Page 1

MC44605

Product Preview

High Safety, Latched Mode,

GreenLine

PWM Controller

for (Multi)Synchronized

Applications

The MC44605 is a high performance current mode controller that is

specifically designed for off–line converters. This circuit has several

distinguishing features that make it particularly suitable for

multisynchronized monitor applications.

The MC44605 synchronization arrangement enables operation from

16 kHz up to 130 kHz. This product was optimized to operate with

universal mains voltage, i.e., from 80 V to 280 V, and its high current

totem pole output makes it ideally suited for driving a power MOSFET.

The MC44605 protections enable a well–controlled and safe power

management. Four major faults while detected, activate the analogic

counter of a disabling block designed to perform a latched circuit

output inhibition.

Current Mode Controller

• Current Mode Operation up to 250 kHz Output Switching Frequency

• Inherent Feed Forward Compensation

• Latching PWM for Cycle–by–Cycle Current Limiting

• Oscillator with Precise Frequency Control

• Externally Programmable Reference Current

• Secondary or Primary Sensing (Availability of Error Amplifier Output)

• Synchronization Facility

• High Current Totem Pole Output

• V

Undervoltage Lockout with Hysteresis

cc

• Low Output dV/dT for Low EMI Radiations

• Low Start–Up and Operating Current

Safety/Protection Features

• Soft–Start Feature

• Demagnetization (Zero Current Detection) Protection

• Overvoltage Protection Facility against Open Loop

• EHT Overvoltage Protection (E.H.T.OVP): Detection of too High

Synchronization Pulses

• Winding Short Circuit Detection (W.S.C.D.)

• Limitation of the Maximum Input Power (M.P.L.): Calculation of

Input Power for Overload Protection

• Overheating Detection (O.H.D.): to Prevent the Power Switch from

an Excessive Heating

Latched Disabling Mode

• When one of the following faults is detected: EHT overvoltage,

Winding Short Circuit (WSCD), a too high input power (M.P.L.),

power switch overheating (O.H.D.), an analogic counter is activated

• If the counter is activated for a time that is long enough, the circuit

gets definitively disabled. The latch can only be reset by making

decrease the Vcc down to about 3 V, i.e., practically by unplugging or

turning off the SMPS.

This document contains information on a product under development. ON Semiconductor

reserves the right to change or discontinue this product without notice.

http://onsemi.com

MARKING

DIAGRAM

16

PDIP–16

P SUFFIX

16

1

Max Power Limitation

Overheating

Detection

Current Sense Input

Demagnetization

Detection Input

ORDERING INFORMATION

Device Package Shipping

MC44605P PDIP–16 25 Units/Rail

CASE 648

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W= Work Week

PIN CONNECTIONS

V

CC

116

V

2

C

Output

3

Gnd

4

5

6

7

8

(Top View)

* Winding Short Circuit Detection

MC44605P

AWLYYWW

1

R

ref

WSCD* Program

15

Voltage Feedback Input

14

Error Amp Output

13

Disabling Block (C

12

Soft–Start Input

11

Osc Capacitor (CT)

10

Sync and

9

EHTOVP Input

)

ext

Semiconductor Components Industries, LLC, 2000

May, 2000 – Rev. 2

1 Publication Order Number:

MC44605/D

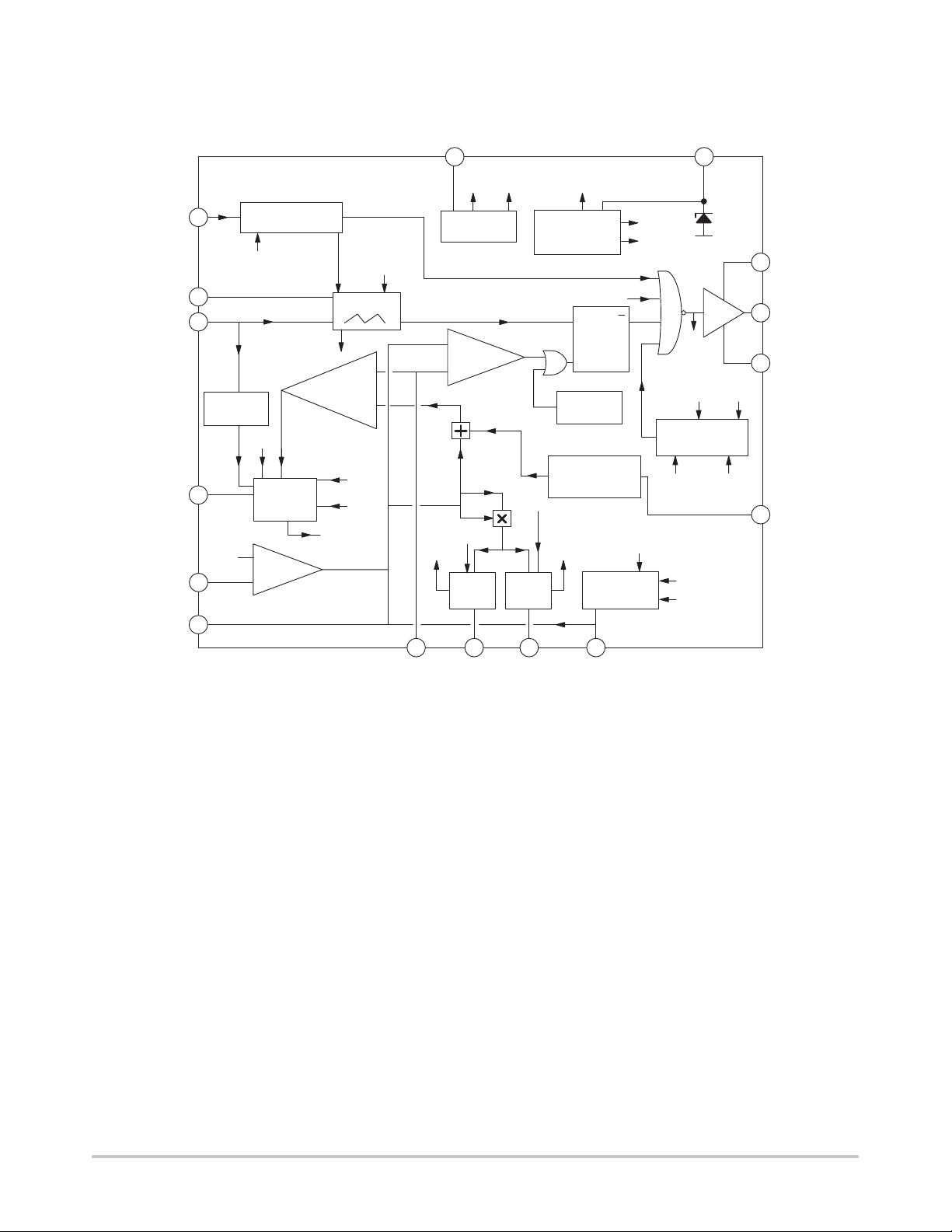

Page 2

MC44605

Block Diagram

Demagnetization

Detection Input

Synchronization

and EHTOVP

Input

Voltage

Feedback

Input

E/A Output

*W.S.C.D. = Winding Short Circuit Detection

8

C

T

10

9

C

12

ext

14

13

Demagnetization

Output

E.H.T.OVP

Block

V

V

ref

Management

CC

V

WSCD

Disabling

Block

+

Error

AMP

–

V

V

DT

Oscillator

Sf

W.S.C.D*

Comparator

dis

MPL

dis

OHD

Dis

out

demag out

I

ref

I

sense

I

Sense

Input

R

ref

16

i

V

ref

ref

Reference

Block

V

S

V

cs

Current

Sense

V

shift

V

cs

Sf

dis

MPL

sense

7 6

V

MPL

block

Maximum

Power

Limitation

2

cs

O.H.D.

block

Heating

Detection

Vccenable

Supply

Initialization

Block

Dis

out

Set

PWM

Latch

Reset

Thermal

Shutdown

V

Level

shift

Programmation

dis

OHD

Soft–Start

115

OverCurrent Soft–Start

Input

Q

UVLO1

UVLO2

I

ref

UVLO2

V

CC

1

18 V

Buffer

V

ref

Over Voltage

Management

V

CC

enable

UVLO1

VCCenable

MC44605

V

CC

15

V

2

C

Output

3

4

Gnd

WSCD

Programmation

http://onsemi.com

2

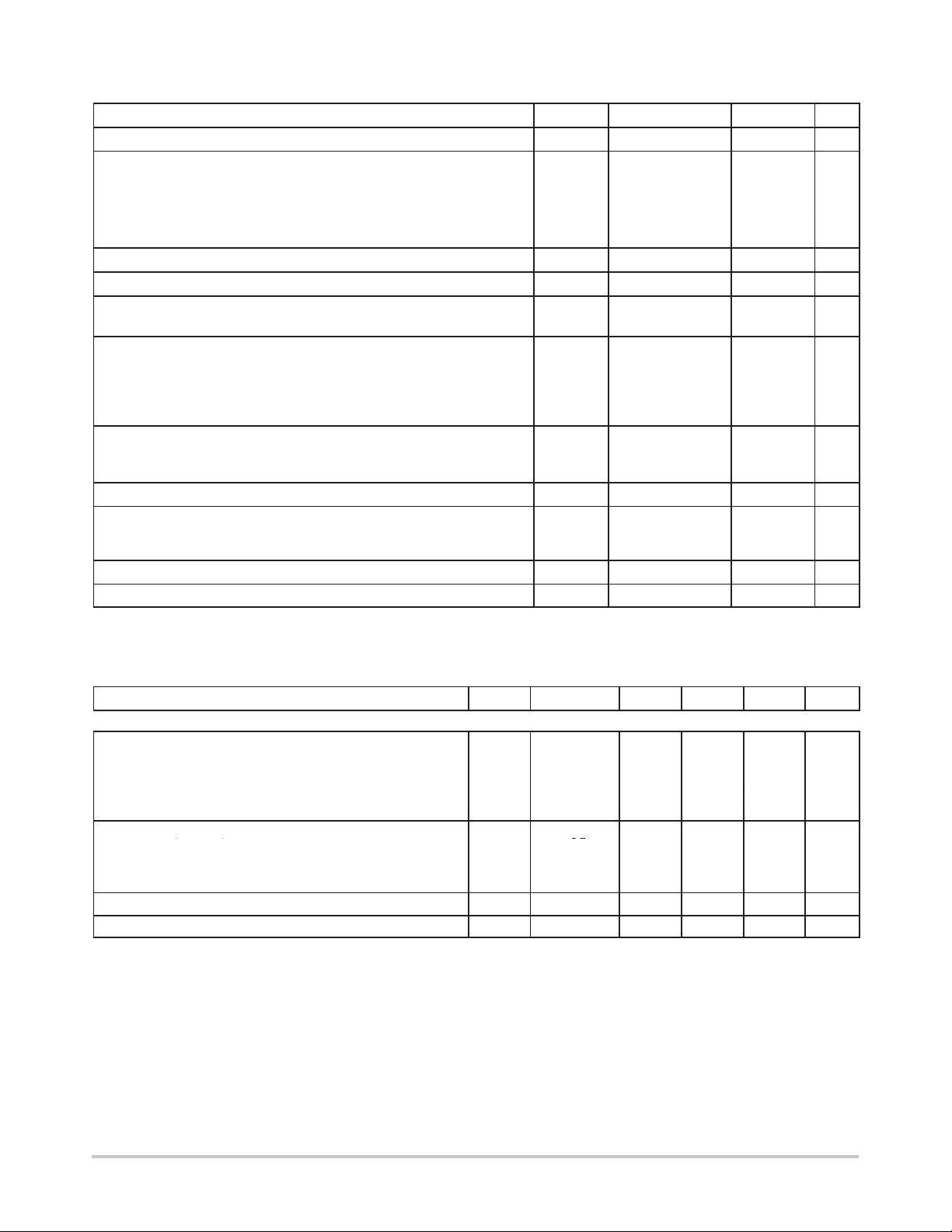

Page 3

MC44605

gg

OL

V

I

A

V

CC

I

Sink

mA

0.1

1.0

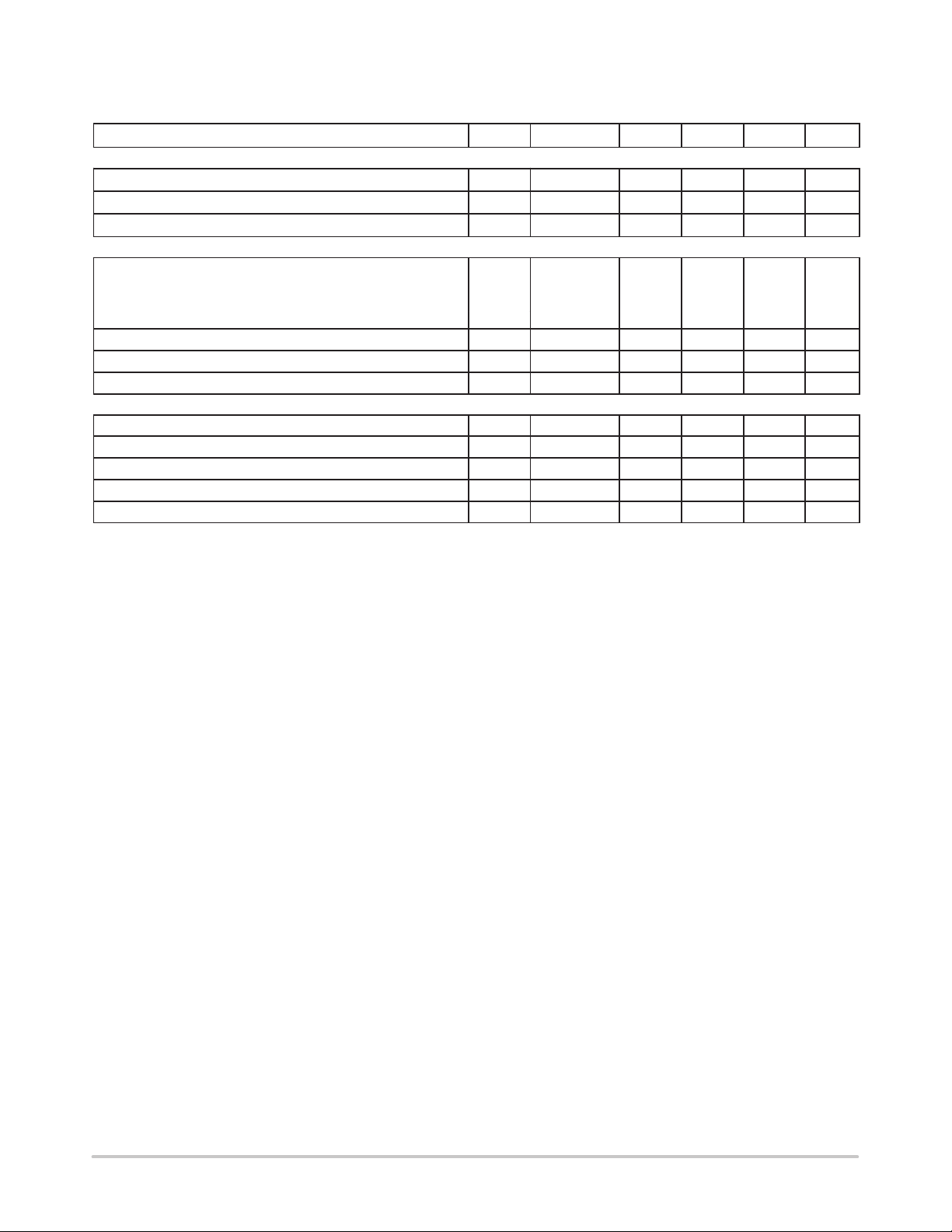

MAXIMUM RATINGS

Rating Pin # Symbol Value Unit

Total Power Supply and Zener Current (ICC + IZ) 40 mA

Output Supply Voltage with Respect to Ground 2

Output Current* 3 mA

Source I

Sink I

Output Energy (Capacitive Load per Cycle) W 5.0 µJ

Soft–Start V

Current Sense, Voltage Feedback, E/A Output, CT, R

WSCD

E.H.T.OVP, Sync Input Current mA

Source 9

Sink 9

Demagnetization Detection Input Current 8 mA

Source I

Sink I

Error Amplifier Output Sink Current 13 I

Power Dissipation and Thermal Characteristics

Maximum Power Dissipation at TA = 85°C P

Thermal Resistance, Junction–to–Air R

Operating Junction Temperature T

Operating Ambient Temperature T

*Maximum package power dissipation must be observed.

, MPL, OHD, C

ref

ext

,

1

6

6

V

C

V

CC

O(Source)

O(Sink)

SS

V

in

I

sync (Source)

I

(Source)

EHT

I

sync (Sink)

I

EHT (Sink)

demag–ib (Source)

demag–ib (Sink)

E/A (Sink)

D

θJA

J

A

18 V

–750

750

–0.3 to 2.2 V V

–0.3 to 5.5 V V

–4.0

10

–4.0

10

20 mA

0.6 W

100 °C/W

150 °C

–25 to +85 °C

ELECTRICAL CHARACTERISTICS (V

values TA = –25° to +85°C unless otherwise noted.) (Note 1.)

Characteristic

OUTPUT SECTION (Note 2.)

Output Voltage* 3 V

Low Level Drop Voltage (I

High Level Drop Voltage(I

Output Voltage During Initialization Phase 3 V

VCC = 0 to 1.0 V, I

= 1.0 to 5.0 V,

CC

= 5.0 to 13 V,

Output Voltage Rising Edge Slew–Rate (CL = 1.0 nF, TJ = 25°C) dVo/dT – 300 – V/µs

Output Voltage Falling Edge Slew–Rate (CL = 1.0 nF, TJ = 25°C) dVo/dT – –300 – V/µs

*VC must be greater than 5.0 V .

1. Adjust VCC above the start–up threshold before setting to 12 V . Low duty cycle pulse techniques are used during test to maintain junction

temperature as close to ambient as possible.

2. No output signal when the Error Amplifier output is in Low State, i.e., when for instance, VFB = 2.7 V.

Sink

Sink

Sink

(I

Sink

Source

(I

Source

= 10 µA

= 100 µ

= 1.0

= 100 mA)

= 500 mA)

= 200 mA)

= 500 mA)

and VC = 12 V, R

CC

= 10 kΩ, CT = 2.2 nF, for typical values TA = 25°C, for min/max

ref

Pin # Symbol Min Typ Max Unit

V

OL

V

OH

OL

–

–

–

–

– –

–

–

1.0

1.4

1.5

2.0

0.1

1.2

2.0

2.0

2.7

1.0

1.0

V

http://onsemi.com

3

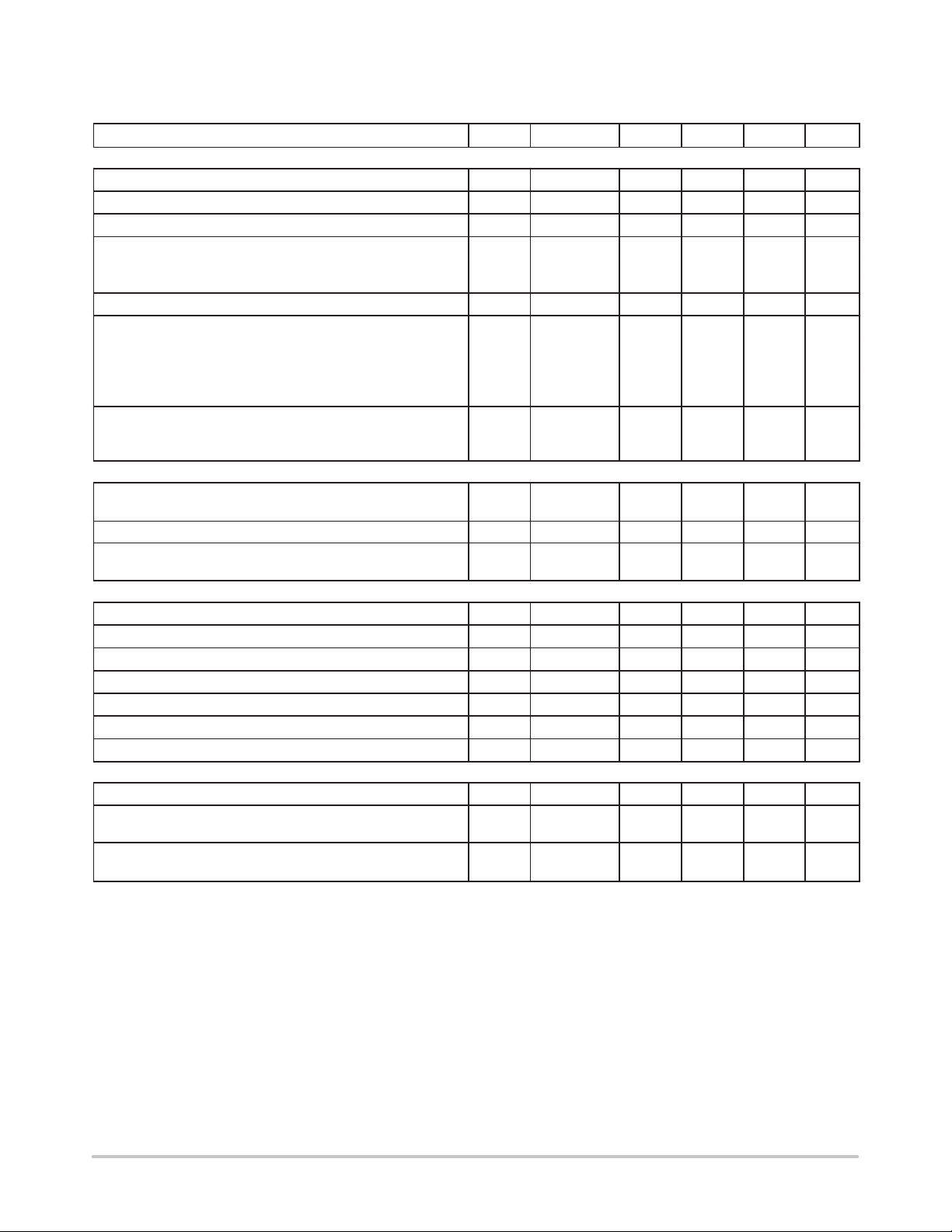

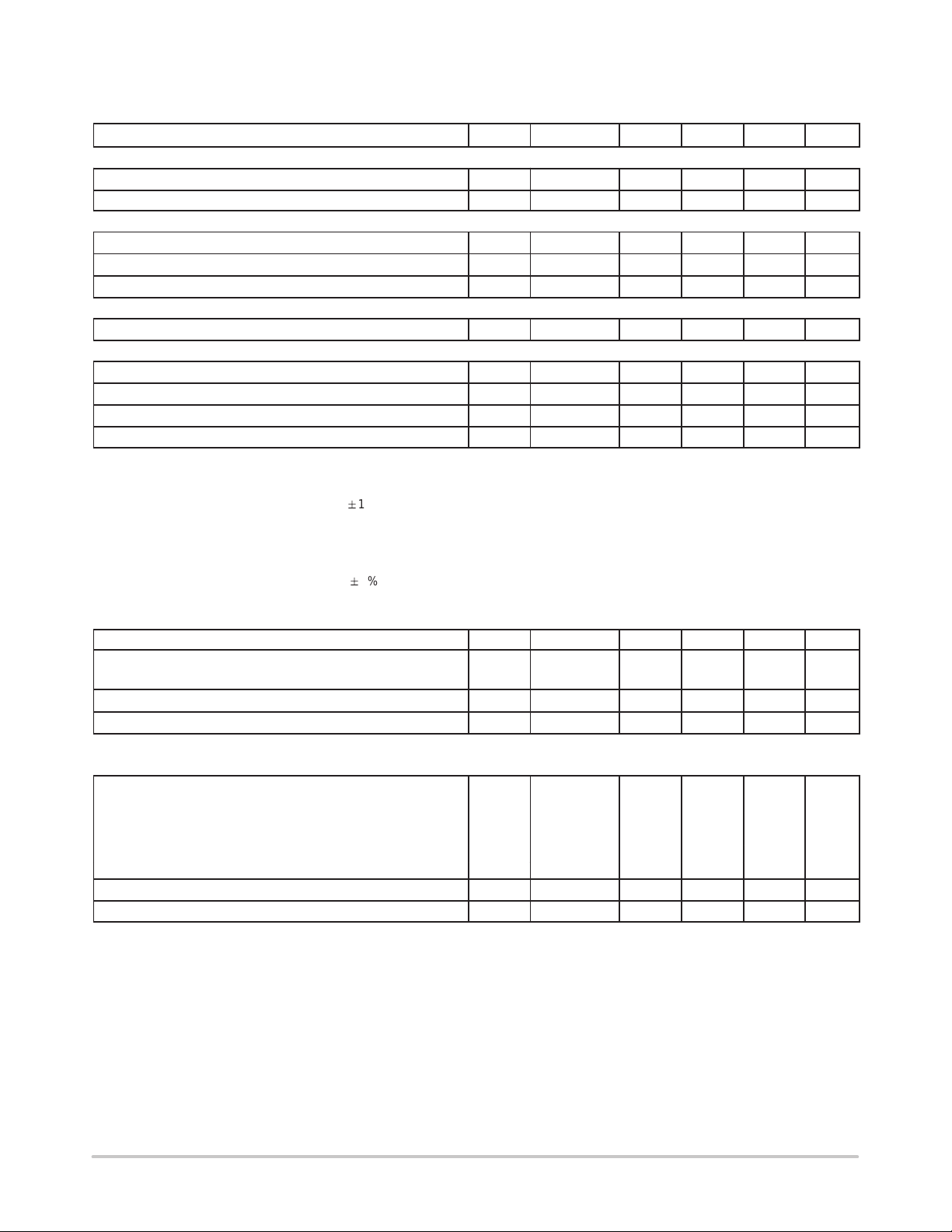

Page 4

MC44605

ELECTRICAL CHARACTERISTICS (V

values TA = –25° to +85°C unless otherwise noted.) (Note 1.)

Characteristic

ERROR AMPLIFIER SECTION

Voltage Feedback Input (V

Input Bias Current (VFB = 2.5 V) 14 I

Open Loop Voltage Gain (V

Unity Gain Bandwidth BW MHz

TJ = 25°C – – –

TA = –25° to +85°C – – 5.5

Voltage Feedback Input Line Regulation (VCC = 10 V to 15 V) V

Output Current 13 mA

Sink (V

TA = –25° to +85°C

Source (V

TA = –25° to +85°C

Output Voltage Swing 13 V

High State (I

Low State (I

CURRENT SENSE SECTION

Maximum Current Sense Input Threshold

(V

Feedback (pin14)

Input Bias Current 7 I

Propagation Delay (Current Sense Input to Output at VTH of

MOS transistor = 3.0 V)

OSCILLATOR AND SYNCHRONIZATION SECTION

Frequency (TA = –25° to +85°C)

Frequency Change with Voltage (VCC = 10 V to 15 V) ∆F

Frequency Change with Temperature (TA = –25° to +85°C) ∆F

Ratio Charge Current/Reference Current (TA = –25° to +85°C) I

Free Mode Oscillator Ratio = I

Synchronization Input Threshold Voltage 9 V

Negative Clamp Level (I

UNDERVOLTAGE LOCKOUT SECTION

Start–up Threshold 1 V

Disable Voltage After Threshold T urn–On (UVLO 1)

(TA = –25° to +85°C)

Disable Voltage After Threshold T urn–On (UVLO 2)

(TA = –25° to +85°C)

1. Adjust VCC above the start–up threshold before setting to 12 V . Low duty cycle pulse techniques are used during test to maintain junction

temperature as close to ambient as possible.

= 1.5 V, VFB = 2.7 V)

E/A out

= 5.0 V, VFB = 2.3 V)

E/A out

E/A out (source)

E/A out (sink)

= 2.3 V and V

syncth–in

= 2.5 V) 14 V

E/A out

= 2.0 V to 4.0 V) A

E/A out

= 0.5 mA, VFB = 2.3 V) V

= 0.33 mA, VFB = 2.7 V) V

Soft–Start (pin11)

discharge

= 2.0 mA) NEG–SYNC –0.65 –0.5 –0.34 V

and VC = 12 V, R

CC

/(I

discharge

= 1.2 V)

+ I

charge

= 10 kΩ, CT = 2.2 nF, for typical values TA = 25°C, for min/max

ref

Pin # Symbol Min Typ Max Unit

FB

FB–ib

VOL

FBline–reg

I

Sink

I

Source

OH

OL

7 V

) D 72 75 78 %

1 V

1 V

cs–th

cs–ib

t

PLH(In/Out)

F

OSC

/∆V – 0.05 – %/V

OSC

/∆T – 0.05 – %/°C

OSC

charge/Iref

syncth

stup–th

disable1

disable2

2.4 2.5 2.6 V

–2.0 –0.6 – µA

65 70 – dB

–10 – 10 mV

2.0 12 –

–2.0 – –0.2

5.5 6.5 7.5

– 1.0 1.1

0.96 1.0 1.04 V

–10 –2.0 – µA

– 120 200 ns

16 – 20 kHz

0.39 – 0.48 –

–250 –200 –150 mV

13.6 14.5 15.4 V

8.3 – 9.6 V

7.0 7.5 8.0 V

http://onsemi.com

4

Page 5

MC44605

ELECTRICAL CHARACTERISTICS (V

values TA = –25° to +85°C unless otherwise noted.) (Note 1.)

Characteristic

REFERENCE SECTION

Reference Output Voltage (VCC = 10 V to 15 V) 16 V

Reference Current Range (I

Reference Voltage Over I

DEMAGNETIZATION DETECTION SECTION (Note 2.)

Demagnetization Detect Input 8

Demagnetization Comparator Threshold (V

Propagation Delay (Input to Output, Low to High) t

Input Bias Current (V

Minimum Off–Time when the pin 8 is grounded T

Negative Clamp Level (I

Positive Clamp Level (I

SOFT–START SECTION (Note 3.)

Ratio Charge Current/I

Discharge Current (V

Clamp Level V

Circuit Inhibition Threshold* V

VCS Soft–Start Clamp Level (R

*The circuit is shutdown if the Soft–Start pin voltage is lower than this level.

1. Adjust VCC above the start–up threshold before setting to 12 V . Low duty cycle pulse techniques are used during test to maintain junction

temperature as close to ambient as possible.

2. This function can be inhibited by connecting pin 8 to GND. In this case, there is a minimum off–time equal to T

3. The MC44605 can be shut down by connecting Soft–Start pin (pin 11) to Ground.

soft–start

= V

ref

ref/Rref

Range ∆V

ref

= 65 mV) I

demag

= –2.0 mA) CLVL–neg –0.50 –0.38 –0.25 V

demag

= +2.0 mA) CLVL–pos 0.50 0.72 0.85 V

demag

(TA = –25° to +85°C) I

ref

= 1.0 V) I

soft–start

and VC = 12 V, R

CC

, R = 5.0 k to 25 kΩ) 16 I

Decreasing) V

pin9

= 5 kΩ) V

= 10 kΩ, CT = 2.2 nF, for typical values TA = 25°C, for min/max

ref

Pin # Symbol Min Typ Max Unit

PLH(In/Out)

ref

ref

ref

demag–th

demag–lb

DEM–GND

ss–ch/Iref

discharge

SS–CLVL

SSinhi

CSsoft–start

2.4 2.5 2.6 V

–500 – –100 µA

–40 – 40 mV

50 65 80 mV

– 0.5 – µs

–0.5 – – µA

1.5 3.0 4.5 µs

0.37 – 0.43 –

1.5 5.0 – mA

2.2 2.4 2.6 V

30 – 150 mV

0.45 0.5 0.55 V

DEM–GND

.

http://onsemi.com

5

Page 6

MC44605

ELECTRICAL CHARACTERISTICS (V

values TA = –25° to +85°C unless otherwise noted.) (Note 1.)

Characteristic

OVERVOLTAGE SECTION

Propagation Delay (VCC > 18.1 V to V

Protection Level on VCC (TA = –25° to +85°C) VCC

EHT OVP SECTION (Note 2.)

Negative Clamp Level (I

EHT OVP Input Threshold V

EHT OVP Input Bias Current (V

WINDING SHORT CIRCUIT DETECTION SECTION

WSCD Threshold with I

MPL & OHD SECTION

MPL Parameter* Γ

MPL Comparator Threshold** V

OHD Parameter*** Γ

OHD Comparator Threshold**** V

*This parameter is defined in the MPL §. This parameter is obtained by measuring the MPL pin average current and dividing this result by the

corresponding squared VCS, the measured frequency value and the CT value deducted from the measured frequency value.

Measurement conditions: V

is typically equal to 18 kHz – R

**The MPL comparator output is Dis

***This parameter is defined in the OHD §. This parameter is obtained by measuring the OHD pin average current and dividing this result by

the corresponding squared VCS value and multiplying it by the R

Measurement conditions: V

is typically equal to 18 kHz – R

****The OHD comparator output is Dis

DISABLING BLOCK SECTION

Delay Pulse Width

Ratio (EHTOVP and WSCD Disabling Capacitor Charge

Current)I

Ratio (MPL and OHD Disabling Capacitor Charge Current)I

Minimum VCC Value Enabling the Disabling Block Latch* V

*Once a fault detection activated it, the Disabling Block Latch gets reset when the VCC becomes lower than this threshold.

TOTAL DEVICE

Power Supply Current

Power Supply Zener Voltage (ICC = 35 mA) V

Thermal Shutdown – – 155 – °C

*Refer to Note 1.

**This consumption is measured while the circuit is inhibited by the Definitive Latch.

1. Adjust VCC above the start–up threshold before setting to 12 V . Low duty cycle pulse techniques are used during test to maintain junction

temperature as close to ambient as possible.

2. This function can be inhibited by connecting pin 9 to GND. In this case, the synchronization block is inhibited too and the MC44605 works

in free mode.

ref

Startup–Up (VCC = 5.0 V with VCC increasing) – 0.35 0.55

Startup–Up (VCC = 9.0 V with VCC increasing) – 0.35 0.55

Startup–Up (VCC = 12 V with VCC increasing) – 0.35 0.55

Operating TA = –25°C to +85°C* – 20 25

Disabling Mode (VCC = 6.0 V)** – – 0.55

synch–in

= 200 µA Vshift 70 100 120 mV

pin15

Feedback(pin 14)

Feedback(pin 14)

out

= –2.0 mA) NEG–SYNC –0.65 –0.5 –0.35 V

EHT OVP(pin 9)

= 10 kΩ "1%, CT = 2.2 nF).

ref

MPL

= 10 kΩ "1%, CT = 2.2 nF).

ref

OHD

and VC = 12 V, R

CC

Low)

= 0 V) 9 I

= 2.3 V , V

.

= 2.3 V , V

.

soft–start(pin 11)

soft–start(pin 11)

ref

= 10 kΩ, CT = 2.2 nF, for typical values TA = 25°C, for min/max

ref

Pin # Symbol Min Typ Max Unit

T

PHL(In/Out)

prot

ref

EHTOVP

MPL

MPL–th

OHD

OHD–th

= 0.5 V and pins 7, 8, and 9 connected to GND (the working frequency

value.

ref

= 0.5 V and pins 7, 8, and 9 connected to GND (the working frequency

T

WSCD

I

Dis–H/Iref

I

Dis–L/Iref

CCDis

I

CC

Z

1.0 – 4.0 µs

15.9 – 18.1 V

7.0 7.4 7.8 V

–5.0 – 0 µA

0.185 0.240 0.295 V

2.4 2.5 2.6 V

1.15 1.50 1.85 V

2.4 2.5 2.6 V

– 4.0 – µs

90 100 110 %

2.7 3.1 3.5 %

1.0 – 5.0 V

18.5 – – V

–1

–1

mA

http://onsemi.com

6

Page 7

MC44605

Pin Name Pin Description

1 V

2 V

3 Output The output current capability is suited for driving a power MOSFET.

4 GND The ground pin is a single return typically connected back to the power

5 Maximum Power Limitation This block enables to estimate the input power. When this calculated power

6 Over–Heating Detection This block estimates the MOSFET heating. When this calculated heating is

7 Current Sense Input A voltage proportional to the current flowing into the power switch is

8 Demagnetization Detection A voltage delivered by an auxiliary transformer winding provides to the

9 Synchronization and E.H.T.OVP Input Activating the synchronization input pin with a pulse higher or equal to the

10 Oscillator Capacitor C

11 Soft–Start A capacitor connected to this pin can temporary reduce the maximum

12 C

13 E/A Output The error amplifier output is made available for loop compensation.

14 Voltage Feedback This is the inverting input of the Error Amplifier. It can be connected to the

15 Winding Short Circuit Detection

16 R

CC

C

T

(Disabling Block) When a too high synchronization pulse voltage (E.H.T.OVP) or a winding

ext

Programmation

ref

This pin is the positive supply of the IC.

The output high state, VOH, is set by the voltage applied to this pin. With a

separate connection to the power source, it gives the possibility to set by

means of an external resistor the output source current at a different value

than the sink current.

source. It is used as control and power ground.

is detected as too high, a fault information is sent to the disabling block in

order to definitively disable the circuit.

too high, the device gets definitively disabled (disabling block action).

connected to this input. The PWM latch uses this information to terminate

the conduction of the output buffer. A maximum level of 1 V allows to limit

the inductor current.

demagnetization pin an indication of the magnetization state of the flyback

energy reservoir. A zero voltage detection corresponds to a complete core

demagnetization. The demagnetization detection prevents the oscillator

from a re–start and so the circuit from a new conduction phase, if the

fly–back is not in a dead–time state. This function can be inhibited by

connecting Pin 8 to GND but in this case, there is a minimum off–time

typically equal to 3 µs.

negative threshold (typically –200 mV) allows the next switching period to

be reinitialized. The oscillator is free when connecting Pin 9 to GND.

When the E.H.T.OVP pin receives a voltage that is greater than 7.5 V, the

disabling block C

disabled if the C

incorporated to detect and disable the device when the synchronization

pulses are too high.

The free mode oscillator frequency is programmed by the capacitor C

choice together with the R

pin 10 and GND, generates the oscillator sawtooth.

inductor peak current. By this way, a soft–start can be performed. By

connecting pin 11 to Ground, the MC44605 is shut down.

short circuit (WSCD) is detected, the capacitor C

a current source I

is charged using I

the circuit is definitively disabled. Then, to restart, the converter must be

switched off in order to make VCC decrease down to about 0 V.

Switching Mode Power Supply output through an optical (or else) feedback

loop or to the subdivided VCC voltage in case of primary sensing technic.

The W.S.C.D. block is incorporated to detect the transformer Winding Short

Circuits. This function is performed by detecting the inductor overcurrents

thanks to a comparator which threshold is programmable to be well

adapted to any application.

The R

perform the precise oscillator waveform. The current range goes from 100

µA up to 500 µA.

value fixes the internal reference current that is particularly used to

ref

capacitor is charged so that the circuit gets definitively

ext

voltage becomes higher than V

ext

resistance value. CT, connected between

ref

. In the case of a MPL or OHD fault detection, C

Dis– H

Dis–L

. If the C

capacitor voltage gets higher than V

ext

. This block is

ref

is charged using

ext

T

ref

ext

,

http://onsemi.com

7

Page 8

MC44605

Summary of the Main Design Equations

The following table consists of equations enabling to dimension a multisynchronized SMPS operating in discontinuous

mode.

Lp

d

Pon

max

(V

DS

(VD)max

max

max

)

max

(ni)

Pin

+

Ipk

max

+

1

+

3

+ǒ2Ǹ

max

AL+

max

2Ǹ·Vac

ƪ

Ǹ

2

2 Pin

+

Ǹ

Ǹ

Pin

max

Rdson

+ǒ2Ǹ

+N

(N n

Pout

+

min

·Vac

min

max

2 Pin

L fsync

Lp

Vac

Vac

max

Vac

n

Vout

L

P

Vout

max

η

min

Ipk

max

N

NVo

)

NVo

fsync

max

min

fsync

max

Ǔ

)(N

Ǔ

Ipk

2

)

ƫ

max

2

)

max

2

max

d

Vout)

Vout

max

Pout

The maximum input power Pin

by the efficiency (η). In this kind of application, the efficiency is generally

taken equal to 80%.

The inductor value Lp must be chosen lower than Lp

this value (to optimize the application design–in).

In effect, if Lp was higher than Lp

working could not be guaranteed (in some cases, the demagnetization

phase would not be finished while a new conduction phase should start to

follow the synchronization).

Ipk

when the power to transfer is maximum at the minimum synchronization

frequency (60 W output, 30 kHz in the proposed application).

d

input voltage when the power demand is maximum while the

synchronization frequency also is maximum.

Pon

Ipk

This conduction losses estimation enables to dimension the power Mosfet.

(V

In fact, this calculation does not take into account the turnings off spikes.

So, it is necessary to take a margin of at least about 50 V.

(VD)max is the maximum voltage the high voltage secondary diode must

be able to face. Because of the turning off spikes, a margin must also be

taken.

(AL) and (ni) are the magnetic parameters.

(ni)

saturated when the peak current is high.

(AL) is the ferrite constant that links the primary inductor value to the

squared number of primary turns: Lp = AL x n

is the maximum power the load may draw in normal working.

max

is easily deducted by dividing Pout

max

or ideally equal to

max

, a synchronized and discontinuous

max

is the maximum inductor peak current. This current is obtained

max

is the maximum duty cycle. The duty cycle is maximum at the lowest

max

is the maximum Mosfet on–time losses that are proportional to

max

, d

max

DS

max

and Rdson (on–time Mosfet resistor).

max

)max is the maximum voltage the power switch must be able to face.

must not exceed the ferrite (ni). Otherwise, the transformer may get

2

.

p

max

Error Amplifier

A fully compensated Error Amplifier with access to the

inverting input and output is provided. It features a typical

DC voltage gain of 70 dB. The non inverting input is

internally biased at 2.5 V and is not pinned out. The

converter output voltage is typically divided down and

monitored by the inverting input. The maximum input bias

current with the inverting input at 2.5 V is –2.0 µA. This can

cause an output voltage error that is equal to the product of

the input bias current and the equivalent input divider source

resistance.

http://onsemi.com

Compensation

R

FB

C

f

R

8

+

1.0 mA

13

R

f

2.5 V

14

Voltage

Feedback

Input

R

1

2

Figure 1. Error Amplifier Compensation

Error

Amplifier

MC44605

From Power Supply Output

2R

R

1.0 V

Gnd

Current

Sense

Comparator

4

Page 9

MC44605

The Error Amp Output (Pin 13) is provided for external

loop compensation. The output voltage is offset by two

diodes drops ([1.4 V) and divided by three before it

connects to the inverting input of the Current Sense

Comparator. This guarantees that no drive pulses appear at

the Source Output (Pin 3) when Pin 13 is at its lowest state

(VOL). This occurs when the power supply is operating and

the load is removed, or at the beginning of a soft–start

interval. The Error Amp minimum feedback resistance is

limited by the amplifier’s minimum source current (0.2 mA)

and the required output voltage (VOH) to reach the current

sense comparator’s 1.0 V clamp level:

R1(min)

(3 1V))1.4 V

+

0.2 mA

+

22 kΩ

Current Sense Comparator and PWM Latch

The MC44605 operates as a current mode controller. The

circuit uses a current sense comparator to compare the

inductor current to the threshold level established by the

Error Amplifier output (Pin 13). When the current reaches

the threshold, the current sense comparator terminates the

output switch conduction that has been initiated by the

oscillator, by resetting the PWM Latch. Thus the error signal

controls the peak inductor current on a cycle–by–cycle

basis. This configuration ensures that only one single pulse

appears at the Source Output during the appropriate

oscillator cycle.

V

in

V

C

14

R

3

Current

Sense

7

2

C

Q1

R

3

R

R

S

V

demag out

Thermal

Protection

UVLO

Dis

out

VS

Current Sense

Comparator

S

Q

R

PWM

Latch

Substrate

Figure 2. Output Totem Pole

The inductor current is converted to a voltage by inserting

the ground referenced sense resistor RS in series with the

power switch Q1.

This voltage is monitored by the Current Sense Input

(Pin 7) and compared to a level derived from the Error Amp

output. The peak inductor current under normal operating

conditions is controlled by the voltage at Pin 13 where:

Ipk[

V

(pin13)

*

3 R

1.4 V

S

The Current Sense Comparator threshold is internally

clamped to 1.0 V. Therefore the maximum peak switch

current is:

I

pk(max)

+

1V

R

S

Undervoltage Lockout Section

As depicted in Figure 3, an undervoltage lockout has been

incorporated to guarantee that the IC is fully functional

before allowing the system working.

In effect, the VCC is connected to the non inverting input

of a comparator that has an upper threshold equal to 14,5 V

(typical V

V

disable 2

) and a lower one equal to 7.5 V (typical

stup–th

). This hysteresis comparator enables or disables

the reference block that generates the voltage and current

sources required by the system.

This block particularly, produces V

I

that is determined by the resistor R

ref

(pin 16 voltage) and

ref

connected between

ref

pin 16 and the ground:

V

+

1

V

7.5 V

C

V

disable1

9.0 V

ref

where V

R

ref

V

ref enable

C

START–UP

0

disable

UVLO1

STAR T–UP

14.5 V

(to SOFTSTAR T)

Figure 3. VCC Management

+

ref

10

UVLO1

2.5 V (typically)

Reference Block:

Voltage and Current

Sources Generator

(V

, I

ref

ref

MC44605

R

ref

Pin 16

, ...)

V

CC

(Pin 1)

I

ref

In addition to this, VCC is compared to a second threshold

level that is nearly equal to 9 V (V

disable1

) so that a signal

UVLO1 is generated to reset the soft start block and so, to

disable the output stage (refer to the Soft–Start §) as soon as

VCC becomes lower than V

disable 1

. In this way, the circuit

is reset and made ready for a next start–up, before the

reference block is disabled (refer to Figure 3). Thus, finally

the upper limit for the minimum normal operating voltage

http://onsemi.com

9

Page 10

MC44605

is 9.4 V (maximum value of V

hysteresis is 4.2 V. [(V

stup–th)min

disable 1

) and so the minimum

= 13.6 V].

The large hysteresis and the low start–up current of the

MC44605 make it ideally suited for off–line converter

applications where efficient bootstrap start–up techniques

are required.

Soft–Start Control Section

The Vcs value is clamped down to the pin 11 voltage.

So, if a capacitor is connected to this pin, its voltage

increases slowly at the start–up (the capacitor is charged by

an internal current source 0.4 I

). So, Vcs is limited during

ref

the start–up and then a soft–start is performed.

This pin can be used to inhibit the circuit by applying a

voltage that is lower than V

(refer to page 4).

SSinhi

Particularly , the MC44605 can be shutdown by connecting

the soft–start pin to ground.

As soon as V

V

disable1

down to V

), a signal UVLO1 is generated until the Vcc falls

dis2

is detected (that is Vcc lower than

dis1

(refer to the undervoltage lockout section §).

During the delay between the disable1 and the disable2,

using a transistor controlled by UVLO1, the pin 11 voltage

is made equal to zero in order to make the soft–start

arrangement ready to work for the next re–start.

V

ref

Vcs

Output

Inhibition

SSlnhi

Pin 11

Soft

Start

Capacitor

0.4 I

2.4 VD

Z

Figure 4. Soft–Start

ref

UVLO1

V

MC44605

Oscillator Section (Figures 5 & 5b)

The oscillator and synchronization behavior is

represented in Figure 5b.

The MC44605 oscillator achieves four functions:

— it fixes the free mode frequency

— it takes into account the synchronization signal

— it does not allow a new power switch conduction if the

flyback is not in a dead–time state when the circuit

works in demagnetization mode (pin 8 connected)

— it builds the Sf pulse required by the MPL block

During the operating mode, the oscillator sawtooth can

vary between a valley value (1.6 V typically) and a peak one

(3.6 V typically) and presents three distinct phases:

— the CT charge

— the CT discharge

— the phase during which the oscillator voltage is

maintained equal to its valley value. This happens at

the end of a discharge cycle when the synchronization

or demagnetization condition does not allow a new C

charge phase. During this sequence, I

compensates the charge current I

REGUL

charge

.

The oscillator has two working modes:

— a free one when there is no synchronization

— a synchronized one.

In the free working, the oscillator grows up from its valley

value to its peak one for the charge phase and when once the

peak value is reached, a discharge sequence makes the C

voltage decrease down to its valley value. When the

decrease phase is finished, a new charge cycle occurs if the

demagnetization condition is achieved (VDT high).

Otherwise there is a REGUL phase until VDT gets high.

In the synchronized mode, the charge cycle is only

allowed when the synchronization signal gets high while a

dead time has been detected (VDT high). This charge phase

is stopped when the synchronization signal has got low and

when the oscillator voltage is higher than V

int

, the

intermediary voltage level used to generate the calibrated

pulse Sf by comparing the CT voltage to this threshold. So,

when these two conditions are performed, a discharge

sequence is set until the oscillator voltage is equal to its

valley value. Then, the CT voltage is maintained constant

thanks to the “REGUL” arrangement until the next

synchronization pulse.

In both cases, during the charge phase, a signal VS is

generated. When Sf becomes high. VS gets high and remains

in this state until the PWN latch is set of Sf is low. Then, V

keeps low until the next Sf high level. This oscillator

behavior is obtained using the process described in

Figure 5b.

T

T

S

http://onsemi.com

10

Page 11

Inductor

current

V

DT

MC44605

a – Free mode

Oscillator

Sf

Output

Synchro

input

V

int

b – Synchronized mode

Inductor

current

V

DT

Oscillator

Sf

Output

V

int

Figure 5b. Oscillator Behavior

http://onsemi.com

11

Page 12

MC44605

In effect, the output of the latch L1 is:

— high during the oscillator capacitor charge and during

the REGUL phase

— low for the oscillator capacitor discharge

Now , the latch L2 is set when the L1 output is high and the

synchronization condition is performed (that is: sync = 1 –

free mode or synchro signal high state) and during the

dead–time (VDT high). So, this latch is set for the CT charge.

On the other hand, this latch is reset by the signal used to

reset L1. Consequently, it is reset at the end of the charge

phase.

So, in any case, QL2 is:

— high during the CT charge cycle

— low in the other cases

Thus, this latch enables to obtain a signal that is high for

the charge phase and low in the other cases, whatever the

mode (synchronized or free) and whatever the

synchronization pulses width (higher than the delay

necessary for the oscillator to reach its intermediary value or

lower than this delay) in the synchronized mode.

That is why:

— the discharge current source must be connected to the

oscillator capacitor when QL1 is low. The condition

(CT voltage higher than the valley value) is added to

stop the discharge phase as soon as the oscillator

voltage is detected as lower than the valley value

(without any delay due to the L1 latch propagation

time).

— the REGUL current source must be connected when:

• QL1 is high (charge or REGUL phase)

• QL2 is low (the oscillator is not in a charge phase)

On the other hand, the oscillator charge is stopped when:

— the oscillator voltage reaches the peak value in the

free mode

— the oscillator voltage is higher than the intermediary

value (V

) and the synchronization signal is negative,

int

in the synchronized mode.

Consequently, in any case, QL2 that is high during the

oscillator charge phase, is high for the delay during which

the oscillator voltage grows from the valley value up to the

intermediary one. That is why the signal Sf (refer to the MPL

block) that must be high when the oscillator voltage is

between the valley value and the intermediary one during

the charge phase (QL2 high), is obtained using an AND gate

with the following inputs:

—QL2 (QL2 high <=> charge phase)

—C

OSCINT

(C

OSCINT

high <=> the CT voltage is lower

than the intermediary value).

So, using the output of this AND gate, Sf is obtained.

This signal Sf is connected to a logic block consisting of

two AND gates and an OR one. This block aims at supplying

a signal VS that:

— gets high as soon as Sf becomes high if the PWM

latch output is low

— gets low as soon as the PWM latch is set and then

remains low until the next cycle.

V

ref

I

charge

C

OSCINT

Vint

3.6 V

1.6 V

10

C

T

01

Synchronization Section (Note 1)

sync

C

OSC HIGH

C

OSCINT

C

OSC LOW

DISCH

C

OSC REGUL

I

regul

Figure 5. Oscillator

&

CT<1.6 V

Q

Q

S

L1

R

&

MC44605

PWM

Latch

Output

Sf

&

Q

L2

VDT (from demag

sync

10

Q

L2

&

block)

&

DISCH

I

DISCH

&

PWM

Latch

VS

Set

S

L2

R

discharge

Q

Q

Q

The synchronization block consists of a protection

arrangement similar to the demagnetization block one (a

diode + a negative active clamping system (Note 2)). In

addition to this, a high value resistor (R – about 50 kΩ) is

incorporated as the pin 9 input is also used by the EHTOVP

section.

The signal obtained at the output of this protection

arrangement, is compared to a negative threshold (–200 mV ,

typically) so that when the synchronization pulse applied to

the pin 9 (through a resistor or a resistors divider to adapt this

input to the EHTOVP function), is higher than this

threshold, the system considers that the synchronization

condition is performed (free mode or synchronization signal

high level).

Note 1. The synchronization can be inhibited by connecting the

pin 9 to the ground. By this means, a free mode is

obtained.

Note 2.This negative active clamping system works even if the

circuit is off. This feature is really useful as

synchronization pulses may be applied while the product

is off.

http://onsemi.com

12

Page 13

MC44605

V

Synchro.

Signal

Pin 9

Figure 6. Synchronization

CC

Negative Active

Clamping System

R

–200 mV

E.H.T. OVP

Block

sync

MC44605

Demagnetization Section

This block is incorporated to detect the complete core

demagnetization in order to prevent the power MOSFET

from switching on if the converter is not in a dead time

phase. That is why this block inhibits any oscillator re–start

as long as the inductor current is not finished (from the

beginning of the on–time to the end of the demagnetization

phase).

In a fly–back, a good means to detect the demagnetization

phase consists in using the VCC winding voltage. In effect,

this voltage is:

— negative during the on–time,

— positive during the off–time,

— equal to zero for the dead–time with generally a

ringing (refer to Figure 7).

Zero

Current

Detection

0.75 V

A diode D is incorporated to clamp the positive applied

voltages while an active clamping system limit the negative

voltages to typically –0.33 V. This negative clamp level is

high enough to avoid the substrate diode switching on.

A latch system is incorporated to keep the

demagnetization block output level low as soon as a voltage

lower than 65 mV is detected and as long as a new restart is

produced (high level on the output (refer to Figure 8). This

process avoids that any ringing on the signal used on the

pin 8, disrupts the demagnetization detection (refer to

Figure 7). Finally, this method results in a very accurate

demagnetization phase detection, and the signal VDT drawn

from this block is high only for the dead time. Therefore, an

oscillator re–start and so, a new power switch conduction is

only allowed during the dead–time.

For a higher safety, the V

demagout

output of the

demagnetization block is also directly connected to the

output, to disable it during the demagnetization phase (refer

to the block diagram).

The demagnetization detection can be inhibited by

connecting pin 8 to the ground but in this case, a timer (about

3 µs) that is incorporated to set the latch when it can not be

set by V

demagout

, results in a minimum off–time (refer to

Figure 8).

Output

Buffer

3 m

V

demag out

s

R

Demag

S

Q

V

Q

CC

Negative Active

Clamping System

V

pin 8

65 mV

–0.33 V

On–Time Off–Time Dead–Time

Figure 7. Demagnetization Detection

That is why, the MC44605 demagnetization detection

consists of a comparator that compares the VCC winding

voltage to a reference that is typically equal to 65 mV.

http://onsemi.com

65 mV

Oscillator

C DEM

V

DT

Figure 8. Demagnetization Block

D

Overvoltage Protection Section

The overvoltage arrangement compares a portion Vcc to

V

(2,5 V) (refer to Figure 9). In fact, this threshold

ref

corresponds to a VCC equal to to 17 V. When the Vcc is

higher than this level, the output is latched off until a new

circuit re–start.

13

Pin 8

Page 14

MC44605

V

Delay

Enable

2.5 V

(V

ref

Out

)

ref

In

C

5.0 µs

τ

In Out

OVLO

(If V

the Output is Disabled)

τ

Delay

2.0 µs

OVP out

V

= 1.0,

OVP out

CC

T

2.5 V

V

0

Figure 9. Overvoltage Protection

A delay (2 µs) is incorporated in order to avoid any

activation due to interferences by only taking into account

the overvoltages that last at least 2 µs.

The VCC is connected when once the circuit has

started–up in order to limit the circuit start–up consumption

(T is switched on when once V

has been generated).

ref

The overvoltage section is enabled 5 µs after the regulator

has started to allow the reference V

to stabilize.

ref

E.H.T. Overvoltage Protection Section

This block uses the synchronization input as this section

is incorporated to detect too high synchronization pulses and

then to activate the device definitive latch in this case.

For instance, if this threshold value is required to be equal

to 30 V, V

must be equal to 7.5 V when the

pin9

synchronization pulse value is 30 V.

So, in this case:

r2

r1)r2

+

7.5

30

Then, the ratio (r1/r2) can be deducted:

r1

+

3

r2

So, as r1 and r2 must be negligible in relation to R (about

50 kΩ), the couple of resistors can be chosen as follows:

r1+3kΩ

and:

r2+1kΩ

Winding Short Circuit Detection Section (WSCD)

The MC44605 being designed to control a Fly–Back

SMPS, this block is incorporated to detect a short circuit on

a transformer winding or on an output diode (refer to

Figure 11).

+

+

AC Line

+

L

L

p

leak

V

Synchro.

Pulses

r1

Pin 9

r2

CC

Negative Active

Clamping System

4 V

2R

R

Synchronization

Block

Disabling

C

EHTOVP

V

ref

MC44605

Block

E.H.T.

OVP

Figure 10. E.H.T. OVP

This block consists of a high impedance resistors bridge

(R is nearly equal to 50 kΩ – refer to Figure 10) so that the

EHTovp threshold is 7.5 V. So, using an external resistors

bridge (r1, r2 <<R), the synchronization pulse level above

which the working must be considered as wrong, can be

adjusted.

MC44605

R

S

Figure 11. Winding Short Circuit Fault

In the case of a Winding Short Circuit, the primary

inductor Lp is short circuited and then the current increase

is only controlled by the leakage inductor L

leak

.

In current mode, the power switch conduction is stopped

when the inductor current is detected as high enough, by the

controller. In fact, when the current sense resistor (Rs)

voltage gets equal to Vcs, the current sense comparator

switches to reset the output.

Now, the circuit has a propagation delay and the power

switch needs some time to turn off. Consequently , there is a

delay δt between the moment at which the Rs voltage gets

equal to Vcs and the actual current increase stop. So, this

results in an overcurrent (refer to Figure 12).

http://onsemi.com

14

Page 15

(VCS + V

shift

)/R

MC44605

Finally, when there is a winding short circuit, an

S

(Vin x dt/L

leak

overcurrent is detected by the WSCD comparator. The

output of this comparator, V

, is connected to the

WSCD

disabling block (refer to the disabling block §).

VCS/R

S

Power Switch Current

d

t

Figure 12. Overcurrent in a WSCD Case

d

t

Vin x dt/L

p

time

Now , in normal working, this overcurrent DIpk is equal to:

Ipk

Vin δt

+

L

P

D

where: Vin is the input voltage (rectified a.c. line)

While in a WSCD case:

(DIpk)

WSCD

Vin δt

+

L

Leak

Consequently, as the leakage inductor value is generally

much lower than the primary one (less than 5% generally),

the overcurrent is much higher in the WSCD case. That is

why this fault can be detected by detecting the high

overcurrents.

So, the WSCD block consists of comparing the sensed

current to a reference equal to: (Vcs + V

shift

), where V

shift

a voltage proportional to the current injected in the pin 15

(refer to Figure 13).

Vin

C

Pin 7

I

sense

Vcs

V

shift

WSCD

V

WSCD

V

shift shift

Figure 13. WSCD

= 500

MC44605

Disabling

Block

3.75 Ω

W

I

shift

R

Pin 15

Now , as the overcurrent level depends on the input voltage

Vin, it is preferable to use a V

voltage instead of a constant V

be connected to Vin through a resistor that fixes V

proportional to this input

shift

. So, the WSCD pin must

shift

shift

by

adjusting the current injected in this pin 15.

Maximum Power Limitation Section (MPL)

The MPL block is designed to calculate this input power

using the following equation:

1

Pin

+

LP

Ipk2

2

f

where: Lp is the inductor value

Ipk is the inductor peak current

f is the switching frequency

As Vcs is proportional to the inductor peak current

(V

= Rs x Ipk), the squared Ipk value is estimated by

cs

building a current source proportional to V

2

. This current

cs

is chopped by a calibrated pulse Sf, generated at each new

oscillator cycle (refer to Figure 14).

Finally, using an external resistor and capacitor network

(R

MPL

, C

) on the MPL pin, a voltage V

MPL

MPL

,

proportional to the input power can be obtained.

In effect,

(Sf)

T

where: k

V

+

MPL

MPL

R

MPL

is the multiplier gain

k

MPL

Vcs2

(Sf) is the width of the calibrated pulse

T is the switching (oscillator) period

Now , as Sf is built comparing the oscillator to a constant

is

level, (Sf) is proportional to R

(Sf)+k1 R

and CT:

ref

ref

C

T

where: k1 is a constant

On the other hand, k

current source I

, is proportional to 1/R

ref

k

MPL

that is depending on the reference

MPL

+k2

1

R

ref

ref

:

where: k2 is a constant

So:

V

+

R

MPL

k1 k2

MPL

Vcs2 f

C

T

where: CT is the oscillator capacitor

Finally:

V

+

R

Γ

where: Γ

MPL

MPL

MPL

MPL

is the MPL parameter as defined in the

Vcs2 f

C

T

specification. This is a constant equal to the product

(k1 x k2).

Now , as:

1

Pin

+

LP

Ipk2

2

f

http://onsemi.com

15

Page 16

MC44605

and:

Vcs+RS

Ipk

So:

to V

2

R

S

, the output

ref

Pin

V

MPL

2 R

+

MPL

Γ

A comparator is used to compare V

of which, Dis

, is connected to the “definitive inhibition

MPL

MPL

L

P

MPL

CT

latch” of the disabling block. So, when the calculated power

is higher than the threshold, the circuit is definitively

disabled (the system considers that there is an overload

condition).

Finally, replacing V

the R

value to be used, can be deducted:

MPL

R

+

MPL

OHD

OHD

C

R

V

MPL

Γ

k

T

by 2.5 V (the threshold value),

MPL

MPL

OHD

OHD

2.5 V

2.5 V

Vcs

Vcs

Output

1.25 L

CT

x

2

V

Dis

Disabling

Block

Dis

R

S

MPL

OHD

MPL

MC44605

P

2

(Pin)

k

MPL

T

MPL

max

2

Vcs

Sf

MPL

C

where: pon are the power switch on–time losses

R

is the conduction MOSFET resistor

dson

d is the duty cycle

As in the MPL section, the squared Ipk term is estimated

by building a current source proportional to Vcs2.

The duty cycle is taken into account thanks to the action

on this current source of a “chopper” controlled by the

circuit output. By this means, the pin 6 average current is

proportional to the squared peak current multiplied to the

duty cycle (refer to Figure 14).

So, using an external resistor and capacitor network

(R

OHD

, C

) on this pin, a voltage V

OHD

OHD

the conduction losses can be obtained.

Like in the MPL block, this voltage V

2.5 V . If V

block is activated by Dis

The external resistor R

calculated V

gets higher than this threshold, the disabling

OHD

(output of the comparator).

OHD

OHD

equal to 2.5 V when the conduction losses

OHD

OHD

choice enables to obtain a

are equal to their maximum value.

In effect,

V

+

R

k

ref

R

Vcs2

:

1

ref

where: k

Now , as k

source I

OHD

OHD

OHD

, is proportional to 1/R

ref

OHD

is the multiplier gain

that is depending on the reference current

k

OHD

OHD

+k2

where: k2 is a constant

So:

2

MPL

R

V

OHD

+

R

OHD

k2

Vcs

R

ref

Finally:

R

Γ

Vcs2

R

ref

where: Γ

+

OHD

V

OHD

is the OHD parameter as defined in the

OHD

OHD

specification. This is a constant equal to k2.

Now , as:

Vcs+RS

Ipk

, proportional to

, is compared to

d

d

d

Figure 14. OHD and MPL

Overheating Detection Section (O.H.D.)

In the MPL block, the converter input power is calculated.

In the O.H.D. block, that is the power MOSFET heating

which is calculated, using the following equation:

1

pon+

R

dson

3

Ipk2

d

http://onsemi.com

So, replacing Vcs and using the pon equation:

2

R

S

, the heating

V

OHD

3 R

+

OHD

R

ref

So, by choosing the value of R

corresponding to V

is determined. If the MOSFET

ref

Γ

R

OHD

dson

OHD

dissipation is such that the heating is higher than this

threshold, the “definitive inhibition latch” of the Disabling

Block is activated and so, the output gets definitively

disabled.

16

p

on

Page 17

MC44605

Consequently, by replacing V

value) in the last equation, the value R

by 2.5 V (threshold

OHD

to use, can be

OHD

deducted:

R

OHD

where: (pon)

acceptable.

+

max

2.5 R

3 Γ

OHD

are the maximum on time losses that are

ref

R

dson

2

R

(pon)

S

max

Disabling Block Section

This section consists of a “definitive inhibition latch”

(directly supplied by the Vcc) that disables the output (the

output is forced to zero).

In effect, this block aims at definitively disabling the

circuit when one of the following faults is detected:

— a Winding Short Circuit

— too high synchronization pulses

— a too high input power

— a too high power switch (MOSFET) heating

The signals corresponding to these faults are high when a

fault is detected (for instance, when the input power is

detected as too high, Dis

MPL

is high).

When one (or several) of these four faults is detected, a

current source charges C

when its voltage becomes higher than V

(with a certain duty cycle) and

ext

, the definitive

ref

inhibition latch is activated. Thus, the circuit gets

definitively disabled after a delay depending on C

ext

.

According to the detected fault, the current that charges

C

is not the same:

ext

The typical values are:

— 260 µA for EHTOVP and WSCD

— 8.5 µA for OHD and MPL

when R

is equal to 10 kΩ.

ref

Pin 12

ext

C

V

ref

3.4% I

ref

10

ext

R

Figure 15. Disabling Block

Dis

Dis

2.5 V

V

10

OHD

MPL

V

Definitive

Inhibition

Latch

Output

Buffer

MC44605

ref

104% I

CC

ref

E.H.T.

Q

Delay

4mS

OVP

S

R

V

WSCD

This latch is reset when the Vcc falls down to about 3 V.

In this case, if a new start up is performed, the circuit will

work normally (until this fault or another one is detected).

Practically, to re–start after a fault has shutdown the

circuit, the converter must be turned off for a time long

enough to enable the Vcc capacitor discharge (repair time...).

Note: As V

is generally a really narrow pulse, it is

WSCD

necessary to add a latch and a delay to build a 4 µs width

pulse when V

WSCD

becomes high.

http://onsemi.com

17

Page 18

90 Vac to

264 Vac

MC44605

Application Schematic

1nF / 1KV

10 nF

22 kΩ

22 kΩ

1.2 kΩ

470

kΩ

RFI

Filter

SYNC

2.2 nF

1 mF

1N4148

1 nF

R1

1Ω / 5W

D1 ... D4

1N4007

3.3 kΩ

9

10

11

12

13

14

15

16

10 kΩ

47 kΩ/2W

8

7

6

5

4

MC44605P

3

2

1

C4....C7

1nF/500V

100 mF

25 V

120 pF

1nF

340 KΩ

39 Ω

100 Ω

100 mF

400 V

27 KΩ

220 nF

4.7mF

V

in

1N4934

1 kΩ

1.8 MΩ

1mF

105

kΩ

MTA4N60E

330 Ω

0.22 Ω

4.7 mF

1 kΩ

47 KΩ

47 nF

1N4937

Laux

1N4937

470 Ω

4.7 MΩ

Lp

470 pF

MR856

100 mF

1N4937

100 mF

1N4937

470 mF

1N4934

1000 mF

1N4934

1000 mF

160 V/0.1 A

2x150 KΩ//

70 V/0.2 A

100 kΩ

40 V/0.5 A

100 kΩ

1305 V/0.65 A

10 kΩ

8 V/0.5 A

2.2 kΩ

V

in

2.2 kΩ

6.8 nF

MOC8103

65 W output SMPS controlled by the MC44605

Mains input range: 90 Vac <–> 264 Vac

Synchronization range: 30 kHz <–> 100 kHz

Orega Transformer ref. G5984–00

(Lp = 195 µH)

http://onsemi.com

18

TL431

10 kΩ

33 nF

270 Ω

226 kΩ

1N4733

100 nF

3.6 kΩ

Page 19

MC44605

30 kHz

y

60 kHz

100 kHz

y

30 kHz

60 kHz

100 kHz

The in ut rms levels at which

Performances

Input Voltage 90–260 Vac

Synchronization Range 30 to 100 kHz

160 V 100 mA

70 V 200 mA

Outputs

Measured Efficiency

(Pout = 64 W)

Standby Losses

(No Load – Pout = 0)

EHTovp Threshold 28 V

Maximum Power

Limitation

Overheating Detection

(Pout = 64 W):

The input rms levels at which

the circuit detects an OHD case.

Winding Short Circuit

Detection

(Tested by short circuiting one output diode or one transformer winding)

40 V 500 mA

13.5 V 650 mA

8 V 500 mA

110 Vac (Input) 80%

110 Vac 2.0 W

220 Vac 3.2 W

110 Vac (Input) 86 W (Input)

30 kHz 85 V

60 kHz 76 V

100 kHz 76 V

Fully Functional

220 Vac 83%

110 Vac 81%

220 Vac 82%

110 Vac 80%

220 Vac 80%

220 Vac 87 W

110 Vac 90 W

220 Vac 95 W

110 Vac 94 W

220 Vac 110 W

http://onsemi.com

19

Page 20

MC44605

P ACKAGE DIMENSIONS

PDIP–16

P SUFFIX

CASE 648–08

ISSUE R

–A–

916

B

18

F

C

S

–T–

H

G

D

16 PL

0.25 (0.010) T

K

M

A

SEATING

PLANE

M

L

J

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. ROUNDED CORNERS OPTIONAL.

DIM MIN MAX MIN MAX

A 0.740 0.770 18.80 19.55

B 0.250 0.270 6.35 6.85

C 0.145 0.175 3.69 4.44

D 0.015 0.021 0.39 0.53

F 0.040 0.70 1.02 1.77

G 0.100 BSC 2.54 BSC

H 0.050 BSC 1.27 BSC

J 0.008 0.015 0.21 0.38

K 0.110 0.130 2.80 3.30

L 0.295 0.305 7.50 7.74

M 0 10 0 10

S 0.020 0.040 0.51 1.01

MILLIMETERSINCHES

____

GreenLine is a trademark of Motorola, Inc.

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone : (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich Time)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse Time)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

http://onsemi.com

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong T ime)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–0031

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

MC44605/D

20

Loading...

Loading...