Page 1

MCP8025/6

3-Phase Brushless DC (BLDC) Motor Gate Driver with Power Module, Sleep Mode, LIN Transceiver

Features

• AEC-Q100 Grade 0 Qualified

• Quiescent Current:

- Sleep Mode: 5 µA Typical

- Standby Mode: < 200 µA

• LIN Transceiver Interface (MCP8025):

- Compliant with LIN Bus Specifications 1.3,

2.2, and SAE J2602

- Supports baud rates up to 20K baud

- Internal pull-up resistor and diode

- Protected against ground shorts

- Protected against loss of ground

- Automatic thermal shutdown

- LIN Bus dominant timeout

• Three Half-Bridge Drivers Configured to Drive

External High-Side NMOS and Low-Side NMOS

MOSFETs:

- Independent input control for high-side

NMOS and low-side NMOS MOSFETs

- Peak output current: 0.5A @ 12V

- Shoot-through protection

- Overcurrent and short circuit protection

• Adjustable Output Buck Regulator (750 mW)

• Fixed Output Linear Regulators:

- 5V@30mA

-12V@30mA

• Operational Amplifiers:

- one in MCP8025

- three in MCP8026

• Overcurrent Comparator with DAC Reference

• Phase Comparator With Multiplexer (MCP8025)

• Neutral Simulator (MCP8025)

• Level Translators (MCP8026)

• Input Voltage Range: 6V – 40V

• Operational Voltage Range:

-6V–19V (MCP8025)

-6V–28V (MCP8026)

• Buck Regulator Undervoltage Lockout: 4.0V

• Undervoltage Lockout (UVLO): 5.5V (except Buck)

• Overvoltage Lockout (OVLO)

-20V (MCP8025)

-32V (MCP8026)

• Transient (100 ms) Voltage Tolerance: 48V

• Extended Temperature Range (T

• Thermal Shutdown

): -40 to +150°C

A

Applications

• Automotive Fuel, Water, Ventilation Motors

• Home Appliances

• Permanent Magnet Synchronous Motor (PMSM)

Control

• Hobby Aircraft, Boats, Vehicles

Description

The MCP8025/6 devices are 3-phase brushless DC

(BLDC) power modules containing three integrated

half-bridge drivers capable of driving three external

NMOS/NMOS transistor pairs. The three half-bridge

drivers are capable of delivering a peak output current

of 0.5A at 12V for driving high-side and low-side NMOS

MOSFET transistors. The drivers have shoot-through,

overcurrent and short-circuit protection. A Sleep Mode

has been added to achieve a typical “key-off” quiescent

current of 5 µA.

The MCP8025 device integrates a comparator, a buck

voltage regulator, two LDO regulators, power

monitoring comparators, an overtemperature sensor, a

LIN transceiver, a zero-crossing detector, a neutral

simulator and an operational amplifier for motor current

monitoring. The phase comparator and multiplexer

allow for hardware commutation detection. The neutral

simulator allows commutation detection without a

neutral tap in the motor. The buck converter is capable

of delivering 750 mW of power for powering a

companion microcontroller. The buck regulator may be

disabled if not used. The on-board 5V and 12V lowdropout voltage regulators are capable of delivering

30 mA of current.

The MCP8026 replaces the LIN transceiver, neutral

simulator and zero-crossing detector in MCP8025 with

two level shifters and two additional op amps.

The MCP8025/6 operation is specified over a

temperature range of -40°C to +150°C.

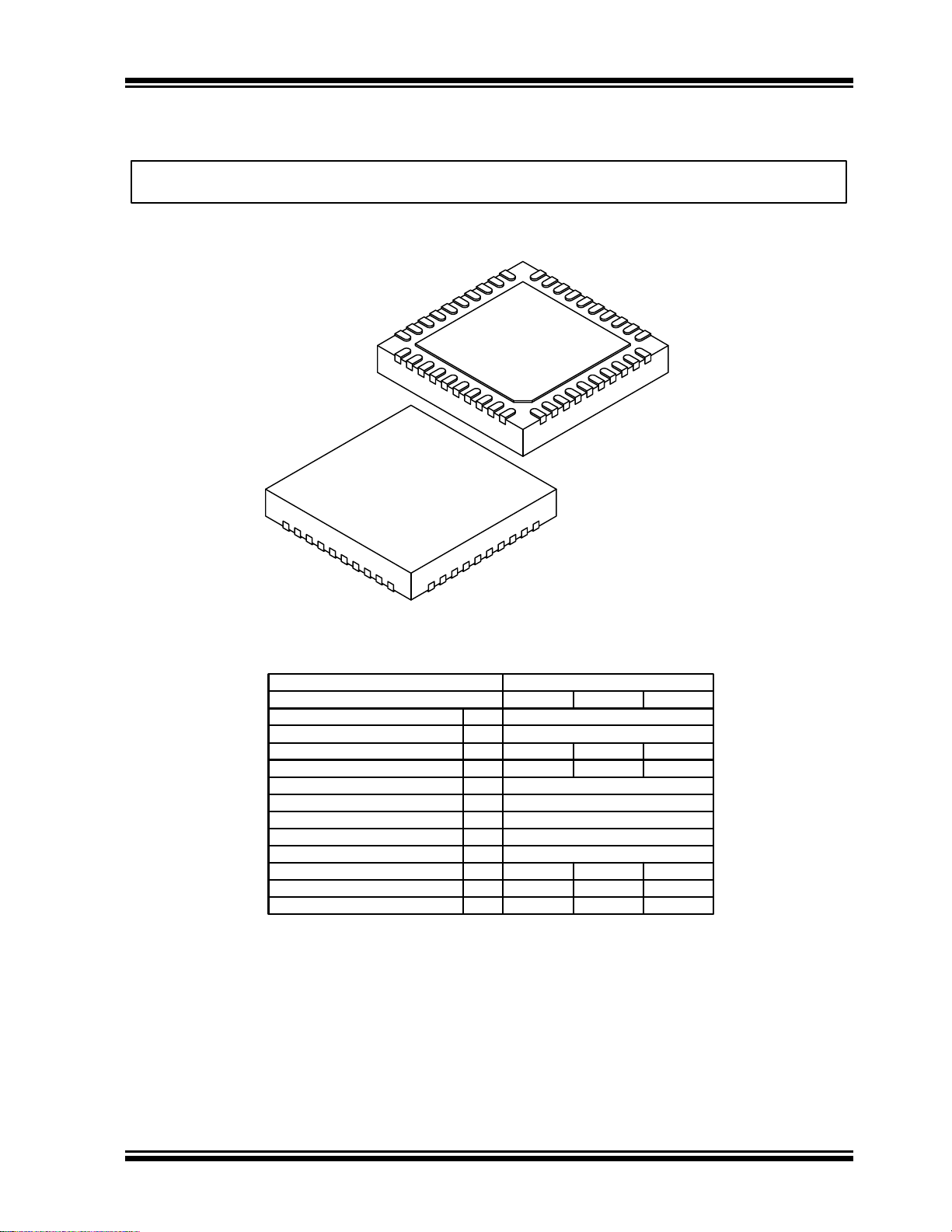

Package options include 40-lead 5x5 QFN and 48-lead

7x7 TQFP with Exposed Pad (EP).

2014 Microchip Technology Inc. DS20005339A-page 1

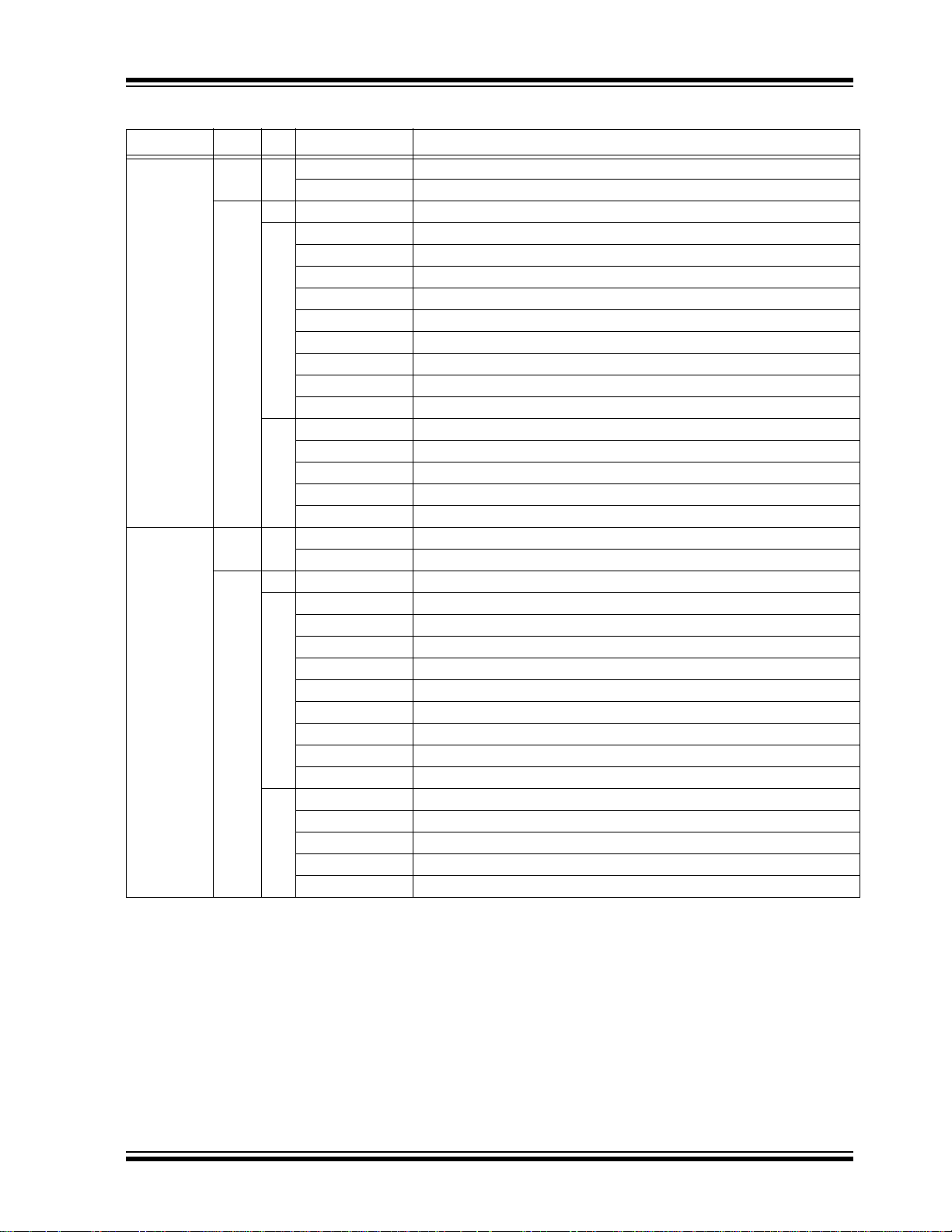

Page 2

MCP8025/6

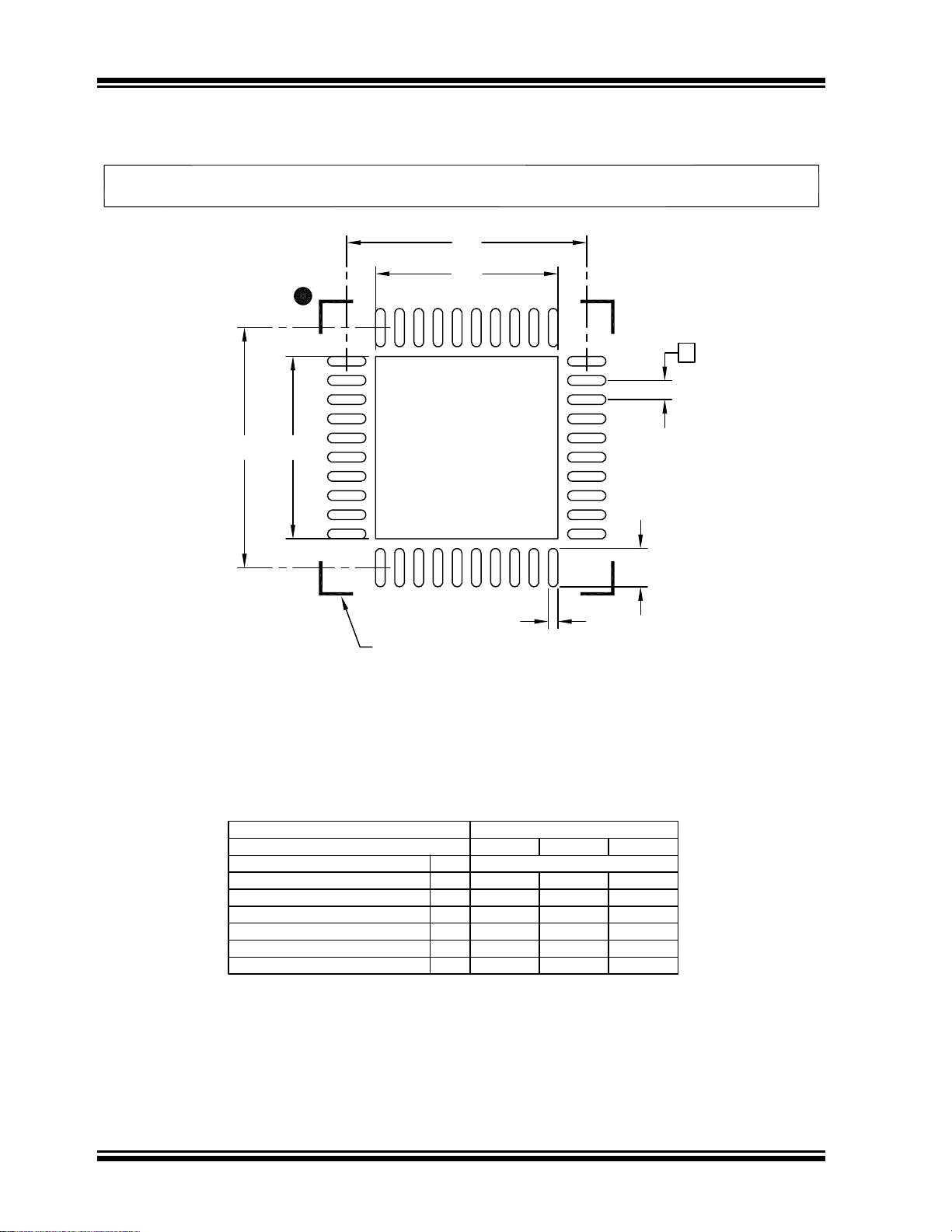

5mm x 5mm QFN-40

7mm x 7mm TQFP-48

+

EP

41

EP

49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

171819

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

1

2

3

4

5

6

7

8

9

10

11

12

131415

16

171819

20

21

222324

36

35

34

33

32

31

30

29

28

27

26

25

484746

45

444342

41

40

393837

PWM2H

PWM1L

PWM1H

CE

LIN_BUS

RX

TX

FAULTn

/TXE

MUX1

MUX2

+12V

V

BA

V

BB

V

BC

PHA

PHB

PHC

HSA

HSB

HSC

ZC_OUT

COMP_REF

ILIMIT_OUT

I_OUT1

I_SENSE1-

I_SENSE1+

P

GND

LSA

LSB

LSC

PWM2L

PWM3H

PWM3L

DE2

CAP1

CAP2

+5VFBVDDLX

PWM2H

PWM1L

PWM1H

CE

LIN_BUS

RX

TX

FAULTn

/TXE

MUX1

MUX2

NC

NC

P

GND

ZC_OUT

COMP_REF

ILIMIT_OUT

I_OUT1

I_SENSE1-

I_SENSE1+

P

GND

LSA

LSB

LSC

P

GND

P

GND

+12V

V

BA

V

BB

V

BC

PHA

PHB

PHC

HSA

HSB

HSC

P

GND

P

GND

PWM2L

PWM3H

PWM3L

DE2

CAP1

CAP2

+5V

FB

VDDLX

V

DD

Package Types – MCP8025

DS20005339A-page 2 2014 Microchip Technology Inc.

Page 3

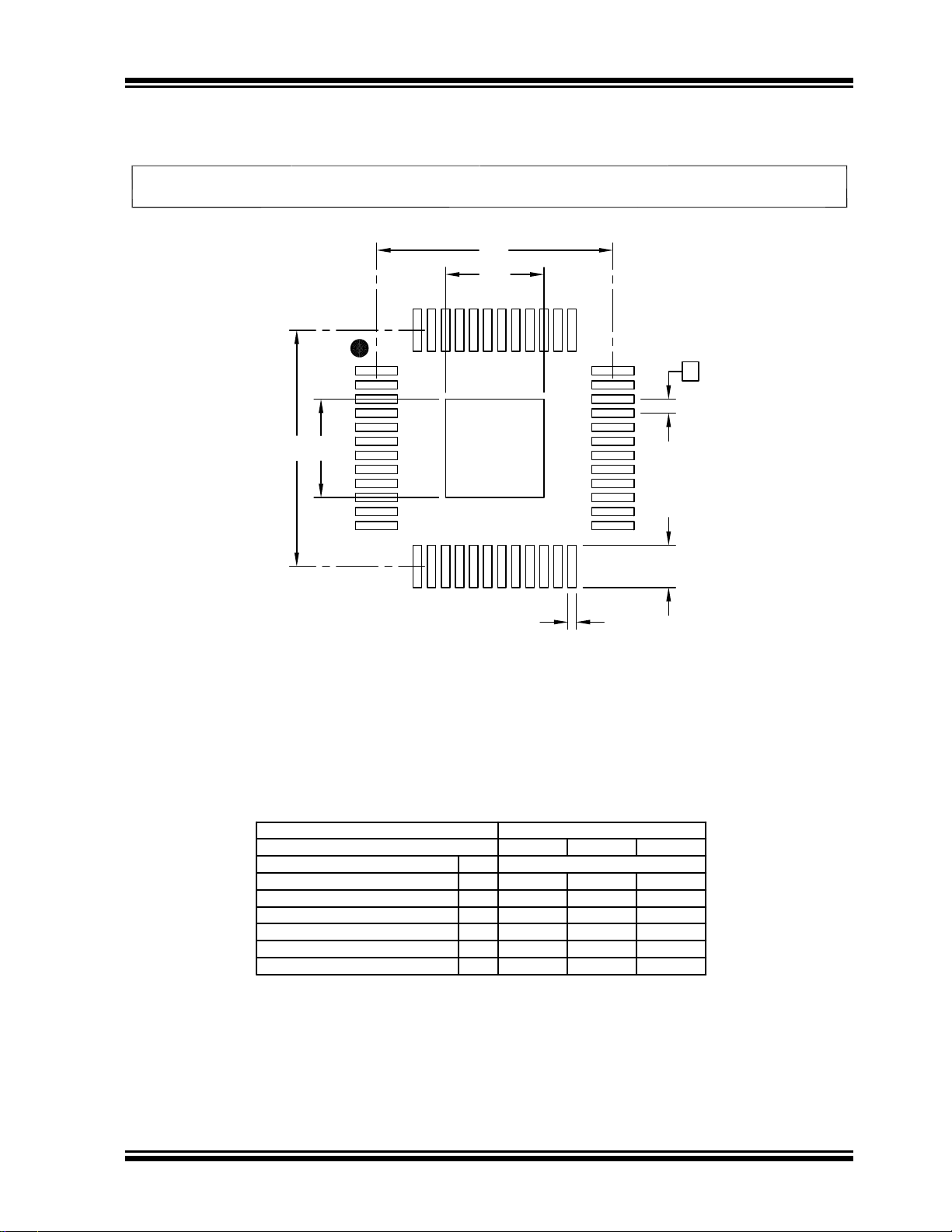

Package Types – MCP8026

5mm x 5mm QFN-40

7mm x 7mm TQFP-48

EP

41

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

171819

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

PWM2H

PWM1L

PWM1H

CE

HV_IN1

LV_O UT1

IOUT3

ISENSE3-

ISENSE3+

IOUT2

+12V

V

BA

V

BB

V

BC

PHA

PHB

PHC

HSA

HSB

HSC

ISENSE2-

ISENSE2+

ILIMIT_OUT

I_OUT1

I_SENSE1-

I_SENSE1+

P

GND

LSA

LSB

LSC

PWM2L

PWM3H

PWM3L

DE2

CAP1

CAP2

+5V

FB

VDDLX

+

EP

49

1

2

3

4

5

6

7

8

9

10

11

12

131415

16

171819

20

21

222324

36

35

34

33

32

31

30

29

28

27

26

25

484746

45

444342

41

40

393837

PWM2H

PWM1L

PWM1H

CE

HV_IN1

LV_OUT1

IOUT3

ISENSE3-

ISENSE3+

IOUT2

LV_OUT2

HV_IN2

P

GND

ISENSE2-

ISENSE2+

ILIMIT_OUT

I_OUT1

I_SENSE1-

I_SENSE1+

P

GND

LSA

LSB

LSC

P

GND

P

GND

+12V

V

BA

V

BB

V

BC

PHA

PHB

PHC

HSA

HSB

HSC

P

GND

P

GND

PWM2L

PWM3H

PWM3L

DE2

CAP1

CAP2

+5V

FB

VDDLX

V

DD

MCP8025/6

2014 Microchip Technology Inc. DS20005339A-page 3

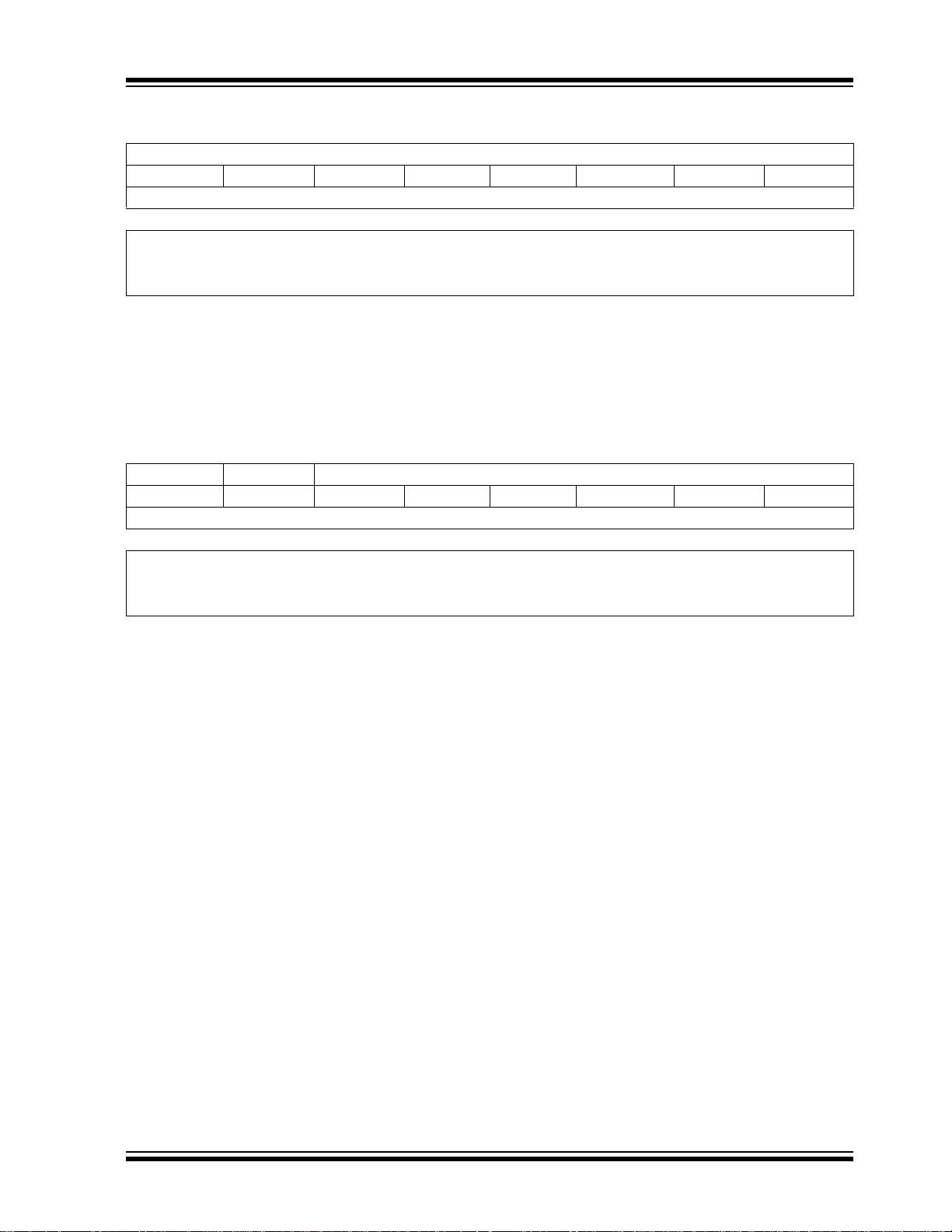

Page 4

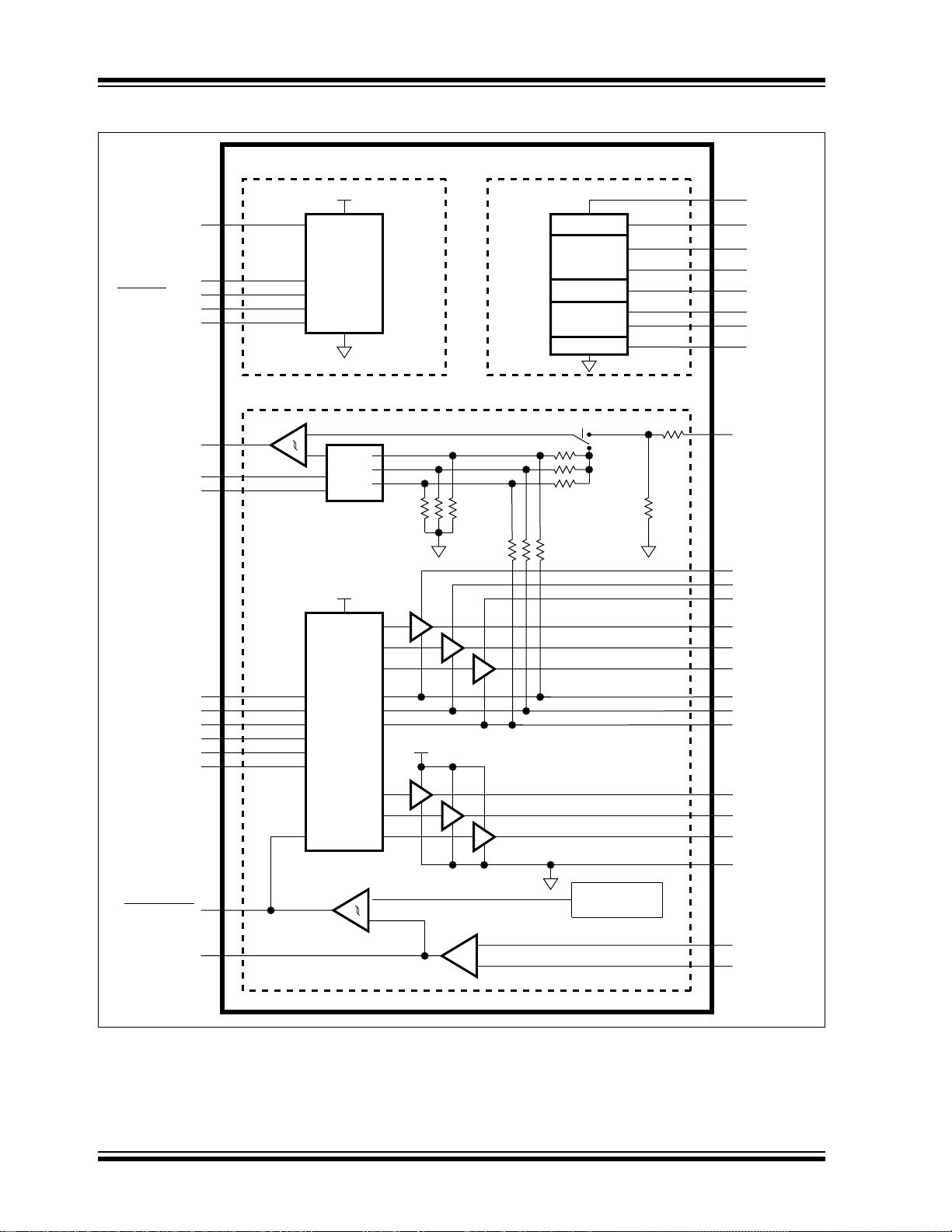

LIN

XCVR

CE

FAULTn/TXE

RX

TX

PWM1H

PWM1L

PWM2H

PWM2L

PWM3H

PWM3L

LIN_BUS

MUX

+

-

PHA

PHB

PHC

PGND

ZC_OUT

COMP_REF

NEUTRAL_SIM

MUX1

MUX2

MOTOR CONTROL UNIT

COMMUNICATION PORT BIAS GENERATOR

+12V

HSA

HSB

HSC

LSA

LSB

LSC

VBA

VBB

VBC

GATE

CONTROL

LOGIC

I

I

I

I

I

I

I

I

I

O

O

O

O

O

O

O

VDD

I_OUT1

+

-

+

-

ILIMIT_OUT

I_SENSE1+

I_SENSE1-

DRIVER

FAULT

VDD

I

I

I/O

I/O

O

I

I

I

I

IO

PHASE DETECT

ILIMIT_REF

LDO

BUCK SMPS

SUPERVISOR

LDO

CHARGE PUMP

DE2

VDD

+5V

LX

FB

+12V

CAP2

CAP1

SIM Select

MCP8025/6

Functional Block Diagram – MCP8025

DS20005339A-page 4 2014 Microchip Technology Inc.

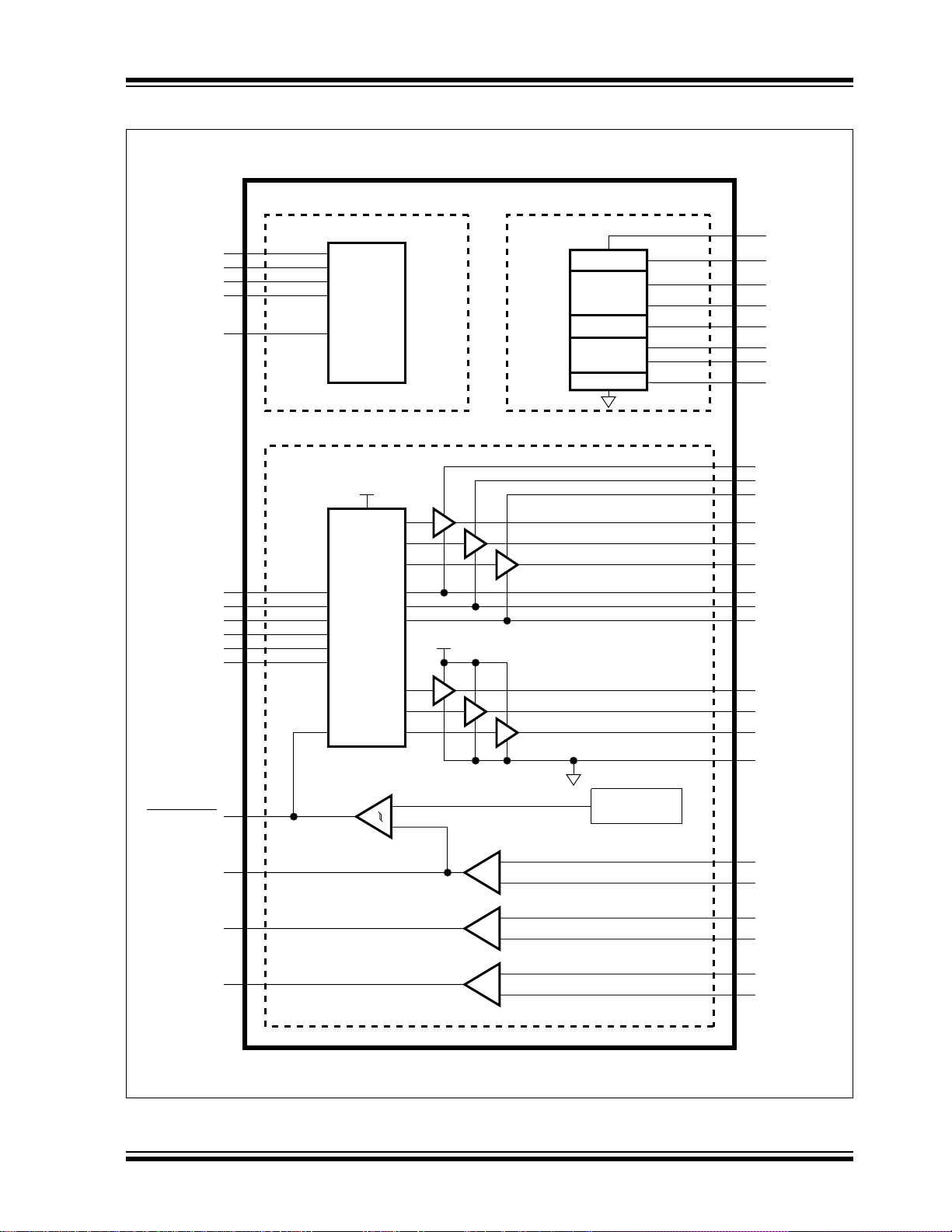

Page 5

GATE

CONTROL

LOGIC

CE

PWM1H

PWM1L

PWM2H

PWM2L

PWM3H

PWM3L

HV_IN1

I_OUT1

+

-

+

-

PHA

PHB

PHC

PGND

ILIMIT_OUT

MOTOR CONTROL UNIT

COMMUNICATION PORT BIAS GENERATOR

+12V

HSA

HSB

HSC

I_SENSE1+

LSA

LSB

LSC

I_SENSE1-

VBA

VBB

VBC

LV_OUT1

LEVEL

TRANSLATOR

VDD

+

-

+

-

I_SENSE2+

I_SENSE2-

I_SENSE3+

I_SENSE3-

I_OUT2

I_OUT3

DRIVER

FAULT

I

I

I

I

I

I

I

I

I

I

I

O

O

O

O

O

O

O

O

LDO

BUCK SMPS

SUPERVISOR

LDO

CHARGE PUMP

DE2

VDD

+5V

LX

FB

+12V

CAP2

CAP1

ILIMIT_REF

HV_IN2

LV_OUT2

O

I

Functional Block Diagram – MCP8026

MCP8025/6

2014 Microchip Technology Inc. DS20005339A-page 5

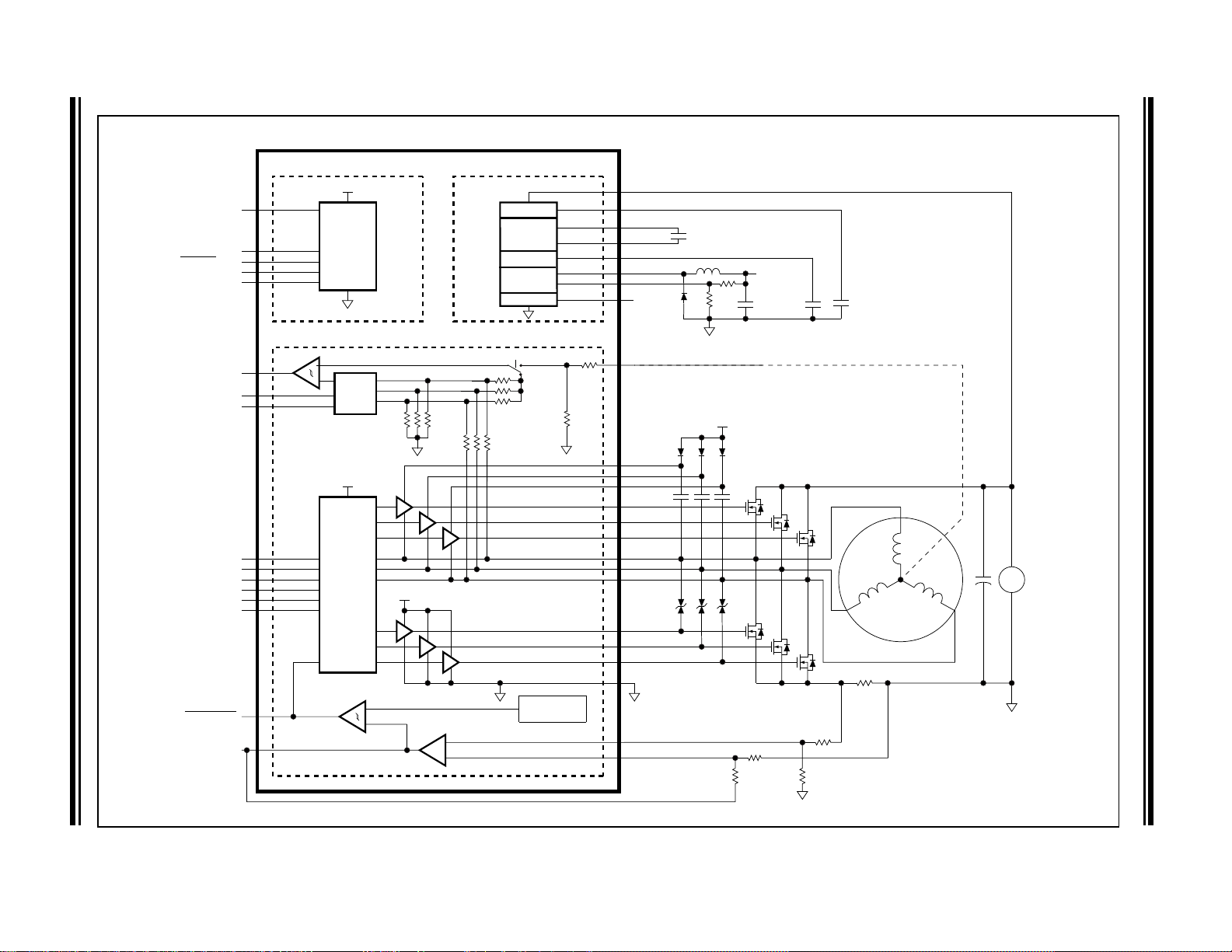

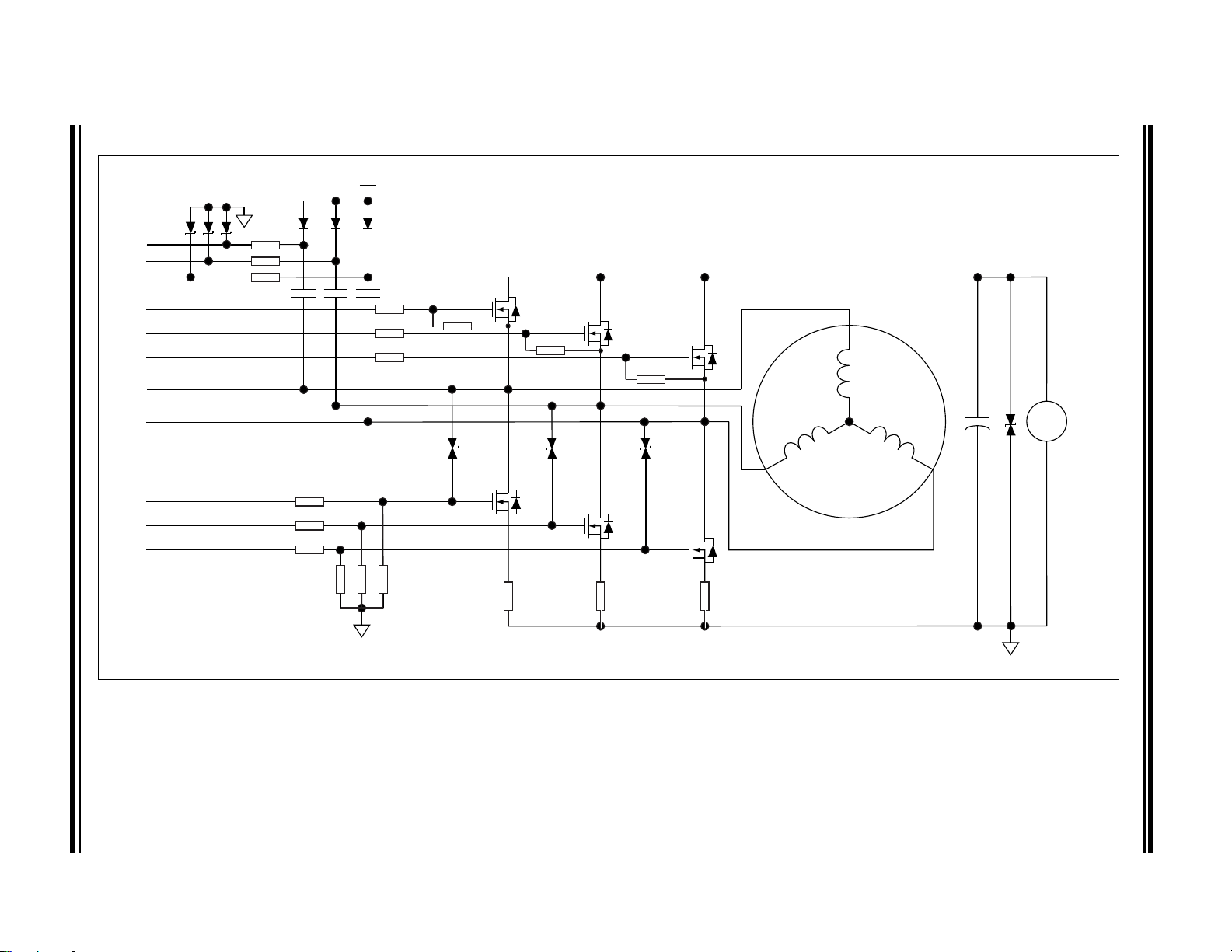

Page 6

DS20005339A-page 6 2014 Microchip Technology Inc.

LIN

XCVR

CE

FAULTn/TXE

RX

TX

PWM1H

PWM1L

PWM2H

PWM2L

PWM3H

PWM3L

LIN_BUS

MUX

+

-

PHA

PHB

PHC

PGND

ZC_OUT

COMP_REF

NEUTRAL_SIM

DE2

MUX1

MUX2

MOTOR CONTROL UNIT

COMMUNICATION PORT BIAS GENERATOR

LDO

BUCK SMPS

SUPERVISOR

VDD

LDO

+5V

LX

FB

+12V

+12V

HSA

HSB

HSC

LSA

LSB

LSC

VBA

VBB

VBC

GATE

CONTROL

LOGIC

I

I

I

I

I

I

I

I

I

O

O

O

O

O

O

O

VDD

I_OUT1

+

-

+

-

ILIMIT_OUT

I_SENSE1+

I_SENSE1-

DRIVER

FAULT

VDD

I

I

I/O

I/O

O

I

I

I

I

IO

CAP1

CHARGE PUMP

CB

A

+

_

E

VADJ

PHASE DETECT

+12V

ILIMIT_REF

CAP2

100 nF

Ceramic

SIM Select

Typical Application Circuit – MCP8025

MCP8025/6

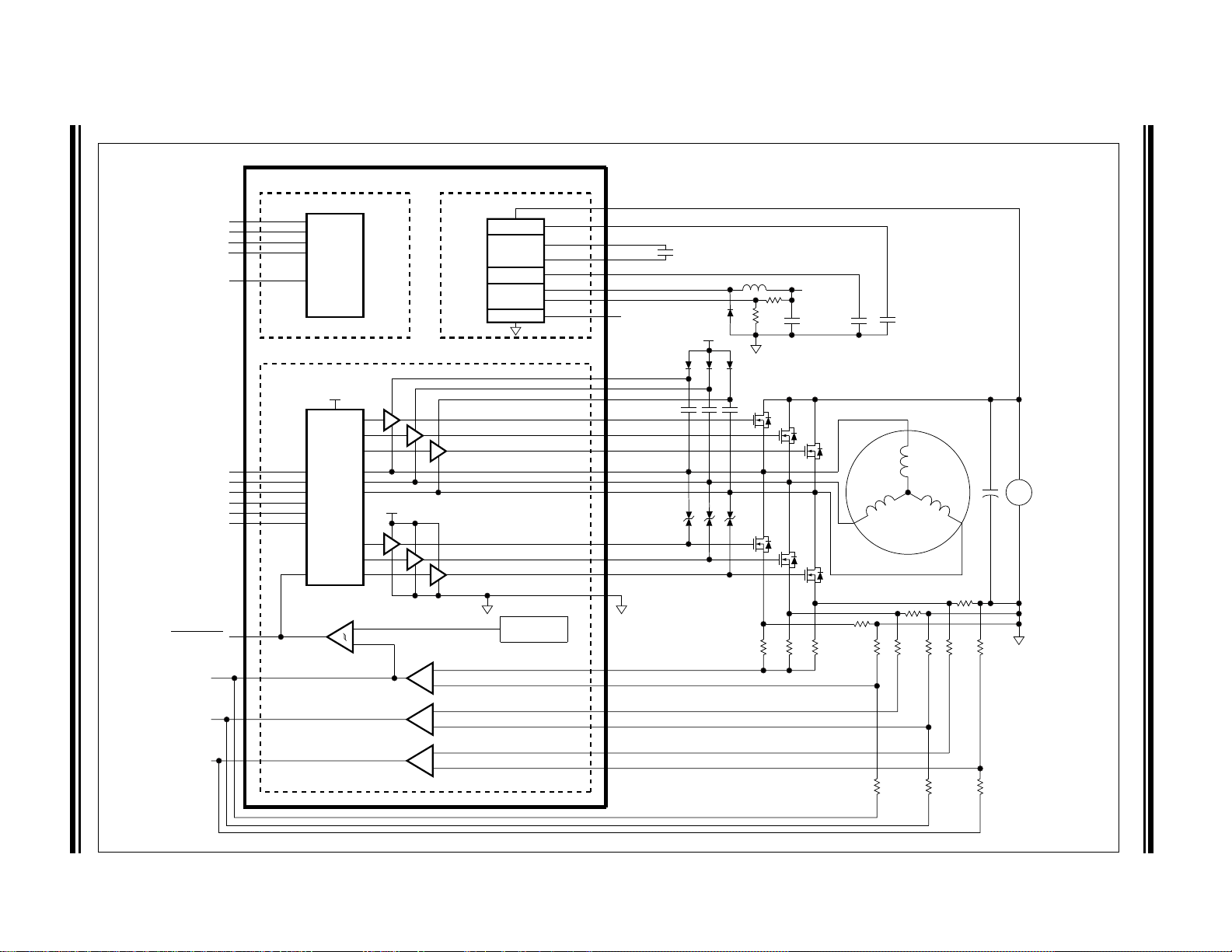

Page 7

2014 Microchip Technology Inc. DS20005339A-page 7

'!4%

#/.42/,

,/')#

#%

07-(

07-,

07-(

07-,

07-(

07-,

(6?).

)?/54

0(!

0("

0(#

0'.$

-/4/2#/.42/,5.)4

#/--5.)#!4)/.0/24

6

(3!

(3"

(3#

)?3%.3%

,3!

,3"

,3#

)?3%.3%

6"!

6""

6"#

,6?/54

,%6%,

42!.3,!4/2

6$$

)?3%.3%

)?3%.3%

)?3%.3%

)?3%.3%

)?/54

)?/54

$2)6%2

&!5,4

)

)

)

)

)

)

)

)

)

)

)

/

/

/

/

/

/

/

/

#"

!

?

%

6

$%

")!3'%.%2!4/2

,$/

"5#+3-03

350%26)3/2

6$$

,$/

6

,8

&"

6

#!0

#(!2'%05-0

6!$*

ILIMIT_REF

#!0

(6?).

,6?/54

/

)

N&

#ERAMIC

),)-)4?/54

Typical Application Circuit – MCP8026

MCP8025/6

Page 8

MCP8025/6

NOTES:

DS20005339A-page 8 2014 Microchip Technology Inc.

Page 9

MCP8025/6

1.0 ELECTRICAL CHARACTERISTICS

† Notice: Stresses above those listed under “Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of

the device at those or any other conditions above those

Absolute Maximum Ratings †

Input Voltage, VDD.............................(GND – 0.3V) to +46.0V

Input Voltage, < 100 ms Transient ...............................+48.0V

Internal Power Dissipation ...........................Internally-Limited

Operating Ambient Temperature Range .......-40°C to +150°C

Operating Junction Temperature (Note 2) ....-40°C to +160°C

Transient Junction Temperature (Note 1)...................+170°C

Storage Temperature (Note 2)......................-55°C to +150°C

Digital I/O .......................................................... -0.3V to 5.5V

LV Analog I/O.................................................... -0.3V to 5.5V

VBx ..................................................(GND – 0.3V) to +46.0V

PHx, HSx .........................................(GND – 5.5V) to +46.0V

ESD and Latch-Up Protection:

, LIN_BUS/HV_IN1 8 kV HBM and 750V CDM

V

DD

All other pins ..................... 2 kV HBM and 750V CDM

Latch-up protection – all pins .............................. > 100 mA

indicated in the operational listings of this specification

is not implied. Exposure to maximum rating conditions

for extended periods may affect device reliability.

Note 1: Transient junction temperatures should not

2: The maximum allowable power dissipation

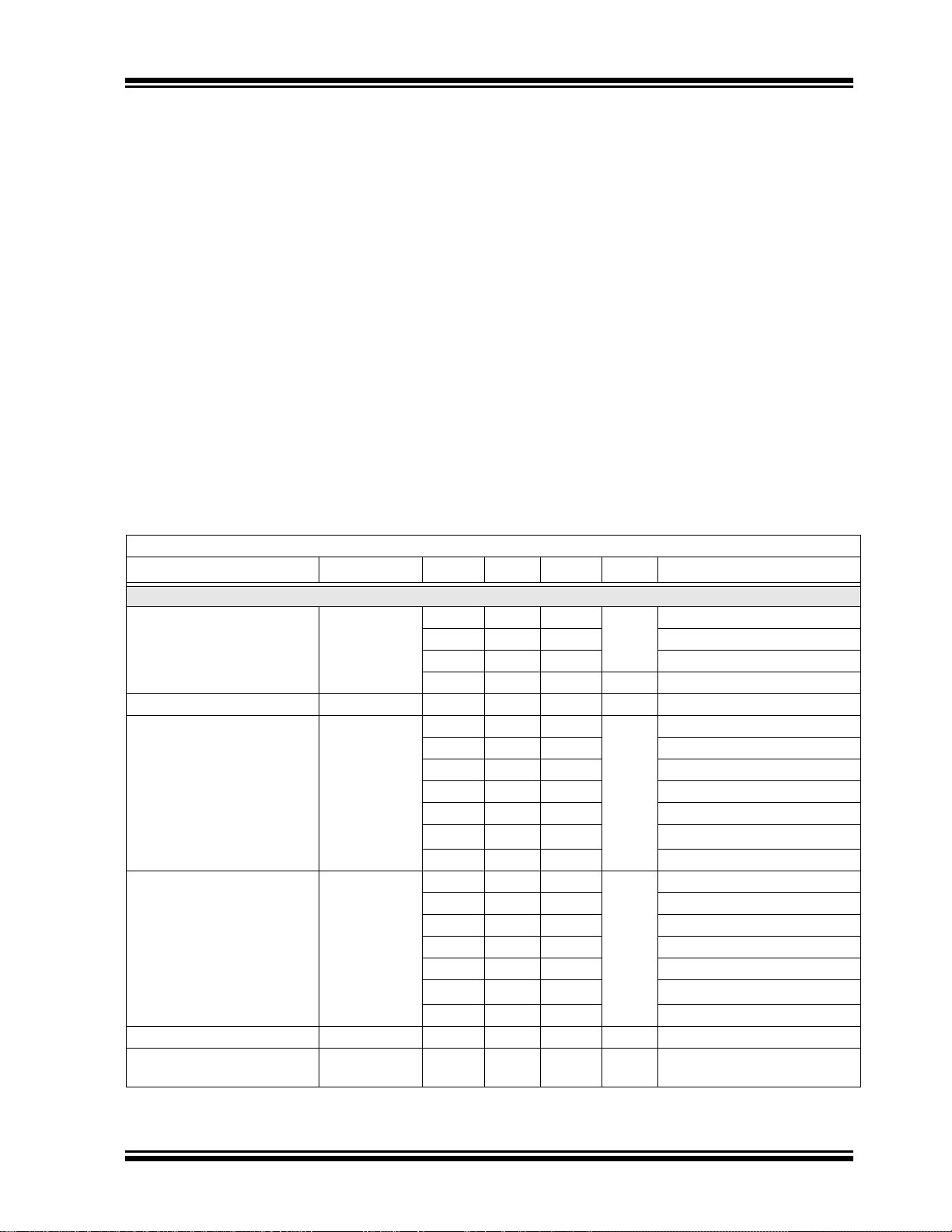

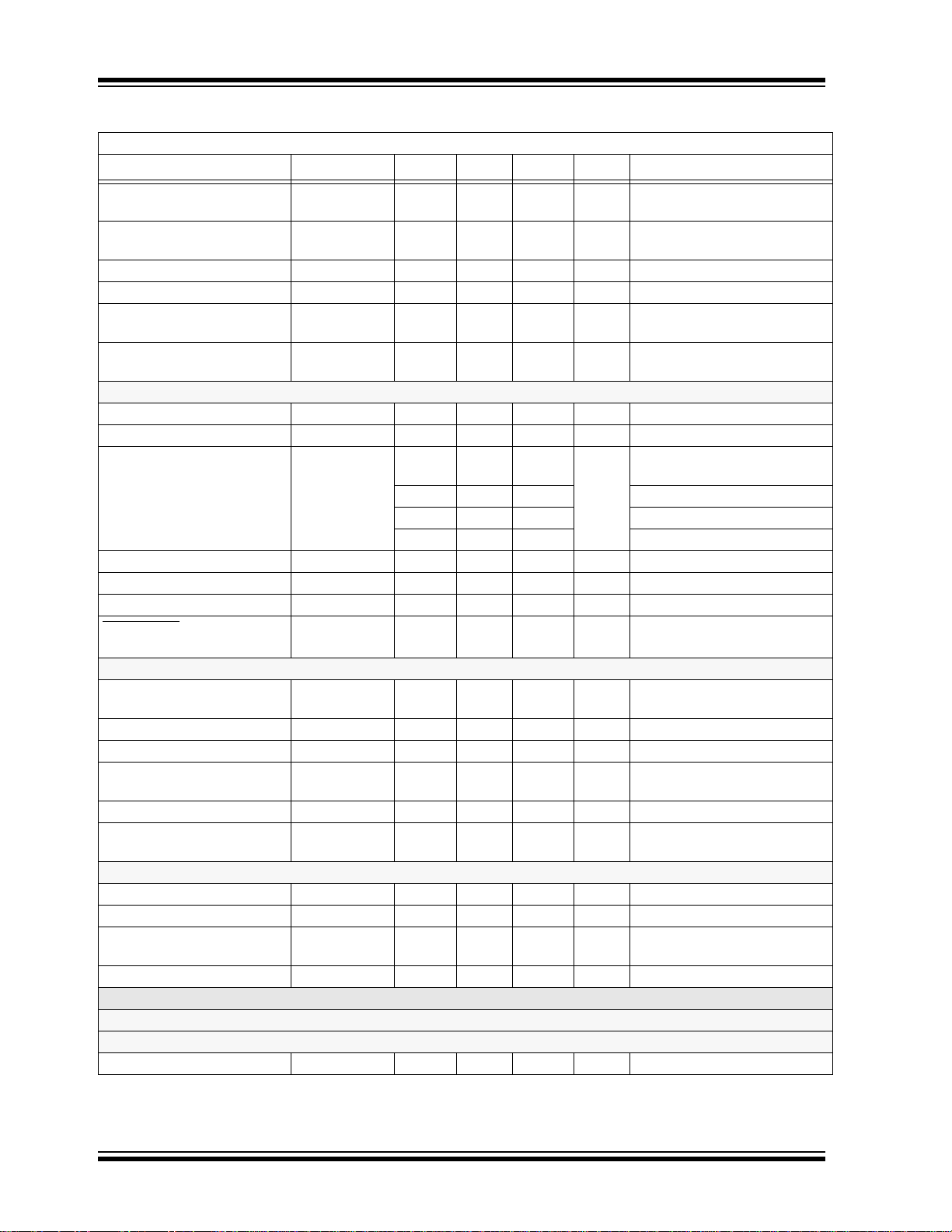

AC/DC CHARACTERISTICS

Electrical Specifications: Unless otherwise noted, T

Parameters Symbol Min. Typ. Max. Units Conditions

POWER SUPPLY INPUT

Input Operating Voltage V

Transient Maximum Voltage V

Input Current (MCP8025)V

Input Current (MCP8026)V

Digital Input/Output DIGITAL

Digital Open-Drain Drive

DD

DDmax

DD

DD

DIGITAL

I/O

IOL

Streng th

Note 1: 1000 hour cumulative maximum for ROM data retention (typical).

2: Limits are by design, not production tested.

= -40°C to +150°C, typical values are for +25°C, VDD=13V.

J

6.0 — 19.0 V Operating (MCP8025)

6.0 — 28.0 Operating (MCP8026)

6.0 — 40.0 Shutdown

4.0 — 32.0 Buck Operating Range

— — 48.0 V < 100 ms

———µAVDD>13V

— 5 15 Sleep Mode

— 175 — Standby, CE = 0V, T

— 175 — Standby, CE = 0V, TJ= +25°C

— 195 300 Standby, CE = 0V, T

—940— Active, CE>V

—1150— Active, VDD=6V, TJ=+25°C

———µAVDD>13V

— 5 15 Sleep Mode

— 120 — Standby, CE = 0V, T

— 120 — Standby, CE = 0V, TJ= +25°C

— 144 300 Standby, CE = 0V, T

—950— Active, CE>V

— 1090 — Active, VDD=6V, TJ=+25°C

0—5.5V

—1—mAVDS<50mV

exceed one second in duration. Sustained

junction temperatures above 170°C may

impact the device reliability.

is a function of ambient temperature, the

maximum allowable junction temperature

and the thermal resistance from junction to

air (i.e., T

, TJ, JA). Exceeding the maxi-

A

mum allowable power dissipation may

cause the device operating junction temperature to exceed the maximum 160°C

rating. Sustained junction temperatures

above 150°C can impact the device reliability and ROM data retention.

=-45°C

J

= +150°C

J

DIG_HI_TH

=-45°C

J

= +150°C

J

DIG_HI_TH

2014 Microchip Technology Inc. DS20005339A-page 9

Page 10

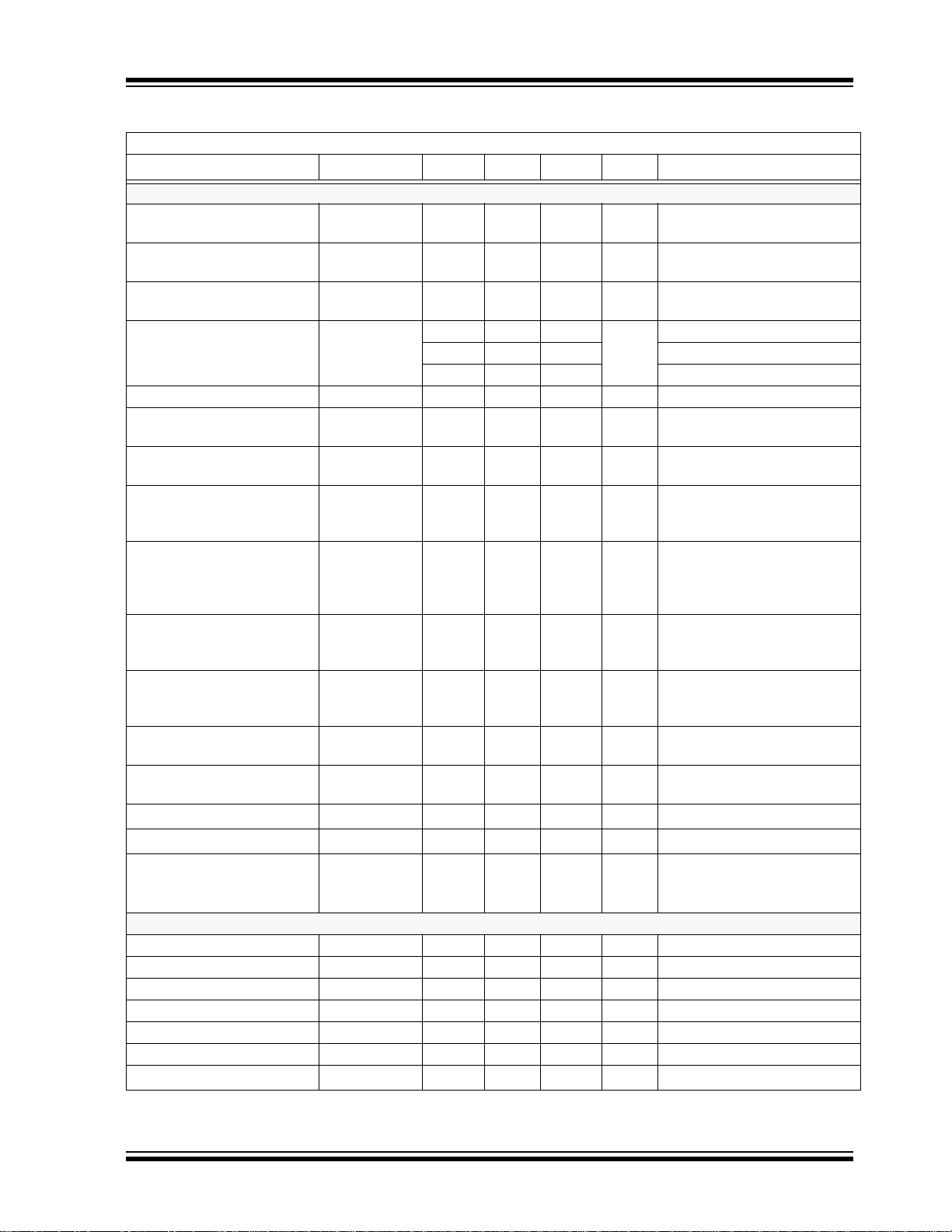

MCP8025/6

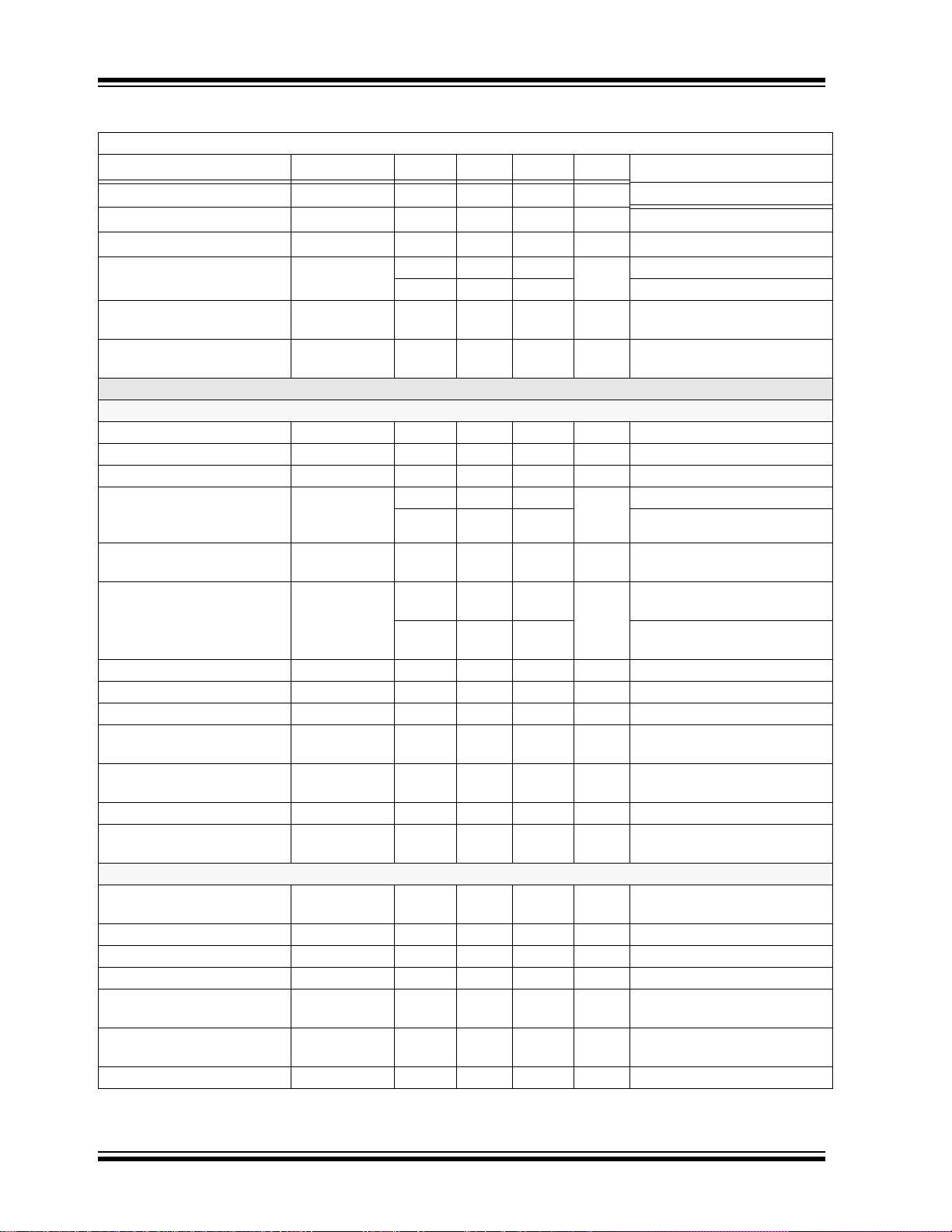

AC/DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, T

Parameters Symbol Min. Typ. Max. Units Conditions

Digital Input Rising Threshold V

Digital Input Falling Threshold V

Digital Input Hysteresis V

Digital Input Current I

Analog Low-Voltage Input ANALOG

Analog Low-Voltage Output

DIG_HI_TH

DIG_LO_TH

DIG_HYS

DIG

ANALOG

VIN

VOUT

BIAS GENERATOR

+12V Regulated Charge Pump

Charge Pump Current I

Charge Pump Start CP

Charge Pump Stop CP

Charge Pump Frequency

CP

CP

START

STOP

FSW

(50% charging/

50% discharging)

Charge Pump Switch

CP

RDSON

Resistance

Output Voltage V

Output Voltage Tolerance |TOLV

Output Current I

Output Current Limit I

Output Voltage Temperature

TCV

OUT12

OUT12

OUT

LIMIT

OUT12

|— — 4.0 %I

Coefficient

Line Regulation |V

(V

OUT

Load Regulation |V

Power Supply Rejection

/

OUT

x VDD)|

OUT/VOUT

|— 0.2 0.5 %I

PSRR — 60 — dB f = 1 kHz, I

Ratio

+5V Linear Regulator

Output Voltage V

Output Voltage Tolerance |TOLV

Output Current I

Output Current Limit I

Output Voltage Temperature

|TCV

OUT5

|— — 4.0 %

OUT5

OUT

LIMIT

|—50—ppm/°C

OUT5

Coefficient

Line Regulation |V

(V

OUT

Load Regulation |V

/

OUT

x VDD)|

OUT/VOUT

|— 0.2 0.5 %I

Note 1: 1000 hour cumulative maximum for ROM data retention (typical).

2: Limits are by design, not production tested.

= -40°C to +150°C, typical values are for +25°C, VDD= 13V.

J

1.26 — — V

——0.54V

—500—mV

—30100µAV

—0.2— V

0 — 5.5 V Excludes LIN and high-voltage

0—V

OUT5

20 — — mA VDD=9.0V

11.0 11.5 — V VDD falling

— 12.0 12.5 V VDD rising

— 76.80 — kHz VDD=9.0V

—0— V

—14— RDSON sum of high side and

—12— VVDD 7.5V, C

—9— V

30 — — mA Average current

40 50 — mA Average current

—50—ppm/°C

—0.10.5%/V13V<V

—5—VVDD=V

30 — — mA Average current

40 50 — mA Average current

—0.10.5%/V6V<V

=3.0V

DIG

=0V

DIG

pins

V Excludes LIN and high-voltage

pins

= 13V (stopped)

DD

low side

=100nF,

DD

OUT5

DD

PUMP

PUMP

< 19V,

=10mA

OUT

+1V,

<19V, I

= 260 nF,

=20mA

OUT

=20mA

I

OUT

=5.1V, C

DD

=15mA

I

OUT

=1mA

OUT

=20mA

I

OUT

= 0.1 mA to 15 mA

OUT

=1mA

I

OUT

= 0.1 mA to 15 mA

OUT

DS20005339A-page 10 2014 Microchip Technology Inc.

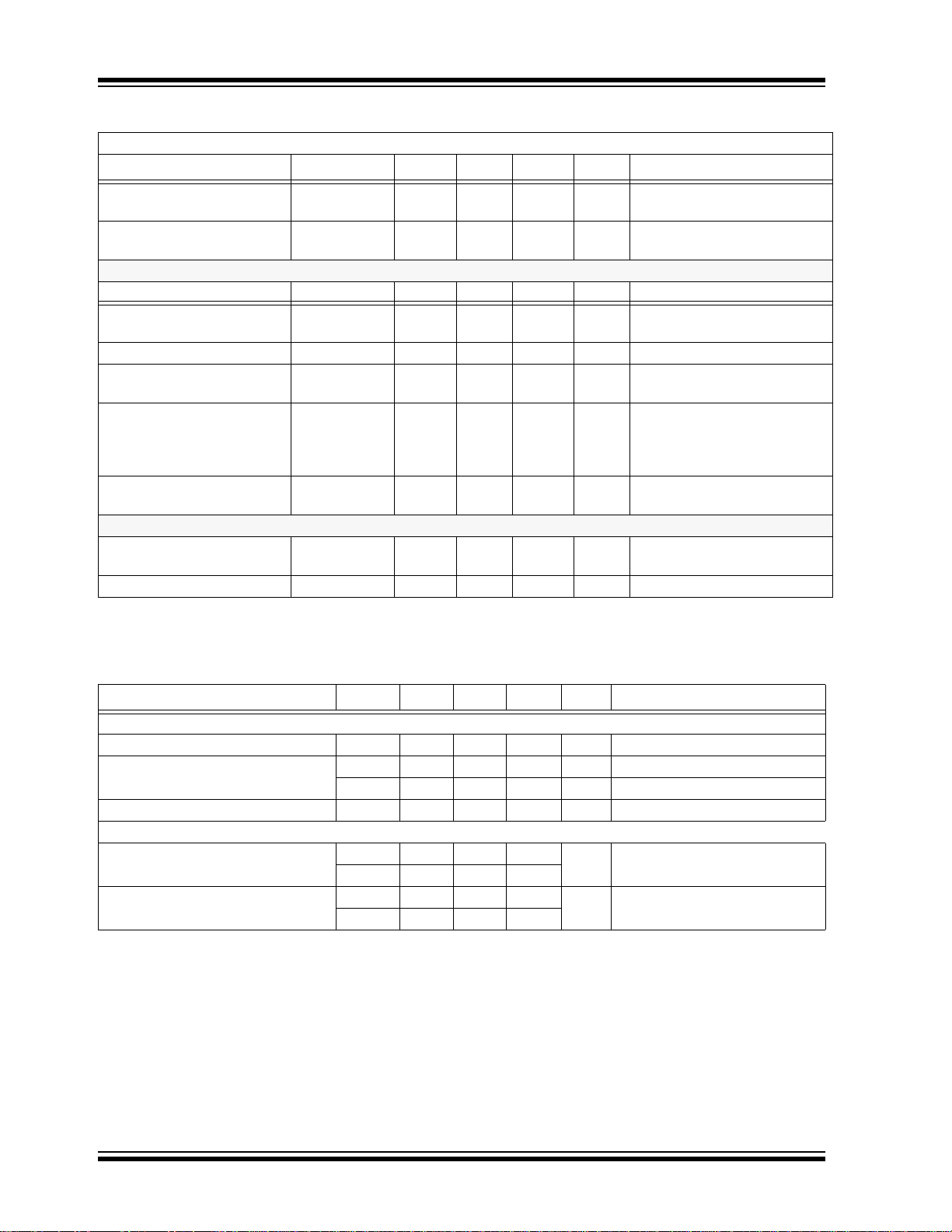

Page 11

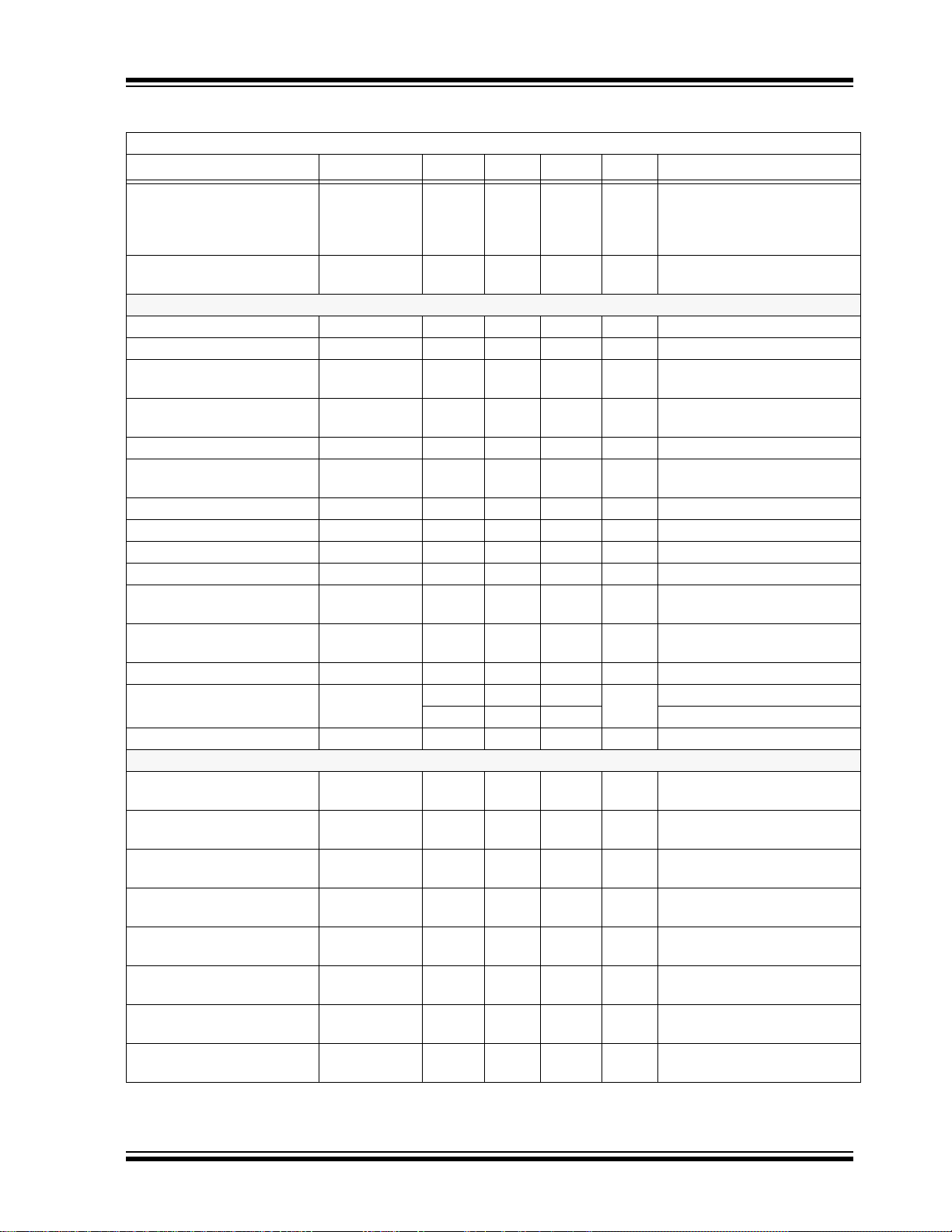

MCP8025/6

AC/DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, T

Parameters Symbol Min. Typ. Max. Units Conditions

Dropout Voltage VDD–V

Power Supply Rejection

OUT5

PSRR — 60 — dB f = 1 kHz, I

Ratio

Buck Regulator

Feedback Voltage V

FB

Feedback Voltage Tolerance TOLVFB ——5.0%IFB=1µA

Feedback Voltage Line

Regulation

Feedback Voltage Load

V

V

V

)/

FB/VFB

|

DD

|—0.10.5%I

FB/VFB

Regulation

Feedback Input Bias Current I

Feedback Voltage

FB

V

BUCK_DIS

To Shutdown Buck Regulator

Switching Frequency f

Duty Cycle Range DC

PMOS Switch On Resistance R

PMOS Switch Current Limit I

Ground Current –

SW

MAX

DSON

P(MAX)

I

GND

PWM Mode

Quiescent Current –

I

Q

PFM Mode

Output Voltage Adjust Range V

Output Current I

Output Power P

OUT

OUT

OUT

V oltage Supervisor

Buck Input Undervoltage

UVLO

BK_STRT

Lockout – Start-Up

Buck Input Undervoltage

UVLO

BK_STOP

Lockout – Shutdown

Buck Input Undervoltage

UVLO

BK_HYS

Lockout Hysteresis

5V LDO Undervoltage Fault

UVLO

5VLDO_INACT

Inactive

5V LDO Undervoltage Fault

UVLO

5VLDO_ACT

Active

5V LDO Undervoltage Fault

UVLO

5VLDO_HYS

Hysteresis

Input Undervoltage Lockout –

UVLO

STRT

Start -Up

Input Undervoltage Lockout -

UVLO

STOP

Shutdown

Note 1: 1000 hour cumulative maximum for ROM data retention (typical).

2: Limits are by design, not production tested.

= -40°C to +150°C, typical values are for +25°C, VDD=13V.

J

—180350mVI

OUT

=20mA,

measurement taken when

output voltage drops 2% from

no-load value.

1.19 1.25 1.31 V

—0.10.5%/VV

= 6V to 28V

DD

= 5 mA to 150 mA

OUT

-100 — +100 nA Sink/Source

2.5 — 5.5 V VDD>6V

—461—kHz

3—96%

—0.6— TJ=25°C

—2.5— A

— 1.5 2.5 mA Switching

—150200µAI

OUT

=0mA

2.0 — 5.0 V

150 — — mA 5V, VDD–V

250 — — 3V, VDD–V

—750—mWP=I

OUTxVOUT

—4.34.5 VVDD rising

3.8 4.0 — V VDD falling

—0.3— V

—4.5— VV

—4.0— VV

OUT5

OUT5

rising

falling

—0.5— V

—6.06.25VVDD rising

5.1 5.5 — V VDD falling

OUT

OUT

OUT

=10mA

>0.5V

> 0.5V

2014 Microchip Technology Inc. DS20005339A-page 11

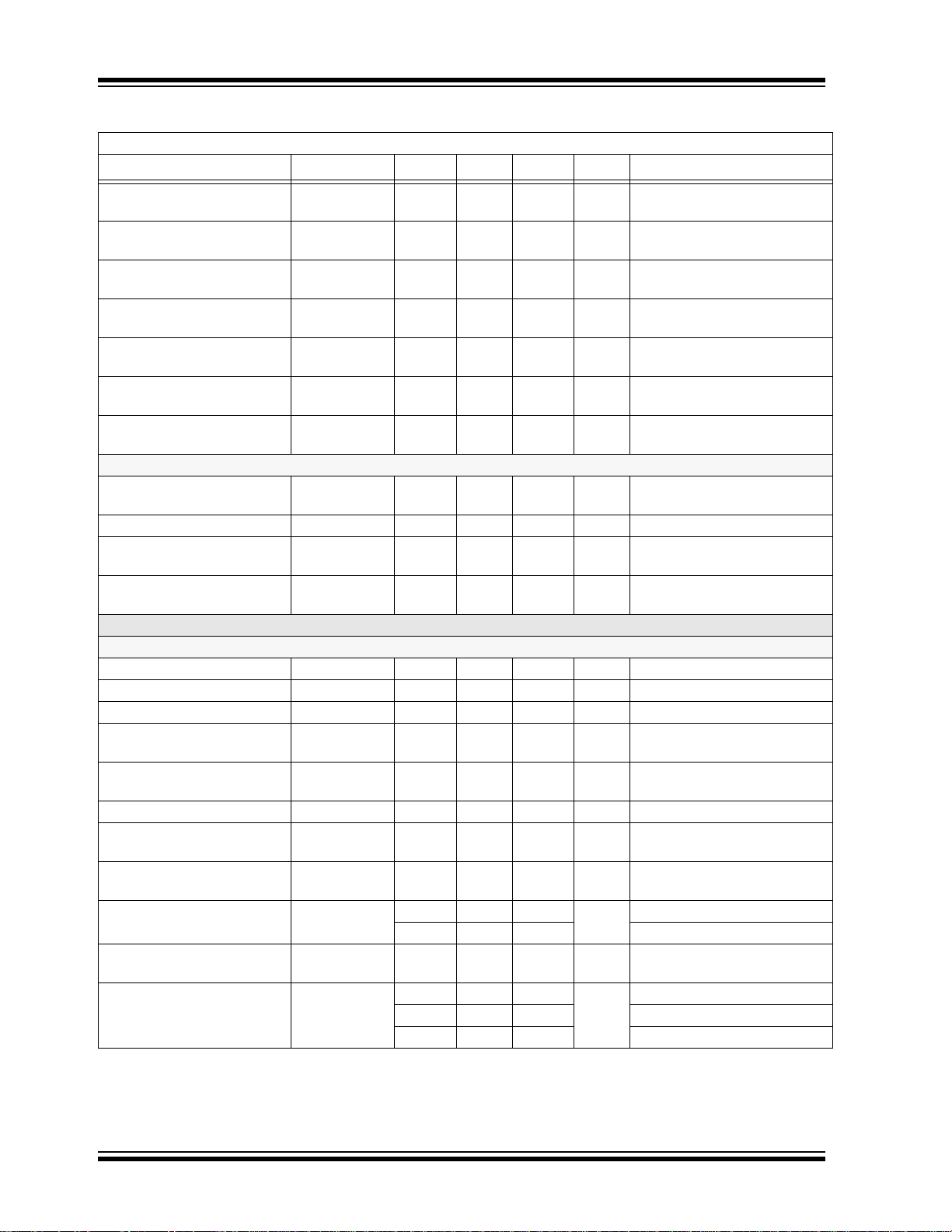

Page 12

MCP8025/6

AC/DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, T

Parameters Symbol Min. Typ. Max. Units Conditions

Input Undervoltage Lockout

UVLO

HYS

Hysteresis

Input Overvoltage Lockout –

DOVLO

STOP

Driver Disabled (MCP8025)

Input Overvoltage Lockout –

DOVLO

STRT

Driver Enabled (MCP8025)

Input Overvoltage Lockout

DOVLO

HYS

Hysteresis (MCP8025)

Input Overvoltage Lockout –

AOVLO

STOP

All Functions Disabled

Input Overvoltage Lockout –

AOVLO

STRT

All Functions Enabled

Input Overvoltage Lockout

AOVLO

HYS

Hysteresis

Temperature Supervisor

Thermal Warning

T

WARN

Temperature

Thermal Warning Hysteresis T

Thermal Shutdown

WARN

T

SD

Temperature

Thermal Shutdown

T

SD

Hysteresis

MOTOR CONTROL UNIT

Output Drivers

PWMH/L Input Pull Down R

Output Driver Source Current I

Output Driver Sink Current I

Output Driver Source

PULLDN

SOURCE

SINK

R

DSON

Resistance

Output Driver Sink

R

DSON

Resistance

Output Driver Blanking t

Output Driver UVLO

BLANK

D

UVLO

Threshold

Output Driver UVLO

t

DUVLO

Minimum Duration

Output Driver HS Drive

V

HS

Voltage

Output Driver LS Drive

V

LS

Voltage

Output Driver Bootstrap

V

BOOTSTRAP

Voltage

Note 1: 1000 hour cumulative maximum for ROM data retention (typical).

2: Limits are by design, not production tested.

= -40°C to +150°C, typical values are for +25°C, VDD= 13V.

J

0.20 0.45 0.70 V

— 20.0 20.5 V VDD rising

18.75 19.5 — V VDD falling

0.15 0.5 0.75 V

— 32.0 33.0 V VDD rising

29.0 30.0 — V VDD falling

1.0 2.0 3.0 V

—72—%TSDRising temperature (115°C)

— 15 — °C Falling temperature

160 170 — °C Rising temperature

— 25 — °C Falling temperature

—47—k

0.3 — — A VDD= 12V, HS[A:C], LS[A:C]

0.3 — — A VDD= 12V, HS[A:C], LS[A:C]

—17— I

—17— I

500 — 4000 ns Configurable

7.2 8.0 — V Config Register 0 bit 3 = 0

t

BLANK

+700

—t

BLANK

+1400

8.0 12 13.5 V With respect to the Phase pin

-5.5 — — With respect to ground

8.0 12 13.5 V With respect to ground

— — — V With respect to ground

— — 44 Continuous

— — 48 < 100 ms

=10mA, VDD= 12V,

OUT

HS[A:C], LS[A:C]

=10mA, VDD= 12V,

OUT

HS[A:C], LS[A:C]

ns Fault latched after t

DUVLO

DS20005339A-page 12 2014 Microchip Technology Inc.

Page 13

AC/DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, T

Parameters Symbol Min. Typ. Max. Units Conditions

Output Driver Phase Pin

V

PHASE

Voltage

Output Driver Short Circuit

D

SC_THR

Protection Threshold

High Side (VDD–V

Low Side (V

PHx–PGND

Output Driver Short Circuit

PHx

)

)

T

SC_DLY

Detected Propagation Delay

Output Driver OVLO Turn-Off

T

OVLO_DLY

Delay

Power-Up or Sleep to

t

POWER

Standby

Standby to Motor Operational t

Fault to Driver Output

MOTOR

T

FAULT_ OFF

Turn-Off

CE Low to Driver Output

T

DEL_OFF

Turn-Off

CE Low to Standby State t

CE Low to Sleep State t

CE Fault Clearing Pulse t

STANDBY

SLEEP

FAULT_CLR

Current Sense Amplifier

Input Offset Voltage V

Input Offset Temperature Drift V

Input Bias Current I

Common Mode Input Range V

OS

CMR

OS

B

/T

A

Note 1: 1000 hour cumulative maximum for ROM data retention (typical).

2: Limits are by design, not production tested.

= -40°C to +150°C, typical values are for +25°C, VDD=13V.

J

— — — V With respect to ground

-5.5 — 44 Continuous

-5.5 — 48 < 100 ms

— — — V Set In Register CFG0

—0.250— 00 (Default)

—0.500— 01

—0.750— 10

—1.000— 11

———nsC

— 430 — Detection after blanking

— 10 — Detection during blanking,

3 5 — µs Detection synchronized with

— — — ms CE High-Low-High

—10— MCP8025

—5— MCP8026

— 5 — µs CE High-Low-High

— — 5 ms Standby state to Operational

— — 10 ms Standby state to Operational

———µsC

— 1 — UVLO, OCP faults

— 10 — All other faults

—100250nsC

— 1 — ms Time after CE = Low,

— 1 — ms Time after CE = Low,

1 — 900 µs CE High-Low-High Transition

-3.0 — +3.0 mV VCM=0V

—±2.0—µV/°CVCM=0V

-1 — +1 µA

-0.3 — 3.5 V

MCP8025/6

= 1000 pF, VDD=12V

LOAD

value is delay after blanking

internal clock (Note 2)

Transition < 100 µs (Fault

Clearing)

Transition < 0.9 ms (Fault

Clearing)

state (MCP8025, Note 2)

state (MCP8026, Note 2)

= 1000 pF, VDD=12V,

LOAD

time after fault occurs.

= 1000 pF, VDD=12V,

LOAD

Time after CE = Low (Note 2)

SLEEP Bit = 0

SLEEP Bit = 1

Time (Note 2)

= -40°C to +150°C

T

A

2014 Microchip Technology Inc. DS20005339A-page 13

Page 14

MCP8025/6

AC/DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, T

Parameters Symbol Min. Typ. Max. Units Conditions

Common Mode Rejection

CMRR — 80 — dB Freq = 1 kHz, I

Ratio

Maximum Output Voltage

, V

V

OL

OH

Swing

Slew Rate SR — ±7 — V/µs Symmetrical

Gain Bandwidth Product GBWP — 10.0 — MHz

Current Comparator

CC

HYS

Hysteresis

Current Comparator

V

CC_CMR

Common Mode Input Range

Current Limit DAC

Resolution — 8 — Bits

Output Voltage Range V

Output Voltage V

Input to Output Delay T

, V

OL

DAC

DELAY

OH

Integral Nonlinearity INL -0.5 — +0.5 %FSR %Full Scale Range, Note 2

Differential Nonlinearity DNL -50 — +50 %LSB %LSB, Note 2

ILIMIT_OUT

Sink Current

IL

OUT

(Open-Drain)

ZC Back EMF Sampler Comparator (MCP8025)

Maximum Output Voltage

Swing

Reference Input Impedance ZC

Input to Output Delay ZC

Voltage Divider RC Time

ZCVOL,

ZCV

OH

ZREF

DELAY

ZC

TRC

Constant

ZC Output Pull-Up Range ZC

ZC Output Sink Current

RPULLUP

ZC

IOL

(Open-Drain)

Back EMF Sampler Phase Multiplexer (MCP8025)

MUX[1:2] Input Pull Down R

Transition Time t

Delay from MUX Select to ZC

PULLDN

MUX

TRAN

DELAY

Out

Phase Filter Capacitors C

PHASE

COMMUNICATION PORTS

Standard LIN (MCP8025)

Microcontroller Interface

TX Input Pull-Up Resistor R

PUTXD

Note 1: 1000 hour cumulative maximum for ROM data retention (typical).

2: Limits are by design, not production tested.

= -40°C to +150°C, typical values are for +25°C, VDD= 13V.

J

OUT

0.05 — 4.5 V I

OUT

= 200 µA

—10—mV

1.0 — 4.5 V

0.991 — 4.503 V I

OUT

=1mA

——— VCFG1 Code x

13.77 mV/bit + 0.991V

— 0.991 — Code 00H

— 1.872 — Code 40H

— 4.503 — Code FFH

—50—µs

—1—mAV

0.05 - 5.0 V I

ILIMIT_OUT

OUT

50 mV

=1mA

—83—k

—-500nsV

IN_STEP

=500mV, Note 2

—100— ns

3.3 10 — k

—1—mAVout 50 mV

—47—k

—150250nsNote 2

—210— ns

— 1.5 — pF MUX input to ground

—48 - k Pull up to 5V

=10µA

DS20005339A-page 14 2014 Microchip Technology Inc.

Page 15

AC/DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, T

Parameters Symbol Min. Typ. Max. Units Conditions

Bus Interface

LIN Bus High-Level Input

V

HI

Voltage

LIN Bus Low-Level Input

V

LO

Voltage

LIN Bus Input Hysteresis V

LIN Bus Low-Level Output

HYS

I

OL

Current

LIN Bus Input Pull-Up Current I

LIN Bus Short Circuit Current

Limit

LIN Bus Low-Level Output

PU

I

SC

V

OL

Voltage

LIN Bus Input Leakage

Current (at receiver during

I

BUS_PAS_DOM

dominant bus level)

LIN Bus Input Leakage

Current (at receiver during

recessive bus level)

I

BUS_PAS_REC

LIN Bus Input Leakage

Current (disconnected from

I

BUS_NO_GND

ground)

LIN Bus Input Leakage

I

BUS_NO_BAT

Current (disconnected from

V

)

DD

Receiver Center Voltage V

LIN Bus Slave Pull-Up

BUS_CNT

R

PULLUP

Resistance

LIN Dominant State Timeout t

Propagation Delay T

Symmetry T

DOM_TOUT

RX_PD

RX_SYM

V oltage Level Translators (MCP8026)

High Voltage Input Range V

Low Voltage Output Range V

IN

OUT

Input Pull-Up Resistor RPU — 30 — k

High-Level Input Voltage V

Low-Level Input Voltage V

Input Hysteresis V

Propagation Delay T

IH

IL

HYS

LV_ OUT

Note 1: 1000 hour cumulative maximum for ROM data retention (typical).

2: Limits are by design, not production tested.

= -40°C to +150°C, typical values are for +25°C, VDD=13V.

J

0.6 x

V

DD

— — V Recessive state

——0.4x

V

DD

— — 0.175 x

V

DD

7.3 — — mA VO=0.2xVDD, VDD=8V

16.5 — — VO=0.2xVDD, VDD= 18V

30.6 — — V

5—180µA

50 — 200 mA

——0.2x

V

DD

-1 — — mA Driver OFF,

— 12 20 µA Driver OFF,

-1 — 1 mA GND = VDD=12V,

——10µAVDD=0V,

0.475 x

V

DD

0.5 x

V

DD

0.525 x

V

DD

20K 30K 47K

—25—ms

— 3.0 6.0 µs Propagation delay of receiver

-2 — +2 µs Symmetry of receiver

0—VDDV

0—5.0VV

0.60 — — V

——0.40VDDVDD=15V

——0.30V

—3.06.0µsNote 2

MCP8025/6

VDominant state

VVHI–V

V

VV

DDVDD

DD

LO

=0.251xVDD, VDD= 18V

O

=0V, VDD=12V

V

BUS

V

V

BUS

7V < V

7V < V

0V < V

0V < V

BUS _CNT

DD

< 19V

BUS

<19V

DD

< 19V

BUS

< 19V

BUS

=(VHI–VLO)/2

propagation delay rising edge

w.r.t.falling edge

=15V

2014 Microchip Technology Inc. DS20005339A-page 15

Page 16

MCP8025/6

AC/DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, T

Parameters Symbol Min. Typ. Max. Units Conditions

Maximum Communication

F

MAX

Frequency

Low-Voltage Output Sink

I

OL

Current (Open-Drain)

DE2 Communications

Baud Rate BAUD — 9600 — BPS

Power-Up Delay PU_DELAY — 1 — ms Time from rising V

DE2 Sink Current DE2

DE2 Message Response

DE2

iSINK

RSP

Time

DE2 Host Wait Time DE2

DE2 Message Receive

DE2

WAIT

RCVTOUT

Timeout

INTERNAL ROM (READ-ONLY MEMORY) DATA RETENTION

Cell High Temperature

HTOL — 1000 — Hours T

Operating Life

Cell Operating Life — 10 — Years T

Note 1: 1000 hour cumulative maximum for ROM data retention (typical).

2: Limits are by design, not production tested.

= -40°C to +150°C, typical values are for +25°C, VDD= 13V.

J

——20kHzNote 2

—1—mAV

OUT

50 mV

to DE2 active

1——mAV

50 mV, Note 2

DE2

0 µs Time from last received Stop bit

to Response Start bit, Note 2

3.125 — — ms Minimum Time For Host

To Wait For Response. Three

packets based on 9600 BAUD,

Note 2

— 5 — ms Time between message bytes

= 150°C (Note 1)

J

= 85°C

J

DD

6V

TEMPERATURE SPECIFICATIONS

Parameters Sym. Min. Typ. Max. Units Conditions

Temperature Ranges (Note 1)

Specified Temperature Range T

Operating Temperature Range T

Storage Temperature Range T

A

A

T

J

A

Package Thermal ResistanceS

Thermal Resistance, 5 mm x 5 mm

40L-QFN

Thermal Resistance, 7 mm x 7 mm

48L-TQFP with Exposed Pad

JA

JC

JA

JC

Note 1: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable

junction temperature and the thermal resistance from junction to air (i.e., T

maximum allowable power dissipation will cause the device operating junction temperature to exceed the

maximum 160°C rating. Sustained junction temperatures above 160°C can impact the device reliability.

2: 1000 hour cumulative maximum for ROM data retention (typical).

-40 +150 °C

-40 +150 °C

-40 +160 °C

-55 +150 °C (Note 2)

— 37 — °C/W 4-Layer JC51-5 standard board,

—6.9—

natural convection

—30—°C/W

—15—

, TJ, JA). Exceeding the

A

DS20005339A-page 16 2014 Microchip Technology Inc.

Page 17

MCP8025/6

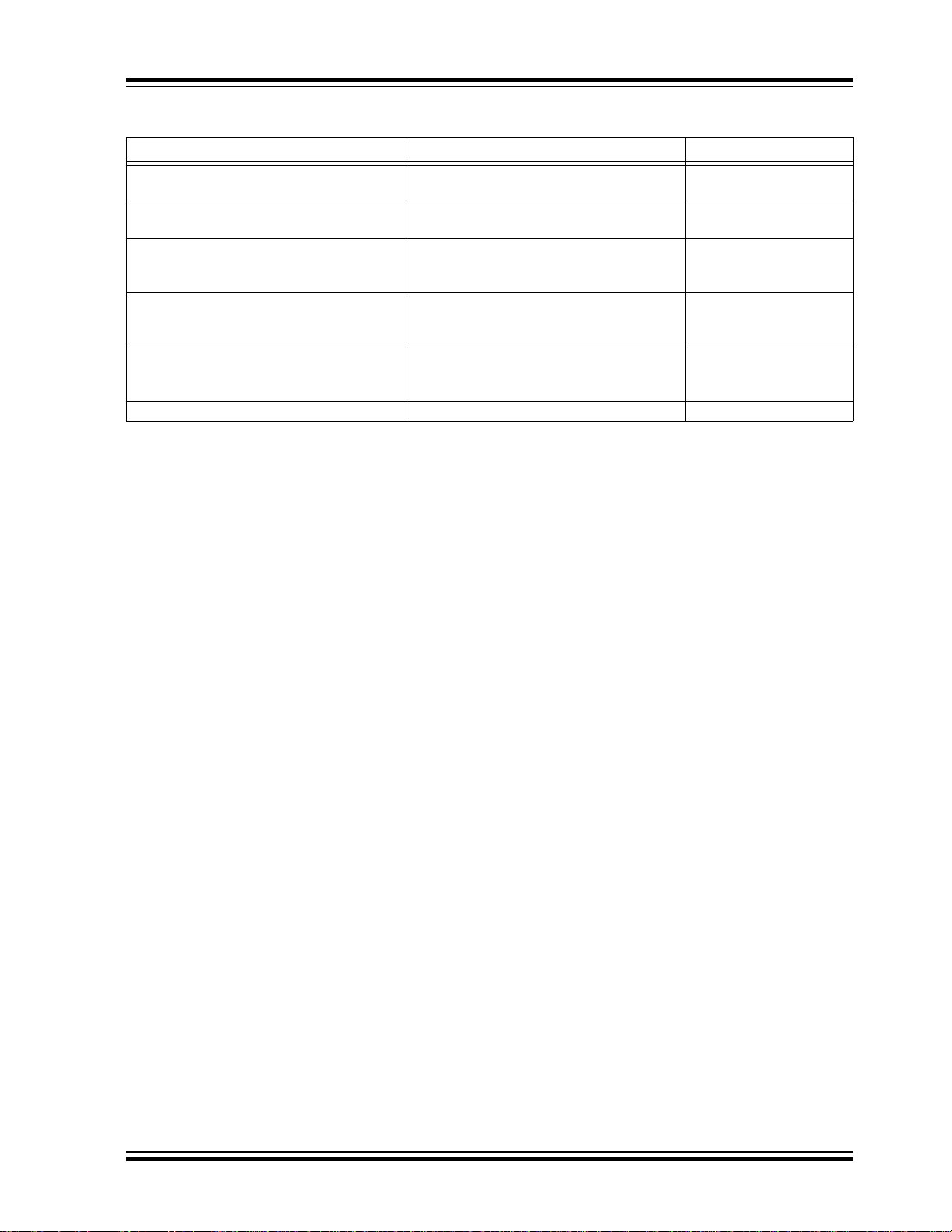

ESD, SUSCEPTIBILITY, SURGE AND LATCH-UP TESTING

Parameter Standard and Test Condition Value

Input voltage surges ISO 16750-2 28V for 1 minute,

45V for 0.5 seconds

ESD according to IBEE LIN EMC

– Pins LIN_BUS, V

ESD HBM with 1.5 k/100 pF CEI/IEC 60749-26: 2006

ESD HBM with 1.5 k/100 pF

– Pins LIN_BUS, V

P

GND

ESD CDM (Charged Device Model,

field-induced method – replaces

machine-model method)

Latch-Up Susceptibility AEC Q100-004, 150°C > 100 mA

(HMM)

DD

, HV_IN1 against

DD

Test specification 1.0 following IEC

61000-4.2

AEC-Q100-002-Ref E

JEDEC JS-001-2012

CEI/IEC 60749-26: 2006

AEC-Q100-002-Ref E

JEDEC JS-001-2012

ESD-STM5.3.1-1999 ± 750V all pins

±8kV

±2kV

±8kV

2014 Microchip Technology Inc. DS20005339A-page 17

Page 18

MCP8025/6

NOTES:

DS20005339A-page 18 2014 Microchip Technology Inc.

Page 19

MCP8025/6

-0.010

-0.008

-0.006

-0.004

-0.002

0.000

0.002

0.004

0.006

0.008

0.010

-45 -20 5 30 55 80 105 130

155

V

OUT

= 5V

V

OUT

= 12V

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

-45 -20 5 30 55 80 105 130

155

Load Regulation (%)

V

OUT

= 5V

V

OUT

= 12V

012345678910

iLIMIT_OUT

DE2

0 5 10 15 20 25 30 35 40 45 50

HSA

V

BA

20

15

10

5

0

25

20

15

10

5

0

VDD= 6V

100

105

110

115

120

125

130

135

140

145

150

7 1013161922252831

Current (mA)

5V LDO

12V LDO

-40

-20

0

20

40

60

80

100

120

140

0

3

6

9

12

15

18

0 20406080100

V

IN

(V)

VIN= 14V

VIN= 15V

V

OUT

(AC)

CIN= C

OUT

= 10 µF

I

OUT

= 20 mA

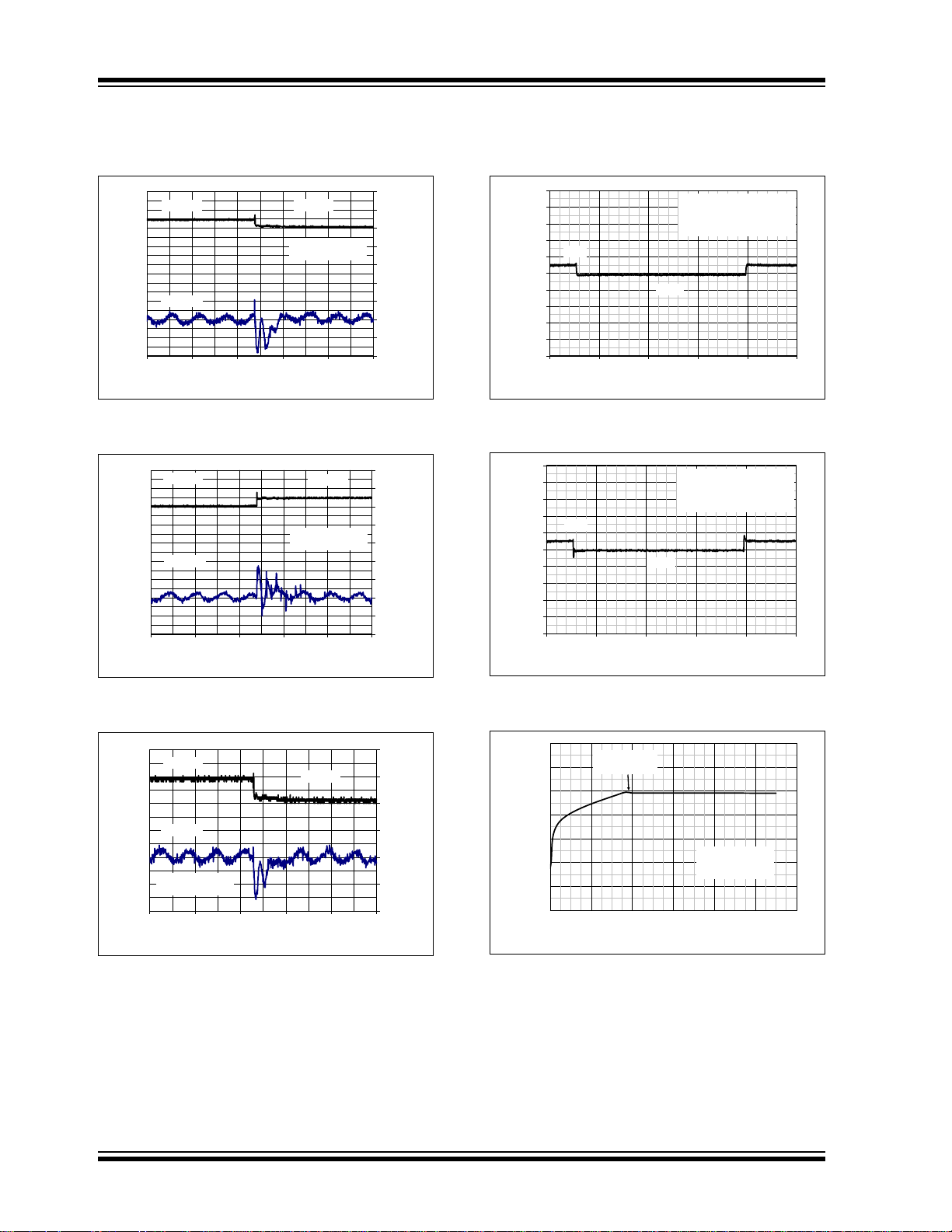

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated, T

= +25°C; Junction Temperature (TJ) is approximated by soaking the device under

A

test to an ambient temperature equal to the desired junction temperature. The test time is small enough such that the

rise in Junction temperature over the Ambient temperature is not significant.

Volts (V)

Line Regulation (%/V)

Temperature (°C)

FIGURE 2-1: LDO Line Regulation vs. Temperature.

FIGURE 2-4: Bootstrap Voltage @ 92% Duty Cycle.

Time (µs)

Temperature (°C)

FIGURE 2-2: LDO Load Regulation vs. Temperature.

FIGURE 2-3: I

Message Delay.

2014 Microchip Technology Inc. DS20005339A-page 19

Time (µs)

LIMIT_OUT

Low to DE2

Voltage (V)

FIGURE 2-5: LDO Short Cir cuit Cur rent vs. Input Voltage.

(mV)

OUT

V

Time (µs)

FIGURE 2-6: 5V LDO Dynamic Linestep –

Rising V

DD

.

Page 20

MCP8025/6

-40

-20

0

20

40

60

80

100

120

140

0

3

6

9

12

15

18

0 20406080100

V

IN

(V)

VIN= 15V

VIN= 14V

V

OUT

(AC)

CIN= C

OUT

= 10 µF

I

OUT

= 20 mA

-40

-20

0

20

40

60

80

100

120

140

0

3

6

9

12

15

18

0 20406080100

IN

VIN= 14V

VIN= 15V

V

OUT

(AC)

CIN= C

OUT

= 10 µF

I

OUT

= 20 mA

-40

-20

0

20

40

60

80

10

11

12

13

14

15

16

0 20406080100

IN

VIN= 15V

VIN= 14V

V

OUT

(AC)

CIN= C

OUT

= 10 µF

I

OUT

= 20 mA

-100

-80

-60

-40

-20

0

20

40

60

80

100

0.0 0.5 1.0 1.5 2.0 2.5

OUT

VIN= 14V

V

OUT

= 5V

C

IN

= C

OUT

= 10 µF

I

OUT

= 1 mA to 20 mA Pulse

20 mA

1 mA

-100

-80

-60

-40

-20

0

20

40

60

80

100

0.0 0.5 1.0 1.5 2.0 2.5

V

OUT

AC (mV)

1 mA

VIN= 14V

V

OUT

= 12V

C

IN

= C

OUT

= 10 µF

I

OUT

= 1 mA to 20 mA Pulse

20 mA

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

6 101418222630

V

OUT

(V)

V

OUT

= 12V

C

IN

= C

OUT

= 10 µF

I

OUT

= 20 mA

Charge Pump

Switch Point

Note: Unless otherwise indicated, T

= +25°C; Junction Temperature (TJ) is approximated by soaking the device under

A

test to an ambient temperature equal to the desired junction temperature. The test time is small enough such that the

rise in Junction temperature over the Ambient temperature is not significant.

(mV)

OUT

V

Time (µs)

FIGURE 2-7: 5V LDO Dynamic Linestep –

Falling V

(V)

V

DD

.

(mV)

OUT

V

AC (mV)

V

Time (ms)

FIGURE 2-10: 5V LDO Dynamic Loadstep.

Time (µs)

FIGURE 2-8: 12V LDO Dynamic Linestep

– Rising V

(V)

V

DD

.

Time (µs)

FIGURE 2-9: 12V LDO Dynamic Linestep

– Falling V

DS20005339A-page 20 2014 Microchip Technology Inc.

.

DD

(mV)

OUT

V

Time (ms)

FIGURE 2-11: 12V LDO Dynamic Loadstep.

VIN(V)

FIGURE 2-12: 12V LDO Output Voltage vs. Rising Input Voltage.

Page 21

MCP8025/6

0

200

400

600

800

1000

-45 -20 5 30 55 80 105 130 155

CE Low

CE High

0

200

400

600

800

1000

1200

-45 -20 5 30 55 80 105 130 155

CE Low

CE High

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Dead Time

PWMxH

PWMxL

Dead Time

10

12

14

16

18

20

22

24

-45 -20 5 30 55 80 105 130 155

R

DSON

(

Ω

)

Low-Side

Note: Unless otherwise indicated, T

= +25°C; Junction Temperature (TJ) is approximated by soaking the device under

A

test to an ambient temperature equal to the desired junction temperature. The test time is small enough such that the

rise in Junction temperature over the Ambient temperature is not significant.

1200

High-Side

Quiescent Current (µA)

Temperature (°C)

FIGURE 2-13: Quiescent Current vs. Temperature (MCP8025).

FIGURE 2-16: Driver R

Temperature.

Temperature(°C)

DSON

vs.

Quiescent Current (µA)

Temperature (°C)

FIGURE 2-14: Quiescent Current vs. Temperature (MCP8026).

Time (µs)

FIGURE 2-15: 500 ns PWM Dead Time Injection.

2014 Microchip Technology Inc. DS20005339A-page 21

Page 22

MCP8025/6

NOTES:

DS20005339A-page 22 2014 Microchip Technology Inc.

Page 23

MCP8025/6

3.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Tables 3-1 and 3-2.

T ABLE 3-1: MCP8025 – PIN FUNCTION TABLE

QFN TQFP Symbol I/O Description

2 1 PWM1L I Digital input, phase A low-side control, 47 k pull down

3 2 PWM1H I Digital input, phase A high-side control, 47 k pull down

4 3 CE I Digital input, device enable, 47 k pull down

— 4 NC — No connection

— 5 NC — No connection

5 6 LIN_BUS I/O LIN Bus physical layer

—7 P

6 8 RX O LIN Bus receive data, open-drain

7 9 TX I LIN Bus transmit data

810FAULTn

9 11 MUX1 I Digital input Back EMF sampler phase multiplexer control, 47 k pull down

10 12 MUX2 I Digital input Back EMF sampler phase multiplexer control, 47 k pull down

11 13 ZC_OUT O Back EMF sampler comparator output, open-drain

12 14 COMP_REF I Back EMF sampler comparator reference

13 15 ILIMIT_OUT

14 16 I_OUT1 O Motor current sense amplifier output

15 17 ISENSE1- I Motor current sense amplifier inverting input

16 18 ISENSE1+ I Motor current sense amplifier non-inverting input

17 19,20 P

18 21 LSA O Phase A low-side N-channel MOSFET driver, active high

19 22 LSB O Phase B low-side N-channel MOSFET driver, active high

20 23 LSC O Phase C low-side N-channel MOSFET driver, active high

—24 P

21 25 HSC O Phase C high-side N-channel MOSFET driver, active high

22 26 HSB O Phase B high-side N-channel MOSFET driver, active high

23 27 HSA O Phase A high-side N-channel MOSFET driver, active high

24 28 PHC I/O Phase C high-side MOSFET driver reference, Back EMF sense input

25 29 PHB I/O Phase B high-side MOSFET driver reference, Back EMF sense input

26 30 PHA I/O Phase A high-side MOSFET driver reference, Back EMF sense input

27 31 V

28 32 V

29 33 V

30 34 +12V Power Analog circuitry and low-side gate drive bias

— 35, 36 P

31 37 LX Power Buck regulator switch node, external inductor connection

32 38, 39 V

33 40 FB I Buck regulator feedback node

34 41 +5V Power Internal circuitry bias

35 42 CAP2 Power Charge pump flying capacitor input

36 43 CAP1 Power Charge pump flying capacitor input

37 44 DE2 O Voltage and temperature supervisor output, open-drain

38 45 PWM3L I Digital input, phase C low-side control, 47 k pull down

39 46 PWM3H I Digital input, phase C high-side control, 47 k pull down

40 47 PWM2L I Digital input, phase B low-side control, 47 k pull down

1 48 PWM2H I Digital input, phase B high-side control, 47 k pull down

EP EP P

GND

/TXE I/O LIN transceiver fault and transmit enable

GND

GND

BC

BB

BA

GND

DD

GND

Power Power 0V reference

O Current limit comparator, MOSFET driver fault output, open-drain

Power Power 0V reference

Power Power 0V reference

Power Phase C high-side MOSFET driver bias

Power Phase B high-side MOSFET driver bias

Power Phase A high-side MOSFET driver bias

Power Power 0V reference

Power Input Supply

Power Exposed Pad. Connect to Power 0V reference.

2014 Microchip Technology Inc. DS20005339A-page 23

Page 24

MCP8025/6

TABLE 3-2: MCP8026 – PIN FUNCTION TABLE

QFN TQFP Symbol I/O Description

2 1 PWM1L I Digital input, phase A low-side control, 47 k pull down

3 2 PWM1H I Digital input, phase A high-side control, 47 k pull down

4 3 CE I Digital input, device enable, 47 k pull down

— 4 LV_OUT2 O Level Translator 2 logic level translated output, open-drain

— 5 HV_IN2 I Level Translator 2 high-voltage input, 30 k configurable pull up

5 6 HV_IN1 I Level Translator 1 high-voltage input, 30 k configurable pull up

—7 P

6 8 LV_OUT1 O Level Translator 1 logic level translated output, open-drain

7 9 I_OUT3 O Motor phase current sense amplifier 3 output

8 10 ISENSE3- I Motor phase current sense amplifier 3 inverting input

9 11 ISENSE3+ I Motor phase current sense amplifier 3 non-inverting input

10 12 I_OUT2 O Motor phase current sense amplifier 2 output

11 13 ISENSE2- I Motor phase current sense amplifier 2 inverting input

12 14 ISENSE2+ I Motor phase current sense amplifier 2 non-inverting input

13 15 ILIMIT_OUT

14 16 I_OUT1 O Motor current sense amplifier 1 output

15 17 ISENSE1- I Motor current sense amplifier 1 inverting input

16 18 ISENSE1+ I Motor current sense amplifier 1 non-inverting input

17 19,20 P

18 21 LSA O Phase A low-side N-Channel MOSFET driver, active high

19 22 LSB O Phase B low-side N-Channel MOSFET driver, active high

20 23 LSC O Phase C low-side N-Channel MOSFET driver, active high

—24 P

21 25 HSC O Phase C high-side N-Channel MOSFET driver, active high

22 26 HSB O Phase B high-side N-Channel MOSFET driver, active high

23 27 HSA O Phase A high-side N-Channel MOSFET driver, active high

24 28 PHC I/O Phase C high-side MOSFET driver reference, back EMF sense input

25 29 PHB I/O Phase B high-side MOSFET driver reference, back EMF sense input

26 30 PHA I/O Phase A high-side MOSFET driver reference, back EMF sense input

27 31 V

28 32 V

29 33 V

30 34 +12V Power Analog circuitry and low-side gate drive bias

— 35,36 P

31 37 LX Power Buck regulator switch node, external inductor connection

32 38, 39 V

33 40 FB I Buck regulator feedback node

34 41 +5V Power Internal circuitry bias

35 42 CAP2 Power Charge pump flying capacitor input

36 43 CAP1 Power Charge pump flying capacitor input

37 44 DE2 O Voltage and temperature supervisor output, open-drain

38 45 PWM3L I Digital input, phase C low-side control, 47 k pull down

39 46 PWM3H I Digital input, phase C high-side control, 47 k pull down

40 47 PWM2L I Digital input, phase B low-side control, 47 k pull down

1 48 PWM2H I Digital input, phase B high-side control, 47 k pull down

EP EP P

GND

GND

GND

BC

BB

BA

GND

DD

GND

Power Power 0V reference

O Current limit comparator, MOSFET driver fault output, open-drain

Power Power 0V reference

Power Power 0V reference

Power Phase C high-side MOSFET driver bias

Power Phase B high-side MOSFET driver bias

Power Phase A high-side MOSFET driver bias

Power Power 0V reference

Power Input supply

Power Exposed Pad. Connect to Power 0V reference.

DS20005339A-page 24 2014 Microchip Technology Inc.

Page 25

MCP8025/6

3.1 Low-Side PWM Inputs (PWM1L, PWM2L, PWM3L)

Digital PWM inputs for low-side driver control. Each

input has a 47 k pull down to ground. The PWM

signals may contain dead-time timing or the system

may use configuration register 2 to set the dead time.

3.2 High-Side PWM Inputs (PWM1H, PWM2H, PWM3H)

Digital PWM inputs for high-side driver control. Each

input has a 47 k pull down to ground. The PWM

signals may contain dead-time timing or the system

may use the configuration register 2 to set the dead

time.

3.3 No Connect (NC)

Reserved. Do not connect.

3.4 Chip Enable Input (CE)

Chip Enable input used to enable/disable the output

driver and on-board functions. When CE is high, all

device functions are enabled. When CE is low, the

device operates in Standby or Sleep mode. When

Standby mode is active, the current amplifiers and the

12V LDO are disabled. The buck regulator, the DE2

pin, the voltage and temperature sensor functions are

not affected. The 5V LDO is disabled on the MCP8026

The H-bridge driver outputs are all set to a low state

within 100 ns of CE = 0. The device transitions to

Standby or Sleep mode 1 ms after CE = 0.

The CE pin may be used to clear any hardware faults.

When a fault occurs, the CE input may be used to clear

the fault by setting the pin low and then high again. The

fault is cleared by the rising edge of the CE signal if the

hardware fault is no longer active.

The CE pin is used to enable Sleep mode when the

SLEEP bit in the CFG0 configuration register is set to 1.

CE must be low for a minimum of 1 ms before the

transition to Standby or Sleep mode occurs. This allows

time for CE to be toggled to clear any faults without

going into Sleep mode.

The CE pin is used to awaken the device from the

Sleep mode state. To awaken the device from a Sleep

mode state, the CE pin must be set low for a minimum

of 250 μs. The device will then wake up with the next

rising edge of the CE pin.

The CE pin has an internal 47 k pull down.

3.5 Level Translators (HV_IN1, HV_IN2, LV_OUT1, LV_OUT2)

Unidirectional digital level translators. These pins

translate digital input signal on the HV_INx pin to a

low-level digital output signal on the LV_OUTx pin. The

HV_INx pins have internal 30 k pull ups to V

are controlled by bit PU30K in the CFG0 configuration

register. The PU30K bit is only sampled during CE = 0.

The HV_IN1 pin has higher ESD protection than the

HV_IN2 pin. The higher ESD protection makes the

HV_IN1 pin better suited for connection to external

switches.

LV_OUT1 and LV_OUT2 are open-drain outputs. An

external pull-up resistor to the low-voltage logic supply

is required.

The HV_IN1 pin may be used to awaken the device

from the Sleep mode state. The MCP8026 will awaken

on the rising edge of the pin after detecting a low state

lasting > 250 µs on the pin.

DD

that

3.6 LIN Transceiver Bus (LIN_BUS)

The bidirectional LIN_BUS interface pin connects to

the LIN Bus network. The LIN_BUS driver is controlled

by the TX pin. The driver is an open-drain output. The

MCP8025 device contains a LIN Bus 30 k pull-up

resistor that may be enabled or disabled by setting the

PU30K bit in the CFG0 configuration register. The pull

up may only be changed while in Standby mode.

During normal operation, the 30 k pull up is always

enabled. In Sleep mode, the 30 k pull up is always

disabled.

The LIN bus may be used to awaken the device from

the Sleep mode state. When a LIN wake-up event is

detected on the LIN_BUS pin, the device will wake up.

The MCP8025 will awaken on the rising edge of the

bus after detecting a dominant state lasting > 150 µs

on the bus. The LIN Bus master must provide the

dominant state for > 250 µs to meet the LIN 2.2A

specifications.

3.7 Power Ground (P

GND

),

Exposed Pad (EP)

Device ground. The PCB ground traces should be short

and wide and should form a STAR pattern to the power

source. The Exposed Pad (EP) must be soldered to the

PCB. The PCB area below the EP should be a copper

pour with thermal vias to help transfer heat away from

the device.

3.8 LIN Transceiver Received Data Output (RX)

The RX output pin follows the state of the LIN_BUS pin.

The data received from the LIN bus is output on the RX

pin for connection to a host MCU.

The RX pin is an open-drain output.

2014 Microchip Technology Inc. DS20005339A-page 25

Page 26

MCP8025/6

3.9 LIN Transceiver Transmit Data Input (TX)

The TX input pin is used to send data to the LIN Bus.

The LIN_BUS pin is low (dominant) when TXD is low

and high (recessive) when TXD is high. Data to be

transmitted from a host MCU is sent to the LIN bus via

the TX pin.

3.10 LIN Transceiver Fault/

Transmit Enable (FAULTn

Fault Detect output and Transmitter Enable input

bidirectional pin. The FAULTn

low whenever a LIN fault occurs. There is a resistor

between the internal fault signal and the FAULTn

pin to allow the pin to be externally driven high after a

fault has occurred. The FAULTn/TXE pin must be

pulsed high to start a transmit. If there is no fault

present when the pin is pulsed, the FAULTn/TXE pin

will latch and be driven high by an internal 100 k

impedance. The FAULTn

monitored for faults.

No external pull up is needed. The microcontroller pin

controlling the FAULTn

between output and input modes.

/TXE pin must be able to switch

/TXE pin will be driven

/TXE pin may then be

/TXE)

/TXE

3.11 Zero-Crossing Multiplexer Inputs (MUX1, MUX2 )

The MUX1 and MUX2 multiplexer inputs select the

desired phase winding to be used as the zero-crossing

Back EMF phase reference. The output of the

multiplexer connects to one input of the zero-crossing

comparator. The other zero-crossing comparator input

connects to the neutral voltage. The MUX1 and MUX2

inputs must be driven by the host processor

synchronously with the motor commutation.

3.14 Current Limit and Driver Fault

Output (ILIMIT_OUT

Dual purpose output pin. The open-drain output goes

low when the current sensed by current sense amplifier

1 exceeds the value set by the internal current

reference DAC. The DAC has an offset of 0.991V

(typical) which represents the zero current flow.

The open-drain output will also go low while a fault is

active. Ta b le 4 - 1 shows the faults that cause the

ILIMIT_OUT

The ILIMIT_OUT

while maintaining less than a 50 mV drop across the

output.

pin to go low.

pin is able to sink 1 mA of current

)

3.15 Operational Amplifier Outputs (I_OUT1, I_OUT2, I_OUT3)

Current sense amplifier outputs. May be used with

feedback resistors to set the current sense gain. The

amplifiers are disabled when CE = 0.

3.16 Operational Amplifier Inputs (ISENSE1 +/-, ISENSE2 +/-, ISENSE3 +/-)

Current sense amplifier inverting and non-inverting

inputs. Used in conjunction with the I_OUTn pin to set

the current sense gain. The amplifiers are disabled

when CE = 0.

3.17 Low-Side N-Channel MOSFET Driver Outputs (LSA, LSB, LSC)

Low-side N-channel MOSFET drive signal. Connect to

the gate of the external MOSFETs. A low-impedance

resistor may be used between these pins and the

MOSFET gates to limit current and slew rate.

3.12 Zero-Crossing Detector Output (ZC_OUT)

The ZC_OUT output pin is the output of the

zero-crossing comparator. When the phase voltage

selected by the multiplexer inputs crosses the neutral

voltage, the zero-crossing detector will change the

output state.

The ZC_OUT output is an open-drain output.

3.18 High-Side N-Channel MOSFET Driver Outputs (HSA, HSB, HSC)

High-side N-channel MOSFET drive signal. Connect to

the gate of the external MOSFETs. A low-impedance

resistor may be used between these pins and the

MOSFET gates to limit current and slew rate.

3.19 Driver Phase Inputs (PHA, PHB, PHC)

3.13 Neutral Voltage Reference Input (COMP_REF)

The COMP_REF input pin is used to connect to the

neutral point of a motor if the neutral point is available.

The COMP_REF input may be selected via a

configuration register as the neutral voltage reference

used by the zero-crossing comparator.

DS20005339A-page 26 2014 Microchip Technology Inc.

Phase signals from motor. These signals provide

high-side N-channel MOSFET driver reference and

Back EMF sense input. The phase signals are also

used with the bootstrap capacitors to provide high-side

gate drive via the V

inputs.

Bx

Page 27

MCP8025/6

3.20 Driver Bootstrap Inputs

(V

, VBB, VBC)

BA

High-side MOSFET driver bias. Connect these pins

between the bootstrap charge pump diode cathode and

the bootstrap charge pump capacitor. The 12V LDO

output is used to provide 12V at the diode anodes. The

phase signals are connected to the other side of the

bootstrap charge pump capacitors. The bootstrap

capacitors charge to 12V when the phase signals are

pulled low by the low-side drivers. When the low-side

drivers turn off and the high-side drivers turn on, the

phase signal is pulled to V

voltage to rise to V

DD

+12V.

, causing the bootstrap

DD

3.21 12V LDO (+12V)

+12-volt Low Dropout (LDO) voltage regulator output.

The +12V LDO may be used to power external devices

such as Hall-effect sensors or amplifiers. The LDO

requires an output capacitor for stability. The positive

side of the output capacitor should be physically

located as close to the +12V pin as is practical. For

most applications, 4.7 µF of capacitance will ensure

stable operation of the LDO circuit. The +12V LDO is

supplied by the internal charge pump when the charge

pump is active. When the charge pump is inactive, the

+12V LDO is supplied by V

The type of capacitor used can be ceramic, tantalum or

aluminum electrolytic. The low ESR characteristics of

the ceramic will yield better noise and PSRR

performance at high frequency.

DD

.

3.22 Buck Regulator Switch Output (LX)

Buck regulator switch node external inductor

connection. Connect this pin to the external inductor

chosen for the buck regulator.

3.23 Power Supply Input (VDD)

3.24 Buck Regulator Feedback Input (FB)

Buck regulator feedback node that is compared to an

internal 1.25V reference voltage. Connect this pin to a

resistor divider that sets the buck regulator output

voltage. Connecting this pin to a separate +2.5V to

+5.5V supply will disable the buck regulator. The FB pin

should not be connected to the +5V LDO to disable the

buck because the +5V LDO starts after the buck in the

internal state machine. The lack of voltage at the FB pin

would cause a buck UVLO fault.

3.25 5V LDO (+5V)

+5-volt Low Dropout (LDO) voltage regulator output.

The +5V LDO may be used to power external devices,

such as Hall-effect sensors or amplifiers. The +5V LDO

is disabled on the MCP8026 when CE = 0. The internal

state machine starts the buck regulator before the +5V

LDO, so the +5V LDO should not be connected to the

buck FB pin to disable the buck regulator. A buck UVLO

fault will occur if the +5V LDO is used to disable the

buck regulator. The LDO requires an output capacitor

for stability. The positive side of the output capacitor

should be physically located as close to the +5V pin as

is practical. For most applications, 4.7 µF of

capacitance will ensure stable operation of the LDO

circuit.

The type of capacitor used can be ceramic, tantalum or

aluminum electrolytic. The low ESR characteristics of

the ceramic will yield better noise and PSRR

performance at high frequency.

3.26 Charge Pump Flying Capacitor (CAP1, CAP2)

Charge pump flying capacitor connections. Connect

the charge pump capacitor across these two pins. The

charge pump flying capacitor supplies the power for the

12V LDO when the charge pump is active.

Connect VDD to the main supply voltage. This voltage

should be the same as the motor voltage. The driver

overcurrent and overvoltage shutdown features are

relative to the V

separate from the motor voltage, the overcurrent and

overvoltage protection features may not be available.

The V

operating limits of the device. Connect a bulk capacitor

close to this pin for good loadstep performance and

transient protection.

The type of capacitor used can be ceramic, tantalum or

aluminum electrolytic. The low ESR characteristics of

the ceramic will yield better noise and PSRR

performance at high frequency.

2014 Microchip Technology Inc. DS20005339A-page 27

voltage must not exceed the maximum

DD

pin. When the VDD voltage is

DD

3.27 Communications Port (DE2)

Open-drain communication node. The DE2

communication is a half-duplex, 9600 baud, 8-bit, no

parity communication link. The open-drain DE2 pin

must be pulled high by an external pull-up resistor. The

pin has a minimum drive capability of 1 mA resulting in

of 50 mV when driven low.

a V

DE2

Page 28

MCP8025/6

NOTES:

DS20005339A-page 28 2014 Microchip Technology Inc.

Page 29

MCP8025/6

OUTPUT

CONTROL

LOGIC

VIN

+

-

LX

FB

+

-

Q1

CURRENT_REF

VDD-12V

BANDGAP

REFERENCE

+

-

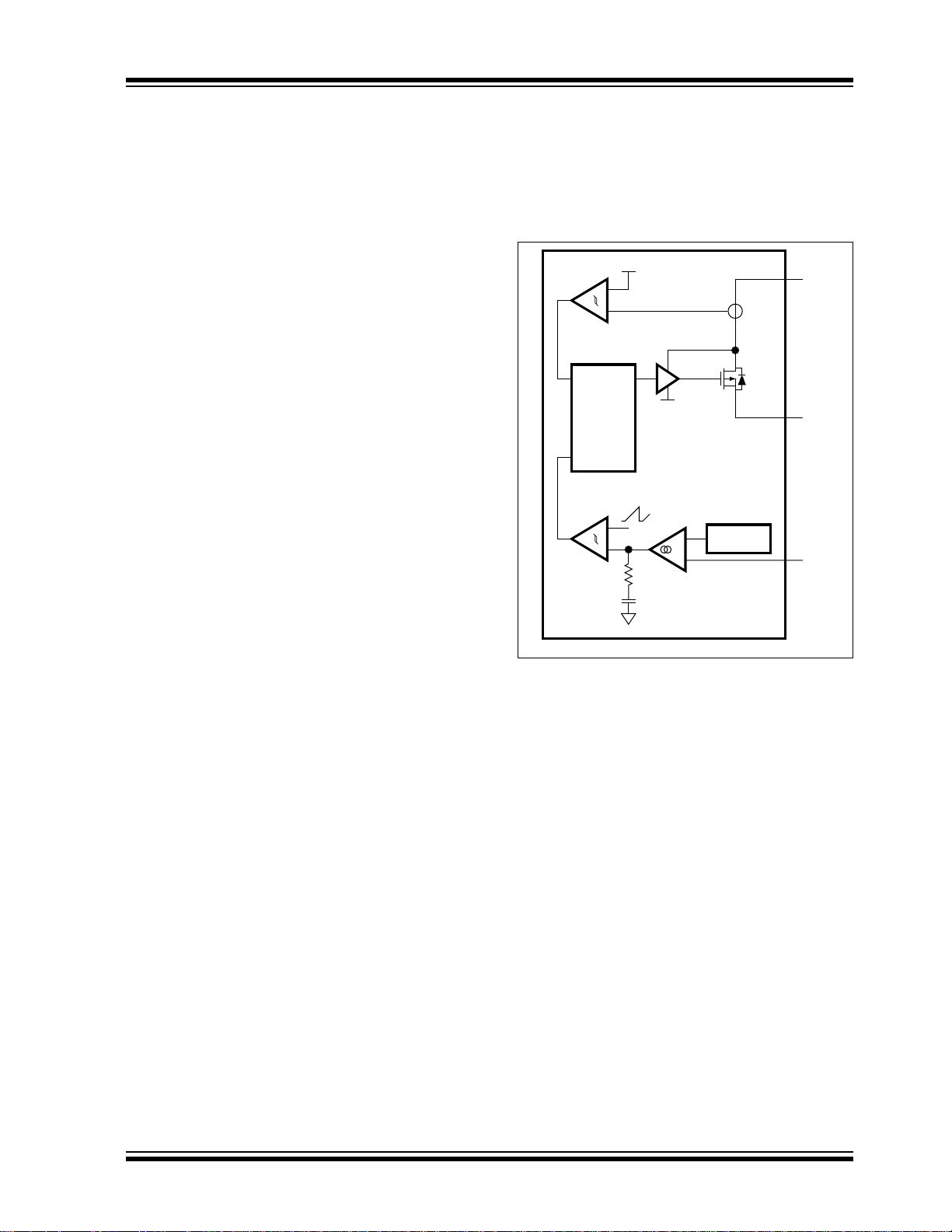

4.0 DETAILED DESCRIPTION

4.1 Bias Generator

The internal bias generator controls three voltage rails.

Two fixed-output low-dropout linear regulators, an

adjustable buck switch-mode power converter and an

unregulated charge pump are controlled through the

bias generator. In addition, the bias generator performs

supervisory functions.

4.1.1 +12V LOW-DROPOUT LINEAR

REGULATOR (LDO)

The +12V rail is used for bias of the 3-phase power

MOSFET bridge.

The regulator is capable of supplying 30 mA of external

load current. The regulator has a minimum overcurrent

limit of 40 mA.

When operating at a supply voltage (V

range of +12V to +12.7V, the +12V charge pump will be

off and the +12V source will be the VDD supply voltage.

The +12V output may be lower than +12V while

operating in the V

range of +12V to +12.7V due to

DD

the dropout voltage of the regulator.

The low-dropout regulators require an output capacitor

connected from V

to GND to stabilize the internal

OUT

control loop. A minimum of 4.7 µF ceramic output

capacitance is required for the 12V LDO.

The +12V LDO is disabled when the Chip Enable (CE)

pin is not active.

Table 4-1 shows the faults that will also disable the

+12V LDO.

4.1.2 +5V LOW-DROPOUT LINEAR

REGULATOR (LDO)

The +5V LDO is used for bias of an external

microcontroller, the internal current sense amplifier and

the gate control logic.

The +5V LDO is capable of supplying 30 mA of external

load current. The regulator has a minimum overcurrent

limit of 40 mA. If additional external current is

required, the buck switch-mode power converter

should be utilized.

A minimum of 4.7 µF ceramic output capacitance is

required for the 5V LDO.

The +5V LDO is disabled when the system is in Sleep

mode. The +5V LDO is enabled in the MCP8025 and

disabled in the MCP8026 when in standby mode.

Table 4-1 shows the faults that will also disable the +5V

LDO.

4.1.3 BUCK SWITCH MODE POWER

SUPPLY (SMPS)

The SMPS is a high-efficiency, fixed-frequency,

step-down DC-DC converter. The SMPS provides all

the active functions for local DC-DC conversion with

fast transient response and accurate regulation.

) that is in the

DD

During normal operation of the buck power stage, Q1 is

repeatedly switched on and off with the on and off times

governed by the control circuit. This switching action

causes a train of pulses at the LX node which are

filtered by the L/C output filter to produce a DC output

voltage, V

. Figure 4-1 depicts the functional block

O

diagram of the SMPS.

FIGURE 4-1: SMPS Functional Block Diagram.

The SMPS is designed to operate in Discontinuous

Conduction Mode (DCM) with Voltage mode control

and current-limit protection. The SMPS is capable of

supplying 750 mW of power to an external load at a

fixed switching frequency of 460 kHz with an input

voltage of 6V. The output of the SMPS is power-limited.

For a programmed output voltage of 3V, the SMPS will

be capable of supplying 250 mA to an external load. An

external diode is required between the LX pin and

ground. The diode will be required to handle the

inductor current when the switch is off. The diode is

external to the device to reduce substrate currents and

power dissipation caused by the switcher. The external

diode carries the current during the switch-off time,

eliminating the current path back through the device.

2014 Microchip Technology Inc. DS20005339A-page 29

Page 30

MCP8025/6

L

MAX

VO1

V

O

V

IN

--------–

T

2I

OCRIT

----------------------------------------------

The SMPS enters Pulse Frequency Modulation (PFM)

mode at light loads, improving efficiency at the expense

of higher output voltage ripple. The PFM circuitry

provides a means to disable the SMPS as well. If the

SMPS is not utilized in the application, connecting the

feedback pin (FB) to an external supply (2.5V to 5.5V)

will force the SMPS to a shutdown state.

The maximum inductor value for operation in

Discontinuous Conduction mode can be determined by

using Equation 4-1.

EQUATION 4-1: L

Using the L

inductor value calculated using

MAX

SIMPLIFIED

MAX

Equation 4-1 will ensure Discontinuous Conduction

mode operation for output load currents below the

critical current level, I

. For example, with an

O(CRIT)

output voltage of +5V, a standard inductor value of

4.7 µH will ensure Discontinuous Conduction mode

operation with an input voltage of 6V, a switching

frequency of 468 kHz and a critical load current of

150 mA.

The output voltage is set by using a resistor divider

network. The resistor divider is connected between the

inductor output and ground. The divider common point

is connected to the FB pin which is then compared to

an internal 1.25V reference voltage.

The buck regulator will set the BIOCPW bit in the STAT0

register and send a STATUS_0 message to the host

whenever the input switching current exceeds 2.5A

peak (typical). The bit will be cleared when the peak

input switching current drops back below the 2.5A

(typical) limit. This is a warning bit only, no action is

taken to shut down the buck operation. The overcurrent

limit will shorten the buck duty cycle and therefore limit

the maximum power out of the buck regulator.

The buck regulator will set the BUVLOW bit in the STAT0

register and send a STATUS_0 message to the host

whenever the output voltage drops below 90% of the

rated output voltage. The bit will be cleared when the

output voltage returns to 94% of the rated value.

If the buck regulator output voltage falls below 80% of

rated output voltage, the device will shut down with a

Buck Undervoltage Lockout Fault. The BUVLOF bit in

the STAT0 register will be set and a STATUS_0

message will be sent to the host. The ILIMIT_OUT

signal will transition low to indicate the fault.

The Voltage Supervisor is designed to shut down the

buck regulator when V

rises above AOVLO

DD

STOP

When shutting down the buck regulator is not

desirable, the user should add a voltage suppression

device to the V

rising above AOVLO

input in order to prevent VDD from

DD

STOP

.

The Voltage Supervisor is also designed to shut down

the buck regulator when V

UVLO

BK_STOP

.

falls below

DD

The device will set the BUVLOF bit in the STAT0 register

and send a STATUS_0 message to the host when the

buck input voltage drops below UVLO

BK_STOP

.

Table 4-1 shows the faults that will disable the buck

regulator.

4.1.4 CHARGE PUMP

An unregulated charge pump is utilized to boost the

input to the +12V LDO during low input conditions.

When the input bias to the device (VDD) drops below

CP

activated, 2 x V

, the charge pump is activated. When

START

is presented to the input of the +12V

DD

LDO, which maintains a minimum of +10V at its output.

The typical charge pump flying capacitor is a 0.1 µF to

1.0 µF ceramic capacitor.

4.1.5 SUPERVISOR

The bias generator incorporates a voltage supervisor

and a temperature supervisor.

4.1.5.1 Brown Out - Configuration Lost

When the device first powers up or when VDD drops

below 3.8V, the brown-out reset warning flag bit

(BORW) in the STAT1 register will be set. The bit is only

a warning indicating that the contents of the configuration registers may have been compromised by a low

supply voltage condition. The host processor should

send new configuration information to the device.

4.1.5.2 Voltage Supervisor

The voltage supervisor protects the device, the

external power MOSFETs and the external

microcontroller from damage caused by overvoltage or

undervoltage of the input supply, V

In the event of an undervoltage condition

< +5.5V) or an overvoltage condition of the

(V

DD

MCP8025 device (V

> +20V), the motor drivers are

DD

switched off. The bias generator, the communication

port and the remainder of the motor control unit remain

active. The failure state is flagged on the DE2 pin with

a status message. In extreme overvoltage conditions

> +32V), all functions are turned off.

(V

DD

In the event of a severe undervoltage condition

< +4.0V), the buck regulator will be disabled. If

(V

DD

the set point of the buck regulator output voltage is

above the buck undervoltage lockout value, the buck

output voltage will decrease as V

.

4.1.5.3 Temperature Supervisor

An integrated temperature sensor self-protects the

device circuitry. If the temperature rises above the

overtemperature shutdown threshold, all functions are

.

DD

decreases.

DD

DS20005339A-page 30 2014 Microchip Technology Inc.

Page 31

MCP8025/6

turned off. Active operation resumes when the

temperature has cooled down below a set hysteresis

value and the fault has been cleared by toggling CE.

It is desirable to signal the microcontroller with a

warning message before the overtemperature

threshold is reached. When the Thermal Warning

Temperature set point is exceeded, a warning message

will be sent to the host microcontroller. The

microcontroller should take appropriate actions to

reduce the temperature rise. The method to signal the

microcontroller is through the DE2 pin.

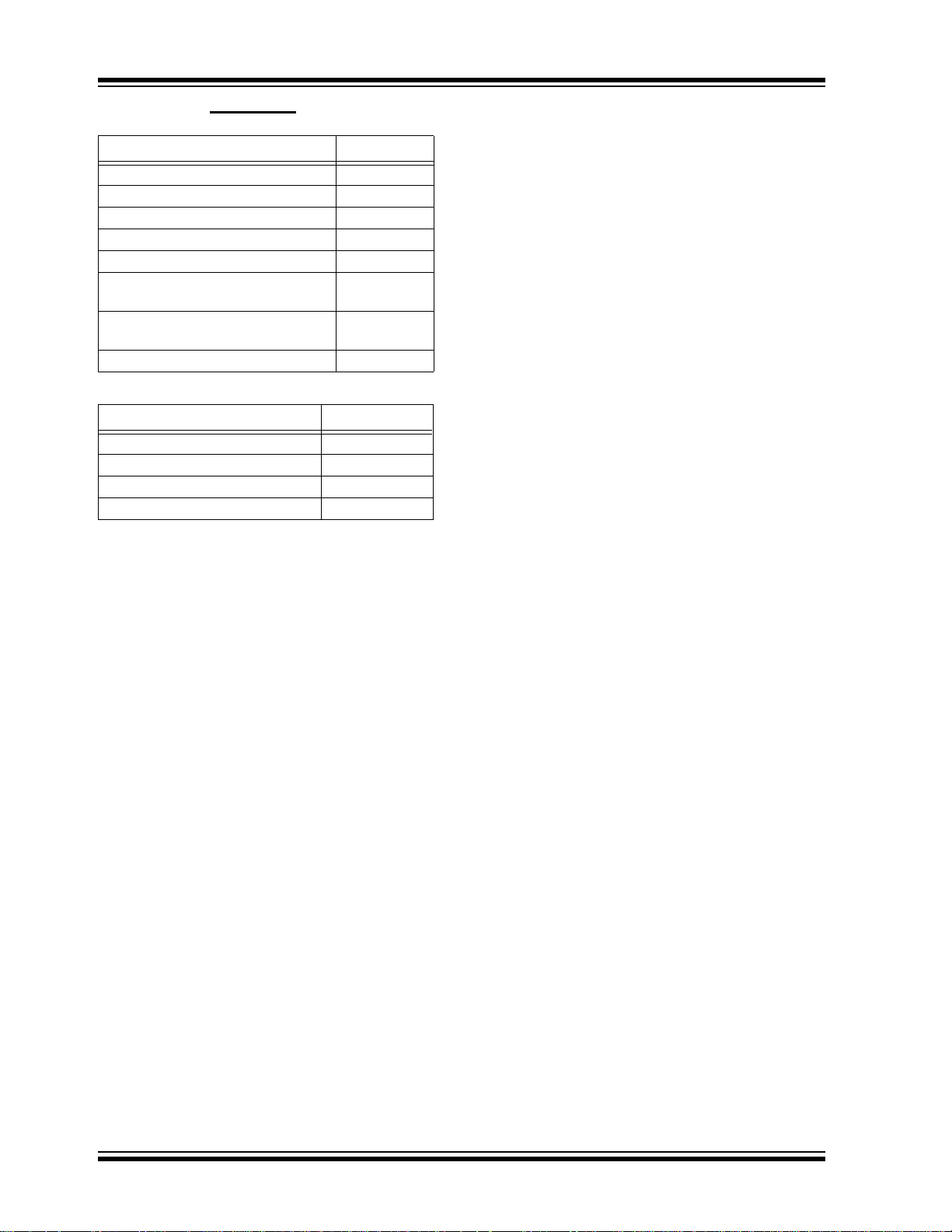

4.1.5.4 Internal Function Block Status

Table 4-1 shows the effects of the CE pin, the faults and

the Sleep bit upon the functional status of the internal

blocks of the MCP8025/6.

TABLE 4-1: INTERNAL FUNCTION BLOCK STATUS

System State Fault Conditions

Sleep CE = 0, SLEEP = 1 ——W——— —

Standby

CE = 0, SLEEP = 0 AAR——A A

(MCP8025)

Standby

CE = 0, SLEEP = 0 —A A——A A

(MCP8026)

Operating CE = 1, I

Faults

CE = 1,

LIMIT_OUT = 0

I

Driver OTP T

VDD UVLO VIN 5.5V — A ——— A A

Buck Input UVLO VIN 4V ————— A A

Buck Output Brownout V

5V LDO UVLO V

BUCK

LIMIT_OUT = 1 AAAAAA A

>160°C ————— A A

J

< 80% (Brownout) — A — — — A A

4V A A R A — A A

OUT5

Driver OVLO (MCP8025) VIN 20V AAAA—A A

32V ————— A A

IN

<8V, V

<8V AAAA—A A

LS[A:C]

>EXTOC<1:0> settingAAAA—A A

Input>2.5A Peak AAAAAA A

<90% AAAAAA A

V

BUCK

>72% T

J

SD_MIN

Warnings

CE = 1,

LIMIT_OUT = 1

I

System OVLO V

MOSFET UVLO V

MOSFET OCP V

Buck OCP I

HS[A:C]

Drain-Source

BUCK

Buck Output

Undervoltage

Driver Temperature T

(115°C for 160°C Driver OTP)

Config Lost (BORW) Set at initial power-up

or when V

<UVLO

DD

BK_STOP

Legend: “A” = ACTIVE (ON), “—” = INACTIVE (OFF), “W” = WAKEUP (from Sleep), “R” = RECEIVER ONLY

OCP = Overcurrent Protection

OTP = Overtemperature Protection

UVLO = Undervoltage Lockout

OVLO = Overvoltage Lockout

Buck

5V LDO

12V LDO

Motor Drivers

LIN, HV_IN1, HV_IN2

AAAAAA A

AAAAAA A

DE2

Internal

UVLO, OVLO, OTP

2014 Microchip Technology Inc. DS20005339A-page 31

Page 32

MCP8025/6

NEUTRAL

AB

C++

3

--------------------------------------- -=

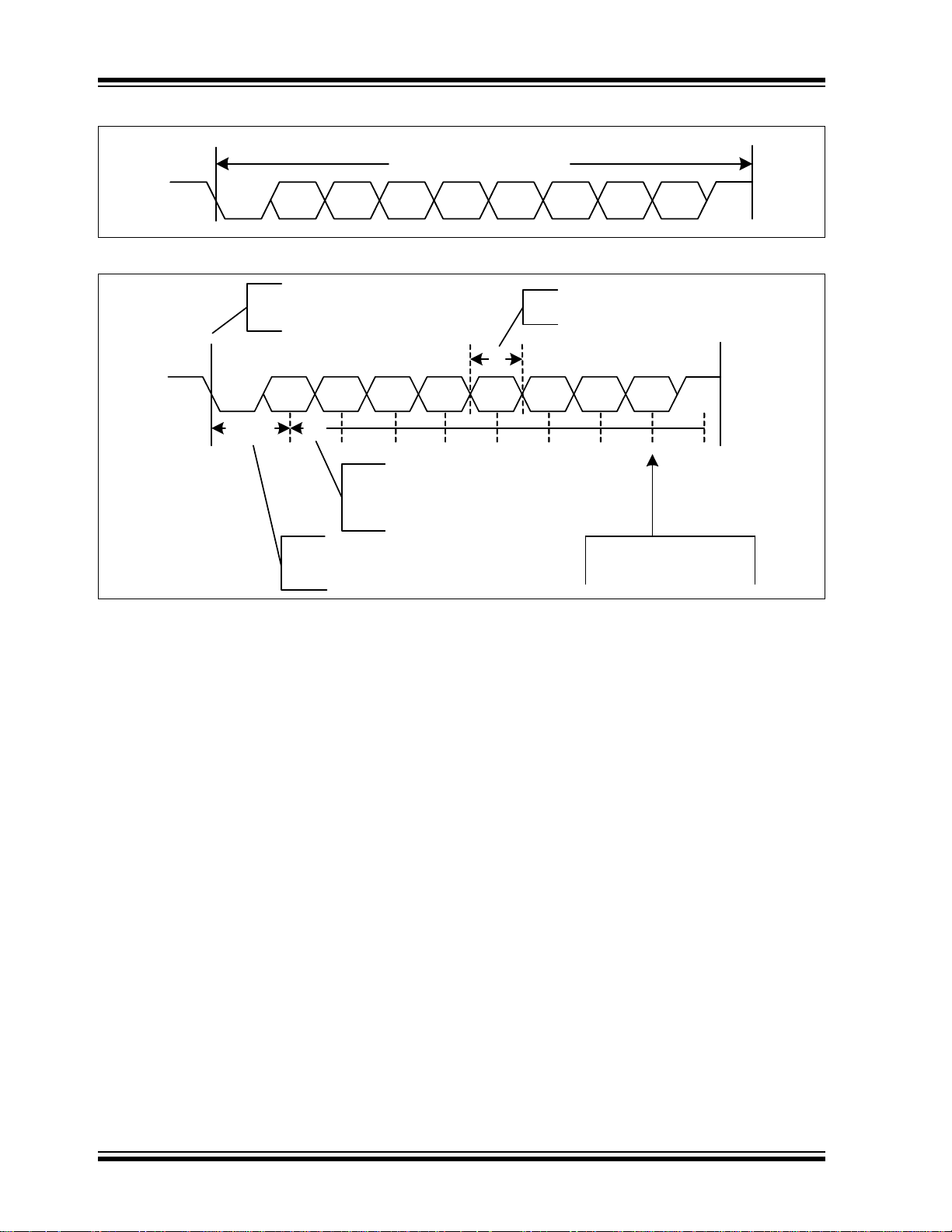

4.2 Motor Control Unit

The motor control unit is comprised of the following:

• External drive for a 3-phase bridge with

NMOS/NMOS MOSFET pairs