Page 1

PRELIMINARY

ML4435 Sensorless BLDC Motor Controller

GENERAL DESCRIPTION

The ML4435 provides all the circuitry for sensorless

speed control of 3 phase Brushless DC Motors. Controller

functions include start-up circuitry, Back EMF commutation control, Pulse Width Modulation (PWM) speed control, pulse-by-pulse current limiting, motor coasting, and

under-voltage protection.

Motor starting is accomplished by commutating the motor

at a low frequency to produce low speed motion. The

low speed motion is used to generate a Back EMF signal.

A back EMF sampling circuit locks on to the motors position and controls commutation timing by forming a phase

locked loop (PLL). The commutation control circuitry also

outputs a speed feedback signal used in the speed control

loop. The speed control loop consists of an error amplifi er

and PWM comparator that produces a PWM duty cycle

for speed regulation. Motor current is limited by a pulseby-pulse PWM shutdown comparator that is tripped by

the voltage across an external current sense resistor. Commutation control, PWM speed control, and current limiting are combined to produce the output driver signals.

Six output drivers are used to provide gating signals to an

external 3 phase bridge power stage sized for the Brushless DC (BLDC) motor voltage and current requirements.

Additional functions include a motor coast function and

an under voltage lock out circuit to shut down the output

drivers in the event of a low voltage condition on the VCC

to the ML4435.

FEATURES

n Proprietary back-EMF sensing commutation technique

for motor communication without hall effect sensors

n PWM pulse-by-pulse current limiting to protect motor

and FET drivers

n Stand-alone operation; motor starts and stops with

power applied to the IC*

n Soft-start function limits start-up current

n PWM speed control for effi ciency and minimum FET

sizing

n Onboard under voltage lock out and power fail detect

n Tach output senses commutation of the motor

* Some External Components Required.

May, 2000PRELIMINARY DATASHEET

Page 2

PRELIMINARY

ML4435

WARRANTY

Micro Linear makes no representations or warranties with respect to the accuracy, utility, or completeness of the contents of

this publication and reserves the right to make changes to specifi cations and product descriptions at any time without notice.

No license, express or implied, by estoppel or otherwise, to any patents or other intellectual property rights is granted by this

document. The circuits contained in this document are offered as possible applications only. Particular uses or applications

may invalidate some of the specifi cations and/or product descriptions contained herein. The customer is urged to perform

its own engineering review before deciding on a particular application. Micro Linear assumes no liability whatsoever,

and disclaims any express or implied warranty, relating to sale and/or use of Micro Linear products including liability

or warranties relating to merchantability, fi tness for a particular purpose, or infringement of any intellectual property

right. Micro Linear products are not designed for use in medical, life saving, or life sustaining applications.

© Micro Linear 2000. is a registered trademark of Micro Linear Corporation. All other trademarks are

the property of their respective owners.

Products described herein may be covered by one or more of the following U.S. patents: 4,897,611; 4,964,026; 5,027,116;

5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940; 5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376;

5,652,479; 5,661,427; 5,663,874; 5,672,959; 5,689,167; 5,714,897; 5,717,798; 5,742,151; 5,747,977; 5,754,012;

5,757,174; 5,767,653; 5,777,514; 5,793,168; 5,798,635; 5,804,950; 5,808,455; 5,811,999; 5,818,207; 5,818,669; 5,825,165;

5,825,223; 5,838,723; 5.844,378; 5,844,941. Japan: 2,598,946; 2,619,299; 2,704,176; 2,821,714. Other patents are pending.

PRELIMINARY DATASHEET

May, 20002

Page 3

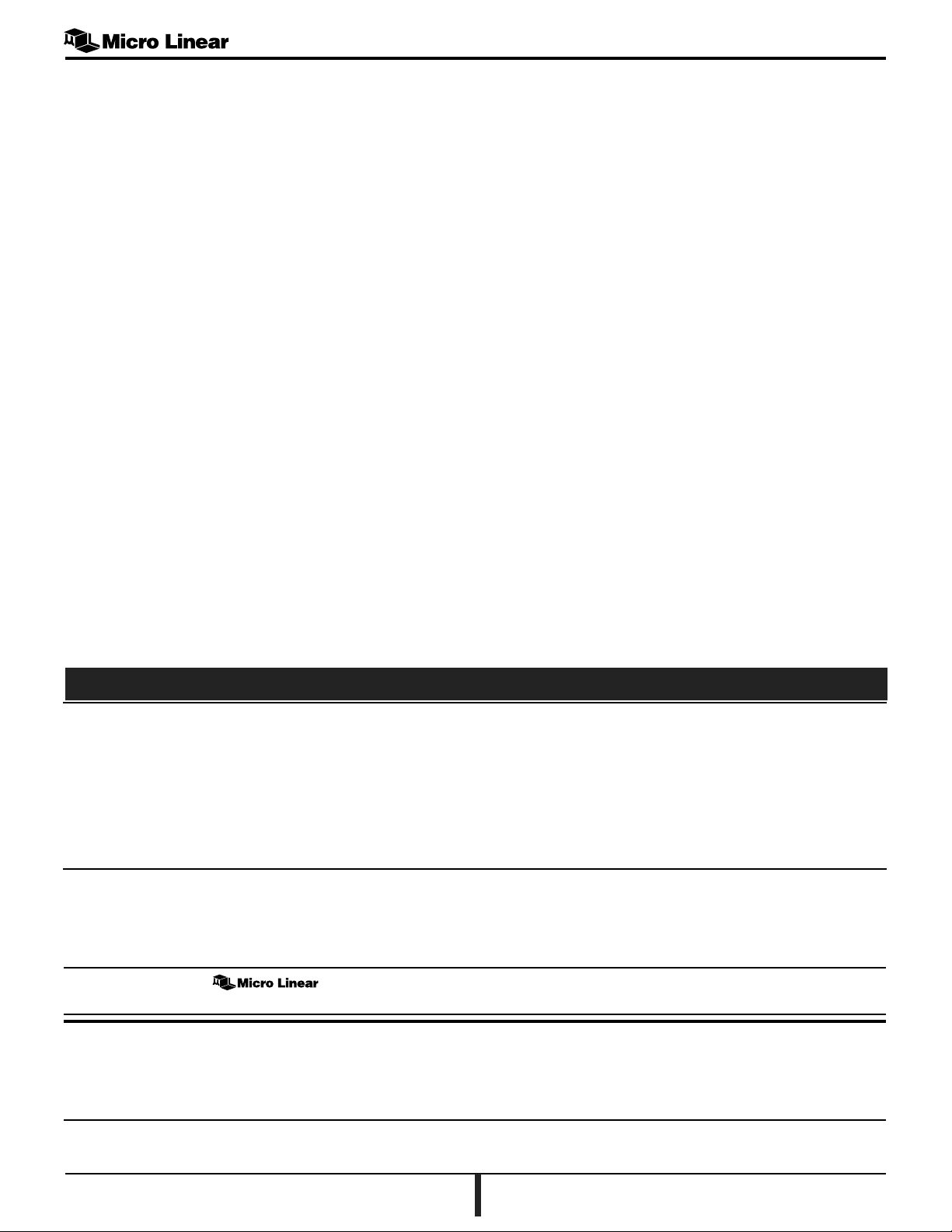

BLOCK DIAGRAM

FB A

14

FB B

15

FB C

16

COMMUTATION

STATE MACHINE

R

3µs

SPEED SET

SPEED COMP

ISENSE

SOFT START

POWER ON

RESET PULSE

5

3

1

19

F

E

8.2 + 0.7V

2.2 + 0.7V

1V

225kΩ

225kΩ

NEUTRAL

5.8kΩ

2.9kΩ

TRIANGLE WAVE

SIMULATOR

A

B

C

D

LEVEL SHIFT

GENERATOR

CURRENT LIMIT

COMPARATOR

MUX

SPEED FB

–

+

COMP

–

PRELIMINARY

SIGN

CHANGER

6

+

0.7V

+

–

BACK

EMF SAMPLER

SPEED

ERROR AMP

+

–

PWM

COMPARATOR

+

–

5V

DQ

R

VREF + 0.7V

+

–

VOLTAGE

CONTROLLED

OSCILLATOR

GATING

LOGIC

AND

OUTPUT

DRIVERS

PULSE-BY-PULSE

CURRENT LIMIT

8.7V

+

–

+

LEVEL

0.97V

SHIFT

0.7V

COAST

UVLO COMPARATOR

COMP

–

1.5V

6V REFERENCE

+

COMP

–

0.9V

VREF

ML4435

18

SPEED FB

2

TACH

20

CVCO

RVCO

4

7

HA

8

HB

9

HC

11

LA

12

LB

13

LC

6

RT VCC GND

1710

ML4435 Block Diagram

May, 2000 PRELIMINARY DATASHEET 3

Page 4

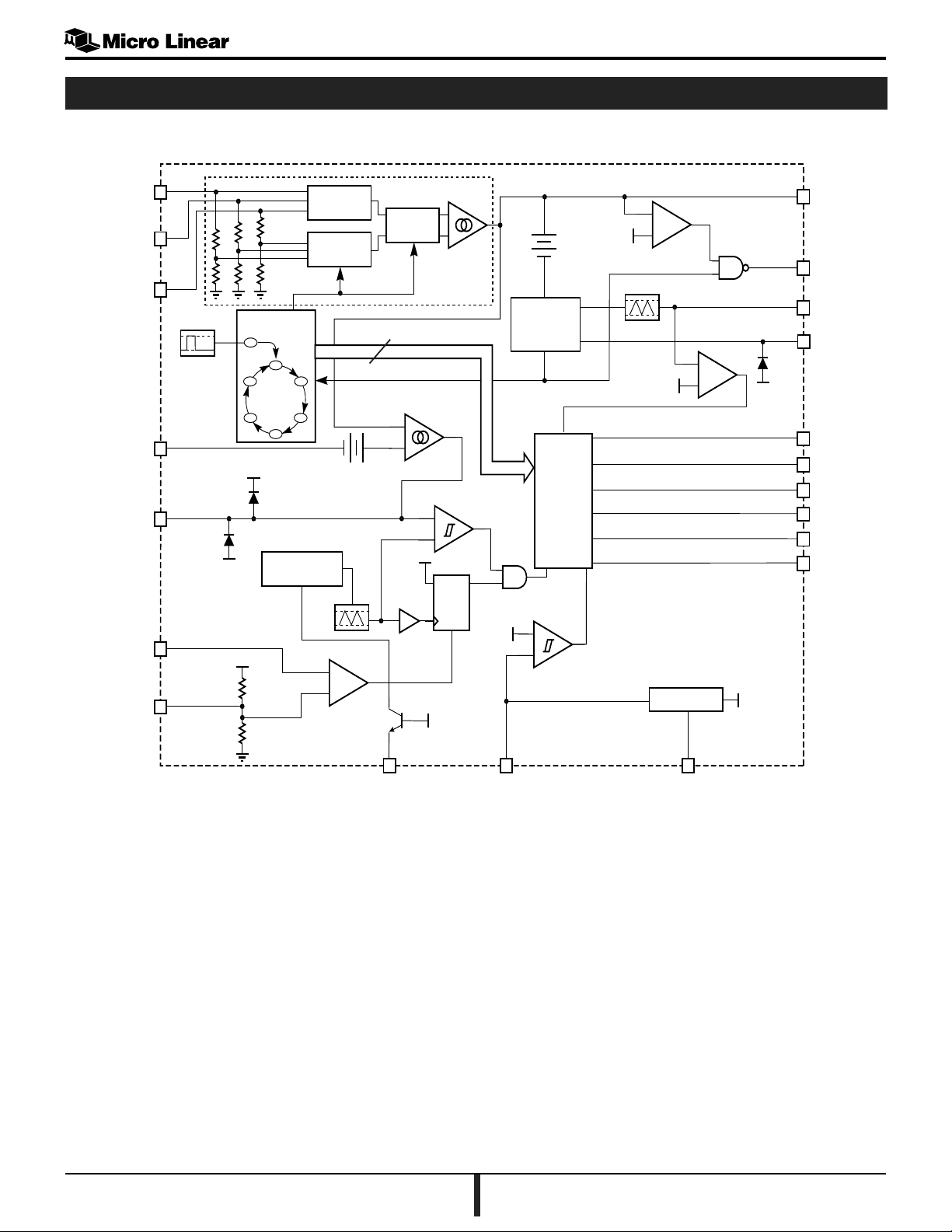

PIN CONFIGURATION

PRELIMINARY

ML4435

20-P n PDIP P20

20-P n SOIC S20

ISENSE

TACH

SPEED COMP

RVCO

SPEED SET

RT

HA

HB

HC

VCC

2

3

4

5

6

9

0

TOP VIEW

20

9

6

5

4

3

2

CVCO

SOFT START

SPEED FB

ND

FB C

FB B

FB A

LC

LB

LA

ML4435

PIN DESCRIPTIONS

PIN NAME FUNCTION

1 ISENSE Motor current sense input which triggers pulse by pulse current limit when

ISENSE exceeds 0.55V

2 TACH A clock output of 6 pulses per commutation cycle when SPEED FB is greater

than 0.97V otherwise the TACH output is at 5V

3 SPEED COMP Connection node for speed loop compensation components

4 RVCO Connection node for external resistor to set VCO frequency

5 SPEED SET DC input for setting motor speed

6 RT External resistor from this pin to ground controls the IC's PWM timing (frequency)

7 HA High-side output driver for motor phase A

8 HB High-side output driver for motor phase B

9 HC High-side output driver for motor phase C

10 VCC Power Supply input

11 LA Low-side output driver signal for motor phase A

12 LB Low-side output driver signal for motor phase B

13 LB Low-side output driver signal for motor phase C

14 FB A Back EMF signal input for motor phase A

15 FB B Back EMF signal input for motor phase B

16 FB C Back EMF signal input for motor phase C

17 GND Signal and power ground

18 SPEED FB Connection node for back-EMF sensing compensation components

19 SOFT START Connection node for external soft start capacitor which reduces start up current

20 CVCO Connection node for external capacitor to set VCO frequency. Forcing this input

below 1.5V causes the commutation to stop and the motor to coast

PRELIMINARY DATASHEET

May, 20004

Page 5

PRELIMINARY

FUNCTIONAL DESCRIPTION

ML4435

COMPONENT SELECTION

Selecting external components for the ML4435 requires

calculations based on the motor’s electrical and mechanical parameters. The following is a list of the motor parameters needed to for these calculations:

The maximum DC motor supply voltage V MOTOR (V)

The maximum operating current I MAX (A)

The winding resistance measured line to line Rl-l Ω

The number of magnetic poles N (Unitless)

The Back EMF constant Ke (V s/RAD)

The torque constant Kτ (N m/A) of the motor (Kτ = Ke

in SI units)

The maximum speed of operation RPMMAX (RPM)

The moment of inertia J (Kg m2 ) of the motor and its

load

The viscous damping factor ζ (Unitless) of the motor and

its load

If one or more of the above values is not known, it is

still possible to pick components for the ML4435, but

some experimentation may be necessary to determine the

optimal values. All quantities are in SI units unless otherwise specifi ed. The following formulas and component

selection graphs should be considered as a starting point

from which to optimize the application. All calculations

for capacitors and resistors should be used as the fi rst

approximation for selecting the closest standard value.

SUPPLY VOLTAGE AND ON-CHIP VOLTAGE

REFERENCE

OUTPUT DRIVERS

The output drivers LA, LB, LC, HA, HB, and HC provide

totem pole output drive signals for a 3 phase bridge power

stage. All control functions in the ML4435 translate to

outputs at these pins. LA, LB, LC provide the low side drive

signals for phases A, B, and C of the 3 phase power stage

and are 12V active high signals. HA, HB, and HC provide

the high side signals for phases A, B, and C of the 3 phase

power stage and are 12V active low signals.

CURRENT LIMITING IN THE 3 PHASE BRIDGE

POWER STAGE

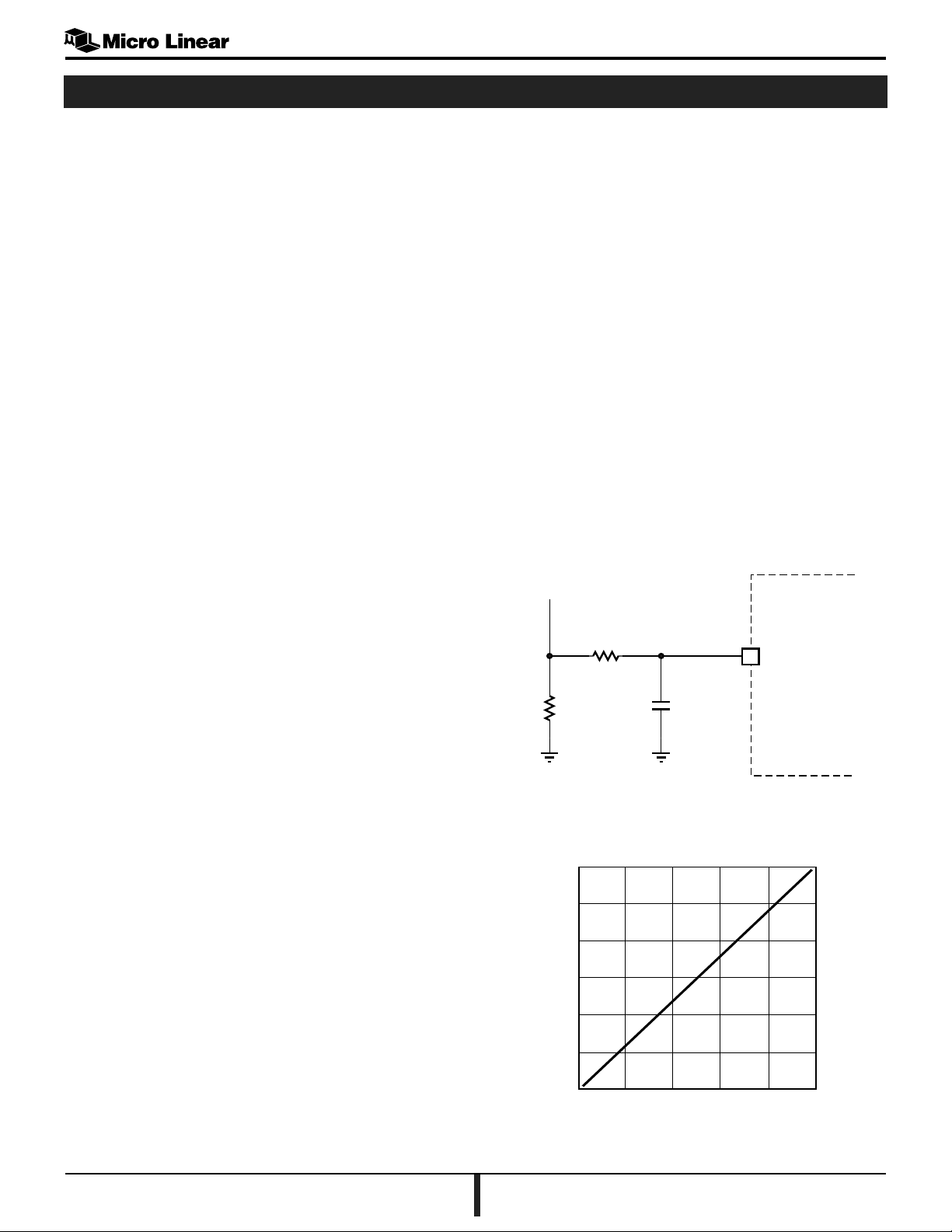

A current sense resistor RSENSE shown in Figure 1 is

installed in the 3 phase power stage to regulate the maximum current in the power stage and the BLDC motor.

Current regulation is accomplished by shutting off the

output drivers LA, LB, and LC for the remainder of the

PWM period if the voltage across RSENSE exceeds the

current limit threshold set by the SOFT START (pin 19).

The maximum power dissipated in RSENSE is shown in

Figure 2.

RSENSE

R

C

ISENSE

VCC

The supply voltage at VCC (pin 10) is nominally

12V ± 10%. A bypass capacitor of 0.1µF to ground as

close as possible to VCC (pin 10) is recommended.

RT

An internal 6V reference is generated inside the ML4435.

The reference appears on RT (pin 6). A resistor to ground

on RT sets the PWM frequency. This resistor can be

replace with a potentiomenter for use in setting the speed

command. This topic is discussed under the PWM SPEED

CONTROL section. Note: Buffer this pin with an op amp

with at least a 1MΩ input impedance if external circuits

are necessary.

May, 2000 PRELIMINARY DATASHEET 5

Figure 1. Current Limit with RSENSE

6

5

4

3

RSENSE Po er Rat n W

2

0

02

Figure 2. RSENSE Power vs. Motor Current

4

IMAX [MOTOR] A

60

Page 6

PRELIMINARY

FUNCTIONAL DESCRIPTION

ML4435

SOFT START

The voltage at SOFT START (pin 19) sets the current limit

threshold. The ML4435 has an internal voltage divider

with a 1.1V supply voltage. This circuit is shown in Figure

3. The divider consists of two 225k Ω resistors setting

the current limit threshold to approximately 0.55V. An

external voltage divider off of VCC or an external reference

can be used to override the default setting of SOFT START

by using a divider with 10 times the current draw of the

internal divider.

.V

225kΩ

CSOFT START

SOFT START

9

0.5V

225kΩ

RSENSE

The function of RSENSE is to provide a voltage proportional to the motor current, for current limiting. The default

trip voltage across RSENSE is 0.6V as set by the SOFT

START (pin 19). The current sense resistor should be a

low inductance resistor such as a carbon composition. For

resistors in the milli ohms range wire wound resistors tend

to have low values of inductance. RSENSE can be selected

using Figure 4. The power rating of RSENSE should be

sized to handle the power dissipation (I MAX squared

times RSENSE) seen at maximum current.

ISENSE FILTER

An RC lowpass fi lter is required at the ISENSE input pin

to remove the voltage spike on the leading edge of the

current sense signal caused by the diode reverse recovery

shoot through current. Absent the fi lter, false triggering of

the current limit could occur.

The recommended starting values for this circuit are

R = 1KΩ and C = 1000pF a confi guration that will fi lter

out spikes less than 1µs long. It is recommended that the

capacitor value not be increased beyond 330pF.

Figure 3. SOFT START Function

A capacitor to ground on the SOFT START pin can be used

to provide a soft ramping of the current limit on power up.

The ramp time can be selected using Figure 4.

30

RAMP TIME s

5

0

050

C SOFT START F

00

Pulse-By-Pulse Current Limiting

When current limit is activated by the voltage on ISENSE

exceeding the voltage on SOFT START the current limit is

tripped, turning off LA, LB, and LC for the remainder of

the PWM period.

COMMUTATION CONTROL

A 3 phase Brushless DC motor requires electronic com-

BEFORE FILTERIN

AFTER FILTERIN

Figure 4. SOFT START Ramp Time vs. CSOFTSTART

PRELIMINARY DATASHEET

Figure 5. ISENSE Filter Wave Forms

May, 20006

Page 7

PRELIMINARY

FUNCTIONAL DESCRIPTION

ML4435

mutation to achieve rotational motion. Electronic commutation requires the switching on and off of the power

switches of a 3 phase half bridge. For torque production

to be achieved in one direction the commutation is dictated by the rotor’s position. Electronic commutation in

the ML4435 is achieved by turning on and off, in the

proper sequence, one L output from one phase and one H

output from another phase. There are six combinations of

L and H outputs (six switching states) that constitute a full

commutation cycle as illustrated in Table 1 labeled state

A through F. This switching sequence is programmed into

the commutation state machine as illustrated in Figure 6.

Clocking of the commutation state machine is provided by

the output of a VCO.

VOLTAGE CONTROLLED OSCILLATOR

The VCO outputs a TTL compatible clock on the TACH

OUTPUT DRIVERS

LA LB LC HA HB HC

LOW LOW HI H LOW HI H HI H

A

(pin 2) proportional to the input voltage to the voltage

controlled oscillator SPEED FB (pin 18). The proportion of

frequency to voltage or VCO constant Kv is set by a resistor

to ground on RVCO (pin 4) and capacitor to ground on

CVCO (pin 20) as shown in Figure 7. RVCO sets up a

current proportional to the VCO input voltage SPEED FB

minus 0.7V. This current is used to charge and discharge

CVCO between the threshold voltages of 2V and 3.75V as

shown in Figure 7. RVCO has a lower voltage limit of 0.2V.

The resulting triangle wave of CVCO corresponds to the

clock on the TACH pin, this is also illustrated in Figure 7. Kv

should be set so that the VCO output frequency corresponds

to the maximum commutation frequency FMAX and thus the

maximum motor speed when the VCO input is equal to or

slightly less than 6V. CVCO and RVCO can be selected by

fi rst calculating FMAX and then using the selection graph in

Figure 8. FMAX is calculated as follows:

FMAX = 0.05 x RPMMAX x N

Where: RPMMAX = The maximum speed of operation

(RPM). N = The number of magnetic poles (Unitless).

TACH

B

LOW LOW HI H HI H LOW HI H

C

STATE

Table 1. Communication Control States

POWER ON

RESET PULSE

HI H LOW LOW HI H LOW HI H

D

HI H LOW LOW HI H HI H LOW

E

LOW HI H LOW HI H HI H LOW

F

LOW

HI H LOW LOW HI H HI H

COMMUTATION

STATE MACHINE

R

3s

A

F

B

= DRIVER ON

CLK VCO

The TACH (pin 2) outputs the VCO frequency. This is 6

SPEED FB

LEVEL

SHIFT

0. V

+

CVCO

20

RVCO

4

VOLTA E

CONTROLLED

OSCILLATOR

3. 5V

2V

0.9V

E

Figure 6. Commutation State Machine

C

D

Figure 7. VCO Control

May, 2000 PRELIMINARY DATASHEET 7

Page 8

PRELIMINARY

FUNCTIONAL DESCRIPTION

ML4435

times the commutation frequency. The TACH out also

indicates a low motor speed by staying TTL high when the

motor is at its minimum speed (SPEED FB below 0.97V).

BACK EMF SAMPLER

The input to the VCO (pin 18) SPEED FB is controlled by

the Back EMF Sampler. The back EMF sense pins FB A,

FB B, and FB C inputs to the back EMF sampler require

a signal from the motor phase leads that is below the

VCC of the ML4435. The phase sense input impedance is

8.7kΩ. If the motor voltage is greater than the VCC of the

ML4435 then this requires a series resistor RFB from the

motor phase lead shown in Figure 8. RFB can be selected

by using the graph in Figure 9 or using the following

equation:

RFB = 8.7k (

VMOTOR

12

-1)W

BLDC

MOTOR

The back EMF sampler takes the motor phase voltages

divided down to signals that are less than VCC (12V

nominal) and calculates the neutral point of the motor by

the following equation:

VNEUTRAL = (FB A + FB B + FB C)/3

This allows the ML4435 to compare the back EMF signal

to the motors neutral point without the need for bringing

out an extra wire on a WYE wound motor. For DELTA

wound motors there isn’t a physical neutral to bring out so

this reference point must be calculated anyway.

The back EMF sampler takes the motor phase that is not

driven (i.e. if LA and HB are on then phase A is driven

low and phase B is driven high then phase C is sampled).

The sampled phase provides a back EMF signal that is

compared against the neutral of the motor. The sampler

is controlled by the commutation state machine. The

sampled back EMF is compared to the neutral through an

error amplifi er. The output of the error amplifi er outputs

a charging or discharging current to SPEED FB (pin 18)

which provides the voltage to the VCO.

RFBA

RFBB

RFBC

ABC

Figure 8. Back EMF Sampler Confi guration

2,000

0,000

,000

6,000

R B F A, B, C Ω

4,000

2,000

FBA

4

FBB

5

6

FBC

BACK EMF SENSING PHASE LOCKED LOOP

COMMUTATION CONTROL

The three blocks: The commutation state machine, the

VCO, and the back EMF sampler form a phase locked

loop that locks the commutation clock onto the back EMF

signal. The complete phase locked loop is illustrated in

Figure 10. The phased locked loop requires a lead lag

fi lter that is set by external components on SPEED FB (pin

18). The fi lter components in Figure 10 work for most

applications. If performance is unstable C1 and C2 can

go up or down a decade in value as low as the C2 stays

equal to C1 x 10.

FBA

4

FBB

5

FBC

6

BACK EMF

SAMPLER

COMMUTATION

STATE MACHINE

VCO

SPEED FB

CSFB

RSFB

CSFB2

RSFB2

0

05

Motor Volta e [Max] V

Figure 9. RFB vs. VMOTOR [MAX]

25 30

20

PRELIMINARY DATASHEET

Figure 10. Phase Locked Loop

May, 20008

Page 9

PRELIMINARY

FUNCTIONAL DESCRIPTION

ML4435

MOTOR START-UP

When power is fi rst applied to the ML4435, the motor is at

rest and thus, the back EMF is equal to zero. The motor

needs to be rotating for the Back EMF sampler to lock onto

the rotor position and commutate the motor. The ML4435

uses a minimum VCO frequency to begin commutating the

motor. This low frequency commutation is set by the 0.2V

clamp on RVCO, this provides a commutation frequency

at 1/30th of the maximum frequency.

RUN MODE

After the Back EMF sensing PLL has locked on to the

motor’s position, the motor is running in closed loop control. At this point, the speed control loop should force the

motor speed to the speed that corresponds to the SPEED

SET voltage.

PWM SPEED CONTROL

Speed control is accomplished by setting a speed command at SPEED SET (pin 5) with an input voltage from 0.2

to 6V. The accuracy of the speed command is determined

by the external components RVCO and CVCO. There are

a number of methods to control the speed command on

the ML4435. One method is to use a potentiometer from

RT to ground with the wiper going to SPEED SET. If SPEED

SET is controlled from a microcontroller, a DAC that uses

RT as its input reference can be used. The RT voltage must

be buffered connecting it to external circuits. The speed

command is compared with the sensed speed from SPEED

FB minus 0.7V (pin 18) through a transconductance error

amplifi er. The output of the speed error amplifi er is SPEED

COMP (pin 3). SPEED COMP is clamped between 8.2V

and 2.2V. A signal of 8.2V corresponds to full PWM duty

cycle and 2.2V corresponds to 0% duty cycle. Speed

loop compensation components are placed on this pin as

shown in Figure 11.

The voltage on SPEED COMP (pin 3) is compared with a

triangle wave oscillator to create a PWM duty cycle. The

PWM oscillator creates a triangle wave function from 3V

to 7V as shown in Figure 11. The frequency of the triangle

wave oscillator is set by a resistor to ground on RT (pin 6).

RT can be selected from the graph in Figure 12.

The PWM duty cycle from the speed control loop is gated

the pulse-by-pulse current limit that controls the LA, LB,

and LC output drivers.

SPEED FB

SPEED

WAVE

ERROR AMP

–

+

V

3V

PWM

COMPARATOR

+

–

SPEED

SET

5

–

+

LEVEL SHIFT

0. V

.2 - 0. V

SPEED

COMP

3

CSE

2.2 + 0. V

TRIAN LE

COMPARATOR

Figure 11. PWM Oscillator Circuit

000

The speed loop compensation components are calculated

as follows:

C

SC

Rsc

144

2

=

=

22π

NxKexVMOTOR R C

×××

.

2

J RI freq

××××

π

VCO VCO

2

10

freq Csc

×× ×

Csc1 = 10 x Csc2

Where freq is the speed loop bandwidth in Hz.

May, 2000 PRELIMINARY DATASHEET 9

RT kΩ

00

0

PWM FRE UENCY kHz

Figure 12. RT vs PWM Frequency

000

Page 10

PRELIMINARY

FUNCTIONAL DESCRIPTION

ML4435

COAST

When CVCO (pin 20) is pulled below 1.5V the output

drivers LA, LB, LC and HA, HB, and HC are turned off.

The COAST function shuts all power off from the motor

allowing it to coast to a stop. The COAST function in (pin

20) is confi gured as shown in Figure 13 and can be driven

by a switch to ground or open collector to ground also

shown in Figure 13.

3. 5V

2V

+

COMP

.5V

–

Figure 13. Coast Control

CVCO

20

COAST

UNDER VOLTAGE PROTECTION

Undervoltage protection is used to protect the 3 phase

bridge power stage from a low VCC condition. Undervoltage is triggered at VCC of 9.2V or under. Undervoltage

also turns off all output drivers LA, LB, LC, HA, HB, and

HC. The comparator that triggers undervoltage protection

has 500mV of hystersis.

INTERFACING THE OUTPUT DRIVERS TO THE 3

PHASE BRIDGE POWER STAGE

The most fl exible confi guration is to use high side drivers

to control N-Channel MOSFETs (or IGBTs) allowing applications from less than 12V up to 170V. Figure 14a shows

the ML4435 and all the support circuitry in a typical

application. Figure 14b shows a power stage using the

IR2118 high side drivers from International Rectifi er and

high voltage MOSFETs.

P

N.C.

2

N.C.

3

4

5

6

TP 3 TACH

C4

TP SPEED SET

C3 2200 F

C5

0.33 F

0F

R6 0k

R k

R4 20k

TP 0 ISENSE

R2 00k

R 90.9k

R3 k

2V

0. F

9

0

2

3

4

5

6

RUN

SW

N.C.

R 0 k

R5

0k

C

.F

C9

.0 F

SW4PDT

COAST

R6

200k

N.C.

N.C.

TP 2

S FB

TP 5 LIMIT

ML4435

ISENSE

2

TACH

3

S COMP

4

RVCO

5

S SET

6

RT

HA

HB

9

HC

0

VCC

C2

C

4F

CVCO

I LIMIT

FB C

FB B

FB A

S FB

20

9

ND

6

5

4

3

2

R k

R9 k

R 2 k

LC

LB

LA

C0

00 F

C

.033 F

2V

9

20

N.C.

2

22

N.C.

23

24

N.C.

25

26

N.C.

IDC 26

Figure 14a. ML4435 Typical Application

PRELIMINARY DATASHEET

May, 200010

Page 11

PRELIMINARY

FUNCTIONAL DESCRIPTION

.5k

PHASE C

TERMINAL

PHASE B

PHASE A TERMINAL

SB

TERMINAL

SA

R44

SC

4

IRF644

5

IRF644

R3

3

IRF644

R32

.5k

.5k

R43 .0k

R3 .0k

6

2

IRF644

IRF644

R49

ML4435

0k

R4

0k

R42

D3 UF4005

W

0.4 Ω

R4

R36

D2 UF4005

R35

F

C6

6

5

U3

2

3

4

IR2

F

C5

0k

0k

F

C4

6

5

U2

2

3

4

IR2

F

C3

0k

2N440

2N440

9

2N4403

F

C9

2N4403

02

F

C

IRF644

F SA FUSE

2

HV

ND

P2

2PIN

P

2

C4

C0

R3 .0k

0.33 F

250V

0.33 F

250V

C3

200V

390 F

R50 0

C2

2V

ND

ND

ISENSE

0

2

3

3

4

5

HA

6

SA

LA

ND

HB

9

SB

LB

HC

ND

4

SC

LC

R30

D UF4005

UNUSED

5

ND

ISENSE

0k

U

ND

6

ND2VND

F

C2

6

2

3

F

C

HA

9

2022223242526

ND

ND

2N440

5

4

IR2

LA

LC

LB

ND

IDC 26

ND

HB

HC

2N4403

F

C

ND

Figure 14b. Power Stage

May, 2000 PRELIMINARY DATASHEET 11

Page 12

PRELIMINARY

ML4435

ELECTRICAL TABLES

Unless otherwise specifi ed, Ta= Operating Temperature Range, VCC= 12V +/- 10%, RT= 50k

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

REFERENCE

RT 5.8 6 6.2 V

VCO

2

RVCO Lower Range

Upper Range

CVCO Lower Threshold

Upper Threshold

Coast Enable Threshold

Back EMF Blanking Threshold

SPEED FEEDBACK

Output Range

V Minimum Frequency

TACH Out Disabled Threshold

I Back EMF Sampler

BACK EMF SENSING

Feed Back Input Range

TACH

TACH Out Low ISINK = 100µA 0.2 0.4 V

TACH Out High ISOURCE =100µA 4.3 4.8 V

SPEED ERROR AMP

SPEED SET Range

I SPEED COMP V SPEED COMP = 5.1V +/-45 µA

SPEED COMP Output Lower Clamp

SPEED COMP Output Upper Clamp

OSCILLATOR

PWM Frequency N1, N2, N3 17 25 33 kHz

Duty Cycle

CURRENT SENSE

V SOFT START 0.48 0.58 0.68 V

ISENSE Threshold

OUTPUTS (N1, N2, N3, P1, P2, AND P3)

Output Low ISINK = 20mA 0 0.5 1 V

Output High (VCC-VOUT) ISOURCE = 20mA 0 0.5 1 V

UNDER-VOLTAGE LOCKOUT

Start Threshold 8.7 9.2 9.7 V

Under Voltage Threshold 8.2 8.7 9.2 V

SUPPLY

ICC Supply Current 15 mA

0.2 V

2

2

2 V

2

3.75 V

2

1.5 V

2

2.875 V

2

0 6.7 V

2

V Speed Feedback 0.9 V

2

TACH Out = Hi 0.97 V

2

V Speed Feedback = 3.3V +/-80 µA

2

FB A, FB B, and FB C 0 VCC V

2

0 6 V

2

I = ±45µA 2.15 V

2

I = ±45µA 8.2 V

2

N1, N2, N3 0 100 %

2

0.58 V

6

V

Note 1: Limits are guaranteed by 100% testing, sampling, or correlation with worst case test conditions

Note 2 Guaranteed by design, not tested

PRELIMINARY DATASHEET

May, 200012

Page 13

PRELIMINARY

ML4435

PHYSICAL DIMENSIONS

20

PIN ID

0.060 MIN

.52 MIN

4 PLACES

0. 0 MAX

4.32 MAX

0. 25 MIN

3. MIN

(inches/millimeters)

Packa e P20

20-P n PDIP

.0 0 - .035

25.65 - 26.29

0.055 - 0.065

.40 - .65

0.0 6 - 0.022

0.40 - 0.56

0. 00 BSC

2.54 BSC

0.240 - 0.260

SEATIN PLANE

6.09 - 6.6

0.0 5 MIN

0.3 MIN

0.295 - 0.325

.49 - .26

0º - 5º

0.00 - 0.0 2

0.20 - 0.3

0.024 - 0.034

0.6 - 0. 6

4 PLACES

0.090 - 0.094

2.2 - 2.39

Packa e S20

20-P n SOIC

0.49 - 0.5 2

PIN ID

2.65 - 3.00

0.050 BSC

.2 BSC

0.0 2 - 0.020

0.30 - 0.5

0.29 - 0.30

0.095 - 0. 0

2.4 - 2. 2

SEATIN PLANE

.39 - .65

0.005 - 0.0 3

0. 3 - 0.33

0.39 - 0.4 2

0. - 0.4

0º - º

0.022 - 0.042

0.56 - .0

0.00 - 0.0 5

0. - 0.3

20

May, 2000 PRELIMINARY DATASHEET 13

Page 14

PRELIMINARY

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML4435CP 0ºC to 70ºC 20 Pin PDIP (P20)

ML4435CS 0ºC to 70ºC 20 Pin SOIC (S20)

ML4435IP -40ºC to 85ºC 20 Pin PDIP (P20)

ML4435IS -40ºC to 85ºC 20 Pin SOIC (S20)

ML4435

Micro Linear Corporation

2092 Concourse Drive

San Jose, CA 95131

Tel: (408) 433-5200

Fax: (408) 432-0295

www.microlinear.com

PRELIMINARY DATASHEET

DS4435-01

May, 200014

Loading...

Loading...