Page 1

MIC2171 Micrel

MIC2171

100kHz 2.5A Switching Regulator

Preliminary Information

General Description

The MIC2171 is a complete 100kHz SMPS current-mode

controller with an internal 65V 2.5A power switch.

Although primarily intended for voltage step-up applications,

the floating switch architecture of the MIC2171 makes it

practical for step-down, inverting, and Cuk configurations as

well as isolated topologies.

Operating from 3V to 40V, the MIC2171 draws only 7mA of

quiescent current, making it attractive for battery operated

supplies.

The MIC2171 is available in a 5-pin TO-220 or TO-263 for

–40°C to +85°C operation.

Features

• 2.5A, 65V internal switch rating

• 3V to 40V input voltage range

• Current-mode operation, 2.5A peak

• Internal cycle-by-cycle current limit

• Thermal shutdown

• Twice the frequency of the LM2577

• Low external parts count

• Operates in most switching topologies

• 7mA quiescent current (operating)

• Fits LT1171/LM2577 TO-220 and TO-263 sockets

Applications

• Laptop/palmtop computers

• Battery operated equipment

• Hand-held instruments

• Off-line converter up to 50W

(requires external power switch)

• Predriver for higher power capability

4

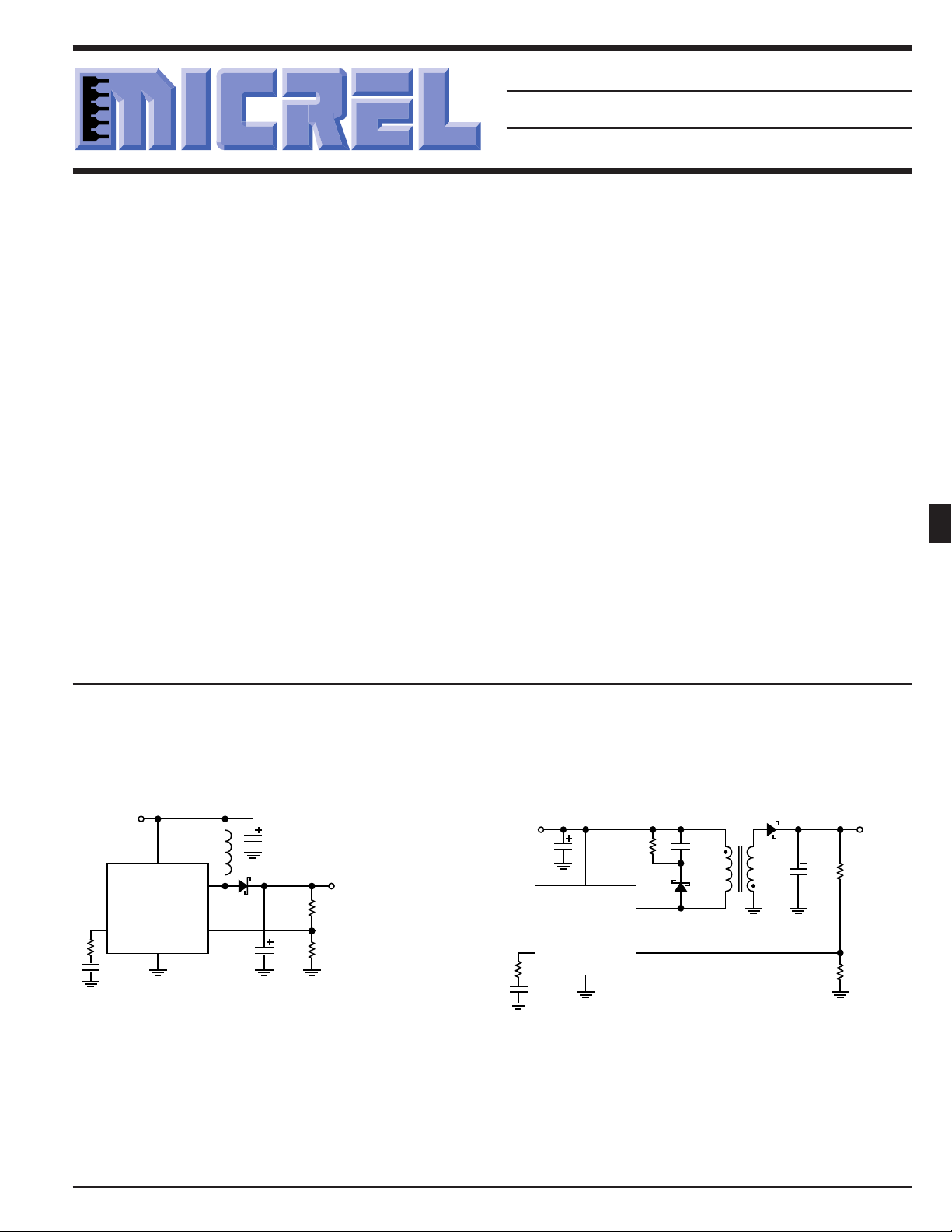

Typical Applications

+5V

(4.75V min.)

IN

MIC2171

COMP

3

1k

* Locate near MIC2171 when supply leads > 2

C3

1µF

GND

SW

FB

15µH

L1

MIC2171 5V to 12V Boost Converter

D1

1N5822

Figure 1.

C1*

47µF

C2

470µF

V

OUT

+12V, 0.25A

R1

10.7k

1%

R2

1.24k

1%

"

V

IN

4V to 6V

C1

47µF

IN

MIC2171

COMP

R3

1k

* Optional voltage clipper (may be req’d if T1 leakage inductance too high)

C2

1µF

GND

R4*

SW

FB

L

C3*

D1*

PRI

1:1.25

= 12µH

T1

D2

1N5818

470µF

Figure 2.

MIC2171 5V Flyback Converter

C4

R1

3.74k

1%

R2

1.24k

1%

V

OUT

5V, 0.5A

1997 4-3

Page 2

MIC2171 Micrel

5IN

4SW

3 GND

2FB

1 COMP

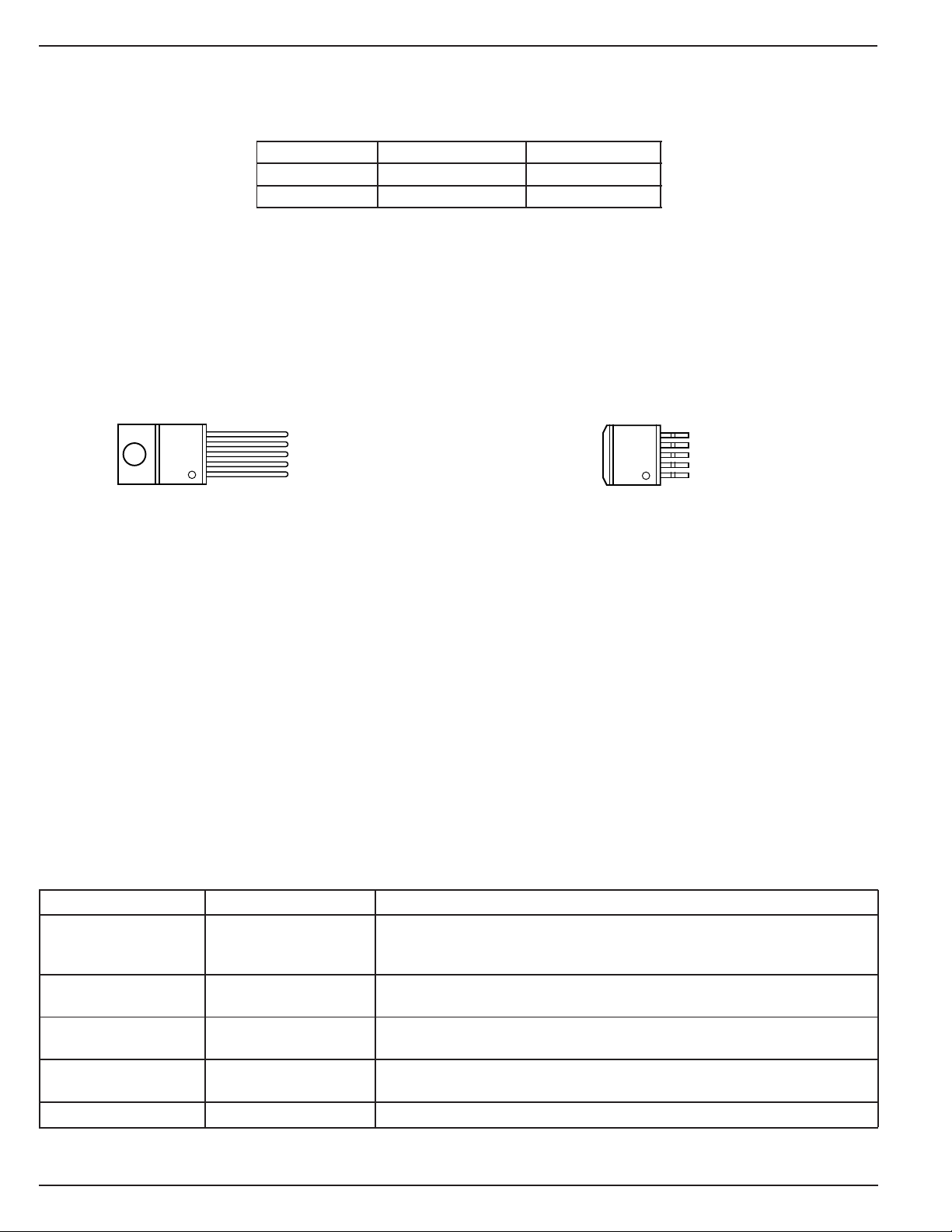

Ordering Information

Part Number Temperature Range Package

MIC2171BT –40°C to +85°C 5-lead TO-220

MIC2171BU –40°C to +85°C 5-lead TO-263

Pin Configuration

5IN

4SW

3 GND

2FB

1 COMP

Tab GND

Pin Description

Pin Number Pin Name Pin Function

1 COMP Frequency Compensation: Output of transconductance-type error amplifier.

2 FB Feedback: Inverting input of error amplifier. Connect to external resistive

3 GND Ground: Connect directly to the input filter capacitor for proper operation

4 SW Power Switch Collector: Collector of NPN switch. Connect to external

5 IN Supply Voltage: 3.0V to 40V

5-lead TO-263 (BU)5-lead TO-220 (BT)

Primary function is for loop stabilization. Can also be used for output voltage

soft-start and current limit tailoring.

divider to set power supply output voltage.

(see applications info).

inductor or input voltage depending on circuit topology.

4-4 1997

Page 3

MIC2171 Micrel

Absolute Maximum Ratings

Input Voltage (VIN) ........................................................40V

Switch Voltage (VSW)....................................................65V

Feedback Voltage (transient, 1ms) (VFB)................... ±15V

Operating Temperature Range ......................–40 to +85°C

Junction Temperature ................................–55°C to 150°C

Thermal Resistance

θJA 5-lead TO-220, Note 1.................................45°C/W

θJA 5-lead TO-263, Note 2.................................45°C/W

Storage Temperature ...............................–65°C to +150°C

Soldering (10 sec.) ..................................................+300°C

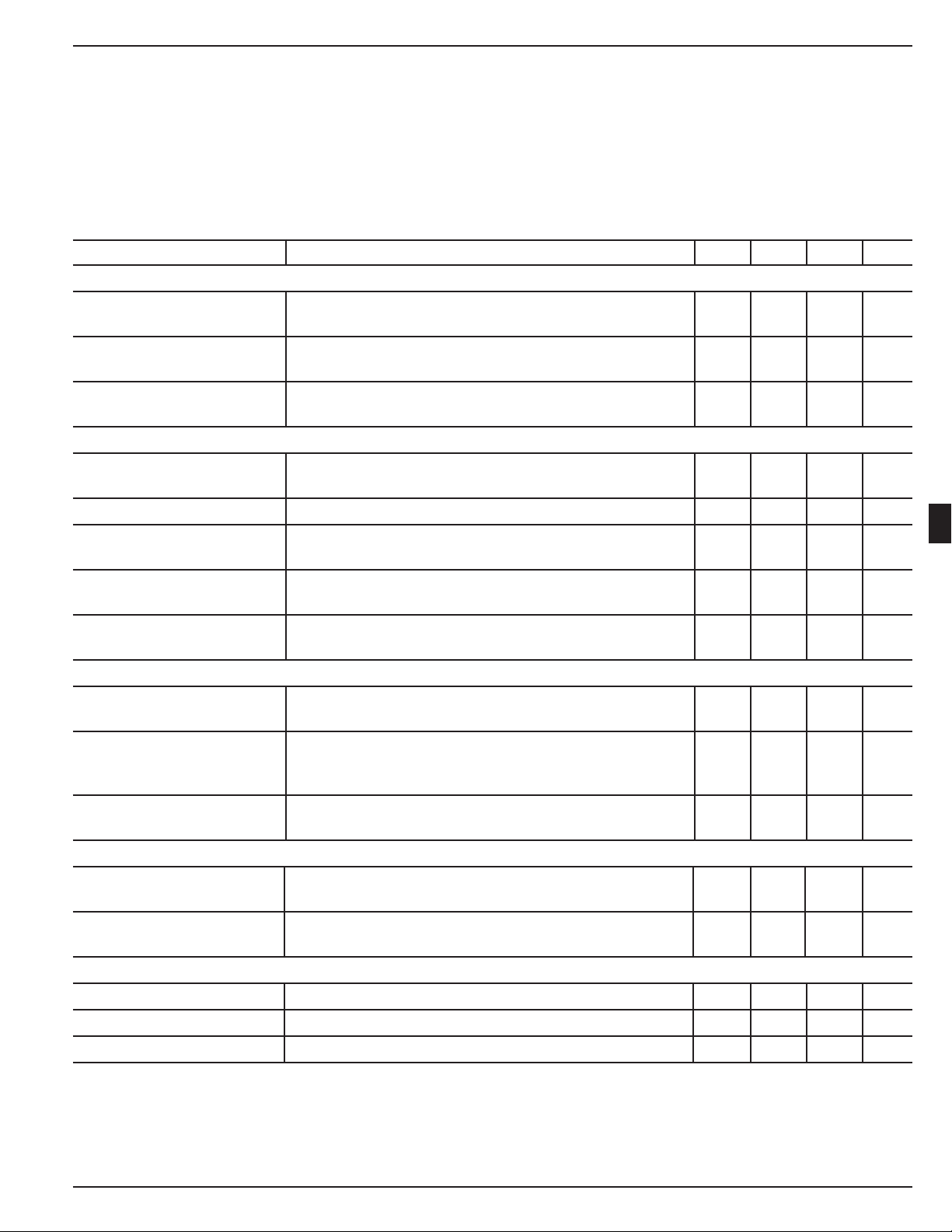

Electrical Characteristics

VIN = 5V; TA = 25°C, bold values indicate –40°C ≤ TA ≤ +85°C; unless noted.

Parameter Conditions Min Typ Max Units

Reference Section

Feedback Voltage (V

Feedback Voltage 3V ≤ V

Line Regulation V

Feedback Bias Current (I

Error Amplifier Section

Transconductance (g

Voltage Gain (AV) 0.9V ≤ V

Output Current V

)V

FB

)V

FB

) ∆I

m

COMP

COMP

= 1.24V 310 750 nA

FB

COMP

COMP

= 1.24V 1.220 1.240 1.264 V

1.214 1.274 V

≤ 40V .06 %/V

IN

= 1.24V

1100 nA

= ±25µA 3.0 3.9 6.0 µA/mV

2.4 7.0 µA/mV

≤ 1.4V 400 800 2000 V/V

COMP

= 1.5V 125 175 350 µA

100 400 µA

4

Output Swing High Clamp, V

= 1V 1.8 2.1 2.3 V

FB

Low Clamp, VFB = 1.5V 0.25 0.35 0.52 V

Compensation Pin Duty Cycle = 0 0.8 0.9 1.08 V

Threshold 0.6 1.25 V

Output Switch Section

ON Resistance I

= 2A, VFB = 0.8V 0.37 0.50 Ω

SW

0.55 Ω

Current Limit Duty Cycle = 50%, T

Duty Cycle = 50%, T

≥ 25°C 2.5 3.6 5 A

J

< 25°C 2.5 4.0 5.5 A

J

Duty Cycle = 80%, Note 3 2.0 3.0 5 A

Breakdown Voltage (BV) 3V ≤ VIN ≤ 40V 65 75 V

ISW = 5mA

Oscillator Section

Frequency (f

) 88 100 112 kHz

O

85 115 kHz

Duty Cycle [δ(max)] 80 90 95 %

Input Supply Voltage Section

Minimum Operating Voltage 2.7 3.0 V

Quiescent Current (IQ) 3V ≤ VIN ≤ 40V, V

Supply Current Increase (∆IIN) ∆ISW = 2A, V

General Note Devices are ESD sensitive. Handling precautions required.

Note 1 Mounted vertically, no external heat sink, 1/4 inch leads soldered to PC board containing approximently 4 inch squared copper area

surrounding leads.

Note 2 All ground leads soldered to approximently 2 inches squared of horizontal PC board copper area.

Note 3 For duty cycles (δ) between 50% and 95%, minimum guaranteed switch current is ICL = 1.66 (2-δ) Amp (Pk).

COMP

= 0.6V, ISW = 0 7 9 mA

COMP

= 1.5V, during swich on-time 9 20 mA

1997 4-5

Page 4

MIC2171 Micrel

Typical Performance Characteristics

Minimum

Operating Voltage

2.9

2.8

2.7

2.6

Switch Current = 2A

2.5

2.4

Minimum Operating Voltage (V)

2.3

-100 -50 0 50 100 150

15

14

13

12

11

10

Supply Current (mA)

Temperature (°C)

Supply Current

ISW = 0

D.C. = 90%

D.C. = 50%

9

8

D.C. = 0%

7

6

5

0 10203040

VIN Operating Voltage (V)

Feedback Bias Current

800

700

600

500

400

300

200

100

Feedback Bias Current (nA)

0

-100 -50 0 50 100 150

Temperature (°C)

50

40

30

20

10

Average Supply Current (mA)

Supply Current

δ = 90%

δ = 50%

0

01234

Switch Current (A)

Feedback Voltage

Line Regulation

5

4

3

2

1

0

-1

-2

-3

-4

Feedback Voltage Change (mV)

-5

0 10203040

10

V

9

COMP

8

7

6

5

4

3

Supply Current (mA)

2

1

0

-100 -50 0 50 100 150

TJ = 125°C

TJ = 25°C

TJ = -40°C

VIN Operating (V)

Supply Current

= 0.6V

Temperature (°C)

Switch On-Voltage

1.6

1.4

1.2

1.0

0.8

0.6

0.4

Switch ON Voltage (V)

0.2

0

0123

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

Transconductance (µA/mV)

0.5

0.0

-100 -50 0 50 100 150

TJ = 25°C

TJ = –40°C

TJ = 125°C

Switch Current (A)

Error Amplifier Gain

Temperature (°C)

Oscillator Frequency

120

110

100

90

80

Frequency (kHz)

70

60

-50 0 50 100 150

Temperature (°C)

7000

6000

5000

4000

3000

2000

Transconductance (µS)

1000

Error Amplifier Gain

0

1 10 100 1000 10000

Frequency (kHz)

8

6

4

2

Switch Current (A)

0

-30

0

30

60

90

120

Phase Shift (°)

150

180

210

1 10 100 1000 10000

Current Limit

–40°C

0 20406080100

25°C

125°C

Duty Cycle (%)

Error Amplifier Phase

Frequency (kHz)

4-6 1997

Page 5

MIC2171 Micrel

Block Diagram MIC2171

IN

FB

1.24V

Ref.

Reg.

Error

Amp.

2.3V

Anti-Sat.

100kHz

Osc.

COMP GND

Logic

Driver

Com-

parator

Current

Amp.

D1

SW

Q1

4

Functional Description

Refer to “Block Diagram MIC2171”.

Internal Power

The MIC2171 operates when VIN is ≥ 2.6V. An internal 2.3V

regulator supplies biasing to all internal circuitry including a

precision 1.24V band gap reference.

PWM Operation

The 100kHz oscillator generates a signal with a duty cycle of

approximately 90%. The current-mode comparator output is

used to reduce the duty cycle when the current amplifier

output voltage exceeds the error amplifier output voltage.

The resulting PWM signal controls a driver which supplies

base current to output transistor Q1.

Current-Mode Advantages

The MIC2171 operates in current mode rather than voltage

mode. There are three distinct advantages to this technique.

Feedback loop compensation is greatly simplified because

inductor current sensing removes a pole from the closed loop

response. Inherent cycle-by-cycle current limiting greatly

improves the power switch reliability and provides automatic

output current limiting. Finally, current-mode operation provides automatic input voltage feed forward which prevents

instantaneous input voltage changes from disturbing the

output voltage setting.

Anti-Saturation

The anti-saturation diode (D1) increases the usable duty

cycle range of the MIC2171 by eliminating the base to

collector stored charge which would delay Q1’s turnoff.

Compensation

Loop stability compensation of the MIC2171 can be accomplished by connecting an appropriate network from either

COMP to circuit ground (see typical Applications) or COMP

to FB.

The error amplifier output (COMP) is also useful for soft start

and current limiting. Because the error amplifier output is a

transconductance type, the output impedance is relatively

high which means the output voltage can be easily clamped

or adjusted externally.

1997 4-7

Page 6

MIC2171 Micrel

Applications Information

Soft Start

A diode-coupled capacitor from COMP to circuit ground

slows the output voltage rise at turn on (Figure 3).

V

IN

IN

MIC2171

COMP

D1

Figure 3. Soft Start

The additional time it takes for the error amplifier to charge the

capacitor corresponds to the time it takes the output to reach

regulation. Diode D1 discharges C1 when VIN is removed.

Current Limit

D2

C1

R1

C2

The device operating losses are the dc losses associated

with biasing all of the internal functions plus the losses of the

power switch driver circuitry. The dc losses are calculated

from the supply voltage (VIN) and device supply current (IQ).

The MIC2171 supply current is almost constant regardless of

the supply voltage (see “Electrical Characteristics”). The

driver section losses (not including the switch) are a function

of supply voltage, power switch current, and duty cycle.

P=V IV I I

(bias+driver) IN

()

+××

()

IN(min)

Q

∆

SW

IN

where:

P

(bias+driver)

V

IN(min)

= device operating losses

= supply voltage = VIN – V

SW

IQ = typical quiescent supply current

ICL = power switch current limit

∆IIN = typical supply current increase

As a practical example refer to Figure 1.

VIN = 5.0V

IQ = 0.007A

ICL = 2.21A

δ = 66.2% (0.662)

Then:

V

IN

GND

R1

Q1

C1

R2

IN

MIC2171

SW

FB

COMP

R3

C2

ICL ≈ 0.6V/R2

Note: Input and output

returns not common.

V

OUT

Figure 4. Current Limit

The maximum current limit of the MIC2171 can be reduced by

adding a voltage clamp to the COMP output (Figure 4). This

feature can be useful in applications requiring either a complete shutdown of Q1’s switching action or a form of current

fold-back limiting. This use of the COMP output does not

disable the oscillator, amplifiers or other circuitry, therefore

the supply current is never less than approximately 5mA.

Thermal Management

Although the MIC2171 family contains thermal protection

circuitry, for best reliability, avoid prolonged operation with

junction temperatures near the rated maximum.

The junction temperature is determined by first calculating

the power dissipation of the device. For the MIC2171, the

total power dissipation is the sum of the device operating

losses and power switch losses.

V = 5 – (2.21 0.37) = 4.18V

IN(min)

P = ( 0.007) + (4.18 2.21 .009)

(bias driver)+

P

(bias+driver)

= 0.1W

×

×××5

Power switch dissipation calculations are greatly simplified

by making two assumptions which are usually fairly accurate.

First, the majority of losses in the power switch are due to

on-losses. To find these losses, assign a resistance value to

the collector/emitter terminals of the device using the saturation voltage versus collector current curves (see Typical

Performance Characteristics). Power switch losses are

calculated by modeling the switch as a resistor with the switch

duty cycle modifying the average power dissipation.

PSW = (ISW)2 RSW δ

where:

δ = duty cycle

V+ V– V

OUT

δ =

F IN(min)

V+V

OUT

F

VSW = ICL (RSW)

V

= output voltage

OUT

VF = D1 forward voltage drop at I

OUT

From the Typical performance Characteristics:

RSW = 0.37Ω

Then:

PSW = (2.21)2 × 0.37 × 0.662

P

= 1.2W

SW)

P

= 1.2 + 0.1

(total)

P

= 1.3W

(total)

4-8 1997

Page 7

MIC2171 Micrel

The junction temperature for any semiconductor is calculated

using the following:

TJ = TA + P

(total) θJA

Where:

TJ = junction temperature

TA = ambient temperature (maximum)

P

= total power dissipation

(total)

θJA = junction to ambient thermal resistance

For the practical example:

TA = 70°C

θJA = 45°C/W (TO-220)

Then:

TJ = 70 + (1.24 × 45)

TJ = 126°C

This junction temperature is below the rated maximum of

150°C.

Grounding

Refer to Figure 5. Heavy lines indicate high current paths.

V

IN

IN

SW

MIC2171

FB

GND

COMP

mode is preferred because the feedback control of the

converter is simpler.

When L1 discharges its current completely during the MIC2171

off-time, it is operating in discontinuous mode.

L1 is operating in continuous mode if it does not discharge

completely before the MIC2171 power switch is turned on

again.

Discontinuous Mode Design

Given the maximum output current, solve equation (1) to

determine whether the device can operate in discontinuous

mode without initiating the internal device current limit.

I

CL

(1)

(1a)

I

OUT

δ =

≤

V+ V– V

OUT

V+V

V

2

V

OUT

F IN(min)

OUT

IN(min)

F

δ

Where:

ICL = internal switch current limit

ICL = 2.5A when δ < 50%

ICL = 1.67 (2 – δ) when δ ≥ 50%

(Refer to Electrical Characteristics.)

I

= maximum output current

OUT

V

= minimum input voltage = VIN – V

IN(min)

SW

δ = duty cycle

V

= required output voltage

OUT

VF = D1 forward voltage drop

For the example in Figure 1.

4

Single point ground

Figure 5. Single Point Ground

A single point ground is strongly recommended for proper

operation.

The signal ground, compensation network ground, and feedback network connections are sensitive to minor voltage

variations. The input and output capacitor grounds and

power ground conductors will exhibit voltage drop when

carrying large currents. Keep the sensitive circuit ground

traces separate from the power ground traces. Small voltage

variations applied to the sensitive circuits can prevent the

MIC2171 or any switching regulator from functioning properly.

Boost Conversion

Refer to Figure 1 for a typical boost conversion application

where a +5V logic supply is available but +12V at 0.25A is

required.

The first step in designing a boost converter is determining

whether inductor L1 will cause the converter to operate in

either continuous or discontinuous mode. Discontinuous

I

= 0.25A

OUT

ICL = 1.67 (2–0.662) = 2.24A

V

IN(min)

= 4.18V

δ = 0.662

V

= 12.0V

OUT

VF = 0.36V (@ .26A, 70°C)

Then:

2.235

I

≤

OUT

I

≤ 0.258A

OUT

.178 0.662

××4

2

12

This value is greater than the 0.25A output current requirement, so we can proceed to find the minimum inductance

value of L1 for discontinuous operation at P

2

V

δ

()

(2)

L1

≥

IN

2 P f

OUT SW

OUT

.

Where:

P

= 12 × 0.25 = 3W

OUT

fSW = 1×105Hz (100kHz)

1997 4-9

Page 8

MIC2171 Micrel

For our practical example:

L1

≥

4.178 .662

()

2

×

3.0 1 10

×××

0

2

5

L1 ≥ 12.4µH (use 15µH)

Equation (3) solves for L1’s maximum current value.

T

V

IN

(3)

I

L1(peak)

=

ON

L1

Where:

TON = δ / fSW = 6.62×10-6 sec

I

L1(peak)

I

L1(peak)

=

= 1.84A

4.178 6.62 10

××

15 10

×

-6

-6

Use a 15µH inductor with a peak current rating of at least 2A.

Flyback Conversion

Flyback converter topology may be used in low power applications where voltage isolation is required or whenever the

input voltage can be less than or greater than the output

voltage. As with the step-up converter the inductor (transformer primary) current can be continuous or discontinuous.

Discontinuous operation is recommended.

Figure 2 shows a practical flyback converter design using the

MIC2171.

Switch Operation

During Q1’s on time (Q1 is the internal NPN transistor—see

block diagrams), energy is stored in T1’s primary inductance.

During Q1’s off time, stored energy is partially discharged into

C4 (output filter capacitor). Careful selection of a low ESR

capacitor for C4 may provide satisfactory output ripple voltage making additional filter stages unnecessary.

C1 (input capacitor) may be reduced or eliminated if the

MIC2171 is located near a low impedance voltage source.

Output Diode

The output diode allows T1 to store energy in its primary

inductance (D2 nonconducting) and release energy into C4

(D2 conducting). The low forward voltage drop of a Schottky

diode minimizes power loss in D2.

Frequency Compensation

A simple frequency compensation network consisting of R3

and C2 prevents output oscillations.

High impedance output stages (transconductance type) in

the MIC2171 often permit simplified loop-stability solutions to

be connected to circuit ground, although a more conventional

technique of connecting the components from the error

amplifier output to its inverting input is also possible.

Voltage Clipper

Care must be taken to minimize T1’s leakage inductance,

otherwise it may be necessary to incorporate the voltage

clipper consisting of D1, R4, and C3 to avoid second break-

down (failure) of the MIC2171’s internal power switch.

Discontinuous Mode Design

When designing a discontinuous flyback converter, first determine whether the device can safely handle the peak

primary current demand placed on it by the output power.

Equation (8) finds the maximum duty cycle required for a

given input voltage and output power. If the duty cycle is

greater than 0.8, discontinuous operation cannot be used.

2 P

(8)

δ

≥

I V – V

CL

OUT

()

IN(min)

SW

For a practical example let: (see Figure 2)

P

= 5.0V × 0.5A = 2.5W

OUT

VIN = 4.0V to 6.0V

ICL = 2.5A when δ < 50%

1.67 (2 – δ) when δ ≥ 50%

Then:

V = V – I R

IN min

()

V

IN(min)

V

IN(min)

IN

= 4 – 0.78V

= 3.22V

×

()

CL SW

δ ≥ 0.74 (74%), less than 0.8 so discontinous is

permitted.

A few iterations of equation (8) may be required if the duty

cycle is found to be greater than 50%.

Calculate the maximum transformer turns ratio a, or

N

PRI/NSEC

, that will guarantee safe operation of the MIC2171

power switch.

(9)

a ≤

V

CE FCE

– V

V

SEC

IN(max)

Where:

a = transformer maximum turns ratio

VCE = power switch collector to emitter

maximum voltage

FCE = safety derating factor (0.8 for most

commercial and industrial applications)

V

V

= maximum input voltage

IN(max)

= transformer secondary voltage (V

SEC

OUT

+ VF)

For the practical example:

VCE = 65V max. for the MIC2171

FCE = 0.8

V

= 5.6V

SEC

Then:

65 × 0.8 – 6.0

a ≤

a ≤ 8.2 (N

5.6

PRI/NSEC

)

Next, calculate the maximum primary inductance required to

store the needed output energy with a power switch duty

cycle of 55%.

4-10 1997

Page 9

MIC2171 Micrel

2

(10)

L

0.5 f V T

≥

PRI

SW

IN(min)

P

OUT

ON

2

Where:

L

= maximum primary inductance

PRI

fSW = device switching frequency (100kHz)

V

= minimum input voltage

IN(min)

TON = power switch on time

Then:

2

-6

L

≥

PRI

L

≥ 11.4µH

PRI

0.5 1 10 3.22 7.4 10

×× ×

5

2

()

××

()

2.5

Use an 12µH primary inductance to overcome circuit inefficiencies.

To complete the design the inductance value of the secondary is found which will guarantee that the energy stored in the

transformer during the power switch on time will be completed discharged into the output during the off-time. This is

necessary when operating in discontinuous-mode.

(11)

L

SEC

≤

0.5 f

SW VSEC

P

OUT

2

T

OFF

2

Where:

L

= maximum secondary inductance

SEC

T

= power switch off time

OFF

Then:

2

-6

L

≤

SEC

L

≤ 7.9µH

SEC

0.5 1 10 5.41 2.6 10

×× ×

5

2

()

××

()

2.5

Finally, recalculate the transformer turns ratio to insure that

it is less than the value earlier found in equation (9).

(12)

a ≤

Then:

a

This ratio is less than the ratio calculated in equation (9).

When specifying the transformer it is necessary to know the

primary peak current which must be withstood without saturating the transformer core.

I

(13)

PEAK(pri)

So:

I =

PEAK(pri)

I

PEAK(pri)

Now find the minimum reverse voltage requirement for the

output rectifier. This rectifier must have an average current

rating greater than the maximum output current of 0.5A.

(14)

VBR≥

Where:

VBR = output rectifier maximum peak

a = transformer turns ratio (1.2)

FBR = reverse voltage safety derating factor (0.8)

Then:

V

V

L

PRI

L

SEC

11.4

= 1.20 ≤

7.9

V

IN(min)

=

3.22 7.6 10

= 2.1A

IN(max)

+ V

V

F

reverse voltage rating

6.0 + 5.0 1.2

≥

BR

≥ 12.5V

BR

()

0.8 1.2

×

T

ON

L

PRI

OUT

-6

a

××

µ

12 H

()

a

BR

×

A 1N5817 will safely handle voltage and current requirements in this example.

4

1997 4-11

Page 10

MIC2171 Micrel

Forward Converters

Micrel’s MIC2171 can be used in several circuit configurations to generate an output voltage which is less than the input

voltage (buck or step-down topology). Figure 7 shows the

MIC2171 in a voltage step-down application. Because of the

internal architecture of these devices, more external components are required to implement a step-down regulator than

with other devices offered by Micrel (refer to the LM257x or

MIC457x family of buck switchers). However, for step-down

conversion requiring a transformer (forward), the MIC2171 is

a good choice.

A 12V to 5V step-down converter using transformer isolation

(forward) is shown in Figure 7. Unlike the isolated flyback

converter which stores energy in the primary inductance

during the controller’s on-time and releases it to the load

during the off-time, the forward converter transfers energy to

the output during the on-time, using the off-time to reset the

transformer core. In the application shown, the transformer

core is reset by the tertiary winding discharging T1’s peak

magnetizing current through D2.

For most forward converters the duty cycle is limited to 50%,

allowing the transformer flux to reset with only two times the

input voltage appearing across the power switch. Although

during normal operation this circuit’s duty cycle is well below

50%, the MIC2172 has a maximum duty cycle capability of

90%. If 90% was required during operation (start-up and high

load currents), a complete reset of the transformer during the

off-time would require the voltage across the power switch to

be ten times the input voltage. This would limit the input

voltage to 6V or less for forward converter applications.

To prevent core saturation, the application given here uses a

duty cycle limiter consisting of Q1, C4 and R3. Whenever the

MIC2171 exceeds a duty cycle of 50%, T1’s reset winding

current turns Q1 on. This action reduces the duty cycle of the

MIC2171 until T1 is able to reset during each cycle.

V

IN

12V

C1

22µF

T1

1:1:1

MIC2171

GND

R1*

IN

SW

FB

COMP

R2

1k

C3

1µF

C2*

D1*

D2

1N5819

†

Q1

* Voltage clipper

†

Duty cycle limiter

C4

R3

†

†

Figure 7. MIC2171 Forward Converter

D3

1N5819

L1 100µH

D4

1N5819

C5

470µF

R4

3.74k

1%

R5

1.24k

1%

V

OUT

5V, 1A

4-12 1997

Loading...

Loading...