Page 1

July 2000

ML4423*

1, 2, or 3-Phase Variable Speed AC Motor Controller

GENERAL DESCRIPTION

The ML4423 provides the PWM sinewave drive signals

necessary for controlling three phase AC induction motors as

well as single and two phase split capacitor AC induction

motors.

A constant voltage/frequency ratio can be maintained

over a frequency range of greater than 10:1, providing

15Hz to 150Hz control. The output variable frequency AC

voltages are sensed and fed back to the controller to track the

sinewave frequency and amplitude set at the speed control

input. Direction, on two and three phase motors, is controlled

by changing the relative phase difference between the motor

windings: 90× for two phase motors and 120× and 240× for three

phase motors.

To protect the motor, power devices, high voltage drivers

and control circuitry, the ML4423 includes fixed period,

pulse by pulse variable duty cycle current limit, deadtime

circuitry, and undervoltage lockout. The ML4423 has

selectable output voltage swing of 5V or 12V for

interfacing to different high side drivers and power devices.

FEATURES

■ Drives single, two, and three phase AC motors

■ Greater than 10:1 variable speed control range

■ Constant V/F ratio with programmable end points

■ Reverse capability for two and three phase motors

■ Low distortion PWM sinewave drive

■ Eliminates run capacitors in PSC motors

■ Coast function for quick power disable

■ Low cost interface for various gate drivers

■ PWM current limit, undervoltage lockout, and

programmable deadtime

■ 12V ±20% operation with onboard 8V reference

(* Indicates Part Is End Of Life As Of July 1, 2000)

BLOCK DIAGRAM

FB A

1

FB C

2

FB B

3

C

12

V

5

V

4

R

6

O

SPEED

MIN

SPEED

+

–

+

–

+

–

+

–

SPEED

CONTROL

SINE A-C

27

GENERATOR

GENERATOR

28

SINE A

SINE B

SINE B-C

GENERATOR

13

PWM

OSCILLATOR

SINE C

F/R

PWM

SINE

WAVE

CONTROL

18

3PH/2PH

UVLO

26

COAST

14

R

DT

9

5V/12 SELECT

GATING

LOGIC

&

OUTPUT

DRIVERS

+

COMP

–

REFERENCE

V

DD

GND R

17 8 7

REF

I

SENSE

0.5V

V

REF

HA

HB

HC

LA

LB

LC

25

24

22

23

21

19

20

16

C

T

15

1

Page 2

ML4423

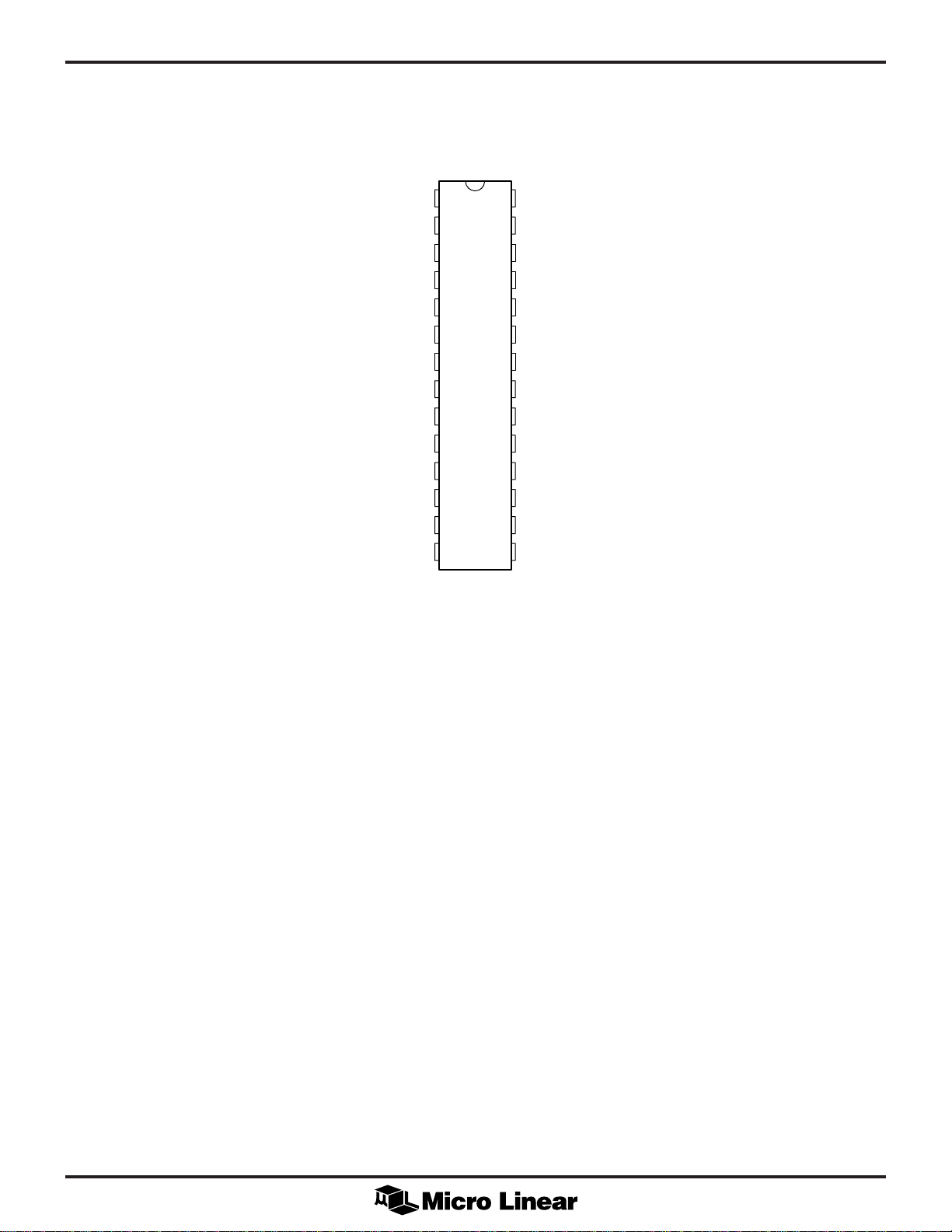

PIN CONFIGURATION

ML4423

28-Pin Narrow PDIP (P28N)

28-Pin SOIC (S28)

SENSE A

SENSE C

SENSE B

V

MIN

V

SPEED

R

SPEED

V

REF

R

REF

R

DT

SINE A-C

1

2

3

4

5

6

7

8

9

10

28

C

GM2

27

C

GM1

26

V

DD

25

5V/12V SELECT

24

HA

23

HC

22

HB

21

LA

20

LC

19

LB

SINE B-C

C

C

COAST

11

12

O

03

T

14

TOP VIEW

18

17

16

15

3PH/2PH

GND

I

SENSE

F/R

2

Page 3

PIN DESCRIPTION

ML4423

PIN NAME FUNCTION

1 FB A Differential input which, in

conjunction with FB C, feeds back the

voltage applied across motor winding

A-C.

2 FB C Input which feeds back the voltage

applied to motor winding C. Reference

voltage for windings A and B.

3 FB B Differential input which, in

conjunction with FB C, feeds back the

voltage applied across motor winding

B-C.

4V

MIN

The voltage on this pin sets the

minimum sinewave amplitude at low

speeds.

5V

SPEED

The voltage on this pin sets the

frequency and amplitude of the

sinewaves generated at SINEA and

SINEB.

6R

SPEED

An external resistor to ground provides

a variable current to the sinewave

generator. The current is proportional

to V

SPEED

.

PIN NAME FUNCTION

13 C

T

An external capacitor to ground sets

the PWM triangle frequency in

conjunction with the external resistor

R

.

REF

14 COAST A logic low input causes all output

drive transistors to turn OFF. An

internal pull-up drives COAST to V

if left unconnected.

15 F/R A logic high input causes phase A to

lead phase B, while a logic low input

causes phase A to lag phase B. An

internal pull-up drives F/R to VDD if

left unconnected.

16 I

SENSE

Motor current sense input.

17 GND Signal and power ground.

18 3PH/2PH Leaving this pin unconnected selects

3-phase drive. Connecting this pin to

VDD selects single/2-phase drive.

19 LB Low side drive output for phase B.

20 LC Low side drive output for phase C.

DD

7V

8R

REF

REF

8V reference output which can be

used for setting V

SPEED

and V

An external resistor to ground provides

a constant current used for setting the

PWM frequency in conjunction with

CT.

9R

DT

An external resistor to ground sets the

deadtime in the output stage to

prevent cross-conduction in the power

devices.

10 SINE A-C A test output for observing the

internally generated sinewave used for

motor winding A-C.

11 SINE B-C A test output for observing the

internally generated sinewave used for

motor winding B-C.

12 C

O

An external capacitor to ground sets

the sinewave frequency in conjunction

with V

SPEED

and R

SPEED

.

MIN

21 LA Low side drive output for phase A.

.

22 HB High side drive output for phase B.

23 HC High side drive output for phase C.

24 HA High side drive output for phase A.

25 5V/12V Input to select 5V or 12V output drive.

SELECT Leaving this pin unconnected selects

5V output drive levels at the driver

outputs. Connecting this pin to V

CC

selects 12V output drive levels at the

driver outputs.

26 V

27 C

DD

GM1

12V power supply input.

An external capacitor to ground sets a

pole in the feedback loop.

28 C

GM2

An external capacitor to ground sets a

pole in the feedback loop.

3

Page 4

ML4423

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

Thermal Resistance (qJA)

Plastic DIP ....................................................... 52ºC/W

Plastic SOIC .................................................... 75ºC/W

device operation is not implied.

V

.............................................................................................. 15V

DD

OPERATING CONDITIONS

Output Drive Current ........................................... ±50mA

Logic Inputs (F/R, COAST) .............................. –0.3 to 7V

Junction Temperature.............................................. 150ºC

Storage Temperature Range ...................... –65ºC to 150ºC

Lead Temperature (Soldering 10 sec) ...................... 260ºC

Temperature Range

C Suffix ...................................................... 0ºC to 70ºC

I Suffix ....................................................–40ºC to 85ºC

VDD...........................................................9.6V to 14.4V

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, VDD = 12V ± 20%, R

C0 = 0.47mF, C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

REFERENCE

V

DIGITAL INPUTS

Output Voltage 7.6 7.8 8.2 V

REF

Line Regulation

Total Variation Line, Temperature

= 220pF, RDT = 166kW, TA = Operating Temperature Range (Note 1).

PWM

= 160kW, R

SPEED

= 250mW, R

SENSE

= 200kW,

REF

V

V

OUTPUT DRIVERS

V

V

SINE WAVE GENERATOR

V

PWM GENERATOR

CURRENT LIMIT

UNDERVOLTAGE LOCKOUT

Input Low Voltage 0.8 V

IL

Input High Voltage 2 V

IH

Output Low Voltage IOL = 20mA, 5V/12V SELECT = V

OL

Output High Voltage IOL = –20mA, 5V/12V SELECT = V

OH

Peak Voltage V

PP

Frequency V

Distortion 5%

Ramp Frequency 25 kHz

Threshold Voltage 0.4 0.5 0.6 V

Threshold Voltage 7.8 8.4 9.2 V

DD

I

= 2mA, 5V/12V SELECT = open 0.1 V

OL

DD

IOL = –2mA, 5V/12V SELECT = open 5 V

= 4.4V 3.4 V

SPEED

= 4.4V 60 Hz

SPEED

1V

V

– 1 V

DD

Hysteresis 0.5 V

SUPPLY

I

Note 1:

CC

VCC Operating Current 10 14 20 mA

Limits are guaranteed by 100% testing, sampling, or correlation with worst-case test conditions.

4

Page 5

FUNCTIONAL DESCRIPTION

ML4423

The ML4423 generates 2 reference sinewaves separated

by 90º or 60º in a closed loop feedback system. These

sinewaves can be varied in amplitude and frequency by

the speed input. Signals across the motor windings are fed

back and the ML4423 drives the external power output

stage with the PWM sinewave signal necessary to cause

the measured (feedback) output waveform to match the

internal reference sinewaves. The ML4423 provides fixed

period, variable duty cycle current limit protection, and

a programmable dead time circuit to prevent cross

conduction in the power output stage. An undervoltage

lockout circuit turns off the external power transistors if

VDD falls below 9V.

CIRCUIT BLOCKS AND COMPONENT SELECTION

R

REF

R

should be set to 200kW. This current along with

REF

C

set the PWM frequency.

PWM

Speed Control

The voltage on V

(pin 5) controls the sinewave

SPEED

frequency and amplitude. A 160kW resistor to ground on

R

(pin 6) converts the voltage on V

SPEED

to a current

SPEED

which is used to control the frequency of the output PWM

sinewaves. The amplitude of the sinewaves increases

linearly with V

until it reahces 4.4V. Above this

SPEED

voltage the amplitude remains constant and only the

frequency changes as shown in Figures 1 and 2.

SINEA and SINEB Generators

The capacitor to ground on C0 sets the frequency of the

sinewave according to the following relationship. C

0

should be a low temperature coefficient capacitor for

stable output frequency.

.

C

×108 800

0

= 58.7Hz and

SINE

(1)

(2)

For R

With V

V

f

SINE

= 160kW

SPEED

f

SINE

= 3V and C0 = 0.47mF, f

SPEED

R

=

4 0 170

CV

0

V

SPEED

=

,

SPEED

SPEED

×

can be observed at test points SINEA (pin 10) and SINE

(pin 11).

PWM Generator

A triangular PWM frequency will be generated on a

capacitor to ground on C

(pin 13). The frequency is

PWM

set by the following equation:

f

PWM

=

200 000,

1

C

×

PWM

(3)

B

150

120

90

60

FREQUENCY (Hz)

30

02468

V

Figure 1. Frequency vs V

SPEED

R

SPEED = 160

C0 = 0.47µF

(V)

SPEED

For C

= 220pF, f

PWM

1.25

1.00

0.75

0.50

NORMALIZED OUPTUT (V)

0.25

0

= 22.7kHz. It is recommended

PWM

4.4V

24

V

(V)

SPEED

Figure 2. Normalized Output Voltage vs V

68

SPEED

5

Page 6

ML4423

Current Limit

Motor current is sensed on I

SENSE

(pin 16). R

LIMIT

should

be selected so that

V

R

LIMIT

For a 2A current limit, R

05.

=

I

MAX

= 0.25W. The 1kW resistor

LIMIT

(4)

and 330pF capacitor filter (shown in figure 3) filter the

high frequency flyback pulses (due to the freewheeling

diode recovery currents) occurring at the output. When

I

is reached the output power will be turned off for

MAX

the remainder of the current PWM cycle, which is

asynchronous with the sinewave frequency. Thus current

limit is fixed-period with variable duty cycle.

PWM SINE Controller

This circuit block compares the sinewaves at SINEA and

SINEB to the sampled inputs SENSEA–SENSEC and

SENSEB–SENSEC, respectively. The PWM loop then

drives the outputs to force these “differential” waveforms

to equal the internal reference waveforms at SINEA and

SINEB. The differential signals SENSEA–SENSEC and

SENSEB–SENSEC will be approximately 1.7 volts zeropeak maximum. The signals at these pins should be

filtered to remove the PWM frequency. The high voltages

at the motor terminals are divided down to 1.7V to

provide voltage feedback to the controller. In figure 3,

the resistors to ground from SENSEA (pin 1) and SENSE

B

(pin 3) should be 1kW. SENSEC (pin 2) should have a

500W to ground because it has 1/2 the input impedance

of the other 2 inputs. The 0.15mF capacitors to ground on

SENSEA and SENSEB and the 0.3mF capacitor to ground

on SENSEC will create a 1kHz low pass filter at these

inputs. V

on the motor is set by the divider ratios.

PEAK

OUTPUT DRIVE

The 6 output drivers of the ML4423 drive the H and L

outputs from 0 to 12 volts (with pin 25 tied to VCC+(12V)).

The outputs will drive about 10mA and are designed to

drive output buffers and high side drivers requiring 12V

swings. The ML4423 provides lower current 0 to 5V drive

for high/low side drivers requiring 5V input signal swings

with pin 25 left unconnected.

PROGRAMMABLE DEADTIME

A dead time circuit is provided to prevent shoot through

currents in the power output stage. The dead time is

controlled by a resistor to ground on RDT (pin 9). The dead

time selected should be large enough to prevent cross

conduction between the upper and lower power devices

of each inverter phase leg.

−

11

()

(6)

DB

With f

PWM

= 166k, t

C

and C

GM1

tR

=×

12 10

DEAD DB

.

= 25kHz, the PWM period is 40ms. With R

= 2ms (~5%).

DEAD

GM2

These two external capacitors to ground each set a pole in

the forward path of the feedback loop in conjunction with

a gm of 1/650W. The pole should be placed at a frequency

higher than the PWM frequency.

g

m

f

>

2π

C

PWM

g

m

(7)

APPLICATION

For the values shown in figure 3:

(V

VV

SPEED

PEAK

= 4.4V)

.

17

=

17

.

V

=

170

=

V

99 1

kk

+

1

k

49 5 500

.

k

500

The ML4423 provides all the signals necessary to drive

the output power stage connected to the motor. The

components around the ML4423 for a typical application

are shown in figure 3. The motor DC supply voltage

should be greater than the largest signal waveform

+

(5)

required or output clipping may result. Figure 4 shows an

alternate circuit using the IR2118.

6

Page 7

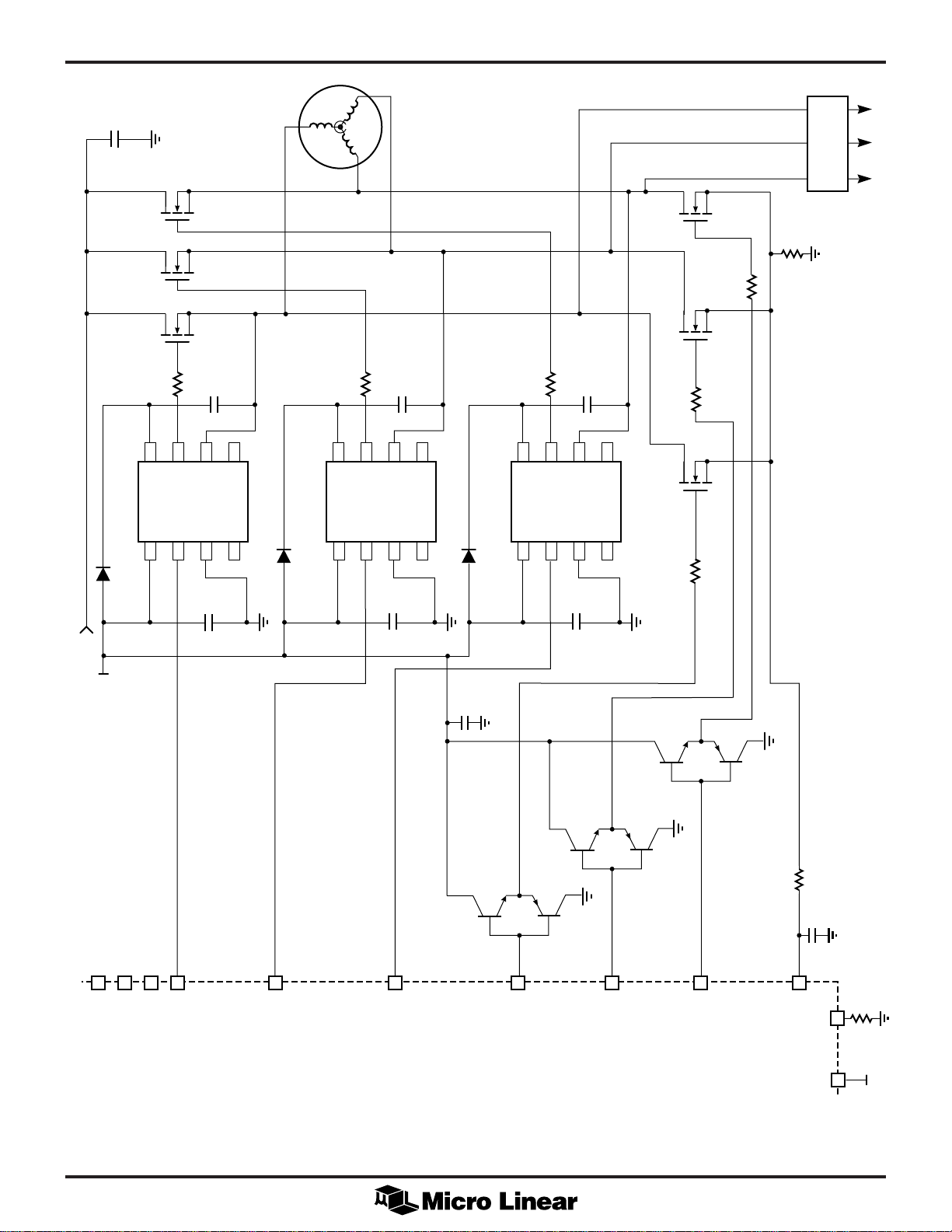

Figure 3. 3-Phase Motor Controller with INT-100 High Voltage Drivers

0.1µF

100kΩ

100kΩ

200kΩ

0.1µF

160kΩ

V

R

SPEED

V

0.1µF

V

REF

R

REF

SPEED

MIN

7

8

5

6

4

GND

12V

V

CC

26

8V REF

SPEED

CONTROLLER

C

GM1

2717

0.47µF

FREQ.

SINE

SINE

28

C

0.001µF0.001µF

12

GM2

C

0

A

B

SINE

A

10 13

AMPLITUDE

SINE

B

C

PWM

GENERATOR

PWM SINE

CONTROLLER

F/R

220pF

PWM

1811

COAST143PH/2PH

ML4423

UNDER VOLTAGE

LOCKOUT

OUTPUT

DRIVE & SHOOT

THROUGH

PROTECTION

CURRENT

LIMIT

5V/12V

SELECT

92515

R

166kΩ

A

99kΩ 49.5kΩ

99kΩ

2

3

1kΩ

+12V

1

H

L

0.15µF

IN

PWR

INT100

IN

4

5

15

1kΩ

11

12,13,14

8

7

SENSE

A

1

SENSE

C

2

SENSE

B

3

+12V

H A

24

L A

21

H B

22

L B

19

H C

23

L C

20

I

SENSE

16

DT

A

+12V

DRIVE

1kΩ

R

LIMIT

330pF 250mΩ

B

DRIVE

0.15µF

C

B

500Ω

0.30µF

+V

MOTOR

170–400V

10Ω

+

1µF

10Ω

C

100Ω

100Ω

Note: Use Extreme caution with high voltage AC motor control and drive circuitry.

When the motor is spinning at the desired speed, and the speed is rapidly reduced,

the energy stored in the rotation will generate a voltage greater than the +V

MOTOR

node,

HV POWER STAGE

and destruction of the power transistors, high side driver, ML4423

controller and the power supply may occur.

ML4423

7

Page 8

ML4423

+

330µF

170 – 360V

400V

IRF740IRF740IRF740

IR2118

MUR150

8

VB

CC

V

1

7

HO

IN

2

B

A

SENSE

A

AC MOTOR

FEEDBACK

NETWORK

B

SENSE

C

C

SENSE

IRF740

25V

1µF

22Ω

25V

1µF

22Ω

C21

25V

22Ω

1µF

LIMIT

22Ω

250mΩ R

22Ω

6

VS

COM

3

25V

5

N/C

N/C

4

1.0µF

IR2118

MUR150

8

VB

VCCIN

1

7

HO

2

25V

6

VS

COM

3

1.0µF

5

N/C

N/C

4

IR2118

MUR150

8

VB

VCCIN

1

7

HO

2

25V

6

VS

COM

3

1.0µF

5

N/C

N/C

4

IRF740 IRF740

22Ω

MOTOR

+V

+12V

1

A

SENSE

2

C

SENSE

3

B

SENSE

24

H A

22

H B

23

H C

+

ML4423

1.0µF

2N3904

21

L A

2N3906

19

L B

20

L C

1kΩ

16

SENSE

I

330pF

240kΩ

9

DT

R

25

5V/12V SELECT

+12V

Figure 4. ML4423 Output Stage Using IR2118 High Side Drivers

8

Page 9

ML4423

PHYSICAL DIMENSIONS

28

PIN 1 ID

1

0.180 MAX

(4.57 MAX)

0.125 - 0.135

(3.18 - 3.43)

inches (millimeters)

Package: P28N

28-Pin Narrow PDIP

1.355 - 1.365

(34.42 - 34.67)

0.045 - 0.055

(1.14 - 1.40)

0.015 - 0.021

(0.38 - 0.53)

0.100 BSC

(2.54 BSC)

SEATING PLANE

0.280 - 0.296

(7.11 - 7.52)

0.020 MIN

(0.51 MIN)

0.299 - 0.325

(7.60 - 8.26)

0º - 15º

0.008 - 0.012

(0.20 - 0.31)

0.024 - 0.034

(0.61 - 0.86)

(4 PLACES)

0.090 - 0.094

(2.28 - 2.39)

Package: S28

28-Pin SOIC

0.699 - 0.713

28

PIN 1 ID

1

(17.75 - 18.11)

0.050 BSC

(1.27 BSC)

0.012 - 0.020

(0.30 - 0.51)

0.291 - 0.301

(7.39 - 7.65)

0.095 - 0.107

(2.41 - 2.72)

SEATING PLANE

0.398 - 0.412

(10.11 - 10.47)

0.005 - 0.013

(0.13 - 0.33)

0º - 8º

0.022 - 0.042

(0.56 - 1.07)

0.009 - 0.013

(0.22 - 0.33)

9

Page 10

ML4423

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML4423CP (End Of Life) 0ºC to 70ºC 28-Pin Narrow PDIP (P28N)

ML4423CS (End Of Life) 0ºC to 70ºC 28-Pin SOIC (S28)

ML4423IP (End Of Life) –40ºC to 85ºC 28-Pin Narrow PDIP (P28N)

ML4423IS (End Of Life) –40ºC to 85ºC 28-Pin Narrow PDIP (P28N)

© Micro Linear 2000. is a registered trademark of Micro Linear Corporation. All other trademarks are the property of their

respective owners.

Products described herein may be covered by one or more of the following U.S. patents: 4,897,611; 4,964,026; 5,027,116;

5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940; 5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376;

5,652,479; 5,661,427; 5,663,874; 5,672,959; 5,689,167; 5,714,897; 5,717,798; 5,742,151; 5,747,977; 5,754,012; 5,757,174;

5,767,653; 5,777,514; 5,793,168; 5,798,635; 5,804,950; 5,808,455; 5,811,999; 5,818,207; 5,818,669; 5,825,165; 5,825,223;

5,838,723; 5.844,378; 5,844,941. Japan: 2,598,946; 2,619,299; 2,704,176; 2,821,714. Other patents are pending.

2092 Concourse Drive

San Jose, CA 95131

Tel: (408) 433-5200

DS4423-01

10

Fax: (408) 432-0295

www.microlinear.com

4/21/98 Printed in U.S.A.

Loading...

Loading...