Page 1

MIC79050 Micrel

4.2V ±0.75%

Li-Ion

Cell

IN BAT

FB

GND

EN

MIC79050-4.2BMM

External PWM*

*See Applications Information

Regulated or

unregulated

wall adapter

MIC79050

Simple Lithium-Ion Battery Charger

Preliminary Information

General Description

The MIC79050 is a simple single-cell lithium-ion battery

charger. It includes an on-chip pass transistor for high precision charging. Featuring ultrahigh precision (+0.75% over the

Li-ion battery charging temperature range) and “zero” off

mode current, the MIC79050 provides a very simple, cost

effective solution for charging lithium-ion battery.

Other features of the MIC79050 include current limit and

thermal shutdown protection. In the event the input voltage to

the charger is disconnected, the MIC79050 also provides

minimal reverse-current and reversed-battery protection.

The MIC79050 is a fixed 4.2V device and comes in the

thermally-enhanced MSO-8, SO-8, and SOT-223 packages.

The 8-pin versions also come equipped with enable and

feedback inputs. All versions are specified over the temperature range of –40°C to +125°C.

Ordering Information

Part Number Voltage Junct. Temp. Range Package

MIC79050-4.2BS 4.2V –40°C to +125°C SOT-223

MIC79050-4.2BM 4.2V –40°C to +125°C SOP-8

MIC79050-4.2BMM 4.2V –40°C to +125°C MSOP-8

Features

• High accuracy charge voltage:

±0.75% over -5°C to + 60°C (Li-ion charging

temperature range)

• “Zero” off-mode current

•10µA reverse leakage

• Ultralow 380mV dropout at 500mA

• Wide input voltage range

• Logic controlled enable input (8-pin devices only)

• Thermal shutdown and current limit protection

• Power MSOP-8, Power SOP-8, and SOT-223

• Pulse charging capability

Applications

• Li-ion battery charger

• Celluar phones

• Palmtop computers

• PDAs

• Self charging battery packs

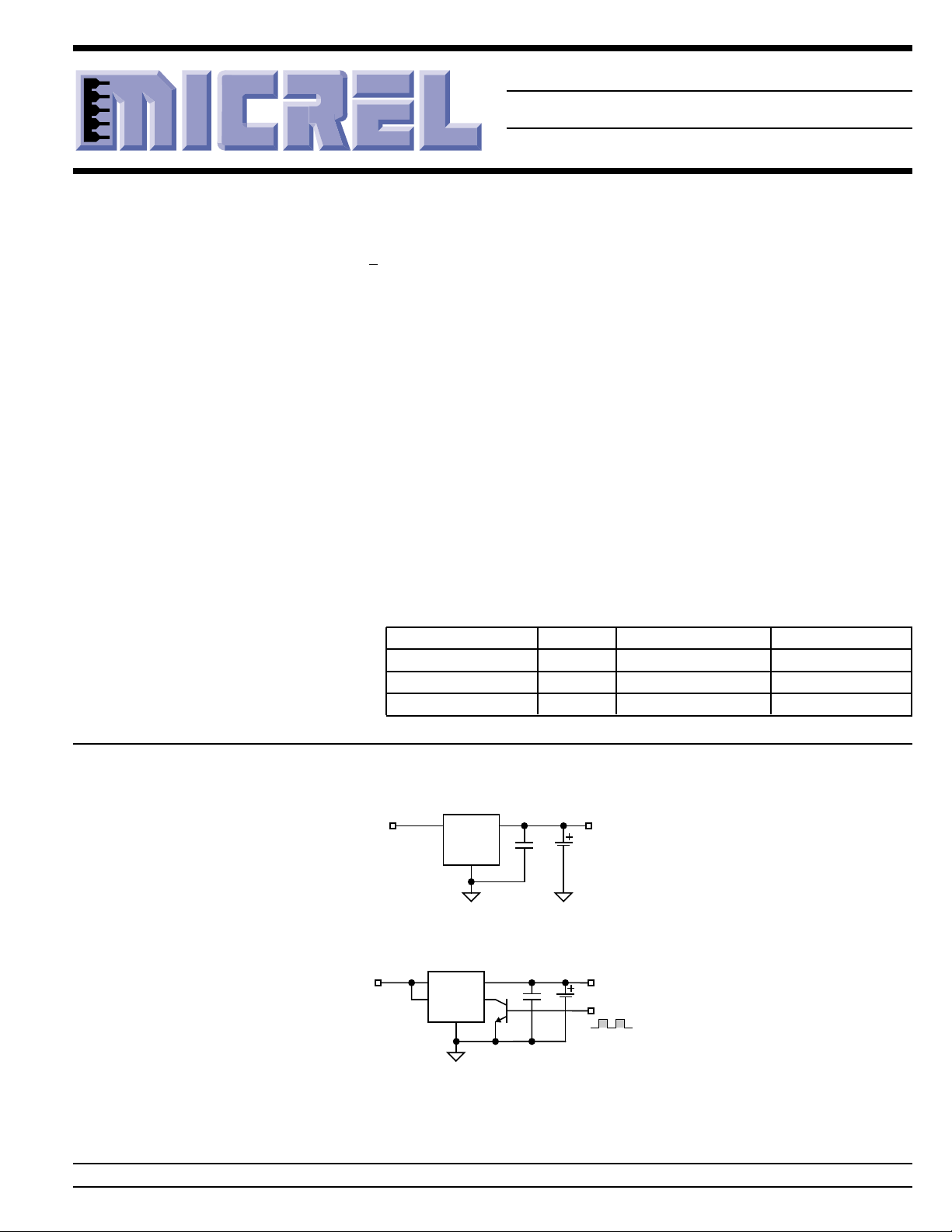

Typical Applications

Regulated or

unregulated

wall adapter

MIC79050-4.2BS

IN BAT

GND

Simplest Battery Charging Solution

Pulse-Charging Application

Micrel, Inc. • 1849 Fortune Drive • San Jose, CA 95131 • USA • tel + 1 (408) 944-0800 • fax + 1 (408) 944-0970 • http://www.micrel.com

June 2000 1 MIC79050

4.2V ±0.75% Over Temp

Li-Ion

Cell

Page 2

MIC79050 Micrel

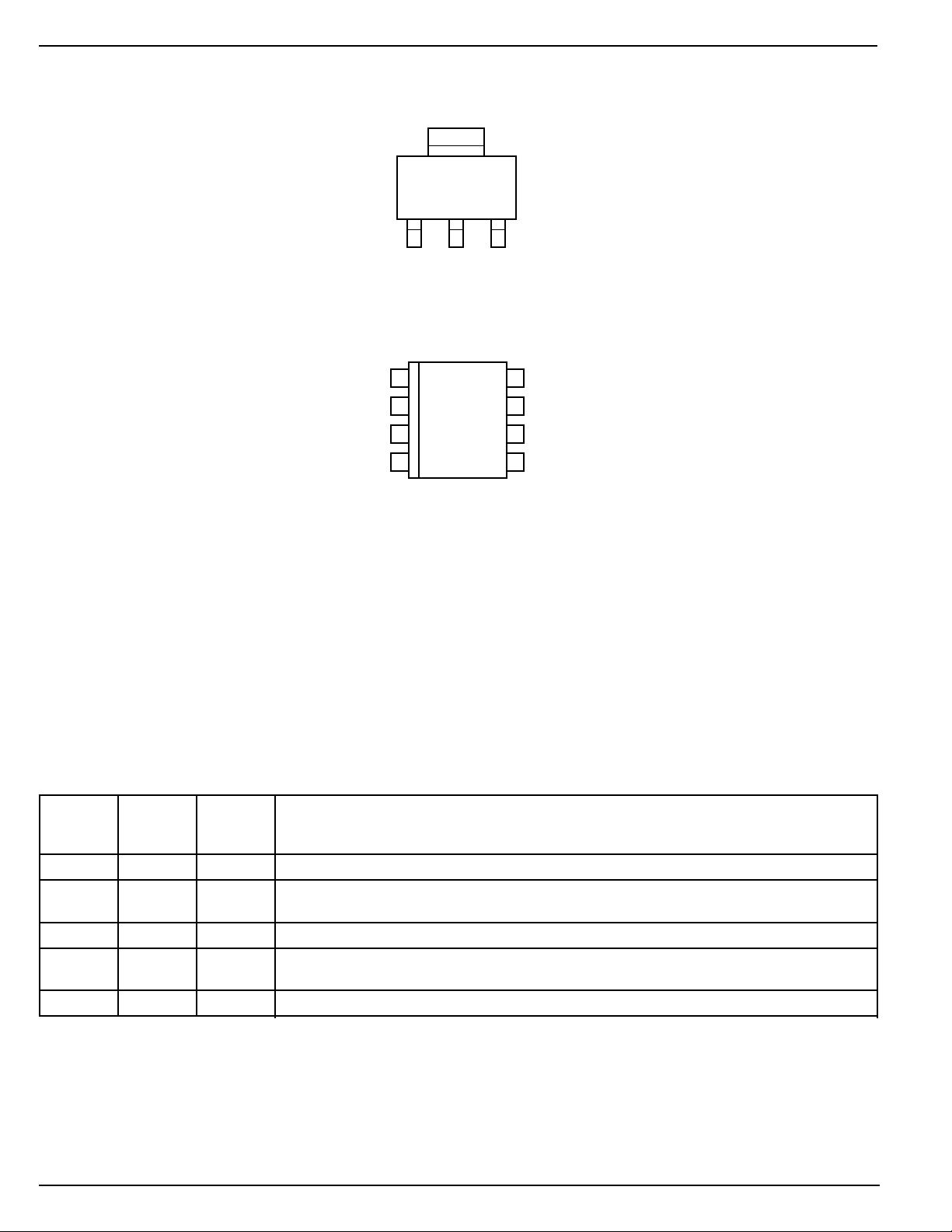

Pin Configuration

GND

TAB

132

IN

GND

BAT

MIC79050-x.xBS

SOT-223

EN

BAT

FB

IN

1

2

3

4

GND

8

GND

7

GND

6

GND

5

MIC79050-x.xBM

SOP-8 and MSOP-8

Pin Description

Pin No. Pin No. Pin Name Pin Function

SOT-223 SOP-8

MSOP-8

1 2 IN Supply Input

2,

TAB 5–8 GND Ground: SOT-223 pin 2 and TAB are internally connected. SO-8 pins 5 through 8 are

internally connected.

3 3 BAT Battery Voltage Output

1 EN Enable (Input): TTL/CMOS compatible control input. Logic high = enable; logic low or open =

shutdown.

4 FB Feedback Node

MIC79050 2 June 2000

Page 3

MIC79050 Micrel

Absolute Maximum Ratings (Note 1)

Supply Input Voltage (V

Power Dissipation (P

Junction Temperature (T

Lead Temperature (soldering, 5 sec.) ....................... 260°C

Storage Temperature (T

) ............................ –20V to +20V

IN

) ............... Internally Limited, Note 3

D

) ....................... –40°C to +125°C

J

) ....................... –65°C to +150°C

S

Operating Ratings (Note 2)

Supply Input Voltage (V

Enable Input Voltage (V

Junction Temperature (TJ) ....................... –40°C to +125°C

Package Thermal Resistance (Note 3) ...............................

MSOP-8 (θ

SOP-8(θ

)......................................................80°C/W

JA

)..........................................................63°C/W

JA

) ........................... +2.5V to +16V

IN

) .................................. 0V to V

EN

SOT-223(θJC)......................................................15°C/W

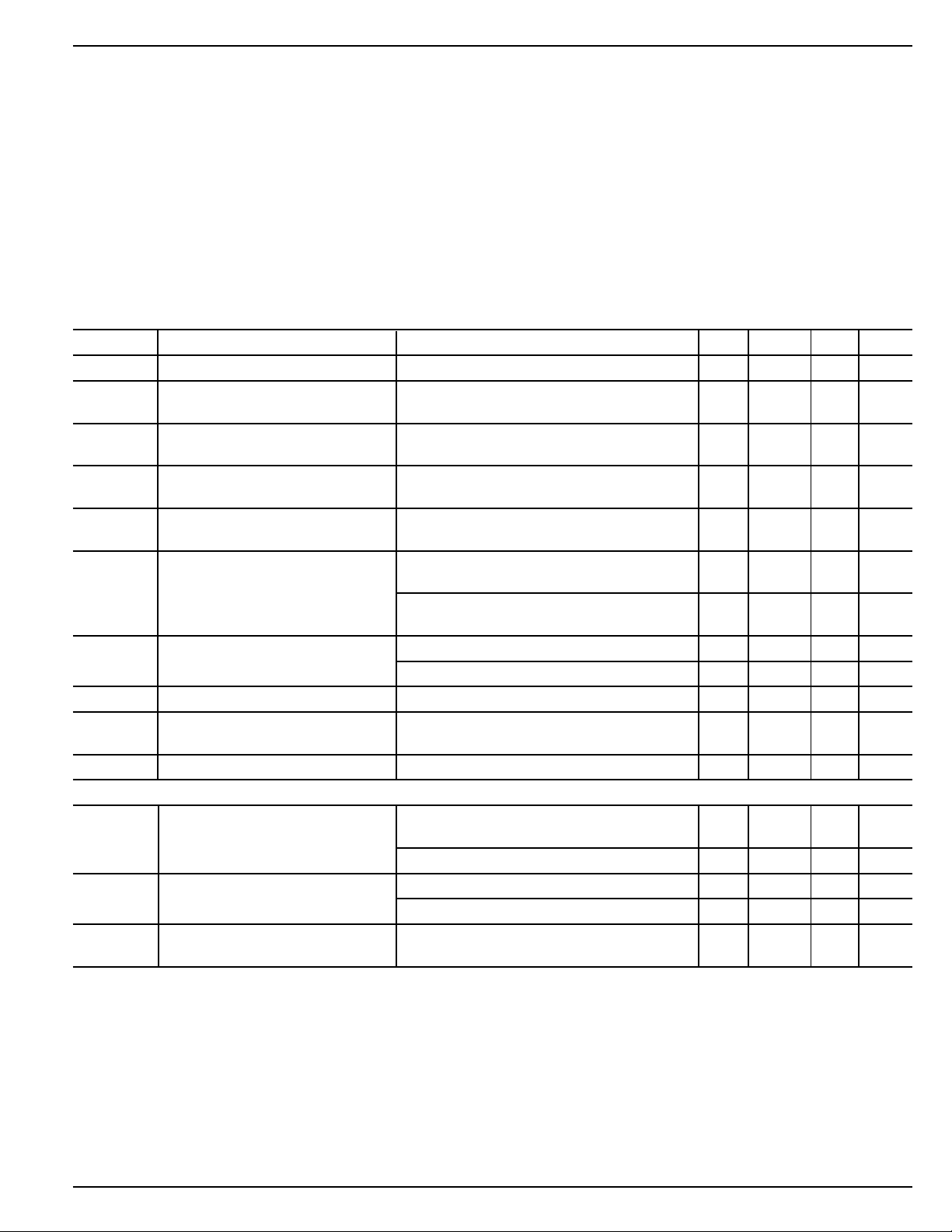

Electrical Characteristics

VIN = V

Symbol Parameter Conditions Min Typical Max Units

V

BAT

∆V

BAT

∆V

BAT/VBAT

∆V

BAT/VBAT

V

– V

IN

I

GND

I

GND

PSRR Ripple Rejection f = 120Hz 75 dB

I

LIMIT

∆V

BAT

ENABLE Input

V

ENL

I

ENL

I

ENH

BAT

+ 1.0V; C

Battery Voltage Accuracy variation from nominal V

= 4.7µF, I

OUT

= 100µA; TJ = 25°C, bold values indicate –40°C ≤ TJ ≤ +125°C; unless noted.

OUT

–5°C to +60°C –0.75 +0.75 %

OUT

/∆T Battery Voltage Note 4 40 ppm/°C

Temperature Coefficient

Line Regulation VIN = V

+ 1V to 16V 0.009 0.05 %/V

BAT

0.1 %/V

Load Regulation I

= 100µA to 500mA, Note 5 0.05 0.5 %

OUT

0.7 %

BAT

Dropout Voltage, Note 6 I

= 500mA 380 500 mV

OUT

600 mV

Ground Pin Current, Notes 7, 8 VEN ≥ 3.0V, I

= 100µA 85 130 µA

OUT

170 µA

V

≥ 3.0V, I

EN

= 500mA 11 20 mA

OUT

25 mA

Ground Pin Quiescent Current, VEN ≤ 0.4V (shutdown) 0.05 3 µA

Note 8

Current Limit V

VEN ≤ 0.18V (shutdown) 0.10 8 µA

= 0V 750 900 mA

BAT

1000 mA

/∆P

Thermal Regulation Note 9 0.05 %/W

D

Enable Input Logic-Low Voltage VEN = logic low (shutdown) 0.4 V

0.18 V

VEN = logic high (enabled) 2.0 V

Enable Input Current V

≤ 0.4V (shutdown) 0.01 –1 µA

ENL

V

≤ 0.18V (shutdown) 0.01 –2 µA

ENL

V

≥ 2.0V (enabled) 5 20 µA

ENH

25 µA

IN

Note 1. Exceeding the absolute maximum rating may damage the device.

Note 2. The device is not guaranteed to function outside its operating rating.

Note 3. The maximum allowable power dissipation at any TA (ambient temperature) is calculated using: P

maximum allowable power dissipation will result in excessive die temperature, and the regulator will go into thermal shutdown.

Note 4. Battery voltage temperature coefficient is the worst case voltage change divided by the total temperature range.

Note 5. Regulation is measured at constant junction temperature using low duty cycle pulse testing. Parts are tested for load regulation in the load

range from 100µA to 500mA. Changes in output voltage due to heating effects are covered by the thermal regulation specification.

Note 6. Dropout voltage is defined as the input to battery output differential at which the battery voltage drops 2% below its nominal value measured at

1V differential.

Note 7: Ground pin current is the charger quiescent current plus pass transistor base current. The total current drawn from the supply is the sum of the

load current plus the ground pin current.

D(max)

= (T

– TA) ÷ θJA. Exceeding the

J(max)

June 2000 3 MIC79050

Page 4

MIC79050 Micrel

Note 8: VEN is the voltage externally applied to devices with the EN (enable) input pin. [MSO-8(MM) and SO-8 (M) packages only.]

Note 9: Thermal regulation is the change in battery voltage at a time “t” after a change in power dissipation is applied, excluding load or line regulation

effects. Specifications are for a 500mA load pulse at V

= 16V for t = 10ms.

IN

MIC79050 4 June 2000

Page 5

MIC79050 Micrel

g

g

3.0

3.2

3.4

3.6

3.8

4.0

-40 0 40 80 120

GROUND CURRENT (mA)

TEMPERATURE (C)

Ground Current

vs. Temperature

0

100

200

300

400

500

600

700

800

-40 0 40 80 120

SHORT CIRCUIT CURRENT (mA)

TEMPERATURE (C)

Short Circuit Current

vs. Temperature

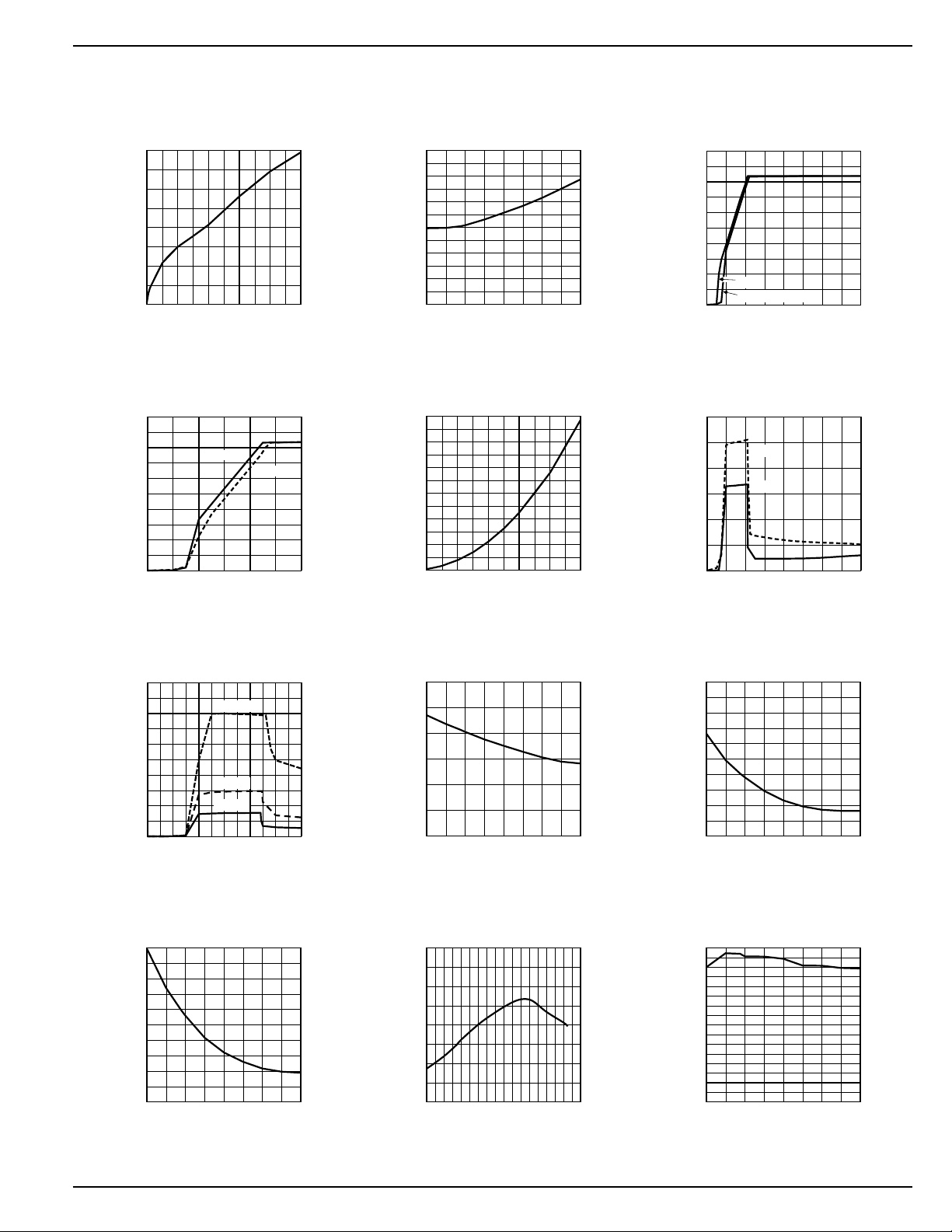

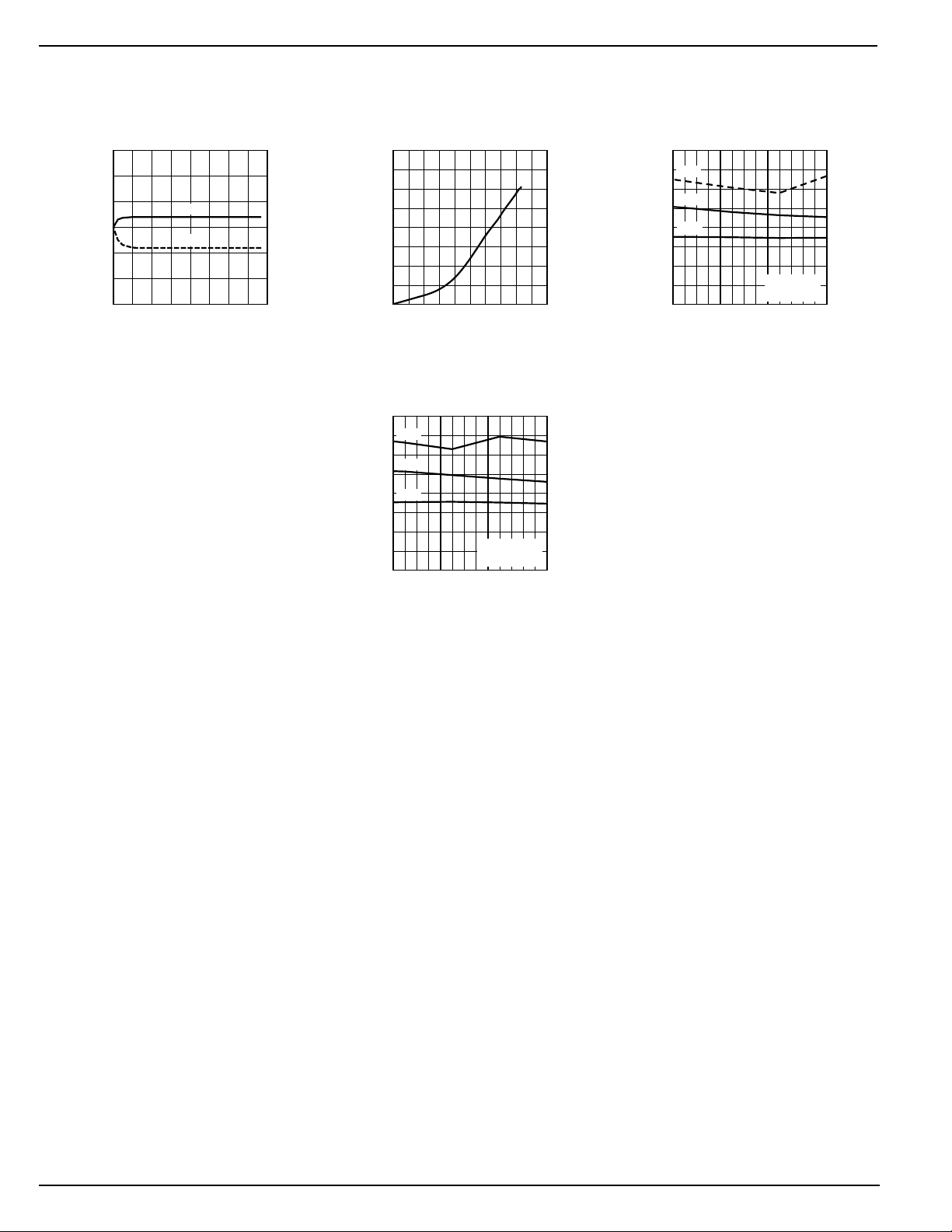

Typical Characteristics

Dropout Voltage

vs. Output Current

400

300

200

100

DROPOUT VOLTAGE (mV)

0

0 100 200 300 400 500

OUTPUT CURRENT (mA)

Dropout Characteristics

5

4

3

2

1

OUTPUT VOLTAGE (V)

0

0246

250mA

500mA

INPUT VOLTAGE (V)

Dropout Voltage

600

500

400

300

200

100

DROPOUT VOLTAGE (mV)

vs. Temperature

0

-40 0 40 80 120

TEMPERATURE (C)

Output Current

12

10

8

6

4

2

GROUND CURRENT (mA)

0

0 100 200 300 400 500

vs. Ground

OUTPUT CURRENT (mA)

Dropout Characteristics

5

4

3

2

1

OUTPUT VOLTAGE (V)

5mA

50mA, 150mA

0

0246810121416

INPUT VOLTAGE (V)

Ground Current

vs. Supply Volta

1.5

50mA

1

5mA

0.5

GROUND CURRENT (mA)

0

0 4 8 12 16

SUPPLY VOLTAGE (V)

e

vs. Supply Volta

25

20

15

10

5

GROUND CURRENT (mA)

0

0123456

SUPPLY VOLTAGE (V)

13.5

13.0

12.5

June 2000 5 MIC79050

12.0

11.5

GROUND CURRENT (mA)

11.0

-40 0 40 80 120

Ground Current

500mA

250mA

125mA

Ground Current

vs. Temperature

TEMPERATURE (C)

Ground Current

e

150

100

GROUND CURRENT (uA)

vs. Temperature

50

0

-40 0 40 80 120

TEMPERATURE (C)

Battery Voltage

4.210

4.205

4.200

4.195

OUTPUT VOLTAGE (V)

4.190

vs. Temperature

-40 -20 0 20 40 60 80 100120140

TEMPERATURE (C)

Page 6

MIC79050 Micrel

Typical Voltage Drift Limits

0.75

0.25

-0.25

-0.75

DRIFT FROM NOMINAL VOUT (%)

0 200 400 600 800

vs. Time

Upper

Lower

TIME (hrs)

Reverse Leakage Current

vs. Output Voltage

20

15

10

5

0

012345

REVERSE LEAKAGE CURRENT (µA)

OUTPUT VOLTAGE (V)

Reverse Leakage Current

vs. Temperature

20

4.2V

15

3.6V

10

3.0V

5

0

-5 5 1525354555

REVERSE LEAKAGE CURRENT (uA)

TEMPERATURE (C)

VIN+V

EN

GROUNDED

Reverse Leakage Current

vs. Output Voltage

20

4.2V

15

3.6V

10

3.0V

5

0

-5 5 1525354555

REVERSE LEAKAGE CURRENT (µA)

TEMPERATURE (C)

VIN+V

EN

FLOATING

MIC79050 6 June 2000

Page 7

MIC79050 Micrel

Block Diagrams

V

IN

IN

V

BAT

Bandgap

Ref.

Current Limit

Thermal Shutdown

MIC79050-x.xBS

GND

3-Pin Version

V

IN

IN

FB

V

BAT

EN

Current Limit

Thermal Shutdown

MIC79050-x.xBMM/M

5-Pin Version

Bandgap

Ref.

V

REF

GND

June 2000 7 MIC79050

Page 8

MIC79050 Micrel

Functional Description

The MIC79050 is a high-accuracy, linear battery charging

circuit designed for the simplest implementation of a single

lithium-ion (Li-ion) battery charger. The part can operate from

a regulated or unregulated power source, making it ideal for

various applications. The MIC79050 can take an unregulated

voltage source and provide an extremely accurate termination voltage. The output voltage varies only 0.75% from

nominal over the standard temperature range for Li-ion

battery charging (–5°C to 60°C). With a minimum of external

components, an accurate constant current charger can be

designed to provide constant current, constant voltage charging for Li-ion cells.

Input Voltage

The MIC79050 can operate with an input voltage up to 16V

(20V absolute maximum), ideal for applications where the

input voltage can float high, such as an unregulated wall

adapter that obeys a load-line. Higher voltages can be

sustained without any performance degradation to the output

voltage. The line regulation of the device is typically 0.009%/V;

that is, a 10V change on the input voltage corresponds to a

0.09% change in output voltage.

Enable

The MIC79050 has an enable pin that allows the charger to

be disabled when the battery is fully charged and the current

drawn by the battery has approached a minimum and/or the

maximum charging time has timed out. When disabled, the

regulator output sinks a minimum of current with the battery

voltage applied directly onto the output. This current is

typically 12µA or less.

Feedback

The feedback pin allows for external manipulation of the

control loop. This node is connected to an external resistive

divider network, which is connected to the internal error

amplifier. This amplifier compares the voltage at the feedback pin to an internal voltage reference. The loop then

corrects for changes in load current or input voltage by

monitoring the output voltage and linearly controlling the

drive to the large, PNP pass element. By externally controlling the voltage at the feedback pin the output can be disabled

or forced to the input voltage. Pulling and holding the feedback pin low forces the output low. Holding the feedback pin

high forces the pass element into saturation, where the output

will be the input minus the saturation (dropout) voltage.

Battery Output

The BAT pin is the output of the MIC79050 and connects

directly to the cell to provide charging current and voltage.

When the input is left floating or grounded, the BAT pin limits

reverse current to <12µA to minimize battery drain.

MIC79050 8 June 2000

Page 9

MIC79050 Micrel

Applications Information

Simple Lithium-Ion Battery Charger.

Figure 1A shows a simple, complete lithium-ion battery

charger. The charging circuit comprises of a cheap wall

adapter, with a load-line characteristic. This characteristic is

always present with cheap adapters due to the internal

impedance of the transformer windings. The load-line of the

unregulated output should be < 4.4V to 4.6V at somewhere

between 0.5C to 1C of the battery under charge. This 4.4 to

4.6V value is an approximate number based on the headroom needed above 4.2V for the MIC79050 to operate

correctly e.g. For a 500mAhr battery, the output of the semiregulated supply should be between 225mA to 500mA ( 0.5C

to 1C ). If it is below 225mA no damage will occur but the

battery will take longer to charge. Figure 1B shows a typical

wall adapter characteristic with an output current of 350mA at

4.5V. This natural impedance of the wall adapter will limit the

max current into the battery, so no external circuitry is needed

to accomplish this.

If extra impedance is needed to achieve the desired loadline,

extra resistance can easily be added in series with the

MIC79050 IN pin.

Impedence

MIC79050-4.2BM

V

S

IN BAT

FB

AC Load-line Wall Adapter

VV

EOC

V

REF

1

=+

REF

= 1.225V

R1

R2

EN

GND

End of Charge

1k

MIC6270

LM4041

CIM3-1.2

10k

R1

R2

Figure 1A. Load-Line Charger With End-Of-Charge Termination Circuit.

Load-Line Source

Characteristics

8

6

4

2

SOURCE VOLTAGE (V)

0

0 0.2 0.4 0.6 0.8

SOURCE CURRENT (A)

4.7µF

Figure 1B. Load-Line Characteristics

of AC Wall Adapter

June 2000 9 MIC79050

Page 10

MIC79050 Micrel

Application Information

End of Charge (V

Unregulated Input

Voltage(V

79050 Programmed

Output Voltage

(No Load Voltage)

Battery Voltage (V

Battery Current (I

EOC

)

)

B

)

B

)

B

State A

Initial Charge

Voltage Charge

Figure 1C. Charging Cycles

The Charging Cycle (See Figure 1C.)

1. State A: Initial charge. Here the battery’s charging

current is limited by the wall adapter’s natural impedance. The battery voltage approaches 4.2V.

2. State B: Constant voltage charge. Here the battery

voltage is at 4.2V ± 0.75% and the current is decaying in

the battery. When the battery has reached approximately 1/10th of its 1C rating, the battery is considered

to have reached full charge. Because of the natural

characteristic impedance of the cheap wall adapters, as

the battery voltage decreases so the input voltage

increases. The MIC6270 and the LM4041 are configured as a simple voltage monitor, indicating when the

V

EOC

State B

Open Circuit

Charger Voltage

State C

End of Charge

State D

Charge Top

State C

input voltage has reached such a level so the current in

the battery is low, indicating full charge.

3. State C: End of charge cycle. When the input voltage,

VS reaches V

an end of charge signal is indicated.

EOC,

4. State D: Top up charge. As soon as enough current is

drawn out of the input source, which pulls the voltage

lower than the V

, the end of charge flag will be

EOC

pulled low and charging will initiate.

Variations on this scheme can be implemented, such as the

circuit shown in Figure 2.

For those designs that have a zero impedance source , see

Figure 3.

5V ±5%@

400mA ±5%

0.050Ω

1k

1k

MIC7300

47k

MIC79050-4.2BM

IN BAT

EN

GND

47k

FB

LM4041

CIM3-1.2

8.06M

Q1

10k

4.7µF

MIC6270

10k

R2

Figure 2. Protected Constant-Current Charger

MIC79050 10 June 2000

Page 11

MIC79050 Micrel

Applications Information

Protected Constant-Current Charger

Another form of charging is using a simple wall adapter that

offers a fixed voltage at a controlled, maximum current rating.

The output of a typical charger will source a fixed voltage at

a maximum current unless that maximum current is exceeded. In the event that the maximum current is exceeded,

the voltage will drop while maintaining that maximum current.

Using an MIC79050 after this type of charger is ideal for

lithium-ion battery charging. The only obstacle is end of

charger termination. Using a simple differential amplifier and

a similar comparator and reference circuit, similar to Figure 1,

completes a single cell lithium-ion battery charger solution.

Figure 2 shows this solution in completion. The source is a

fixed 5V source capable of a maximum of 400mA of current.

When the battery demands full current (fast charge), the

source will provide only 400mA and the input will be pulled

down. The output of the MIC79050 will follow the input minus

a small voltage drop. When the battery approaches full

charge, the current will taper off. As the current across R

approaches 50mA, the output of the differential amplifier

(MIC7300) will approach 1.225V, the reference voltage set by

the LM4041. When it drops below the reference voltage, the

output of the comparator (MIC6270) will allow the base of Q1

to be pulled high through R2.

Zero-Output Impedance Source Charging

Input voltage sources that have very low output impedances

can be a challenge due to the nature of the source. Using the

circuit in Figure 3 will provide a constant-current and constant

voltage charging algorithm with the appropriate end-of-charge

termination. The main loop consists of an op-amp controlling

the feedback pin through the schottky diode, D1. The charge

current through RS is held constant by the op-amp circuit until

the output draws less than the set charge-current. At this

point, the output goes constant-voltage. When the current

through RS gets to less than 50mA, the difference amp output

becomes less than the reference voltage of the MIC834 and

the output pulls low. This sets the output of the MIC79050 less

than nominal, stopping current flow and terminating charge.

Lithium-Ion Battery Charging

Single lithium-ion cells are typically charged by providing a

constant current and terminating the charge with constant

voltage. The charge cycle must be initiated by ensuring that

the battery is not in deep discharge. If the battery voltage is

below 2.5V, it is commonly recommended to trickle charge

the battery with 5mA to 10mA of current until the output is

above 2.5V. At this point the battery can be charged with

constant current until it reaches its top off voltage (4.2V for a

typical single lithium-ion cell) or a time out occurs.

For the constant-voltage portion of the charging circuit, an

extremely accurate termination voltage is highly recommended. The higher the accuracy of the termination circuit,

the more energy the battery will store. Since lithium-ion cells

do not exhibit a memory effect, less accurate termination

does not harm the cell but simply stores less usable energy

in the battery. The charge cycle is completed by disabling the

charge circuit after the termination current drops below a

minimum recommended level, typically 50mA or less, depending on the manufacturer’s recommendation, or if the

circuit times out.

Time Out

The time-out aspect of lithium-ion battery charging can be

added as a safety feature of the circuit. Often times this

function is incorporated in the software portion of an application using a real-time clock to count out the maximum amount

of time allowed in the charging cycle. When the maximum

recommended charge time for the specific cell has been

exceeded, the enable pin of the MIC79050 can be pulled low,

and the output will float to the battery voltage, no longer

providing current to the output.

As a second option, the feedback pin of the MIC79050 can be

modulated as in Figure 4. Figure 4. shows a simple circuit

where the MIC834, an integrated comparator and reference,

monitors the battery voltage and disables the MIC79050

S

output after the voltage on the battery exceeds a set vaue.

When the voltage decays below this set threshold, the

MIC834 drives Q1 low allowing the MIC79050 to turn on

again and provide current to the battery until it is fully charged.

This form of pulse charging is an acceptable way of maintaining the full charge on a cell until it is ready to be used.

MIC79050-4.2BMM

VIN

GND

IN BAT

FB

EN

GND

4.7µF

MIC834

VDD OUT

R1100k

GNDINP

R2

VV1

V

==++

BAT(low) REF

=1.240V

REF

Figure 4. Pulse Charging For

Top-off Voltage

Charging Rate

Lithium-ion cells are typically charged at rates that are

fractional multiples of their rated capacity. The maximum

varies between 1C – 1.3C (1× to 1.3× the capacity of the cell).

The MIC79050 can be used for any cell size. The size of the

cell and the current capability of the input source will determine the overall circuit charge rate. For example, a 1200mAh

battery charged with the MIC79050 can be charged at a

maximum of 0.5C. There is no adverse effects to charging at

lower charge rates; that charging will just take longer. Charging at rates greater than 1C are not recommended, or do they

decrease the charge time linearly.

The MIC79050 is capable of providing 500mA of current at its

nominal rated output voltage of 4.2V. If the input is brought

Li-Ion

Cell

R1

R2

June 2000 11 MIC79050

Page 12

MIC79050 Micrel

below the nominal output voltage, the output will follow the

input, less the saturation voltage drop of the pass element. If

the cell draws more than the maximum output current of the

device, the output will be pulled low, charging the cell at

600mA to 700mA current. If the input is a fixed source with a

low output impedance, this could lead to a large drop across

the MIC79050 and excess heating. By driving the feedback

pin with an external PWM-circuit, the MIC79050 can be used

to pulse charge the battery to reduce power dissipation and

bring the device and the entire unit down to a lower operating

temperature. Figure 5 shows a typical configuration for a

PWM-based pulse-charging topology. Two circuits are shown

in Figure 5: circuit a uses an external PWM signal to control

the charger, while circuit b uses the MIC4417 as a low dutycycle oscillator to drive the base of Q1. (Consult the battery

manufacturer for optimal pulse-charging techniques).

MIC79050-4.2BMM

VIN

IN BAT

FB

EN

GND

4.7µF

External PWM

Li-Ion

Cell

Figure 5A.

MIC79050-4.2BMM

VIN=4.5V to 16V

IN BAT

FB

EN

GND

4.7µF

1kΩ

40kΩ

Li-Ion

Cell

MIC4417

200pF

Figure 5B. PWM Based Pulse-charging

Applications

Figure 6 shows another application to increase the output

current capability of the MIC79050. By adding an external

PNP power transistor, higher output current can be obtained

while maintaining the same accuracy. The internal PNP now

becomes the driver of a darlington array of PNP transistors,

obtaining much higher output currents for applications where

the charge rate of the battery is much higher.

MIC79050-4.2BMM

IN BAT

FB

EN

GND

4.7µF

Figure 6. High Current Charging

Regulated Input Source Charging

When providing a constant-current, constant-voltage, charger

solution from a well-regulated adapter circuit, the MIC79050

can be used with external components to provide a constant

voltage, constant-current charger solution. Figure 7 shows a

configuration for a high-side battery charger circuit that

monitors input current to the battery and allows a constant

current charge that is accurately terminated with the

MIC79050. The circuit works best with smaller batteries,

charging at C rates in the 300mA to 500mA range. The

MIC7300 op-amp compares the drop across a current sense

resistor and compares that to a high-side voltage reference,

the LM4041, pulling the feedback pin low when the circuit is

in the constant-current mode. When the current through the

resistor drops and the battery gets closer to full charge, the

output of the op-amp rises and allows the internal feedback

network of the regulator take over, regulating the output to

4.2V.

MIC79050-4.2BMM

IN BAT

EN

GND

MIC7300

0.01µF

FB

SD101

4.7µF

I

CC

mV

80

==

R

S

LM4041CIM3-1.2

10k

R

S

16.2k

221k

Figure 7. Constant Current,

Constant Voltage Charger

Simple Charging

The MIC79050 is available in a three-terminal package,

allowing for extremely simple battery charging. When used

with a current-limited, low-power input supply, the MIC79050-

4.2BS completes a very simple, low-charge-rate, battery-

charger circuit. It provides the accuracy required for termination, while a current-limited input supply offers the constantcurrent portion of the algorithm.

Thermal Considerations

The MIC79050 is offered in three packages for the various

applications. The SOT-223 is most thermally efficient of the

three packages, with the power SOP-8 and the power MSOP-8

following suit.

Power SOP-8 Thermal Characteristics

One of the secrets of the MIC79050’s performance is its

power SO-8 package featuring half the thermal resistance of

a standard SO-8 package. Lower thermal resistance means

more output current or higher input voltage for a given

package size.

Lower thermal resistance is achieved by joining the four

ground leads with the die attach paddle to create a singlepiece electrical and thermal conductor. This concept has

MIC79050 12 June 2000

Page 13

MIC79050 Micrel

been used by MOSFET manufacturers for years, proving

very reliable and cost effective for the user.

Thermal resistance consists of two main elements, θJC, or

thermal resistance junction to case and θCA, thermal resistance case to ambient (Figure 8). θJC is the resistance from

the die to the leads of the package. θCA is the resistance from

the leads to the ambient air and it includes θCS, thermal

resistance case to sink, and θSA, thermal resistance sink to

ambient. Using the power SOP-8 reduces the θ

dramati-

JC

cally and allows the user to reduce θCA. The total thermal

resistance, θ JA, junction to ambient thermal resistance, is the

limiting factor in calculating the maximum power dissipation

capability of the device. Typically, the power SOP-8 has a θ

JC

of 20°C/W, this is significantly lower than the standard SOP8 which is typically 75°C/W. θCA is reduced because pins 58 can now be soldered directly to a ground plane, which

significantly reduces the case to sink thermal resistance and

sink to ambient thermal resistance.

Figure 9. Copper Area vs. Power-SOP

Where ∆T = T

T

j(max)

T

a(max)

temperature

900

800

)

∆TJA =

2

700

600

500

400

300

200

COPPER AREA (mm

100

0

0 0.25 0.50 0.75 1.00 1.25 1.50

40°C

50°C

55°C

65°C

75°C

85°C

POWER DISSIPATION (W)

Power Dissipation (∆TJA)

– T

j(max)

a(max)

= 125°C

= maximum ambient operating

100°C

For example, the maximum ambient temperature is 40°C, the

∆T is determined as follows:

SOP-8

∆T = +125°C – 40°C

∆T = +85°C

Using Figure 9, the minimum amount of required copper can

be determined based on the required power dissipation.

Power dissipation in a linear regulator is calculated as fol-

θ

JA

θ

θ

JC

CA

AMBIENT

ground plane

heat sink area

lows:

PD = (Vin-Vout)*Iout + Vin*Ignd

For example, using the charging circuit in Figure 7, assume

the input is a fixed 5V and the output is pulled down to 4.2V

printed circuit board

Figure 8. Thermal Resistance

at a charge current of 500mA. The power dissipation in the

MIC79050 is calculated as follows:

PD = (5V – 4.2V)*0.5A + 5V*0.012A

The MIC79050 is rated to a maximum junction temperature

of 125°C. It is important not to exceed this maximum junction

temperature during operation of the device. To prevent this

maximum junction temperature from being exceeded, the

appropriate ground plane heat sink must be used.

Figure 9 shows curves of copper area versus power dissipation, each trace corresponding to different temperature rises

above ambient. From these curves, the minimum area of

copper necessary for the part to operate safely can be

determined. The maximum allowable temperature rise must

be calculated to determine operation along which curve.

PD = 0.460W

From Figure 9, the minimum amount of copper required to

operate this application at a ∆T of 85C is less than 50mm2.

Quick Method

Determine the power dissipation requirements for the design

along with the maximum ambient temperature at which the

device will be operated. Refer to Figure 10 , which shows safe

operating curves for 3 different ambient temperatures: +25°C,

+50°C and +85°C. From these curves, the minimum amount

of copper can be determined by knowing the maximum power

dissipation required. If the maximum ambient temperature is

+40°C and the power dissipation is as above, 0.46W, the

curve in Figure 10 shows that the required area of copper is

50mm2.

The θJA of this package is ideally 63°C/W, but it will vary

depending upon the availability of copper ground plane to

which it is attached.

June 2000 13 MIC79050

Page 14

MIC79050 Micrel

40

C

100

C

900

TJ = 125°C

800

)

2

700

600

500

400

300

200

COPPER AREA (mm

100

0

85°C 50°C 25°C

0 0.25 0.50 0.75 1.00 1.25 1.50

POWER DISSIPATION (W)

900

TJ = 125°C

800

)

2

700

600

500

400

300

200

COPPER AREA (mm

100

85°C 50°C 25°C

0

0 0.25 0.50 0.75 1.00 1.25 1.50

POWER DISSIPATION (W)

Figure 10. Copper Area vs. Power-SOP

Power Dissipation (TA)

Power MSOP-8 Thermal Characteristics

The power-MSO-8 package follows the same idea as the

power-SO-8 package, using four ground leads with the die

attach paddle to create a single-piece electrical and thermal

conductor, reducing thermal resistance and increasing power

dissipation capability.

The same method of determining the heat sink area used for

the power-SOP-8 can be applied directly to the powerMSOP-8. The same two curves showing power dissipation

versus copper area are reproduced for the power-MSOP-8

and they can be applied identically.

Quick Method

Determine the power dissipation requirements for the design

along with the maximum ambient temperature at which the

device will be operated. Refer to Figure 12, which shows safe

operating curves for 3 different ambient temperatures, +25°C,

+50°C and +85°C. From these curves, the minimum amount

of copper can be determined by knowing the maximum power

dissipation required. If the maximum ambient temperature is

+25°C and the power dissipation is 1W, the curve in Figure

12v shows that the required area of copper is 500mm2,when

using the power MSOP-8

900

800

)

2

700

600

500

400

300

200

COPPER AREA (mm

100

0

°

50°C

55°C

0 0.25 0.50 0.75 1.00 1.25 1.50

POWER DISSIPATION (W)

°

65°C

75°C

85°C

Figure 12. Copper Area vs. Power-MSOP

Power Dissipation (TA)

Figure 11. Copper Area vs. Power-MSOP

Power Dissipation (∆TJA)

MIC79050 14 June 2000

Page 15

MIC79050 Micrel

16°

10°

0.84 (0.033)

0.64 (0.025)

1.04 (0.041)

0.85 (0.033)

2.41 (0.095)

2.21 (0.087)

4.7 (0.185)

4.5 (0.177)

6.70 (0.264)

6.30 (0.248)

7.49 (0.295)

6.71 (0.264)

3.71 (0.146)

3.30 (0.130)

3.15 (0.124)

2.90 (0.114)

10°

MAX

0.10 (0.004)

0.02 (0.0008)

0.38 (0.015)

0.25 (0.010)

C

L

DIMENSIONS:

MM (INCH)

C

L

1.70 (0.067)

1.52 (0.060)

0.91 (0.036) MIN

Package Information

SOT-223 (S)

0.026 (0.65)

MAX)

0.157 (3.99)

0.150 (3.81)

0.050 (1.27)

0.064 (1.63)

0.045 (1.14)

TYP

0.197 (5.0)

0.189 (4.8)

PIN 1

0.020 (0.51)

0.013 (0.33)

0.0098 (0.249)

0.0040 (0.102)

0°–8°

SEATING

PLANE

DIMENSIONS:

INCHES (MM)

0.050 (1.27)

0.016 (0.40)

0.244 (6.20)

0.228 (5.79)

45°

0.010 (0.25)

0.007 (0.18)

8-Pin SOP (M)

June 2000 15 MIC79050

Page 16

MIC79050 Micrel

0.122 (3.10)

0.112 (2.84)

0.036 (0.90)

0.032 (0.81)

0.012 (0.03)

0.0256 (0.65) TYP

0.199 (5.05)

0.187 (4.74)

0.120 (3.05)

0.116 (2.95)

0.043 (1.09)

0.038 (0.97)

0.008 (0.20)

0.004 (0.10)

8-Pin MSOP (MM)

0.012 (0.30) R

5° MAX

0° MIN

DIMENSIONS:

INCH (MM)

0.007 (0.18)

0.005 (0.13)

0.012 (0.03) R

0.039 (0.99)

0.035 (0.89)

0.021 (0.53)

MIC79050 16 June 2000

Page 17

MIC79050 Micrel

June 2000 17 MIC79050

Page 18

MIC79050 Micrel

MICREL INC. 1849 FORTUNE DRIVE SAN JOSE, CA 95131 USA

TEL + 1 (408) 944-0800 FAX + 1 (408) 944-0970 WEB http://www.micrel.com

This information is believed to be accurate and reliable, however no responsibility is assumed by Micrel for its use nor for any infringement of patents or

other rights of third parties resulting from its use. No license is granted by implication or otherwise under any patent or patent right of Micrel Inc.

© 2000 Micrel Incorporated

MIC79050 18 June 2000

Page 19

MIC79050 Micrel

June 2000 19 MIC79050

Page 20

MIC79050 Micrel

MIC79050 20 June 2000

Loading...

Loading...