Page 1

3–1

Motorola Bipolar Power Transistor Device Data

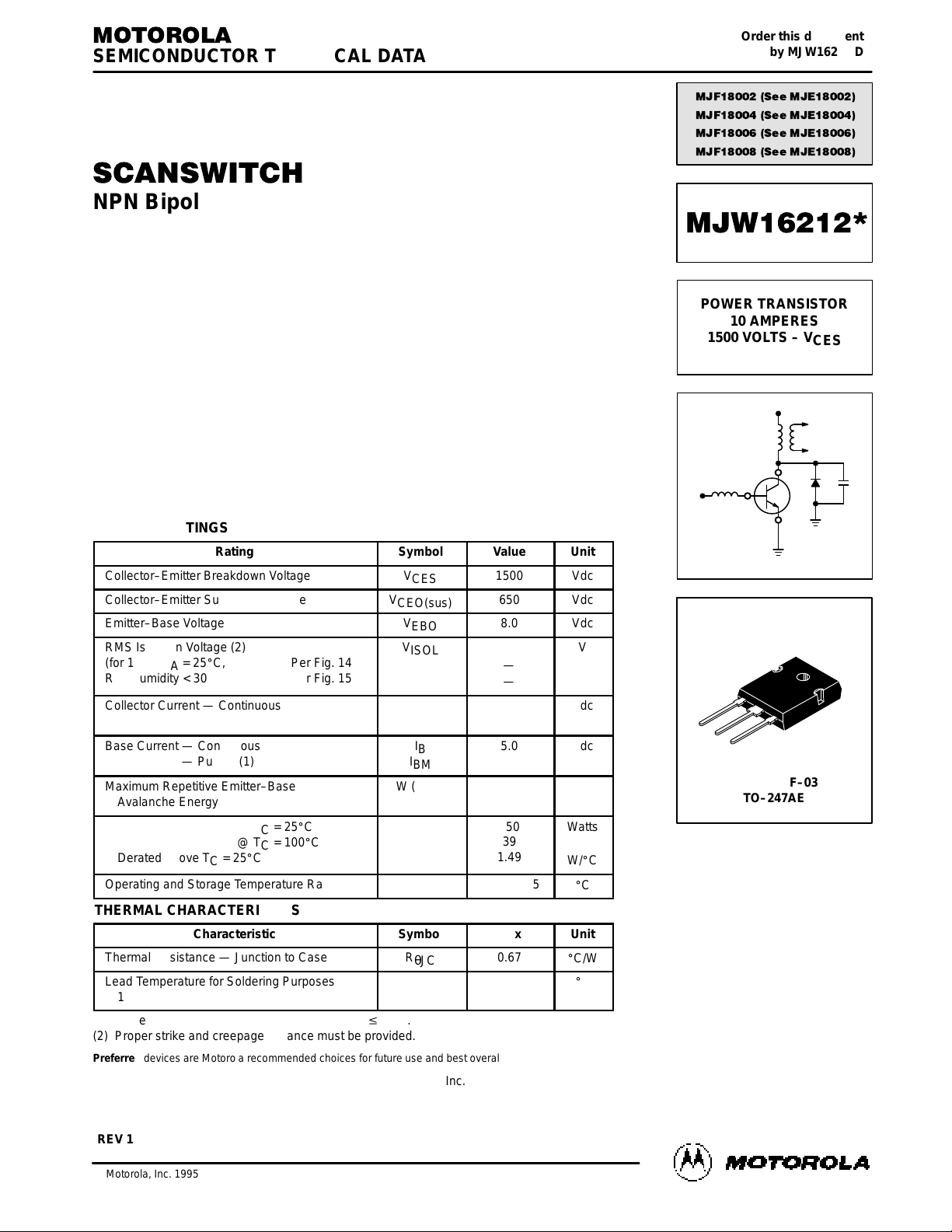

NPN Bipolar Power Deflection Transistor

For High and Very High Resolution Monitors

The MJW16212 is a state–of–the–art SWITCHMODE bipolar power transistor. It

is specifically designed for use in horizontal deflection circuits for 20 mm diameter

neck, high and very high resolution, full page, monochrome monitors.

• 1500 Volt Collector–Emitter Breakdown Capability

• Typical Dynamic Desaturation Specified (New Turn–Off Characteristic)

• Application Specific State–of–the–Art Die Design

• Fast Switching:

200 ns Inductive Fall Time (Typ)

2000 ns Inductive Storage Time (Typ)

• Low Saturation Voltage:

0.15 Volts at 5.5 Amps Collector Current and 2.5 A Base Drive

• Low Collector–Emitter Leakage Current — 250 µA Max at 1500 Volts — V

CES

• High Emitter–Base Breakdown Capability For High Voltage Off Drive Circuits —

8.0 Volts (Min)

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Collector–Emitter Breakdown Voltage

V

CES

1500

Vdc

Collector–Emitter Sustaining Voltage

V

CEO(sus)

650

Vdc

Emitter–Base Voltage

V

EBO

8.0

Vdc

RMS Isolation Voltage (2)

(for 1 sec, TA = 25_C, Per Fig. 14

Rel. Humidity < 30%) Per Fig. 15

V

ISOL

—

—

V

Collector Current — Continuous

Collector Current — Pulsed (1)

I

C

I

CM

10

15

Adc

Base Current — Continuous

Base Current — Pulsed (1)

I

B

I

BM

5.0

10

Adc

Maximum Repetitive Emitter–Base

Avalanche Energy

W (BER)

0.2

mJ

Total Power Dissipation @ TC = 25_C

Total Power Dissipation @ TC = 100_C

Derated above TC = 25_C

P

D

150

39

1.49

Watts

W/_C

Operating and Storage Temperature Range

TJ, T

stg

–55 to 125

_

C

THERMAL CHARACTERISTICS

Characteristic

Symbol

Max

Unit

Thermal Resistance — Junction to Case

R

θJC

0.67

_

C/W

Lead Temperature for Soldering Purposes

1/8″ from the case for 5 seconds

T

L

275

_

C

(1) Pulse Test: Pulse Width = 5.0 ms, Duty Cycle v 10%.

(2) Proper strike and creepage distance must be provided.

Preferred devices are Motorola recommended choices for future use and best overall value.

SCANSWITCH and SWITCHMODE are trademarks of Motorola Inc.

SEMICONDUCTOR TECHNICAL DATA

Order this document

by MJW16212/D

Motorola, Inc. 1995

POWER TRANSISTOR

10 AMPERES

1500 VOLTS – V

CES

50 AND 150 WATTS

*Motorola Preferred Device

CASE 340F–03

TO–247AE

REV 1

Page 2

MJW16212

3–2

Motorola Bipolar Power Transistor Device Data

ELECTRICAL CHARACTERISTICS (T

C

= 25_C unless otherwise noted)

Characteristic

Symbol

Min

Typ

Max

ÎÎÎ

ÎÎÎ

ÎÎÎ

Unit

OFF CHARACTERISTICS (2)

Collector Cutoff Current (VCE = 1500 V, VBE = 0 V)

Collector Cutoff Current (VCE = 1200 V, VBE = 0 V)

I

CES

—

—

—

—

250

25

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

µAdc

Emitter–Base Leakage (VEB = 8.0 Vdc, IC = 0)

I

EBO

—

—

25

ÎÎÎ

ÎÎÎ

ÎÎÎ

µAdc

Emitter–Base Breakdown Voltage (IE = 1.0 mA, IC = 0)

V

(BR)EBO

8.0

11

—

ÎÎÎ

ÎÎÎ

ÎÎÎ

Vdc

Collector–Emitter Sustaining Voltage (Table 1) (IC = 10 mAdc, IB = 0)

V

CEO(sus)

650

—

—

ÎÎÎ

ÎÎÎ

ÎÎÎ

Vdc

ON CHARACTERISTICS (2)

Collector–Emitter Saturation Voltage (IC = 5.5 Adc, IB = 2.2 Adc)

Collector–Emitter Saturation Voltage (IC = 3.0 Adc, IB = 400 mAdc)

V

CE(sat)

—

—

0.15

0.14

1.0

1.0

ÎÎÎ

ÎÎÎ

ÎÎÎ

Vdc

Base–Emitter Saturation Voltage (IC = 5.5 Adc, IB = 2.2 Adc)

V

BE(sat)

—

0.9

1.5

ÎÎÎ

ÎÎÎ

ÎÎÎ

Vdc

DC Current Gain (IC = 1.0 A, VCE = 5.0 Vdc)

DC Current Gain (IC = 10 A, VCE = 5.0 Vdc)

h

FE

—

4.0

24

6.0

—

10

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

—

DYNAMIC CHARACTERISTICS

Dynamic Desaturation Interval (IC = 5.5 A, IB1 = 2.2 A, LB = 1.5 µH)

t

ds

—

350

—

ÎÎÎ

ÎÎÎ

ÎÎÎ

ns

Output Capacitance

(VCE = 10 Vdc, IE = 0, f

test

= 100 kHz)

C

ob

—

180

350

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

pF

Gain Bandwidth Product

(VCE = 10 Vdc, IC = 0.5 A, f

test

= 1.0 MHz)

f

T

—

2.75

—

ÎÎÎ

ÎÎÎ

ÎÎÎ

MHz

Emitter–Base Turn–Off Energy

(EB

(avalanche)

= 500 ns, RBE = 22 Ω)

EB

(off)

—

35

—

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

µJ

Collector–Heatsink Capacitance — MJF16212 Isolated Package

(Mounted on a 1″ x 2″ x 1/16″ Copper Heatsink, VCE = 0, f

test

= 100 kHz)

C

c–hs

—

5.0

—

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

pF

SWITCHING CHARACTERISTICS

Inductive Load (IC = 5.5 A, IB = 2.2 A), High Resolution Deflection

Simulator Circuit Table 2

Storage

Fall Time

t

sv

t

fi

—

—

2000

200

4000

350

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ns

(2) Pulse Test: Pulse Width = 300 µs, Duty Cycle v 2.0%.

I

C

, COLLECTOR CURRENT (A)

VCE, COLLECTOR–EMITTER VOLTAGE (V)

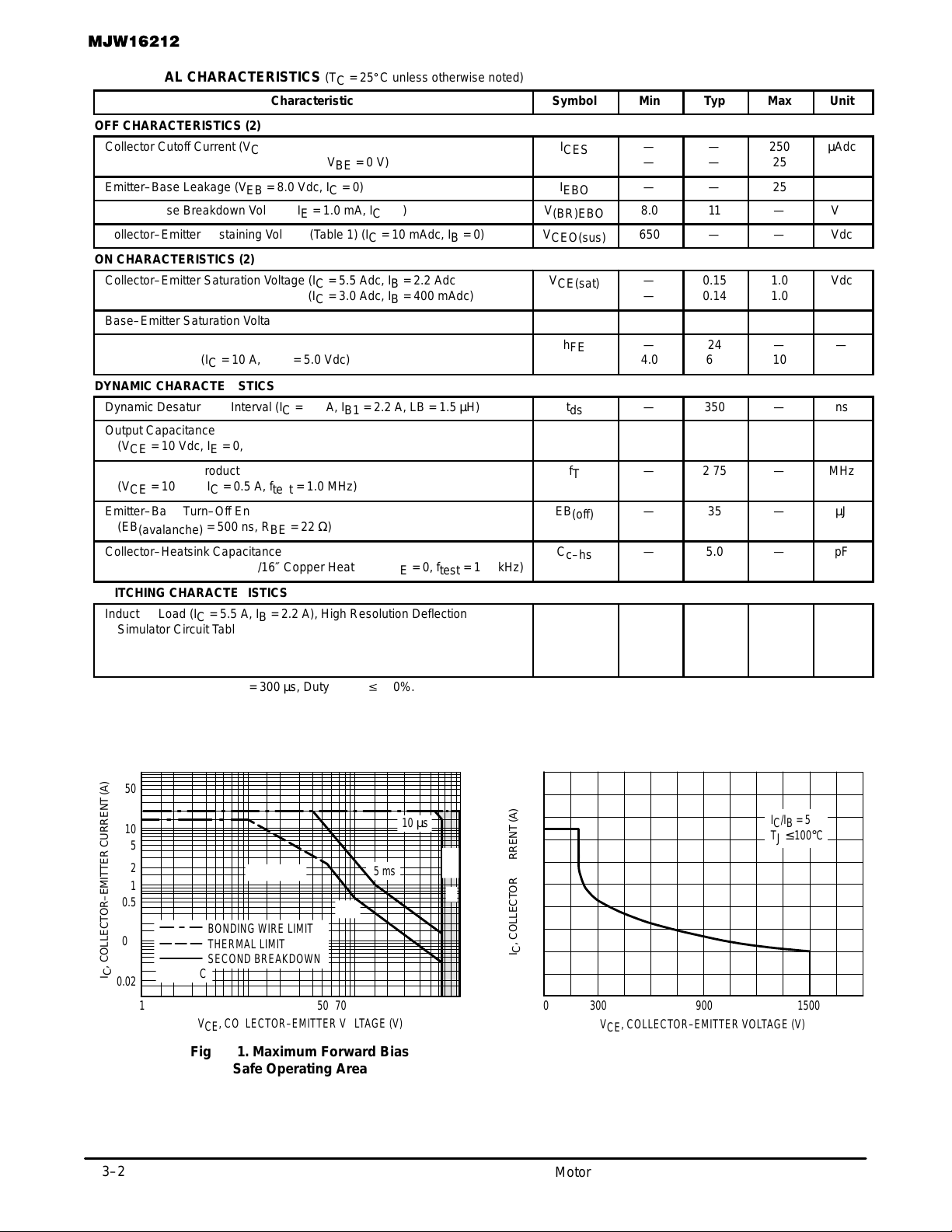

Figure 1. Maximum Forward Bias

Safe Operating Area

50

1

10

1

0.02

70

BONDING WIRE LIMIT

THERMAL LIMIT

SECOND BREAKDOWN

I

C

, COLLECTOR–EMITTER CURRENT (A)

0.1

7 20 1K

20

0.2

DC

TJ = 25°C

5 ms

10 µs

2

5

0.5

50 300 1500

IC/IB = 5

TJ

≤

100°C

0

VCE, COLLECTOR–EMITTER VOLTAGE (V)

900

Figure 2. Maximum Reverse Bias

Safe Operating Area

10

18

6

2

600 1200

100

0.05

0.01

1003 10 20030

MJH16212

14

2 300 5005 700

100

ns

II

SAFE OPERATING AREA

Page 3

MJW16212

3–3

Motorola Bipolar Power Transistor Device Data

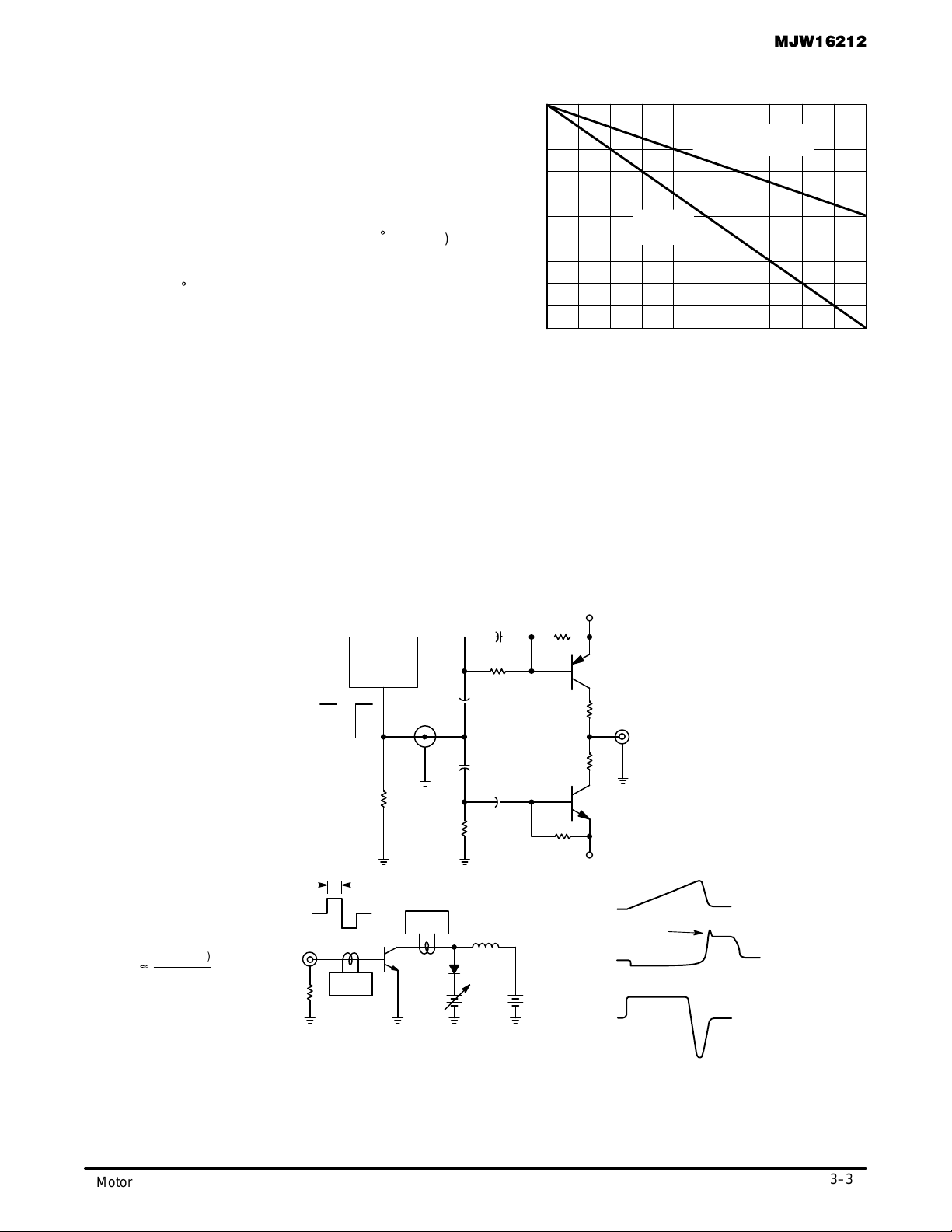

SAFE OPERATING AREA (continued)

FORWARD BIAS

There are two limitations on the power handling ability of a

transistor: average junction temperature and second breakdown. Safe operating area curves indicate IC – VCE limits of

the transistor that must be observed for reliable operation;

i.e., the transistor must not be subjected to greater dissipation than the curves indicate.

The data of Figure 1 is based on TC = 25_C; T

J(pk)

is

variable depending on power level. Second breakdown pulse

limits are valid for duty cycles to 10% but must be derated

when TC ≥ 25_C. Second breakdown limitations do not derate the same as thermal limitations. Allowable current at the

voltages shown on Figure 1 may be found at any case temperature by using the appropriate curve on Figure 3.

At high case temperatures, thermal limitations will reduce

the power that can be handled to values less than the limitations imposed by second breakdown.

Figure 3. Power Derating

25

TC, CASE TEMPERATURE (

°

C)

0

45 85 125

0.6

POWER DERATING FACTOR

SECOND BREAKDOWN

DERATING

1

0.8

0.4

0.2

65

THERMAL

DERATING

105

REVERSE BIAS

For inductive loads, high voltage and high current must be

sustained simultaneously during turn–off, in most cases, with

the base–to–emitter junction reverse biased. Under these

conditions the collector voltage must be held to a safe level

at or below a specific value of collector current. This can be

accomplished by several means such as active clamping,

RC snubbing, load line shaping, etc.

The safe level for these devices is specified as Reverse

Biased Safe Operating Area and represents the voltage–

current condition allowable during reverse biased turnoff.

This rating is verified under clamped conditions so that the

device is never subjected to an avalanche mode. Figure 2

gives the RBSOA characteristics.

H.P. 214

OR EQUIV.

P.G.

0

≈

–35 V

50

500

1

µ

F

100

–V

2N5337

2N6191

+V

≈

11 V

100

0.02

µ

F

20

10 µF

0.02

µ

F

+ –

R

B1

R

B2

A

A

50

T

1

+V

0 V

–V

*I

B

*I

C

T.U.T.

L

MR856

V

clamp

V

CC

I

C

V

CE

I

B

I

B1

I

B2

I

C(pk)

V

CE(pk)

T1[

L

coil(ICpk

)

V

CC

Note: Adjust –V to obtain desired V

BE(off)

at Point A.

T1 adjusted to obtain I

C(pk)

V

(BR)CEO

L = 10 mH

RB2 = ∞

VCC = 20 Volts

RBSOA

L = 200 µH

RB2 = 0

VCC = 20 Volts

RB1 selected for desired I

B1

*Tektronix

*P–6042 or

*Equivalent

+

–

Table 1. RBSOA/V

(BR)CEO(SUS)

Test Circuit

Page 4

MJW16212

3–4

Motorola Bipolar Power Transistor Device Data

C, CAPACITANCE (pF)

f , TRANSITION FREQUENCY

τ

V

BE

, BASE–EMITTER VOLTAGE (V)

V

CE

, COLLECTOR–EMITTER VOLTAGE (V) V

CE

, COLLECTOR–EMITTER VOLTAGE (V)

Figure 4. Typical Collector–Emitter

Saturation Region

IB, BASE CURRENT (A)

0.7

0.1

.03

0.3

0.3

10 A

.05 1 2

4 5.5IC = 2

0.03

0.1 0.2 0.5

0.02

5

10

Figure 5. Typical Emitter–Base

Saturation Voltage

0.30.2 0.5

5

0.7

0.1

0.70.1 1 10

10

2

TJ = 25°C

2 3 5 7

IC, COLLECTOR CURRENT (A)

IC/IB = 5

TJ = 100

°

C

0.3

0.5

0.07

0.2

0.05

0.01

3

7

2

1

3

7

1

0.2

3

0.5

IC, COLLECTOR CURRENT (A)

Figure 6. Typical Collector–Emitter

Saturation Voltage

0.5

3

0.2

5

10

1

0.1

7

0.3

2

0.7

0.5 32 50.7 1

0.1 0.2 0.3

7

IC, COLLECTOR CURRENT (A)

Figure 7. Typical Transition Frequency

VCE = 10 V

f

(test)

= 1 MHz

TC = 25°C

0 1 2 3 4 65

5

2

0

4

3

1

Figure 8. Typical Capacitance

10000

VR, REVERSE VOLTAGE (V)

C

ib

1

500

20

1

7 50 300

1000

50

2

2000

100

5000

200

10

3 10 100

705 30 200 1000

5

2 20 500

f

test

= 1 MHz

8

.02

.01 5 7

10

= 25°C

IC/IB = 10

TJ = 100

°

C

= 25°C

IC/IB = 5

TJ = 100

°

C

= 25°C

IC/IB = 10

TJ = 100

°

C

= 25°C

10

C

ob

Page 5

MJW16212

3–5

Motorola Bipolar Power Transistor Device Data

DYNAMIC DESATURATIION

The SCANSWITCH series of bipolar power transistors are

specifically designed to meet the unique requirements of horizontal deflection circuits in computer monitor applications.

Historically, deflection transistor design was focused on minimizing collector current fall time. While fall time is a valid

figure of merit, a more important indicator of circuit performance as scan rates are increased is a new characteristic,

“dynamic desaturation.” In order to assure a linear collector

current ramp, the output transistor must remain in hard saturation during storage time and exhibit a rapid turn–off transition. A sluggish transition results in serious consequences.

As the saturation voltage of the output transistor increases,

the voltage across the yoke drops. Roll off in the collector

current ramp results in improper beam deflection and distortion of the image at the right edge of the screen. Design

changes have been made in the structure of the SCANSWITCH series of devices which minimize the dynamic desaturation interval. Dynamic desaturation has been defined in

terms of the time required for the VCE to rise from 1.0 to

5.0 volts (Figures 9 and 10) and typical performance at optimized drive conditions has been specified. Optimization of

device structure results in a linear collector current ramp, excellent turn–off switching performance, and significantly lower overall power dissipation.

U2

MC7812

V

I

V

O

G

N

D

+

+

+

+

+24 V

C1

100

µ

F

C2

10

µ

F

C3

10

µ

F

R7

2.7 k

R8

9.1 k

R9

470

R10

47

C5

0.1

C4

0.005

R2

R510R3250

R6

1 k

R12

470

1 W

D1

MUR110

T1

LB

R4

22

Q4

DUT

V

CE

CY

LY

C6

100

µ

F

R5

1 k

(IC)

(IB)

Q5

MJ11016

Q2

MJ11016

Q3

MJE

15031

R11

470

1 W

100 V

D2

MUR460

U1

MC1391P

%

OSC V

CC

OUT

GND

7 6

8 1

2

(DC)

BS170

Q1

SYNC

Table 2. High Resolution Deflection Application Simulator

R1

1 k

6.2 V

T1:Ferroxcube Pot Core #1811 P3C8 LB = 1.5 µH

Primary/Sec. Turns Ratio = 18:6 CY = 0.01 µF

Gapped for LP = 30 µH LY = 13 µH

V

CE

, COLLECTOR–EMITTER VOLTAGE (V)

I

B

, BASE CURRENT (A)

Figure 9. Deflection Simulator Circuit Base

Drive Waveform

TIME (2 µs/DIV)

IB1 = 1.3 A

Figure 10. Definition of Dynamic

Desaturation Measurement

TIME (ns)

t

ds

DYNAMIC DESATURATION TIME

IS MEASURED FROM VCE = 1 V

TO VCE = 5 V

1

4

5

0

3

2

0 6 84

2 10

IB2 = 4.9 A

Page 6

MJW16212

3–6

Motorola Bipolar Power Transistor Device Data

IC, COLLECTOR CURRENT (A)

Figure 11. Typical Resistive Storage Time

t

s

, RESISTIVE STORAGE TIME ( s)

15

5

2

3

7

1 2 753

IC, COLLECTOR CURRENT (A)

Figure 12. Typical Resistive Fall Time

t

f

, RESISTIVE FALL TIME ( s)

700

100

300

1500

2 3 5 71 10

200

500

β

f

= 5

TJ = 25

°

C

µ

µ

IB2 = I

B1

IB2 = 2 (IB1)

β

f

= 5

TJ = 25

°

C

IB2 = I

B1

IB2 = 2 (IB1)

10

1000

1

10 15 15

ts and t

f

+15

150

Ω

100

Ω

100 µF

MTP8P10

MPF930

MPF930

MUR105

MJE210

150

Ω

500 µF

V

off

50

Ω

+10 V

MTP12N10

MTP8P10

R

B1

R

B2

A

1

µ

F

1

µ

F

T.U.T.

*I

C

*I

B

A

R

L

V

CC

V

(off)

adjusted

to give specified

off drive

V

CC

250 V

R

L

28 Ω

I

C

5.5 A

I

B1

1.1 A

I

B2

Per Spec

R

B1

3.3 Ω

R

B2

Per Spec

Table 3. Resistive Load Switching

t, TIME (ms)

0.01

1 100.1

1

0.2

0.1

0.05

r(t), TRANSIENT THERMAL

R

θ

JC

(t) = r(t) R

θ

JC

R

θ

JC

= 0.7

°

C/W MAX

D CURVES APPLY FOR POWER

PULSE TRAIN SHOWN

READ TIME AT t

1

T

J(pk)

– TC = P

(pk)

R

θ

JC

(t)

P

(pk)

t

1

t

2

DUTY CYCLE, D = t1/t

2

SINGLE PULSE

RESISTANCE (NORMALIZED)

Figure 13. Thermal Response

0.5

D = 0.5

100 1000 10000

0.2

0.1

Page 7

MJW16212

3–7

Motorola Bipolar Power Transistor Device Data

EMITTER–BASE TURN–OFF ENERGY, EB

(off)

Emitter–base turn–off energy is a n ew specification

included o n the S CANSWITCH d ata s heets. Typical

techniques for driving horizontal outputs rely on a pulse

transformer to supply forward base current, and a turnoff network that includes a series base inductor to limit the rate of

transition from forward to reverse. An alternate drive scheme

has been used to characterize the SCANSWITCH series of

devices (see Figure 2). This circuit ramps the base drive to

eliminate the heavy overdrive at the beginning of the collector current ramp and underdrive just prior to turn–off observed in typical drive topologies. This high performance

drive has two additional important advantages. First, the configuration of T1 allows Lb to be placed outside the path of forward base current making it unnecessary to expend energy

to reverse the current flow as in a series based inductor. Second, there is no base resistor to limit forward base current

and hence no power loss associated with setting the value of

the forward base current. The ramp generating process

stores rather than dissipates energy. Tailoring the amount of

energy stored in T1 to the amount of energy, EB

(off)

, that is

required to turn the output transistor off results in essentially

lossless operation. [Note: B+ and the primary inductance of

T1 (LP) are chosen such that 1/2LPl

b

2

= EB

(off)

.]

Figure 14. Screw or Clip Mounting Position

for Isolation Test Number 1

*Measurement made between leads and heatsink with all leads shorted together

LEADS

HEATSINK

0.099” MIN

Figure 15. Screw or Clip Mounting Position

for Isolation Test Number 2

MOUNTED

FULLY ISOLATED

PACKAGE

LEADS

HEATSINK

MOUNTED

FULLY ISOLATED

PACKAGE

0.110” MIN

TEST CONDITIONS FOR ISOLATION TESTS* (MJF16212 ONLY)

4–40 SCREW

PLAIN WASHER

HEATSINK

COMPRESSION WASHER

NUT

CLIP

HEATSINK

Laboratory tests on a limited number of samples indicate, when using the screw and compression washer mounting technique, a screw

torque of 6 to 8 in.lbs is sufficient to provide maximum power dissipation capability . The compression washer helps to maintain a constant pressure on the package over time and during large temperature excursions.

Destructive laboratory tests show that using a hex head 4-40 screw, without washers, and applying a torque in excess of 20 in.lbs will

cause the plastic to crack around the mounting hole, resulting in a loss of isolation capability.

Additional tests on slotted 4-40 screws indicate that the screw slot fails between 15 to 20 in.lbs without adversely affecting the package. However, in order to positively ensure the package integrity of the fully isolated device, Motorola does not recommend exceeding 10

in.lbs of mounting torque under any mounting conditions.

Figure 16. Typical Mounting Techniques*

Figure 16a. Screw–Mounted Figure 16b. Clip–Mounted

MOUNTING INFORMATION** (MJF16212 ONLY)

**For more information about mounting power semiconductors see Application Note AN1040.

Page 8

MJW16212

3–8

Motorola Bipolar Power Transistor Device Data

PACKAGE DIMENSIONS

CASE 340F–03

TO–247AE

ISSUE E

DIMAMIN MAX MIN MAX

INCHES

20.40 20.90 0.803 0.823

MILLIMETERS

B 15.44 15.95 0.608 0.628

C 4.70 5.21 0.185 0.205

D 1.09 1.30 0.043 0.051

E 1.50 1.63 0.059 0.064

F 1.80 2.18 0.071 0.086

G 5.45 BSC 0.215 BSC

H 2.56 2.87 0.101 0.113

J 0.48 0.68 0.019 0.027

K 15.57 16.08 0.613 0.633

L 7.26 7.50 0.286 0.295

P 3.10 3.38 0.122 0.133

Q 3.50 3.70 0.138 0.145

R 3.30 3.80 0.130 0.150

U 5.30 BSC 0.209 BSC

V 3.05 3.40 0.120 0.134

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

STYLE 3:

PIN 1. BASE

2. COLLECTOR

3. EMITTER

4. COLLECTOR

R

P

A

K

V

F

D

G

U

L

E

0.25 (0.010)MT B

M

0.25 (0.010)MY Q

S

J

H

C

4

1 2 3

–T–

–B–

–Y–

–Q–

How to reach us:

USA /EUROPE: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, Toshikatsu Otsuki,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 6F Seibu–Butsuryu–Center, 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–3521–8315

MFAX: RMFAX0@email.sps.mot.com – TOUCHTONE (602) 244–6609 HONG KONG: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit,

and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters can and do vary in different

applications. All operating parameters, including “T ypicals” must be validated for each customer application by customer’s technical experts. Motorola does

not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of

the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such

unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

MJW16212/D

*MJW16212/D*

◊

Loading...

Loading...