Page 1

DATA SHEET

MOS INTEGRA TED CIRCUIT

MC-4R128FKE6D

Direct Rambus DRAM RIMMTM Module

128M-BYTE (64M-WORD x 16-BIT)

Description

The Direct Rambus RIMM module is a general-purpose high-performance memory module subsystem suitable for

use in a broad range of applications including computer memory, personal computers, workstations, and other

applications where high bandwidth and low latency are required.

MC-4R128FKE6D modules consists of four 288M Direct Rambus DRAM (Direct RDRAM) devices (

These are extremely high-speed CMOS DRAMs organized as 16M words by 18 bits. The use of Rambus Signaling

Level (RSL) technology permits 600MHz, 711MHz or 800MHz transfer rates while using conventional system and

board design technologies.

Direct RDRAM devices are capable of sustained data transfers at 1.25 ns per two bytes (10 ns per sixteen bytes).

The architecture of the Direct RDRAM enables the highest sustained bandwidth for multiple, simultaneous,

randomly addressed memory transactions. The separate control and data buses with independent row and column

control yield over 95 % bus efficiency. The Direct RDRAM's 32 banks support up to four simultaneous transactions

per device.

Features

PD488588).

µ

• 184 edge connector pads with 1mm pad spacing

• 128 MB Direct RDRAM storage

• Each RDRAM

• Gold plated contacts

• RDRAMs use Chip Scale Package (CSP)

• Serial Presence Detect support

• Operates from a 2.5 V supply

• Powerdown self refresh modes

• Separate Row and Column buses for higher efficiency

• Over Drive Factor (ODF) support

Document No. E0093N20 (Ver. 2.0)

Date Published June 2002 (K) Japan

URL: http://www.elpida.com

has 32 banks, for 128 banks total on module

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local Elpida Memory, Inc. for

availability and additional information.

Elpida Memory, Inc. i s a joint venture DRAM company of NEC Corporati on and Hi tachi, Ltd.

Elpida Memory,Inc. 2001-2002

Page 2

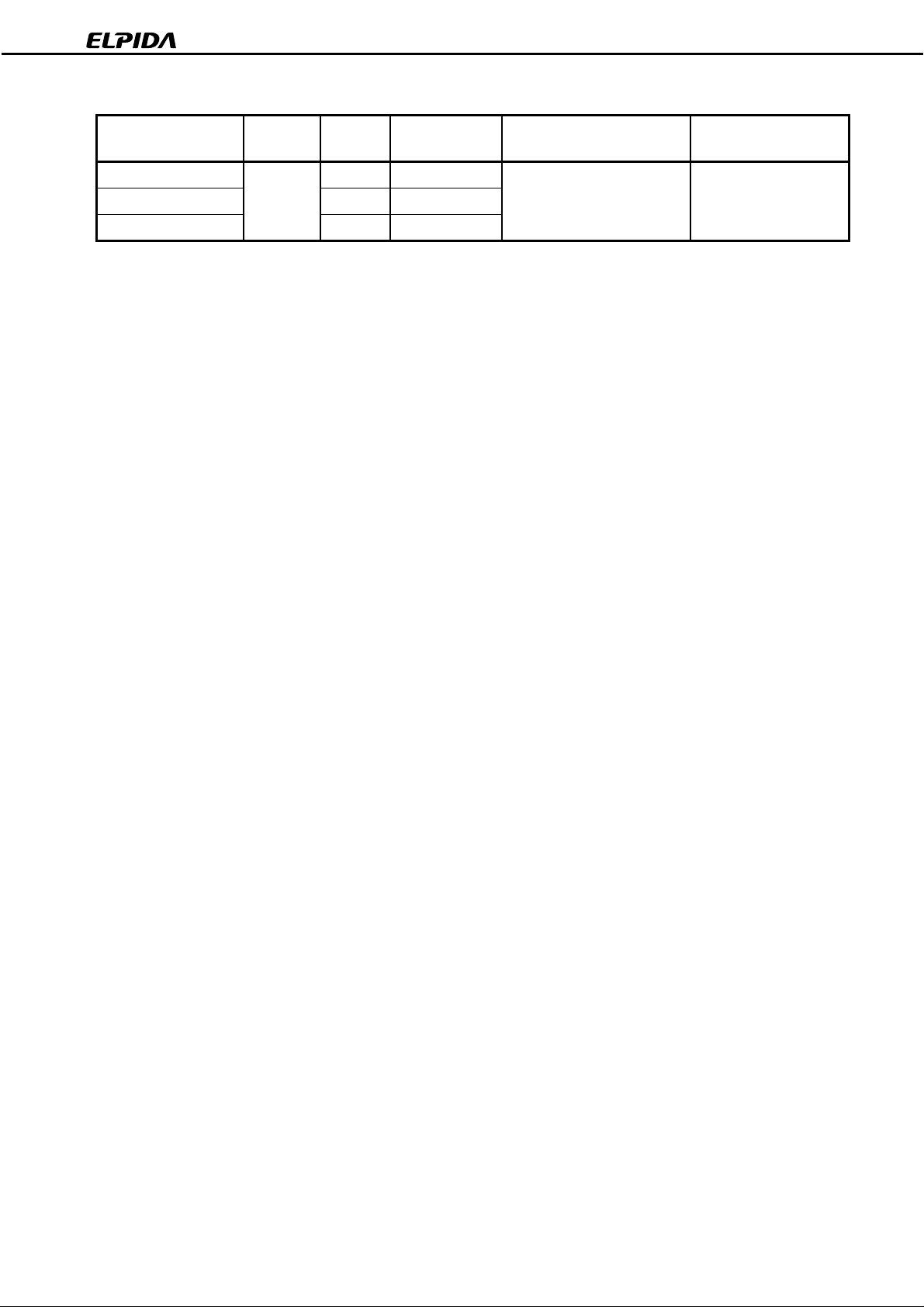

Order information

MC-4R128FKE6D

Part number Organization I/O Freq.

MHz

MC-4R128FKE6D - 845 64M x 16 800 45 184 edge connector pads RIMM 4 pieces of

MC-4R128FKE6D - 745 711 45 with heat spreader

MC-4R128FKE6D - 653 600 53 Edge connector : Gold plated FBGA (µBGA) package

RAS access time

ns

Package Mounted devices

PD488588FF

µ

2

Data Sheet

E0093N20 (Ver. 2.0)

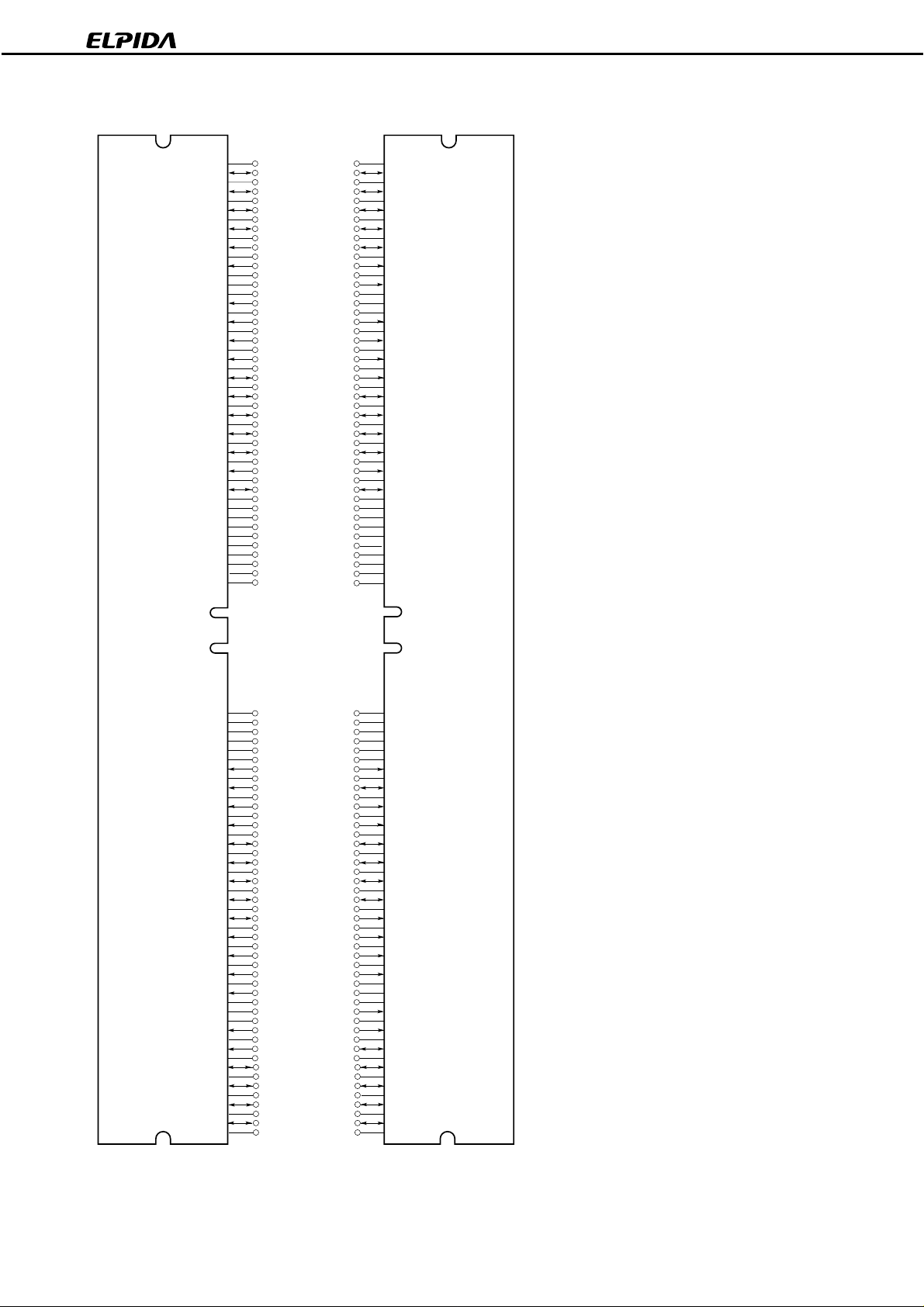

Page 3

Module Pad Configuration

MC-4R128FKE6D

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

B37

B38

B39

B40

B41

B42

B43

B44

B45

B46

B1

B2

B3

B4

B5

B6

B7

B8

B9

GND

LDQA7

GND

LDQA5

GND

LDQA3

GND

LDQA1

GND

LCFM

GND

LCFMN

GND

NC

GND

LROW2

GND

LROW0

GND

LCOL3

GND

LCOL1

GND

LDQB0

GND

LDQB2

GND

LDQB4

GND

LDQB6

GND

LDQB8

GND

LCMD

CMOS

V

SIN

CMOS

V

NC

GND

NC

DD

V

V

DD

NC

NC

NC

NC

GND

LDQA8

GND

LDQA6

GND

LDQA4

GND

LDQA2

GND

LDQA0

GND

LCTMN

GND

LCTM

GND

NC

GND

LROW1

GND

LCOL4

GND

LCOL2

GND

LCOL0

GND

LDQB1

GND

LDQB3

GND

LDQB5

GND

LDQB7

GND

LSCK

V

CMOS

SOUT

V

CMOS

NC

GND

NC

V

V

NC

NC

NC

NC

DD

DD

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

A36

A37

A38

A39

A40

A41

A42

A43

A44

A45

A46

Side B Side A

B47

B48

B49

B50

B51

B52

B53

B54

B55

B56

B57

B58

B59

B60

B61

B62

B63

B64

B65

B66

B67

B68

B69

B70

B71

B72

B73

B74

B75

B76

B77

B78

B79

B80

B81

B82

B83

B84

B85

B86

B87

B88

B89

B90

B91

B92

NC

NC

NC

NC

V

REF

GND

SA0

V

DD

SA1

SV

DD

SA2

V

DD

RCMD

GND

RDQB8

GND

RDQB6

GND

RDQB4

GND

RDQB2

GND

RDQB0

GND

RCOL1

GND

RCOL3

GND

RROW0

GND

RROW2

GND

NC

GND

RCFMN

GND

RCFM

GND

RDQA1

GND

RDQA3

GND

RDQA5

GND

RDQA7

GND

NC

NC

NC

NC

V

REF

GND

SCL

V

SDA

SV

SWP

V

RSCK

GND

RDQB7

GND

RDQB5

GND

RDQB3

GND

RDQB1

GND

RCOL0

GND

RCOL2

GND

RCOL4

GND

RROW1

GND

NC

GND

RCTM

GND

RCTMN

GND

RDQA0

GND

RDQA2

GND

RDQA4

GND

RDQA6

GND

RDQA8

GND

A47

A48

A49

A50

A51

A52

A53

DD

DD

DD

A54

A55

A56

A57

A58

A59

A60

A61

A62

A63

A64

A65

A66

A67

A68

A69

A70

A71

A72

A73

A74

A75

A76

A77

A78

A79

A80

A81

A82

A83

A84

A85

A86

A87

A88

A89

A90

A91

A92

LCFM, LCFMN,

RCFM, RCFMN : Clock from master

LCTM, LCTMN,

RCTM, RCTMN : Clock to master

LCMD, RCMD : Serial Command Pad

LROW2 - LROW0,

RROW2 - RROW0 : Row bus

LCOL4 - LCOL0,

RCOL4 - RCOL0 : Column bus

LDQA8 - LDQA0,

RDQA8 - RDQA0 : Data bus A

LDQB8 - LDQB0,

RDQB8 - RDQB0 : Data bus B

LSCK, RSCK : Clock input

SA0 - SA2 : Serial Presence Detect Address

SCL, SDA : Serial Presence Detect Clock

SIN, SOUT : Serial I/O

SVDD : SPD Voltage

SWP : Serial Presence Detect Write Protect

V

: Supply voltage for serial pads

CMOS

VDD : Supply voltage

V

: Logic threshold

REF

GND : Ground reference

NC : These pads are not connected

Data Sheet

E0093N20 (Ver. 2.0)

3

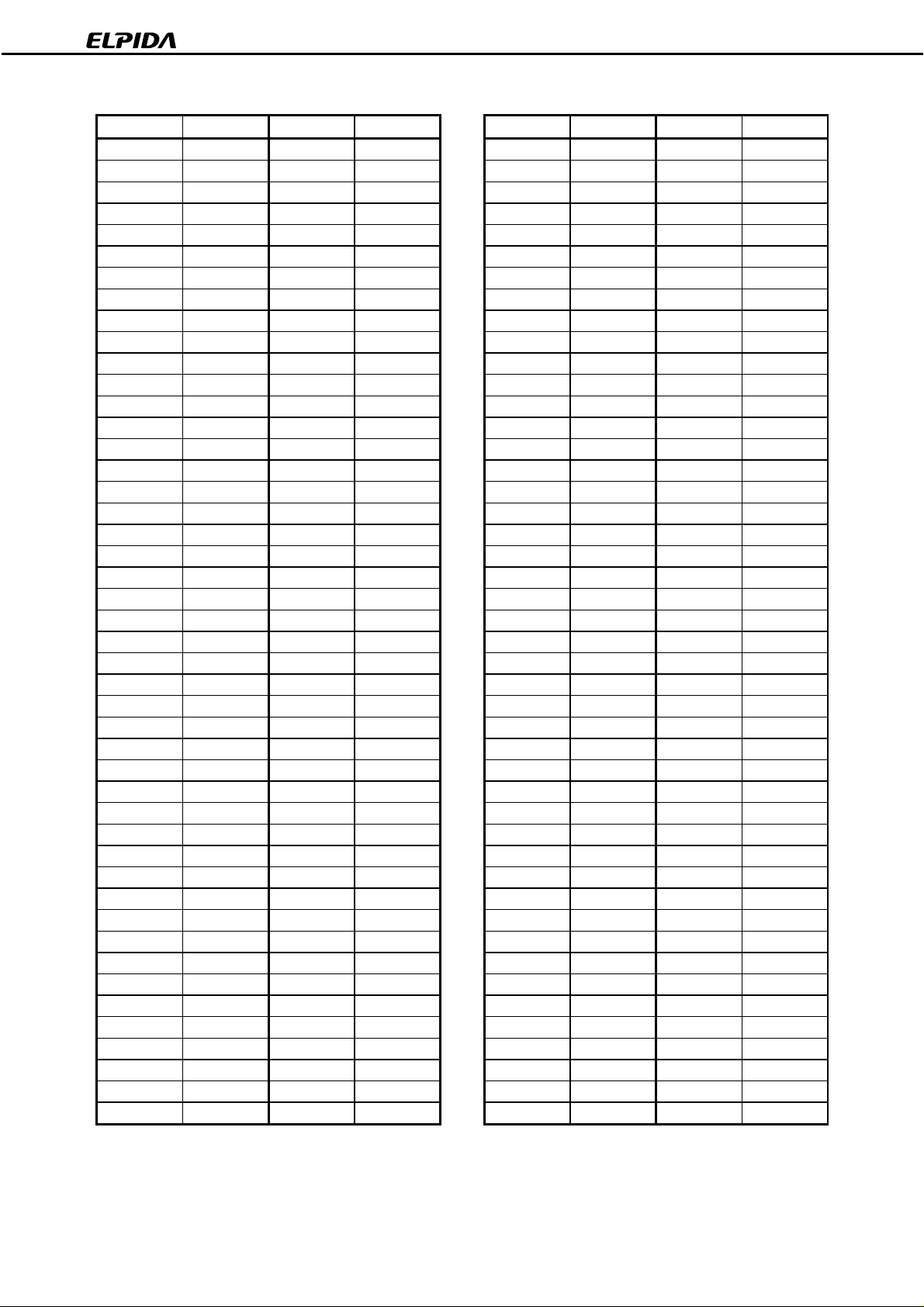

Page 4

MC-4R128FKE6D

Module Pad Names

Pad Signal Name Pad Signal Name Pad Signal Name Pad Signal Name

A1 GND B1 GND A47 NC B47 NC

A2 LDQA8 B2 LDQA7 A48 NC B48 NC

A3 GND B3 GND A49 NC B49 NC

A4 LDQA6 B4 LDQA5 A50 NC B50 NC

A5 GND B5 GND A51 V

REF

B51 V

A6 LDQA4 B6 LDQA3 A52 GND B52 GND

A7 GND B7 GND A53 SCL B53 SA0

A8 LDQA2 B8 LDQA1 A54 VDD B54 VDD

A9 GND B9 GND A55 SDA B55 SA1

A10 LDQA0 B10 LCFM A56 SVDD B56 SVDD

A11 GND B11 GND A57 SWP B57 SA2

A12 LCTMN B12 LCFMN A58 VDD B58 VDD

A13 GND B13 GND A59 RSCK B59 RCMD

A14 LCTM B14 NC A60 GND B60 GND

A15 GND B15 GND A61 RDQB7 B61 RDQB8

A16 NC B16 LROW2 A62 GND B62 GND

A17 GND B17 GND A63 RDQB5 B63 RDQB6

A18 LROW1 B18 LROW0 A64 GND B64 GND

A19 GND B19 GND A65 RDQB3 B65 RDQB4

A20 LCOL4 B20 LCOL3 A66 GND B66 GND

A21 GND B21 GND A67 RDQB1 B67 RDQB2

A22 LCOL2 B22 LCOL1 A68 GND B68 GND

A23 GND B23 GND A69 RCOL0 B69 RDQB0

A24 LCOL0 B24 LDQB0 A70 GND B70 GND

A25 GND B25 GND A71 RCOL2 B71 RCOL1

A26 LDQB1 B26 LDQB2 A72 GND B72 GND

A27 GND B27 GND A73 RCOL4 B73 RCOL3

A28 LDQB3 B28 LDQB4 A74 GND B74 GND

A29 GND B29 GND A75 RROW1 B75 RROW0

A30 LDQB5 B30 LDQB6 A76 GND B76 GND

A31 GND B31 GND A77 NC B77 RROW2

A32 LDQB7 B32 LDQB8 A78 GND B78 GND

A33 GND B33 GND A79 RCTM B79 NC

A34 LSCK B34 LCMD A80 GND B80 GND

A35 V

CMOS

B35 V

CMOS

A81 RCTMN B81 RCFMN

A36 SOUT B36 SIN A82 GND B82 GND

A37 V

CMOS

B37 V

CMOS

A83 RDQA0 B83 RCFM

A38 NC B38 NC A84 GND B84 GND

A39 GND B39 GND A85 RDQA2 B85 RDQA1

A40 NC B40 NC A86 GND B86 GND

A41 VDD B41 VDD A87 RDQA4 B87 RDQA3

A42 VDD B42 VDD A88 GND B88 GND

A43 NC B43 NC A89 RDQA6 B89 RDQA5

A44 NC B44 NC A90 GND B90 GND

A45 NC B45 NC A91 RDQA8 B91 RDQA7

A46 NC B46 NC A92 GND B92 GND

REF

4

Data Sheet

E0093N20 (Ver. 2.0)

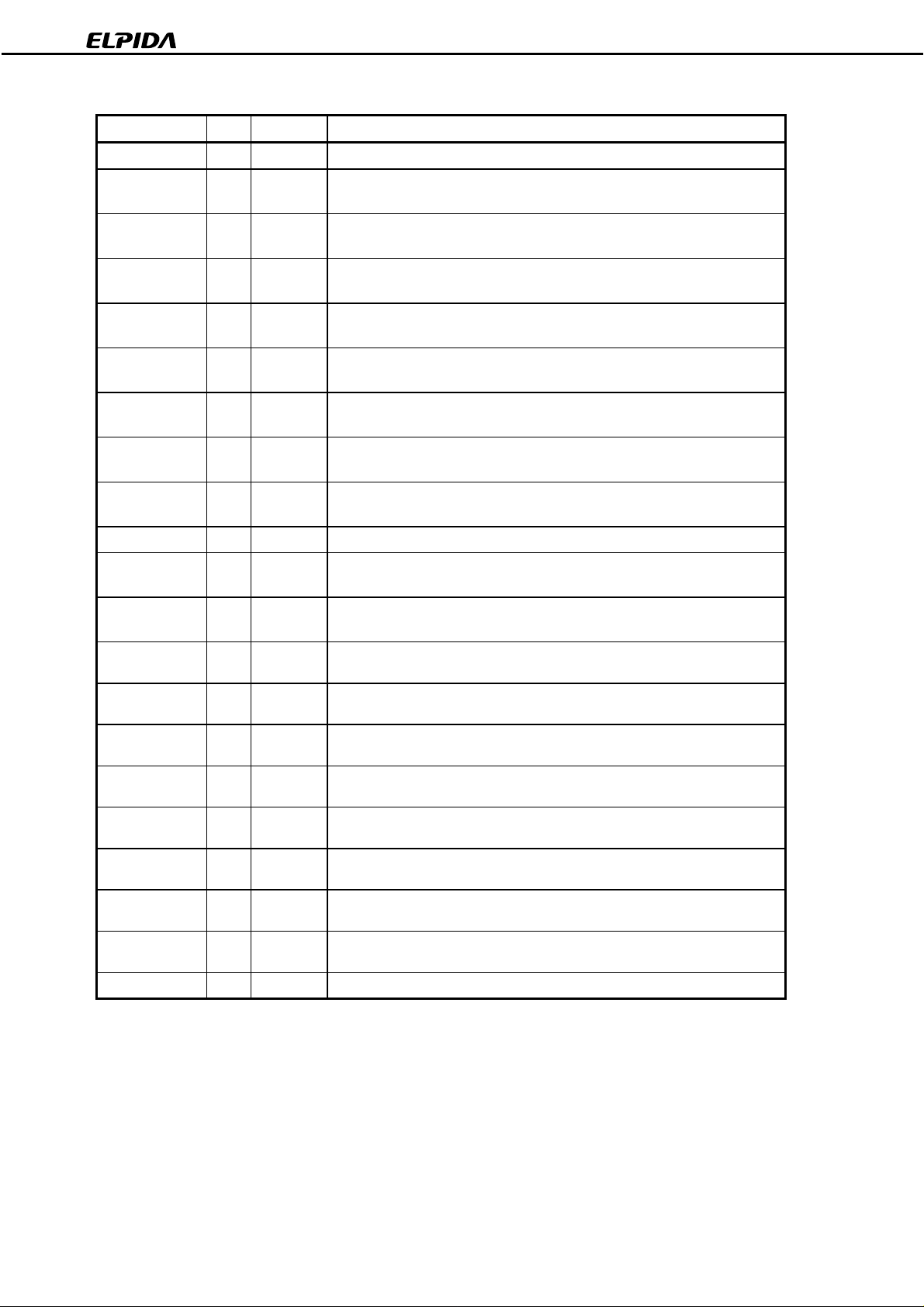

Page 5

MC-4R128FKE6D

Module Connector Pad Description (1/2)

Signal I/O Type Description

GND – – Ground reference for RDRAM core and interface. 72 P CB connector pads.

LCFM I RSL Clock from master. Interface clock used for receiving RSL si gnal s from the

Channel. Positive polarit y.

LCFMN I RSL Clock from master. Interface clock used for receiving RSL si gnal s from the

Channel. Negative polarity.

LCMD I V

LCOL4..LCOL0 I RSL Column bus. 5-bit bus containing control and addres s information for column

LCTM I RSL Clock to master. Interface cl ock used for transmitti ng RS L signals to the

LCTMN I RSL Clock to master. Interface cl ock used for transmitti ng RS L signals to the

LDQA8..LDQA0 I/O RSL Data bus A. A 9-bit bus c arryi ng a byte of read or write data between the Channel

LDQB8..LDQB0 I/O RSL Data bus B. A 9-bit bus c arryi ng a byte of read or write data between the Channel

LROW2..LROW0 I RSL Row bus. 3-bit bus containing control and address inform ation for row accesses.

LSCK I V

NC – – These pads are not connected. These 24 connector pads are reserved for future

RCFM I RSL Clock from master. Interface clock used for receiving RSL signals from the

RCFMN I RSL Clock from master. Interface cloc k used for receiving RSL signals from the

RCMD I V

RCOL4..RCOL0 I RSL Column bus. 5-bit bus containing control and address inf ormation for column

RCTM I RSL Clock to m aster. Interface clock us ed for transmitting RSL signals to the

RCTMN I RSL Clock to m aster. Interface clock used for transmitting RSL si gnal s to the

RDQA8..RDQA0 I/O RSL Data bus A. A 9-bit bus carrying a byte of read or write data between the Channel

RDQB8..RDQB0 I/O RSL Data bus B. A 9-bit bus carrying a byte of read or write data between the Channel

RROW2..RROW0 I RSL Row bus. 3-bit bus containing control and address information for row accesses.

Serial Command used t o read from and write to the control registers. Also used

CMOS

for power management.

accesses.

Channel. Positive polarit y.

Channel. Negative polarity.

and the RDRAM. LDQA8 is non-functi onal on modules with x16 RDRAM devices.

and the RDRAM. LDQB8 is non-functi onal on modules with x16 RDRAM devices.

Serial clock input. Clock source used to read from and write to the RDRAM

CMOS

control registers.

use.

Channel. Positive polarit y.

Channel. Negative polarity.

Serial Command Input used to read from and write to the control registers. Also

CMOS

used for power management.

accesses.

Channel. Positive polarit y.

Channel. Negative polarity.

and the RDRAM. RDQA8 is non-functi onal on modules with x16 RDRAM devices.

and the RDRAM. RDQB8 is non-functi onal on modules with x16 RDRAM devices.

Data Sheet

E0093N20 (Ver. 2.0)

5

Page 6

MC-4R128FKE6D

(2/2)

Signal I/O Type Description

RSCK I V

Serial clock input. Clock source used to read from and write to the RDRAM

CMOS

control registers.

SA0 I SVDD Serial Presence Detect Address 0.

SA1 I SVDD Serial Presence Detect Address 1.

SA2 I SVDD Serial Presence Detect Address 2.

SCL I SVDD Serial Presence Detect Clock.

SDA I/O SVDD Serial Presence Detect Data (Open Collector I/O).

SIN I/O V

Serial I/O for reading from and writing to the control registers. Attaches to SIO0

CMOS

of the first RDRAM on the module.

SOUT I/O V

Serial I/O for reading from and writing to the control registers. Attaches to SIO1

CMOS

of the last RDRAM on the modul e.

SVDD — — SPD Voltage. Used for signals SCL, SDA, S WP, SA0, SA1 and SA2.

SWP I SVDD Serial Presence Detect Write Protect (active high). When low, the SPD can be

written as well as read.

V

— — CMOS I/O Voltage. Us ed for signals CMD, SCK, SIN, SOUT.

CMOS

VDD — — Supply voltage for the RDRA M core and i nterface logic.

REF

V

— — Logic t hreshold reference voltage for RSL signals.

6

Data Sheet

E0093N20 (Ver. 2.0)

Page 7

Block Diagram

V

REF

LCMD

LSCK

SIN

LDQB 7

LDQB 8

DQB 7

DQB 8

SIO 0

SIO 1

SCK

CMD

REF

V

DQB 7

DQB 8

SIO 0

SIO 1

SCK

CMD

REF

V

LDQB 5

LDQB 6

DQB 5

DQB 6

DQB 5

DQB 6

LDQB 3

LDQB 4

DQB 3

DQB 4

DQB 3

DQB 4

LDQB 1

LDQB 2

DQB 1

DQB 2

DQB 1

DQB 2

LDQB 0

LCOL 0

COL 0

DQB 0

COL 0

DQB 0

LCOL 2

LCOL 1

COL 2

COL 1

COL 2

COL 1

LCOL 4

LCOL 3

COL 4

COL 3

COL 4

COL 3

LROW 1

LROW 0

ROW 1

ROW 0

U1

ROW 1

ROW 0

U2

LROW 2

LCTMN

CTMN

ROW 2

CTMN

ROW 2

LCTM

CTM

CTM

LCFMN

LCFM

CFM

CFMN

CFM

CFMN

LDQA 1

LDQA 0

DQA 1

DQA 0

DQA 1

DQA 0

LDQA 3

LDQA 2

DQA 3

DQA 2

DQA 3

DQA 2

MC-4R128FKE6D

LDQA 8

LDQA 7

LDQA 6

LDQA 5

LDQA 4

DQA 5

DQA 4

DQA 5

DQA 4

DQA 7

DQA 6

DQA 7

DQA 6

DQA 8

DQA 8

V

CMOS

V

DD

RSCK

RCMD

SOUT

DQB 7

DQB 8

SIO 0

SIO 1

SCK

CMD

REF

V

DQB 7

DQB 8

SIO 0

SIO 1

SCK

CMD

REF

V

RDQB 7

RDQB 8

DQB 5

DQB 6

DQB 5

DQB 6

RDQB 5

RDQB 6

DQB 3

DQB 4

DQB 3

DQB 4

RDQB 3

RDQB 4

DQB 1

DQB 2

DQB 1

DQB 2

RDQB 1

RDQB 2

SCL

SWP

47 kΩ

COL 0

DQB 0

COL 0

DQB 0

RCOL 0

RDQB 0

COL 2

COL 1

COL 2

COL 1

RCOL 2

RCOL 1

COL 3

COL 3

RCOL 3

SCL

WP

A0

SA0

ROW 0

COL 4

U3

ROW 0

COL 4

U4

RROW 0

RCOL 4

SV

DD

V

CC

U0

A1 A2

SA1 SA2

ROW 2

ROW 1

ROW 2

ROW 1

RROW 2

RROW 1

SDA

CTM

CTMN

CTM

CTMN

RCTM

RCTMN

CFM

CFMN

CFM

CFMN

RCFM

RCFMN

DQA 0

DQA 0

RDQA 0

SDA

DQA 2

DQA 1

DQA 2

DQA 1

RDQA 2

RDQA 1

DQA 4

DQA 3

DQA 4

DQA 3

RDQA 4

RDQA 3

DQA 6

DQA 5

DQA 6

DQA 5

RDQA 6

RDQA 5

DQA 8

DQA 7

DQA 8

DQA 7

RDQA 8

RDQA 7

SERIAL PD

Remarks 1. Rambus Channel signals form a loop through the RIMM module, with the exception of the SIO chain.

2. See Serial Presence Detection Specification for information on the SPD device and its contents.

Data Sheet

E0093N20 (Ver. 2.0)

7

Page 8

MC-4R128FKE6D

Electrical Specification

Absolute Maximum Ratings

Symbol Parameter MIN. MAX. Unit

I,ABS

V

Voltage applied to any RSL or CMOS signal pad with respect to GND −0.3 VDD + 0.3 V

DD,ABS

V

Voltage on VDD with respect to GND −0.5 VDD + 1.0 V

STORE

T

Storage temperature −50 +100 °C

Caution Exposing the device to stress above those listed in Absolute Maximum Ratings could cause

permanent damage. The device is not meant to be operated under conditions outside the limits

described in the operational section of this specification. Exposure to Absolute Maximum Rating

conditions for extended periods may affect device reliability.

DC Recommended Electrical Conditions

Symbol Parameter and conditions MIN. MAX. Unit

VDD Supply voltage 2.50 − 0.13 2.50 + 0.13 V

V

CMOS I/O power supply at pad 2.5V controllers 2.5 − 0.13 2.5 + 0.25 V

CMOS

1.8V controllers 1.8 − 0.1 1.8 + 0.2

REF

V

Reference voltage 1.4 − 0.2 1.4 + 0.2 V

IL

V

RSL input low voltage V

VIH RSL input high voltage V

IL,CMOS

V

CMOS input low voltage −0.3 0.5V

IH,CMOS

V

CMOS input hi gh vol tage 0.5V

OL,CMOS

V

CMOS output low voltage, I

OH,CMOS

V

CMOS output high voltage, I

REF

I

V

SCK,CMD

I

CMOS input leakage current, (0 ≤ V

SIN,SOUT

I

CMOS input leakage current, (0 ≤ V

REF

current, V

REF,MAX

OL,CMOS

= 1 mA

OH,CMOS

= −0.25 mA V

−40.0 +40.0

≤ VDD) −40.0 +40.0

CMOS

≤ VDD) −10.0 +10.0

CMOS

REF

− 0.5 V

REF

+ 0.2 V

+0.25 V

CMOS

—

− 0.3

CMOS

REF

− 0.2 V

REF

+ 0.5 V

− 0.25 V

CMOS

+ 0.3 V

CMOS

0.3 V

—

V

A

µ

A

µ

A

µ

8

Data Sheet

E0093N20 (Ver. 2.0)

Page 9

MC-4R128FKE6D

AC Electrical Specifications

Symbol Parameter and Conditions MIN. TYP. MAX. Unit

Z Module Impedance of RSL signals 25.2 28.0 30.8 Ω

Module Impedance of SCK and CMD signal s 23.8 28.0 32.2

Average clock delay from finger to finger of all RS L clock nets 1.28 ns

PD

T

(CTM, CTMN,CFM, and CFMN)

Note1,2

PD

∆T

PD-CMOS

∆T

PD- SCK,CMD

∆T

Vα/V

IN

Propagation delay variation of RSL si gnal s with respect to TPD

Propagation delay variation of SCK si gnal with respect to an average clock

Note1

delay

Propagation delay variation of CMD signal with respect to SCK s i gnal −200 +200 ps

Attenuation Limit -845 12.0 %

-745 12.0

-653 10.5

Forward crosstalk coeffi cient -845 2.0 %

IN

VXF/V

(300ps input rise time 20% - 80%) -745 2.0

-653 2.0

Backward crosstalk coefficient -845 1.5 %

IN

VXB/V

(300ps input rise time 20% - 80%) -745 1.5

-653 1.5

RDC DC Resistance Limit -845 0.6 Ω

-745 0.6

-653 0.6

−21 +21 ps

−250 +250 ps

or Average clock delay is defined as the average delay from finger to finger of all RSL clock nets (CTM,

Notes 1. T

PD

CTMN, CFM, and CFMN).

2. If the RIMM module meets the following specification, then it is compliant to the specification.

If the RIMM module does not meet these specifications, then the specification can be adjusted by the

Specification” table.

“Adjusted ∆T

PD

PD

Adjusted ∆∆∆∆T

Specification

Symbol Parameter and conditions Adjusted MIN./MAX. Absolut e Unit

MIN. MAX.

Note

PD

Propagation delay variation of RSL signals with respect to TPD +/− [17+(18*N*∆Z0)]

∆T

−30 +30 ps

Note N = Number of RDRAM devices installed on the RIMM module.

MIN. Z0) / (MIN. Z0)

∆Z0 = delta Z0% = (MAX. Z0

−

(MAX. Z0 and MIN. Z0 are obtained from the loaded (high impedance) impedance coupons of all RSL layers

on the module.)

Data Sheet

E0093N20 (Ver. 2.0)

9

Page 10

RIMM Module Current Profile

IDD

DD1

I

DD2

I

DD3

I

DD4

I

DD5

I

DD6

I

One RDRAM in Read

One RDRAM in Read

One RDRAM in Read

One RDRAM in Write, bal ance in NAP mode

One RDRAM in Write, bal ance in Standby mode

One RDRAM in Write, bal ance in Active mode

RIMM module power conditions

Note2

, balance in NAP mode

Note2

, balance in Standby mode

Note2

, balance in Active mode

Note1

MC-4R128FKE6D

MAX. Unit

-845 642.6 mA

-745 592.6

-653 532.6

-845 900 mA

-745 820

-653 730

-845 1035 mA

-745 955

-653 865

-845 732.6 mA

-745 682.6

-653 632.6

-845 990 mA

-745 910

-653 830

-845 1125 mA

-745 1045

-653 965

Notes 1. Actual power will depend on individual RDRAM component specifications, memory controller and usage

patterns. Power does not include Refresh Current.

2.

I/O current is a function of the % of 1’s, to add I/O power for 50 % 1’s for a x16 need to add 257 mA or 290

mA for x18 ECC module for the following : V

= 2.5 V, V

DD

= 1.8 V, V

TERM

= 1.4 V and V

REF

DIL

= V

− 0.5 V.

REF

10

Data Sheet

E0093N20 (Ver. 2.0)

Page 11

Package Drawings

184 EDGE CONNECTOR PADS RIMM (SOCKET TYPE) (1/2)

EEPROM

R

A (AREA B)

288 M Direct RDRAM

MC-4R128FKE6D

M1 (AREA B)

P

ON M

K

G

S

L

H

B

detail of A part

W

Y

X

A

A1 (AREA A)

R1.00

Q

B

I

J

M2 (AREA A)

T

FDE

C

ITEM MILLIMETERS

133.35 TYP.

A

133.35±0.13

A1

55.175

B

1.00±0.10

B1

11.50

detail of B part

C1

B1

Z

R1.00

C

C1

D

E

F

G

H

I

J

K

L

M

M1

M2

N

O

P

Q

R

S

T

W

X

Y

Z

3.00±0.10

45.00

32.00

45.00

5.675

47.625

25.40

47.625

6.35

1.00 TYP.

34.925±0.13

15.145

19.78

29.21

17.78

4.00±0.10

R 2.00

3.00±0.10

φ

2.44

1.27±0.10

0.80±0.05

2.99

0.30

2.00±0.10

ECA-TS2-0012-02

Data Sheet

E0093N20 (Ver. 2.0)

11

Page 12

184 EDGE CONNECTOR PADS RIMM (SOCKET TYPE) (2/2)

A

MC-4R128FKE6D

B

E

Pad A1 Pad A92

C C

D

ITEM

A

B

C

D

E

F

G

H

DESCRIPTION

PCB length

PCB height

Center-center pad width from pad A1 to A46,

A47 to A92, B1 to B46 or B47 to B92

Spacing from PCB left edge to connector key notch

Spacing from contact pad PCB edge

to side edge retainer notch

PCB thickness

Heat spreader thickness from PCB surface (one side) to

heat spreader top surface

RIMM thickness

MIN.

133.22

34.795

44.95

-

-

1.17

-

-

TYP.

133.35

34.925

45.00

55.175

17.78

1.27

-

-

MAX.

133.48

35.055

45.05

-

-

1.37

3.09

4.46

G

F

H

UNIT

mm

mm

mm

mm

mm

mm

mm

mm

12

Data Sheet

E0093N20 (Ver. 2.0)

ECA-TS2-0012-02

Page 13

MC-4R128FKE6D

CAUTION FOR HANDLING MEMORY MODULES

When handling or inserting memory modules, be sure not to touch any components on the modules, such as

the memory ICs, chip capacitors and chip resistors. It is necessary to avoid undue mechanical stress on

these components to prevent damaging them.

In particular, do not push module cover or drop the modules in order to protect from mechanical defects,

which would be electrical defects.

When re-packing memory modules, be sure the modules are not touching each other.

Modules in contact with other modules may cause excessive mechanical stress, which may damage the

modules.

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR MOS DEVICES

Exposing the MOS devices to a strong electric field can cause destruction of the gate

oxide and ultimately degrade the MOS devices operation. Steps must be taken to stop

generation of static electricity as much as possible, and quickly dissipate it, when once

it has occurred. Environmental control must be adequate. When it is dry, humidifier

should be used. It is recommended to avoid using insulators that easily build static

electricity. MOS devices must be stored and transported in an anti-static container,

static shielding bag or conductive material. All test and measurement tools including

work bench and floor should be grounded. The operator should be grounded using

wrist strap. MOS devices must not be touched with bare hands. Similar precautions

need to be taken for PW boards with semiconductor MOS devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS DEVICES

No connection for CMOS devices input pins can be a cause of malfunction. If no

connection is provided to the input pins, it is possible that an internal input level may be

generated due to noise, etc., hence causing malfunction. CMOS devices behave

differently than Bipolar or NMOS devices. Input levels of CMOS devices must be fixed

high or low by using a pull-up or pull-down circuitry. Each unused pin should be connected

to V

DD

or GND with a resistor, if it is considered to have a possibility of being an output

pin. The unused pins must be handled in accordance with the related specifications.

MDE0202

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Power-on does not necessarily define initial status of MOS devices. Production process

of MOS does not define the initial operation status of the device. Immediately after the

power source is turned ON, the MOS devices with reset function have not yet been

initialized. Hence, power-on does not guarantee output pin levels, I/O settings or

contents of registers. MOS devices are not initialized until the reset signal is received.

Reset operation must be executed immediately after power-on for MOS devices having

reset function.

Data Sheet

E0093N20 (Ver. 2.0)

CME0107

13

Page 14

MC-4R128FKE6D

Rambus, RDRAM and the Rambus logo are registered trademarks of Rambus Inc.

RIMM, SO-RIMM, RaSer and QRSL are trademarks of Rambus Inc.

µµµµ

BGA is a registered trademark of Tessera, Inc

The information in this document is subject to change without notice. Before using this document, confirm that this is the latest version.

No part of this document may be copied or reproduced in any form or by any means without the prior

written consent of Elpida Memory, Inc.

Elpida Memory, Inc. does not assume any liability for infringement of any intellectual property rights

(including but not limited to patents, copyrights, and circuit layout licenses) of Elpida Memory, Inc. or

third parties by or arising from the use of the products or information listed in this document. No license,

express, implied or otherwise, is granted under any patents, copyrights or other intellectual property

rights of Elpida Memory, Inc. or others.

Descriptions of circuits, software and other related information in this document are provided for

illustrative purposes in semiconductor product operation and application examples. The incorporation of

these circuits, software and information in the design of the customer's equipment shall be done under

the full responsibility of the customer. Elpida Memory, Inc. assumes no responsibility for any losses

incurred by customers or third parties arising from the use of these circuits, software and information.

[Product applications]

Elpida Memory, Inc. makes every attempt to ensure that its products are of high quality and reliability.

However, users are instructed to contact Elpida Memory's sales office before using the product in

aerospace, aeronautics, nuclear power, combustion control, transportation, traffic, safety equipment,

medical equipment for life support, or other such application in which especially high quality and

reliability is demanded or where its failure or malfunction may directly threaten human life or cause risk

of bodily injury.

[Product usage]

Design your application so that the product is used within the ranges and conditions guaranteed by

Elpida Memory, Inc., including the maximum ratings, operating supply voltage range, heat radiation

characteristics, installation conditions and other related characteristics. Elpida Memory, Inc. bears no

responsibility for failure or damage when the product is used beyond the guaranteed ranges and

conditions. Even within the guaranteed ranges and conditions, consider normally foreseeable failure

rates or failure modes in semiconductor devices and employ systemic measures such as fail-safes, so

that the equipment incorporating Elpida Memory, Inc. products does not cause bodily injury, fire or other

consequential damage due to the operation of the Elpida Memory, Inc. product.

[Usage environment]

This product is not designed to be resistant to electromagnetic waves or radiation. This product must be

used in a non-condensing environment.

If you export the products or technology described in this document that are controlled by the Foreign

Exchange and Foreign Trade Law of Japan, you must follow the necessary procedures in accordance

with the relevant laws and regulations of Japan. Also, if you export products/technology controlled by

U.S. export control regulations, or another country's export control laws or regulations, you must follow

the necessary procedures in accordance with such laws or regulations.

If these products/technology are sold, leased, or transferred to a third party, or a third party is granted

license to use these products, that third party must be made aware that they are responsible for

compliance with the relevant laws and regulations.

M01E0107

Loading...

Loading...