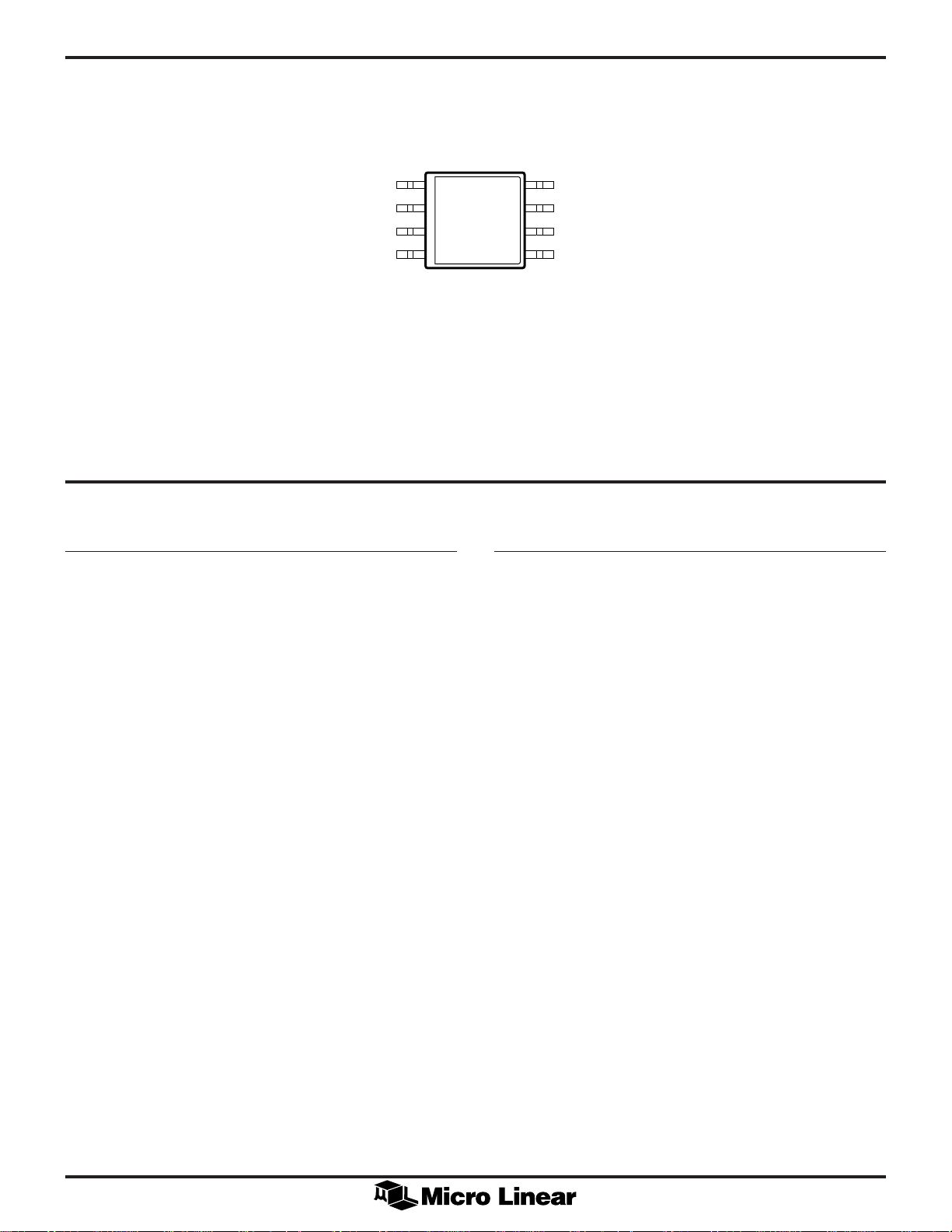

PIN CONFIGURATION

ML4866

8-Pin SOIC (S08)

V

OUT

COMP

V

REF

BURST

PIN DESCRIPTION

PIN NAME FUNCTION

1V

OUT

2 COMP Connection point for an external

Regulated 3.3V output

compensation network

1

2

3

4

TOP VIEW

8

7

6

5

PIN NAME FUNCTION

5V

IN

GND

V

L

SHDN

V

IN

Input voltage

6 SHDN Pulling this pin low shuts down the

regulator

3V

REF

1.25V reference output

4 BURST This pin controls when the control

circuit switches between PWM and

PFM modes of operation

7V

L

Buck inductor connection

8 GND Ground

2

Page 3

ML4866

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

OPERATING CONDITIONS

Temperature Range

ML4866CS ................................................. 0ºC to 70ºC

ML4866ES .............................................. -20ºC to 70ºC

ML4866IS ............................................... -40ºC to 85ºC

VIN Operating Range ...................................3.5V to 6.5V

V

................................................................................................... 7V

IN

Voltage on any other pin .........GND - 0.3V to VIN + 0.3V

Peak Switch Current (I

Average Switch Current (I

) ......................................... 2A

PEAK

).....................................1A

AVG

Junction Temperature.............................................. 150ºC

Storage Temperature Range ....................... -65ºC to 150ºC

Lead Temperature (Soldering 10 Sec.)..................... 260ºC

Thermal Resistance (qJA).................................... 160ºC/W

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, VIN = 5V, L = 50µH, C

TA = Operating Temperature Range (Note 1)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

REFERENCE

V

REF

PWM REGULATOR

Output Voltage 0 < I(V

= 100µF, R

OUT

) < –5µA, I

REF

COMP

OUT

= 390kW, C

= 0mA 1.22 1.25 1.27 V

COMP

= 15nF,

f

OSC

SHUTDOWN

Oscillator Initial Accuracy I

Oscillator Total Variation Line and Temp 90 130 185 kHz

Soft Start VIN to V

BURST Burst Mode Threshold 250 400 mV

BURST PWM Mode Threshold 500 850 mV

BURST Bias Current 35 µA

Output Voltage I

Line Regulation VIN = 4V to 6.5V, TA = 25°C ±2 %

Load Regulation I

Temperature Stability TA = -40°C to 85°C ±1 %

Total Variation Line, Load, Temp ±5 %

UVLO Startup Threshold 3.2 3.5 V

UVLO Shutdown Threshold 2.9 3.1 V

Delay 3 5 ms

OUT

= 200mA, TA = 25°C 100 115 165 kHz

OUT

= 200mA 3.2 3.3 3.4 V

OUT

I

= 20mA, BURST = 0V 3.28 3.38 3.48 V

OUT

= 100mA to 500mA, ±2.5 %

OUT

TA = 25°C

I

= 5mA to 100mA, ±2.5 %

OUT

BURST = 0V, TA = 25°C

SHDN Threshold 2V

SHDN Bias Current –5 µA

3

Page 4

ML4866

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

SUPPLY

I

Note 1: Limits are guaranteed by 100% testing, sampling, or correlation with worst case test conditions.

VIN Current I

IN

(Continued)

= 0mA, BURST = 5V 400 500 µA

OUT

I

= 0mA, BURST = 0V 120 220 µA

OUT

SHDN = 0V 20 35 µA

FUNCTIONAL DESCRIPTION

The ML4866 is a current-mode, step-down (buck)

converter designed to keep the buck inductor current in

the continuous conduction mode (CCM). Current-mode

operation provides faster output response to input voltage

and output current changes along with cycle-by-cycle

current limiting. CCM inductor current is preferred when

the highest conversion efficiencies are required.

For high efficiencies at low output current, the ML4866

contains an autoburst function which automatically

switches from pulse width modulation (PWM) to pulsed

frequency modulation (PFM) operation when the output

current drops below 100mA. Selection of either mode is

possible by applying the correct logic level signal to the

BURST pin. When operating in PWM mode, loop

compensation of the ML4866 is simplified due to its

transconductance type error amplifier.

An under voltage lockout (UVLO) circuit within the

ML4866 enables the converter when the input voltage

is greater than 3.25V and disables it when the input

voltage is below 3.10V. The IC can also be disabled

externally by applying a logic low signal to the SHDN

pin. When disabled, the ML4866 draws less than 20µA of

current.

ramping the inductor current down to 0mA. This action is

repeated until the output voltage returns to its nominal

setting and begins again when the output drops below its

nominal setting. The rate or frequency at which this

“bursting” occurs is directly proportional to the output

current. When the average output current rises above

130mA, the ML4866 returns to PWM operation.

For applications having a load current range of less than

100mA and greater than 130mA, the BURST pin should be

left open and bypassed to ground with a 15nF or larger

capacitor. It is possible to tailor an application for the

highest possible efficiency by externally forcing the

ML4866 into either control mode. Applying a logic low

level to BURST forces the IC into PFM mode. Conversely,

a logic high places it in PWM mode. Care should be

taken to avoid reducing the efficiency by placing the

controller in the least efficient mode for a given output

current.

The internal 1.25V bandgap reference is made available

via the V

pin, and may be used for general

REF

applications requiring less than 10µA of current. For

proper operation, this pin must always be bypassed to

GND with a 100nF capacitor.

BURST MODE

Burst (PFM) mode is a method of regulating the output

voltage by applying a variable frequency modulation

technique to the buck inductor. This method maintains

higher efficiencies at light loads than if PWM were used.

If BURST is left open, the ML4866 switches from PWM

mode to PFM mode when the output current falls below

100mA. When the output voltage falls out of regulation

while in PFM mode, the internal buck switch turns on and

ramps the inductor current up to 300mA. The buck switch

then turns off and the synchronous switch turns on,

4

V

– V

IN

OUT

L

Figure 1. Inductor Current

–V

OUT

L

∆I

Page 5

ML4866

DESIGN CONSIDERATIONS

INDUCTOR SELECTION

Figure 1 shows the inductor current in a step-down

converter operating in CCM. Note that the inductor

current does not reach zero during each switching cycle.

This is unlike discontinuous conduction mode (DCM)

where the inductor current is allowed to reach zero. CCM

operation generally results in lower peak to peak output

ripple voltage and higher circuit efficiencies because of

lower peak and RMS currents in the switching FETs and

buck inductor. The minimum value of inductance required

for CCM operation with a 6.5V input and a load range of

100mA to 500mA is:

VV V

-

()

L

L

OUT IN MAX OUT

>

VI f

2

IN MAX OUT MIN SW

() ()

33 65 33

.(. .)

VmAkHz

2 65 100 120

.

To guarantee reliable operation, the peak inductor current

must be between 80% and 85% of its maximum rated

value. This value is the sum of the inductor peak to peak

current and the maximum output current:

-

I

LP P

I

LP P()

II

LPEAK OUT MAX

II

L PEAK OUT MAX() ()

2

=

()

–

-

2 3 465 40 3465

=

–

=+

() ()

=+

For the highest efficiency, inductor core and copper losses

must be minimized. Good high frequency core material

such as Kool-Mu, ferrite or Molyperm are popular choices

for this converter. Disregarding physical size

requirements, the lowest loss inductor will generally be

the one with the highest peak current rating.

Figure 2 displays the efficiency of the ML4866 under

various input voltage and output current conditions. These

results were obtained using a Coiltronics CTX100-4

inductor having the following specifications:

()

VVV

-

VVV

OUT MAX IN MIN OUT MAX

() () ()

Vf L

.(..)

VV V

.

VkHz H

m

40 90 100

()

IN MIN SW MIN

VVV

() ()

-

OUT MAX IN MIN OUT MAX

.(..)

3465 40 3465

.

40 120 100

()

() () ()

VfL

IN MIN SW

()

-

VV V

m

VkHz H

H>

>

68

m

=

103

mA

=

550

(1)

(2)

(3)

mA

100

98

96

94

I

= 10mA

OUT

92

EFFICIENCY (%)

90

88

I

= 500mA

OUT

86

4.0 5.0 6.55.5

3.5 4.5 6.0

I

= 100mA

OUT

INPUT VOLTAGE (V)

Figure 2. Efficiency vs. Input Voltage

A partial listing of inductor manufacturers with standard

parts which meet the criteria for use with the ML4866 is

given below.

Coiltronics (561) 241-7876

Dale (605) 665-9301

Coilcraft (847) 639-6400

XFMRS, Inc (317) 834-1066

Sumida (847) 956-0666

CAPACITOR SELECTION

A typical digital system requires a peak to peak output

ripple voltage of no greater than 1% to 3% of the nominal

output voltage. In a step-down converter, the largest

contributor to ripple voltage is almost always the product

of the inductor peak-to-peak current times the output

capacitor’s equivalent series resistance. To select the

correct capacitor, first calculate the minimum

capacitance value required:

VV V

-

()

C

>

OUT

C

>

OUT

OUT IN MAX OUT

VVLf

8

P P MAX IN MAX SW

-

() ()

mV V H kHz

m

8 33 65 100 120

()

.(. .)

33 65 33

VV

-

.

2

2

(4)

m

.

>

427

Next, calculate the maximum permissible ESR of the

output capacitor:

F

Nominal Inductance - 100µH

Peak Current Rating - 950mA

DC Resistance - 175mW

(. )

0033

ESR <<

(.)

01

.

033

W

(5)

When limited space is available, tantalum capacitors are

the best choice. Electrolytic capacitors can be used and

will be less expensive, but the ESR for low capacitance

values as needed here will be much higher than for the

same value tantalum. Table 2 lists the ESR values for a

number of general purpose tantalum capacitors which are

widely available from a number of sources. A 47µF

capacitor was chosen for the design example.

5

Page 6

ML4866

DESIGN CONSIDERATIONS

(Continued)

FREQUENCY COMPENSATION

Frequency compensation of the ML4866 is required when

the converter is operating in PWM mode. Two simple

methods are provided to ensure the converter is frequency

stable. Both these methods will work only if the inductor

current is selected to be in CCM at the maximum load

current (see Inductor Selection). The first, called dominant

pole compensation, is used when non-varying loads are

expected. This method requires a single capacitor

connected from the error amplifier output (COMP Pin) to

ground.

For loads which change suddenly, the transient response

(or bandwidth) of the circuit must be increased to prevent

the output voltage from going outside of the regulation

band. The method used to accomplish this is called

zero/pole compensation and requires a series resistor

capacitor network from COMP to ground.

To determine which method works best for a given

application, apply the components found from the

zero/pole compensation method to an actual circuit

and examine the output voltage variation. If the voltage

variation is acceptable, connect the simpler, single

capacitor and re-check the output voltage for acceptable

load transient response.

VARYING LOAD CURRENT

To minimize output voltage variations due to rapidly

changing load currents, use the series RC zero

compensation method to find the compensation network

component values that will improve the output voltage

response to load transients.

The unity gain bandwidth of the converter is extended to

15kHz using an RC network determined by:

R

C

COMP

COMP

G

>=,

g

m

=

50

p

Where f0 = 15kHz, f

390kW, 5%), and C

where G

1

R

COMP

COMP

= 16nF (use 15nF).

COMP

f

O

f

COMP

= 640Hz, R

> 375kW (use

COMP

(7)

(8)

Either method of compensation for CCM mode with result

in continued stability as the ML4866 changes to DCM

mode at lighter load currents. Figure 3 shows a typical

application circuit for the ML4866.

NON-VARYING LOAD CURRENT

For the best possible response to load transients using only

a single capacitor, dominant pole compensation is

implemented with a single capacitor value of:

g

C

COMP

Where f

COMP

gm = 62.5µmho, and C

18nF or 22nF capacitor). The value of C

m

=

f

2

COMP

is the unity gain crossover point (640Hz),

> 15.5nF (choose a standard

COMP

COMP

can be

(6)

increased but at the risk of increased output voltage

variations with transient loads.

VOLTAGE ESR @

CAPACITANCE RATING SIZE 100kHz

4.7µF 16V 3216 0.490W

10µF 6.3V 3216 0.368W

22µF 16V 7343 0.149W

33µF 6.3V 6032 0.291W

47µF 10V 7343 0.144W

100µF 6.3V 7343 0.088W

390kΩ

15nF

100nF

V

OUT

COMP

V

REF

BURST

15nF

100µH

ML4866

1

2

3

4

8

7

6

5

GND

V

SHDN

V

100µF

V

OUT

3.3V

33µF

L

IN

V

3.5V to 6.5V

100nF

IN

Table 2. ESR Values for Low Cost Tantalum Capacitors

6

Figure 3. Typical Application Circuit

Page 7

LAYOUT

For proper performance, all components should be placed

as close to the ML4866 as possible. Particular attention

should be paid to minimize the length of the connections

between the COMP and V

bringing these traces and the associated components

close to VL.

It is always recommended that a 10µF or greater

capacitor be connected to VIN of the ML4866. A 33µF

tantalum capacitor and 100nF film or ceramic capacitor

is recommended when powering the ML4866 from

Lithium or Alkaline cells.

Ground and power planes must be large enough to carry

the current the converter has been designed to supply.

A sample PC board layout is shown in Figure 4.

pins to GND. Also avoid

REF

ML4866

Figure 4. Sample PC Board Layout

7

Page 8

ML4866

PHYSICAL DIMENSIONS

0.017 - 0.027

(0.43 - 0.69)

(4 PLACES)

0.055 - 0.061

(1.40 - 1.55)

inches (millimeters)

Package: S08

8-Pin SOIC

0.189 - 0.199

(4.80 - 5.06)

8

PIN 1 ID

1

0.050 BSC

(1.27 BSC)

0.012 - 0.020

(0.30 - 0.51)

SEATING PLANE

0.148 - 0.158

(3.76 - 4.01)

0.059 - 0.069

(1.49 - 1.75)

0.004 - 0.010

(0.10 - 0.26)

0.228 - 0.244

(5.79 - 6.20)

0º - 8º

0.015 - 0.035

(0.38 - 0.89)

0.006 - 0.010

(0.15 - 0.26)

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML4866CS (End Of Life)0ºC to 70ºC8-Pin SOIC (S08)

ML4866ES (EOL) -20ºC to 70ºC8-Pin SOIC (S08)

ML4866IS (Obsolete)-40ºC to 85ºC8-Pin SOIC (S08)

© Micro Linear 1997. is a registered trademark of Micro Linear Corporation. All other trademarks are the property of their respective owners.

Products described herein may be covered by one or more of the following U.S. patents: 4,897,611; 4,964,026; 5,027,116; 5,281,862; 5,283,483; 5,418,502; 5,508,570;

5,510,727; 5,523,940; 5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376; 5,652,479; 5,661,427; 5,663,874. Japan: 2,598,946; 2,619,299. Other patents are pending.

Micro Linear reserves the right to make changes to any product herein to improve reliability, function or design. Micro Linear does not assume any liability arising out of

the application or use of any product described herein, neither does it convey any license under its patent right nor the rights of others. The circuits contained in this data

sheet are offered as possible applications only. Micro Linear makes no warranties or representations as to whether the illustrated circuits infringe any intellectual property

rights of others, and will accept no responsibility or liability for use of any application herein. The customer is urged to consult with appropriate legal counsel before

deciding on a particular application.

8

DS4866-01

2092 Concourse Drive

San Jose, CA 95131

Tel: (408) 433-5200

Fax: (408) 432-0295

www.microlinear.com

9/8/97 Printed in U.S.A.

Loading...

Loading...