Page 1

www.fairchildsemi.com

ML4854

Adjustable, Low-Current, 2-Cell Boost Regulator

with Shutdown and Low Battery Detect

Features

• 95% Efficiency at 200mA Load Current

• Integrated Peak Current Limit

• Variable Output Voltage Determined by External Resistors

• Variable On-time Pulse Frequency Modulation (PFM)

• Fully Internal Synchronous Rectifier (no external diodes)

for High Efficiency and Low Peak Currents

• Low-Battery Detection

• Logic Controlled Shutdown with True Load Disconnect

Applications

• 2-3 alkaline/NiMH cells or 1 Li-Ion cell Operated Devices

• Cell Phones

• Medical Devices

•PDAs

• Portable Instrumentation

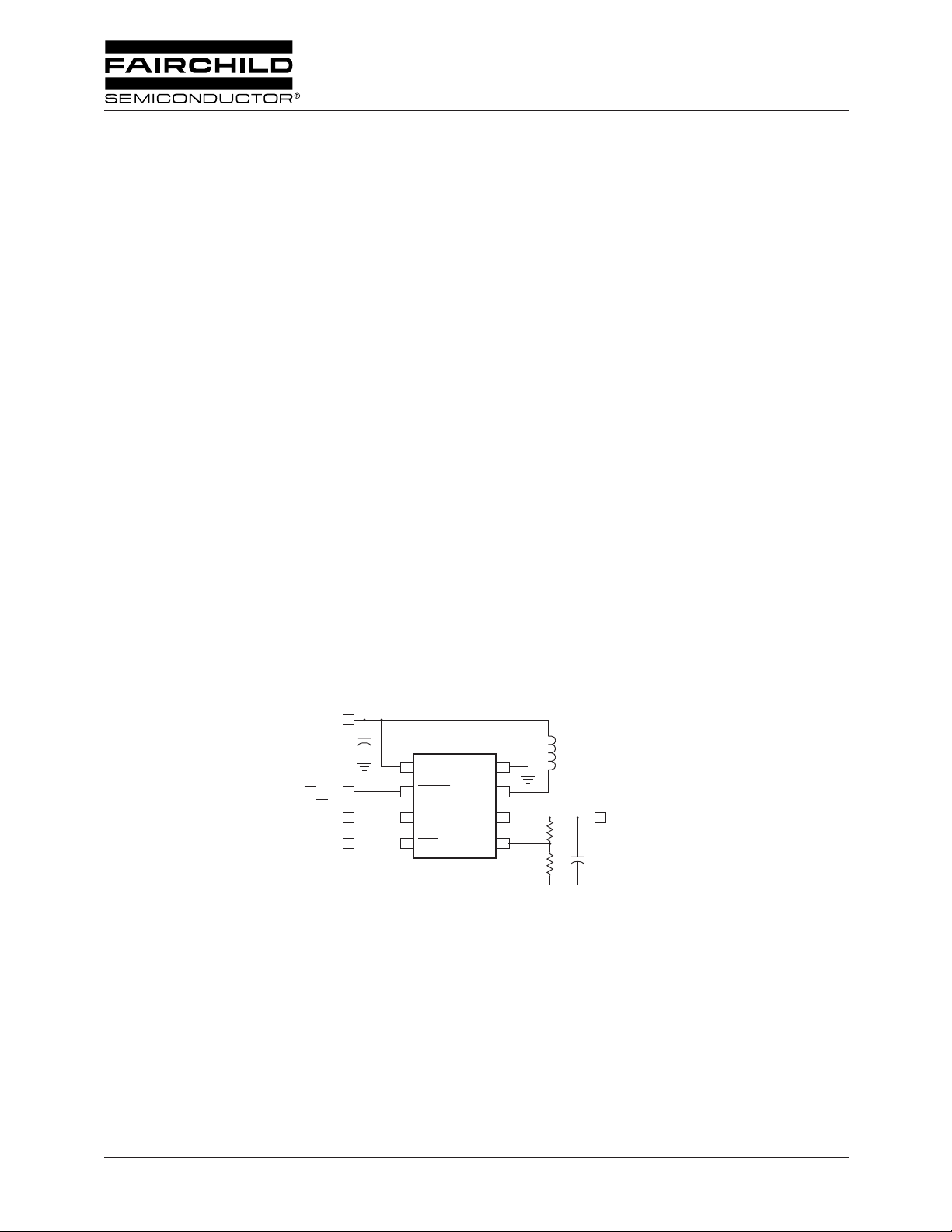

Typical Application

Input 1.6V

to 4.5V

ML4854

V

1

On

Off

Low Battery

Detect In

Low Battery

Detect Out

2

3

4

IN

SHDN

LBI

LB0

General Description

The ML4854 is a low power boost regulator designed for

low voltage DC to DC conversion in two-cell battery powered systems such as cell phones and PDAs. The converter

starts up at 1.3V and has an operating input voltage range

from 1.6V to 4.5V. After the start it operates at an input

voltage as low as 0.8V. Output voltage can be adjusted by

external resistors from 3.3V to 5V with a maximum load

current of 0.5A.

Quiescent current in shut down mode is less than 30µA,

which maximizes the battery live time. The ON time changes

with the input voltage to maintain the ripple current constant

and to provide the highest efficiency over a wide load range,

while maintaining low peak currents in the boost inductor.

The combination of integrated synchronous rectification,

variable frequency operation, and low supply current make

ML4854 ideal for portable applications.

The ML4854 is available in an 8 lead TSSOP package.

GND

8

7

V

L

6

V

OUT

5

FB

Output 3.3V to 5V

up to 0.5A

REV. 1.0.7 5/6/03

Page 2

PRODUCT SPECIFICATION ML4854

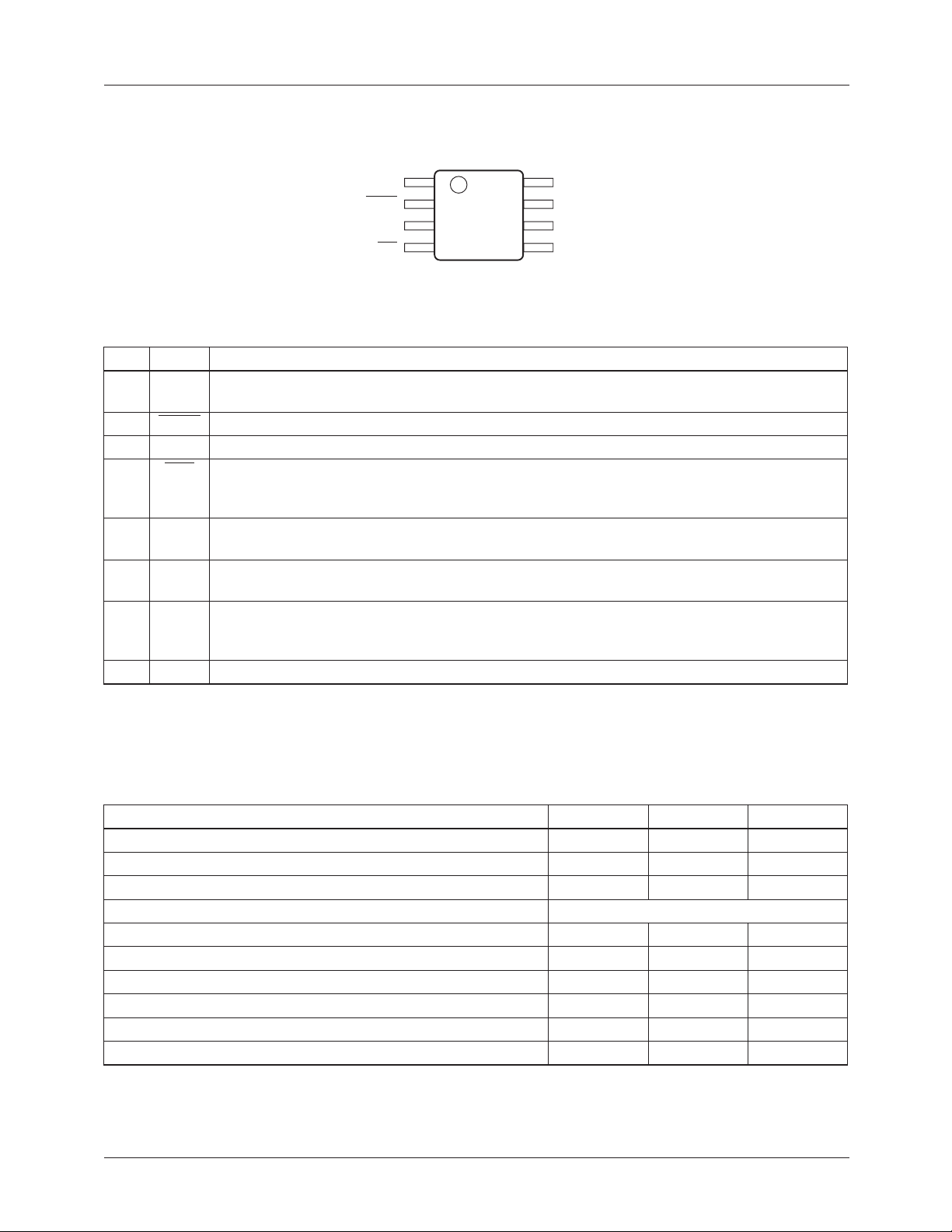

Pin Configuration

8-Lead TSSOP (T08)

V

SHDN

LBI

LB0

IN

1

2

3

4

TOP VIEW

Pin Description

PIN NAME FUNCTION

1 V

2 SHDN Shut Down . Pulling this pin low shuts down the regulator, isolating the load from the input.

3 LBI Low-Battery Input . Pulling this pin below a threshold causes the LBO pin to go low.

4 LBO Low-Battery Output . This pin provides an active low signal to alert the user when the LBI

5FB Programming Feedback Pin . Sets the output voltage. This pin is used to adjust the output

6V

OUT

7V

8 GND Ground of the IC .

Battery Input Voltage . Supplies the IC during start-up. After the output is running, the IC draws

IN

power from V

OUT

.

voltage falls below its targeted value. The open-drain output can be used to reset a

microcontroller.

voltage via a resistive divider from V

OUT

Boost regulator output . Output voltage can be set to be in the 3 to 5V range. Startup at

moderate load is achievable at input voltages around 1.25V.

Boost inductor connection . An inductor is connected between this pin and V

L

the output supply, this pin pulls low, charging the inductor, then shuts off dumping the energy

through the synchronous rectifier to the output.

8

7

6

5

GND

V

L

V

OUT

FB

.

. When servicing

IN

Absolute Maximum Ratings

Absolute maximum ratings are those values, beyond which the device could be permanently damaged. Absolute maximum

ratings are stress ratings only and functional device operation is not implied.

Parameter Min. Max. Units

,

V

V

IN

Switch Voltage (V

Voltage on any other Pin -0.3 V

Peak Switch Current (Ipeak) — Internally Limited —

Output Current (I

Continuous Power Dissipation 320 mW

Thermal Resistance ( θ

Junction Temperature 150 °C

Storage Temperature Range -65 +165 °C

Lead Temperature (soldering, 10s) 300 °C

2

Voltages (Relative to GND) -0.3 7 V

OUT

to GND) -0.3 V

L

) 500 mA

OUT

) 124 °C/W

JA

OUT

OUT

+0.3

+0.3

V

V

REV. 1.0.7 5/6/03

Page 3

µ

µ

µ

µ

µ

µ

µ

ML4854 PRODUCT SPECIFICATION

Recommended Operating Conditions

Parameter Min. Max. Units

Temperature Range -40 +85 °C

Operating Range

V

IN

Operating Range

V

OUT

1.6 0.9 V

OUT

3.0 5.0 V

V

Electrical Characteristics

Unless otherwise specified, V

at T

= +25°C

A

Parameter Conditions Min. Typ. Max. Units

Start Up Voltage I

Operating Voltage After start I

Output Voltage V

Output Voltage Adjust Range 3 5 V

Steady State Output Current

(see diagram)

Pulse Width V

Minimum Off-Time 0.5

Line Regulation V

Load Regulation 0 to 250mA V

Feedback Voltage (VFB) 1.230 V

LBI Threshold Voltage 0.390 V

LBI Hysteresys 25 mV

Internal NFET, PFET ON Resist. I

Efficiency (I

Quiescent Current – SHDN SHDN=0V, R1 excluded,V

LBO Output Voltage V

SHDN Input Voltage @V

SHDN Input Voltage @V

=1.6V to 3V, I

IN

=3V V

IN

=1.6V V

IN

=1mA, T

LOAD

<1mA 1.25 1.5 V

LOAD

LOAD

(nom.)=3.3V

OUT

V

(nom.)=5V

OUT

V

=3.3V, V

OUT

V

=5V, V

OUT

= 3V 0.8 1.32 1.9

IN

V

= 2.4V 1.2 1.64 2.3

IN

V

= 1.8V 1.8 2.15 3.1

IN

V

= 1.5V 2.2 2.57 4.0

IN

=1.6V to 3V, I

IN

V

=5V 0.5 %

OUT

0 to 150mA V

= 100mA 275 m Ω

LOAD

=200mA) V

LOAD

IN

=2.5V 330 mA

IN

IN

IN

SHDN=3V, R1 excluded,V

= 0, I

LBI

=3.3V/5V 1.6 V

OUT

=3.3V/5V 0.8 V

OUT

=1mA 0.2 V

SINK

=-40°C to +85°C. Test Circuit Fig.1. Typical values are

A

=10mA, V

=3.3V/5V 0.8 V

OUT

3.15

4.775

3.3

5

=2.5V 500 mA

=2mA, V

OUT

=2.4V ,V

=2.4V ,V

=3V, V

IN

OUT

OUT

=3.3V 0.5 %

OUT

=3.3V 1.0 %

=5V 1.0 %

= 3.3V 95 %

OUT

=3V 26 100

IN

=3V 85 200

IN

3.45

5.225

V

V

s

s

s

s

s

A

A

REV. 1.0.7 5/6/03

3

Page 4

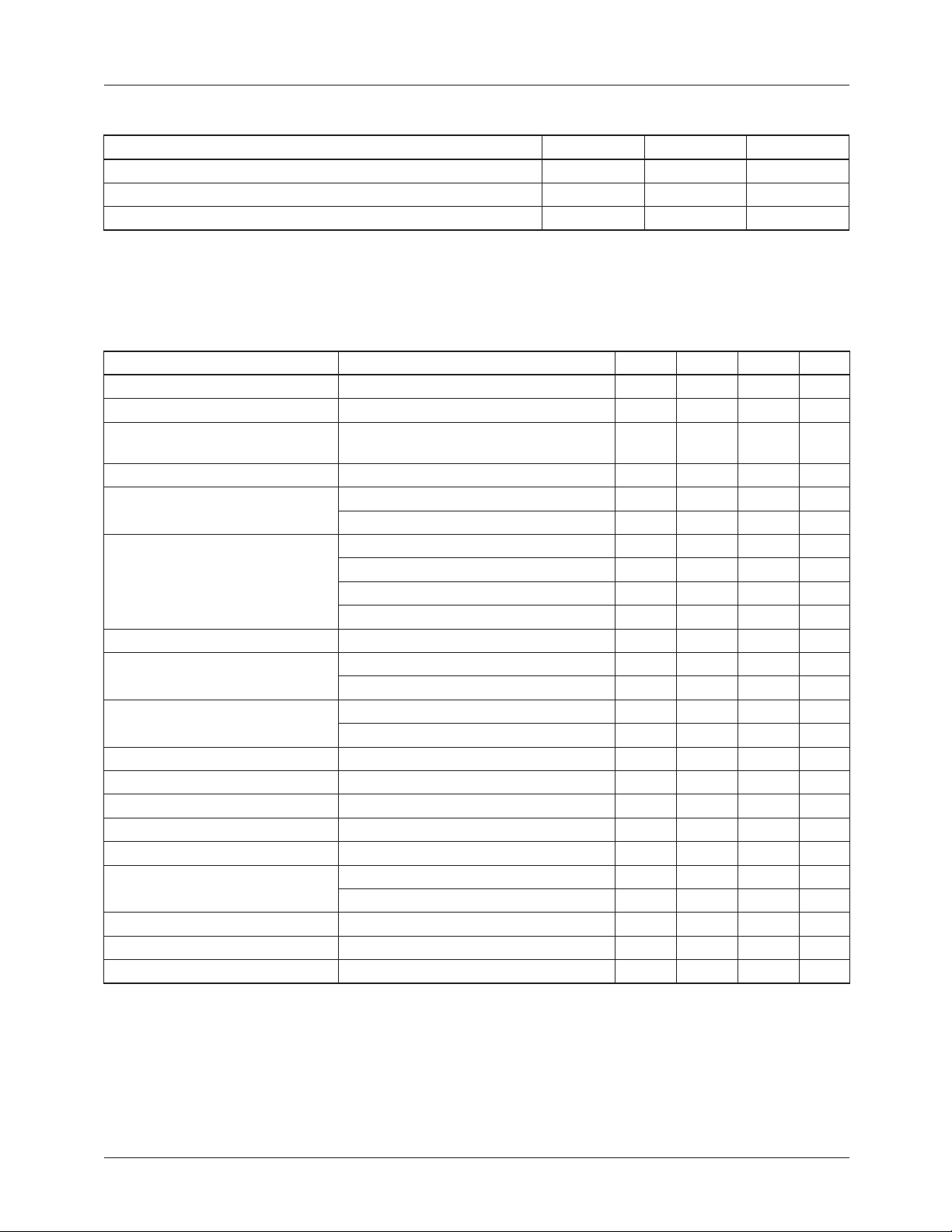

PRODUCT SPECIFICATION ML4854

UP1B

L1

10uH

ML4854

100

Gnd

Vout

VL

FB

8

7

6

JP1

R6

287K

C3

18pF

C4

1.

0uF

R4

402K

R5

240K

J1

SCOPE JACK

+

C2

47uF

10V

VOUT

1

2

3.3V to 5.0V

C5

1uF

0.

GND1

1

2

VIN

2

1

1.6V to 3.0V

SHDN

2

1

Reset

2

1

Ext

Pull Up

2

1

GND

2

1

+

C1

47µF

R1

750K

R2

240K

JP2

JP3

U1

1

2

3

4 5

R3

100K

Vin

Shut down

LBI

LBO

Figure 1. Test Circuit

4

REV. 1.0.7 5/6/03

Page 5

ML4854 PRODUCT SPECIFICATION

Typical Operating Characteristics

Maximum Steady State Load

Current vs. Input Voltage

500

400

300

200

Max.Load Current, mA

100

1.5 2 2.5 3

100.0

90.0

80.0

70.0

60.0

50.0

40.0

Efficiency, %

30.0

20.0

10.0

0.0

Vin=3V

0.1 1 10 100 1000

= 3.3V

V

OUT

V

= 5V

OUT

Input Voltage, V

Efficiency vs. Load Current

Vout = 5V

Vin=2.0V

Output Current, mA

Vin=1.5V

(L=10µH, C

100.0

90.0

80.0

70.0

60.0

50.0

40.0

Efficiency, %

30.0

20.0

10.0

Output Voltage, V

=47µF, C

IN

Vin=3V

0.0

0.1 1 10 100 1000

Starting Up and Turning Off VOUT=3.3V

4

TURN OFF:

Iload=10mA

3.5

3

2.5

2

1.5

1

0.5

0

0 0.2

=47µF//1.0µF T=25°C)

OUT

Efficiency vs. Load Current

Vout = 3.3V

Vin=2.0V

Output Current, mA

Iload=10mA/50mA

0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

Input (Battery) Voltage, V

load=50mA

Vin=1.5V

START UP

Iload=50mA

Iload=10mA

5

4

3

2

Output Voltage, V

1

0

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8

REV. 1.0.7 5/6/03

Starting Up and turning Off VOUT=5V

Iload=10mA/50mA

TURN OFF:

Iload=10mA

load=50mA

Input (Battery) Voltage, V

START UP:

Iload=50mA

Iload=10mA

No-Load Battery Current vs. Input Battery

300

250

200

150

100

Battery Current, µA

50

0

0 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3.0

Shut Down

Voltage

Vout=5V

Vout=3.3V

Battery Voltage, V

5

Page 6

PRODUCT SPECIFICATION ML4854

Typical Operating Characteristics

Line Transient Response @100mA Load

Exiting Shutdown

(Continued)

Inductor Current and Switching Node Voltage

Inductor

Current

V

L

Load Transient Response

I

LOAD

V

OUT

V

SHDN

Heavy-Load Switching Waveforms

V

L

I

L

V

OUT

V

OUT

6

REV. 1.0.7 5/6/03

Page 7

ML4854 PRODUCT SPECIFICATION

Typical Operating Characteristics

Output Voltage vs. Temperature

3.33

3.325

3.32

3.315

3.31

3.305

Output voltage, V

3.3

3.295

3.29

-50

Start-up Voltage vs. Load Current Switch ON Resistance vs. Temperature

1.8

1.6

Vout=5V

1.4

Start-up Voltage, V

1.2

1

0 50 100 150 200 250 300 -60

50mA

300 mA

0 50 100

Temperature, C

Vout=3.3V

Load Current, mA

(Continued)

Output Voltage,V

mohm

Switch Resistance,

Output Voltage vs. Temperature

5.09

5.08

5.07

5.06

5.05

5.04

5.03

5.02

-50 0 50 100

350

300

250

200

150

100

50

0

-40 -20 0 20 40 60 80 100

50 mA

200mA

Temperature, C

N-ch

P-ch

Temperature, C

500

450

400

350

300

250

200

150

100

Average Frequency, kHz

50

0

REV. 1.0.7 5/6/03

Operating Frequency, Vout=3.3V

f kHz @ I load=50 mA

f kHz @ I load=150 mA

f kHz @ I load=300 mA

f kHz @ I load=200 mA

f kHz @ I load=250 mA

SHDN Threshold Voltage vs. Input Voltage

2.5

2

1.5

1

SHDN Voltage (V)

0.5

0

001.522.533.5 12345

Input Voltage (V)Vin, V

7

Page 8

PRODUCT SPECIFICATION ML4854

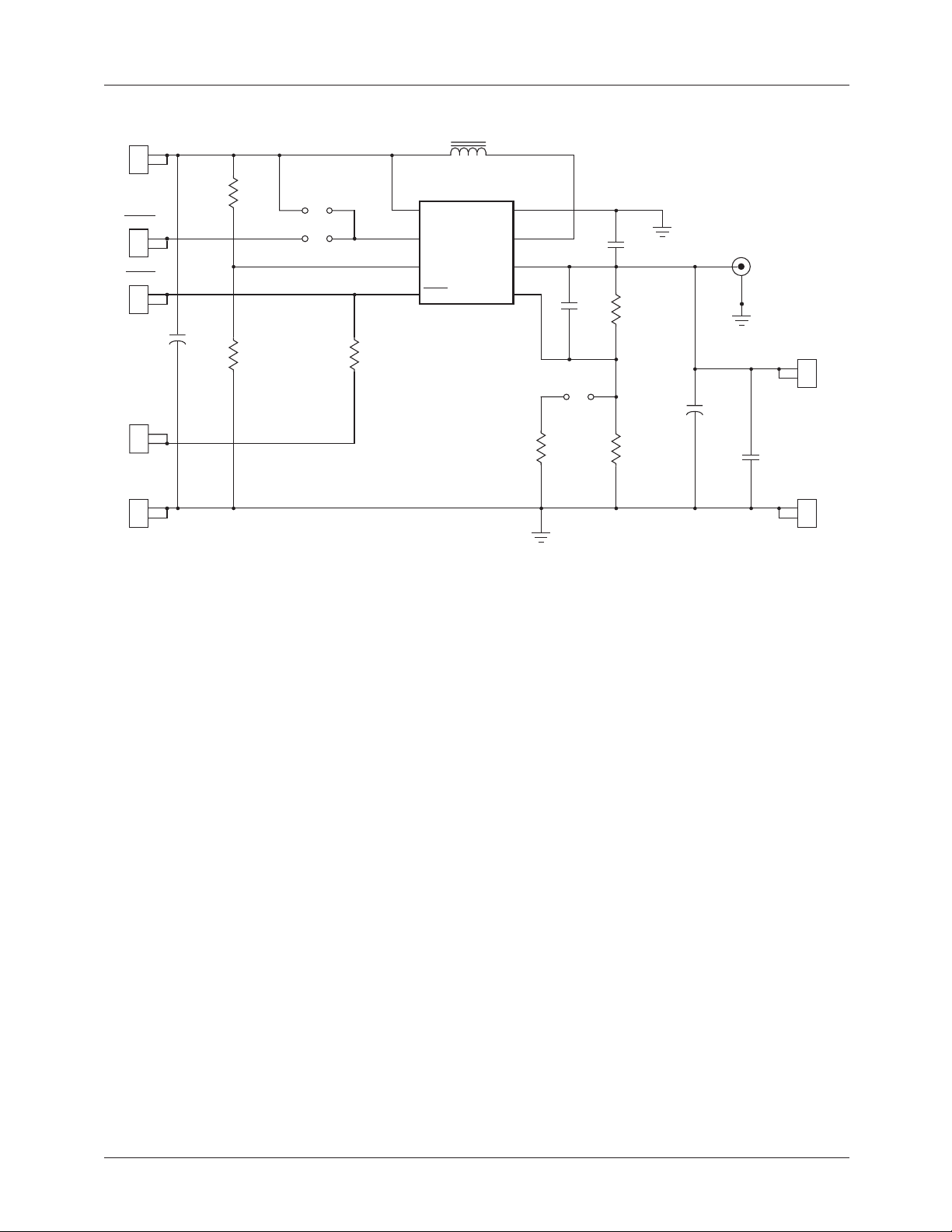

Block Diagram

LBO

47

LBI

3

0.39V

V

IN

1

Functional Description

Minimum

Off-Time

Logic

–

A3

+

V

OUT

Start-Up

Variable

I

LIMIT

SHDN

On-Time

One Shot

Q

Boost regulator

ML4854 is an adjustable boost regulator that combines variable ON and minimum OFF architecture with synchronous

rectification. Unique control circuitry provides high-efficiency power conversion for both light and heavy loads by

transitioning between discontinuous and continuous conduction based on load conditions. There is no oscillator; a constant-peak-current limit of 1.5A in the switch allows the

inductor current to vary between this peak limit and some

lesser value. The switching frequency depends upon the load

and the input voltage, and can range up to 650kHz.

The input voltage (V

external Inductor to the V

V

closes through the external resistive voltage divider to

OUT

the feedback pin VFB. The transfer ratio of this divider determines the output voltage. When VFB voltage drops below

V

=1.23V, the error amplifier A1 signals to the regulator

REF

to deliver a charge to the output by triggering the Variable

On-Time One Shot. This generates a pulse at the gate of the

Power NMOS transistor Q1. This transistor will charge the

Inductor L1 for the time interval (TON) resulting in a peak

current given by:

I

L PEAK()

TONVIN×

---------------------------=

IN

L

1

) comes to V

pin of the device. The loop from

L

pin and through the

IN

V

L

I

LIMIT

Synchronous

Rectifier

Control

N1

1

When the one shot times out, the Q1 transistor releases the

VL pin, allowing the inductor to fly-back and momentary

charge the output through the body diode of the transistor

Q2. But, as the voltage across the Q2 changes polarity, its

gate will be driven low by the Synchronous Rectifier Control

Circuit (SRC), causing Q2 to short out its body diode. The

inductor then delivers the charge to the load by discharging

into it through Q2.

Under lightly loaded conditions, the amount of energy

delivered in this single pulse satisfies the voltage-control

loop, and the converter does not command any more energy

pulses until the output again drops below the lower-voltage

threshold. Under medium and heavy loads, a single energy

pulse is not sufficient to force the output voltage above its

upper threshold before the minimum off time has expired

and a second charge cycle is commanded. Since the inductor

current has not reached zero in this case, the peak current is

greater than the previous value at the end of the second

cycle. The result is a ratcheting of inductor current until

either the output voltage is satisfied, or the converter reaches

its set current limit.

After a period of time T

mum Off–Time Logic and if V

Variable On-Time One Shot will be turned ON again and the

process repeats.

The output capacitor of the converter (see Test circuit) filters

the variable component, limiting the output voltage ripple to

a value determined by its capacitance and its ESR.

Current

Limit

Control

REF

SHDN

2

V

OUT

6

V

FB

5

), the

Control

Logic

SHDN

Q

2

+

A2

–

I

LIMIT

–

A1

+

V

REF

8

GND

> 0.5µS, determined by Mini-

OFF

is low (VFB<V

OUT

8

REV. 1.0.7 5/6/03

Page 9

ML4854 PRODUCT SPECIFICATION

The synchronous rectifier significantly improves efficiency

without the addition of an external component, so that

conversion efficiency can be as high as 94% over a large load

range, as shown in the “Typical Operating Characteristics.”

Even at light loads, the efficiency stays high because the

switching losses of the converter are minimized by reducing

the switching frequency.

Error Detection Comparator (LBI – LBO)

An additional comparator A3 is provided to detect low VIN

or any other error conditions that is important to the user.

The non-inverting input of the comparator is internally

connected to a reference threshold voltage V

inverting input is connected to the LBI pin. The output of

the low battery comparator is a simple open-drain output

that goes active low if the battery voltage drops below the

programmed threshold voltage on LBI. The output requires a

pull-up resistor, with a recommended value of 100 kΩ, be

connected only to V

OUT

.

The low-battery detector circuit is typically used to supervise

the battery voltage and to generate an error flag or a RESET

command when the battery voltage drops below a user-set

threshold voltage. The function is active only when the

device is enabled. When the device is disabled, the LBO-pin

is high impedance.

while the

th

Setting the LBI Threshold of Low-Battery

Detector Circuit

The LBO-pin goes active low when the voltage on the

LBI-pin decreases below the set threshold typical voltage of

390 mV, which is set by the internal reference voltage.

The battery voltage, at which the detection circuit switches,

can be programmed with a resistive divider connected to

the LBI-pin. The resistive divider scales down the battery

voltage to a voltage level of tenths of volt, which is then

compared to the LBI threshold voltage. The LBI-pin has a

built-in hysteresis of 25 mV. The resistor values R1 and R2

can be calculated using the following equation:

V

= 0.39 x (R1+R2)/R2

IN_MIN

The value of R2 should be 270k or less to minimize bias current errors. R1 is then found by rearranging the equation:

R1=R2 x ( V

IN_MIN

/0.39 - 1)

If the low-battery detection circuit is not used, the LBI-pin

should be connected to GND (or to VIN) and the LBO-pin

can be left unconnected or tied to GND. Do not let the LBIpin float.

Component selection

Shutdown

The device enters shutdown when V

mately less than 0.5VIN). During shutdown the regulator

stops switching, all internal control circuitry including the

low-battery comparator is switched off and the load is

disconnected from the input. The output voltage may drop

below the input voltage during shutdown. The typical dependence shutdown voltage versus input voltage and the timing

process of the exiting shutdown are shown in the “Typical

Operating Characteristics.” For normal operation V

should be driven up 0.8VIN or connected to the VIN.

is low (approxi-

SHDN

SHDN

Application Information

Selecting the Output Voltage

The output voltage V

choosing resistors R4 and R5 of the divider in the feedback

circuit (see Test Circuit). The value of the R5 is recommended to be less than 270k. R4 can be calculated using

the following equation:

R4= R5[(V

where V

OUT/VREF

= 1.23V

REF

A compensation capacitor C3=18pF parallel with R4 provides better pulse grouping.

can be adjusted from 3V to 5V,

OUT

) – 1]

Output capacitor selection

The major parameter necessary to define the output capacitor

is the maximum allowed output voltage ripple of the converter. This ripple is determined by two parameters of the

capacitor, the capacitance and the ESR.

The contribution due to the capacitance can be determined

by looking at the change in capacitor voltage required to

store the energy delivered by the inductor in a single charge

–discharge cycle, as determined by the formula:

2

OUT

-----------------------------------------------------------=

2L× CV

∆V

T

ON

For example, if VIN=3V, V

2

V

×

IN

–()×

OUTVIN

OUT

=5V, L=10µH, TON =1.2µs,

C=47µF, the calculation by this formula gives an expected

output ripple due to only the capacitor value of 6.5mV.

In continuous inductor mode operation, this additional component of the ripple, due to capacitor ESR, can be calculated

using equation:

∆V

ESR

I

OUT

ESR()

-------------

×=

1D–

INtON

-------------------------+

2L

×

V

Where D is the duty cycle.

An additional ripple of 28 mV, at 100mA load current, is the

result of using a ceramic capacitor with an ESR of 70mΩ.

The total ripple is the sum of the ripple caused by the capacitance and the ripple caused by the ESR of the capacitor. In

this example, the total ripple is 34.5mV. It is possible to

REV. 1.0.7 5/6/03 9

Page 10

PRODUCT SPECIFICATION ML4854

improve the design by enlarging the capacitor or using

smaller capacitors in parallel to reduce the ESR or by using

better capacitors with lower ESR.

Tradeoffs have to be made between performance and costs of

the external parts of the converter circuit. For common, general purpose applications, a ceramic output capacitor with a

capacitance of 47µF and ESR less than 0.1Ω could be a good

choice. If a tantalum capacitor is used, a 100nF ceramic

capacitor in parallel, placed close to the IC, is recommended.

Input Capacitor Selection

Since the ML4854 does not require a large decoupling

capacitor at the input to operate properly, a 47µF capacitor is

sufficient for most applications requiring a good transient

response of the regulator. Optimum efficiency occurs when

the capacitor value is large enough to decouple the source

impedance. This usually occurs for capacitor values in

excess of 47µF.

Table 1. Recommended capacitors

Vendor Description

MuRata X5R Ceramic

AVX TAJ,TPS series tantalum

Sprague 595D series tantalum

Kemet T494 series tantalum

Inductor Selection

To select the boost inductor, it is necessary to keep the possible peak inductor current below the absolute peak current

limit of the power switch of the device. The highest peak

current through the inductor and the switch depends on the

load current (I

voltage (V

OUT

), the input voltage(VIN) and the output

LOAD

).

The maximum load current depends upon the inductance L,

according to the equation:

V

–

OUTVIN

VINI

I

LOADmax

------------------------------------------------------------------------------------

where, by design, t

–

LIMtOFFmin

OFFmin

efficiency η is usually 0.9. For VIN=3V, V

resulting I

LOADmax

will be around 0.4A.

------------------------------

V

OUT

= 0.5µS, I

2L

= 0.8A and the

LIM

OUT

=5V the

η×=

The second parameter for choosing the inductor is the

desired current ripple in the inductor. Normally, it is advisable to work with a ripple of less than 20% of the average

inductor current. A larger inductor value provides a smaller

ripple which reduces the magnetic hysteresis losses in the

inductor, as well as output voltage ripple and EMI. But in the

same way, regulation time at load changes will rise. Due to

the nature of the “go/no go” control, larger inductor values

typically result in larger overall voltage ripple, because once

the output voltage level is satisfied, the converter goes discontinuous, resulting in the residual energy of the inductor,

causing overshoot. The losses in the inductor caused by

magnetic hysteresis losses and copper losses are a major

parameter for total circuit efficiency. For better efficiency the

ESR of the inductor should be kept as low as possible. Lower

value inductors typically offer lower ESR and smaller

physical size.

An inductor value of 10 µH works well in most applications,

but values between 5 µH to 22 µH are also acceptable. A

MuRata LQ66C100M4, 10µH surface-mount inductor is

suitable, having a current rating of 1.6A and a max. ESR of

36 mΩ. Other choices for surface-mount inductors are

shown in Table 2.

Table 2. Recommended Inductors

Supplier Manufacturer Part Number

MuRata LQ66C100M4

Coilcraft DT1608C-103

Coiltronics UP1B100

Sumida CDR63B-100

Thermal considerations

Implementation of integrated circuits in low-profile surfacemount packages typically requires special attention to power

dissipation. Many system-dependent issues such as thermal

coupling, airflow, added heat sinks and convection surfaces,

and the presence of other heat-generating components affect

the power-dissipation limits of a given component.

Three basic approaches for enhancing thermal performance

are:

• Improving the power dissipation capability of the PCB

design

• Improving the thermal coupling of the component to the

PCB

• Introducing airflow in the system

The maximum junction temperature, T

J (MAX)

of the

ML4854 devices is 150°C. The thermal resistance of the

8-pin TSSOP package (T08) is θJA = 124°C/W. Specified

regulator operation is assured to a maximum ambient

temperature T

of 85°C. Therefore, the maximum

A(MAX)

power dissipation is about 320 mW. More power can be dissipated if the maximum ambient temperature of the application is lower, according to the relation:

P

D(MAX)

= [T

J(MAX)

–T

A(MAX)

] / θ

JA

Layout and Grounding

Considerations

Careful design of printed circuit board is recommended since

high frequency switching and high peak currents are present

in DC/DC converters applications. A general rule is to place

the converter circuitry well away from any sensitive analog

10 REV. 1.0.7 5/6/03

Page 11

ML4854 PRODUCT SPECIFICATION

components. The PCB layout should be based on some

simple rules to minimize EMI and to ensure good regulation

performances:

1. Place the IC, inductor, input and output capacitor as

close together as possible.

2. Keep the output capacitor as close to the ML4854 as

possible with very short traces to V

and GND pins.

OUT

Typically it should be within 0.25 inches or 6 mm.

3. Keep the traces for the power components wide,

typically > 50 mils or 1.25 mm.

4. Place the external networks for LBI and FB close to

ML4854, but as far away as possible from the power

components to prevent voltage transient from coupling

into sensitive nodes.

Application Example:

Using ML4854 as a constant current source to drive four LEDs:

Cin

+

1

2

3

4

+

L

ML4854

+

Cout

8

7

6

5

D1

D2

D3

R

R

R

5. On multilayer boards, use component side copper for

grounding around the IC and connect back to a quiet

ground plane using vias. The ground planes act as

electrostatic shields for some of the RF energy radiated.

6. The connection of the GND pin of the IC (pin 8) to the

overall grounding system should be directly to the

bottom of the output filter capacitor. A star grounding

system radiating from where the power enters the PCB,

is a recommended practice.

L = 10µH

Cin = Cout = 10µF

R = 62 ohm

D1...D4 = QTLP 600C-EB (blue)

D4

R

The current through the LEDs is maintained constant within a large input voltage range as shown in the diagram below:

ML4854 feeds LED QTLP 600C-EB

20

19.8

19.6

19.4

19.2

19

18.8

18.6

18.4

LED Current (mA)

18.2

18

01234

Input Voltage (V)

5

REV. 1.0.7 5/6/03 11

Page 12

PRODUCT SPECIFICATION ML4854

Mechanical Dimensions

Package: T08

8-Lead TSSOP

0.113 - 0.123

(2.87 - 3.12)

8

PIN 1 ID

0.033 - 0.037

(0.84 - 0.94)

1

0.026 BSC

(0.65 BSC)

0.008 - 0.012

(0.20 - 0.30)

SEATING PLANE

0.169 - 0.177

(4.29 - 4.50)

0.043 MAX

(1.10 MAX)

0.002 - 0.006

(0.05 - 0.71)

0.246 - 0.258

(6.25 - 6.55)

0°-8°

0.020 - 0.028

(0.51 - 0.71)

0.004 - 0.008

(0.10 - 0.20)

12 REV. 1.0.7 5/6/03

Page 13

PRODUCT SPECIFICATION ML4854

Ordering Information

Part Number Temperature Range Package

ML4854IT –40°C to 85°C 8 Pin TSSOP (T08)

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO

ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME

ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN;

NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and (c) whose failure to perform

when properly used in accordance with instructions for use

provided in the labeling, can be reasonably expected to

result in a significant injury of the user.

2. A critical component in any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

www.fairchildsemi.com

5/6/03 0.0m 004

2003 Fairchild Semiconductor Corporation

Stock#DS30004854

Loading...

Loading...