Page 1

MC7660

Charge Pump DC-to-DC

V oltage Converter

The MC7660 is a pin–compatible replacement for the Industry

standard ICL7660 charge pump voltage converter . It converts a +1.5V

to +10V input to a corresponding –1.5V to –10V output using only two

low–cost capacitors, eliminating inductors and their associated cost,

size and EMI.

The on–board oscillator operates at a nominal frequency of 10kHz.

Operation below 10kHz (for lower supply current applications) is

possible by connecting an external capacitor from OSC to ground

(with pin 1 open).

The MC7660 is available in an 8–pin SOIC package in extended

temperature range.

Features

• Converts +5V Supply to –5V Supply

• Wide Input Voltage Range: 1.5V to 10V

• Ef ficient Voltage Conversion: 99.9%

• Excellent Power Efficiency: 98%

• Low Power Supply: 80µA @ 5V

• Low Cost and Easy to Use

– Only Two External Capacitors Required

• Available in Small Outline (SO) Package

• ESD Protection: ≥ 2.5kV

• No Dx Diode Required for High Voltage Operation

Typical Applications

• RS–232 Negative Bias

• Display Bias

• Data Aquisition Negative Supply Generation

IN

http://onsemi.com

SO–8

D SUFFIX

CASE 751

PIN CONFIGURATION

(Top View)

+

V

NC

1

+

2

CAP

3

GND

–

4

CAP

ORDERING INFORMATION

Device Package Shipping

MC7660DR2 8–Pin SOIC 2500 Tape/Reel

8

7

OSC

6

LV

5

V

OUT

OSC

LV

7

6

RC

OSCILLATOR

INTERNAL

REGULATOR

MC7660

Semiconductor Components Industries, LLC, 1999

February , 2000 – Rev. 2

VOLTAGE

FUNCTIONAL BLOCK DIAGRAM

V+ CAP+

28

VOLTAGE–

B

2

LEVEL

TRANSLATOR

3

GND

1 Publication Order Number:

LOGIC

NETWORK

4

CAP–

5

V

OUT

MC7660/D

Page 2

MC7660

ABSOLUTE MAXIMUM RATINGS*

Parameter Value Unit

Supply Voltage +10.5 V

LV and OSC Inputs Voltage (Note 1.)

V+ < 5.5V

V+ > 5.5V

Current Into LV (Note 1.) V+ > 3.5V

Output Short Duration (V

SUPPLY

≤ 5.5V) Continuous

Power Dissipation (TA ≤ 70°C)

Derate above 50°C

–0.3 to (V+ + 0.3)

(V+ – 5.5) to (V+ + 0.3)

20 µA

470

5.5

Operating Temperature Range

–40 to +85

Storage Temperature Range –65 to +150 °C

Lead Temperature (Soldering, 10 Seconds) +300 °C

* Maximum Ratings are those values beyond which damage to the device may occur.

1. Connecting any input terminal to voltages greater than V+ or less than GND may cause destructive latch–up. It is recommended that no inputs

from sources operating from external supplies be applied prior to ”power up” of the MC7660.

V

mW

mW/°C

°C

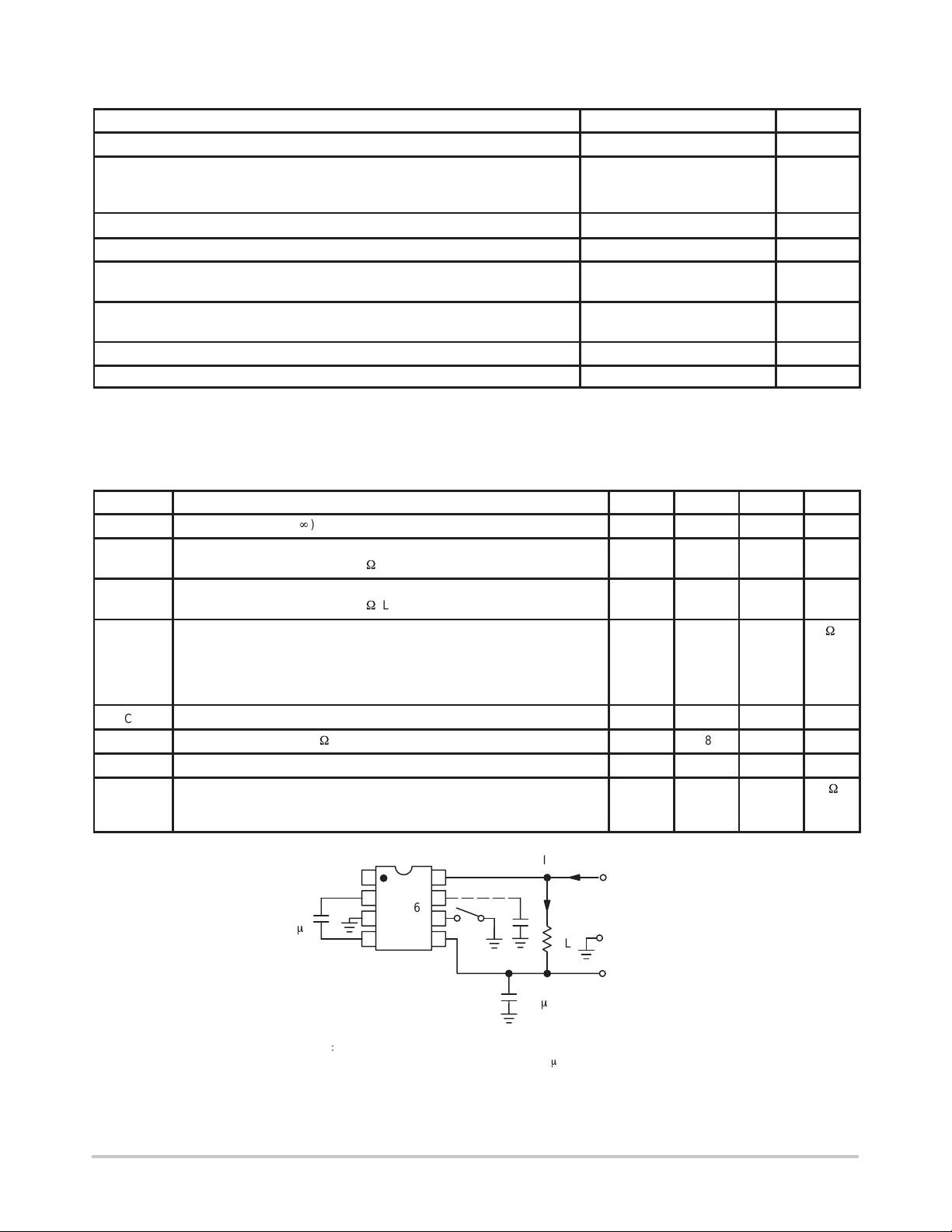

ELECTRICAL CHARACTERISTICS (Specifications Measured Over Operating Temperature Range, V+ = 5V, C

Test Circuit

(Figure 1), unless otherwise noted.

OSC

Symbol Characteristic Min Typ Max Unit

+

I

+

V

H

+

V

L

R

OUT

F

OSC

P

EFF

V

OUT EFF

Z

OSC

Supply Current (RL = R) — 80 180 µA

Supply Voltage Range, High

(–40°C ≤ TA ≤ +85°C, RL = 10 kW, LV Open)

3.0 — 10

Supply Voltage Range, Low

(–40°C ≤ TA ≤ +85°C, RL = 10 kW, LV to GND)

1.5 — 3.5

Output Source Resistance

I

= 20mA, TA = 25°C

OUT

I

= 20mA, 0°C ≤ TA ≤ +70°C

OUT

I

= 20mA, –40°C ≤ TA ≤ +85°C

OUT

V+ =2V, I

= 3 mA, LV to GND, 0°C ≤ TA ≤ +70°C

OUT

—

—

—

—

70

—

—

150

100

120

130

300

Oscillator Frequency (Pin 7 Open) — 10 — kHz

Power Efficiency (RL = 5kW)

95 98 — %

Voltage Conversion Efficiency 97 99.9 — %

Oscillator Impedance

V+ = 2V

V+ = 5V

C1

10 mF

—

—

I

1

2

+

MC7660

3

4

8

7

C

6

5

OSC

S

V+

I

L

R

L

(+6 V)

V

O

*

1000

100

—

—

= 0,

V

V

W

k

W

*NOTE: For large values of C

of C1 and C2 should be increased to 100 mF.

Figure 1. MC7660 T est Circuit

http://onsemi.com

C2

10 mF

+

(>1000 pF), the values

OSC

2

Page 3

MC7660

APPLICATIONS INFORMATION

Detailed Description

The MC7660 contains all the necessary circuitry to

implement a voltage inverter, with the exception of two

external capacitors, which may be inexpensive 10 µF

polarized electrolytic capacitors. Operation is best

understood by considering Figure 2, which shows an

idealized voltage inverter. Capacitor C

voltage, V

+

, for the half cycle when switches S1 and S3 are

is charged to a

1

closed. (Note: Switches S2 and S4 are open during this half

cycle.) During the second half cycle of operation, switches

S2 and S4 are closed, with S1 and S3 open, thereby shifting

capacitor C1 negatively by V+ volts. Charge is then

transferred from C

to C2, such that the voltage on C2 is

1

exactly V+, assuming ideal switches and no load on C2.

V+

GND

Figure 2. Idealized Charge Pump Inverter

S1 S2

S3 S4

C1

C2

V

–V

OUT

IN

=

The four switches in Figure 2 are MOS power switches;

S

is a P–channel device, and S2, S3 and S4 are N–channel

1

devices. The main difficulty with this approach is that in

integrating the switches, the substrates of S3 and S4 must

always remain reverse–biased with respect to their sources,

but not so much as to degrade their ON resistances. In

addition, at circuit start–up, and under output short circuit

conditions (V

= V+), the output voltage must be sensed

OUT

and the substrate bias adjusted accordingly. Failure to

accomplish this will result in high power losses and probable

device latch–up.

This problem is eliminated in the MC7660 by a logic

network which senses the output voltage (V

) together

OUT

with the level translators, and switches the substrates of S

and S4 to the correct level to maintain necessary reverse bias.

The voltage regulator portion of the MC7660 is an integral

part of the anti–latch–up circuitry. Its inherent voltage drop

can, however, degrade operation at low voltages. To

improve low–voltage operation, the LV pin should be

connected to GND, disabling the regulator. For supply

voltages greater than 3.5V , the L V terminal must be left open

to ensure latch–up–proof operation and prevent device

damage.

Theoretical Power Efficiency Considerations

In theory, a capacitive charge pump can approach 100%

efficiency if certain conditions are met:

(1) The drive circuitry consumes minimal power.

(2) The output switches have extremely low ON

resistance and virtually no offset.

(3) The impedances of the pump and reservoir

capacitors are negligible at the pump frequency.

The MC7660 approaches these conditions for negative

voltage multiplication if large values of C

and C2 are used.

1

Energy is lost only in the transfer of charge between

capacitors if a change in voltage occurs. The energy lost

is defined by:

2

E = 1/2 C

and V2 are the voltages on C1 during the pump and

V

1

1

(V

1

— V

2

)

2

transfer cycles. If the impedances of C1 and C2 are relatively

high at the pump frequency (refer to Figure 2), compared to

the value of R

, there will be a substantial difference in

L

voltages V1 and V2. Therefore, it is not only desirable to

make C2 as large as possible to eliminate output voltage

ripple, but also to employ a correspondingly large value for

C

in order to achieve maximum efficiency of operation.

1

Dos and Don’ts

• Do not exceed maximum supply voltages.

• Do not connect LV terminal to GND for supply voltages

greater than 3.5V.

• Do not short circuit the output to V

+

supply for voltages

above 5.5V for extended periods; however, transient

conditions including start–up are okay.

• When using polarized capacitors in the inverting mode,

3

the + terminal of C

must be connected to pin 2 of the

1

MC7660 and the + terminal of C2 must be connected to

GND Pin 3.

http://onsemi.com

3

Page 4

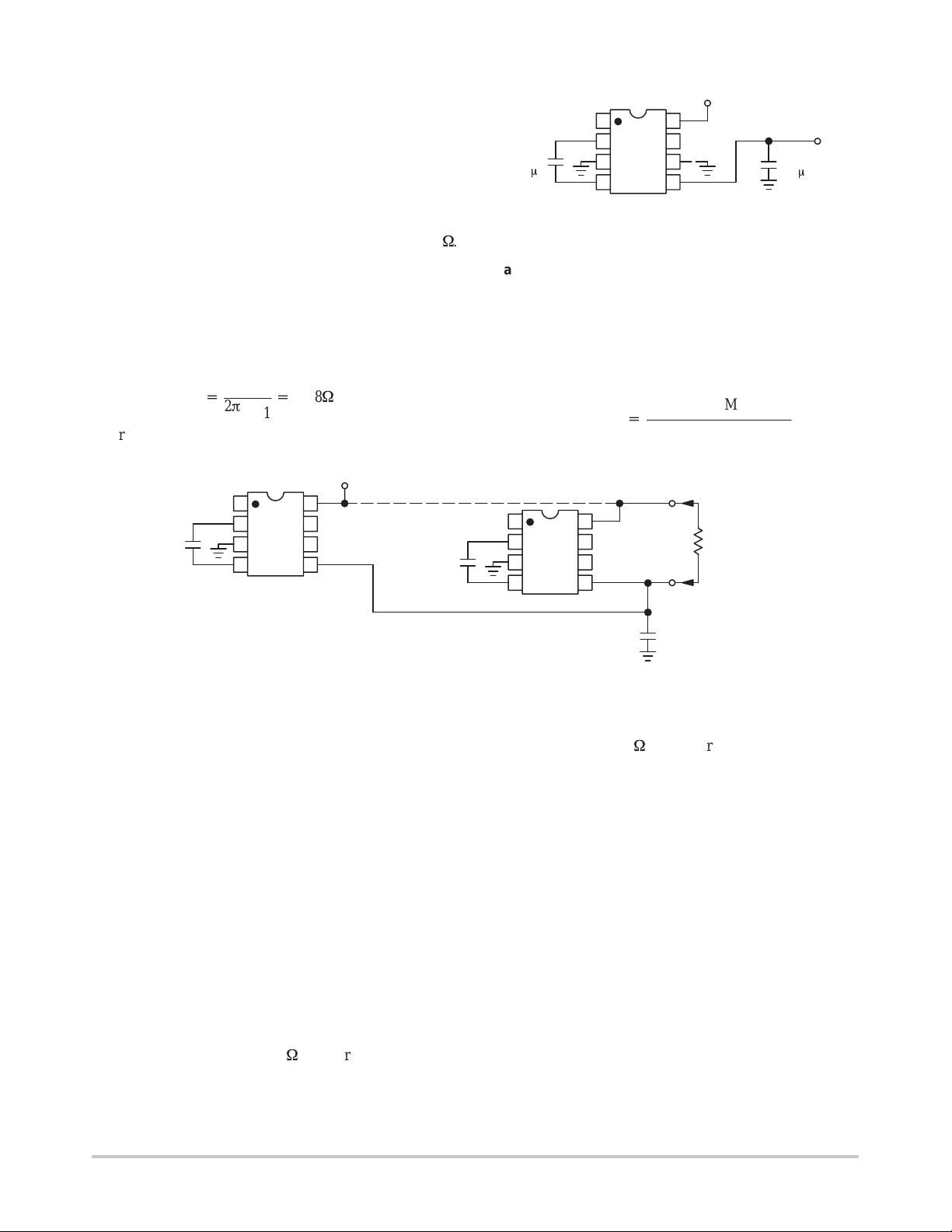

Simple Negative V oltage Converter

Figure 3 shows typical connections to provide a negative

supply where a positive supply is available. A similar

scheme may be employed for supply voltages anywhere in

the operating range of +1.5V to +10V, keeping in mind that

pin 6 (LV) is tied to the supply negative (GND) only for

supply voltages below 3.5V.

The output characteristics of the circuit in Figure 3 are

those of a nearly ideal voltage source in series with 70W.

Thus, for a load current of –10mA and a supply voltage of

+5V, the output voltage would be –4.3V.

The dynamic output impedance of the MC7660 is due,

primarily, to capacitive reactance of the charge transfer

capacitor (C

). Since this capacitor is connected to the output

1

for only 1/2 of the cycle, the equation is:

XC+

where f = 10kHz and C

2

2pfC

= 10µF.

1

+

3.18W,

1

+

V

MC7660

Parallel Devices

paralleled to reduce output resistance (Figure 4). The

reservoir capacitor, C

requires its own pump capacitor, C1. The resultant output

resistance would be approximately:

+

V

8

7

6

5

V

OUT

C2

10 mF

+

C1

10 mF

1

2

+

MC7660

3

4

Figure 3. Simple Negative Converter

Any number of MC7660 voltage converters may be

, serves all devices, while each device

2

R

(of MC7660)

R

OUT

OUT

+

n (number of devices)

8

7

6

5

C1

C1

1

2

MC7660

3

4

Figure 4. Paralleling Devices Lowers Output Impedance

Cascading Devices

The MC7660 may be cascaded as shown (Figure 5) to

produce larger negative multiplication of the initial supply

voltage. However, due to the finite efficiency of each device,

the practical limit is 10 devices for light loads. The output

voltage is defined by:

V

= –n (VIN)

OUT

where n is an integer representing the number of devices

cascaded. The resulting output resistance would be

approximately the weighted sum of the individual MC7660

R

values.

OUT

Changing the MC7660 Oscillator Frequency

It may be desirable in some applications (due to noise or

other considerations) to increase the oscillator frequency.

This is achieved by overdriving the oscillator from an

external clock, as shown in Figure 6. In order to prevent

possible device latch–up, a 1kW resistor must be used in

series with the clock output. In a situation where the designer

1

2

MC7660

3

4

8

7

6

5

R

L

C2

+

has generated the external clock frequency using TTL logic,

the addition of a 10kW pull–up resistor to V+ supply is

required. Note that the pump frequency with external

clocking, as with internal clocking, will be 1/2 of the clock

frequency. Output transitions occur on the positive–going

edge of the clock.

It is also possible to increase the conversion efficiency of

the MC7660 at low load levels by lowering the oscillator

frequency. This reduces the switching losses, and is

achieved by connecting an additional capacitor, C

OSC

, as

shown in Figure 7. Lowering the oscillator frequency will

cause an undesirable increase in the impedance of the pump

(C

) and the reservoir (C2) capacitors. To overcome this,

1

increase the values of C1 and C2 by the same factor that the

frequency has been reduced. For example, the addition of a

100pF capacitor between pin 7 (OSC) and pin 8 (V

+

) will

lower the oscillator frequency to 1kHz from its nominal

frequency of 10kHz (a multiple of 10), and necessitate a

corresponding increase in the values of C1 and C2 (from

10µF to 100µF).

http://onsemi.com

4

Page 5

MC7660

+

V

10 mF

*NOTE: V

1

2

+

MC7660

3

4

= –n V+ for 1.5 V ≤ V+ ≤ 10 V

OUT

“1”

8

7

6

5

Figure 5. Increased Output V oltage by Cascading Devices

10 mF

+

V

1

2

+

MC7660

3

4

8

1 k

7

6

5

+

V

W

CMOS

GATE

V

OUT

10 mF

+

Figure 6. External Clocking

+

V

8

7

6

5

C

OSC

V

OUT

C2

+

C1

1

2

+

MC7660

3

4

Figure 7. Lowering Oscillator Frequency

Positive V oltage Multiplication

The MC7660 may be employed to achieve positive

voltage multiplication using the circuit shown in Figure 8.

In this application, the pump inverter switches of the

MC7660 are used to charge C1 to a voltage level of V

+

– V

(where V+ is the supply voltage and VF is the forward voltage

drop of diode D1). On the transfer cycle, the voltage on C

plus the supply voltage (V+) is applied through diode D2 to

capacitor C2. The voltage thus created on C2 becomes (2 V+)

– (2 VF), or twice the supply voltage minus the combined

forward voltage drops of diodes D

The source impedance of the output (V

the output current, but for V

and D2.

1

) will depend on

+

= 5V and an output current of

OUT

10 mA, it will be approximately 60W.

10 mF

1

2

+

MC7660

3

4

1

2

3

4

“n”

MC7660

8

7

6

5

+

8

D1

7

6

5

V

+

10 mF

+

C1

V

D2

OUT

*

V

(2 V+) – (2 VF)

+

Figure 8. Positive V oltage Multiplier

Combined Negative V oltage Conversion and Positive

Supply Multiplication

Figure 9 combines the functions shown in Figures 3 and

8 to provide negative voltage conversion and positive

voltage multiplication simultaneously . This approach would

be, for example, suitable for generating +9V and –5V from

an existing +5V supply. In this instance, capacitors C

C3 perform the pump and reservoir functions, respectively,

for the generation of the negative voltage, while capacitors

C2 and C4 are pump and reservoir, respectively, for the

multiplied positive voltage. There is a penalty in this

configuration which combines both functions, however, in

that the source impedances of the generated supplies will be

somewhat higher due to the finite impedance of the common

charge pump driver at pin 2 of the device.

+

F

C1

1

2

MC7660

3

4

C2

1

+

V

8

D1

7

6

5

+

+

D2

+

V

–(V+ – VF)

V

(2 V+) – (2 VF)

OUT

C2

OUT

C3

OUT

C4

=

and

1

=

=

http://onsemi.com

5

Figure 9. Combined Negative Converter and

Positive Muliplier

Page 6

MC7660

Efficient Positive V oltage Multiplication/Conversion

Since the switches that allow the charge pumping

operation are bidirectional, the charge transfer can be

performed backwards as easily as forwards. Figure 10 shows

a MC7660 transforming –5V to +5V (or +5V to +10V , etc.).

The only problem here is that the internal clock and

1

2

C1

10 mF

+

MC7660

3

4

Figure 10. Positive V oltage Conversion

V oltage Splitting

The same bidirectional characteristics used in Figure 10

can also be used to split a higher supply in half, as shown in

Figure 11. The combined load will be evenly shared between

the two sides. Once again, a high value resistor to the L V pin

ensures start–up. Because the switches share the load in

V

8

7

6

5

switch–drive section will not operate until some positive

voltage has been generated. An initial inefficient pump, as

shown in Figure 9, could be used to start this circuit up, after

which it will bypass the other (D

and D2 in Figure 9 would

1

never turn on), or else the diode and resistor shown dotted

in Figure 10 can be used to ”force” the internal regulator on.

–

= –V

OUT

+

1 M

W

V– INPUT

10 mF

parallel, the output impedance is much lower than in the

standard circuits, and higher currents can be drawn from the

device. By using this circuit, and then the circuit of Figure

5, +15V can be converted (via +7.5V and –7.5V) to a

nominal –15V, though with rather high series resistance

(~250W).

R

V

R

L1

OUT

L2

+

50 mF

)

–

*

V

V

+

2

50 mF

+

–

100 k

50 mF

+

1

2

MC7660

3

100 k

W

W

+

–

4

8

7

1 M

W

6

5

V

–

V

Figure 11. Splitting a Supply in Half

http://onsemi.com

6

Page 7

MC7660

TYPICAL PERFORMANCE CHARACTERISTICS

12

10

8

6

4

2

SUPPLY VOLTAGE (VOLTS)

0

–55 –25 0 25 50 75 125

SUPPLY VOLTAGE RANGE

100

TEMPERATURE (°C)

Figure 12. Operating Voltage versus

Temperature

10 k

W

TA = +25°C

1 k

100

10

OUTPUT SOURCE RESISTANCE ( )

01234 6 8

SUPPLY VOLTAGE (VOLTS)

57

Figure 14. Output Source Resistance versus

Supply V oltage

100

98

I

= 1 mA

OUT

96

94

92

I

= 15 mA

OUT

90

88

86

EFFICIENCY (%)

84

POWER CONVERSION

TA = +25°C

V+ = +5 V

82

80

100 1 k 10 k

OSCILLATOR FREQUENCY (Hz)

Figure 13. Power Conversion Efficiency

versus Oscillator Frequency

350

W

I

300

250

200

150

100

50

0

OUTPUT SOURCE RESISTANCE ( )

–55 –25 0 25 50 75 125

= 1 mA

OUT

V+ = +2 V

V+ = +5 V

TEMPERATURE (°C)

Figure 15. Output Source Resistance

versus T emperature

100

10 k

TA = +25°C

V+ = +5 V

1 k

100

OSCILLATOR FREQUENCY (Hz)

10

1 10 100 1000 10 k

OSCILLATOR CAPACITANCE (pF)

Figure 16. Frequency of Oscillation versus

Oscillator Capacitance

OSCILLATOR FREQUENCY (kHz)

http://onsemi.com

7

20

V+ = +5 V

18

16

14

12

10

8

6

–55 –25 0 25 50 75 125

TEMPERATURE (°C)

100

Figure 17. Unloaded Oscillator Frequency

versus T emperature

Page 8

MC7660

TYPICAL CHARACTERISTICS (Cont.)

0

–1

–2

–3

–4

–5

–6

–7

–8

OUTPUT VOLTAGE (VOLTS)

–9

–10

0102030 506040

OUTPUT CURRENT (mA)

TA = +25°C

LV OPEN

Figure 18. Output Voltage versus

Output Current

100

90

80

70

60

50

40

30

20

10

POWER CONVERSION EFFICIENCY (%)

TA = +25°C

V+ = +2 V

0

0 1.5 3.0 4.5 6.0 9.0

LOAD CURRENT (mA)

Figure 20. Supply Current and Power

Conversion Efficiency versus Load Current

7.5

5

4

TA = +25°C

V+ = +5 V

3

2

1

0

–1

–2

–3

OUTPUT VOLTAGE (VOLTS)

–4

80 9070

100

–5

010 80

SLOPE 55

20 30 40 50 60 70

LOAD CURRENT (mA)

W

Figure 19. Output Voltage versus

Load Current

20

18

SUPPLY CURRENT (mA)

16

14

12

10

8

6

4

2

0

100

90

80

70

60

50

40

30

20

10

0

0 10203040 60

POWER CONVERSION EFFICIENCY (%)

LOAD CURRENT (mA)

TA = +25°C

V+ = +5 V

50

100

90

80

70

60

50

40

30

20

10

0

SUPPLY CURRENT (mA)

Figure 21. Supply Current and Power

Conversion Efficiency versus Load Current

2

TA = +25°C

1

V+ = +2 V

0

–1

OUTPUT VOLTAGE (VOLTS)

–2

012 345 8

LOAD CURRENT (mA)

SLOPE 150

W

67

Figure 22. Output Voltage versus Load Current

http://onsemi.com

8

Page 9

MC7660

P ACKAGE DIMENSIONS

8–Pin SOIC

PLASTIC PACKAGE

CASE 751–06

ISSUE T

A

E

B

C

A1

D

58

0.25MB

1

H

4

e

M

h

X 45

_

q

C

A

SEATING

PLANE

0.10

L

B

SS

A0.25MCB

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. DIMENSIONS ARE IN MILLIMETER.

3. DIMENSION D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 1.35 1.75

A1 0.10 0.25

B 0.35 0.49

C 0.19 0.25

D 4.80 5.00

E

3.80 4.00

1.27 BSCe

H 5.80 6.20

h

0.25 0.50

L 0.40 1.25

0 7

q

__

http://onsemi.com

9

Page 10

Notes

MC7660

http://onsemi.com

10

Page 11

Notes

MC7660

http://onsemi.com

11

Page 12

MC7660

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich Time)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse Time)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

12

MC7660/D

Loading...

Loading...