Datasheet MIC384-1BM, MIC384-1BMM, MIC384-2BM, MIC384-2BMM, MIC384-0BMM Datasheet (MICREL)

...Page 1

MIC384 Micrel

MIC384

Three-Zone Thermal Supervisor

Advance Information

General Description

The MIC384 is a versatile digital thermal supervisor capable

of measuring temperature using its own internal sensor and

two inexpensive external sensors or embedded silicon diodes such as those found in the Intel Pentium III* CPU. A 2wire serial interface is provided to allow communication with

either I2C** or SMBus* masters. The open-drain interrupt

output pin can be used as either an over-temperature alarm

or a thermostatic control signal.

Interrupt mask and status bits are provided for reduced

software overhead. Fault queues prevent nuisance tripping

due to thermal or electrical noise. A programmable address

pin permits two devices to share the bus. (Alternate base

addresses available – contact Micrel.) Superior performance, low power and small size makes the MIC384 an

excellent choice for multiple zone thermal management

applications.

*SMBus and Pentium III are trademarks of Intel Corporation.

**I2C is a trademark of Philips Electronics, N.V.

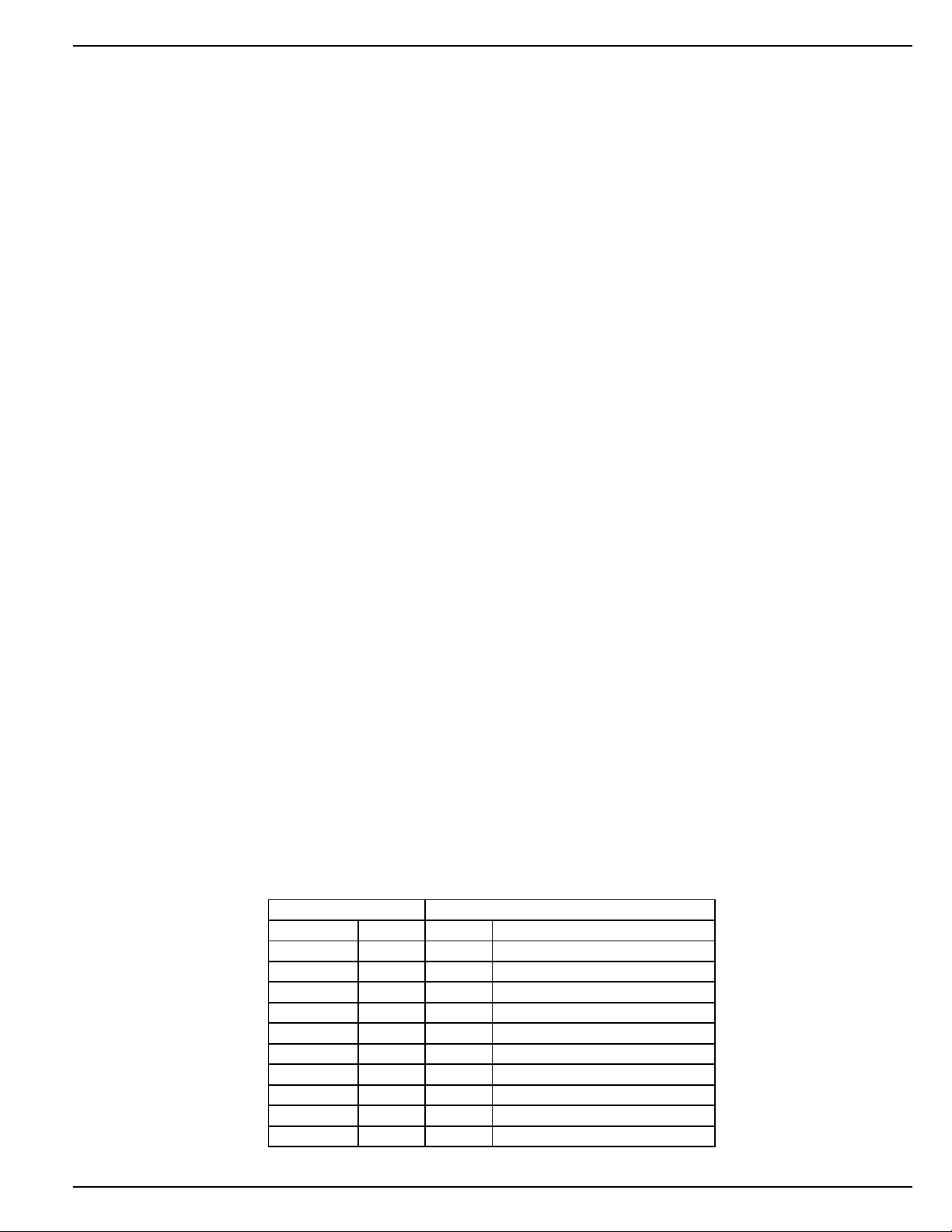

Ordering Information

Part Number Base Address(*

MIC384-0BM 100 100x –55°C to +125°C 8-Lead SOP

MIC384-1BM 100 101x –55°C to +125°C 8-Lead SOP Contact Factory

MIC384-2BM 100 110x –55°C to +125°C 8-Lead SOP Contact Factory

MIC384-3BM 100 111x –55°C to +125°C 8-Lead SOP Contact Factory

MIC384-0BMM 100 100x –55°C to +125°C 8-Lead MSOP

MIC384-1BMM 100 101x –55°C to +125°C 8-Lead MSOP Contact Factory

MIC384-2BMM 100 110x –55°C to +125°C 8-Lead MSOP Contact Factory

MIC384-3BMM 100 111x –55°C to +125°C 8-Lead MSOP Contact Factory

* The least-significant bit of the slave address is determined by the state of the A0 pin.

Features

• Measures Local and Two Remote Temperatures

• 2-Wire SMBus-compatible Interface

• Programmable Thermostat Settings for All Three Zones

• Open-Drain Interrupt Output Pin

• Interrupt Mask and Status Bits

• Fault Queues to Prevent Nuisance Tripping

• Low Power Shutdown Mode

• Failsafe response to diode faults

• 2.7V to 5.5V Power Supply Range

• 8-Lead SOIC and MSOP Packages

Applications

• Desktop, Server and Notebook Computers

• Power Supplies

• Test and Measurement Equipment

• Wireless Systems

• Networking/Datacom Hardware

)

Junction Temp. Range Package Notes

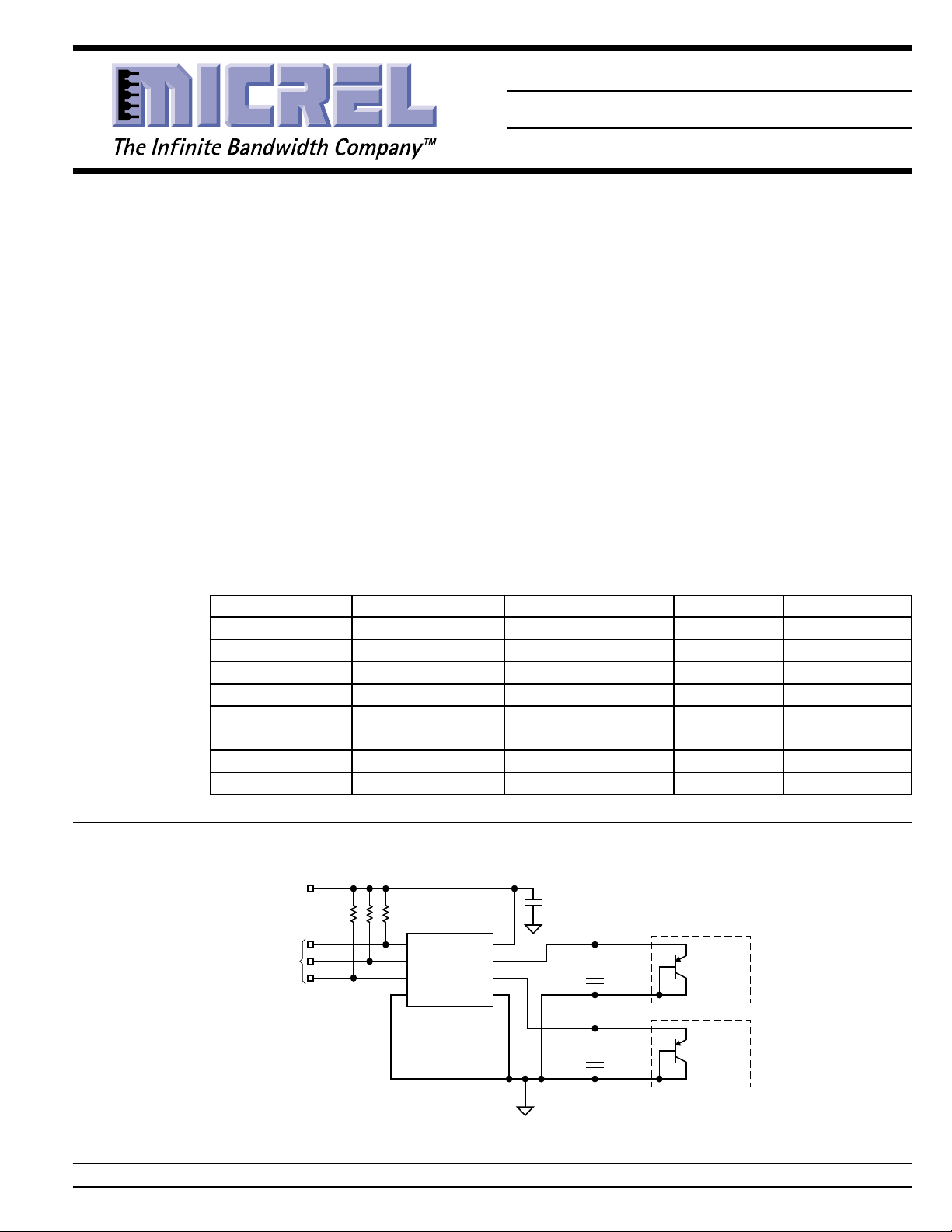

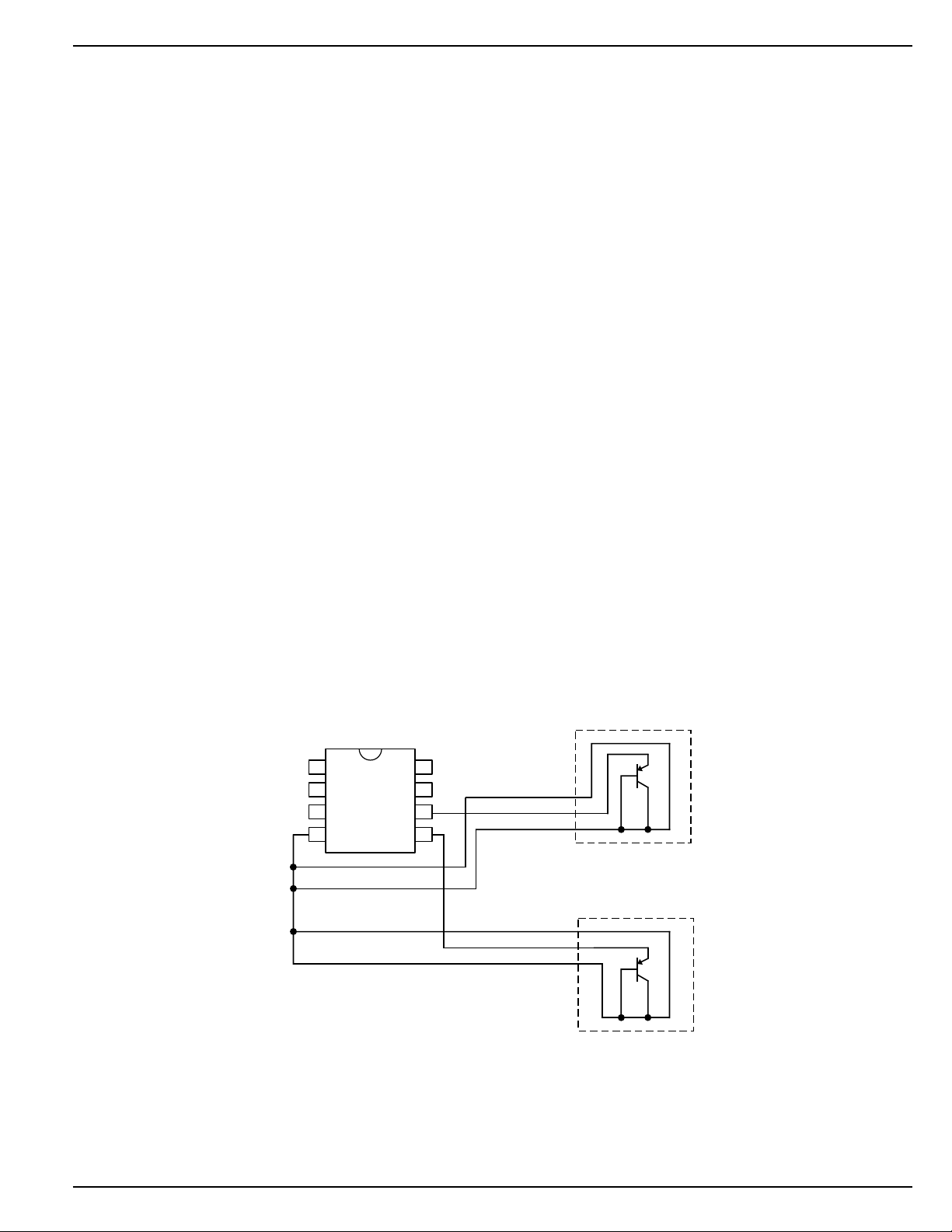

T ypical Application

3.3V

3 × 10k

FROM

SERIAL BUS

HOST

pull-ups

DATA

CLK

/INT

GND

MIC384

VDD

T1

T2

A0

3-Channel SMBus Temperature Measurement System

Micrel, Inc. • 1849 Fortune Drive • San Jose, CA 95131 • USA • tel + 1 (408) 944-0800 • fax + 1 (408) 944-0970 • http://www.micrel.com

September 2000 1 MIC384

0.1µF

2200pF

2200pF

REMOTE

DIODE

REMOTE

DIODE

Page 2

MIC384 Micrel

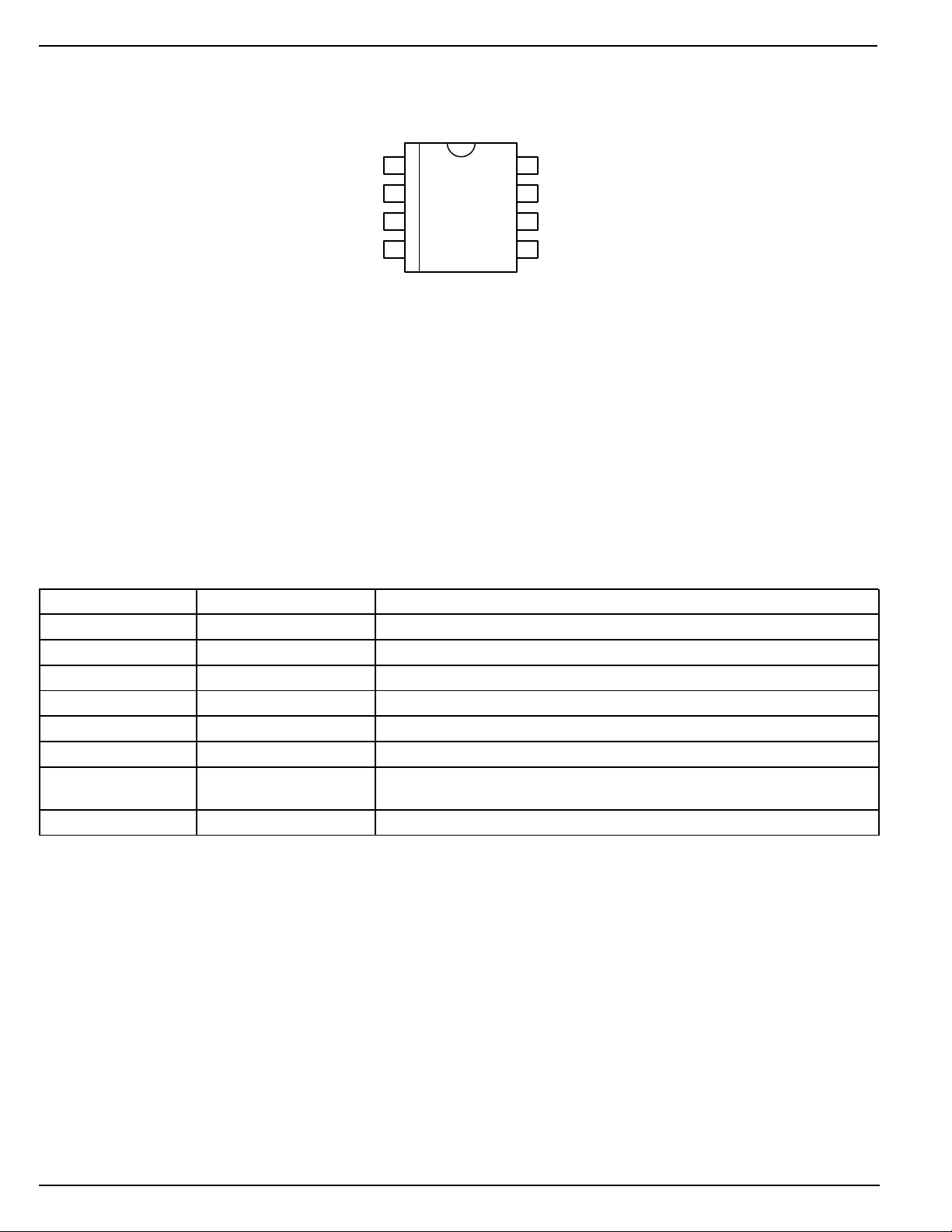

Pin Configuration

CLK

/INT

GND

Pin Description

Pin Number Pin Name Pin Function

1 DATA Digital I/O: Open-drain. Serial data input/output.

2 CLK Digital Input: The host provides the serial bit clock on this input.

3 /INT Digital Output: Open-drain. Interrupt or thermostat output.

4 GND Ground: Power and signal return for all IC functions.

5 T2 Analog Input: Connection to remote temperature sensor (diode junction)

6 T1 Analog Input: Connection to remote temperature sensor (diode junction)

7 A0 Digital Input: Slave address selection input. See Table 1. MIC284 Slave

8 VDD Analog Input: Power supply input to the IC.

1DATA

2

3

4

Address Setings.

8 VDD

A0

7

T1

6

T2

5

MIC384 2 September 2000

Page 3

MIC384 Micrel

Absolute Maximum Ratings (Note 1)

Power Supply Voltage, V

Voltage on Any Pin................................–0.3V to V

Current Into Any Pin.................................................±10mA

Power Dissipation, T

A

Junction Temperature ............................................. +150°C

................................................... 6.0V

DD

+0.3V

DD

= +125°C ...............................30mW

Operating Ratings (Note 2)

Power Supply Voltage, V

Ambient Temperature Range (T

Package Thermal Resistance (θ

SOP.................................................................+152°C/W

MSOP..............................................................+206°C/W

.............................. +2.7V to +5.5V

DD

) ............-55°C to +125°C

A

)

JA

Storage Temperature ............................... –65°C to +150°C

ESD Ratings (Note 3)

Human Body Model.................................................. TBD V

Machine Model......................................................... TBD V

Soldering

Vapor Phase (60 sec.) .............................+220°C +5⁄–0°C

Infrared (15 sec.)...................................... +235°C +5⁄–0°C

Electrical Characteristics

2.7V ≤ VDD ≤ 5.5; TA = +25°C, bold values indicate –55°C ≤ TA ≤ +125°C, Note 4; unless noted.

Symbol Parameter Condition Min Typ Max Units

Power Supply

I

DD

t

POR

V

POR

V

HYST

Temperature-to-Digital Converter Characteristics

t

CONV0

t

CONV1

Remote Temperature Inputs (T1, T2)

I

F

Address Input (A0)

V

IL

V

IH

C

IN

I

LEAK

Supply Current /INT, open, A0 = VDD or GND, 350 750 µA

CLK = DATA = high, normal mode

/INT, open, A0 = V

shutdown mode, CLK = 100kHz

/INT, open, A0 = V

shutdown mode, CLK = DATA = high

Power-On Reset Time; Note 7 VDD > V

POR

or GND, 3 µA

DD

or GND, 1 10 µA

DD

200 µs

Power-On Reset Voltage all registers reset to default values, 2.0 2.7 V

A/D conversions initiated

Power-On Reset Hysteresis Voltage 250 mV

Accuracy—Local Temperature 0°C ≤ T

≤ +100°C, /INT open, ±1 ±2 °C

A

Note 4, 9 3V ≤ VDD ≤ 3.6V

–55°C ≤ T

≤ +125°C, /INT open, ±2 ±3 °C

A

3V ≤ VDD ≤ 3.6V

Accuracy—Remote Temperature 0°C ≤ T

≤ +100°C, /INT open, ±1 ±3 °C

D

Note 5, 4, 9 3V ≤ VDD ≤ 3.6V, 0°C ≤ TA ≤ +85°C

–55°C ≤ T

≤ +125°C, /INT open, ±2 ±5 °C

D

3V ≤ VDD ≤ 3.6V, 0°C ≤ TA ≤ +85°C

Conversion Time, local zone 50 80 ms

Note 7, 8

Conversion Time, remote zone

Note 7, 8 100 160 ms

Current to External Diode high level, T1 or T2 forced to 1.5V 224 400 µA

Note 7

low level 7.5 14 µA

Low Input Voltage 2.7V ≤ VDD ≤ 5.5V 0.6 V

High Input Voltage 2.7V ≤ VDD ≤ 5.5V 2.0 V

Input Capacitance 10 pF

Input Current ±0.01 ±1 µA

September 2000 3 MIC384

Page 4

MIC384 Micrel

Symbol Parameter Condition Min Typ Max Units

Serial Data I/O Pin (DATA)

V

OL

V

IL

V

IH

C

IN

I

LEAK

Serial Clock Input (CLK)

V

IL

V

IH

C

IN

I

LEAK

Status Output (/INT)

V

OL

t

INT

t

nINT

T_SET0 Default T_SET0 Value t

T_HYST0 Default T_HYST0 Value t

T_SET1 Default T_SET1 Value t

T_HYST1 Default T_HYST1 Value t

T_SET2 Default T_SET2 Value t

T_HYST2 Default T_HYST2 Value t

Serial Interface Timing (Note 7)

t

1

t

2

t

3

t

4

t

5

Low Output Voltage IOL = 3mA 0.4 V

Note 6 IOL = 6mA 0.8 V

Low Input Voltage 2.7V ≤ VDD ≤ 5.5V 0.3V

High Input Voltage 2.7V ≤ VDD ≤ 5.5V 0.7V

DD

DD

V

V

Input Capacitance 10 pF

Input current ±0.01 ±1 µA

Low Input Voltage 2.7V ≤ VDD ≤ 5.5V 0.3V

High Input Voltage 2.7V ≤ VDD ≤ 5.5V 0.7V

DD

DD

V

V

Input Capacitance 10 pF

Input current ±0.01 ±1 µA

Low Output Voltage, IOL = 3mA 0.4 V

Note 6

Interrupt Propagation Delay,

Note 7, 8 to /INT < VOL, FQ = 00, R

IOL = 6mA 0.8 V

from

TEMPx > T_SETx or TEMPx < T_HYSTx

= 10kΩ

PULLUP

t

CONV

+1

µs

Interrupt Reset Propagation Delay, from any register read to /INT > VOH, 1 µs

Note 7 R

POR

POR

POR

POR

POR

POR

= 10kΩ

PULLUP

after VDD > V

after VDD > V

after VDD > V

after VDD > V

after VDD > V

after VDD > V

POR

POR

POR

POR

POR

POR

81 81 81 °C

76 76 76 °C

97 97 97 °C

92 92 92 °C

97 97 97 °C

92 92 92 °C

CLK (Clock) Period 2.5 µs

Data In Setup Time to CLK High 100 ns

Data Out Stable After CLK Low 0 ns

DATA Low Setup Time to CLK Low start condition 100 ns

DATA High Hold Time stop condition 100 ns

After CLK High

Note 1. Exceeding the absolute maximum rating may damage the device.

Note 2. The device is not guaranteed to function outside its operating rating.

Note 3. Devices are ESD sensitive. Handling precautions recommended.

Note 4. Final test on outgoing product is performed at TA = TBD°C.

Note 5. TD is the temperature of the remote diode junction. Testing is performed using a single unit of one of the transistors listed in Table 6.

Note 6. Current into this pin will result in self-heating of the MIC384. Sink current should be minimized for best accuracy.

Note 7. Guaranteed by design over the operating temperature range. Not 100% production tested.

Note 8. t

Human body model: 1.5k in series with 100pF. Machine model: 200pF, no series resistance.

CONV

= t

CONV0

+(2 X t

CONV1

). t

is the conversion time for the local zone; t

CONV0

is the conversion time for the remote zones.`

CONV1

MIC384 4 September 2000

Page 5

MIC384 Micrel

Note 9. Accuracy specification does not include quantization noise, which may be as great as ±1⁄2LSB (±0.5°C).

Timing Diagram

t

1

SCL

SDA Data In

SDA Data Out

t

4

t

2

Serial Interface Timing

t

3

t

5

September 2000 5 MIC384

Page 6

MIC384 Micrel

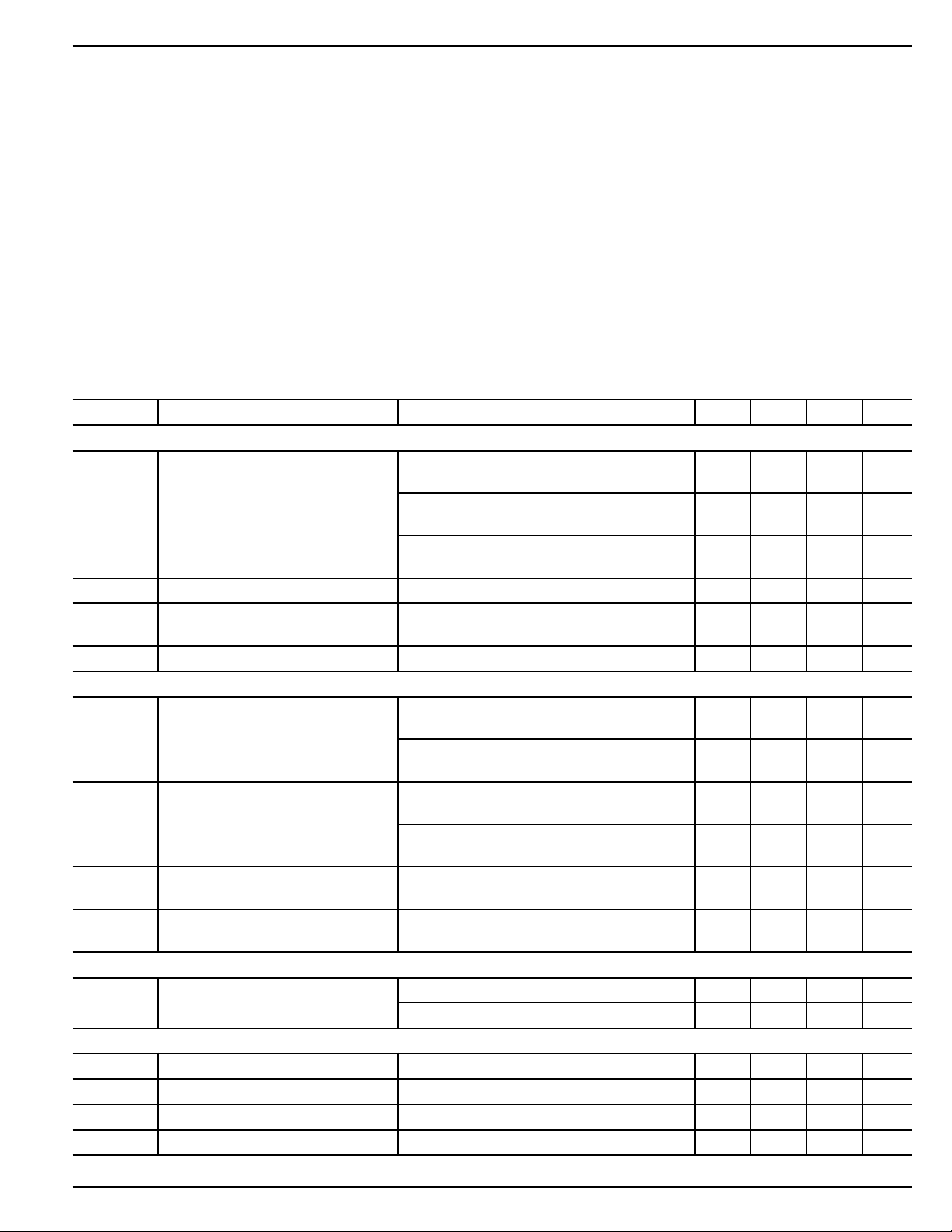

Functional Diagram

VDD

8-Bit Sigma-Delta ADC

T1

T2

3:1

MUX

∑

∫

DATA

CLK

A0

MIC384

Bandgap

Sensor

and

Reference

2-Wire

Serial Bus

Interface

Pointer

Register

1-Bit

DAC

Registers

Temperature

Setpoint

Registers

Temperature

Hysteresis

Registers

Configuration

Register

Result

GND

Digital Filter

and

Control

Logic

State

Machine

and

Digital

Comparator

Open-Drain

Output

/INT

Functional Description

Pin Descriptions

VDD: Power supply input. See electrical specifications.

GND: Ground return for all MIC384 functions.

CLK: Clock input to the MIC384 from the two-wire serial bus.

The clock signal is provided by the host, and is shared by all

devices on the bus.

DATA: Serial data I/O pin that connects to the two-wire serial

bus. DATA is bi-directional and has an open-drain output

driver. An external pull-up resistor or current source somewhere in the system is necessary on this line. This line is

shared by all devices on the bus.

A0: This inputs sets the least significant bit of the MIC384’s

7-bit slave address. The six most-significant bits are fixed

and are determined by the part number ordered. (See ordering information table above.) Each MIC384 will only respond

to its own unique slave address, allowing up to eight MIC384’s

to share a single bus. A match between the MIC384’s

address and the address specified in the serial bit stream

must be made to initiate communication. A0 should be tied

directly to VDD or ground. See "Temperature Measurement

and Power On" for more information. A0 determines the slave

address as shown in Table 1:

rebmuNtraP

0-483CIM0 0001001

1-483CIM0 0101001

2-483CIM0 0011001

3-483CIM0 0111001

stupnIsserddAevalS483CIM

0AyraniBxeH

b

11001001

11101001

11011001

11111001

b

b

b

b

b

b

b

84

h

94

h

A4

h

B4

h

C4

h

D4

h

E4

h

F4

h

Table 1. MIC384 Slave Address Settings

/INT: Temperature events are indicated to external circuitry

via this output. Operation of the /INT output is controlled by

the MODE and IM bits in the MIC384’s configuration register.

See "Comparator and Interrupt Modes" below. This output is

open-drain and may be wire-OR’ed with other open-drain

signals. Most systems will require a pull-up resistor or current

source on this pin. If the IM bit in the configuration register is

MIC384 6 September 2000

Page 7

MIC384 Micrel

set, it prevents the /INT output from sinking current. In I

and SMBus systems, the IM bit is therefore an interrupt mask

bit.

T1 and T2: The T1 and T2 pins connect to off-chip PN diode

junctions, for monitoring the temperature at remote locations.

The remote diodes may be embedded thermal sensing

junctions in integrated circuits so equipped (such as Intel's

Pentium III), or discrete 2N3906-type bipolar transistors with

base and collector tied together.

Temperature Measurement

The temperature-to-digital converter is built around a switched

current source and an eight-bit analog-to-digital converter.

The temperature is calculated by measuring the forward

voltage of a diode junction at two different bias current levels.

An internal multiplexer directs the current source’s output to

either the internal or one of the external diode junctions. The

MIC384 uses two’s-complement data to represent temperatures. If the MSB of a temperature value is zero, the

temperature is zero or positive. If the MSB is one, the

temperature is negative. More detail on this is given in the

"Temperature Data Format" section below. A “temperature

event” results if the value in any of the temperature result

registers (TEMPx) becomes greater than the value in the

corresponding temperature setpoint register (T_SETx). Another temperature event occurs if and when the measured

temperature subsequently falls below the temperature hysteresis setting in T_HYSTx.

During normal operation the MIC384 continuously performs

temperature-to-digital conversions, compares the results

against the setpoint and hysteresis registers, and updates

the state of /INT and the status bits accordingly. The remote

zones are converted first, followed by the local zone

(T1⇒T2⇒LOCAL). The states of /INT and the status bits are

updated after each measurement is taken.

Diode Faults

The MIC384 is designed to respond in a failsafe manner to

hardware faults in the external sensing circuitry. If the

C

value less than 127°C (7F

be generated on /INT if so enabled. The temperature

reported for the external zone will remain +127°C until the

fault condition is cleared. This fault detection mechanism

requires that the MIC384 complete the number of conversion

cycles specified by Fault_Queue (see below). The part will

therefore require one or more conversion cycles following

power-on or a transition from shutdown to normal operation

before reporting an external diode fault.

Serial Port Operation

The MIC384 uses standard SMBus Write_Byte and

Read_Byte operations for communication with its host. The

SMBus Write_Byte operation involves sending the device’s

slave address (with the R/W bit low to signal a write operation), followed by a command byte and a data byte. The

SMBus Read_Byte operation is similar, but is a composite

write and read operation: the host first sends the device’s

slave address followed by the command byte, as in a write

operation. A new start bit must then be sent to the MIC384,

followed by a repeat of the slave address with the R/W bit

(LSB) set to the high (read) state. The data to be read from

the part may then be clocked out.

The command byte is eight bits wide. This byte carries the

address of the MIC384 register to be operated upon, and is

stored in the part’s pointer register. The pointer register is an

internal write-only register. The command byte (pointer

register) values corresponding to the various MIC384 registers are shown in Table 2. Command byte values other than

those explicitly shown are reserved, and should not be used.

Any command byte sent to the MIC384 will persist in the

pointer register indefinitely until it is overwritten by another

command byte. If the location latched in the pointer register

from the last operation is known to be correct (i.e., points to

the desired register), then the Receive_Byte procedure may

be used. To perform a Receive_Byte, the host sends an

address byte to select the MIC384, and then retrieves the

data byte. Figures 1 through 3 show the formats for these

procedures.

= 0111 1111b). An interrupt will

h

2

connection to an external diode is lost or the sense line (T1

or T2) is shorted to V

or ground, the temperature data

DD

reported by the A/D converter will be forced to its full-scale

value (+127°C). This will cause a temperature event to occur

if the setpoint register for the corresponding zone is set to any

etyB_dnammoCretsigeRtegraT

yraniBxeHlebaLnoitpircseD

00000000

b

10000000

b

01000000

b

11000000

b

00001000

b

01001000

b

11001000

b

00000100

b

01000100

b

11000100

b

00

h

10

h

20

h

30

h

01

h

21

h

31

h

02

h

22

h

32

h

0PMETerutarepmetlacol

GIFNOCretsigernoitarugifnoc

0TSYH_Tsiseretsyherutarepmetlacol

0TES_Ttniopteserutarepmetlacol

1PMETerutarepmet1enozetomer

1TSYH_Tsiseretsyherutarepmet1enozetomer

1TES_Ttniopteserutarepmet1enozetomer

2PMETerutarepmet2enozetomer

2TSYH_Tsiseretsyherutarepmet2enozetomer

2TES_Ttniopteserutarepmet2enozetomer

Table 2. MIC384 Register Addresses

September 2000 7 MIC384

Page 8

MIC384 Micrel

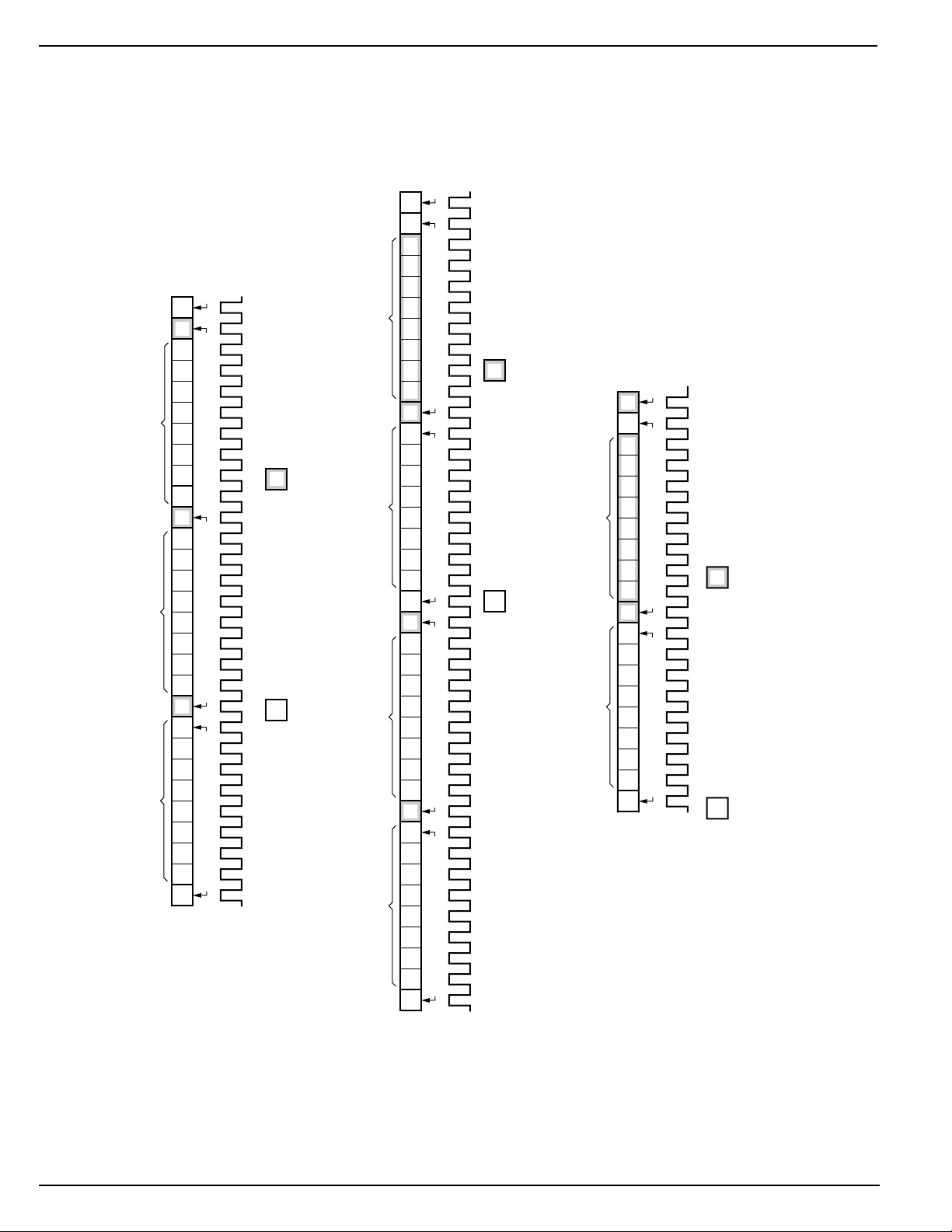

S1001

XXA0

0A00XXXXXXA

XXX XXXXX

/A P

MIC384 Slave Address

DATA

CLK

Command Byte

Data Byte to MIC384

START

STOP

R/W = WRITE

ACKNOWLEDGE ACKNOWLEDGE

NOT ACKNOWLEDGE

Master-to-slave transmission Slave-to-master response

S1001

XXA0 XXA0

0A00XXXXXXAS1 1 100

XXX XXXX

A

X

/A P

MIC384 Slave Address

DATA

CLK

Command Byte

MIC384 Slave Address

Data Read From MIC384

START

START

STOP

R/W = WRITE

R/W = READ

ACKNOWLEDGE ACKNOWLEDGE ACKNOWLEDGE

NOT ACKNOWLEDGE

Master-to-slave transmission Slave-to-master response

S1001

XXA0

1A /A

XXX XXX PXX

MIC384 Slave Address

DATA

CLK

Data Byte from MIC384

START

STOP

R/W = READ

ACKNOWLEDGE NOT ACKNOWLEDGE

Master-to-slave transmission Slave-to-master response

Figure 1. WRITE_BYTE Protocol

Figure 2. READ_BYTE Protocol

Figure 3. RECEIVE_BYTE

MIC384 8 September 2000

Page 9

MIC384 Micrel

S1001

XXX

AXX XXXXXXXA

MIC384 Slave Address

First Byte of Transaction

START

ACKNOWLEDGE ACKNOWLEDGE

R/W = DONT CARE

/A PXX XXXXXX

Last Byte of Transaction

A/D Converter

in Standby

Conversion

in Progress

New Conversion

in Progress

New Conversion

Begins

Conversion Interrupted

By MIC384 Acknowledge

First

Result

Ready

t

CONV1

STOP

NOT ACKNOWLEDGE

…

Master-to-slave transmission Slave-to-master response

A

SS1000

XXA0 XXA0

0A00000001A 10 100 XX XXXXXX/AP

MIC384 Slave Address

Temperature event occurs

MIC384 Slave Address

INT

Command Byte = 01

h

= CONFIG

CONFIG Value*

START

START

STOP

R/W = WRITE

ACKNOWLEDGE

ACKNOWLEDGE

ACKNOWLEDGE

R/W = READ

NOT ACKNOWLEDGE

Master-to-slave transmission Slave-to-master response

t

n/INT

t

/INT

* Status bits in CONFIG are cleared to zero following this operation

Figure 4. A/D Converter Timing

Figure 5. Responding to Interrupts

September 2000 9 MIC384

Page 10

MIC384 Micrel

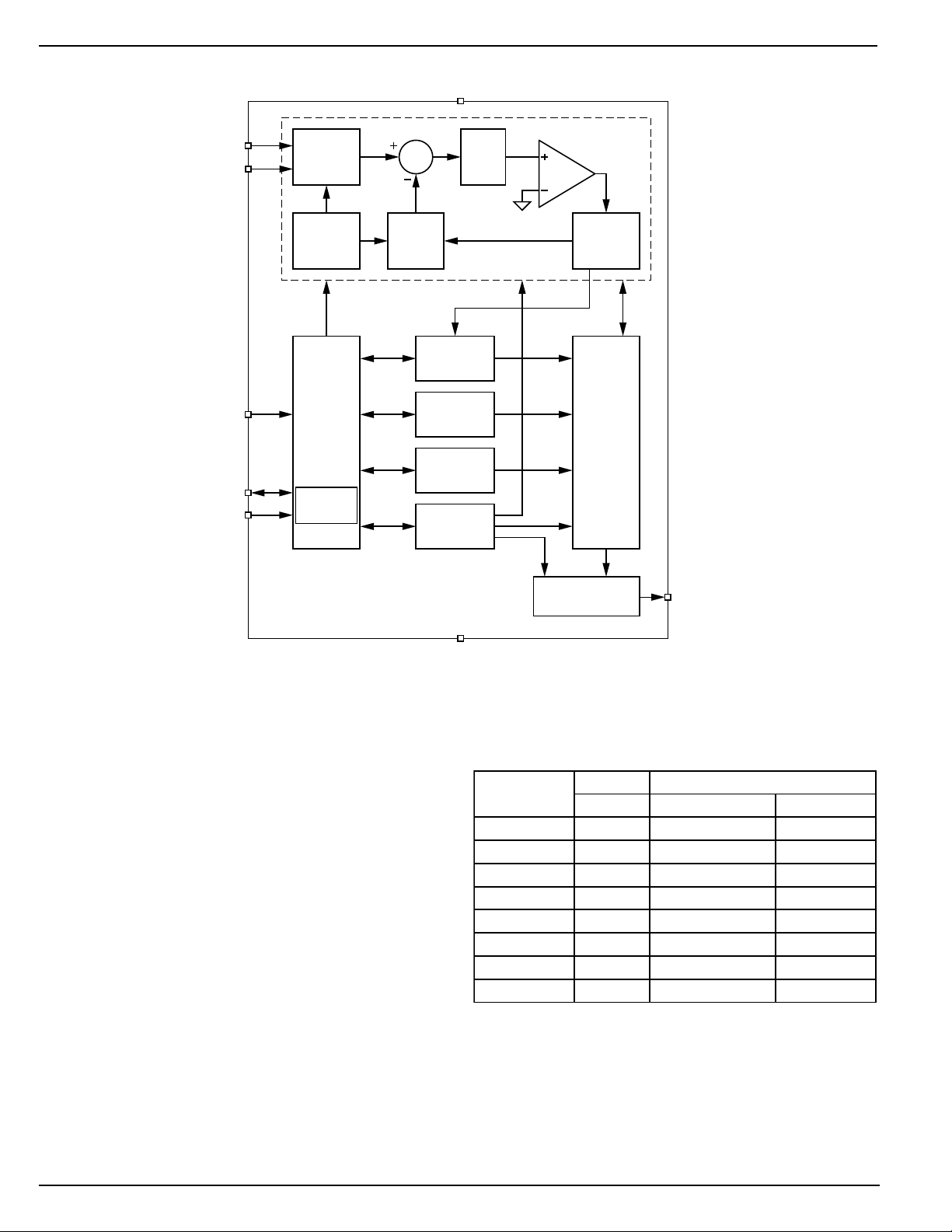

Temperature Data Format

The LSB of each register represents one degree Centigrade.

The values are in a two’s complement format, wherein the

most significant bit (D7) represents the sign: zero for positive

temperatures and one for negative temperatures. Table 3

shows examples of the data format used by the MIC384 for

temperatures.

A/D Converter Timing

Whenever the MIC384 is not in its low power shutdown mode,

the internal A/D converter (ADC) attempts to make continuous conversions unless interrupted by a bus transaction

accessing the MIC384.

Upon powering up or coming out of shutdown mode, the ADC

will begin acquiring temperature data starting with the first

external zone, zone 1, then the second external zone, zone

2, and finally the internal zone, zone 0. Results for zone 1 will

be valid after t

another t

CONV1

, results for zone two will be ready after

CONV1

, and for the local zone t

later. Figure 4

CONV0

shows this behavior. The conversion time is twice as long for

external conversions as it is for internal conversions. This

allws the use of a filter capacitor on T1 and/or T2 without a

loss of accuracy due to the resulting longer settling times.

Upon powering up, coming out of shutdown mode, or resuming operation following a serial bus transaction, the ADC will

begin aquiring temperature data with the first external zone

(zone 1), followed by the second external zone (zone 2), and

then the internal zone (zone 0). If the ADC in interrupted by

a serial bus transaction, it will restart the conversion that was

interrupted and then continue in the normal sequence. This

sequence will repeat indefinitely until the MIC384 is shut

down, powered off, or is interrupted by a serial bus transaction as described above.

Power On

When power is initially applied, the MIC384’s internal registers are set to their default states. Also at this time, the level

on the address input, A0, is read to establish the device’s

slave address. The MIC384’s power-up default state can be

summarized as follows:

• Normal mode operation (i.e., part is not in

shutdown)

• /INT function is set to comparator mode

• Fault queue depth = 1 (FQ=00)

• Interrupts are enabled (IM = 0)

• T_SET0 = 81°C; T_HYST0 = 76°C

• T_SET1 = 97°C; T_HYST1 = 92°C

• T_SET2 = 97°C; T_HYST2 = 92°C

• Initialized to recognize overtemperature faults

Comparator and Interrupt Modes

Depending on the setting of the MODE bit in the configuration

register, the /INT output will behave either as an interrupt

request signal or a thermostatic control signal. Thermostatic

operation is known as

comparator mode

. The /INT output is

asserted when the measured temperature, as reported in any

of the TEMPx registers, exceeds the threshold programmed

into the corresponding T_SETx register for the number of

conversions specified by Fault_Queue (described below). In

comparator mode, /INT will remain asserted and the status

bit(s) will remain high unless and until the measured temperature falls below the value in the T_HYSTx register for

Fault_Queue conversions. No action on the part of the host

is required for operation in comparator mode. Note that

entering shutdown mode will not affect the state of /INT when

the device is in comparator mode.

In

interrupt mode

, once a temperature event has caused a

status bit to be set and the /INT output to be asserted, they will

not be automatically de-asserted when the measured temperature falls below T_HYSTx. They can only be de-asserted

by reading any of the MIC384’s internal registers or by putting

the device into shutdown mode. If the most recent temperature event was an overtemperature condition, Sx will not be

set again, and /INT cannot be reasserted, until the device has

detected that TEMPx < T_HYSTx. Similarly, if the most

recent temperature event was an undertemperature condition, Sx will not be set again, and /INT cannot be reasserted,

until the device has detected that TEMPx > T_SETx. This

keeps the internal logic of the MIC384 backward compatible

with that of the LM75 and similar devices. In both modes, the

MIC384 will be responsive to over-temperature events at

power-up. See "Interrupt Generation", below.

Shutdown Mode

Setting the SHDN bit in the configuration register halts the

otherwise continuous conversions by the A/D converter. The

MIC384’s power consumption drops to 1µA typical in shutdown mode. All registers may be read from or written to while

in shutdown mode. Serial bus activity will slightly increase the

part’s power consumption.

Entering shutdown mode will not affect the state of /INT when

the device is in comparator mode (MODE = 0). It will retain

its state until after the device exits shutdown mode and

resumes A/D conversions.

However, if the device is shut down while in interrupt mode,

the /INT pin will be unconditionally de-asserted and the

internal latches holding the interrupt status will be cleared.

Therefore, no interrupts will be generated while the MIC384

MIC384 10 September 2000

Page 11

MIC384 Micrel

erutarepmeTyraniBxeH

C°521+10111110

C°001+00100110

C°52+10011000

C°0.1+10000000

C°000000000

C°0.1– 11111111

C°52– 11100111

C°04– 00011011

C°55– 10010011

b

b

b

b

b

b

b

b

b

Table 3. Digital Temperature Format

D7

h

46

h

91

h

10

h

00

h

FF

h

7E

h

8D

h

9C

h

September 2000 11 MIC384

Page 12

MIC384 Micrel

is in shutdown mode, and the interrupt status will not be

retained. Since entering shutdown mode stops A/D conversions, the MIC384 is incapable of detecting or reporting

temperature events of any kind while in shutdown. Diode

faults require one or more A/D conversion cycles to be

recognized, and therefore will not be reported either while the

device is in shutdown (see "Diode Faults" above).

Fault_Queue

Fault queues (programmable digital filters) are provided in

the MIC384 to prevent false tripping due to thermal or

electrical noise. The two bits in CONFIG[4:3] set the depth of

Fault_Queue. Fault_Queue then determines the number of

consecutive temperature events (TEMPx > T_SETx, or TEMPx

< T_HYSTx) which must occur in order for the condition to be

considered valid. There are separate fault queues for each

zone. As an example, assume the part is in comparator

mode, and CONFIG[4:3] is programmed with 10

. The

b

measured temperature in zone one would have to exceed

T_SET1 for four consecutive A/D conversions before /INT

would be asserted or the S1 status bit set. Similarly, TEMP1

would then have to be less than T_HYST1 for four consecutive conversions before /INT would be reset. Like any filter,

the fault queue function also has the effect of delaying the

detection of temperature events. In this example, it would

take 4 x t

to detect a temperature event. The depth of

CONV

Fault_Queue vs. D[4:3] of the configuration register is shown

in Table 4.

]3:4[GIFNOChtpeDeueuQ_tluaF

00*noisrevnoc1

10snoisrevnoc2

01snoisrevnoc4

11snoisrevnoc6

gnittestluafeD*

Table 4. Fault_Queue Depth Settings

Interrupt Generation

Assuming the MIC384 is in interrupt mode and interrupts are

enabled, there are seven different conditions that will cause

the MIC384 to set one of the status bits, S0, S1, or S2, in

CONFIG and assert its /INT output. These conditions are

listed in Table 5. When a temperature event occurs, the

corresponding status bit will be set in CONFIG. This action

cannot be masked. However, a temperature event will only

generate an interrupt signal on /INT if it is specifically enabled

by the interrupt mask bit (IM =0 in CONFIG). Following an

interrupt, the host should read the contents of the configuration register to confirm that the MIC384 was the source of the

interrupt. A read operation on

any

register will cause /INT to

be de-asserted. This is shown in Figure 5. The status bits will

only be cleared once CONFIG has been read.

Since temperature-to-digital conversions continue while /INT

is asserted, the measured temperature could change between the MIC384’s assertion of /INT and the host’s response. It is good practice for the interrupt service routine to

read the value in TEMPx, to verify that the over-temperature

or under-temperature condition still exists. In addition, more

than one temperature event may have occurred simultaneously or in rapid succession between the assertion of /INT

and servicing of the MIC384 by the host. The interrupt service

routine should allow for this eventuality. Keep in mind that

clearing the status bits and deasserting /INT is not sufficient

to allow further interrupts to occur. TEMPx must become less

than T_HYSTx if the last event was an over-temperature

condition, or greater than T_SETx if the last event was an

under-temperature condition, before /INT can be asserted

again.

Putting the device into shutdown mode will de-assert /INT

and clear the status bits (S0, S1, and S2). This should not be

done before completing the appropriate interrupt service

routine(s).

Polling

The MIC384 may either be polled by the host, or request the

host’s attention via the /INT pin. In the case of polled

operation, the host periodically reads the contents of CONFIG

to check the state of the status bits. The act of reading

CONFIG clears the status bits. If more than one event that

sets a given status bit occurs before the host polls the

MIC384, only the fact that at least one such event has

occurred will be apparent to the host. For polled systems, the

interrupt mask bit should be set (IM = 1). This will disable

interrupts from the MIC384 and prevent the /INT pin from

sinking current.

MIC384 12 September 2000

Page 13

MIC384 Micrel

tnevE*noitidnoC**esnopser482CIM

lacol,erutarepmethgih0TES_T>0PMETTNI/tressa,GIFNOCni0Stes

,erutarepmethgih

1enozetomer

,erutarepmethgih

2enozetomer

1TES_T>1PMETTNI/tressa,GIFNOCni1Stes

2TES_T>1PMETTNI/tressa,GIFNOCni2Stes

lacol,erutarepmetwol0TSYH_T<0PMETTNI/tressa,GIFNOCni0Stes

,erutarepmetwol

1enozetomer

,erutarepmetwol

2enozetomer

tluafedoid

delbaneerastpurretnisemussA**

DNG

1TSYH_T<1PMETTNI/tressa,GIFNOCni1Stes

2TSYH_T<1PMETTNI/tressa,GIFNOCni2Stes

roDDVotdetrohsronepo2Tro1T

dezingocerebotnoisrevnocEUEUQ_TLUAFrofeurtebtsumnoitidnoC*

f7=C°721+nehtsseleulavynaottesera2TES_Tdna1TES_TtahtsemussA***

h

,GIFNOCni2Sro/dna1SdnaTIRCtes

***TIRC/dnaTNI/tressa

11111110=

b

Table 5. MIC384 Temperature Events

September 2000 13 MIC384

Page 14

MIC384 Micrel

Register Set and Programmer’s Model

Internal Register Set

emaNnoitpircseDetyBdnammoCnoitarepOtluafeDpU-rewoP

0PMET

GIFNOCretsigernoitarugifnoc10

0TSYH_T

0TES_T

1PMET

enoz

enoz

1enoz

1TSYH_T1enoz,gnittessiseretsyh21

1TES_T

2PMET

1enoz

2enoz

,erutarepmetderusaem

enozlacol

lacol,gnittessiseretsyh

lacol,tniopteserutarepmet

,erutarepmetderusaem

,tniopteserutarepmet

,erutarepmetderusaem

00

h

h

20

h

30

h

01

h

h

31

h

ylnodaertib-800

etirw/daertib-800

etirw/daertib-8C4

etirw/daertib-815

ylnodaertib-800

etirw/daertib-8C5

etirw/daertib-816

h02ylnodaertib-800

2TSYH_T2enoz,gnittessiseretsyhh22etirw/daertib-8C5

2TES_T

2enoz

,tniopteserutarepmet

h32etirw/daertib-816

h

h

h

h

h

h

h

h

h

)1(

)C°0(

)2(

h

)C°67+(

)C°18+(

)1(

)C°0(

)C°29+(

)C°79+(

)1(

)C°0(

)C°29+(

)C°79+(

(1) TEMPx will contain measured temperature data after the completion of one conversion cycle.

(2) After the first Fault_Queue conversions are complete, status bits will be set if TEMPx > T_SETx.

Detailed Register Descriptions

Configuration Register

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

ylnodaerylnodaerylnodaeretirw/daeretirw/daeretirw/daeretirw/daer

0enoz

sutats

)0S(

stiBnoitcnuFnoitarepO

0S)ylnodaer(sutatstpurretnilacol tneveon=0,deruccotneve=1

1S)ylnodaer(sutatstpurretni1enozetomer tneveon=0,deruccotneve=1

2S)ylnodaer(sutatstpurretni2enozetomer tneveon=0,deruccotneve=1

]0:1[QFhtpedeueuQ_tluaF

MIksamtpurretni delbanestpurretni=0,delbasid=1

EDOM

NDHS

)GIFNOC(RETSIGERNOITARUGIFNOC

etirW/daeRtiB-8

1enoz

sutats

)1S(

2enoz

sutats

)2S(

eueuqtluaf

htped

)]0:1[QF(

tpurretni

ksam

)MI(

TNI/PMC

edom

)EDOM(

nwodtuhS

)NDHS(

,snoisrevnoc2=10,noisrevnoc1=00

snoisrevnoc6=11,snoisrevnoc4=01

tpurretni/rotarapmoc

nipTNI/rofnoitcelesedom

nwodtuhs/lamron

noitcelesedomgnitarepo

lamron=0

,edomtpurretni=1

edomrotarapmoc=0

,nwodtuhs=1

CONFIG Power-Up Value: 0000 0000b = 00

(*)

h

• not in shutdown mode

• comparator mode

• Fault_Queue depth = 1

• interrupts enabled.

• no temperature events pending

CONFIG Command Byte Value: 0000 0001b = 01

* Following the first Fault_Queue conversions, one or more of the status bits may be set.

h

MIC384 14 September 2000

Page 15

MIC384 Micrel

Local Temperature Result Register

)0PMET(STLUSERERUTAREPMETLACOL

ylnOdaeRtiB-8

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

*CDAmorfataderutarepmetlacol

stiBnoitcnuFnoitarepO

]0:7[D

*enoz

lacolehtrofataderutarepmetderusaem

ylnodaer

TEMP0 Power-Up Value: 0000 0000b = 00h (0°C)

TEMP0 Command Byte Value: 0000 0000b = 00

†

h

Local Hysteresis Register

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

stiBnoitcnuFnoitarepO

]0:7[D*gnittessiseretsyherutarepmetlacoletirw/daer

T_HYST0 Power-Up Value: 0100 1100b = 4Ch (+76°C)

T_HYST0 Command Byte Value: 0000 0010b = 02

h

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000

†

TEMP0 will contain measured temperature data after the

completion of one conversion.

etirW/daeRtiB-8

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000b. See "Temperature Data Format" for more details.

. See "Temperature Data Format" for more details.

b

)0TSYH_T(SISERETSYHERUTAREPMETLACOL

gnittessiseretsyherutarepmetlacol

Local Temperature Setpoint Register

)0TES_T(TNIOPTESERUTAREPMETLACOL

etirW/daeRtiB-8

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

tniopteserutarepmetlacol

stiBnoitcnuFnoitarepO

]0:7[D*tniopteserutarepmetlacoletirw/daer

T_SET0 Power-Up Value: 0101 0001b = 51h (+81°C)

T_SET0 Command Byte Value: 0000 0011b = 03

h

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000b. See "Temperature Data Format" for more details.

September 2000 15 MIC384

Page 16

MIC384 Micrel

Remote Zone 1 Temperature Result Register

)1PMET(TLUSERERUTAREPMET1ENOZETOMER

ylnOdaeRtiB-8

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

*CDAmorfataderutarepmet1enozetomer

stiBnoitcnuFnoitarepO

]0:7[D

*enoenoz

etomerrofataderutarepmetderusaem

ylnodaer

TEMP1 Power-Up Value: 0000 0000b = 00h (0°C)

TEMP1 Command Byte Value: 0001 0000b = 10

†

h

Remote Zone 1 Hysteresis Register

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

stiBnoitcnuFnoitarepO

]0:7[D*siseretsyherutarepmetenoenozetomeretirw/daer

T_HYST1 Power-Up Value: 0101 1100b = 5Ch (+92°C)

T_HYST1 Command Byte Value: 0001 0010b = 12

h

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000

†

TEMP1 will contain measured temperature data for the

selected zone after the completion of one conversion.

etirW/daeRtiB-8

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000b. See "Temperature Data Format" for more details.

. See "Temperature Data Format" for more details.

b

)1TSYH_T(RETSIGERSISERETSYHERUTAREPMET1ENOZETOMER

*siseretsyherutarepmet1enozetomer

Remote Zone 1 Temperature Setpoint Register

)1TES_T(TNIOPTESERUTAREPMET1ENOZETOMER

etirW/daeRtiB-8

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

tniopteserutarepmet1enozetomer

stiBnoitcnuFnoitarepO

]0:7[D*tniopteserutarepmetenoenozetomeretirw/daer

T_SET1 Power-Up Value: 0110 0001b = 61h (+97°C)

T_SET1 Command Byte Value: 0001 0011b = 13

h

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000b. See "Temperature Data Format" for more details.

MIC384 16 September 2000

Page 17

MIC384 Micrel

Remote Zone 2 Temperature Result Register

)2PMET(RETSIGERSTLUSERERUTAREPMET2ENOZETOMER

ylnOdaeRtiB-8

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

*CDAmorfataderutarepmet2enozetomer

stiBnoitcnuFnoitarepO

]0:7[D

*2enoz

etomerrofataderutarepmetderusaem

ylnodaer

TEMP2 Power-Up Value: 0000 0000b = 00h (0°C)

TEMP2 Command Byte Value: 0010 0000b = 20

†

h

Remote Zone 2 Hysteresis Register

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

stiBnoitcnuFnoitarepO

]0:7[D

*gnittes

T_HYST2 Power-Up Value: 0101 1100b = 5Ch (+92°C)

T_HYST2 Command Byte Value: 0010 0010b = 22

h

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000

†

TEMP2 will contain measured temperature data for the

selected zone after the completion of one conversion.

etirW/daeRtiB-8

siseretsyherutarepmet2enozetomer

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000b. See "Temperature Data Format" for more details.

. See "Temperature Data Format" for more details.

b

)2TSYH_T(RETSIGERSISERETSYH2ENOZETOMER

gnittessiseretsyherutarepmet2enozetomer

etirw/daer

Remote Zone 2 Setpoint Register

)2TES_T(TNIOPTESERUTAREPMET2ENOZETOMER

etirW/daeRtiB-8

]7[D]6[D]5[D]4[D]3[D]2[D]1[D]0[D

BSM6tib5tib4tib3tib2tib1tibBSL

tniopteserutarepmet2enozetomer

stiBnoitcnuFnoitarepO

]0:7[D*tniopteserutarepmet2enozetomeretirw/daer

T_SET2 Power-Up Value: 0110 0001b = 61h (+97°C)

T_SET2 Command Byte Value: 0010 0011b = 23

h

* Each LSB represents one degree Centigrade. The values are

in a two's complement format such that 0°C is reported as

0000 0000b. See "Temperature Data Format" for more details.

September 2000 17 MIC384

Page 18

MIC384 Micrel

Applications

Remote Diode Selection

Most small-signal PNP transistors with characteristics similar

to the JEDEC 2N3906 will perform well as remote temperature sensors. Table 6 lists several examples of such parts

that Micrel has tested for use with the MIC384. Other

transistors equivalent to these should also work well.

Minimizing Errors

Self-Heating

One concern when using a part with the temperature accuracy and resolution of the MIC384 is to avoid errors in

measuring the local temperature induced by self-heating.

Self-heating is caused by the power naturally dissipated

inside the device due to operating supply current and I/O sink

currents (VDD × IDD ) + (VOL × IOL). In order to understand

what level of error this represents, and how to reduce that

error, the dissipation in the MIC384 must be calculated and

its effects reduced to a temperature offset.

The worst-case operating condition for the MIC384 is when

VDD = 5.5V, MSOP-08 package. The maximum power

dissipated in the part is given in Equation 1 below.

In most applications, the /INT output will be low for at most a

few milliseconds before the host resets it back to the high

state, making its duty cycle low enough that its contribution to

self-heating of the MIC384 is negligible. Similarly, the DATA

pin will in all likelihood have a duty cycle of substantially less

than 25% in the low state. These considerations, combined

with more typical device and application parameters, give a

better system-level view of device self-heating in interruptmode. This is illustrated in Equation 2.

If the part is to be used in comparator mode, calculations

similar to those shown above (accounting for the expected

value and duty cycle of I

the temperature error due to self-heating.

) will give a good estimate of

OL(INT)

P [(I V ) (I ) (I V )]

=×+ + ×

DDDDD

P [(0.75mA 5.5V) (6mA 0.8V) (6mA 0.8V)]

= ×+×+×

D

P 13.73mW

=

D

R of MSOP-08 package is 206 C/ W

−

q(j a)

Maximum T relative to T due to self-heating is 13.73mW 206 C/ W = 2.83 C

∆×°°

OL(DATA) OL(/INT) OL(/INT)

°

JA

Equation 1. Worst-Case Self-Heating

In any application, the best test is to verify performance

against calculation in the final application environment. This

is especially true when dealing with systems for which some

of the thermal data (e.g., PC board thermal conductivity and

ambient temperature) may be poorly defined or unobtainable

except by empirical means.

Series resistance

The operation of the MIC384 depends upon sensing the

∆V

of a diode-connected PNP transistor (“diode”) at two

CB-E

different current levels. For remote temperature measurements, this is done using external diodes connected between

T1, T2 and ground.

Since this technique relies upon measuring the relatively

small voltage difference resulting from two levels of current

through the external diodes, any resistance in series with

those diodes will cause an error in the temperature reading

from the MIC384. A good rule of thumb is this: for each ohm

in series with a zone's external transistor, there will be a 0.9°C

error in the MIC384’s temperature measurement. It isn’t

difficult to keep the series resistance well below an ohm

(typically < 0.1Ω), so this will rarely be an issue.

Filter capacitor selection

It is sometimes desirable to use a filter capacitor between the

T1 and/or T2 pins and the GND pin of the MIC384. The use

of these capacitors is recommended in environments with a

lot of high frequency noise (such as digital switching noise),

or if long wires are used to attach to the remote diodes. The

maximum recommended total capacitance from the T1 or T2

pin to GND is 2700pF. This typically suggests the use of

2200pF NP0 or C0G ceramic capacitors with a 10% tolerance.

If a remote diode is to be at a distance of more than ≈ 6"—12"

from the MIC384, using twisted pair wiring or shielded microphone cable for the connections to the diode can significantly

help reduce noise pickup. If using a long run of shielded cable,

remember to subtract the cable’s conductor-to-shield capacitance from the 2700pF maximum total capacitance.

[(0.350mA I 3.3V) (25% 1.5mA I 0.3V) (1% 1.5mA I 0.3V)]=1.27mW

T (1.27mW 206 C / W)

∆= × °

J

T

∆= °0.262 C

J

×+× ×+× ×

DD(typ)

OL(DATA) OL(/INT)

Equation 2. Real-World Self-heating Example

Vendor Part Number Package

Fairchild MMBT3906 SOT-23

On Semiconductor MMBT3906L SOT-23

Phillips Semiconductor PMBT3906 SOT-23

Samsung KST3906-TF SOT-23

Table 6. Transistors Suitable for Remote Temperature Sensing Use

MIC384 18 September 2000

Page 19

MIC384 Micrel

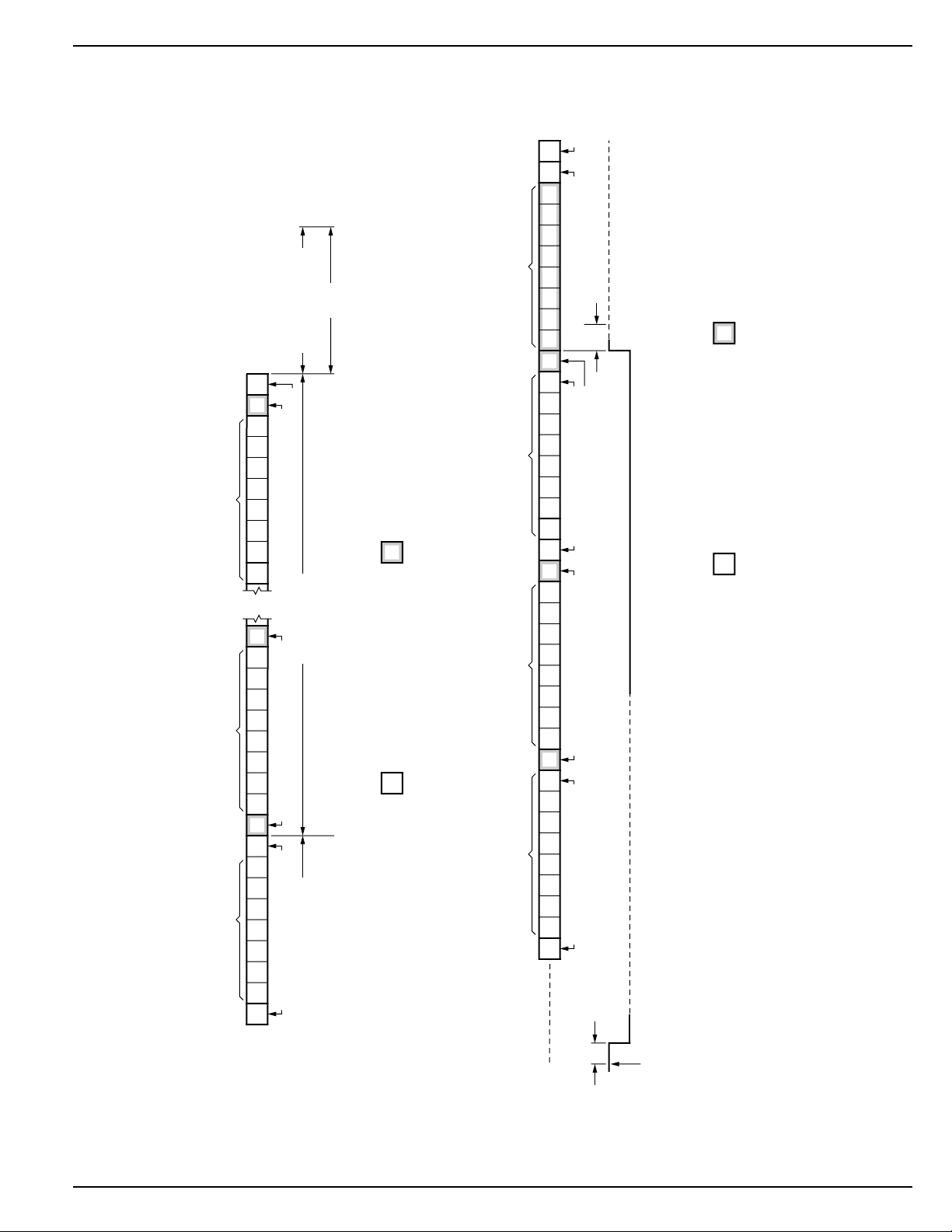

Layout Considerations

The following guidelines should be kept in mind when designing and laying out circuits using the MIC384:

1. Place the MIC384 as close to the remote diodes

as possible, while taking care to avoid severe

noise sources such as high frequency power

transformers, CRTs, memory and data busses,

and the like.

2. Since any conductance from the various voltages on the PC Board to the T1 or T2 line can

induce serious errors, it is good practice to

guard the remote diodes’ emitter traces with

pairs of ground traces. These ground traces

should be returned to the MIC384’s own ground

pin. They should not be grounded at any other

part of their run. However, it is highly desirable

to use these guard traces to carry the diodes’

own ground return back to the ground pin of the

MIC384, thereby providing a Kelvin connection

for the base of the diodes. See Figure 6.

3. When using the MIC384 to sense the temperature of a processor or other device which has an

integral thermal diode, e.g., Intel’s Pentium III,

connect the emitter and base of the remote

sensor to the MIC384 using the guard traces

and Kelvin return shown in Figure 6. The

collector of the remote diode is typically inaccessible to the user on these devices. To allow for

this, the MIC384 has superb rejection of noise

appearing from collector to GND, as long as the

base to ground connection is relatively quiet.

4. Due to the small currents involved in the measurement of the remote diode’s ∆V

BE

, it is

important to adequately clean the PC board after

soldering to prevent current leakage. This is

most likely to show up as an issue in situations

where water-soluble soldering fluxes are used.

5. In general, wider traces for the ground and T1/

T2 lines will help reduce susceptibility to radiated noise (wider traces are less inductive). Use

trace widths and spacing of 10 mils wherever

possible and provide a ground plane under the

MIC384 and under the connections from the

MIC384 to the remote diodes. This will help

guard against stray noise pickup.

6. Always place a good quality 0.1µF power supply

bypass capacitor directly adjacent to, or underneath, the MIC384. Surface-mount capacitors

are preferable because of their low inductance.

7. When the MIC384 is being powered from

particularly noisy power supplies, or from

supplies which may have sudden high-amplitude

spikes appearing on them, it can be helpful to

add additional power supply filtering. This

should be implemented as a 100Ω resistor in

series with the part’s VDD pin, and an additional

4.7µF, 6.3V electrolytic capacitor from VDD to

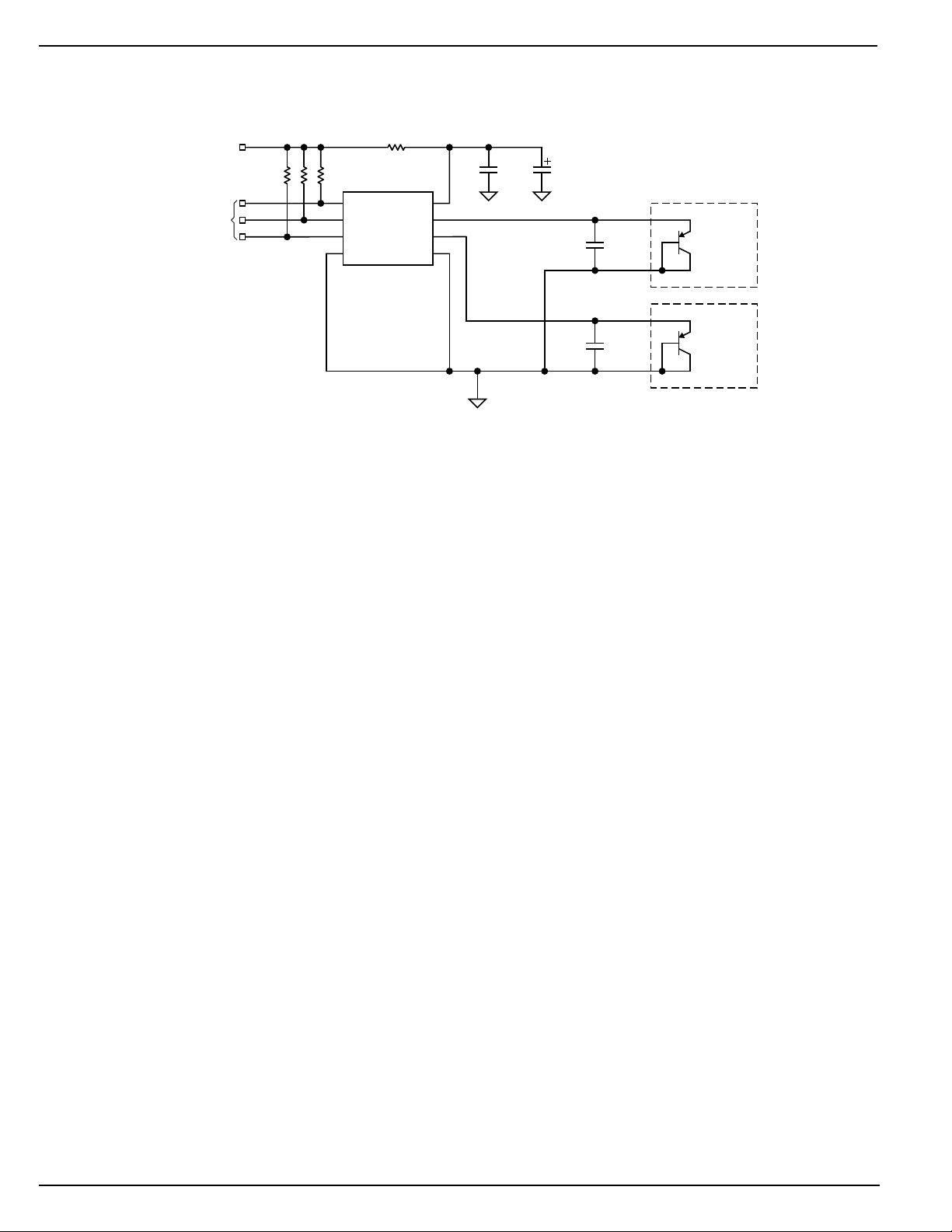

GND. See Figure 7.

MIC384

DATA

1

CLK

2

/INT

3

GND

VDD

A0

T1

T2

8

7

6

54

GUARD/RETURN

REMOTE DIODE (T1)

GUARD/RETURN

GUARD/RETURN

REMOTE DIODE (T2)

GUARD/RETURN

Figure 6. Guard Traces/Kelvin Ground Returns

September 2000 19 MIC384

Page 20

MIC384 Micrel

3.3V

FROM

SERIAL BUS

HOST

10k pull-ups

100

4.7µF0.1µF

MIC384

DATA

CLK

/ INT

GND

VDD

A0

T1

T2

2200pF

2200pF

Figure 7. VDD Decoupling for Very Noisy Supplies

Remote

Diode

Remote

Diode

MIC384 20 September 2000

Page 21

MIC384 Micrel

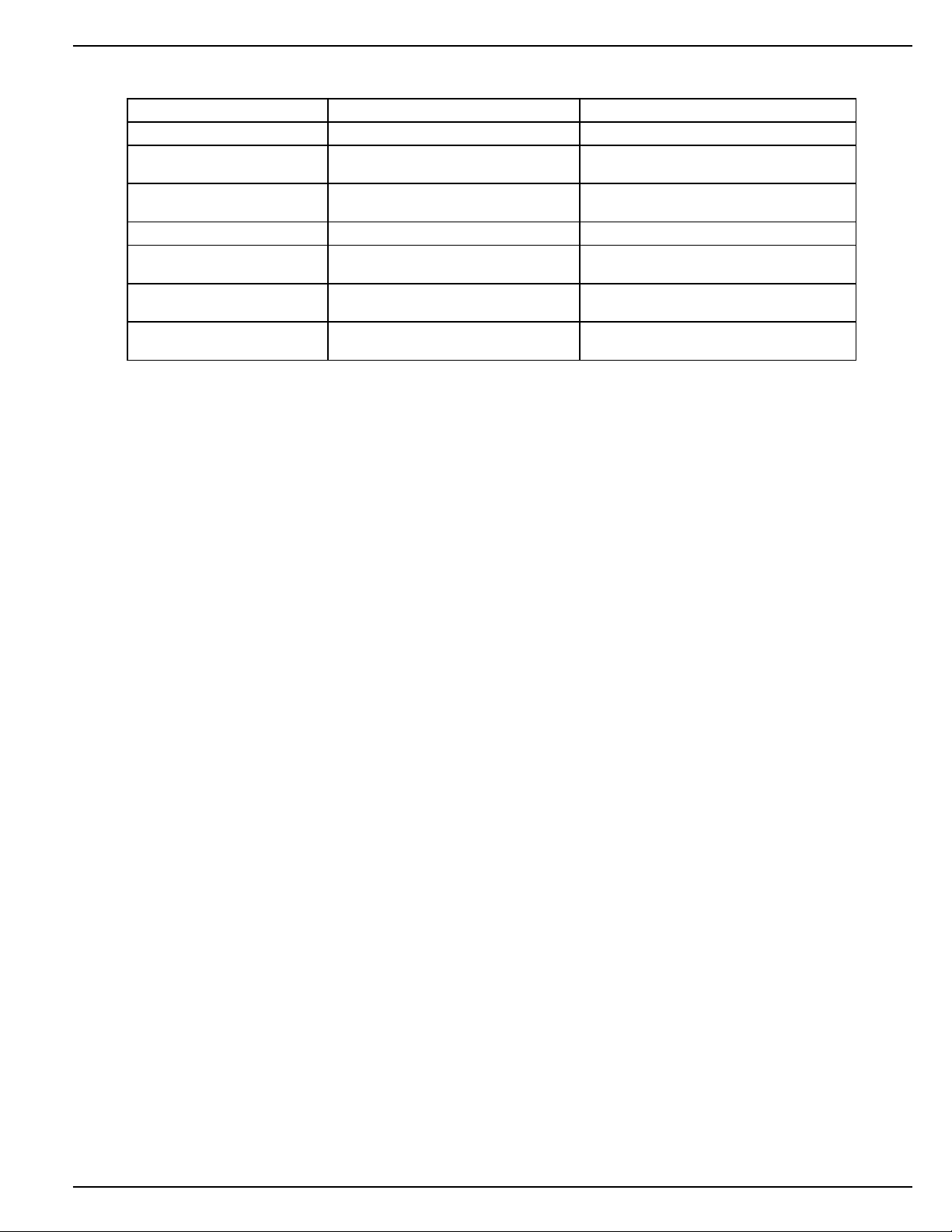

Package Information

0.026 (0.65)

MAX)

PIN 1

0.157 (3.99)

0.150 (3.81)

0.064 (1.63)

0.045 (1.14)

0.122 (3.10)

0.112 (2.84)

0.036 (0.90)

0.032 (0.81)

0.050 (1.27)

TYP

0.197 (5.0)

0.189 (4.8)

0.020 (0.51)

0.013 (0.33)

0.0098 (0.249)

0.0040 (0.102)

SEATING

PLANE

8-Lead SOP (M)

0.199 (5.05)

0.187 (4.74)

0.120 (3.05)

0.116 (2.95)

0.043 (1.09)

0.038 (0.97)

DIMENSIONS:

INCHES (MM)

0°–8°

0.012 (0.30) R

45°

0.050 (1.27)

0.016 (0.40)

0.244 (6.20)

0.228 (5.79)

DIMENSIONS:

INCH (MM)

0.010 (0.25)

0.007 (0.18)

0.007 (0.18)

0.005 (0.13)

0.012 (0.03)

0.0256 (0.65) TYP

0.008 (0.20)

0.004 (0.10)

5° MAX

0° MIN

0.012 (0.03) R

0.039 (0.99)

0.035 (0.89)

0.021 (0.53)

8-Lead MSOP (MM)

MICREL INC. 1849 FORTUNE DRIVE SAN JOSE, CA 95131 USA

TEL + 1 (408) 944-0800 FAX + 1 (408) 944-0970 WEB http://www.micrel.com

This information is believed to be accurate and reliable, however no responsibility is assumed by Micrel for its use nor for any infringement of patents or

other rights of third parties resulting from its use. No license is granted by implication or otherwise under any patent or patent right of Micrel Inc.

© 2000 Micrel Incorporated

September 2000 21 MIC384

Loading...

Loading...