Page 1

MGC3130

Single-Zone 3D Tracking and Gesture Controller Data Sheet

Introduction:

The MGC3130 is a three-dimensional (3D) gesture

recognition and tracking controller chip based on

Microchip’s patented GestIC

user command input with natural hand and finger

movements. Utilizing the principles of electrical nearfield sensing, the MGC3130 contains all the building

blocks to develop robust 3D input sensing systems.

Implemented as a low-power mixed-signal

configurable controller, it provides a large set of smart

functional features with integrated signal driver, a

frequency adaptive input path for automatic noise

suppression and a digital signal processing unit.

Microchip’s on-chip Colibri Suite minimizes processing

needs, reduces system power consumption and results

in low software development efforts for fast time-tomarket success. The MGC3130 is a unique solution

that provides gesture information as well as positional

data of the human hand in real time and allows

realization of a new generation of user interfaces

across various industries.

®

technology. It enables

Applications:

• Displays

• Notebooks/Keyboards/PC Peripherals

• Mobile Phones

• Tablet Computers

• Electronic Readers

• Remote Controls

• Game Controllers

Power Features:

• Variety of Several Power Operation modes

include:

- Processing mode: 20 mA @ 3.3V, typical

- Programmable Self Wake-up: 110 µA @ 3.3V

- Deep Sleep: 9 µA @ 3.3V, typical

Key Features:

• Recognition of 3D Hand Gestures and x, y, z

Positional Data

• Proximity and Touch Sensing Capabilities

• Built-in Colibri Gesture Suite

• Advanced 3D Signal Processing Unit

• Detection Range: 0 to 15 cm

• Receiver Sensitivity: <1 fF

• Position Rate: 200 positions/sec

• Spatial Resolution: up to 150 dpi

• Carrier Frequency: 44 kHz to 115 kHz

• Channels Supported:

- Five receive (Rx) channels

- One transmit (Tx) channel

• On-chip Auto Calibration

• Low Noise Radiation due to Low Transmit Voltage

and Slew Rate Control

• Noise Susceptibility Reduction:

- On-chip analog filtering

- On-chip digital filtering

- Automatic frequency hopping

• Enables the use of Low-Cost Electrode Material

including:

- Printed circuit board

- Conductive paint

- Conductive foil

- Laser Direct Structuring (LDS)

- Touch panel ITO structures

• Field Upgrade Capability

• Small Outline, 28-lead QFN package, 5x5 mm

• Operating Voltage: 2.5V to 3.465V (single supply)

• Temperature Range: -20°C to +85°C

Peripheral Features:

•2x I2C™ or SPI Interface for Configuration and

Streamin g of Positional and Gesture Data

• Multi-zone Support via Master/Slave Architecture

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 1

Page 2

MGC3130

QFN

1

2

3

4

5

6

715

8

9

10

11

12

13

14

16

17

18

19

20

21

26

25

24

23

22

28

27

VCAPS

VINDS

VSS2

RX0

RX1

RX2

RX3

RX4

V

CAPA

VSS3

VCAPD

EIO0

EIO1

EIO2

EIO5/SI1

EIO4/SI0

EIO3

NC

NC

NC

IS2

EIO6/SI2

MCLR

T

XD

NC

V

SS1

VDD

EIO7/SI3

MGC3130

EXP-29

Package Type

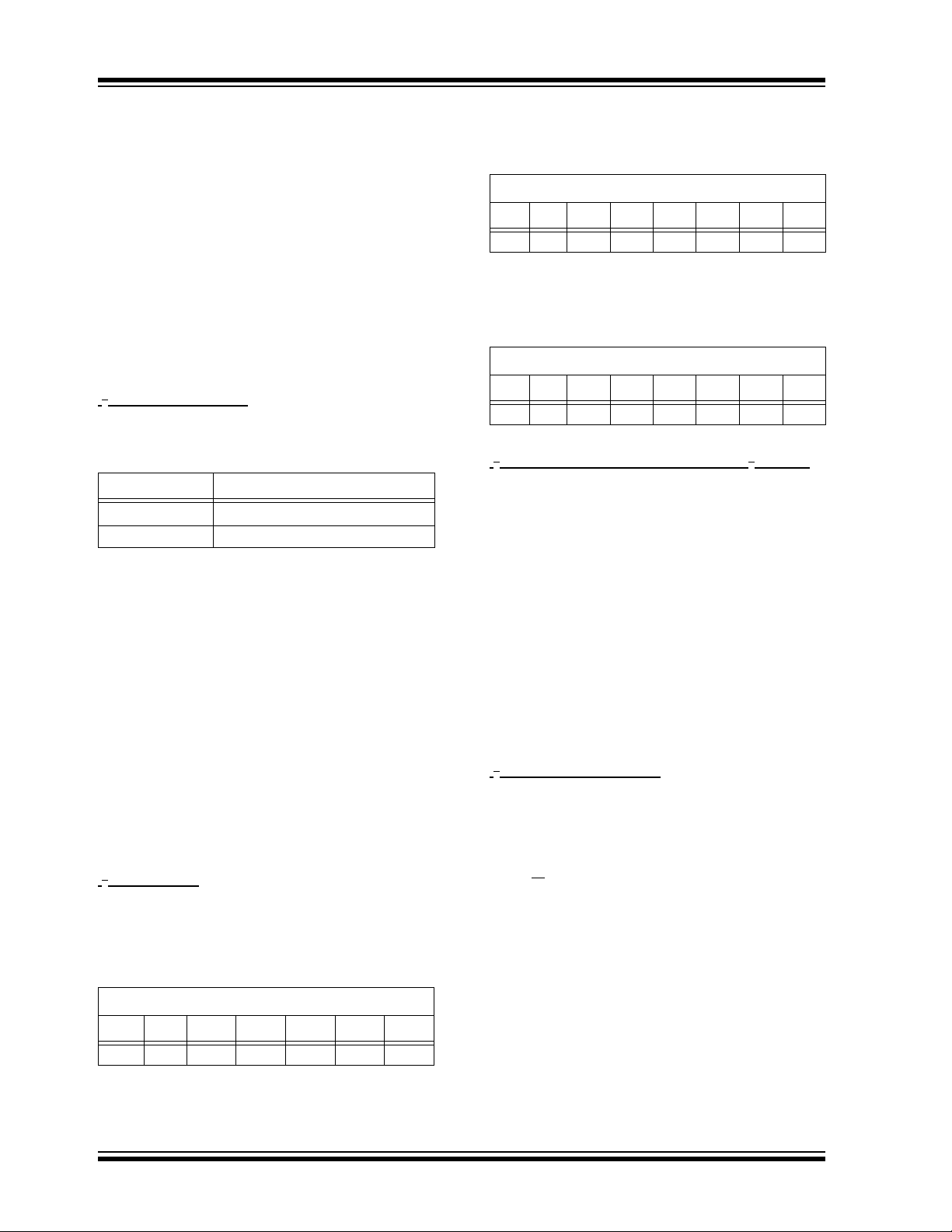

The device is available in 28-lead QFN packaging (see

Figure 1).

FIGURE 1: 28-PIN DIAGRAM (MGC3130)

DS40001667C-page 2 Advance Information 2012-2013 Microchip Technology Inc.

Page 3

MGC3130

TABLE 1: 28-PIN QFN PINOUT DESCRIPTION

Pin Name

VCAPS 1P— External filter capacitor (10 µF) connection for internal STEP-UP

V

INDS 2P

SS2 3P

V

RX0 4 I Analog

RX1 5 I Analog

RX2 6 I Analog

RX3 7 I Analog

RX4 8 I Analog

CAPA 9P

V

SS3 10 P

V

CAPD 11 P

V

EIO0 12 I/O ST Extended IO0 (EIO0)/Transfer Status (TS). TS line requires

EIO1 13 I/O ST Extended IO1 (EIO1)/Interface Selection Pin 1 (IS1).

EIO2 14 I/O ST Extended IO2 (EIO2)/IRQ0.

IS2 15 I ST Interface Selection Pin 2 (IS2).

NC 16

NC 17

NC 18

EIO3 19 I/O ST Extended IO3 (EIO3)/IRQ1/SYNC.

EIO4/SI0 20 I/O ST Extended IO4 (EIO4)/Serial Interface 0 (SI0): I2C™_SDA0/

EIO5/SI1 21 I/O ST Extended IO5 (EIO5)/Serial Interface 1 (SI1): I

EIO6/SI2 22 I/O ST Extended IO6 (EIO6)/Serial Interface 2 (SI2): I

EIO7/SI3 23 I/O ST Extended IO7 (EIO7)/Serial Interface 3 (SI3): I

MCLR

T

XD 25 O Analog Transmit electrode connection.

NC 26

SS1 27 P

V

VDD 28 P

EXP 29 P

Legend: P = Power; ST = Schmitt Trigger input with CMOS levels; O = Output; I = Input; — = N/A

Pin

Number

Pin Type Buffer Type Description

converter (optional).

—

External inductor (4.7 µH) + Schottky diode connection for internal

STEP-UP converter usage (optional).

—

Ground reference for the STEP-UP converter.

Analog input channels: Receive electrode connection.

—

External filter capacitor (4.7 µF) connection for internal analog

voltage regulator (3V).

—

—

Common ground reference for analog and digital domain.

External filter capacitor (4.7 µF) connection for internal digital

voltage regulator (1.8V).

external 10 kpull-up

——

——

——

Reserved: do not connect.

Reserved: do not connect.

Reserved: do not connect.

SPI_MISO. When I

2

C™ is used, this line requires an external 1.8

kpull-up.

2

C™_SCL0/SPI_-

MOSI. When I

2

C™ is used, this line requires an external 1.8 k

pull-up.

2

C™_SDA1/

SPI_CS. When I

2

C™ is used, this line requires an external 1.8 k

pull-up.

2

C™_SCL1/SPI_S-

CLK. When I

2

C™ is used, this line requires an external 1.8 k

pull-up.

24 I/P ST Master Clear (Reset) input. This pin is an active-low Reset to the

device. It requires external 10 kpull-up.

——

—

—

Reserved: do not connect.

Common ground reference for analog and digital domains.

Positive supply for peripheral logic and I/O pins.

It requires an external filtering capacitor (100 nF).

—

Exposed pad. It should be connected to Ground.

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 3

Page 4

MGC3130

Table of Contents

1.0 Theory of Operation: Electrical Near-Field (E-Field Sensing).................................................................................................... 5

2.0 Feature Description.................................................................................................................................................................... 7

3.0 System Architecture ................................................................................................................................................................ 10

4.0 Functional Description ............................................................................................................................................................. 13

5.0 Application Architecture ........................................................................................................................................................... 23

6.0 Interface Description ................................................................................................................................................................ 24

7.0 Hardware Integration ............................................................................................................................................................... 33

8.0 Development Support .............................................................................................................................................................. 36

9.0 Electrical Specifications ........................................................................................................................................................... 37

10.0 Packaging Information ............................................................................................................................................................. 38

The Microchip Web Site....................................................................................................................................................................... 43

Customer Change Notification Service ................................................................................................................................................ 43

Customer Support ................................................................................................................................................................................ 43

Product Identification System .............................................................................................................................................................. 44

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

DS40001667C-page 4 Advance Information 2012-2013 Microchip Technology Inc.

Page 5

MGC3130

1.0 THEORY OF OPERATION: ELECTRICAL NEAR-FIELD (E-FIELD) SENSING

Microchip’s GestIC is a 3D sensor technology which

utilizes an electric field (E-field) for advanced proximity

sensing. It allows realization of new user interface

applications by detection, tracking and classification of

a user’s hand or finger motion in free space.

E-fields are generated by electrical charges and

propagate three-dimensionally around the surface,

carrying the electrical charge.

Applying direct voltages (DC) to an electrode results in

a constant electric field. Applying alternating voltages

(AC) makes the charges vary over time and thus, the

field. When the charge varies sinusoidal with frequency

f, the resulting electromagnetic wave is characterized

by wavelength λ = c/f, where c is the wave propagation

velocity — in vacuum, the speed of light. In cases

where the wavelength is much larger than the electrode

geometry, the magnetic component is practically zero

and no wave propagation takes place. The result is

quasi-static electrical near field that can be used for

sensing conductive objects such as the human body.

Microchip’s GestIC technology uses transmit (Tx)

frequencies in the range of 100 kHz which reflects a

wavelength of about three kilometers. With electrode

geometries of typically less than fourteen by fourteen

centimeters, this wavelength is much larger in

comparison.

In case a person’s hand or finger intrudes the electrical

field, the field becomes distorted. The field lines are

drawn to the hand due to the conductivity of the human

body itself and shunted to ground. The threedimensional electric field decreases locally. Microchip’s

GestIC technology uses a minimum number of four

receiver (Rx) electrodes to detect the E-field variations

at different positions to measure the origin of the

electric field distortion from the varying signals

received. The information is used to calculate the

position, track movements and to classify movement

patterns (gestures).

The simulation results in Figure 1-1 and Figure 1-2

show the influence of an earth-grounded body to the

electric field. The proximity of the body causes a compression of the equipotential lines and shifts the Rx

electrode signal levels to a lower potential which can be

measured.

FIGURE 1-1: EQUIPOTENTIAL LINES

OF AN UNDISTORTED

E-FIELD

FIGURE 1-2: EQUIPOTENTIAL LINES

OF A DISTORTED E-FIELD

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 5

Page 6

MGC3130

1.1 GestIC Technology Benefits

• GestIC E-field sensors are not impacted by

ambient influences such as light or sound, which

have a negative impact to the majority of other 3D

technologies.

• The GestIC technology has a high immunity to

noise, provides high update rates and resolution,

low latency and is also not affected by clothing,

surface texture or reflectivity.

• A carrier frequency in the range of 44-115 kHz is

being used with the benefit of being outside the

regulated radio frequency range. In the same

manner, GestIC is not affected by radio

interference.

• Usage of thin low-cost materials as electrodes

allow low system cost at slim industrial housing

designs.

• The further use of existing capacitive sensor

structures such as a touch panel’s ITO coating

allow additional cost savings and ease the

integration of the technology.

• Electrodes are invisible to the users’ eye since

they are implemented underneath the housing

surface or integrated into a touch panel’s ITO

structure.

• GestIC works centrically over the full sensing

space. Thus, it provides full surface coverage

without any detection blind spots.

• Only one GestIC transmitter electrode is used for

E-field generations. The benefit is an overall low

power consumption and low radiated EMC noise.

• Since GestIC is basically processing raw

electrode signals and computes them in real time

into pre-processed gestures and accurate x, y, z

positional data, it provides a highly flexible user

interface technology for any kind of electronic

devices.

DS40001667C-page 6 Advance Information 2012-2013 Microchip Technology Inc.

Page 7

MGC3130

Digital Signal Processing

Colibri Suite

Position

Tracking

Gesture

Recognition

Approach

Detection

2.0 FEATURE DESCRIPTION

2.1 Gesture Definition

A hand gesture is the movement of the hand to express

an idea or meaning. The GestIC technology accurately

allows sensing of a user’s free space hand motion for

contact free position tracking, as well as three-dimensional (3D) gesture recognition based on classified

movement patterns.

2.2 GestIC Library

MGC3130 is being provided with a GestIC Library,

stored on the chip’s Flash memory. The library

includes:

• Colibri Suite: Digital Signal Processing (DSP)

algorithms and feature implementations.

• System Control: MGC3130 hardware control

features such as Analog Front End (AFE) access,

interface control and parameters storage.

• Library Loader: GestIC Library update through the

application host’s interface.

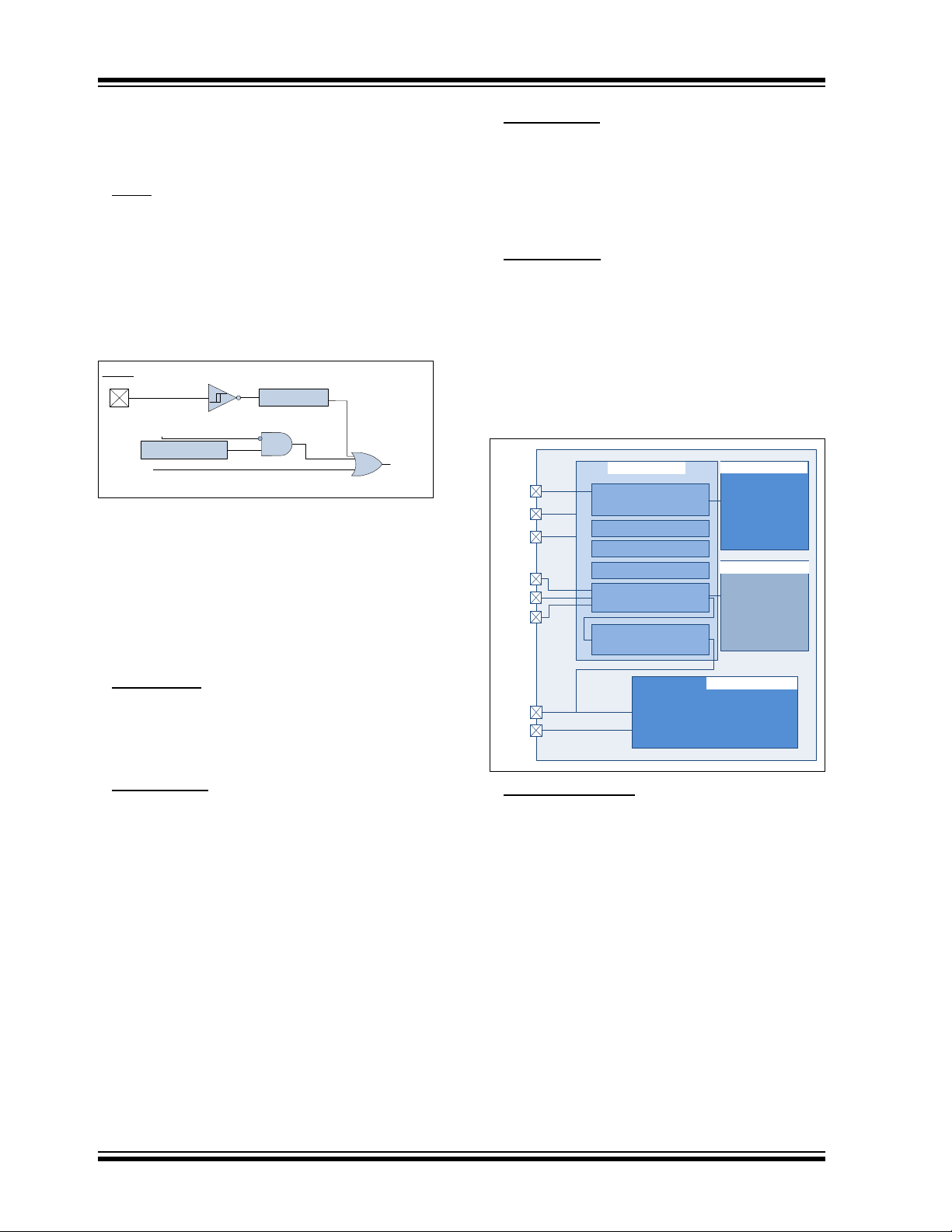

2.2.1 COLIBRI SUITE

The Colibri Suite combines data acquisition, digital

signal processing and interpretation.

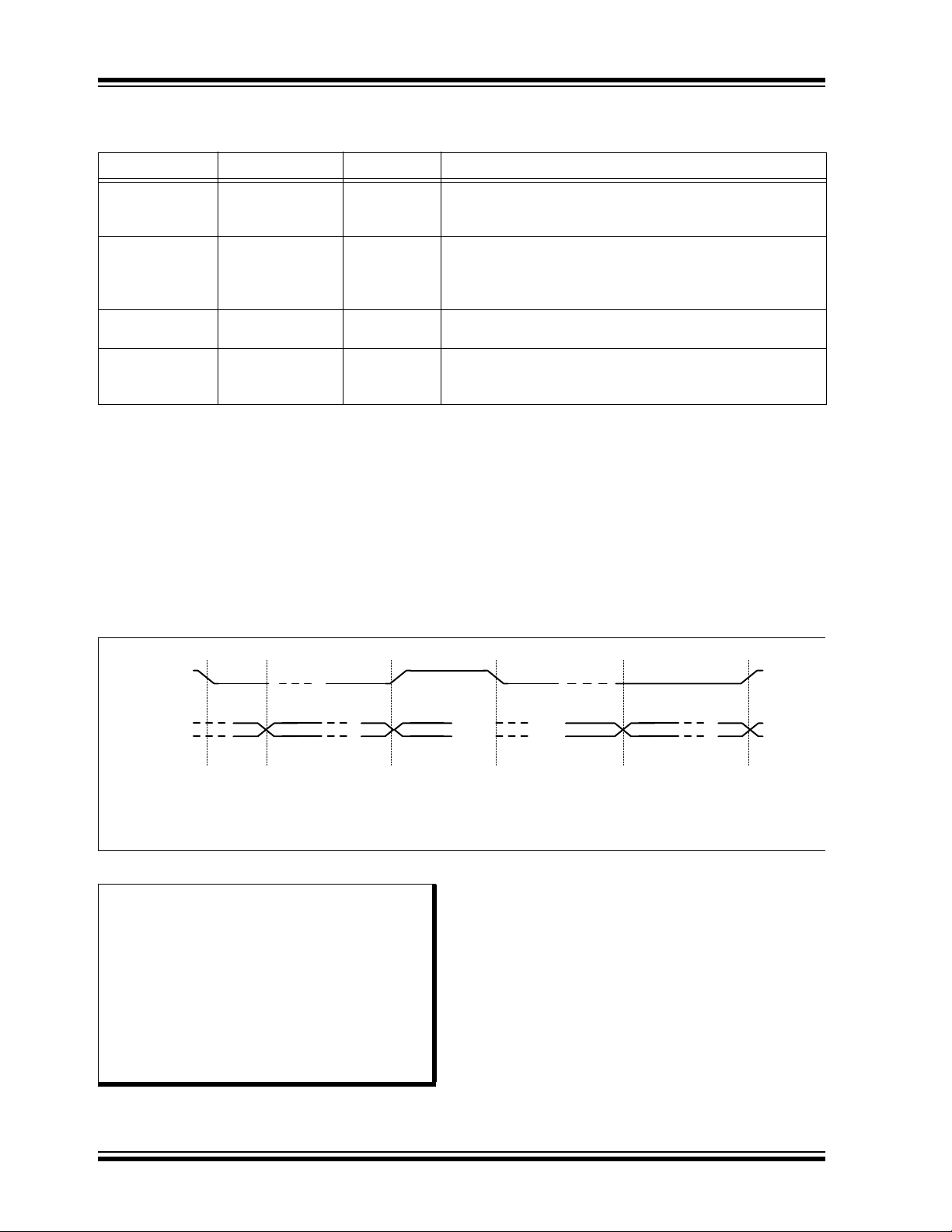

The Colibri Suite functional features are illustrated in

Figure 2-1 and described in the following sections.

FIGURE 2-1: COLIBRI SUITE CORE

2.2.1.1 Position Tracking

The Colibri Suite’s Position Tracking feature provides

three-dimensional hand position over time and area.

The absolute position data is provided according to the

defined origin of the Cartesian coordinate system (x, y,

z). Position Tracking data is continuously acquired in

parallel to Gesture Recognition. With a position rate of

up to 200 positions/sec., a maximum spatial resolution

of 150 dpi is achieved.

ELEMENTS

2.2.1.2 Gesture Recognition

The Colibri Suite’s gesture recognition model detects

and classifies hand movement patterns performed

inside the sensing area.

Using advanced stochastic classification based on

Hidden Markov Model (HMM), industry best gesture

recognition rate is being achieved. In addition, there

are some gestures derived from the combination of

Gesture Recognition and spatial information.

The Colibri Suite includes a set of predefined hand

gestures which contains flick, circular and symbol

gestures as the ones outlined below:

• Flick gestures

A flick gesture is a unidirectional gesture in a quick

flicking motion. An example may be a hand movement

from West to East within the sensing area, from South

to North, etc.

• Circular gestures

A circular gesture is a round-shaped hand movement

defined by direction (clockwise/counterclockwise)

without any specific start position of the user’s hand.

Two types of circular gestures are distinguished by

GestIC technology:

1. Discrete Circles

Discrete Circles are recognized after performing a

hand movement inside the sensing area. The

recognition result (direction: clockwise/

counterclockwise) is provided after the hand movement

stops or the hand exits the detection area. The Discrete

Circles are typically used as dedicated application

control commands.

2. AirWheel

An AirWheel is the recognition of continuouslyperformed circles inside the sensing area and provides

information about the rotational movement in real time.

It starts after at least one quadrant of a circle is

recognized and provides continuously counter

information which increments/decrements according to

the movement’s direction (clockwise/

counterclockwise). The AirWheel can be adjusted for

convenient usage in various applications (e.g., volume

control, sensitivity adjustment or light dimming).

ensor Touch Gestures

•S

A Sensor Touch is a multi-zone gesture that reports up

to five concurrently-performed touches on the system’s

electrodes.

The Sensor Touch provides information about Touch

and Tapping:

1. Touch

The Sensor Touch indicates an event during which a

GestIC electrode is touched. This allows distinction

between short and long touches.

2. Tap and Double Tap

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 7

Page 8

MGC3130

Touch

Touch

detected

Tap

Tap

detected

Single Tap Duration

0s-1s

Double Tap

Double Tap

detected

Double Tap Duration

0s-1s

The Tap and Double Tap signalize short taps and

double taps on each system electrode. The Tap length

and Double Tap interval are adjustable.

- Single Tap Delay: A Single Tap is detected

when touching the surface of an electrode

first and after the hand is pulled out of the

touch area. The Single Tap is only detected

when the timing between the touch and the

release of the touch event is smaller than the

adjusted delay. Increasing the time allows the

user more time to perform the tap. The range

for the adjusted delay can be between 0s and

1s.

- Double Tap Delay: The double tap is detected

FIGURE 2-2: SENSOR TOUCH DIAGRAM

when two taps are performed within the

adjusted delay. The range for the adjusted

delay can be between 0s and 1s. The smaller

the selected delay is, the faster the two taps

have to be executed.

• Gesture Port

The Gesture Port enables a flexible mapping of Colibri

Suite feature events to certain output signals at defined

MGC3130’s pins. The individual feature events can be

mapped to one of five EIO Pins and trigger a variety of

signal changes (Permanent high, Permanent low, Toggle, Pulse (5 ms), High Active, Low Active). The Gesture Port simplifies and enhances embedded system

integration.

DS40001667C-page 8 Advance Information 2012-2013 Microchip Technology Inc.

Page 9

2.2.1.3 Approach Detection

Current

time

Periodic Approach Scans

Calibration

Scan

Periodic Approach Scans

Calibration

Scan

Periodic Approach Scans

Calibration

Scan

Periodic Approach Scans

Scan Interval

20ms-150ms

Calibrati on Start Scan Interv al

2s-10s

I

sleep

= 9µA

I

5CHSCAN

= 20mA

I

5CHSCAN

: Scan Phase with 5 active RX channel s: Calibrat ion Scan

I

sleep

: Sleep Phase

Calibrati on Final Scan Interv al

2s-1024s

Calibrati on Transition Ti me (Non-user act ivity timeout)

2s-255s

Processing

Mode

Idle Timeout

5s-1024s

Self Wake-up mode

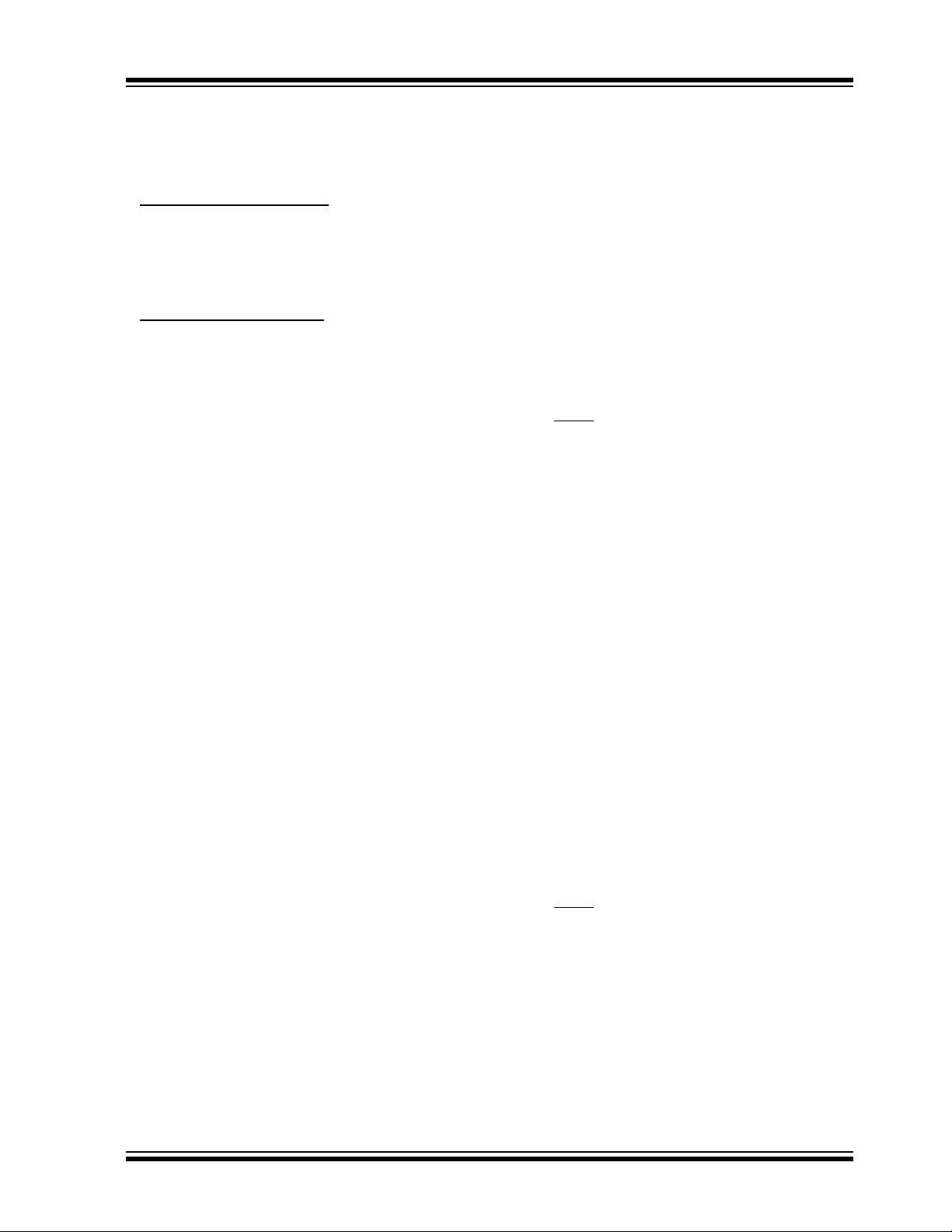

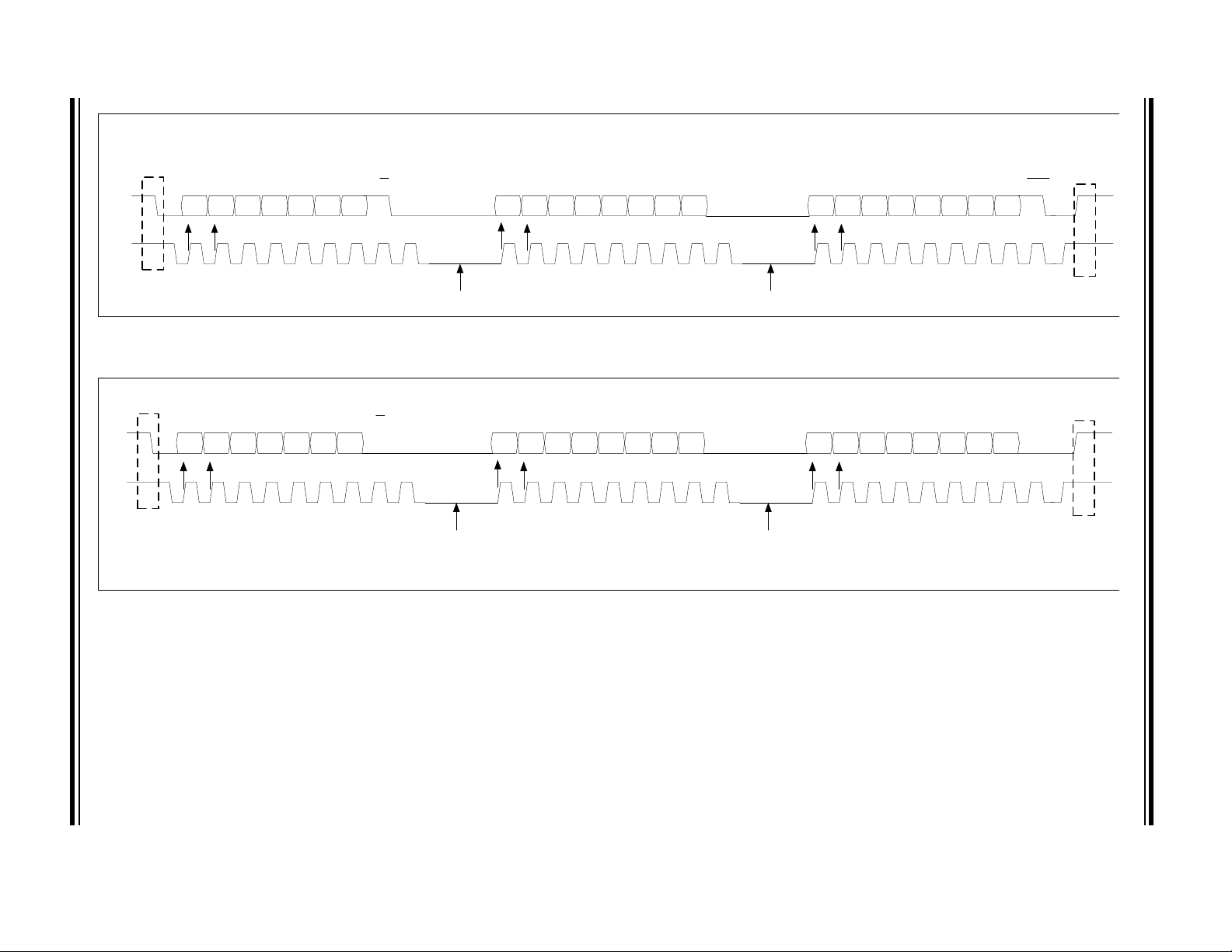

Approach Detection is an embedded power-saving

feature of Microchip’s Colibri Suite. It sends MGC3130

to Sleep mode and scans periodically the sensing area

to detect the presence of a human hand.

Utilizing the in-built Self Wake-up mode, Approach

Detection alternates between Sleep and Scan phases.

During the Scan phases, the approach of a human

hand can be detected while very low power is

consumed. For more details, please see

Section 4.2.4.3 “Self Wake-up Mode”.

A detected approach of a user exceeding configured

threshold criteria will alternate the MGC3130 from Self

Wake-up to Processing mode or even the application

host in the overall system.

Within the Approach Detection sequence, the following

scans are performed:

• Approach Scan

during the Scan phase of the MGC3130’s Self

Wake-up mode. Typically, 1 Rx channel is active

but more channels can be activated via GestIC

Library. The time interval (Scan Interval) between

two consecutive Approach Scans is configurable.

For typical applications, the scan cycle is in a

range of 20 ms to 150 ms. During the Approach

Scan, the activated Rx channels are monitored for

signal changes which are caused by, for example,

an approaching human hand and exceeding the

defined threshold. This allows an autonomous

wake-up of the MGC3130 and host applications at

very low-power consumption.

: An Approach Scan is performed

MGC3130

(1)

• Calibration Scan

feature includes the possibility to perform

additional Calibration Scans for the continuous

adaptation of the electrode system to

environmental changes.

A Calibration Scan is performed during the Scan

phase of the MGC3130’s Self Wake-up mode.

Five Rx channels are active to calibrate the

sensor signals. The Calibration Scan is usually

performed in configurable intervals from 2s to

1024s.

To reduce the power consumption, the number of

scans per second can be decreased after a

certain time of non-user activity. Colibri Suite

provides a full user flexibility to configure the

starting Calibration Scans rate (Calibration Start

Scan Interval), non-user activity time-out

(Calibration Transition Time) and the Calibration

Scans rate (Calibration Final Scan Interval) which

will be used afterwards. A typical implementation

uses Calibration Scans every 2s during the first

two minutes, and every 10s afterwards, until an

approach is detected.

Note 1: The Calibration Scan is only needed for

applications using the Position Tracking

feature.

The timing sequence of the Approach Detection feature

is illustrated in Figure 2-3.

: The Approach Detection

FIGURE 2-3: APPROACH DETECTION SEQUENCE

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 9

Page 10

MGC3130

MGC3130

Controller

Analog Front End

Communications

Interfaces

GestIC

®

Library

External

Electrodes

Tx

Rx5

Signal Processing

Unit

To application

host

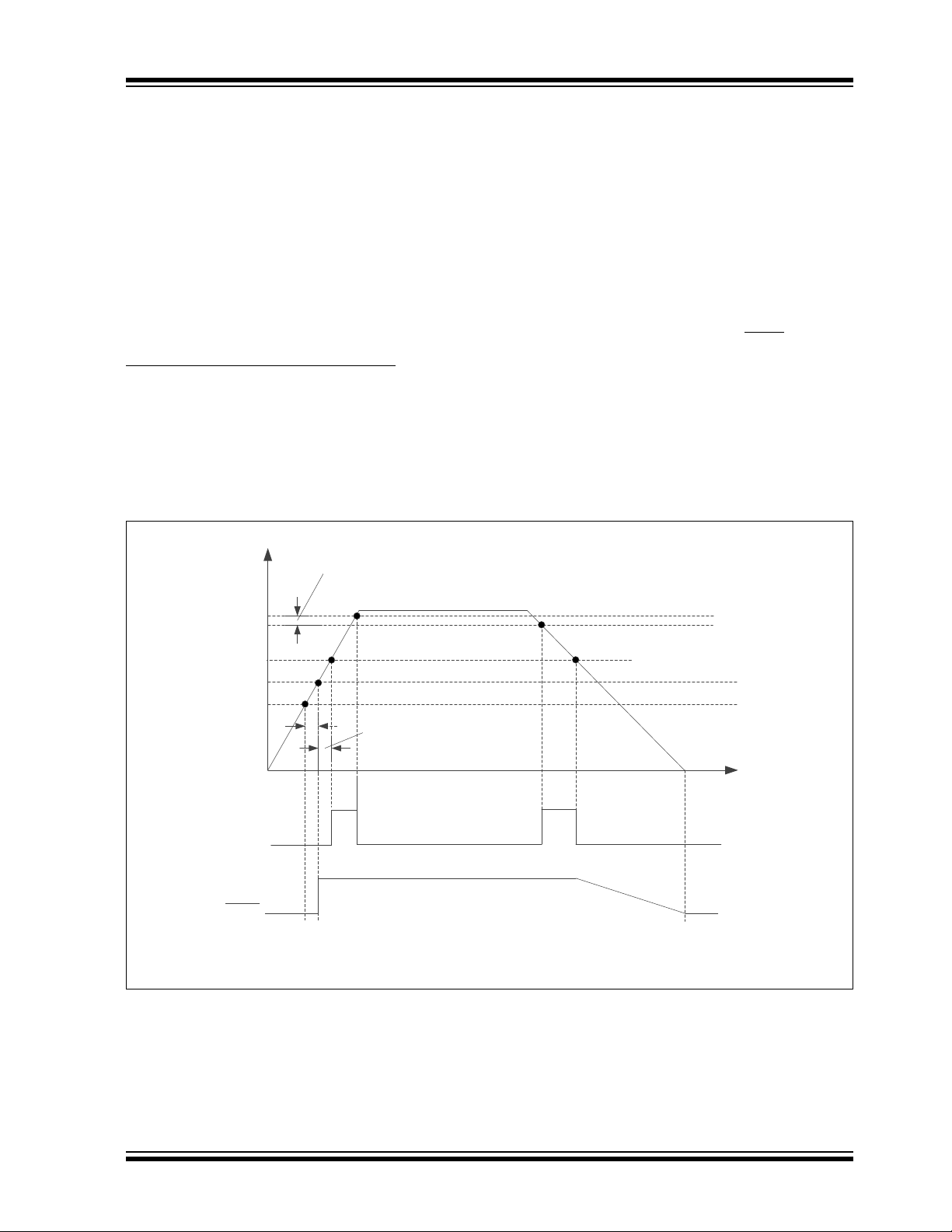

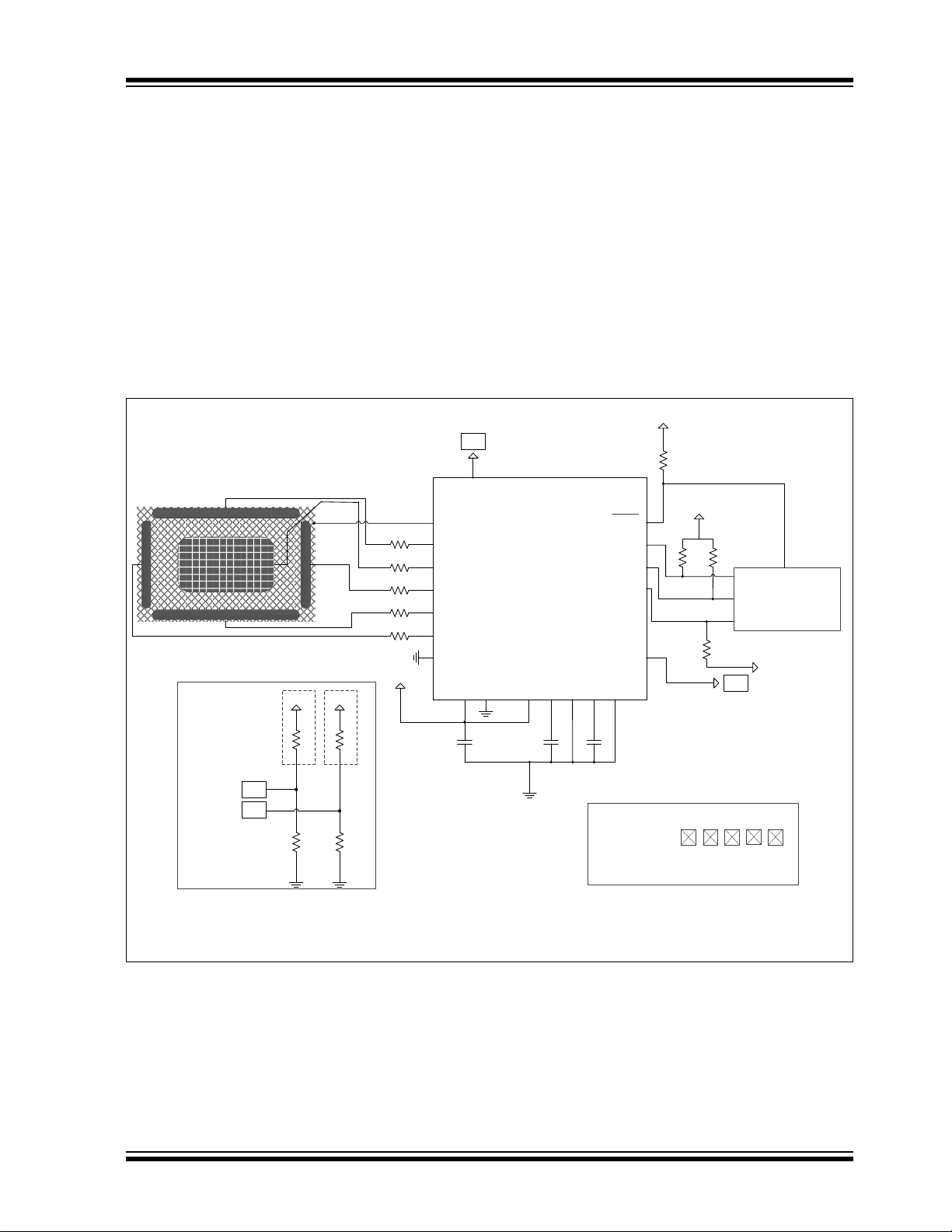

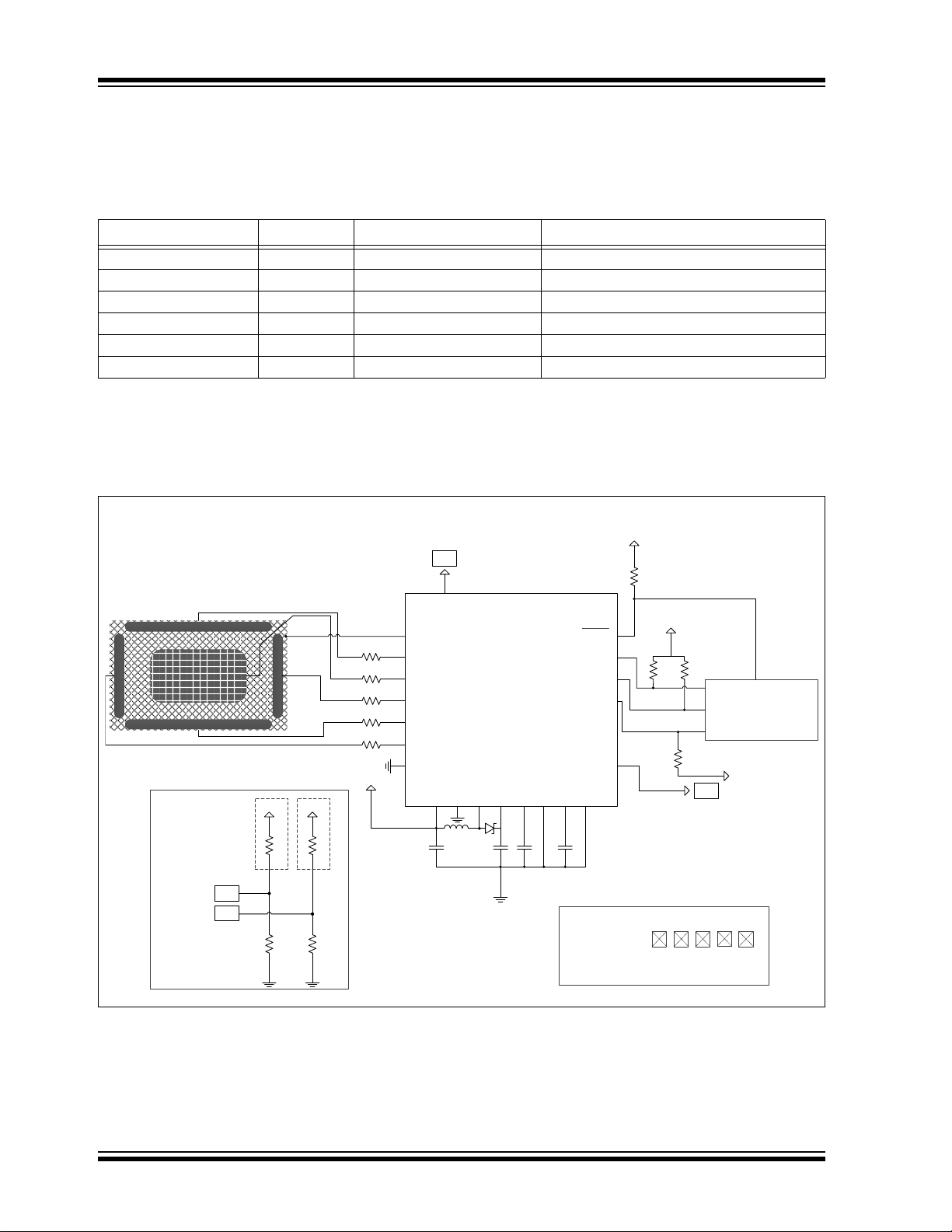

3.0 SYSTEM ARCHITECTURE

The MGC3130 is the first product based on Microchip’s

GestIC technology. It is developed as a mixed-signal

configurable controller. The entire system solution is

composed by three main building blocks (see

Figure 3-1):

• MGC3130 Controller

• GestIC Library

• External Electrodes

3.1 MGC3130 Controller

The MGC3130 features the following main building

blocks:

• Low Noise Analog Front End (AFE)

• Digital Signal Processing Unit (SPU)

• Flexible Communication Interfaces

It provides a transmit signal to generate the E-field,

conditions the analog signals from the receiving

electrodes and processes these data digitally on the

SPU. Data exchange between the MGC3130 and the

host is conducted via the controller’s communication

interface. For details, please refer to Section 4.0

“Functional Description”.

3.2 GestIC Library

The embedded GestIC Library is optimized to ensure

continuous and real-time free-space Position Tracking

and Gesture Recognition concurrently. It is fullyconfigurable and allows required parameterization for

individual application and external electrodes.

3.3 External Electrodes

Electrodes are connected to MGC3130. An electrode

needs to be individually designed for optimal E-field

distribution and detection of E-field variations inflicted

by a user.

FIGURE 3-1: MGC3130 CONTROLLER SYSTEM ARCHITECTURE

DS40001667C-page 10 Advance Information 2012-2013 Microchip Technology Inc.

Page 11

MGC3130

C

RxTx

C

TxG

C

RxG

System ground

Transmitter signal

Electrode signal

C

H

Earth ground

E-field

To MGC3130

V

Tx

System

Ground

e

Rx

e

Tx

V

RxBuf

V

RxBuf

V

Tx

C

RxTx

C

RxTx

C

RxGCH

++

---------------------------------------------- -=

3.3.1 ELECTRODE EQUIVALENT CIRCUIT

The hand Position Tracking and Gesture Recognition

capabilities of a GestIC system depends on the

electrodes design and their material characteristics.

A simplified equivalent circuit model of a generic

GestIC electrode system is illustrated in Figure 3-2.

FIGURE 3-2: ELECTRODES CAPACITIVE EQUIVALENT CIRCUITRY EARTH GROUNDED

•VTX: Tx electrode voltage

•V

•C

•C

•C

•C

•e

•e

The Rx and Tx electrodes in a GestIC electrode system

build a capacitance voltage divider with the

capacitances C

the electrode design. C

capacitance to system ground driven by the Tx signal.

The Rx electrode measures the potential of the

generated E-field. If a conductive object (e.g., a hand)

approaches the Rx electrode, C

capacitance. This minuscule change in the femtofarad

range is detected by the MGC3130 receiver.

The equivalent circuit formula for the earth-grounded

circuitry is described in Equation 3-1.

: MGC3130 Rx input voltage

RXBUf

: Capacitance between receive electrode and

H

hand (earth ground). The user’s hand can always

be considered as earth-grounded due to the

comparable large size of the human body.

: Capacitance between receive and transmit

RXTX

electrodes

: Capacitance of the receive (Rx) electrode

RXG

to system ground + input capacitance of the

MGC3130 receiver circuit

: Capacitance of the transmit (Tx) electrode

TxG

to system ground

: Rx electrode

Rx

: Tx electrode

Tx

RxTx

and C

which are determined by

RxG

represents the Tx electrode

TxG

changes its

H

EQUATION 3-1: ELECTRODES

EQUIVALENT CIRCUIT

A common example of an earth-grounded device is a

notebook, even with no ground connection via power

supply or ethernet connection. Due to its larger form

factor, it presents a high earth-ground capacitance in

the range of 50 pF and thus, it can be assumed as an

earth-grounded GestIC system.

A brief overview of the typical values of the electrodes

capacitances is summarized in Tab le 3- 1.

TABLE 3-1: ELECTRODES

CAPACITANCES TYPICAL

VALUES

Capacity Typical Value

C

RXTX

C

TXG

C

RXG

C

H

10...30 pF

10...1000 pF

10...30 pF

<1 pF

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 11

Page 12

MGC3130

South

West

East

Center

North

Top Layer (Lateral Rx)

Top Layer (Center Rx)

Tx Layer

Note: Ideal designs have low C

ensure higher sensitivity of the electrode

system. Optimal results are achieved with

C

RxTx

range.

and C

values being in the same

RxG

RxTx

and C

RxG

to

3.3.2 STANDARD ELECTRODE DESIGN

The MGC3130 electrode system is typically a doublelayer design with a Tx transmit electrode at the bottom

layer to shield against device ground and thus, ensure

high receive sensitivity. Up to five comparably smaller

Rx electrodes are placed above the Tx layer providing

the spatial resolution of the GestIC system. Tx and Rx

FIGURE 3-3: FRAME SHAPE ELECTRODES

are separated by a thin isolating layer. The Rx

electrodes are typically arranged in a frame

configuration as shown in Figure 3-3. The frame

defines the inside sensing area with maximum

dimensions of 14x14 centimeters. An optional fifth

electrode in the center of the frame may be used to

improve the distance measurement and add simple

touch functionality.

The electrodes’ shapes can be designed solid or

structured. In addition to the distance and the material

between the Rx and Tx electrodes, the shape structure

density also controls the capacitance C

the sensitivity of the system.

RXTX

and thus,

DS40001667C-page 12 Advance Information 2012-2013 Microchip Technology Inc.

Page 13

MGC3130

Host

Signal

Processing

Unit (SPU)

Power Management

Unit (PMU)

Internal clockTX Signal Generation

External

Electrodes

Communication

control

I2C

TM

SPI

MGC3130

Controller

Signal

conditioning

ADC

Signal

conditioning

ADC

Signal

conditioning

ADC

Signal

conditioning

ADC

Signal

conditioning

ADC

FLASH

memory

IOs

Reset block

Voltage Reference

(V

REF)

TXD

RX0

RX1

RX2

RX3

RX4

MCLR

SI0

SI1

SI2

SI3

EIO1

EIO2

EIO3

IS2

EIO0

INTERNAL BUS

Low-Power

Wake-up

4.0 FUNCTIONAL DESCRIPTION

Zone Design) or a single MGC3130 and another circuit

with a corresponding interface, such as a touch screen

Microchip Technology’s MGC3130 configurable

controller uses up to five E-field receiving electrodes.

Featuring a Signal Processing Unit (SPU), a wide

range of 3D gesture applications are being preprocessed on the MGC3130, which allows short

development cycles.

Always-on 3D sensing, even for battery-driven mobile

devices, is enabled due to the chip’s low-power design

and variety of programmable power modes. A Self

Wake-up mode triggers interrupts to the application

host reacting to interaction of a user with the device

and supporting the host system in overall power

controller.

GestIC sensing electrodes are driven by a low-voltage

signal with a frequency in the range of 100 kHz, which

allows their electrical conductive structure to be made

of any low-cost material. Even the reuse of existing

conductive structures, such as a display’s ITO coating,

is feasible, making the MGC3130 an overall, very costeffective system solution.

Figure 4-1 provides an overview of the main building

blocks of MGC3130. These blocks will be described in

the following sections.

reduction.

Featuring a programmable 4-pin digital interface, the

MGC3130 matches a multitude of hardware

requirements. Developers have the choice of data

exchange via I

2

C interfaces, developers have the option to set up a

I

2

C or SPI. Since the device provides two

master-slave architecture between two MGC3130

devices to add an additional sensing area (e.g., Two-

FIGURE 4-1: MGC3130 CONTROLLER BLOCK DIAGRAM

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 13

Page 14

MGC3130

MCLR

Glitch Filter

Deep sleep

WDTR

Software Reset (SWR)

WDT Time-out

SYSRST

SPU

Digital

Peripherals

Reset Block

Internal Osc.

VDDC Domain

Analog voltage

regulator

Digital voltage

regulator

Flash

Memory

Wake-up logic

WDTR

EIO

VDDM Domain

STEP-UP converter

VCAPS

VSS2

VDD

VSS1

V

CAPA

V

SS3

ADC

Signal Conditioning Blocks

VDDA Domain

VCAPD

VINDS

VDD Domain

4.1 Reset Block

The Reset block combines all Reset sources. It

controls the device system’s Reset signal (SYSRST).

The following is a list of device Reset sources:

•MCLR

• SWR: Software Reset available through GestIC

• WDTR: Watchdog Timer Reset

A simplified block diagram of the Reset block is

illustrated in Figure 4-2.

FIGURE 4-2: SYSTEM RESET BLOCK

: Master Clear Reset pin

Library

DIAGRAM

• V

DDA Domain: This domain is powered by

DDA = 3.0V. It is generated by an embedded low-

V

impedance and fast linear voltage regulator.

During Deep Sleep mode, the analog voltage

regulator is switched off. V

DDA is the internal

analog power supply voltage for the ADCs and

the signal conditioning. An external block

capacitor, C

• V

DDM Domain: This domain is powered by

DDM = 3.3V. VDDM is the internal power supply

V

EFCA, is required on VCAPA pin.

voltage for the internal Flash memory. This power

supply is depending on VDD voltage range. If

DD ≥ 3.3V, the memory is directly powered

V

through the V

DD pin. In case of VDD < 3.3V, the

Flash power supply is generated internally by an

embedded STEP-UP converter.

FIGURE 4-3: POWER SCHEME BLOCK

DIAGRAM

4.2 Power Control and Clocks

4.2.1 POWER MANAGEMENT UNIT (PMU)

The device requires a 3.3V ±5% supply voltage at VDD.

Enabling the internal STEP-UP converter extends the

voltage range to 2.5 to 3.465V.

According to Figure 4-3, the used power domains are

as follows:

DD Domain: This domain is powered by

• V

DD = 2.5V to 3.465V (typical VDD = 3.3V). VDD is

V

the external power supply for EIO, wake-up logic,

WDTR, internal regulators and STEP-UP

converter. It is provided externally through the

DD pin.

V

• V

DDC Domain: This domain is powered by

DDC = 1.8V. It is generated by an embedded low-

V

impedance and fast linear voltage regulator. The

voltage regulator is working under all conditions

(also during Deep Sleep mode) preserving the

MGC3130 data context. V

power supply voltage for digital blocks, Reset

block and RC oscillators. An external block

capacitor, C

DS40001667C-page 14 Advance Information 2012-2013 Microchip Technology Inc.

EFCD, is required on VCAPD pin.

DDC is the internal

• STEP-UP Converter: The STEP-UP converter is

generating 3.3V from the connected supply

voltage V

DD (if it is lower than 3.3V). This voltage

is required by the internal Flash memory. The

required voltage reference is taken from the

voltage reference block. During Deep Sleep

mode, the converter is switched off. It requires an

external connected inductor, a filtering capacitor

and a Schottky diode connected to the V

CAPS pins. If the supply voltage is high enough,

V

INDS and

the STEP-UP converter will be disabled. Please

refer to Section 9.0 “Electrical Specifications”

for more details.

Page 15

MGC3130

MCLR

STEP-UP

1.5V

V

STEP-UP

VDD

2.5V

time

3.465V

3.3V

t1: t

RSTDLY

: Reset delay typically 200 μs, 120 μs minimum

t2: t

PWRT

: Power-up Time-out

2V

t1

t2

Hysteresis

4.2.2 POWER SUPERVISORS

During the Power-up sequence, the system is kept

under Reset condition for approximately 200 µs (Reset

delay: t

(1.2V minimum). During this delay, the system Reset

will remain low and the VDD should reach typically 2V.

When the Reset delay is elapsed, the system Reset is

released (high) and the system starts Power-up/Timeout (t

PWRT

the target application (if the STEP-UP will be used or

not) and on the used V

out period (t

(see Tab le 4- 3).

STEP-UP applications (2.5V

The system starts when (see Figure 4-5):

• Power-up/Time-out period (t

DD = 2.5V is already reached before the end of

•V

t

STEP-UP

) after the VDD =1.5V voltage is reached

RSTDLY

) sequence. The system start depends on

DD voltage. The Power-up/Time-

) after Reset takes 36 LSO cycles.

PWRT

VDD < 3.3V):

) is elapsed

PWRT

during the t

(See Table 4-3). 2.5V is

PWRT

The STEP-UP converter starts automatically from 2.5V

if the external STEP-UP components are assembled. It

stays activated until a 3.465V V

reached.

For V

converter will automatically stop operating and the

GestIC Library can disable it. For more details, please

refer to Figure 4-5.

The power-up sequence begins by increasing the

voltage on the V

rise time is faster than 6 V/ms, the system starts

correctly.

If the slope is less than 6 V/ms, the MCLR

be held low, by external circuitry, until a valid operating

VDD level is reached.

the minimum voltage needed to power the

STEP-UP.

FIGURE 4-4: STEP-UP APPLICATIONS START-UP

DD voltage level is

DD input beyond this level, the STEP-UP

DD pin (from 0V). If the slope of the VDD

pin should

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 15

Page 16

MGC3130

MCLR

1.5V

V

DD

time

3.3V

t1: t

RSTDLY

: Reset delay typically 200 μs, 120 μs minimum

t2: t

PWRT

: Power-up Time-out

2V

t1

t2

Standard applications (without STEP-UP) (3.3V VDD

3.465V):

The system starts when (see Figure 4-5):

• Power-up/Time-out period (t

•V

DD = 3.3V is already reached before the end of

timing

t

PWRT

The power-up sequence begins by increasing the

voltage on the V

DD pin (from 0V). If the slope of the VDD

rise time is faster than 4.5 V/ms, the system starts

correctly.

If the slope is less than 4.5 V/ms, the MCLR

be held low, by external circuitry, until a valid operating

VDD level is reached.

FIGURE 4-5: POWER SUPERVISORS

PWRT

) is elapsed

pin must

DS40001667C-page 16 Advance Information 2012-2013 Microchip Technology Inc.

Page 17

MGC3130

4.2.3 CLOCKS

The MGC3130 is embedding two internal oscillators,

high speed and low speed. The High-Speed Oscillator

(HSO) is factory-trimmed, achieving high accuracy.

• High-Speed Oscillator (HSO)

The MGC3130 is clocked by an internal HSO running

at 22.5 MHz ±10% and consuming very low power. This

clock is used to generate the Tx signal, to trigger the

ADC conversions and to run the SPU. During Deep

Sleep mode, the HSO clock is switched off.

• Low-Speed Oscillator (LSO)

This low-speed and ultra-low-power oscillator is

typically 32 kHz with a tolerance of ±10 kHz. It is used

during power-saving modes.

:

:

4.2.4 OPERATION MODES

MGC3130 offers three operation modes that allow the

user to balance power consumption with device

functionality. In all of the modes described in this

section, power saving is configured by GestIC Library

messages.

4.2.4.1 Processing Mode

In this mode, all power domains are enabled and the

SPU is running continuously. All peripheral digital

blocks are active. Each Rx channel can be activated

individually by GestIC Library depending on the

application. Gesture Recognition and Position Tracking

require the Processing Operation mode.

4.2.4.2 Deep Sleep Mode

During the Deep Sleep mode, VDDM and VDDA are

turned off, and V

of the SPU.

The mode includes the following characteristics:

• The SPU is halted

• The High-Speed Oscillator is shut down

• The Low-Speed Oscillator is running

• The Watchdog is switched off

• Host interface pins are active for wake-up

This leads to the lowest possible power consumption of

MGC3130.

The MGC3130 will resume from Deep Sleep if one of

the following events occurs:

• External Interrupt (IRQ0) or I

Detection

• On MCLR Reset

The Deep Sleep mode can be enabled by GestIC

Library messages.

DDC is still powered to retain the data

2

C0 Start Bit

4.2.4.3 Self Wake-up Mode

The Self Wake-up mode is a Low-Power mode allowing

an autonomous wake-up of the MGC3130 and

application host. In this mode, the MGC3130 is

automatically and periodically alternating between

Sleep and Scan phases.

The MGC3130’s fast wake-up, typically below 1 ms,

allows to perform scans in very efficient periods and to

maximize the Sleep phase.

The periodic Wake-up sequence is triggered by a

programmable wake-up timer running at LSO

frequency and which can be adjusted by the Approach

Detection feature.

The MGC3130 enters the Self Wake-up mode by a

GestIC Library message or by a non-activity time-out.

Non-activity means no user detection within the

sensing area.

The MGC3130 will resume from Self Wake-up on one

of the following events:

• Wake-up timer overflow event

• External Interrupt (IRQ0) or I

detection

• On MCLR or WDTR

2

C0 Start Bit

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 17

Page 18

MGC3130

Wake-up IRQ from host

or I²C

TM

start detected

Approach detected

No user interaction

(Time-out)

t

I

I

DS

(1)

=9µA

I

PEAK

(1)

= 20mA

I

SW1

(1)

= 200µA

Deep Sleep Self Wake-up Self Wake-upProcessing

I

PEAK

: Processing mode with 5 Rx Channels

I

SW1

: Self Wake-up with 150 ms Approach Scan and 10s Calibration Scan

I

SW2

: Self Wake-up with 150 ms Approach Scan and without Calibration Scan

I

DS

: Deep Sleep

(1) These are preliminary values @ 3.3V, typical

I

SW2

(1)

= 110µA

I

peak

10 N

RxChannels

2+mA=

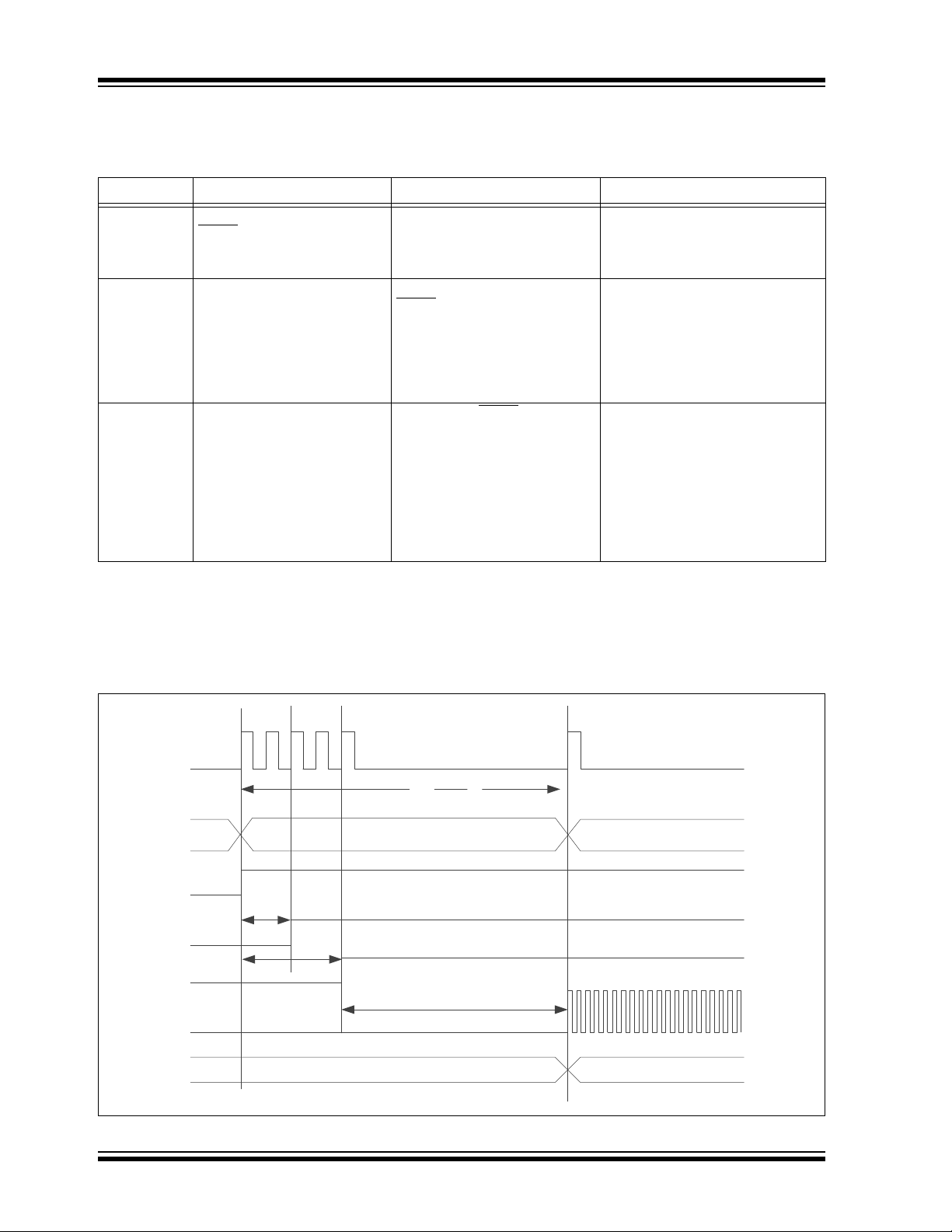

4.2.4.4 MGC3130 Power Profile

The MGC3130 power profile is illustrated in Figure 4-6.

FIGURE 4-6: MGC3130 POWER PROFILE

MGC3130 current consumption for the different

operation modes are summarized in Ta bl e 4 -1 .

TABLE 4-1: CURRENT CONSUMPTION OVERVIEW

Mode Current Consumption Conditions

Processing mode 20 mA V

Self Wake-up mode 110 µA V

Deep Sleep mode 9 µA VDD = 3.3V

The Processing mode current consumption depends

on the number of active Rx channels, N

can be determined by Equation 4-1.

EQUATION 4-1: PROCESSING MODE

RxChannels

CURRENT

CONSUMPTION

DD = 3.3V

5 Rx Channels activated

DD = 3.3V

No Calibration Scan

Approach Scan each 150 ms

200 µA VDD = 3.3V

Calibration Scan each 10s

Approach Scan each 150 ms

Changing these parameters results in different current

, and

consumption values.

Figure 4-7 and Figure 4-8 describe the Self Wake-up

mode current consumption according to the Approach

Scan and Calibration Scan period change.

The Self Wake-up mode current consumption depends

on the Approach Detection feature configuration:

Approach Scan and Calibration Scan repetition period.

DS40001667C-page 18 Advance Information 2012-2013 Microchip Technology Inc.

Page 19

MGC3130

0,11

0,77

0,57

1,21

0,20

0,86

0,00

0,20

0,40

0,60

0,80

1,00

1,20

1,40

0 50 100 150 200

Current Consumption [mA]

Time Interval between Approach Scans[ms]

no Calibration Scan

Calibration Scan every 2s

Calibration Scan every 10s

1,21

1,07

0,99

0,95

0,92

0,90

0,88

0,87

0,86

0,00

0,20

0,40

0,60

0,80

1,00

1,20

1,40

024681012

Current Consumption (mA)

Time interval between Calibration Scans (s)

FIGURE 4-7: CURRENT CONSUMPTION FOR VARYING TIME INTERVALS BETWEEN

APPROACH SCANS AND CALIBRATION SCANS

FIGURE 4-8: CURRENT CONSUMPTION FOR A FIXED TIME INTERVAL BETWEEN

APPROACH SCANS OF 20 ms

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 19

Page 20

MGC3130

LSO

SPU CLK

STEP-UP enable

SPU halted SPU running

Power-Up

Processing operation

HSO enable

V

REF enable

Reset or Deep

Sleep

t

PWRT

t

HSO

t

STEP-UP

t

SPUCLK

4.2.4.5 Operation Modes Summary

Table 4-2 summarizes the MGC3130 operation modes.

TABLE 4-2: OPERATION MODES SUMMARY

Mode Entry Exit Comments

Processing I

2

C™0/IRQ0/Approach/

/WDTR/SW Reset

MCLR

Self Wake-up Time-out/GestIC

Message

®

Deep Sleep GestIC

Library Message I2C™0/IRQ0/MCLR - SPU halted, Analog Voltage

®

Library

®

GestIC

Library Message/Non-

Activity Time-out/WDTR

I2C™0/IRQ0/Wake-up Timer/

/WDTR

MCLR

- Processing mode with up to five

electrodes continuously running

- Full positioning and

Gesture Recognition capabilities

- Scan phase with a configurable

number of Rx active channels,

wake-up timer is used to resume

the system

- Approach detection capability

- Fast wake-up time

- Very low-power consumption

Regulator OFF, STEP-UP OFF,

Watchdog OFF

- No positioning or gesture

detection

- Extreme low-power consumption

- Needs trigger from application

host to switch into Self Wake-up or

Processing mode

4.2.5 POWER-UP/DOWN SEQUENCE

Figure 4-9 represents the power-up sequence timings

after a Reset or Deep Sleep state.

FIGURE 4-9: POWER-UP SEQUENCE TIMINGS

DS40001667C-page 20 Advance Information 2012-2013 Microchip Technology Inc.

Page 21

Power-up Phases

LSO

SPU CLK

STEP-UP enable

SPU halted

SPU running

HSO enable

V

REF

enable

Processing operation

Power

down

Request

Deep Sleep

• Reset or Deep Sleep: The system is kept in Reset

or is in Deep Sleep mode

• Power-up: Phase when the system starts up after

Reset/Deep Sleep has been released

• Processing operation: Processing mode is started

• Power-up Time-out

TABLE 4-3: POWER-UP TIME-OUT (t

Signal Symbol

VREF Enable t

HSO Enable t

STEP-UP t

SPU CLK t

Power-Up

Time-Out

VREF

HSO

STEP-UP

SPUCLK

t

PWRT

PWRT

MGC3130

)

Delay in LSO Cycles

After Reset

After Deep Sleep

(STEP-UP On)

000

222

44x

30 30 8

36 36 10

After Deep Sleep

(STEP-UP Off)

Signal References

Figure 4-10 illustrates the power-down sequence

timings.

• LSO: Low-Speed Oscillator clock

• HSO: High-Speed Oscillator clock

•VREF Enable: Voltage Reference enable signal

• HSO Enable: High-Speed Oscillator enable signal

• STEP-UP Enable: STEP-UP converter enable

signal

FIGURE 4-10: POWER-DOWN SEQUENCE TIMINGS

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 21

Page 22

MGC3130

Rx gain

VDDA/2

Signal Conditioning Block

Rx Input

Signal

matching

Buffer

Power-down Phases

• Processing Operation: Processing mode is

activated

• Request: Request to enter Deep Sleep mode

• Power-down: Power-down state (all analog

signals are down)

• Deep Sleep: Deep Sleep mode has been entered

Signal References

• LSO: Low-Speed Oscillator clock

• HSO: High-Speed Oscillator clock

•VREF Enable: Voltage Reference enable signal

• HSO Enable: High-Speed Oscillator enable signal

• STEP-UP enable: STEP-UP converter enable

signal

4.3 Transmit Signal Generation

The Tx signal generation block provides a bandwidth

limited square wave signal for the transmit electrode.

Frequency hopping adjusts automatically the Tx carrier

frequency in the range of 44-115 kHz, depending on

the environmental noise conditions. GestIC Library

automatically selects the lowest noise working

frequency in case the sensor signal is compromised.

Frequencies can be enabled/disabled via the GestIC

Library.

4.4 Receive (Rx) Channels

There are five identical Rx channels that can be used

for five respective receive electrodes. Four receive

electrodes are required for Position Tracking and

Gesture Recognition. A fifth electrode can be used for

touch detection and to improve distance measurement.

Each channel has its own analog signal conditioning

stage, followed by a dedicated ADC. For specific

features such as Approach Detection, individual Rx

channels can be activated or deactivated via the

GestIC Library. According to the electrode

characteristics, the channels have to be

parameterized.

The signal conditioning block contains analog filtering

and amplification as shown in Figure 4-11.

FIGURE 4-11: SIGNAL CONDITIONING

BLOCK

For individual electrode characteristics, the Rx

channels can be configured as follows:

• Signal matching: The received signal is sampled

at a sampling rate, equal to twice the Tx

frequency providing a high and low ADC sample.

The signal matching block adjusts the received

signal towards the same value of high and low

ADC samples. The offset can be adjusted

accordingly.

• The matched signal output is amplified using a

programmable gain amplifier to achieve a better

sensitivity.

4.5 Analog-to-Digital Converter (ADC)

As outlined in Section 4.4 “Receive (Rx) Channels”,

each Rx channel features a dedicated ADC. The ADC

trigger source can be selected between the internal

clock and an external sync signal. ADC samples are

synchronous with twice the Tx transmit frequency. The

external sync signal is reserved for dual chip/dual zone

designs.

4.6 Signal Processing Unit (SPU)

The MGC3130 features a Signal Processing Unit

(SPU) to control the hardware blocks and process the

advanced DSP algorithms included in the GestIC

Library. It provides filtered sensor data, continuous

position information and recognized gestures to the

application host. The host combines the information

and controls its application.

4.7 Parameters Storage

DS40001667C-page 22 Advance Information 2012-2013 Microchip Technology Inc.

The MGC3130 provides an embedded 32 kBytes Flash

memory which is dedicated for the GestIC Library and

storage of the individual configuration parameters.

These parameters have to be set according to the

individual electrode design and application. The

GestIC Library and parameters are loaded into

MGC3130 with the provided software tools or,

alternatively, via GestIC Library messages by the

application host. For more details on the MGC3130

tools, please refer to Section 8.0 “Development

Support”.

Page 23

MGC3130

MGC3130

Single Zone

I2CTM0 I2C

TM

GPIOEIO0

Host

MGC3130

Dual Zone

Master

I2CTM0

I2C

TM

GPIOEIO0

Host

EIO2

I2CTM1

MGC3130

Dual Zone

Slave

I2CTM0

EIO0

EIO3

EIO3

5.0 APPLICATION ARCHITECTURE

MGC3130 supports two different implementations:

single-zone design and dual-zone design.

Note: Currently, only single-zone I2C™ Slave

mode is supported. Other modes are

planned for future releases of GestIC

Library. Please contact your Microchip

representative for further details.

5.1 Single-Zone Design

The standard MGC3130 implementation is a singlezone design. This configuration is based on one

MGC3130 connected to an application host. The

interface can be either configured as I

slave, SPI master or SPI slave, depending on the

overall system design (see Figure 5-1).

Data reporting and flow-control scenarios are

described below for either I

2

• If MGC3130 is I

C or SPI slave and the host is I2C

2

C or SPI configurations:

or SPI master:

- Host interface is I2C0

- EIO0 is toggled indicating that new data is

available and checking whether the host has

already started data reading or not.

• If MGC3130 is I

2

C or SPI slave:

I

2

C or SPI master and the host is

- Data is sent to the host automatically when

ready

- Data is sent on an EIO toggle of the host

system

2

C master, I2C

®

5.2 Dual-Zone Design

In addition to a single-zone design, the MGC3130’s 4-pin

digital interface also allows dual-zone designs by adding

a second MGC3130, as shown in Figure 5-2. A dual-zone

design allows detection of users hand motion in two

independent zones (e.g., one for each hand) to expand

user input options. In such a configuration, one MGC3130

acts as the dual-zone master device and the second acts

as dual-zone slave device. The communication data flow

is as follows: Position tracking data and recognized

gestures from the dual-zone slave is transferred to the

host via the MGC3130 dual-zone master.

FIGURE 5-2: DUAL-ZONE DESIGN

FIGURE 5-1: SINGLE-ZONE DESIGN

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 23

Page 24

MGC3130

6.0 INTERFACE DESCRIPTION

The MGC3130 supports two communication

interfaces: I

Note: Currently, only single-zone I

6.1 Interface Selection

The MGC3130 interface selection pin, IS2, is used to

select I

addresses.

TABLE 6-1: MGC3130 INTERFACE

IS2 IS1 Mode (Address)

00 I

10 I2C™0 Slave Address 2 (0x43)

6.2 Extended Input Output (EIO)

The MGC3130 provides four input/output pins with

extended features. These pins are controlled by GestIC

Library and listed in Table 6-2.

TABLE 6-2: MGC3130 EXTENDED IOS

Pin Pin Number Multiplexed Functions

EIO0 12 TS

EIO1 13 IS1/Gesture Port

EIO2 14 IRQ0/Gesture Port

EIO3 19 IRQ1/SYNC/Gesture Port

EIO4 20 I

EIO5 21 I2C0

EIO6 22 I2C1/Gesture Port

EIO7 23 I

2

C and SPI.

2

mode with I

modes are planned for future releases of

GestIC

Microchip representative for further

details.

2

C slave address. There are two different

2

C0 is supported. Other

®

Library. Please contact your

C™ Slave

SELECTION PINS

2

C™0 Slave Address 1 (0x42)

FUNCTIONS

2

C0

2

C1/Gesture Port

6.3 Interrupt Requests

MGC3130 IRQ0 and IRQ1 interrupt lines are used by

the host to wake-up the MGC3130 from Deep Sleep

and Self Wake-up modes. If a wake-up event is

detected on IRQ0 or IRQ1 lines, the MGC3130

switches to the Processing mode.

The IRQ0 and IRQ1 lines are only used when

MGC3130 is configured as I

2

C master.

6.4 Synchronization

The MGC3130 Tx signal can be output on the SYNC

pin. The SYNC pin can be also used as an ADC trigger

input. In future, this configuration is used for dual-zone

design implementations. The Tx signal is output on the

SYNC pin of the dual-zone master and connected to

the SYNC pin of the dual-zone slave.

6.5 Gesture Port

The MGC3130 provides five output pins which can be

used to output the Colibri Suite features events. These

pins are controlled by GestIC Library to signal to the

host that an event occurred. The host does not need to

monitor the I

only has to monitor the Gesture Port pins. This feature

is used in parallel to I2C communication.

The Colibri Suite Gesture Port feature mapping is

illustrated in Figure 6-1.

2

C bus to get GestIC Library events, but

DS40001667C-page 24 Advance Information 2012-2013 Microchip Technology Inc.

Page 25

FIGURE 6-1: GESTURE PORT MAPPING

EventOutput1..8

To EIOs

Gesture Selection

[0:2]

Electrode Selection

[0:2]

Gesture

Wake-up after Approach Detection

Action Selection

[0:2]

EventInput

Selection [0:1]

Sensor Touch

Flick West -> East

Flick East -> West

Flick North -> South

Flick South -> North

Circle ClockWise

Circle Counter-ClockWise

Permanent high

Permanent low

Sensor Touch

Selection [0:1]

Touch

Tap

Double Tap

Colibri Suite Events

MGC3130 Pins Events mapping

High active

Low active

Toggle

Pulse (5ms)

EIO1,2,3,6,7

EventOutput 1

EventOutput 8

...

MGC3130

The Colibri Suite can generate up to eight event

outputs which can be mapped to any EIO (1, 2, 3, 6 or

7). It is also possible to map more than one event

output by one EIO.

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 25

Page 26

MGC3130

TABLE 6-3: COLIBRI SUITE EVENTS

Gesture Port Mapping Parameter Description

Gesture Selection Selects the gestures which will be used as event.

Gesture Selection can be:

• Flick West/East

• Flick East/West

• Flick North/South

• Flick South/North

• Circle clockwise

• Circle Counter clockwise

Sensor Touch Selection Selects the sensor touch which will be used as event.

Sensor Touch Selection can be:

•Touch

•Tap

• Double Tap

Electrode Selection Selects the electrode which will be used for Sensor Touch.

Electrode Selection can be:

•West

•East

•North

•South

•Center

Event Input Selection Selects the event which will trigger an event output on the

EIOs.

Event Input Selection can be:

•Gesture

• Sensor Touch

• Wake-up after Approach Detection

Action Selection Selects the signal format which will be output on the EIOs.

See Figure 6-2 and Ta bl e 6 -4 .

Action Selection can be:

• Permanent High

• Permanent Low

• Toggle

•Pulse (5 ms)

• High Active

• Low Active

DS40001667C-page 26 Advance Information 2012-2013 Microchip Technology Inc.

Page 27

FIGURE 6-2: GESTURE PORT ACTION

Permanent high

Toggle

Event

Event Event Event

Pulse (5ms)

Event

Permanent low

Event

High active

Touch detected Touch released

Low active

Touch detected Touch released

MGC3130

TABLE 6-4: GPIO PORT ACTION MAPPING

Action

Event

Gesture X X X X

Touch X X X X X X

Single Tap X X X X

Double Tap X X X X

Wake-up after Approach Detection X X

Permanent

High

Permanent

Low

Toggle Pulse (5 ms) High Active Low Active

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 27

Page 28

MGC3130

6.6 Communication Interfaces

6.6.1 I2C

The MGC3130 supports two I2C interfaces. Only I2C0

is used in a single-zone configuration.

I2C0 and I2C1 features:

• Two ports: SCL0, SDA0 and SCL1, SDA1

• Master and Slave mode

• Up to 400 kHz

• 7-bit Addressing mode

• Hardware state machine for basic protocol

handling

• Support for repeated start and clock stretching

(Byte mode)

• No multi-master support

2

C Hardware Interface

I

A summary of the hardware interface pins is shown

below in Tab le 6 -5 .

TABLE 6-5: I2C™ PIN DESCRIPTION

MGC3130 Pin Multiplexed Functions

SCL Serial Clock to Master I2C™

SDA Serial Data to Master I2C™

•SCL Pin

- The SCL (Serial Clock) pin is electrically

open-drain and requires a pull-up resistor of

typically 1.8 kΩ (for a maximum bus load

capacitance of 200 pF), from SCL to V

SCL Idle state is high.

•SDA Pin

- The SDA (Serial Data) pin is electrically

open-drain and requires a pull-up resistor of

typically 1.8 kΩ (for a maximum bus load

capacitance of 200 pF), from SDA to V

- SDA Idle state is high.

- Master write data is latched in on SCL rising

edges.

- Master read data is latched out on SCL falling

edges to ensure it is valid during the

subsequent SCL high time.

2

C Addressing:

I

The MGC3130 Device ID 7-bit address is: 0x42

(0b1000010) or 0x43 (0b1000011) depending on the

interface selection pin configuration (IS2). Please refer

to Tab le 6- 6.

TABLE 6-6: I2C™ DEVICE ID ADDRESS

Device ID Address, 7-bit

A6 A5 A4 A3 A2 A1 A0

100001IS2

DD.

DD.

TABLE 6-7: I2C™ DEVICE WRITE ID

ADDRESS (0x84 OR 0x86)

I2C™ Device Write ID Address

A7 A6 A5 A4 A3 A2 A1 A0

100001IS2 0

TABLE 6-8: I2C™ DEVICE READ ID

ADDRESS (0x85 OR 0x87)

I2C™ Device Read ID Address

A7 A6 A5 A4 A3 A2 A1 A0

100001IS2 1

2

C Master Read Bit Timing (MGC3130 I2C Slave)

I

Master read is to receive position data, gesture reports

and command responses from the MGC3130. The

timing diagram is shown in Figure 6-4.

• Address bits are latched into the MGC3130 on the

rising edges of SCL.

• Data bits are latched out of the MGC3130 on the

rising edges of SCL.

• ACK bit:

- MGC3130 presents the ACK bit on the ninth

clock for address acknowledgment

2

C master presents the ACK bit on the ninth

-I

clock for data acknowledgment

•The I2C master must monitor the SCL pin prior to

asserting another clock pulse, as the MGC3130

may be holding off the I

the clock.

I2C Communication Steps

1. SCL and SDA lines are Idle high.

2

2. I

C master presents Start bit to the MGC3130 by

taking SDA high-to-low, followed by taking SCL

high-to-low.

3. I2C master presents 7-bit address, followed by a

= 1 (Read mode) bit to the MGC3130 on

R/W

SDA, at the rising edge of eight master clock

(SCL) cycles.

4. MGC3130 compares the received address to its

Device ID. If they match, the MGC3130

acknowledges (ACK) the master sent address

by presenting a low on SDA, followed by a lowhigh-low on SCL.

2

5. I

C master monitors SCL, as the MGC3130 may

be clock stretching, holding SCL low to indicate

that the I2C master should wait.

2

C master by stretching

DS40001667C-page 28 Advance Information 2012-2013 Microchip Technology Inc.

Page 29

MGC3130

6. I2C master receives eight data bits (MSB first)

presented on SDA by the MGC3130, at eight

sequential I2C master clock (SCL) cycles. The

data is latched out on SCL falling edges to

ensure it is valid during the subsequent SCL

high time.

7. If data transfer is not complete, then:

-I2C master acknowledges (ACK) reception of

the eight data bits by presenting a low on

SDA, followed by a low-high-low on SCL.

- Go to step 5.

8. If data transfer is complete, then:

-I2C master acknowledges (ACK) reception of

the eight data bits and a completed data

transfer by presenting a high on SDA,

followed by a low-high-low on SCL.

2

C Master Write Bit Timing (MGC3130 Slave)

I

I2C master write is to send supported commands to the

MGC3130. The timing diagram is shown in Figure 6-5.

• Address bits are latched into the MGC3130 on the

rising edges of SCL.

• Data bits are latched into the MGC3130 on the

rising edges of SCL.

• ACK bit:

- MGC3130 presents the ACK bit on the ninth

clock for address acknowledgment

2

C master presents the ACK bit on the ninth

-I

clock for data acknowledgment

• The master must monitor the SCL pin prior to

asserting another clock pulse, as the MGC3130

may be holding off the master by stretching the

clock.

I2C Communication Steps

1. SCL and SDA lines are Idle high.

2. I2C master presents Start bit to the MGC3130 by

taking SDA high-to-low, followed by taking SCL

high-to-low.

2

C master presents 7-bit address, followed by a

3. I

= 0 (Write mode) bit to the MGC3130 on

R/W

SDA, at the rising edge of eight master clock

(SCL) cycles.

4. MGC3130 compares the received address to its

Device ID. If they match, the MGC3130

acknowledges (ACK) the I

2

C master sent

address by presenting a low on SDA, followed

by a low-high-low on SCL.

5. I2C master monitors SCL, as the MGC3130 may

be clock stretching, holding SCL low to indicate

2

C master should wait.

the I

6. I2C master presents eight data bits (MSB first) to

the MGC3130 on SDA, at the rising edge of

eight master clock (SCL) cycles.

7. MGC3130 acknowledges (ACK) receipt of the

eight data bits by presenting a low on SDA, followed by a low-high-low on SCL.

8. If data transfer is not complete, then go to step

5.

9. Master presents a Stop bit to the MGC3130 by

taking SCL low-high, followed by taking SDA

low-to-high.

6.6.2 TRANSFER STATUS LINE

MGC3130 requires a dedicated Transfer Status line

(TS) which features a data transfer status function. It is

used by both I2C Master and Slave to control data flow.

The TS (Transfer Status) line is electrically open-drain

and requires a pull-up resistor of typically 10 k, from

TS to V

The MGC3130 (I

host controller (I

which can be transferred. The host controller uses the

TS line to indicate that data is being transferred and

prevents MGC3130 from updating its data buffer.

Table 6-9 shows how the TS line is used in the different

states of communication.

DD. TS Idle state is high.

2

C Slave) uses this line to inform the

2

C Master) that there is data available

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 29

Page 30

MGC3130

Transfer Status

(TS)

I2CTM Bus

MGC3130 Related Transfer MGC3130 Related Transfer

TS line pulled

low by master

when transfer

is started

TS line released

by master and

MGC3130 when

transfer is

finished

TS line pulled

by MGC3130

to request a

data transfer

MGC3130 buffer

can be updated

Non MGC3130 related transfer or Bus Idle

TS line pulled

low by master

when transfer is

started

MGC3130 buffer

can be updated

TS line pulled

by MGC3130

to request a

data transfer

TS line released

by master and

MGC3130 when

transfer is

finished

TABLE 6-9: USAGE OF TRANSFER STATUS LINE

MGC3130 Host Controller TS Line Status

Released (H) Released (H) High Host finished reading data (Transfer end). No more data to

be transferred to the host. MGC3130 is allowed to update the

data buffer.

Asserted (L) Released (H) Low Data from MGC3130 is available to be sent, but the host has

not yet started reading. If the host is busy and did not start

reading before the next data update (5 ms), the MGC3130

will assert the TS line high while updating the data buffer.

Asserted (L) Asserted (L) Low Host starts reading. MGC3130 data buffer will not be updated

until the end of transfer (host releases TS high).

Released (H) Asserted (L) Low MGC3130 is ready to update the data buffer, but the host is

still reading the previous data. MGC3130 is allowed to

update the data only when the host releases the TS high.

MGC3130 can update the I2C buffer only when the TS

is released by both chips and a data transfer can only

be started when MGC3130 pulls the TS low.

This procedure secures that:

• the host is always informed when new sensor

data is available

• buffer updates in MGC3130 are always

completed before data is sent to the I

Figure 6-3 shows the complete communication

protocol.

2

C bus

FIGURE 6-3: MGC3130 COMMUNICATION PROTOCOL

Note 1: The stop condition after an I2C™ data

transmission is generated by the host

controller (I2C Master) after the data

transfer is completed. Thus, it is

recommended to verify the amount of

bytes to be read in the message header

(Size field).

2: Transfer Status is only needed for data

transfer from MGC3130 to the host controller. Writing to MGC3130 does not

require the additional TS signal.

In addition to the standard I2C interface, the

communication between MGC3130 and the host

controller requires a proper handling of the Transfer

Status.

DS40001667C-page 30 Advance Information 2012-2013 Microchip Technology Inc.

Page 31

6.6.3 SPI

SPI features:

• One Port: SCLK, CS, MOSI, MISO

• Master and Slave mode

• Up to 3 MHz

• Support of all clock edge and polarity options

2

Note: Currently, only single-zone I

mode with I

modes are planned for future releases of

GestIC

Microchip representative for further

details.

SPI Hardware Interface

A summary of the hardware interface pins is shown

below in Tab le 6 - 10 .

2

C0 is supported. Other

®

Library. Please contact your

C™ Slave

TABLE 6-10: SPI PIN DESCRIPTION

MGC3130 Pin Description

SCLK Master Clock

CS

MISO Master Input Slave Output

MOSI Master Output Slave Input

Chip Select

MGC3130

• SCLK Pin:

- The MGC3130 controller’s SCLK pin drives

the communication bus clock.

- The Idle state of the SCLK should be low.

- Data is transmitted on the falling edge of

SCLK.

•MOSI Pin:

- The MGC3130 controller’s MOSI pin sends/

reads serial data to/from the slave/host.

•MISO Pin:

- The MGC3130 controller’s MISO pin reads/

sends serial data from/to the slave/host.

Pin:

•CS

- The MGC3130 controller’s CS

device selection functionality.

pin provides

TABLE 6-11: SPI CS PIN DESCRIPTION

CS Pin Description

V

SS Active

VDD Inactive

2012-2013 Microchip Technology Inc. Advance Information DS40001667C-page 31

Page 32

DS40001667C-page 32 Advance Information 2012-2013 Microchip Technology Inc.

312 456789 312 456789 312 456789

A7 A6 A5 A4 A3 A2 A1

1

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

Address R/W ACK ACK ACKData Data

Address Bits Latched in Data Bits Valid Out Data Bits Valid Out

SCL may be stretched SCL may be stretched

S

P

Start Bit

Stop Bit

SDA

SCL

312 456789 312 456789 312 456789

A7 A6 A5 A4 A3 A2 A1

0

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

Address R/W ACK ACK ACKData Data

Address Bits Latched in Data Bits Valid Out Data Bits Valid Out

SCL may be stretched SCL may be stretched

S

P

Start Bit

Stop Bit

SDA

SCL

FIGURE 6-4: I2C™ MASTER READ BIT TIMING DIAGRAM

MGC3130

FIGURE 6-5: I

2

C™ MASTER WRITE BIT TIMING DIAGRAM

Page 33

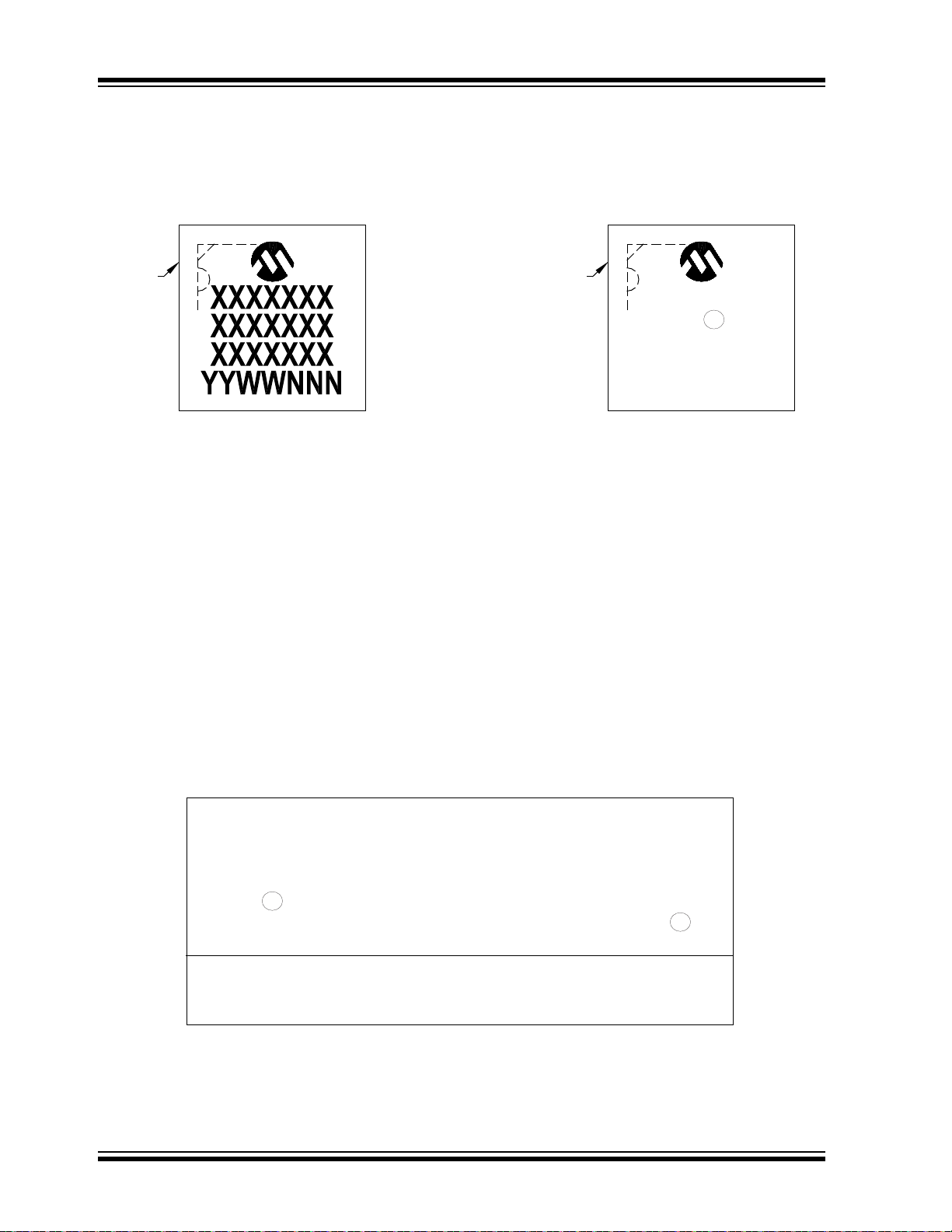

MGC3130

MGC3130

VDD

VSS1

VSS3

VDD

100 nF

4.7 μF

4.7 μF

IS2

MCLR

SI0

SI1

EIO0

SDA

SCL

GPIO/IRQ

HOST

VDD

1.8 kΩ

1.8 kΩ

RESET

10 kΩ

VDD

TXD

RX0

RX1

RX2

RX3

RX4

VDD

VINDS

VCAPS

VCAPA

VCAPD

EXP

VSS1

NC

NC

NC

VSS2

EIO7

EIO1

EIO6

NC

North Electrode

South Electrode

East Electrode

WestElectrode

Center Electrode

IS1

IS2

R9 (10 kΩ)

C1

C3

C2

R1

R2

R3

10 kΩ

10 kΩ

10 kΩ

10 kΩ

IS1

IS2

VDD VDD

R6

R8

R5 (n.p)

R7 (n.p)

R10 (10 kΩ)

R11 (10 kΩ)

R12 (10 kΩ)

R13 (10 kΩ)

VDD

10 kΩ

R4

EIO2

EIO3

n.p: not populated

Gesture Port

EIO7

EIO1

EIO6

EIO2

EIO3