Page 1

Sensorless Spindle Motor Controller

GENERAL DESCRIPTION

The ML4411 provides complete commutation for delta or

wye wound Brushless DC (BLDC) motors without the need

for signals from Hall Effect Sensors. This IC senses the

back EMF of the three motor windings (no neutral

required) to determine the proper commutation phase

angle using Phase Lock Loop techniques. This technique

will commutate virtually any 3-phase BLDC motor and is

insensitive to PWM noise and motor snubbing. The

ML4411 is architecturally similar to the ML4410 but with

improved braking and brown-out recovery circuitry.

Included in the ML4411 is the circuitry necessary for a

Hard Disk Drive microcontroller driven control loop.

The ML4411 controls motor current with either a constant

off-time PWM or linear current control driven by the

microcontroller. Braking and Power Fail are also included

in the ML4411.

The timing of the start-up sequencing is determined by the

micro, allowing the system to be optimized for a wide

range of motors and inertial loads.

May 1997

ML4411*/ML4411A**

The ML4411A includes a comparator on the P3 output to

prevent cross-conduction.

FEATURES

■ Back-EMF commutation provides maximum torque

for minimum “spin-up” time for spindle motors

■ Accurate, jitter-free phase locked motor speed

feedback output

■ Linear or PWM motor current control

■ Easy microcontroller interface for optimized start-up

sequencing and speed control

■ Power fail detect circuit with delayed braking

■ Drives external N-channel FETs and P-channel FETs

■ Back-EMF comparator detects motor rotation after

power fail for fast re-lock after brownout

The ML4411 modulates the gates of external N-Channel

power MOSFETs to regulate the motor current. The IC

drives P-Channel MOSFETs directly.

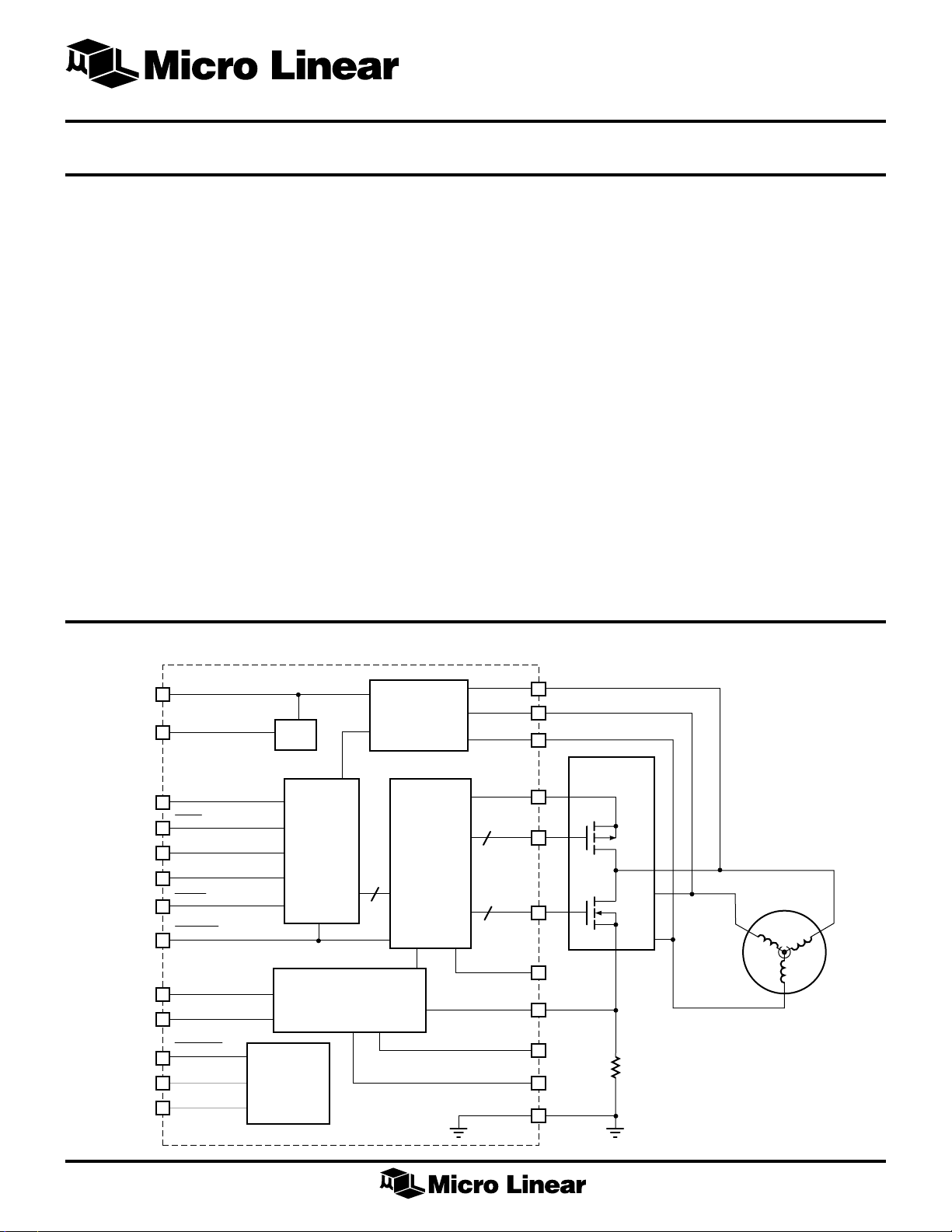

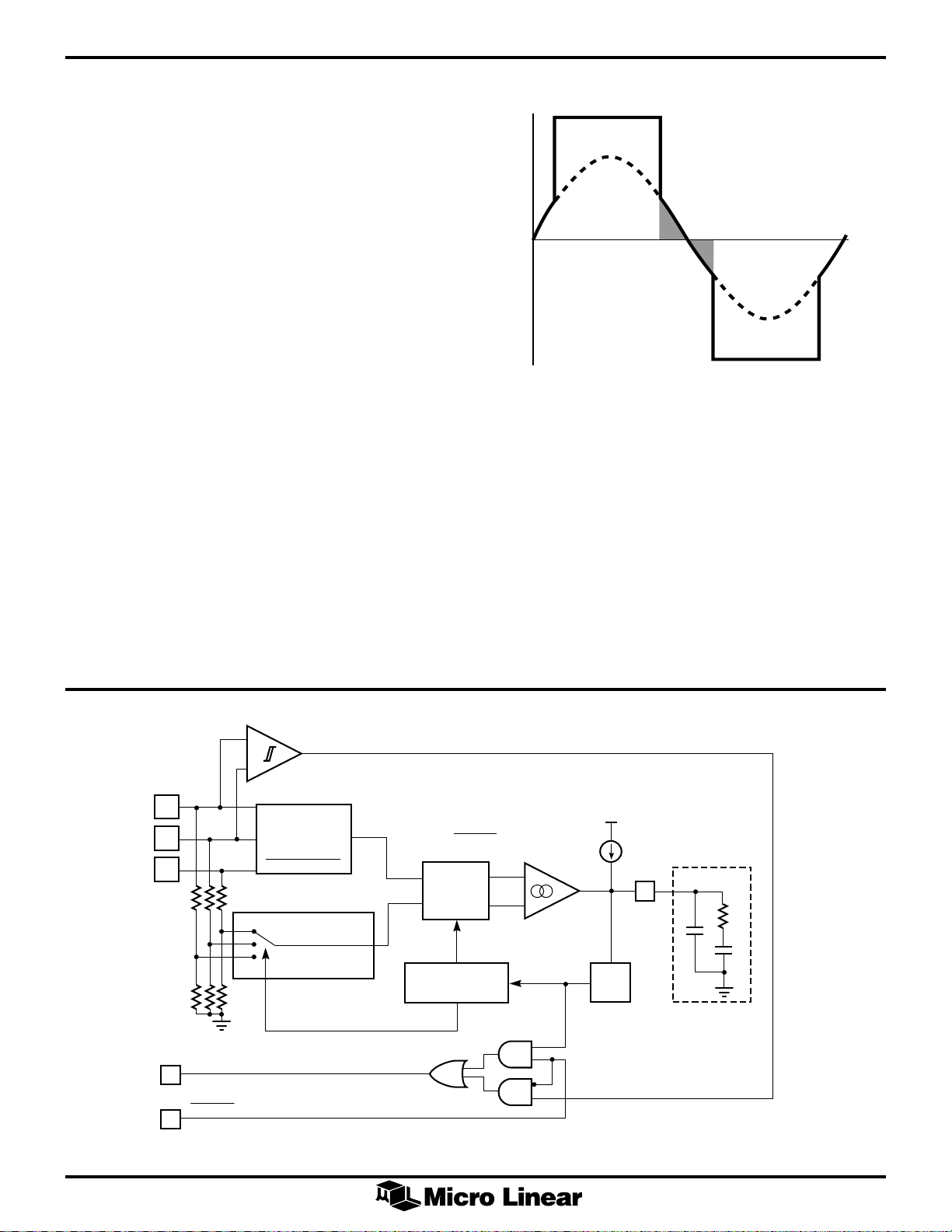

BLOCK DIAGRAM

RC

20

C

VCO

14

VCO/TACH OUT

15

RESET

16

I

RAMP

21

ENABLE E/A

18

BRAKE

26

DIS PWR

8

I

CMD

28

I

LIMIT

27

PWR FAIL

17

+5

19

VCC

25

VCO

LOGIC

AND

CONTROL

LINEAR OR PWM

CURRENT CONTROL

POWER

FAIL

DETECT

BACK-EMF

SAMPLER

GATE

DRIVE

6

* This Product Is Obsolete

** This Product Is End Of Life As Of August 1, 2000

PH1

22

PH2

23

PH3

24

POWER

DRIVERS

BLDC

MOTOR

PATENTED

3

3

VCC2

P1-3

N1-3

C

BRK

I

SENSE

C

C

OTA

GND

4

7

12

OS

13

6

1

1

Page 2

ML4411/ML4411A

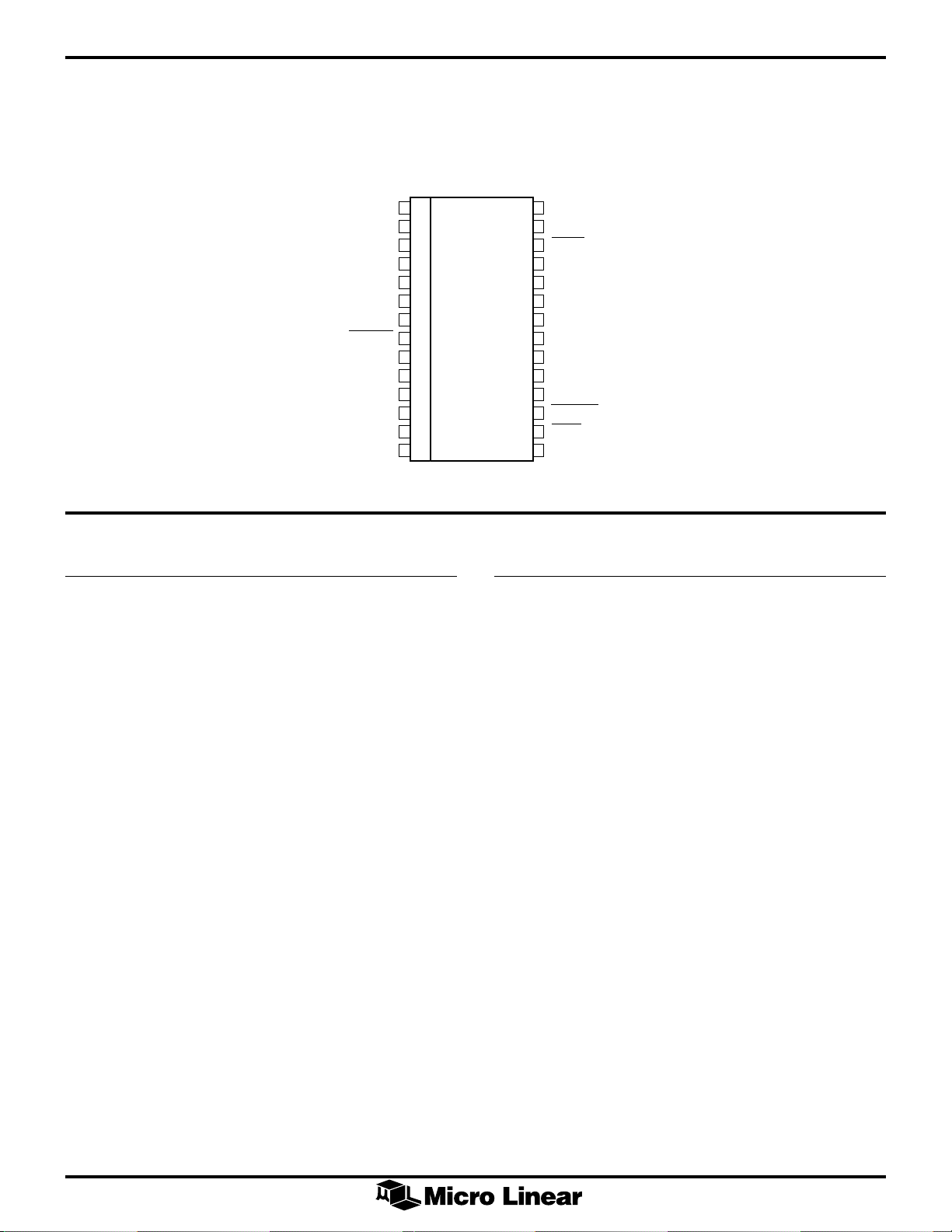

PIN CONFIGURATION

ML4411

28-Pin SOIC (S28W)

GND

VCC2

C

OTA

C

BRK

DIS PWR

N1

N2

N3

I

SENSE

C

C

VCO

1

P1

2

P2

3

4

P3

5

6

7

8

9

10

11

12

13

OS

14

TOP VIEW

I

28

I

27

BRAKE

26

VCC

25

PH3

24

PH2

23

PH1

22

I

21

RC

20

+5V

19

ENABLE E/A

18

PWR FAIL

17

RESET

16

VCO/TACH OUT

15

CMD

LIMIT

RAMP

PIN DESCRIPTION

PIN NAME FUNCTION PIN NAME FUNCTION

1 GND Signal and Power Ground

2 P1 Drives the external P-channel

transistor driving motor PH1

3 P2 Drives the external P-channel

transistor driving motor PH2

4V

CC2

12V power and power for the

braking function

5 P3 Drives the external P-channel

transistor driving motor PH3

6C

OTA

Compensation capacitor for linear

motor current amplifier loop

7C

BRK

Capacitor which stores energy to

charge N-channel MOSFETs for

braking with power off.

8 DIS PWR A logic 0 on this pin turns off the N

and P outputs and causes the TACH

comparator output to appear on TACH

OUT

9-11 N1, N2 N3 Drives the external N-channel

MOSFETs for PH1, PH2, PH3

12 I

13 C

SENSE

OS

Motor current sense input

Timing capacitor for fixed off-time

PWM current control

14 C

VCO

Timing capacitor for VCO

15 VCO/TACH Logic Output from VCO or TACH

OUT comparator

16 RESET Input which holds VCO off and sets the

IC to the RESET condition

17 PWR FAIL A “0” output indicates 5V or 12V is

under-voltage. This is an open

collector output with a 4.5ký pull-up

to +5V

18 ENABLE E/A A ”1” logic input enables the error

amplifier and closes the back-EMF

feedback loop

19 +5V 5V power supply input

20 RC VCO loop filter components

21 I

RAMP

Current into this pin sets the initial

acceleration rate of the VCO during

start-up

22 PH1 Motor Terminal 1

23 PH2 Motor Terminal 2

24 PH3 Motor Terminal 3

25 V

CC

12V power supply. Terminal which is

sensed for power fail

26 BRAKE A ”0” activates the braking circuit

27 I

LIMIT

Sets the threshold for the PWM

comparator

28 I

CMD

Current Command for Linear Current

amplifier

2

Page 3

ML4411/ML4411A

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

Supply Voltage (pins 4, 25) ........................................ 14V

OPERATING CONDITIONS

Temperature Range ........................................0°C to 70°C

VCC Voltage +12V (pin 25) ........................... 12V ± 10%

+5V (pin 19) ................................................ 5V ± 10%

I(RAMP) current (Pin 21)................................. 0 to 100µA

I Control Voltage Range (pins 27, 28) ................ 0V to 7V

Output Current (pins 2, 3, 5, 9,10,11) .................±150mA

Logic Inputs (pins 16, 17, 18, 25) .................... –0.3 to 7V

Junction Temperature ............................................ 150°C

Storage Temperature Range ..................... –65°C to 150°C

Lead Temperature (Soldering 10 sec.) .................... 150°C

Thermal Resistance (qJA) ...................................... 60°C/W

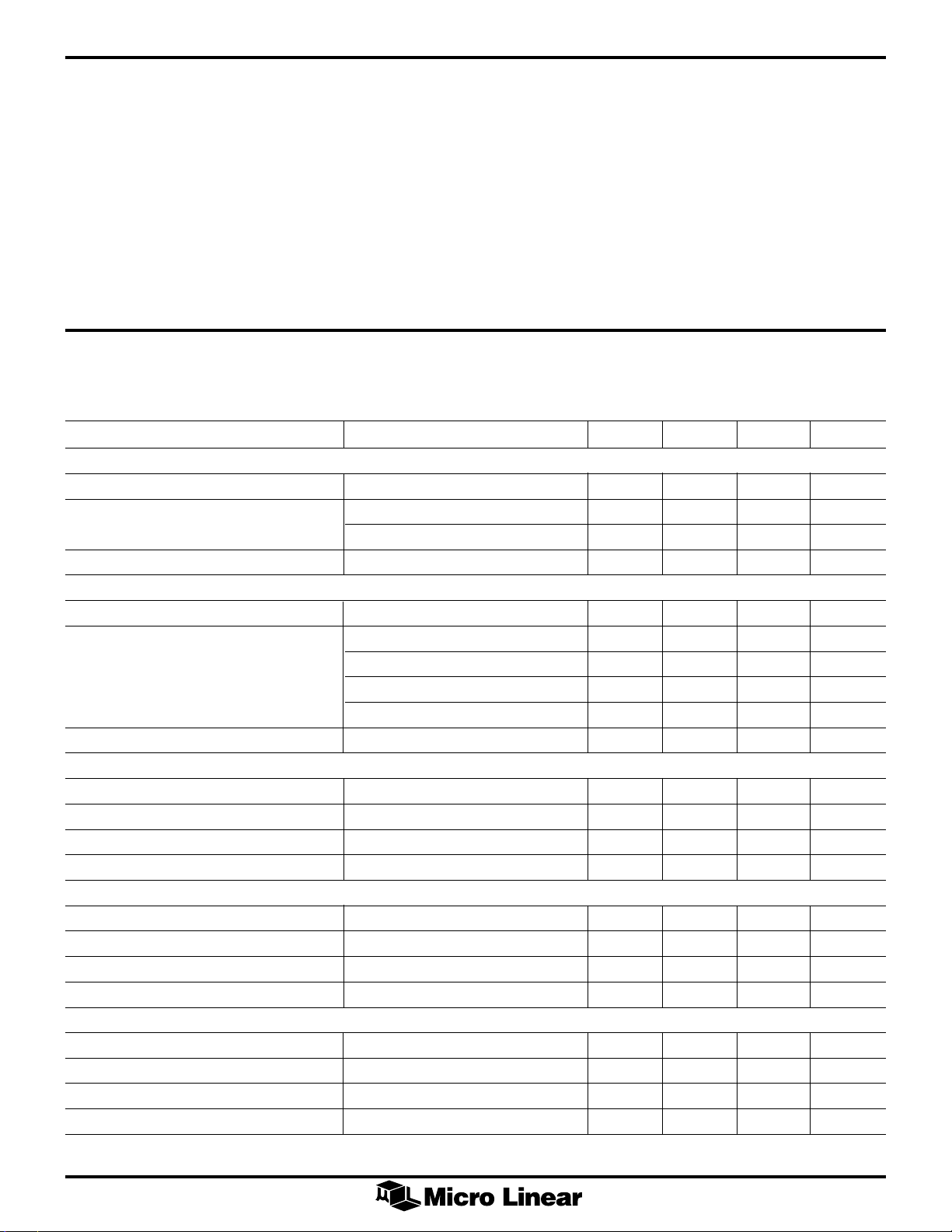

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, TA = Operating Temperature Range, V

C

= 0.02µF

OS

PARAMETER CONDITIONS MIN TYP MAX UNITS

Oscillator (VCO) Section (V

Frequency vs. V

Frequency V

Reset Voltage at C

Sampling Amplifier (Note 1)

V

RC

I

RC

V

PIN21

Motor Current Control Section

I

Gain V

SENSE

One Shot Off Time 12 25 33 µs

I

Transconductance Gain 0.19 mmho

CMD

I

, I

CMD

LIM

Power Fail Detection Circuit

12V Threshold 9.1 9.8 10.5 V

Hysteresis 150 mV

5V Threshold 3.8 4.25 4.5 V

Hysteresis 70 mV

Logic Inputs

Voltage High (VIH)2V

Voltage Low (VIL) 0.8 V

Current High (IIH)V

Current Low (IIL)V

PIN 20

VCO

Bias Current VIN = 0 0 –100 –400 nA

PIN16

= 5V)

1V - V

VCO

V

VCO

Mode = 0 125 250 mV

State R 125 250 mV

V

PIN18

V

PIN18

V

PIN18

V

PIN18

R

PIN21

PIN27

= 2.7V –10 1 10 µA

IN

= 0.4V –500 –350 –200 µA

IN

- 10V 300 Hz/V

PIN20

= 6V 1450 1800 2150 Hz

= 0.5V 70 140 210 Hz

= 0V, R

= 5V, State A, V

= 5V, State A, V

= 5V, State A, V

= 39ký to +5V 1.0 1.1 1.20 V

= 5V, 0V - V

RAMP

PIN28

= V

CC

= 39ký 70 100 130 µA

= 4V 30 50 90 µA

PH2

= 6V –13 2 13 µA

PH2

= 8V –30 –50 –90 µA

PH2

- 2.5V 4.5 5 5.5 V/V

= 12V, R

CC2

SENSE

= 1ý, C

OTA

= C

VCO

= 0.01µF,

3

Page 4

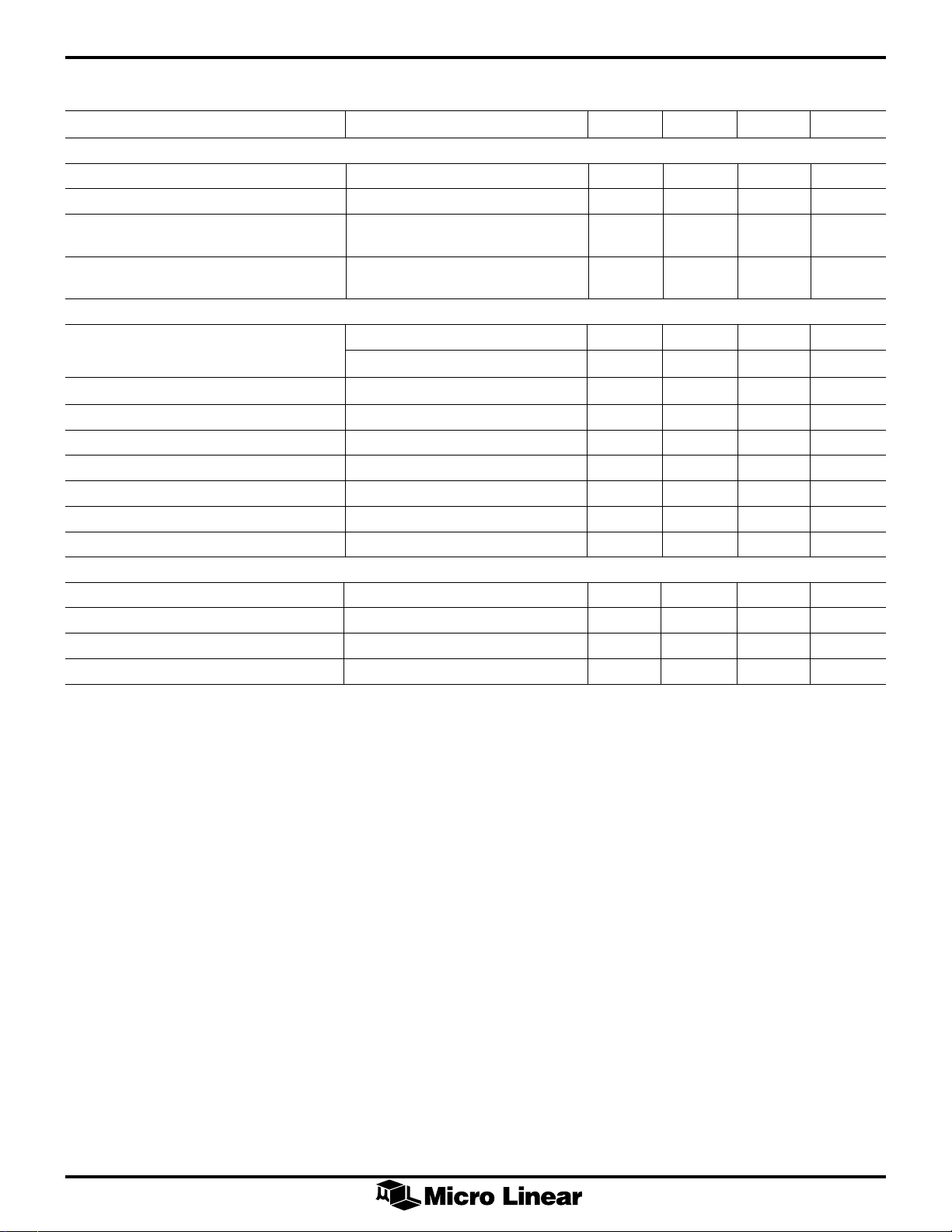

ML4411/ML4411A

ELECTRICAL CHARACTERISTICS (Continued)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Braking Circuit (V

Brake Active Threshold 0.8 1.2 1.6 V

PIN 26 Bias Current V

N-Channel Leakage V

Current VCC, V

C

BRK

Outputs (I

CMD

= I

IP Low VP = 0.8V 5 7 19.5 mA

VP High IP = –10µA VCC – 0.4 V

P3 Comparator Threshold V

VN High V

VN Low IN = 1mA 0.2 0.7 V

LOGIC Low (VOL)I

VCO/TACH V

OH

POWER FAIL V

Supply Currents (N and P Outputs Open)

5V Current 34mA

V

Current 38 50 mA

CC

V

Current ML4411 2 3 mA

CC2

V

Current ML4411A 2.6 3.75 mA

CC2

Note 1. For explanation of states, see Figure 5 and Table 1.

OH

PIN17

LIMIT

= 0V)

= 2.5V)

= 0V 0.3 1 µA

PIN26

, V

CC

V

PIN17

V

PIN7

V

= 0.4V 2 4 mA

P

PIN12

OUT

I

OUT

I

OUT

= 0V 0 0.06 10 nA

CC2

= 0V, VN = 4V

CC2

= 0V, V

= 3V 20 85 µA

PIN26

= 6V

= 0V V

– 1.6 V

CC2

– 3.2 10 VCC – 1.2 V

CC2

– 0.8 V

CC2

= 0.4mA 0.5 V

= –100µA 2.4 V

= –10µA V

PIN19

– 0.2 V

PIN19

– 0.1 V

PIN19

V

4

Page 5

FUNCTIONAL DESCRIPTION

ML4411/ML4411A

The ML4411 provides closed-loop commutation for

3-phase brushless motors. To accomplish this task, a VCO,

integrating Back-EMF Sampling error amplifier and

sequencer form a phase-locked loop, locking the VCO to

the back-EMF of the motor. The IC also contains circuitry

to control motor current with either linear or constant offtime PWM modes. Braking and power fail detection

functions are also provided on chip. The ML4411 is

designed to drive external power transistors (N-channel

sinking transistors and PNP sourcing transistors) directly.

Start-up sequencing and motor speed control are

accomplished by a microcontroller. Speed sensing is

accomplished by monitoring the output of the VCO,

which will be a signal which is phased-locked to the

commutation frequency of the motor.

BACK-EMF SENSING AND COMMUTATOR

The ML4411 contains a patented back-EMF sensing

circuit which samples the phase which is not energized

(Shaded area in figure 2) to determine whether to increase

or decrease the commutator (VCO) frequency. A late

commutation causes the error amplifier to charge the

filter (RC) on pin 20, increasing the VCO input while

early

commutation causes pin 20 discharge. Analog speed

control loops can use pin 20 as a speed feedback voltage.

The input impedance of the three PH inputs is about 8Ký

to GND. When operating with a higher voltage motor, the

PH inputs should be divided down in voltage so that the

maximum voltage at any PH input does not exceed VCC.

NEUTRAL

0 60 120 180 240 0300

Figure 2. Typical motor phase waveform with Back-EMF

superimposed (Ideal Commutation)

VCO AND PHASE DETECTOR CALCULATIONS

The VCO should be set so that at the maximum frequency

of operation (the running speed of the motor) the VCO

control voltage will be no higher than VCC

– 1V. The

MIN

VCO maximum frequency will be:

F POLES RPM

=× ×005.

MAX

where POLES is the number of poles on the motor and

RPM is the maximum motor speed in Revolutions Per

ΦA

ΦB

ΦC

8K

8K

VCO /TACH OUT

DIS PWR

ROTATION

+

SENSE

–

NEUTRAL

SIMULATOR

ΦA + ΦB + ΦC

MULTIPLEXER

Va – Vb

=

I

RC

8K

6

SIGN

CHANGER

COMMUTATION

LOGIC

a

+

b

–

FIGURE 1. BACK EMKF sensing block diagram

+

I(PIN 21)

LOOP FILTER

RC

R

C1

C2

VCO

5

Page 6

Minute.

ML4411/ML4411A

The minimum VCO gain derived from the specification

table (using the minimum Fvco at V

−

×

VCO

6

= 9.5V, then

−

6

K

VCO MIN

()

242 10

=

Assuming that the V

××

95 242 10

C

VCO

..

=

.

C

VCO(MAX)

F

MAX

VCO

= 6V) is:

or

C

=

VCO

3000

2500

2000

1500

1000

FREQUENCY (Hz)

460

POLES RPM

×

F

µ

0.01µF

0.02µF

START-UP SEQUENCING

When the motor is initially at rest, it is generating no

back-EMF. Because a back-EMF signal is required for

closed loop commutation, the motor must be started

“open-loop” until a velocity sufficient to generate some

back-EMF is attained (around 100 RPM). The following

steps are a typical procedure for starting a motor which is

at rest.

Step 1: The IC is held in reset (state R) with full power

applied to the windings (see figure 6). This aligns the rotor

to a position which is 30° (electrical) before the center of

the first commutation state.

Step 2: Reset is released, and a fixed current is input to

pin 21 and appears as a current on pin 20, and will ramp

the VCO input voltage, accelerating the motor at a fixed

rate.

Step 3: When the motor speed reaches about 100 RPM,

the back EMF loop can be closed by pulling pin 18 high.

500

0

024681012

V

(VOLTS)

VCO

Figure 3. VCO Output Frequency vs. V

VCO

(Pin 20)

Figure 4 shows the transfer function of the Phase Lock

Loop with the phase detector formed from the sampled

phase through the Gm amplifier with the loop filtered

formed by R, C1, and C2.

The impedance of the loop filter is

Zs

SAMPLED

PHASE

RC

()

=

Csss

1

1

F

OUT

LEAD

ω

()

+

LAG

K

–4

VCO

VCO

Gm = 1.25 x 10

+

–

(HZ/V)

RC

Z

RC

R

C1

ω

()

+

Figure 4. Back EMF Phase Lock Loop Components

C2

RESET/

ALIGN

P1, P3, N2 ON

VCO FREQUENCY

0

RESET

ENABLE E/A

OPEN-LOOP

(STEPPING)

CLOSED LOOP

Figure 6. Typical Start-up Sequence.

Using this technique, some reverse rotation is possible.

The maximum amount of reverse rotation is 360/N, where

N is the number of poles. For an 8 pole motor, 45° reverse

rotation is possible.

For quick recovery following a momentary power failure,

the following steps can be taken:

PIN PIN PIN I

STEP 16 18 21 I

1 0 0 FIXED I

2 1 0 FIXED I

3110 I

LIMIT

CMD

MAX

MAX

MAX

Where the lead and lag frequencies are set by:

1

=

ω

ω

LEAD

LAG

RC

CC

+

12

=

RC C

2

12

6

Table 2. Start-up Sequence.

Page 7

ML4411/ML4411A

OUTPUTS INPUT

STATE N1 N2 N3 P1 P2 P3 SAMPLING

R OR 0 OFF ON OFF ON OFF ON N/A

A OFF OFF ON ON OFF OFF PH2

B OFF OFF ON OFF ON OFF PH1

C ON OFF OFF OFF ON OFF PH3

D ON OFF OFF OFF OFF ON PH2

E OFF ON OFF OFF OFF ON PH1

F OFF ON OFF ON OFF OFF PH3

Table 1. Commutation States.

RESET

4.3 V

C

VCO

2.3 V

VCO OUT

STATE

R

0A BC D E F A

Figure 5. Commutation Timing and Sequencing.

Step 1a: The IC is held in reset (state R) with I

CMD

low

and DIS PWR low. The Micro Processor monitors the VCO/

TACH OUT pin to determine if a signal is present. If a

signal is present, the frequency is determined (by

measuring the period). If a signal is not present, proceed

to the routine described above for starting a motor which

is a rest.

Step 2a: Release RESET and DIS PWR. Apply a current to

pin 21 and monitor the VCO/TACH OUT pin for VCO

frequency.

Step 3a: When the VCO frequency approaches 6 X the

motor frequency (or where the motor frequency has

decelerated to by coasting during the time the VCO

frequency was ramping up) the back EMF loop can be

closed by pulling pin 18 high and motor current brought

up with I

CMD

or I

LIMIT

.

ADJUSTING OPEN LOOP STEP RATE

I

should be set so that the VCO’s frequency ramp

RAMP

during “open loop stepping” phase of motor starting is less

than the motor’s acceleration rate. In other words, the

motor must be able to keep up with the VCO’s ramp rate

in open loop stepping mode. The VCO’s input voltage

(V

) ramp rate is given by:

PIN 20

dV

VCO RAMP

dt

I

≈

CC

12

+

since

FKV

=×

VCO VCO VCO

−

6

×

K

VCO MAX

()

then combining the 3 equations I

410

=

C

VCO

can be calculated

RAMP

from the desired maximum open loop stepping rate the

motor can follow.

I

RAMP

dF

VCO VCO

<

dt

CCC

()

×+

12

6

−

410

×

7

Page 8

ML4411/ML4411A

The motor will start more consistently and tolerate a wider

variation in open loop step rate if there is some damping

on the motor (such as head drag) during the open loop

modes.

The tolerance of the open loop step VCO acceleration

C2, and C

dF

VCO

depends on the tolerances of K

dt

. For more optimum spin up times, these

VCO

VCO

, I

RAMP

, C1,

variables can be digitally “calibrated” out by the

microprocessor using the following procedure:

1. Reset the IC by holding pin 16 low for at least 5µs.

2. Go into open loop step mode with no current on

the motor and measure the difference between the

first two complete VCO periods with the PWM

signal at 50% duty cycle:

ENABLE E/A = (see below)

I

= 0V

CMD

PWM OUT = 50%

MicroP ML4411

PWM OUT

IN

I(RAMP)

VCO/TACH OUT

Figure 7. Auto-Calibration of Open-Loop Step

Rate.

3. Compute a correction factor to adjust I

RAMP

current

by changing the PWM duty cycle from the

Micro (D.C.)

F DESIRED

()

∆

DC NEW

..( ) %

=×50

VCO

F MEASURED

()

∆

VCO

4. Use new computed duty cycle for open loop

stepping mode and proceed with a normal start-up

sequence.

If this auto calibration is used ENABLE E/A can be tied

permanently high, eliminating a line from the Micro.

Since there is offset associated with the Phase Detector

Error Amp (E/A), more current than is being injected by

I

may be taken out of pin 20 if the offset is positive

RAMP

(into pin 20) if the error amp were enabled during the

open loop stepping mode. In that case, V

would not

VCO

rise and the motor would not step properly. The effect of

E/A offset can also be canceled out by the auto calibration

algorithm described above allowing the E/A to be

permanently enabled.

PWM AND LINEAR CURRENT CONTROL

To facilitate speed control, the ML4411 includes two

current control loops — linear and PWM (figure 9). The

linear control loop senses the motor current on the I

terminal through R

. An internal current sense

SENSE

SENSE

amplifier’s (A2) output modulates the gates of the 3 Nchannel MOSFET’s when OTA OUT is tied to OTA IN, or

can modulate a single MOSFET gate tied to OTA OUT.

When operated in this mode, OTA IN is tied to 12V, and

N1-N3 are saturated switches. This method produces the

lowest current ripple at the expense of an extra MOSFET.

The linear current control modulates the gates of the

external MOSFET drivers. Amplifier A2 is a

transconductance amplifier which amplifies the difference

between I

CMD

and I

. The transconductance gain of

SENSE

A2 is:

ý

−

g

=×

1 875 10

.

m

The current loop is compensated by C

4

which forms a

OTA

pole given by

P

C

OTA

−

4

×

9 375 10

.

=

ω

This time constant should be fast enough so that the

current loop settles in less than 10% of T

highest motor speed to avoid torque ripple to V

VCO

at the

TH

mismatch of the N-Channel MOSFETs.

The I

input pin should be kept below 1V. If I

SENSE

SENSE

goes above 1V, a bias current of about –300µA will flow

out of pin 12 and the N outputs will be inhibited. Bringing

I

below 0.7V removes the bias current to its normal

SENSE

level. For this reason, the noise filter resistor on the I

SENSE

pin (1Ký on Figure 10) should be less than 1.5Ký.

The noise filter time constant should be great enough to

filter the leading edge current spike when the N-FETs turn

on but small enough to avoid excessive phase shift in the

I

signal.

SENSE

OUTPUT DRIVERS

The motor’s source drivers (P1 thru P3) are open-collector

NPN’s with internal 16Ký pull-up resistors. N3is inhibited

until P3 is within 1.4V (typ) of V

on the ML4411A.

CC2

Drivers N1 through N3 are totem-pole outputs capable of

sourcing and sinking 10mA. Switching noise in the

external MOSFETs can be reduced by adding resistance in

series with the gates.

V

sC

OTA

−

4

×

1 875 10

.

A

=

8

Page 9

BRAKING

As shown in figure 9, the braking circuit pulls the N-

Channel MOSFET gates high when BRAKE falls below a

1.4V threshold. After a power failure, C

slowly through R

providing a delay for retract to occur

DLY

is discharged

DLY

before the braking circuit is activated. The N-Channel

buffer (B1) tri-states when the BRAKE pin reaches 2.1V to

ensure that no charge from C

is lost through the pull-

BRK

down transistor in B1. To brake the motor with external

signals, first disable power by pulling pin 8 low, then pull

pin 26 below 1.4V using an open drain (or diode isolated)

output.

The bias current for the Braking circuits comes from

VCC2. When the N-Channel MOSFETs turn on, no

additional power is generated for VCC2 (motor back-EMF

rectified through out the MOSFET body diodes). After

VCC2 drops below 4V, Q2 turns off. Continued braking

relies on the CGS of the N-Channel MOSFETs to sustain

the MOSFET gate enhancement voltage.

ML4411/ML4411A

60

50

40

(µs)

30

OFF

T

20

10

0

0 0.01 0.02 0.03 0.04 0.05

C

OS

Figure 8. I

Output Off-Time vs. COS.

LIMIT

VCC2

16K

POWER FAIL

17 +5

R

C

DLY

DLY

26

8

27

28

12

4.5K

COMM. LOGIC

BRAKE

1.4V

DIS PWR

I

LIMIT

I

CMD

I

SENSE

DIS PWR

+

–

A

= 5

V

A1

VCC2 – 3V

UVLO

VCC2

2.1V

A4

COMMUTATION

UVLO

+

–

+

–

VCC2

+

A5

–

LOGIC

A3

+

–

1K

A6

P3 ONLY

A2

Q

ONE

SHOT

Q2

VCC

VCC2

TRI-

ST.

B1

VIN

C

BRK

P1 . . . P3

Q1

N1 . . . N3

7

R

SENSE

C

OS

13

VCC

C

OTA

6

Figure 9. Current Control, Output Drive and Braking Circuits.

9

Page 10

ML4411/ML4411A

APPLICATIONS

Figure 10 shows a typical application of the ML4411 in a

hard disk drive spindle control. Although the timing

necessary to start the motor in most applications would be

generated by a microcontroller, Fig. 11 shows a simple

“one shot” start-up timing approach.

Speed control can be accomplished either by:

1. Sensing the VCO OUT frequency with a

Microcontroller and adjusting I

via an analog

CMD

output form the Micro (PWM DAC).

2. Using analog circuitry for speed control. (Fig. 12).

1N5819

+12V

10

0.1

Q1

TO VCC

OUTPUT STAGE HINTS

In the circuit in Figure 10, Q1, Q2, and Q3 are IRFR9024

or equivalent. Q4, Q5, and Q6 are IRFR024 or equivalent.

New MOSFET packaging technology such as the Little

Foot series may decrease the PC board space. These

packages, however have much lower thermal inertia and

dissipation capabilities than the larger packages, and care

should be taken not to exceed their rated current and

junction temperature.

Since the output section in a full bridge application

consists of three half-H switches, cross-conduction can

occur. Cross-conduction is the condition where an N-FET

and P-FET in the same phase of the bridge conduct

simultaneously. This could happen under two conditions

(see figure 13):

VCC2

0.110

1K 1K 1K

Q2

Q3

510

510

100pF

0.02

+12

0.01

0.01

0.22

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Q4

GND

P1

P2

VCC2

P3

C

OTA

C

BRK

DIS PWR

N1

N2

N3

I

SENSE

C

OS

C

VCO

I

CMD

I

LIMIT

BRAKE

VCC

PH3

PH2

PH1

I

RAMP

+5V

ENABLE E/A

PWR FAIL

RESET

VCO/TACH OUT

RC

Q5

Q6

510

5K

+5

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1M

+12

+5

I

COMMAND

0.22

+5

510K

0.5

5K

ENABLE ERROR AMP

RESET (FROM MICRO)

POWER FAIL TO MICRO

VCO OUT

DISABLE POWER

10

Figure 10. ML4411 Typical Application

Page 11

ML4411/ML4411A

ML4411

PIN 17

TO ML4411

PIN 20

SYMBOL VALUE

A1 LM358

IC1 74HC14

D1, D2 IN4148

R1 1Mý

R2 1Mý

R3 100Ký

+5V

R1

1/6

D1

C1

IC1

R2

D2

C2

Figure 11. Analog Start-up Circuit

–

A1

+

R3

+12V

R5

R6

C3

R4

–

A1

+

SYMBOL VALUE

R4 100Ký

R5 50Ký

R6 50Ký

C1 3.3µF

C2 3.3µF

C3 0.47µF

1/6

IC1

1/6

IC1

TO ML4411

PIN 16

TO ML4411

PIN 18

TO ML4411

PIN 28

VCC2

1K

P

INHIBIT N3

–

A6

+

ML4411A ONLY

16K

P3

Q2

4

5

Figure 13. Alternate cross-conduction prevention for

ML4411A

In Condition 2 above, the P-Channel MOSFET is pulled up

inside the ML4411 with a 16Ký resistor. If the current

through C(CGp) is greater than VTH Þ 16K when the

N-FET turns on, the P-FET could turn on simultaneously,

causing cross-conduction. Adding R1 as shown in Figure

14 eliminates this. The size of R1 will depend on the fall

time of the phase voltage, and the size of the C(DGp). D1

may be needed for high power applications to limit the

negative current pulled (through C(DGn)) out of the

substrate diode in the ML4411 when P-FET turns off.

VCC2

R1

RG(P)

C(DGp)

C(DGn)

RG(N)

D1

P

N

Figure 14. Causes of Cross-conduction

Figure 12. Analog Speed Control

1. When transitioning from mode 0 to mode A (see table

1) P3 goes from on to off at the same time N3 goes

from off to on. If the P3 turns off slowly and N3 turns

on quickly, cross-conduction may occur. This condition

has been prevented inside the IC on the ML4411A

through the addition of comparator A6 on the P3

output (Figure 9). This comparator may cause an

oscillation when the N3 switches on due to the

capacitive coupling effect described below pulling the

P3 pin below VCC2-1.4V. To avoid this, use the circuit

in Figure 13.

2. When the MOSFET in the same phase switches on gate

current flows due to capacitive coupling of current

through the MOSFET’s drain to gate capacitance. This

could cause the device that was off to be turned on.

Adding a series damping resistor to the N-FET gate (RGn)

will slow the fall time. The damping resistor should be

low enough to:

Avoid turning on the N-Channel gate when the PNP

turns on via the same mechanism outlined in condition

2 above

Not severely increase the switching losses in the N-FET

UNIPOLAR OPERATION

Unipolar mode offers the potential advantage of lower

motor drive cost by only requiring the use of 3 transistors

to drive the motor. The ML4411 will operate in unipolar

mode (Figure 15) provided the following precautions are

taken:

1. The IC supplies should not exceed 12V + 10%.

2. The phase pins on the IC should not exceed the

supply voltage.

11

Page 12

ML4411/ML4411A

10K

10K 10K

+V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

0.01

+V

0.5Ω

1.2K

+12

+5

0.02

0.01

+12

Figure 15. ML4411 Unipolar Drive Application

In unipolar operation, the motor‘s windings must be

allowed to drive freely to:

V

F(MAX)

= V

SUPPLY (MAX)

+ V

EMF (MAX)

Therefore, there can be no diodes to clamp the inductive

energy to V

. This energy must be clamped,

SUPPLY

however, to avoid an over-voltage condition on the

MOSFETs and other components. Typically, a V

CLAMP

voltage is created to provide the clamping voltage. The

inductive energy may either be dissipated (Figure 16) or

alternately efficiently regenerated back to the system

supply (Figure 17).

The circuit in Figure 15 is designed to minimize the

external components necessary, at some compromise to

performance. The 3 resistors from the motor phase

windings to the PH inputs work with the ML4411‘s 8Ký

internal resistance to ground to divide the motor‘s

phase voltage down, providing input signals that do not

exceed 12V.

V

= +24V

12V

BATTERY

CLAMP

C1

0.1

+12V

5V

REG

12V

LDO

10

+12V TO

VCC AND VCC2

+5V

0.1

0.11000

3.3K

+12

2.2

+5

+5

+12

+5

+

–

1M

+5

1M

C

DLY

GND

P1

P2

VCC2

P3

C

OTA

C

BRK

DIS PWR

N1

N2

N3

I

SENSE

C

OS

C

VCO

I

CMD

I

LIMIT

BRAKE

VCC

PH3

PH2

PH1

I

RAMP

+5V

ENABLE E/A

PWR FAIL

RESET

VCO/TACH OUT

RC

28

27

26

25

24

23

22

21

20

19

18

17

16

15

This circuit uses analog speed regulation. The 1Mý

resistor from Pin 20 to the speed regulation op amp

provides the function of injecting current into the VCO

loop filter for the open loop stepping phase of start-up

operation. The “one shot” circuitry to time the reset is

replaced by a diode and RC delay from the rising edge or

the POWERFAIL signal. The error amplifier is left enabled

continuously since at low speeds its current contribution

is negligible. The current injected into the loop filter must

be greater than the leakage current from the phase

detector amplifier for the motor to start reliably.

V

= +24V

CLAMP

50% DUTY

CYCLE

12V

BATTERY

L1

D1

0.1

Figure 17. Non-Dissipative Clamping Technique

10K

5V

REG

12V

LDO

12

Figure 16. Dissipative Clamping Technique

Page 13

ML4411/ML4411A

HIGHER VOLTAGE MOTOR DRIVE

To drive a higher voltage motor, the same precautions

regarding ML4411 voltage limitations as were outlined for

Unipolar drive above should be followed. Figures 14–16

provide several methods of translating the ML4411‘s P

outputs to drive a higher voltage.

+V

Q1

Q3

PML4411

+12V

Figure 18. High Voltage Translation using PNP Power

Transistor

+V

Q2

Q1

Q3

PML4411

+12V

Figure 19. High Voltage Translation using “Composite”

PNP Power Transistor

+V

Q2

Q1

PML4411

Q3

Figure 20. High Voltage Translation with NPN

Darlington

13

Page 14

ML4411/ML4411A

PHYSICAL DIMENSIONS inches (millimeters)

Package: S28

28-Pin SOIC

0.699 - 0.713

28

(17.75 - 18.11)

0.024 - 0.034

(0.61 - 0.86)

(4 PLACES)

0.090 - 0.094

(2.28 - 2.39)

0.291 - 0.301

(7.39 - 7.65)

PIN 1 ID

1

0.050 BSC

(1.27 BSC)

0.012 - 0.020

(0.30 - 0.51)

0.095 - 0.107

(2.41 - 2.72)

SEATING PLANE

0.398 - 0.412

(10.11 - 10.47)

0.005 - 0.013

(0.13 - 0.33)

0º - 8º

0.022 - 0.042

(0.56 - 1.07)

0.009 - 0.013

(0.22 - 0.33)

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML4411CS (Obsolete) 0°C to 70°C 28-Pin Wide SOIC (S28W)

ML4411ACS (End Of Life) 0°C to 70°C 28-Pin Wide SOIC (S28W)

© Micro Linear 1997 is a registered trademark of Micro Linear Corporation

Products described in this document may be covered by one or more of the following patents, U.S.: 4,897,611; 4,964,026; 5,027,116; 5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940;

5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376; Japan: 2598946; 2619299. Other patents are pending.

Micro Linear reserves the right to make changes to any product herein to improve reliability, function or design.

Micro Linear does not assume any liability arising out of the application or use of any product described herein,

neither does it convey any license under its patent right nor the rights of others. The circuits contained in this

data sheet are offered as possible applications only. Micro Linear makes no warranties or representations as to

whether the illustrated circuits infringe any intellectual property rights of others, and will accept no responsibility

or liability for use of any application herein. The customer is urged to consult with appropriate legal counsel

before deciding on a particular application.

14

2092 Concourse Drive

San Jose, CA 95131

Tel: 408/433-5200

Fax: 408/432-0295

DS4411-01

Loading...

Loading...