Page 1

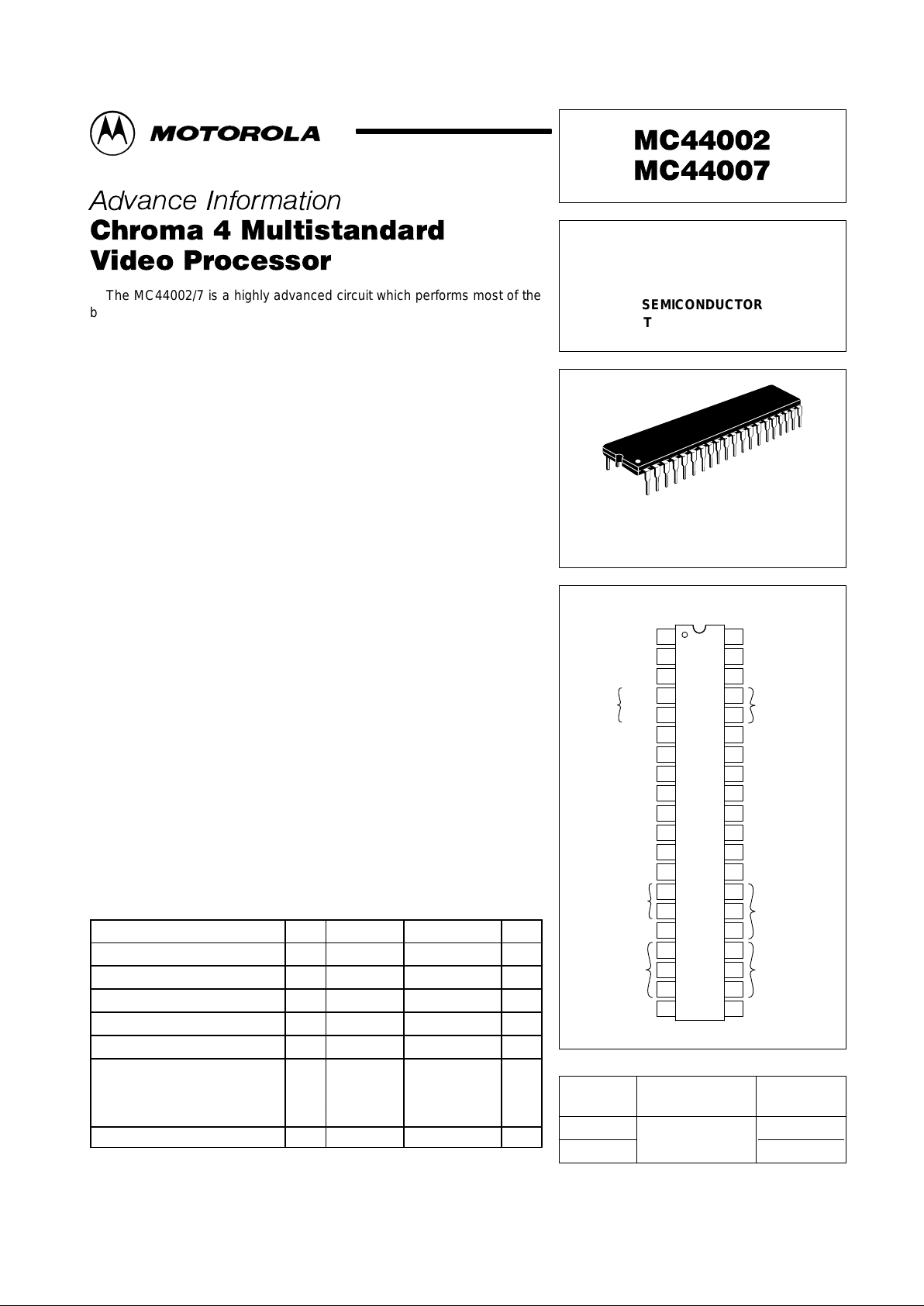

Device

Operating

Temperature Range

Package

SEMICONDUCTOR

TECHNICAL DATA

CHROMA 4

VIDEO PROCESSOR

ORDERING INFORMATION

MC44002P

TA = 0° to +70°C

Plastic DIP

P SUFFIX

PLASTIC PACKAGE

CASE 711

40

1

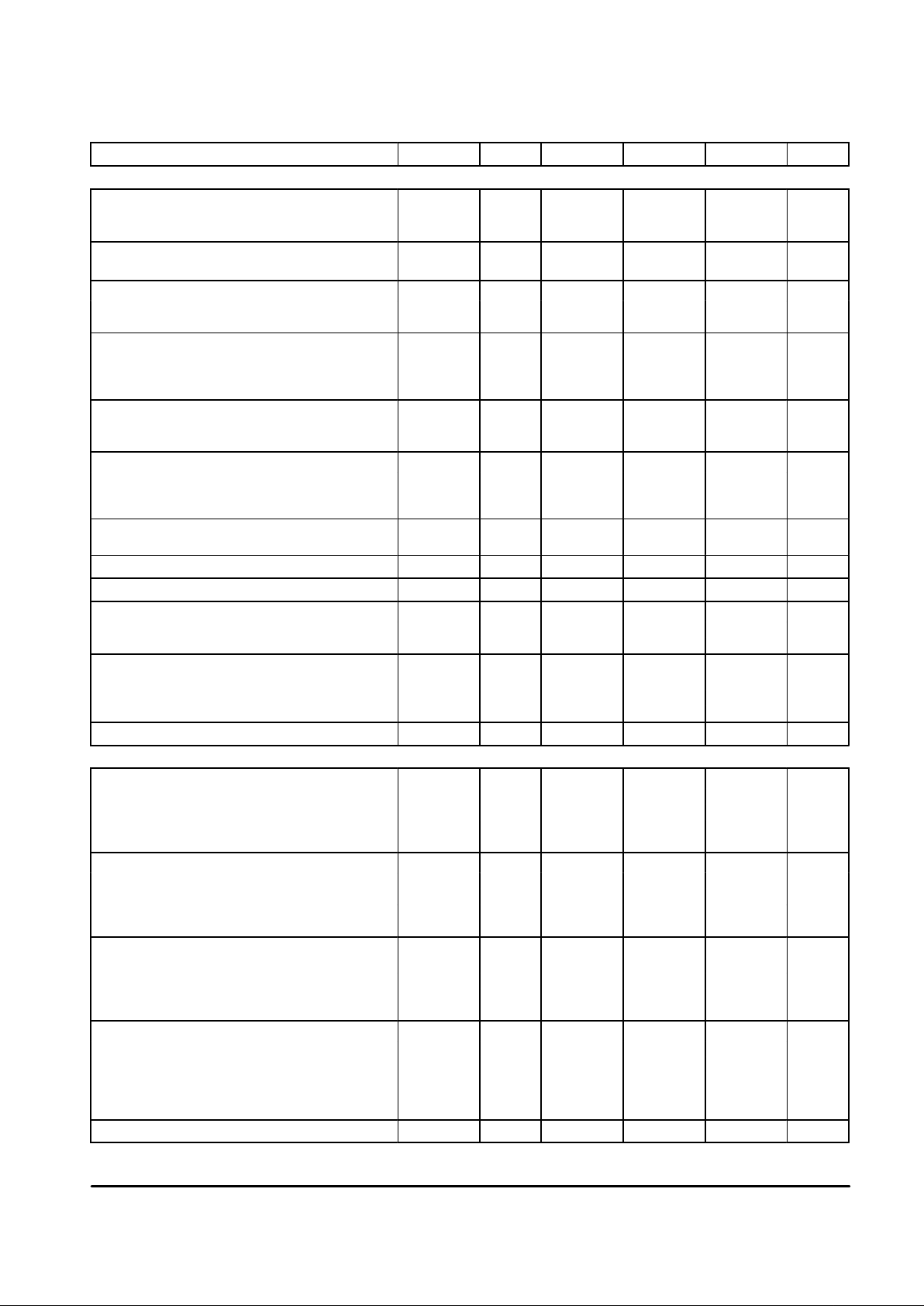

PIN CONNECTIONS

Order this document by MC44002/D

38

40

39

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

(Top View)

ACC

Video 2

I

ref

Clock

Data

V-Ramp

V-Drive

E-W Drive

Osc Loop Filter

Ident

R-Y

B-Y

V

CC

Gnd

(17.7 MHz)

I

Anode

Analog Contrast

SECAM Cal Loop

H-Drive

H-Flyback Input

2

1

(14.3 MHz)

Sandcastle

System Select

Y1 Output

Y1 Clamp

R-Y

B-Y

Signal Gnd

R

G

B

Feedback

Y2

R

G

B

Fast Commutate

Outputs

H-Loop Filter

Inputs

Inputs

Crystals

Outputs

Video 1 In

I2C

MC44007P Plastic DIP

1

MOTOROLA ANALOG IC DEVICE DATA

The MC44002/7 is a highly advanced circuit which performs most of the

basic functions required for a color TV . All of its advanced features are under

processor control via an I2C bus, enabling potentiometer controls to be

removed completely. In this way the component count may be reduced

dramatically , allowing significant cost savings together with the possibility of

implementing sophisticated automatic test routines. Using the MC44002/7,

TV manufacturers will be able to build a standard chassis for anywhere in the

world. Additional features include 4 selectable matrix modes (primarily for

NTSC), fast beam current limiting and 16:9 display.

• Operation from a Single 5.0 V Supply; Typical Current Consumption

Only 120 mA

• Full P AL/SECAM/NTSC Capability (4 Matrix Modes)

• Dual Composite Video or S-VHS Inputs

• All Chroma/Luma Channel Filtering, and Luma Delay Line Are

Integrated Using Sampled Data Filters Requiring No External

Components

• Filters Automatically Commutate with Change of Standard

• Chroma Delay Line is Realized with a 16 Pin Companion Device, the

MC44140

• RGB Drives Incorporate Contrast and Brightness Controls and Auto

Gray Scale

• Switched RGB Inputs with Separate Saturation Control

• Auxiliary Y, R-Y, B-Y Inputs

• Line Timebase Featuring H-Phase Control, T ime Constant and

Switchable Phase Detector Gain

• Vertical Timebase Incorporating Vertical Geometry Corrections

• 16:9 Display Mode Capability

• E-W Parabola Drive Incorporating Horizontal Geometry Corrections

• Beam Current Monitor with Breathing Compensation

• Analog Contrast Control, Allowing Fast Beam Current Limitation

• MC44007 Decoders P AL/NTSC Only

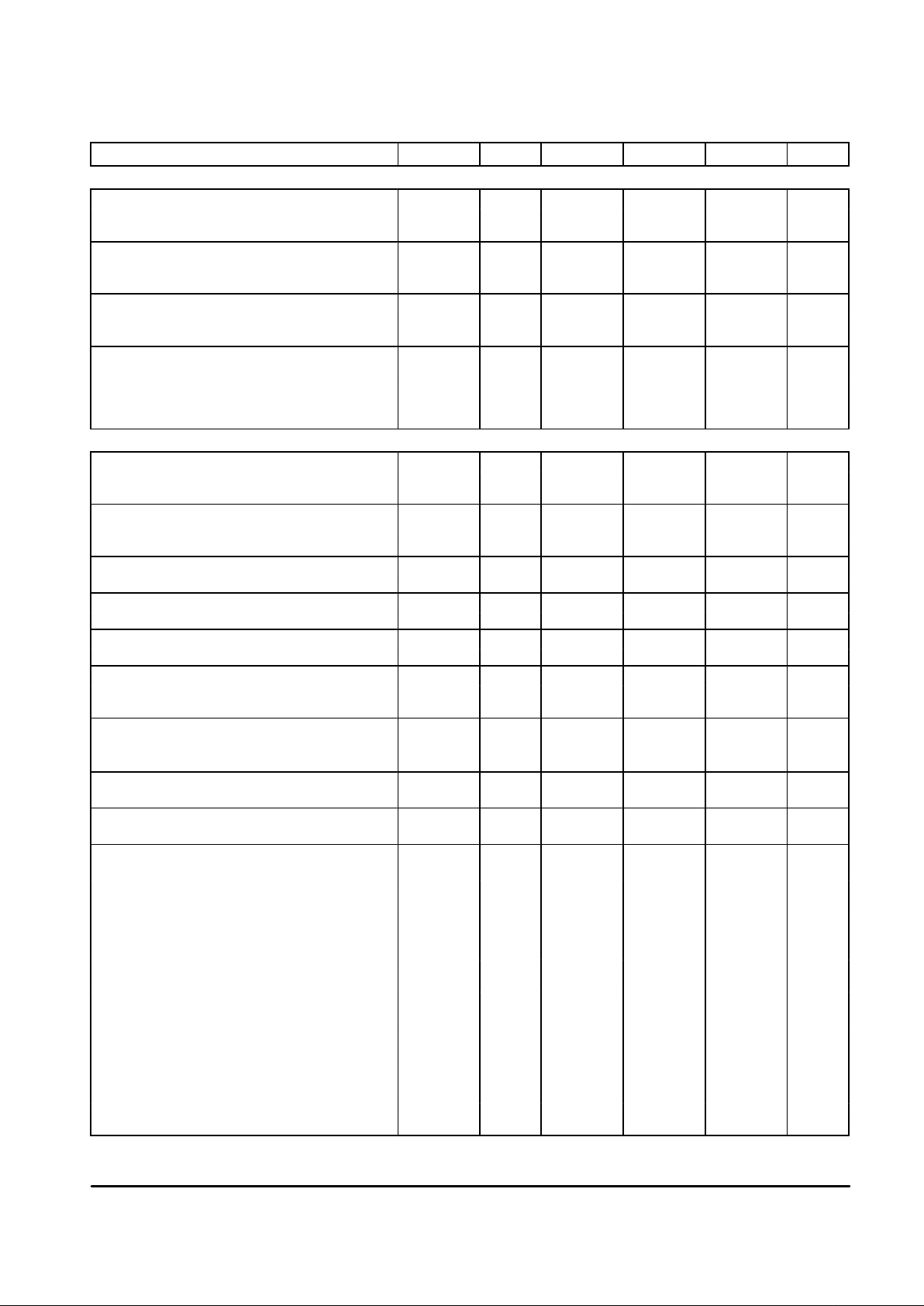

MAXIMUM RATINGS

(TA = 25°C, unless otherwise noted.)

Rating

Pin Symbol Value Unit

Supply Voltage 35 V

CC

6.0 Vdc

Operating Ambient Temperature – T

A

0 to + 70 °C

Storage Temperature – T

stg

– 65 to +150 °C

Junction Temperature – T

J

+150 °C

Drive Output Sink Current 12 I

12

2.0 mA

Applied Voltage Range: Vdc

Feedback 20 V

20

0 to +8.0

Anode Current 9 V

9

– 2.0 to V

CC

All Other Pins – V

i

0 to V

CC

ESD V

NOTE: ESD data available upon request.

This document contains information on a new product. Specifications and information herein

are subject to change without notice.

Motorola, Inc. 1996 Rev 1

Page 2

MC44002 MC44007

2

MOTOROLA ANALOG IC DEVICE DATA

MAXIMUM RATINGS

(TA = 25°C, unless otherwise noted.)

Rating UnitValueSymbolPin

Human Body Model – – ±2000

Machine Model – – ±200

NOTE: ESD data available upon request.

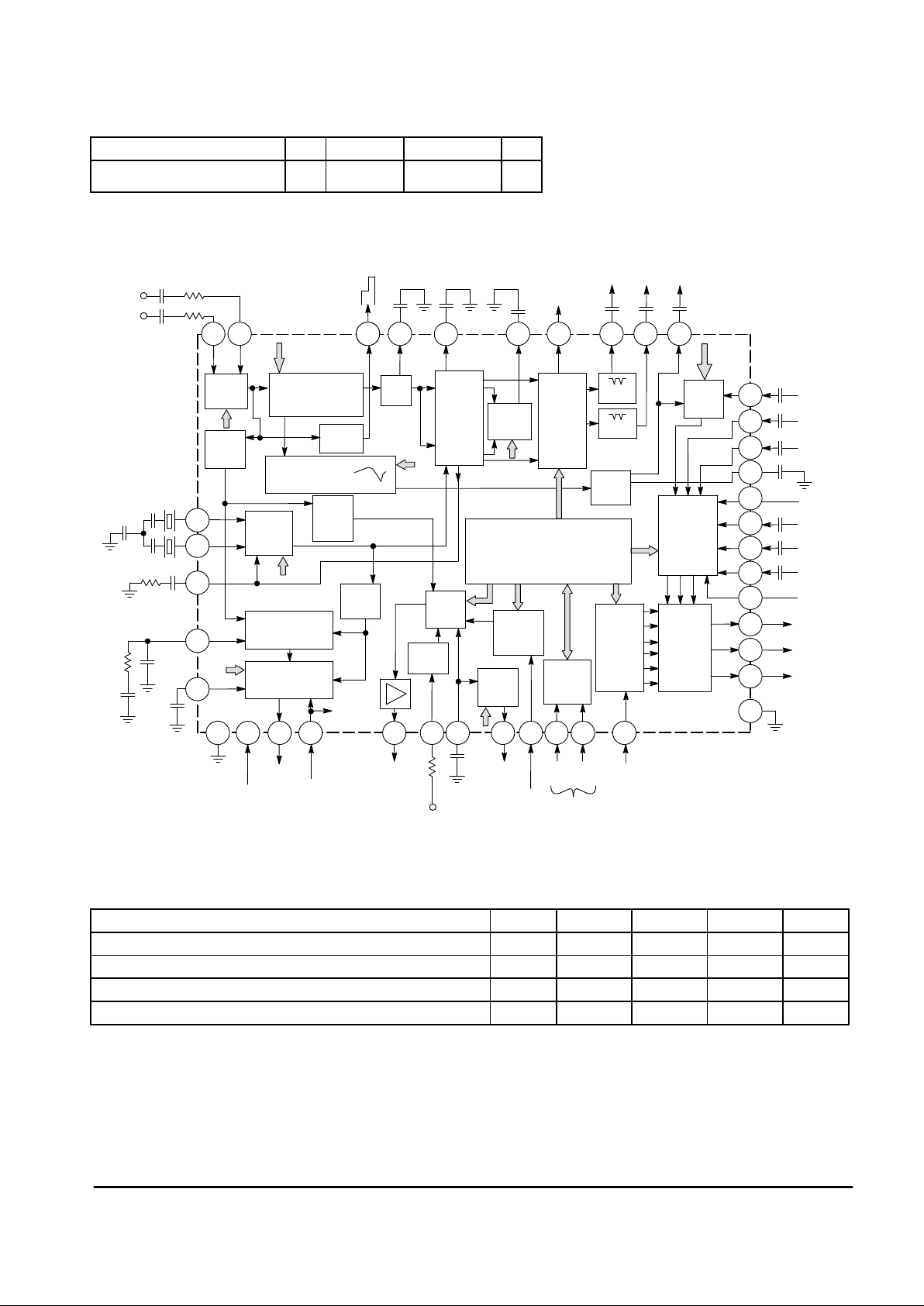

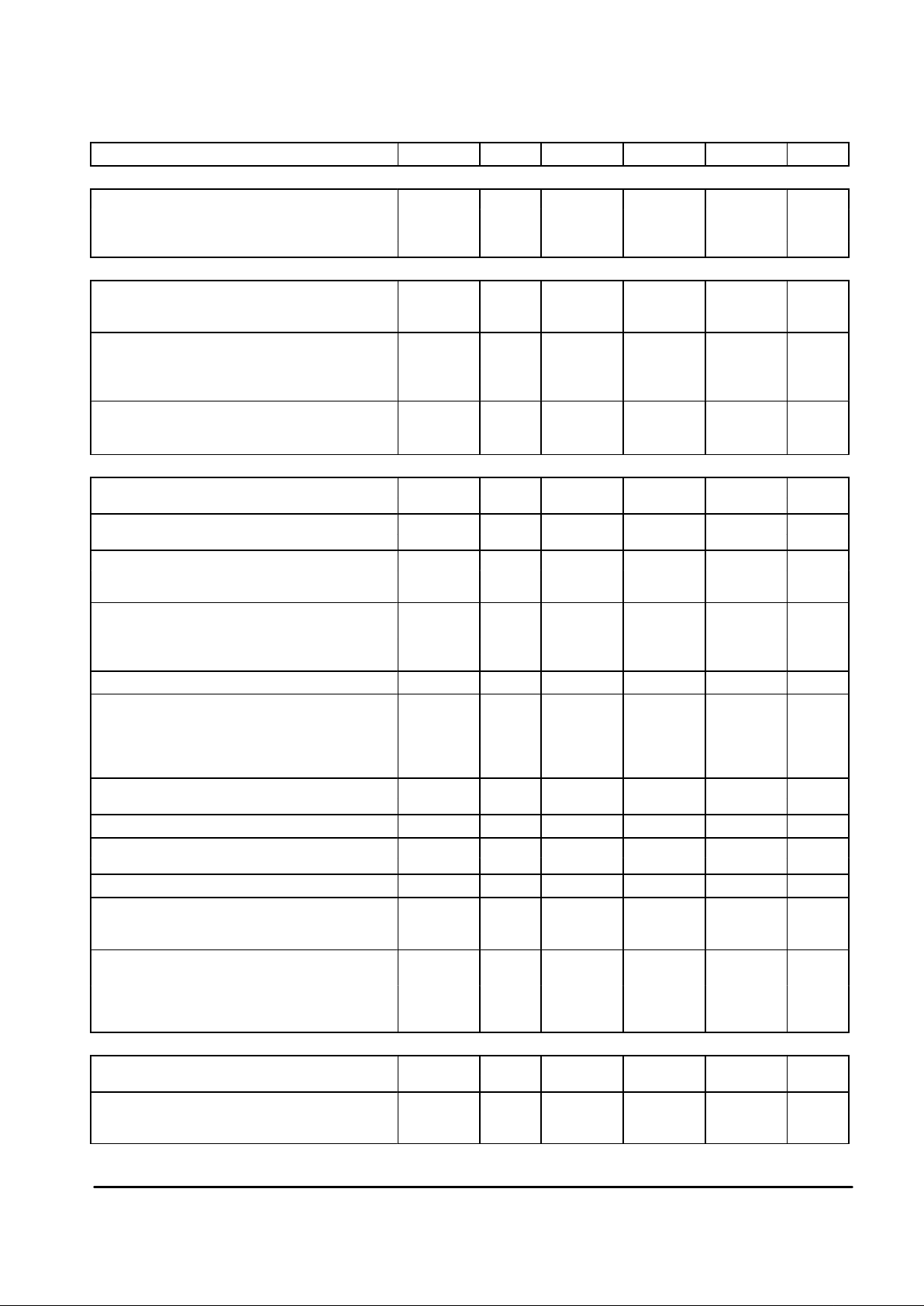

Chroma

T ake–Of f

Filter

Matrix

Switching

&

RGB Sat

Control

Luma

Select

17.7 MHz

Video 1

(S-VHS)

Video 2

Y2

R-Y

B-Y

Fast Comm.

Filter

Filter

System

Select

Sat &

Hue

System

R-Y B-Y Y1

Memory/Control Registers

Y1

Clamp

Parab

Gen

Beam

Current

Monitor

Control

Loops

Rx/Tx

Red

Green

Blue

Red

Green

Blue

RGB

Outputs

Analog

Contrast

FdbckDataClk

Anode

Current

E-W

Drive

Freq

Divider

Flyback

Sense

14.3 MHz

Loop

2

H Flyback

Pulse

H Drive

5.0 V

V Drive

5.0 V

I

ref

V

Sync

PAL/

NTSC/

SECAM

Decoder

Ident

Clk

Vert

Sync

Sep

Osc

PLL 1

Ramp

Gen

Luma Delay

Peaking & Trap

ACC

SandCastle

Sync

Sep

Input

Select

240

31

13038 37 36 29

14

15

39

32

33

25

27

26

28

21

24

22

17

18

19

16

10

205498637131235

34

23

Simplified Block Diagram

11

I2C

Bus

This device contains 6,245 active transistors.

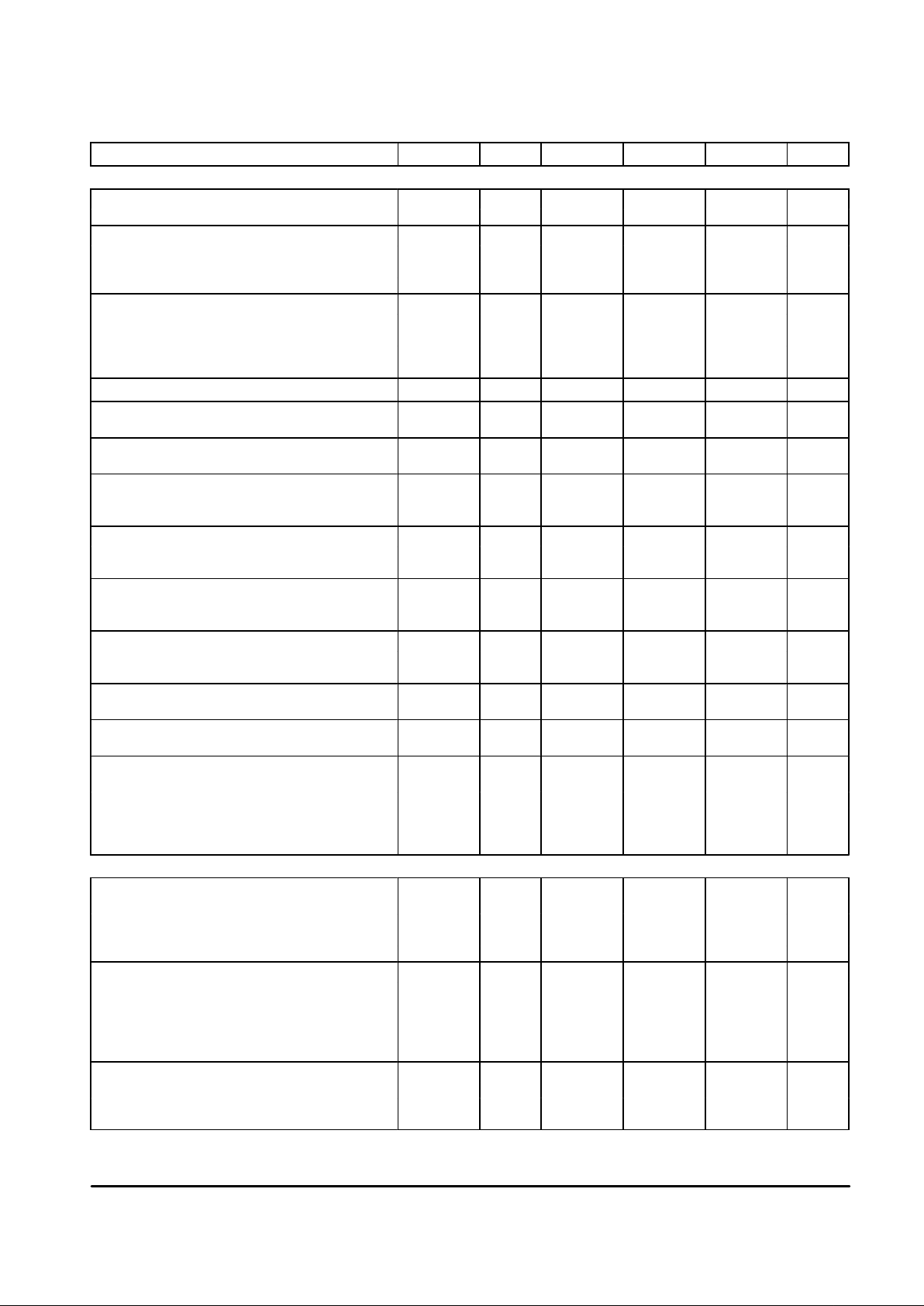

ELECTRICAL CHARACTERISTICS (V

CC

= 5.0 Vdc, I3 = 70 µA, TA = 25°C, unless otherwise noted.)

Characteristic

Pin Min Typ Max Unit

Supply Voltage 35 4.75 5.0 5.25 V

Operating Current 35 90 120 180 mA

Reference Current, Input Voltage 3 1.0 1.3 1.6 V

Thermal Resistance, Junction–to–Ambient – – 56 – °C/W

NOTES: Composite Video Input Signal Level = 1.0 Vpp Horizontal Timebase started (subaddress 00)

Black-to-White = 0.Vpp7 , Syn-to-Black = 0.3 Vpp Vertical Breathing control set to 00; V9 = 0 V

PAL/NTSC = 75% color bars; Burst = 300 mVpp All other analog controls set to midrange 32

SECAM = 75% color bars Video Peaking “P1, P2, P3” bits high

Page 3

MC44002 MC44007

3

MOTOROLA ANALOG IC DEVICE DATA

TEST CONDITIONS (unless otherwise noted.)

VCC = 5.0 V

I

ref

= 70 µA

TA = 25°C

Video Composite Input = 1.0 Vpp

– Black–to–White = 0.7 Vpp

– Black–to–Sync = 0.3 Vpp

Horizontal Timebase Started (Reg. 00)

Vertical Breathing Control Set to 00

Pin 9 = 0 V

Pin 10 = 5.0 V

PAL/NTSC = 75% Color Bars

–Burst = 300 mVpp

SECAM = 75% Color Bars (MC44002 only)

All Analog Controls Set to Midpoint (32)

Luma Peaking at Min. (P1 – P3 = 111)

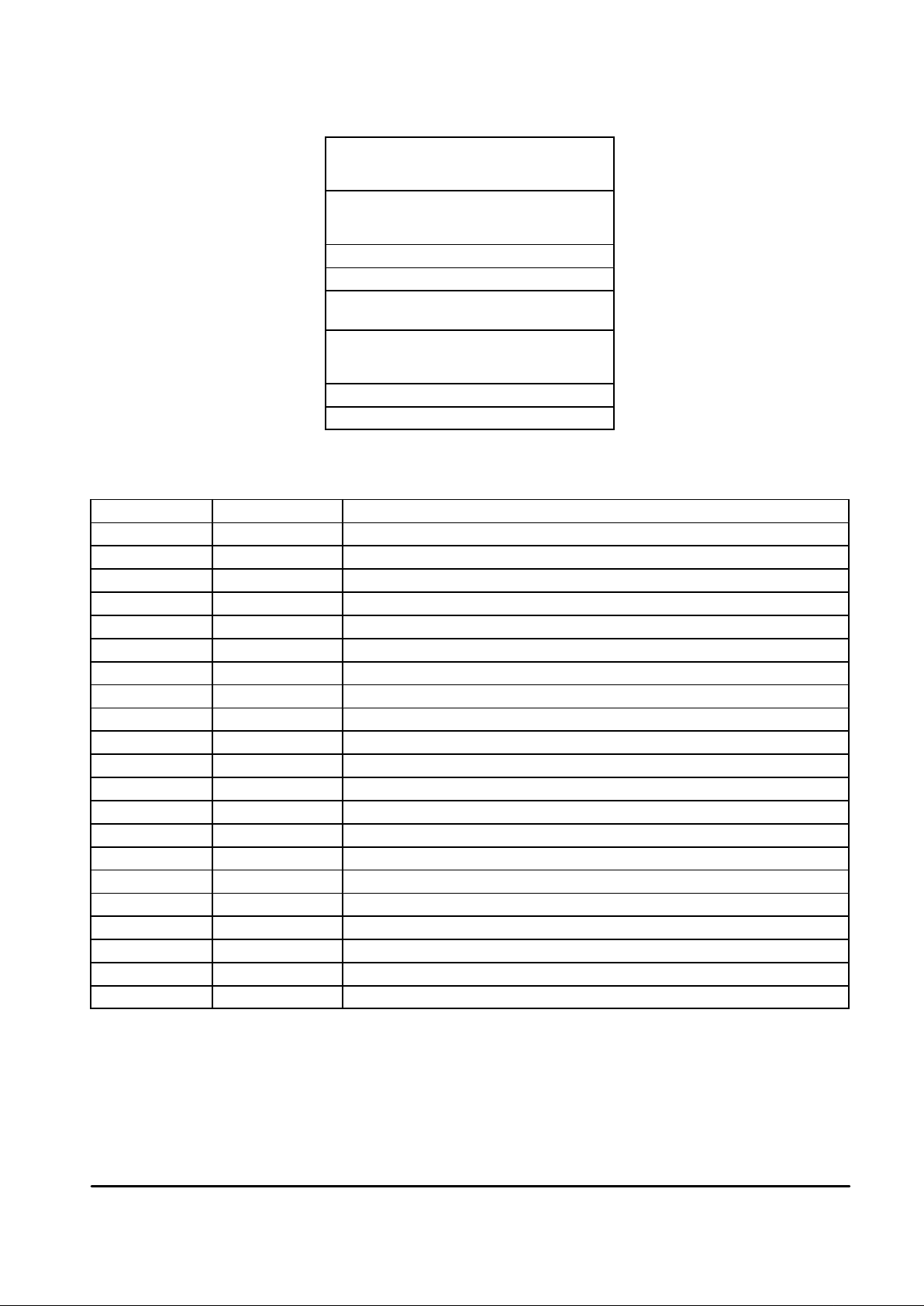

Control Bits Setup

Name Value Function Status

V1/V2 1 Video Input 1 Selected

H EN 0 Horizontal Drive Enabled

BRI EN 1 “Bright” Sample “On”

HGAIN1 0 Horizontal Phase Detector Gain Reduced by 3 Enabled

YX EN 0 Luma Matrix Disabled

Y1 EN 1 Luma from Filters “On”

D EN 0 RGB Inputs Enabled

XS 0 Pin 33 Crystal Enabled

TEST 1 Outputs Sampled Once/Field

FSI 0 50 Hz Field Rate

T3 1 Low Pass Filter Enabled

VD1 1 4:3 Display Mode

2xFh 0 Horizontal Drive at 1xFh

NORM 0 Horizontal Reference Divider for 17.7 MHz

HGAIN2 1 Horizontal Phase Detector Gain Reduced by 2 Enabled

INTSEL 1 Long Vertical Time Constant

Y2 EN 0 External Luma Input “Off”

SSD 0 SECAM Mode Select Enabled

CALKIL 1 Horizontal Calibration Loop Enabled

BAI 1 Vertical Blanking for 625 Lines

S–VHS 1 Composite Video Input

Page 4

MC44002 MC44007

4

MOTOROLA ANALOG IC DEVICE DATA

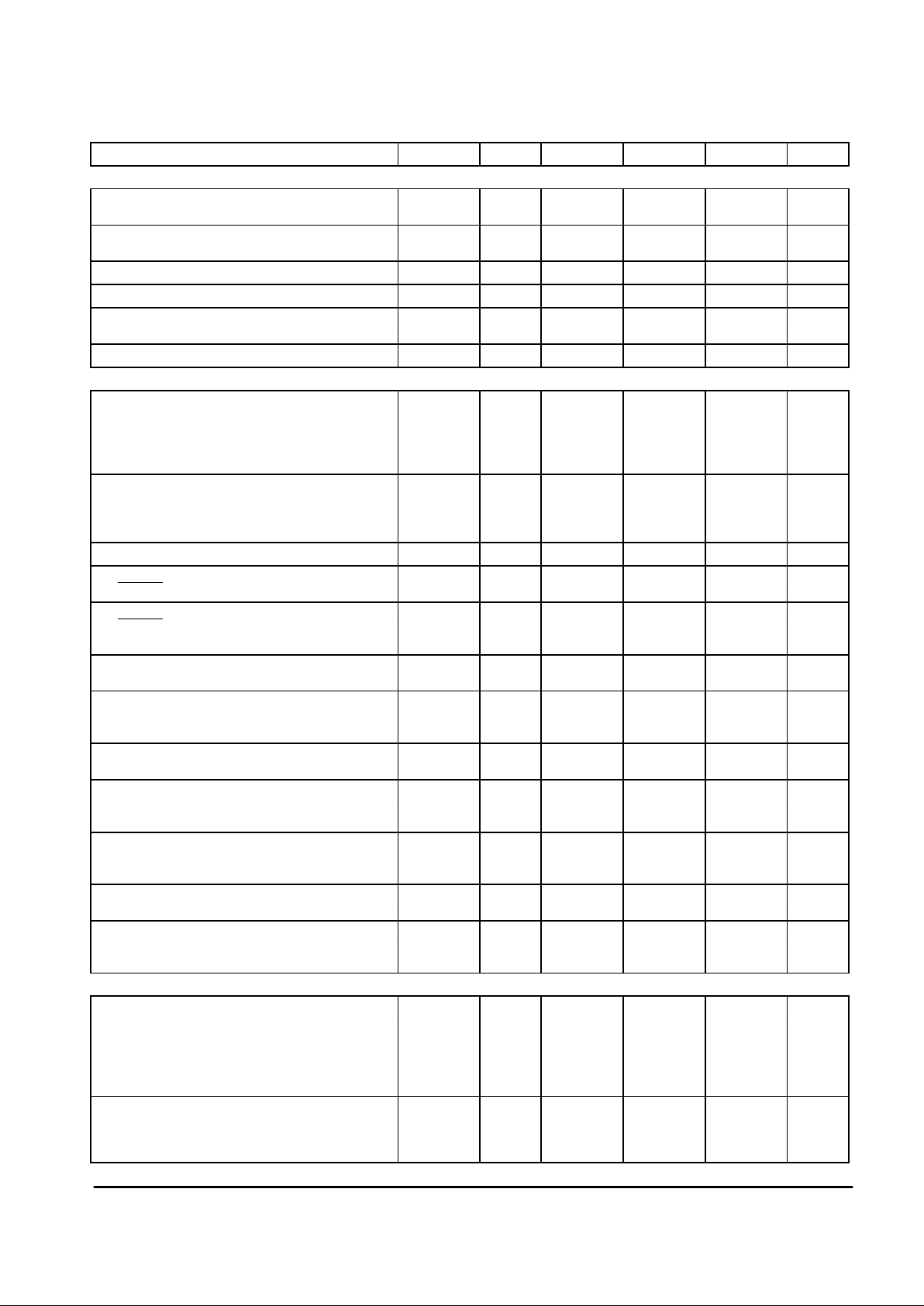

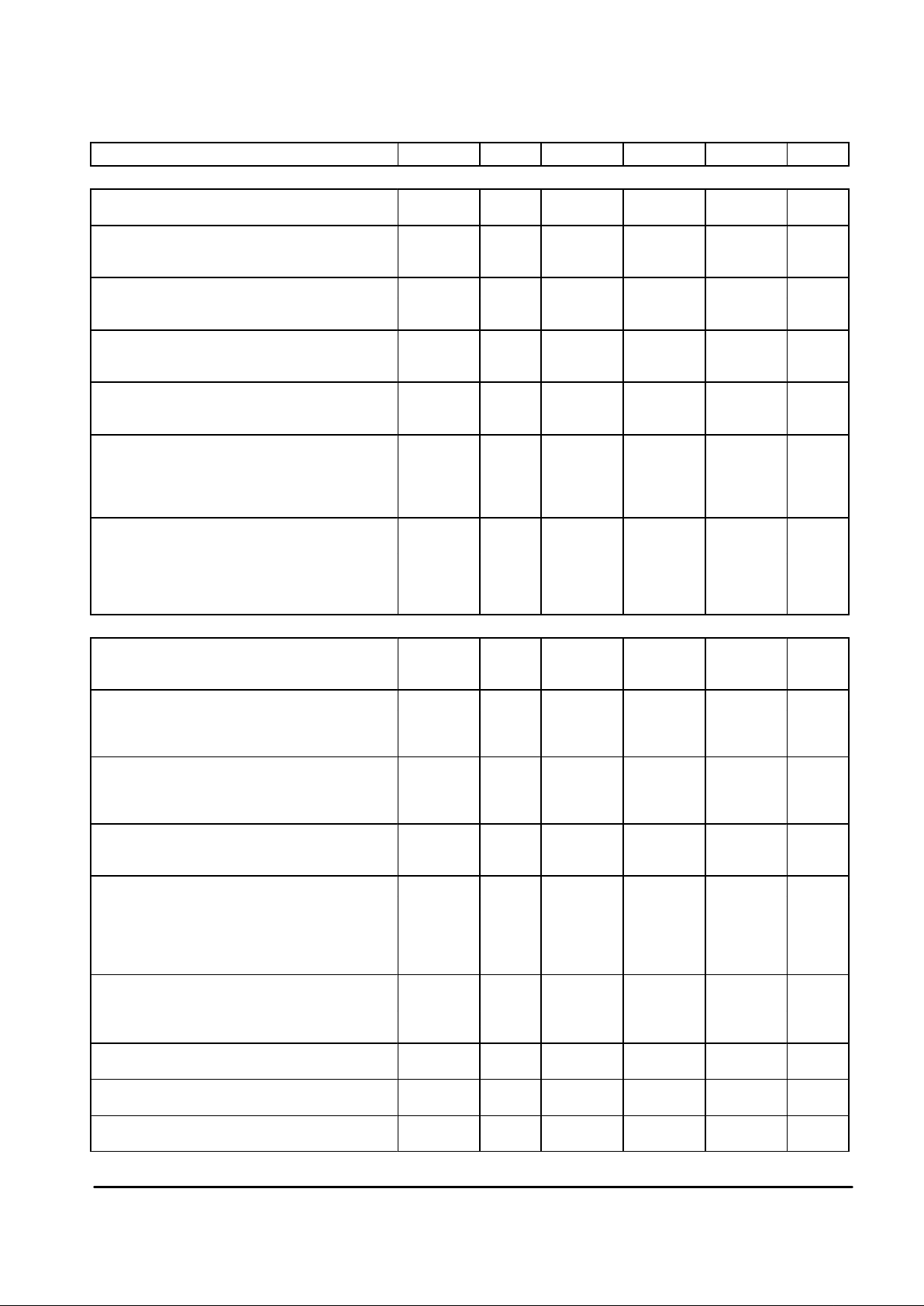

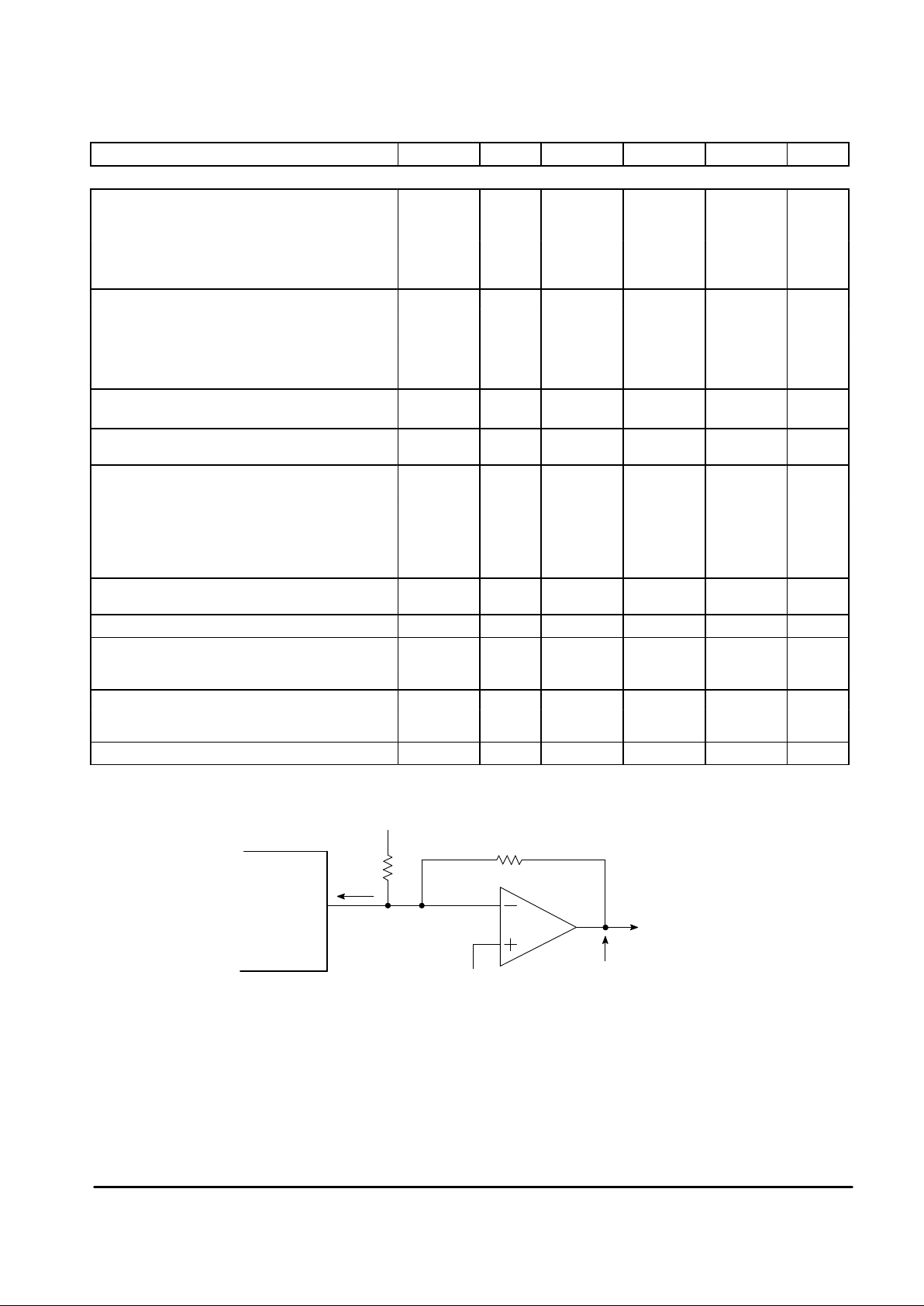

ELECTRICAL CHARACTERISTICS

Parameter Symbol Pin Min Typ Max Unit

BUS REQUIREMENTS

Maximum Output Low Voltage V

OL(max)

5 – 0.7 – V

I

sink

= 1.0 mA, Device in “Read” Mode

Maximum Sink Current I

sink(max)

5 – 1.0 – mA

VOL = 0.7 V , Device in “Read” Mode

Minimum Input High Voltage V

IH(min)

5 – 3.0 – V

Maximum Input Low Voltage V

IL(max)

5 – 1.5 – V

Maximum Rise Time t

r(max)

4, 5 – 1.0 – µs

Between VIH and VIL Levels

SCL Clock Frequency f

SCL

4 – – 100 kHz

HORIZONTAL TIMEBASE

Free–Running Frequency (Calibration Mode) – 31 kHz

17.734475 MHz Crystal. “NORM” Bit = 0;

“H EN” Bit = 1 (Horizontal Drive Disabled)

15.39 15.625 15.85

14.31818 MHz Crystal. “NORM” Bit = 1;

“H EN” Bit = 1 (Horizontal Drive Disabled)

15.42 15.75 15.98

H–Loop 1 (Pin 15 Current Forced to ± 20 µA) – 12 kHz

Minimum Frequency 13.85 14.25 14.65

Maximum Frequency 16.05 16.55 17.05

Frequency Range – 2.3 –

VCO Control Gain – 12, 15 1.9 2.4 2.9 kHz/V

Phase Detector Gain – 15 18 27 39 µA/µs

“HGAIN1” Bit = 1; “HGAIN2” Bit = 0

Phase Detector Gain Reduction Factor – 15 –

“HGAIN1“ Bit Switched from 1 to 0 2.5 3.0 3.5

“HGAIN2“ Bit Switched from 0 to 1 1.75 2.0 2.25

Line Drive Output Saturation Voltage – 12 – 0.25 0.5 V

I12 = 1.0 mA

Horizontal Drive Pulse Low – 12 – 27 – µs

Defined by Internal Counter, Deflection Transistor

“Off”, Period is 64 µs

Horizontal Flyback Input Resistance – 13 – 50 – kΩ

V13 = 2.0 V

Horizontal Flyback Clamping Voltages – 13 V

I13 = 500 µA – 5.7 –

I13 = –50 µA – –0.5 –

Horizontal Flyback Threshold Current – 13 30 – – µA

Should be Externally Limited to 500 µA Peak by an

External Resistor

Horizontal Phase Control Range – 12 8.0 – 12 µs

Flyback Duration: 12 µs

External Delay Compensation – 12, 13 6.0 – 18 µs

From Horizontal Drive to Center of Flyback Pulse.

Flyback Duration: 12 µs

VERTICAL TIMEBASE (All Values are Related to Pin 3 Reference Current)

Vertical Drive Amplitude (4:3 Display) – 7 V

(00) 1.15 1.33 1.5

(32) 1.55 1.75 1.95

(63) 1.95 2.18 2.4

C6 = 82 nF, Assuming Zero Tolerance

Capacitance, “VDI” Set to “1”

Vertical Drive Amplitude Control Range (4:3 Display) – 7 0.75 0.85 1.0 V

C6 = 82 nF, Assuming Zero Tolerance Capacitance,

“VDI” Set to “1”, Vertical Amplitude Varied from

(00) to (63)

Page 5

MC44002 MC44007

5

MOTOROLA ANALOG IC DEVICE DATA

ELECTRICAL CHARACTERISTICS (continued)

Parameter UnitMaxTypMinPinSymbol

VERTICAL TIMEBASE (All Values are Related to Pin 3 Reference Current)

Ramp Amplitude Ratio Between 4:3 and 16:9 Display

Modes

– 7 0.7 0.8 0.9 –

Vertical Amplitude = (32)

Maximum Ramp Amplitude Change With 525/625

Mode Change

– 7 – 2.0 – %

Vertical Ramp Low Voltage (4:3 Display) – 7 – 0.65 – V

Pin 6 Voltage Set to 0 V, “VDI” Set to “1”, Vertical

Position = (00)

Vertical Ramp Low Voltage (16:9 Display) – 7 – 0.85 – V

Pin 6 Voltage Set to 0 V, “VDI” Set to “0”, Vertical

Position = (00), Measured After 16:9 Holding

Period

Vertical Ramp High Voltage – 7 – 4.15 – V

Pin 6 Open, “VDI” Set to “0” or “1”, Vertical

Position = (63)

Vertical Ramp Position Control Range – 7 ±0.5 ±0.75 ±1.0 V

Versus Vertical Ramp Voltage at Vertical Position

(32), Measured at Vm, “VDI” Set to “0” or “1”,

Vertical Position Varied from (00) to (63)

Vertical Ramp Clamping Duration (tc) – 7 – 512 – µs

Defined by Internal Counter

Maximum Output Source Current – 7 1.0 – – mA

Maximum Output Sink Current – 7 200 – – µA

Vertical Linearity – 7 –

(00) – 0.8 –

(63) – 1.1 –

Change in Ramp current as Pin 9 Current Varied from

0 to 6.4 µA

– 6 µA

Vertical Breathing Correction = (63) 0.15 0.75 1.3

Vertical Breathing Correction = (00) – 0 –

Gain V7/V6 – 6, 7 0.9 0.95 1.0 V/V

E–W CORRECTION (V6(b) = 0.2 V , V6(m) = 1.1 V, V6(e) = 2.0 V)

Horizontal Amplitude – 8 µA

(00) 0 0.2 20

(63) 150 300 –

Corner Correction = (00), Tilt = (32), Parabola

Amplitude = (00), Measured at Tm.

Parabola Amplitude – 8 µA

(00) 0 0.2 10

(63) 100 250 –

Corner Correction = (00), Horizontal Amplitude =

(32), Tilt = (32), Measured at Tb, Tm and T

e.

Corner Correction – 8 µA

(00) 0 0.2 10

(63) – –150 –30

Horizontal Amplitude = (63), Parabola Amplitude =

(00), Tilt = (32), Measured at Tb, Tm and Te.

Parabola Tilt – 8 –

(00) – 1.9 –

(63) – –1.9 –

Corner Correction = (00), Horizontal Amplitude =

(32), Parabola Amplitude = (32), Measured at Tb,

Tm and Te.

E–W Drive Output Voltage – 8 1.0 – V

CC

V

Page 6

MC44002 MC44007

6

MOTOROLA ANALOG IC DEVICE DATA

ELECTRICAL CHARACTERISTICS (continued)

Parameter UnitMaxTypMinPinSymbol

E–W CORRECTION (V6(b) = 0.2 V, V6(m) = 1.1 V, V6(e) = 2.0 V)

E–W DACs Differential Non–Linearity Error – 8 LSB

At Minor Transitions: Steps 0–1: 1–2; 3–4; 7–8;

15–16.

–1.0 – 1.0

At Major Transition: Step 31–32 –2.0 – 1.0

SYNC SEPARATOR

Sync Amplitude to Operate the Device – 2, 40 100 – – mV

From Black to Sync, Black Picture, Standard Timing

Specifications on Sync Signal

22, 23,

24, 25

– 160 –

Vertical Sync Separator Delay T ime: t

d

– 2, 40 µs

“INTSEL” = 0 – 36 –

“INTSEL” = 1 – 68 –

From Vertical Sync Pulse to Vertical Ramp Reset

Vertical Sync Window – 2, 40,

22, 23,

24, 25

448 – 740 Half

Lines

COMPOSITE VIDEO PROCESSING (All measurements in NORMAL mode, unless otherwise noted.)

Composite Video Input Amplitude – 2, 40 0.7 1.0 1.4 Vpp

Load Impedance 75 Ω, Less than 5% Distortion

Video 1/Video 2 Input Crosstalk – 29 – – –40 dB

@ f = (2.0 MHz), Measured on Y1 Output

Variable Input LPF Cut–Of f Frequency – 29 MHz

17.7 MHz Crystal Selected – 6.0 –

14.3 MHz Crystal Selected – 4.85 –

Chroma Subcarrier Rejection – 29 dB

PAL 4.43 MHz (17.7 MHz Crystal Selected) 25 30 –

NTSC 3.58 MHz (14.3 MHz Crystal Selected) 25 30 –

SECAM (FoR and FoB) (17.7 MHz Crystal Selected) 18 20 –

Y1 Output Resistance – 29 – – 300 Ω

Y1 Bandwidth (–3.0 dB) – 29 MHz

PAL

Minimum Peaking, “T3” Set to 1 (Input LPF “On”)

2.5 3.0 –

SECAM

Minimum Peaking, “T3” Set to 0 (Input LPF “Off”)

2.5 3.0 –

Luma Peaking Range – 29 6.0 8.5 – dB

Measured at 3.0 MHz, 17.7 MHz Crystal Selected

Luma Gain (@ 100 kHz) – 2, 40, 29 0.9 1.1 1.3 V/V

Overshoot – 29 – 5.0 – %

Peaking at Step 3 (100)

Source Impedance – 2, 40 0 – 1.5 kΩ

Luma Delay Range – 29 ns

PAL/SECAM (17.7 MHz Crystal Selected) – 280 –

NTSC 3.58 (14.3 MHz Crystal Selected) – 350 –

Video In to Luma Out Delay Difference Between PAL

and SECAM (MC44002 only)

– 29, 40 – 260 – ns

Luma Delay Minimum: (D1 D2 D3) = (0 0 0), Green

to Magenta Transition, “T3” Set to 1 in PAL, to 0 in

SECAM

PAL/NTSC DECODER

Chroma Output Variation – 36, 37 – – 3.0 dB

For a Burst Input Varied from 60 mV to 600 mV

Color Kill Attenuation – 36, 37 40 – – dB

Referred to Standard Color Video Input,

Monochrome Mode Selected

Page 7

MC44002 MC44007

7

MOTOROLA ANALOG IC DEVICE DATA

ELECTRICAL CHARACTERISTICS (continued)

Parameter UnitMaxTypMinPinSymbol

PAL/NTSC DECODER

Color Difference Output Distortion – 36, 37 – – 5.0 %

@ 1.5 V Output Signal

Residual Chroma Subcarrier Rejection – 36, 37 dB

PAL 40 – –

NTSC 40 – –

Referred to Video Input

Oscillator Pull–In Range – 32, 33 Hz

PAL ±350 – –

NTSC ±400 – –

Referred to Nominal Subcarrier Frequency, with

Ideal Xtal

R–Y, B–Y Channel Separation – 36, 37 30 – – dB

B–Y/R–Y Amplitude Ratio – 36, 37 – 1.3 – V/V

At Standard Color Bars Signal

B–Y/R–Y Amplitude Ratio Spread – 36, 37 –2.0 – 2.0 dB

At Standard Color Bars Signal

Minimum Burst Level for “ACC Active” Flag “On” – 2, 40 – 10 20 mVpp

Standard Set to PAL or NTSC, Increasing Burst

Level Steps

Minimum Burst Level for “PAL Identified” Flag “On” – 2, 40 – 5.0 20 mVpp

Standard Set to PAL or NTSC, Increasing Burst

Level Steps

Maximum Burst Level for “ACC Active” Flag “Off” – 2, 40 – 5.0 – mVpp

Standard Set to PAL or NTSC, Decreasing Burst

Level Steps

Maximum Burst Level for “PAL Identified” Flag “Of f” – 2, 40 – 1.0 – mVpp

Standard Set to PAL or NTSC, Decreasing Burst

Level Steps

(B–Y) Color Difference Output Levels – 36 0.7 1.1 1.5 V

Relative to 75% Color Bars

Hue DAC Control Range – 36, 37 ±20 – – Deg

Hue Control Register Varying from (00) to (63)

Chroma to Luma Delay – 29, 36 ns

PAL – 80 –

NTSC – 100 –

Measured on (B–Y) Output, Luma Delay Set to

Minimum: (D1 D2 D3) = (0 0 0), Green to Magenta

Transition, “T3” Set to 1

DELAY LINE CONTROL SIGNALS

System Select – 30

PAL – 75 400 mV

NTSC 1.4 1.65 1.9 V

SECAM (MC44002 only) 2.75 3.0 3.25 V

EXTERNAL 3.7 4.0 4.3 V

Sandcastle – 31

Level 1 3.7 4.0 4.3 V

Level 2 2.75 2.95 3.15 V

Level 3 1..3 1.55 1.8 V

Level 4 – 75 – mV

See Figure 4

Sandcastle – 31 µs

t1 5.0 6.0 7.0

t2 4.0 5.0 6.0

See Figure 4, Values Defined by Internal Counter

Page 8

MC44002 MC44007

8

MOTOROLA ANALOG IC DEVICE DATA

ELECTRICAL CHARACTERISTICS (continued)

Parameter UnitMaxTypMinPinSymbol

S–VHS VIDEO PROCESSING (S–VHS Set to 0, “T3” Set to 0)

Y1 Bandwidth – 29 3.2 3.5 – MHz

Luma Peaking Set to Minimum

Minimum Burst Level for “ACC Active” Flag “On” – 2, 40 – 10 20 mVpp

Standard Set to PAL or NTSC, Increasing Burst

Level Steps

Minimum Burst Level for “PAL Identified” Flag “On” – 2, 40 – 5.0 20 mVpp

Standard Set to PAL or NTSC, Increasing Burst

Level Steps

Maximum Burst Level for “ACC Active” Flag “Off” – 2, 40 – 5.0 – mVpp

Standard Set to PAL or NTSC, Decreasing Burst

Level Steps

Maximum Burst Level for “PAL Identified” Flag “Of f” – 2, 40 – 1.0 – mVpp

Standard Set to PAL or NTSC, Decreasing Burst

Level Steps

Video In to Luma Out Delay Difference Between

S–VHS and Normal Mode

– 2, 40, 29 – 310 – ns

Luma Delay Minimum in Normal Mode, Set to Step

6 in S–VHS Mode, Green to Magenta Transition,

“T3” Set to 1 in Normal Mode, to 0 in S–VHS Mode

Chroma to Luma Delay Difference Between S–VHS

and Normal Mode

– 29, 36,

2, 40

– 60 – ns

Measured on (B–Y) Output, Luma Delay Minimum

in Normal Mode, Set to Step 6 in S–VHS Mode,

Green to Magenta Transition, “T3” Set to 1 in

Normal Mode, to 0 in S–VHS Mode

SECAM DECODER (MC44002 ONL Y)

Minimum Subcarrier Level for “SECAM Identified”

Flag

– 2, 40 – 10 20 mVpp

Measured at foR

Color Kill Attenuation – 36, 37 40 50 – dB

Monochrome Mode Selected Referred to Color

Difference Output Signal with SECAM Selected

and Identified

Color Difference Zero Level Error – 36, 37 – ±1.0 ±3.0 %

Relative to 75% Color Bars, Difference Between

Signal Measured at t1 and Active Black Level

(Black Bar)

Color Difference Output Distortion – 36, 37 – – 5.0 %

Subcarrier Level at foR = 20–400 mV @ 1.5 V

Output Signal

Transient Response – ns

(B–Y) 36 – 650 800

(R–Y) 37 – 750 900

Generator Rise Time – 600 ns (B–Y), Green to

Magenta Transition, Measured Between 10% and

90% Levels

B–Y/R–Y Amplitude – 36, 37

Ratio – 1.3 – V/V

Ratio Spread –2.0 – 2.0 dB

Relative to 75% Color Bars

Residual Carrier and Harmonics (4.0 to 13.5 MHz) – 36, 37 – – 1.0 %

At Standard Color Bars Signal

(B–Y) Color Difference Output Levels – 36 – 1.1 – V

Relative to 75% Color Bars

PAL/SECAM Color Dif ference Ratio – 36 0.8 1.0 1.2 –

Nominal Input Signals

Page 9

MC44002 MC44007

9

MOTOROLA ANALOG IC DEVICE DATA

ELECTRICAL CHARACTERISTICS (continued)

Parameter UnitMaxTypMinPinSymbol

SECAM DECODER (MC44002 ONL Y)

Chroma to Luma Delay – 29, 36 – 420 – ns

Luma Delay Set to Minimum: (D1 D2 D3) = (0 0 0),

Green to Magenta Transition, “T3” Set to 0

Patterning – 36 – – 5.0 %

Full Screen 75% Color Frequency, 500 kHz Low

Pass Filter, Relative to Black to Color Output Signal

Line to Line Luma Levels Difference – 29 – – 1.5 %

Full Screen 75% Y ellow Color Frequency, Relative

to Black to Yellow Output Signal

Chroma to Luma Delay Difference Between P AL and

SECAM

– 29, 36 – 340 – ns

Measured on (B–Y) Output, Luma Delay Set to

Minimum: (D1 D2 D3) = (0 0 0), Green to Magenta

Transition, “T3” Set to 0 in SECAM, to 1 in PAL

COLOR DIFFERENCE STAGES

RGB Input Amplitude – 22, 23, 500 700 1000 mVpp

Black to Peak (Less than 5% Distortion at RGB

Outputs)

24

Fast Commutate – 21 V

Low Level – – 0.5

High Level 1.0 – –

Y2 Input Amplitude – 25 0.7 1.0 1.4 Vpp

(Less than 5% Distortion at RGB Outputs)

Color Difference Input Amplitude – 26, 27 – – 1.8 Vpp

(Less than 5% Distortion at RGB Outputs)

Y2/Y1 Crosstalk – 25, 29 – –40 –30 dB

Measured at RGB Outputs, Measured at f = (2.0 MHz)

RGB to Y Crosstalk – 22, 23, – –40 –30 dB

Measured at RGB Outputs, Measured at f = (2.0 MHz) 24, 25,

29

RGB Transconductance Bandwidth (@ –1.0 dB) – 24, 17,

23, 18,

22, 19

6.5 – – MHz

Gain Reduction in ACL Mode – 10, 17, – 12.5 – dB

Pin 10 Voltage Varying from 0 to 5.0 v 18, 19

Gain Reduction Sensitivity in ACL Mode – 10, 17, – 20 – dB/V

Pin 10 Voltage Varying from 2.0 to 2.5 V 18, 19

Demodulation Angles and Amplitudes – – Deg

Mode A Rm – 0.562 –

Ra – 90 –

Gm – 0.344 –

Ga – 237 –

Mode B Rm – 0.9 –

Ra – 100 –

Gm – 0.3 –

Ga – 236 –

Mode C Rm – 0.9 –

Ra – 106 –

Gm – 0.3 –

Ga – 240 –

Mode D Rm – 0.91 –

Ra – 106 –

Gm – 0.31 –

Ga – 246 –

Definitions: Rm/Gm = Module, Ra/Ga = Argument

Page 10

MC44002 MC44007

10

MOTOROLA ANALOG IC DEVICE DATA

ELECTRICAL CHARACTERISTICS (continued)

Parameter UnitMaxTypMinPinSymbol

RGB OUTPUT STAGES

Low Dark Sample Output Current – 17, 18, mA

Red 19 – – 3.15

Green – – 3.15

Blue – – 3.15

Dark Sample Cathode Current 5.0 to 15 µA, DC

DAC Set to Full Scale, See Figure 1

High Dark Sample Output Current – 17, 18, mA

Red 19 3.95 – –

Green 3.95 – –

Blue 3.95 – –

Dark Sample Cathode Current 5.0 to 15 µA, DC

DAC Set to Zero, See Figure 1

Blanking Output Current – 17, 18,

19

6.0 – – mA

Maximum Y to RGB Output Transconductance – 17, 18, 6.0 7.0 8.0 mA/V

Gain DAC Set to Full Scale 19

Brightness – – V

(00) – 30 –

(63) – –20 –

Wrt Dark Sample Cathode Voltage,

High Voltage Output Stage T ransimpedance

39 kΩ, Dark Sample Cathode Current 15 µA, Dark

Sample Cathode Voltage 140 V

RGB Dark Sample Current Intensity Range – 20 15 20 – dB

RGB Intensity DACs Varying from (00) to (63)

Bright to Dark Sample Current Ratio – 20 8.0 9.5 11 µA/µA

Leakage Loop – 20 µA

Sink Current 20 – –

Source Current 5.0 – –

Average Beam Current Detection Level – 9 V

Excess Flag 0.9 1.0 1.1

Overload Flag –1.3 –1.2 –1.1

Peak Beam Current Detection Level – 20 6.5 6.8 7.1 V

Figure 1. Example of Output Circuitry

Vp, V

ref

, R

FDBK

and Rp values will determine the exact operating point.

For example, let us take:

Vp = 5.0 V R

FDBK

= 39 kΩ

V

ref

= 3.6 V

Rp = 6.8 kΩ

The formula giving the Dark Cathode Voltage with above circuit is: Vdk = V

ref

+ R

FDBK

*(V

ref

– Vp + lodk*Rp) / R

p

With above application, component values and lodk specifications, all 3 cathodes on all devices will always have a range of at least 120 V to 150 V.

By changing the values of Vp, V

ref

and Rp, the cathode voltage range may be shifted up or down as required.

lodk

V

ref

V

dk

Picture Tube

Cathode

R

FDBK

R

P

V

P

Pins 17, 18, 19

MC44002/7P

Page 11

MC44002 MC44007

11

MOTOROLA ANALOG IC DEVICE DATA

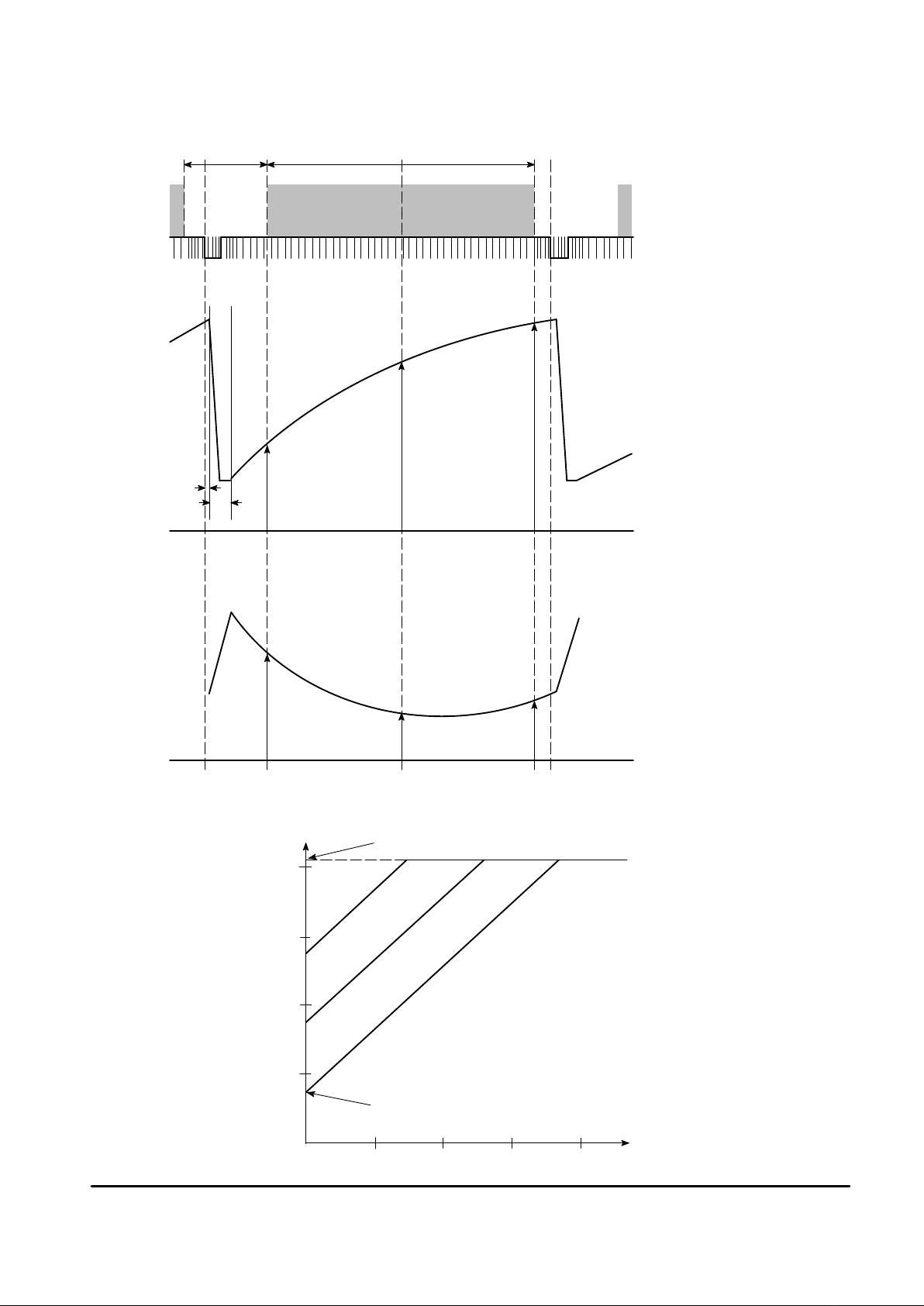

Figure 2. Vertical Waveforms

Figure 3. Vertical Ramp Positions (V7 versus V6)

1.6 ms 18.4 ms

T

b

T

m

T

e

V

b

V

m

V

e

I

b

I

m

I

e

t

d

t

c

Video Signal

Vertical Ramp W aveform

Parabola Waveform

V Ramp High Voltage

V Ramp Low Voltage

(XX) = Values of (80) Register

(63)

Pin 6 Voltage (V)

Pin 7 Voltage (V)

4

1

(32) (00)

3

2

1

234

Page 12

MC44002 MC44007

12

MOTOROLA ANALOG IC DEVICE DATA

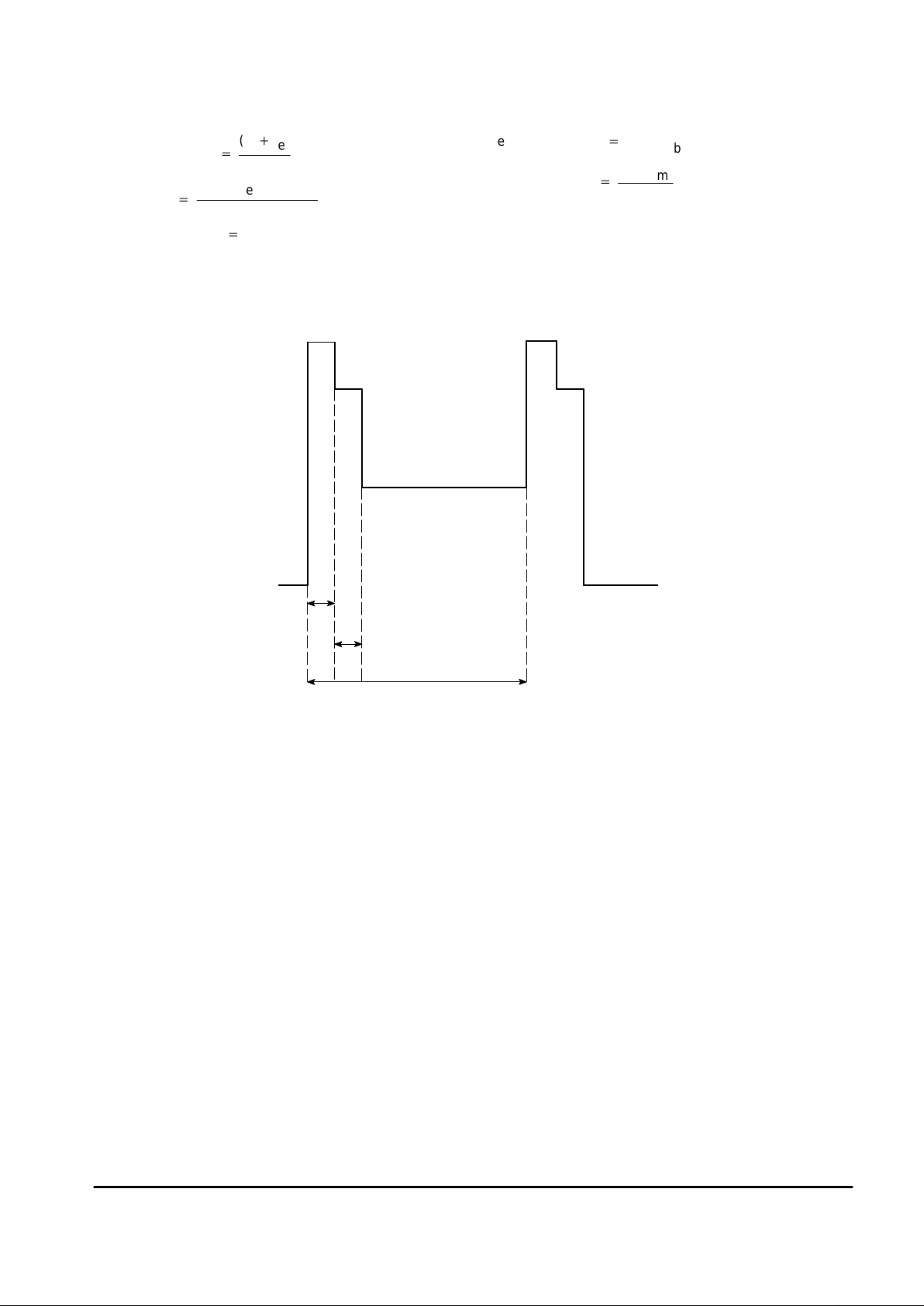

Definitions

Parabola Amplitude

+

(ib)

ie)

2

–i

m

Parabola Tilt

+

(ie–ib)

Parabola Amplitude

Horizontal Amplitude+i

m

Vertical Amplitude+Ve–V

b

Vertical Linearity

+

(Ve–Vm)

Vm–V

b

Corner correction is calculated in the same way as Parabola Amplitude.

Figure 4. Sandcastle Output (Pin 31)

64 µs

1

2

4

3

t1

t2

GENERAL DESCRIPTION OF THE CHROMA 4 SYSTEM

Figure 5 shows a simplified block diagram representation

of the basic system using the MC44002/7 and its companion

device the MC44140 chroma delay line. The MC44002/7 has

been designed to carry out all the processing of video

signals, display controls and timebase functions. There are

two video inputs which can be used for normal composite

video or separate Y and C inputs. In either case, the inputs

are interchangeable and selection is made via the I2C bus.

The video is decoded within the MC44002/7 and involves

separation, filtering, delay of the luminance part of the signal

and demodulation of the chroma into color difference signals.

The luminance (called Y1) together with the demodulated

R-Y and B-Y are all then brought out from the IC. The color

difference signals then enter the MC44140 which performs

color correction in PAL and the delay line function in SECAM.

Corrected color difference signals then re-enter the

MC44002/7.

Page 13

MC44002 MC44007

13

MOTOROLA ANALOG IC DEVICE DATA

Figure 5. Connection to TV Chassis

B

B

G

G

R

R

G2

G1

EHT

V O/P

Stage

V-Scan

Coils

26 V

Line O/P

Stage

E-W

Amplifier

Diode Modulator

Linearity

H-Scan

Coils

Focus

EHT

Tripler

5.0 V

Line Output

Transformer

H-Flyback

H-Drive

Anode Current

E-W Drive

V-Drive

Analog

Contrast

R-O/P

G-O/P

B-O/P

Feedback

0 V

Data

Clock

14.3 MHz

17.7 MHz

Fast Commutate

B In

G In

R In

Y2 In

Ext B-Y

Ext R-Y

B-Y In

R-Y In

B-Y Out

R-Y Out

Y1 Out

Video 2

Video 1

G3

I2C Bus

MC44002/7

MC44140

H.T.

Comp Video

or

S-VHS

Beam Current

Limitation

12 V

The next stage is called the color difference stage where a

number of control functions are carried out together with

matrixing of the components to derive RGB signals. At this

point a number of auxiliary signals may also be switched in,

again all under MCU control. External RGB (text) and Fast

Commutate enter here; also an external luminance (Y2) may

be used instead of Y1. External R-Y and B-Y are switched in

via the delay line circuit to save pins on the main device. The

Y2 and External R-Y, B-Y will obviously be of considerable

benefit from the system point of view for use with external

decoders.

The final stage of video processing is the RGB outputs which

drive the high voltage amplifiers connected to the tube

cathodes. These outputs are controlled by a sophisticated

digital servo-loop which is maintained and stabilized by a

sequentially sampled beam current feedback system.

Automatic gray scale control is featured as a part of this system.

Both horizontal and vertical timebases are incorporated

into the MC44002/7 and control is via the I2C bus. The

horizontal timebase employs a dual loop system of a PLL and

variable phase shifter, and the vertical uses a countdown

system. For the vertical, a field rate sawtooth is available

which is used to drive an external power amplifier with

flyback generator (usually a single IC). The line output

consists of a pulse which drives a conventional line output

stage in the normal way. The line flyback pulse is sensed and

used by the second loop for horizontal phase shift.

Where E-W correction is required, a parabola waveform is

available for this which, with the addition of a power amplifier,

can be used with a diode modulator type line output stage for

dynamic width and E-W control. The bottom of the EHT

overwinding is returned to the MC44002/7 and is used for

anode current monitoring.

Fast beam current limitation is also made possible by the

use of an analog contrast control.

A much more detailed description of each stage of the

MC44002/7 will be found in the next section. Information on

the delay line is to be found in its own data sheet.

Page 14

MC44002 MC44007

14

MOTOROLA ANALOG IC DEVICE DATA

Introduction

The following information describes the basic operation of

the MC44002/7 IC together with the MC44140 chroma delay

line. The MC44002/7 is a highly advanced circuit which

performs all the video processing, timebase and display

functions needed for a modern color TV . The device employs

analog circuitry but with the difference that all its advanced

features are under processor control, enabling external

filtering and potentiometer adjustments to be removed

completely. Sophisticated feedback control techniques have

been used throughout the design to ensure stable operating

conditions and the absence of drift with age.

The IC described herein is one of a new generation of TV

circuits, which make use of a serial data bus to carry out

control functions. Its revolutionary design concept permits a

level of integration and degree of flexibility never achieved

before. The MC44002/7 consists of a single bipolar VLSI chip

which uses a high density, high frequency, low voltage

process called MOSAIC 1.5. Contained within this single 40

pin package is all the circuitry needed for the video signal

processing, horizontal and vertical timebases and CRT

display control for today’s color TV. Furthermore, all the user

controls and manufacturer’s set-up adjustments are under

the control of the processor I2C bus, eliminating the need for

potentiometer controls. The MC44002/7 offers an enormous

variety of different options configurable in software, to cater

to virtually any video standard or circumstance commonly

met. The decoder section offers full multistandard capability,

able to handle PAL, SECAM (MC44002 only) and NTSC

standards with 4 matrix modes available. Practically all the

filtering is carried out onboard the IC by means of sampled

data filters, and requires no external components or

adjustment.

Digital Interface

One of the most important features of MC44002/7 is the

use of processor control to replace external potentiometer

and filter adjustments. Great flexibility is possible using

processor control, as each user can configure the software to

suit their individual application. The circuit operates on a

bidirectional serial data bus, based on the well known I2C

bus. This system is rapidly becoming a world standard for the

control of consumer equipment.

I2C Bus

It is not within the scope of this data sheet to describe in

detail the functioning of the I2C bus. Basically, the I2C bus is

a two-wire bidirectional system consisting of a clock and a

serial data stream. The write cycle consists of 3 bytes of data

and 3 acknowledge bits. The first byte is the Chip Address,

the second the Sub-address to identify the location in the

memory, and the third byte is the data. When the address’

Read/Write bit is high, the second and third bytes are used to

transmit status flags back to the MCU.

Figure 6 shows a block diagram of the MC44002/7 Bus

Interface/Decoder. To begin with, the start bit is recognized

by means of the data going low during CLK high. This causes

the Counter and all the latches to be reset. For a write

operation, the Write address ($88) is read into the Shift

Register. If the correct address is identified, the Chip Address

Latch is set and at CLK 9 an acknowledge is sent.

The second byte is now read into the Shift Register and is

used to select the Sub-address. At CLK 18 a Sub-address

Enable is sent to the memory to allow the Data in the register

to be changed. Also, at CLK 18 another acknowledge is sent.

The third byte is now read into the Shift Register and the

Data bussed into the memory. The Data in the Sub-address

location already selected is then altered. A third acknowledge

is sent at CLK 27 to complete the cycle.

A Read address ($89) indicates that the MCU wants to

read the MC44002/7 status flags. In this instance, the

Read/Write Latch is set, causing the Memory Enable and

Subaddress Enable to be inhibited, and the flags to be written

onto the data line. Two of the status flags are permanently

wired one-high and one-low (O.K. and Fault), to provide a

check on the communication medium between the

MC44002/7 and the MCU.

At start-up the Counter is automatically reset and the Data

for each Sub-address is read in from the MCU. Only after the

entire memory contents have been transmitted, is Data 00

sent to register 00 to start the Horizontal Drive.

The MC44002/7 needs the full 27 clock cycles, or a stop

condition, to properly release the I2C bus.

4

Figure 6. I2C Bus Interface and Decoder

8-Bit Shift Register

Read/Write

Latch

Chip-Address

Latch

Sub-Address

Latches

Memory &

Sub-Address

Decoding

Acknowledge

Data

Clock

Clock Counter

Reset

Start-Bit

Recognition

5

8-Bit

8-Bit

8-Bit

Page 15

MC44002 MC44007

15

MOTOROLA ANALOG IC DEVICE DATA

A

D

Bits 6,7Bits 6,7Bits 6,7Bits 6,7Bits 6,7

I-88I-87I-7AI-79I-78

Figure 7. MC44002/7 Memory Map

Data 0

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

MSB

LSB

A

D

A

D

A

D

A

D

Memory Sub-Address 77

Digital Register, Bits 0-7

Memory Sub-Address 78

Analog Register, Bits 0-5

Memory Sub-Address 79

Analog Register, Bits 0-5

Memory Sub-Address 7A

Analog Register, Bits 0-5

Memory Sub-Address 87

Analog Register, Bits 0-5

Memory Sub-Address 88

Analog Register, Bits 0-5

Memory

Figure 7 shows a diagram of the MC44002/7 Memory

Map. It has 18 bytes of memory which are located at hex

sub-addresses 77 to 88. Sub-address 77 is used to set up the

vertical timebase mode of the IC and for S-VHS switching,

and consists of 8 separate data bits. The remaining 17 bytes

use the least significant 6-bits as an analog control register.

The contents of each are D/A converted, providing an analog

control current which is distributed to the appropriate part of

the circuit. Bits 6 and 7 are used singularly for switching

control functions.

Chroma Decoder

The main function of this section is to decode the incoming

composite video, which may be in any of the PAL, NTSC or

SECAM (MC44002 only) Standards, and to retrieve the

luminance and color difference signals. In addition, the signal

filtering and luma delay line functions are carried out in this

section by means of sampled data filters.

The entire decoder section operates in sampled data

mode using clocks generated by external crystals. The

oscillator, which is phase-locked in the usual way for

PAL/NTSC modes, provides the clock function for the whole

circuit. The crystals are selected by the MCU by means of a

control bit (XS). Only crystals appropriate to the standards

which are going to be received need to be fitted. A 17.7 MHz

crystal (4x PAL subcarrier) is used for PAL and SECAM

systems (50 Hz, 625 lines); and 14.3 MHz (4x NTSC

subcarrier) for the NTSC system (60 Hz, 525 lines). Nearly all

the filters, together with the luma delay line and peaking,

have been integrated, requiring no external components or

any adjustment. The filter characteristics are entirely

determined by the clocks and by capacitor ratios, and are

thus completely independent of variations in the

manufacturing process. The PAL/NTSC subcarrier PLL and

ACC loop filters have not been integrated in order to facilitate

testing. These filters consist of fixed external components.

Figure 8 is a block diagram of the main features of the

chroma decoder. Selection is first made between the Video 1

and Video 2 inputs. These may be either normal composite

video or separate luma and chroma which may enter the IC at

either pin. Commands from the MCU are used to route the

signals through the appropriate delay and filter sections.

In PAL/NTSC, a variable low pass filter, which can be

software bypassed (control bit T3), is then used to

compensate for IF filtering and the Q of the external sound

traps. Filter response is controlled by means of control bits

T1 and T2. It is not recommended to use this filter in SECAM

or in S–VHS, as luma–chroma delays will not be optimized.

Next, the video enters the luma path. The PAL/NTSC or

SECAM chroma signals are separated out by transversal

high pass filters. In SECAM mode, the chroma trap frequency

is dynamically steered to follow the instantaneous frequency

of the chroma.

Then, another transversal filter provides luma peaking,

which is also active in S–VHS mode. The high frequency

luma may be peaked (at about 3.0 MHz with the 17.7 MHz

crystal, and 2.4 MHz with the 14.3 MHz crystal) in 7 steps up

to a maximum of 8.5 dB, by a control word from the MCU.

Another control word is used to trim the delay in the luma

channel. Five steps of 56 ns (70 ns with the 14.3 MHz crystal)

are possible, giving a total programmable delay of 280 ns.

Steps 6 and 7 are used in S–VHS mode. The resulting

processed luma signal then proceeds to the color difference

section after being low–pass filtered by an active filter to

remove components of the crystal frequency, and twice that

frequency. The luma component (Y1) is made available at

Pin 29 for use with auxiliary external functions, as well as

testing.

When in the S–VHS mode, the S–VHS control bit controls

the signal paths. The luma signal bypasses the first section of

the luma channel, which contains the chroma trap. The

S–VHS chroma is passed directly to the PAL/NTSC decoder

without further filtering.

As all the delay and filter responses are determined by the

crystal, they automatically commute to the new standard

when the crystal is changed over. Thus, when the 14.3 MHz

clock is being used, the chroma trap moves to 3.58 MHz.

The filtered PAL/NTSC and SECAM chroma signals are

decoded by their respective circuits. The P AL/NTSC decoder

employs a conventional design, using ACC action for gain

control and the common double balanced multipliers to

retrieve the color difference signals. The SECAM decoder is

discussed in a separate subsection.

Page 16

MC44002 MC44007

16

MOTOROLA ANALOG IC DEVICE DATA

PAL/NTSC

(MCU)

29

36

37

391

B-Y

R-Y

SECAM

Decoder

32

33

Oscillator

14.3MHz

17.7MHz

C

C

PLL

ACC

PAL/NTSC Decoder

4.4/8.8MHz

R-Y

System Select

Hue Controls

V

U

Ident

(MCU)

B-Y

4.4/8.8MHz

Luma

Luma

Delay

Line

Ident Data

(MCU)

Luma–Chroma Filters

t1, t2

Video 2

Video 1

38

Figure 8. Chroma Decoder

AGC Q

S-VHS

Crystal

Select

S-VHS

Delay ADJ

To Color

Difference

Stage

11

SECAM

Cal

Loop

2

40

Peaking

Syn

Sep

t3

Input

Select

Y1

NOTES: SECAM decoding

available in the MC44002 only.

The actual decision as to a signal’s identity is made by the

MCU based on data provided by 3 flags returned to it,

namely: ACC Active, PAL Identified, and SECAM Identified.

Control bits SSA–SSD must be sent to set the decoder to

the correct standard.

This allows a maximum of flexibility, since the software

may be written to accommodate many different sets of

circumstances. For example, channel information could be

taken into account if certain channels always carry signals in

the same standard. Alternatively, if one standard is never

going to be received, the software can be adapted to this

circumstance. If none of the flags are on, color killing can be

implemented by the MCU. This occurs if the net Ident Signal

is too low, or if the ACC circuit is inactive due to too low a

signal level.

The demodulated color difference signals now enter the

Hue control section, where selection is made between

PAL/NTSC and SECAM outputs. The Hue control is simply

realized by altering the amplitudes of both color difference

signals together. Hue control is only a requirement in NTSC

mode and would not normally be used for other standards.

The function is usually carried out prior to demodulation of

the chroma by shifting the phase of the subcarrier reference,

causing decoding to take place along different axes. In the

MC44002/7, Hue control is performed on the already

demodulated color difference signals. A proportion of the R-Y

signal is added or subtracted to the B-Y signal and

vice-versa. This has the same effect as altering the reference

phase. If desired, the MC44002/7 can apply the Hue control

to simple PAL signals.

After manipulation by the Saturation and Hue controls, the

color difference signals are finally filtered to reduce any

remaining subcarrier and multiplier products. Before leaving

the chip at Pins 36 and 37, the signals are blanked during line

and frame intervals. The 64 µs chroma delay line is carried

out by a companion device, the MC44140.

SECAM Decoder (MC44002 only)

The SECAM signal from the high-pass filter enters tightly

controlled AGC amplifiers wrapped around a cloche filter

which is a sampled recursive type, with the AGC derived from

a signal squarer. Next, the signal is blanked during the

calibration gate period and a reference 4.43 MHz is inserted

during this time. The SECAM signal is then passed through a

limiter.

The frequency demodulator function is carried out by a

frequency-locked-loop (F.L.L.). This consists of three

components: a tracking filter, a phase detector and a loop

filter. The center frequency of the tracking filter depends on

three factors: internal R-C product, ADJUST voltage, and

TUNING voltage. The tracking filter is dynamically tuned by

the TUNING feedback from the loop-filter forming the F.L.L.

The ADJUST control calibrates the F.L.L. and compensates

for variations in the R-C product. After the F.L.L., the color

difference signals are passed to another block where several

functions are carried out. The signals are de-emphasized

and outputs are provided to the Ident section. Another

function of this section is to generate the I

COMP

signal used

for calibrating the F.L.L. This signal is blanked during the

H-IG period to ensure that (R-Y) and (B-Y) output signals

have a clean dc level for clamping purposes.

In addition, components are added to compensate for the

R-C product, and tuning offsets are introduced during the

active lines for F0R/F0B.

Calibration of the F.L.L. takes place during every field

blanking interval, starting from field retrace and ending just

before the SECAM vertical Ident sequence (bottles). The

calibration current I

CAL

is derived from I

COMP

during the

Page 17

MC44002 MC44007

17

MOTOROLA ANALOG IC DEVICE DATA

calibration gate (CAL) and integrated by an external

capacitor on Pin 11. The resulting voltage V

EXT

is then

transformed to generate the ADJUST control voltage

removing from the loop range most of the variations due to

internal RC products and temperature.

Color Difference Stages

This stage accepts luminance and color difference

signals, together with external R,G,B and Fast Commutation

inputs and carries out various functions on them, including

clamping, blanking, switching and matrixing. The outputs,

consisting of processed R,G,B signals, are then passed to

the Auto Gray Scale section.

A block diagram of this stage is shown in Figure 10. The

Y2, R-Y, B-Y together with R, G and B are all external inputs

to the chip. The Y1 signal comes from the decoder section.

Each of the signals is back-porch clamped and then blanked.

The Y2 and R,G,B inputs have their own simple sync

separators, the output from which may be used as the

primary synchronization for the chip by means of commands

from the MCU.

The Fast Commutation is an active high input used to drive

a high speed switch; for switching between the Y and color

difference inputs and the R,G,B (text) inputs.

After blanking, the Y1 and Y2 channels go to the Luma

Selector which is controlled by means of 2 bits from the MCU.

From here the selected luma signal goes to the RGB matrix.

The two color difference signals pass through the saturation

control. From here they go to a matrix in which G-Y is

generated from the R-Y and B-Y, and lastly , to another matrix

where Y is added to the three color difference signals to

derive R,G,B.

Control bits (via the I2C bus) allow the matrix coefficients

to be adjusted in order to suit different requirements,

particularly in NTSC. Table 1 shows the theoretical

demodulation angles and amplitudes and the corresponding

matrix coefficient values for each of the 4 selectable modes.

(The A mode corresponds to the standard PAL/SECAM/NTSC

mode). Although primarily intended for NTSC, this feature can

also act on PAL/SECAM or external RGB signals.

The R,G,B inputs may take one of two different paths.

They may either go straight to the output without further

processing, or via a separate matrix and the saturation

control. The path taken is controlled in software. When the

latter route is selected, the R,G,B signals undergo a matrix

operation to derive Y. From this, R-Y and B-Y are easily

derived by subtraction from R and B; the derived color

difference signals are then subjected to saturation control.

This extra circuitry allows another feature to be added to the

TV set, namely the ability to adjust the color saturation of the

RGB inputs. After the saturation control the derived signals

are processed as before.

Table 1. Matrix Modes Coefficients

A B C C

RR 1.0 1.577 1.539 1.556

RB 0 –0.156 –0.248 –0.251

GR –0.513 –0.443 –0.462 –0.504

GB –0.187 –0.168 –0.150 –0.125

BB 1.0 1.0 1.0 1.0

BR 0 0 0 0

Rm 0.562 0.9 0.9 0.91

Gm 0.344 0.3 0.3 0.31

Ra 90 100 106 106

Ga 237 236 240 246

NOTE: BB = Gain of (B

out

/(B–Y)in) = 1 (reference). BR = Gain of (B

out

/(R–Y)in) = 0 (theoretically).

Figure 9. SECAM Decoder (MC44002 only)

SECAM

I/P

VA1 Adjust

RC-T

Compensation

Ident

Out

De-emphasis

Tuning Offsets

Output Interface

PHIG

I

RC

Fbk

I

COMP

CAL

11

SECAM

Cal

Loop

I

CAL

AGC

A1 A2

CAL

X

2

Squarer

Timing SignalsSECAM Out

(R-Y/B-Y Sequen.)

FLL Demodulator

Phase

Detector

FLL Tracking

Filter

Loop

Filter

Cloche Filter

H

H Clamp

Calibration

Switch

Adjust

4.43MHz

Limiter

V

Tun

Page 18

MC44002 MC44007

18

MOTOROLA ANALOG IC DEVICE DATA

Clamp

Clamp

Clamp

Blanking

26

25

Y1

Sync

Separator

Clamp

Y1, Y2 Select

Luma

Selector

Gate

Outputs

19

18

17

Gate

Gate

R-Y

Gen

B-Y

Gen

R

G

B

Y Matrix

Blanking/Fast

Commutation

Logic

Blanking

Burst Gate

Bypass

YX EN

Blanking

Sync

Separator

ClampClampClamp

22232421

Fast

Commutation

Y2

Y1

Saturation

Control

Figure 10. Color Difference Stages

Matrix

28

Inputs

27

BGRF/C

B

G

R

B-Y

Y2

R-Y

Y1 Clamp

Analog

Contrast

10

BCL

Inputs

Page 19

MC44002 MC44007

19

MOTOROLA ANALOG IC DEVICE DATA

In order to implement automatic beam current limiting

(BCL), the possibility of fast contrast reduction has been

added. For normal operation, the Contrast control is

achieved by auto grey scale output loops and is I2C bus

controlled (see Section 4). In the case of excess beam

current, this control is not fast enough to protect the tube and

power supply stages. It is now possible, by acting on the

Pin 10 voltage, to reduce the contrast about 12 dB by

reducing the luma gain and saturation. In the case of direct

RGB mode, the RGB gains are also reduced.

Figure 11. Typical Contrast Reduction

PIN 10 VOLTAGE (V)

0 1.0 2.0 3.0 4.0 5.0

1.0

–1.0

–3.0

–5.0

–7.0

–9.0

–11

–13

RELATIVE CONTRAST LEVEL (dB)

Figure 11 is showing the typical analog CONTRAST

reduction possible as a function of the voltage on Pin 10. Two

solutions are possible for obtaining the BCL function:

1st solution:

A measure of the average and/or peak beam

current is applied to Pin 10, which causes a reduction of the

RGB drive levels to the high voltage video amplifiers. In this

case, no software control is required, but variations in color

balance and saturation may be observed. A typical

application is shown in Figure 12.

2nd solution:

The beam current flags are read and acted

on by the MCU, which reduces the I2C bus CONTRAST

control to maintain the average beam current below the

desired level. In the case of rapid and extreme beam current

changes (black to white picture at high contrast level), the

circuit of Figure 12 may be used as a fast aging protection

while the MCU is reducing the CONTRAST through I2C bus.

The average of this method is to make any color

balance/saturation variation only transient.

Figure 12. Automatic Beam

Current Limiter Application

470 n

270 k

R8 R9

1.0 M

R4

10 k

R1

C2 C3

12 V

2.2 M

C5C1 10 n

EHT

R3

33 k

10 n 4.7

µ

D1

1N4148

910

Auto Gray Scale Control Loops

This section supplies current drives to the RGB cathode

amplifiers and receives a signal feedback from them,

proportional to the combined cathode currents. The current

feedback is used to establish a set of feedback loops to

control the dc level of the cathode voltage (cut–off), and gain

of the signal at the cathode (white balance). There are three

loops to control the dark currents dark loops and another

three to control the gains bright loops. The system uses 3

lines at the end of the vertical suppression period and just

before the beginning of the picture for sampling the cathode

current (i.e., one line for red, one for green and one for blue).

The first half of reach line is used for adjusting the gain of the

channel and is usually called the “bright” adjustment period.

The second half of the line is used for adjusting the dc level of

the channel and is called the “dark” adjustment.

The theoretical circuit diagram for one channel is shown in

Figure 13 along with the basic equations. The dc level (ldc)

and gain (G) are both controlled by 7 bit DACs which receive

data directly from latches in which the required values are

stored between sampling periods.

Figure 13. Bright/Dark Current Control

Brightness (B)

I

Cont

Pins 17,

18 or 19

Bright

Dark

Bright Dark

I

Pict

Gain (G) Output Buffer (A)

I

O

I

DC

Picture Output Current: I

O(Pict)

= A x [ IDC = G x ((B x I

Cont

) + I

Pict

)]

Dark Sample Output Current: I

O(dk)

= A x I

DC

Bright Sample Output Current: I

O(br)

= I

O(dk)

– A x G X I

Cont

Black Level Output Current: I

O(bk)

= I

O(dk)

– B x A x G x I

Cont

Black Level Output Current: I

O(bk)

= I

O(dk)

x B x [I

O(dk)

– I

O(br)

]

A block diagram of the complete system is illustrated in

Figure 16. Data words from the MCU which represent the

RGB color temperatures selected at the factory, are stored in

Latches 1,2,3 and D/A converted by DAC1,2,3 to reference

currents. During the bright adjustment period, a reference

current pulse, whose amplitude depends on the Contrast

setting, is output to the cathode of the tube. The gain control

is adjusted to bring the feedback current to the same value as

the bright reference current, which is defined by the color

intensity setting of the output considered. The currents must

match each other. If not, a current will flow in resistor R

producing an error voltage. This is then buffered into

comparators Comp1, 2 and is compared with voltage

references V

ref1

and V

ref2

. If the error voltage is greater than

V

ref1

, Comp1 causes the counter to count up. If the error

voltage is less than V

ref2

, Comp2 sends a count-down

command. In this way, a “deadband” is set up to prevent the

outputs from continuously changing. With the color intensity

DAC set to about 32d, the bright cathode current is 100 µA

(10 times the dark current).

During Load the contents of the counter are loaded into

Latch 6 (for red dc) and then D/A converted. The resulting dc

current is then applied as an offset to the red output amplifier,

completing the loop. During the dark adjustment period, the

same intensity data is used but divided by a common factor

(typically 10). A black level reference pulse is applied and the

feedback loop adjusts the dc levels of the cathode to obtain a

set of cathode currents equal to the dark reference currents

Page 20

MC44002 MC44007

20

MOTOROLA ANALOG IC DEVICE DATA

(10 µA). Therefore, the image color will always be adjusted to

match the dark level color, i.e. grey scale tracking is ensured.

The Load/Backload sequencer is used to control which

latch is being addressed at any given time by means of the

timing signals input to it. The backload command sends the

data from the appropriate latch to the Up/Down Counter,

ready to be modified if necessary.

The Brightness control is affected by simply changing the

dc pedestal of all three drives by the same amount, and does

not form part of the feedback loop. The Contrast is adjusted

to a set of values dependent on the level of the bright pulse

applied during the set–up period. This level is set by a control

word from the MCU. Once the loops have stabilized under

normal working conditions, they may be deactivated by

means of a control bit from the MCU. When, however, any

change is made to either contrast or RGB intensity, the loops

must be reactivated. For normal operation, it is not necessary

to deactivate the bright loops.

Increasing the RGB intensity values will cause the

Black–to–White cathode voltage amplitude to increase for a

given Contrast setting. The White balance can therefore be

set by adjusting the relative values of R, G and B intensity. An

extra loop has been included via Latch 4 and DAC 4, which

operates during the field flyback time to compensate for

offsets within the loop. This has the effect of counteracting

any input offset from the Buffer/Amp and will also

compensate for cathode leakage should this be needed.

A second output of the reference currents from the RGB

DACs are used to compare with preset limits, to ensure that

the loops are working within their range of control. Should the

limits be exceeded in either direction, flags are returned to

the MCU to request that the G2 control be adjusted up or

down as appropriate. Once set–up, the servo loops maintain

the same conditions throughout the life of the TV.

Horizontal Timebase

The horizontal timebase consists of a PLL which locks up

to the incoming horizontal sync, and a phase detector and

shifter whose purpose is to maintain the H-Drive in phase

with the line flyback pulse.

Because of on-chip component tolerances, the

free-running oscillator frequency cannot be set more

accurately than ± 40%; this range would be too much for the

line output stage to cope with. For this reason the

free-running frequency is calibrated periodically by other

means. During startup and whenever there is a channel

change, the phase detector is disconnected from the VCO for

2 lines during the blanking interval. A block diagram of the

line timebase is given in Figure 14. The calibration loop

consists of a frequency comparator driving an Up/Down

Counter. The count is D/A converted to give a dc bias which

is used to correct a 1.0 MHz VCO. The 1.0 MHz is divided by

64 to give line frequency and this is returned to the frequency

comparator. This compares Fh from the VCO with a

reference derived from dividing down the subcarrier

frequency. Any dif ference in frequency will result in an output

from the comparator, causing the counter to count up or

down; and thus closing the loop. Since the horizontal

oscillator is quite stable, this calibration does not need to be

carried out very often. After switch–on, the calibration loop

need only be enabled when the timebase goes out of lock.

A Coincidence Detector looks at the PLL Fh and compares

it with the incoming H-sync. If they are not in lock, a flag is

returned to the MCU. To allow for use with VCRs, the gain of

the phase detector may be switched by means of commands

from the MCU (bits HGAIN1 and HGAIN2). The gain of the

phase detector is switched to the maximum value at the end

of the vertical sync pulse and then reduced to the selected

value after about 11 lines. This allows the horizontal timebase

to rapidly compensate any horizontal phase jump (e.g. with a

VCR) during the vertical blanking period, thus avoiding

bending at the top of the picture.

Twice line frequency is output from the PLL which may be

divided by either 1 or 2 depending on the command of the

MCU. The x2 Fh will be used with Feature Boxes. The phase

of the Fh and flyback pulses are compared in a phase

detector, whose output drives a phase shifter. A 6-bit control

word and D/A converter are used to apply an offset to the

phase detector giving a horizontal phase shift control.

The presence of the horizontal flyback pulse is detected; if

it is missing a warning flag is sent back to the MCU which can

take appropriate action.

Vertical Timebase

The vertical timebase consists of two sections; a digital

section which includes a vertical sync separator and

standard recognition; and an analog section which generates

a vertical ramp which may be modified under MCU control to

allow for geometrical adjustments. A parabola is also

generated and may be used for pin-cushion (E-W) correction

and width control (see Figure 15).

In the digital section, the MC44002/7 uses a video sync

separator which works using feedback, such that the

threshold level of a comparator (slice level) is always

maintained at the center of the sync pulse. Sync from any of

the auxiliary inputs may also be used. The composite sync is

fed to a vertical sync separator, where vertical sync is

derived. This consists of a comparator, up/down counter and

decoder. The counter counts up when sync is high, and down

when sync is low. The output of the decoder is compared with

a threshold level, the threshold only being reached with a

high count during the broad pulses in the field interval.

When “Auto Countdown” is selected, the vertical timebase

in fact starts off in the “Injection Lock” mode. This means that

the timebase locks immediately to the first signal received, in

exactly the same way as an old type injection locked

timebase. A coincidence detector looks for counts of the right

number (525 e.g.), and causes a 4 bit counter to count up.

When there are 8 consecutive coincidences, the vertical

countdown is engaged, and the MSB of the counter is

brought out to set the flag. Similarly , non–coincidence, which

will occur if synchronizing pulses are missing or in the wrong

place, or if there is noise on the signals, causes the counter to

count down. When the count goes back to zero, after 8

noncoincidences, the timebase automatically reverts to

“Injection Lock” mode.

If it is known that lock will be lost (e.g., channel change), it

is possible to jump straight into Injection Lock mode and not

have to wait for the 8 consecutive non-coincidences. In this

way the new channel will be captured rapidly. Once locked on

to the new channel, “auto countdown” is then reselected by

the MCU.

Under some conditions such as some VCRs in Search

mode, it is possible to get signals having an incorrect number

of lines, meaning that the countdown flag will go off because

of successive non-coincidences. In these circumstances, if

“auto countdown” is selected, the timebase will automatically

lock to the signal in the Injection Lock mode. The fact that the

Page 21

MC44002 MC44007

21

MOTOROLA ANALOG IC DEVICE DATA

flag is effectively saying that the vertical timebase is out of

lock need not be a cause for major concern, since the

horizontal timebase will still be locked to the signal, and has

its own flag – “Horizontal out of lock”. The vertical countdown

and horizontal lock flags both perform an independent test for

the presence of a valid signal. A logical OR function can be

performed on the two flags, such that if either are present

then by definition a valid signal is present.

The vertical oscillator has end-stops set at two line-count

decodes as given below:

50 x 625 / 740 = 42.2 Hz (min)

50 x 625 / 448 = 69.8 Hz (max)

These figures assume that the horizontal timebase is

running at 15,625 Hz. When the vertical timebase is in

Injection Lock mode, the line counter reset is inhibited so that

it ignores any sync pulses before a count of 448 is reached.

This prevents any possible attempted synchronization in the

middle of the picture. If the count reaches 740 lines, then

there is an automatic reset which effectively sets the lower

frequency limit. The choice of these limits is a compromise

between a wide window for rapid signal capture and a narrow

window for good noise immunity.

It is also possible to run the timebase in 2.0 V mode as

there are decodes for 100 Hz (2 x 50 Hz) operation with

upper and lower limits in proportion. This is, of course,

intended to be used in conjunction with field and frame

memory stores. The similar decodes which would be

necessary to allow 120 Hz (2 x 60 Hz) operation have not, for

the present, been implemented. Finally, the timebase can be

forced into a count of either 625 or 525 by commands from

the MCU; in this mode the input signal, if present, is ignored

completely. If there is no signal present save for noise, then

this feature can be used to obtain a stable raster.

In the analog section, an adjustable current source is used

to charge an external capacitor at Pin 6 to generate a vertical

ramp. The amplitude of the ramp is varied according to the

current source (Height), and is automatically adapted when

the 525 standard is recognized by multiplying by 1.2. The

Linearity control is achieved by squaring the ramp and either

adding or subtracting a portion of it to the main linear current.

In addition, a correction current, depending on the level of

anode current, is applied in the sense of oppose a change of

picture height with EHT (Breathing).

The final ramp with corrections added is then passed to a

driver/amplifier and is output at Pin 7. The vertical ramp can

be used to drive a separate vertical deflection power circuit

with local feedback control. Vertical “S” Correction will then

be made using fixed components within the feedback loop of

the power op amp. The vertical position can be adjusted

under MCU control – this is achieved by varying the dc output

level at Pin 7. The vertical amplitude can be reduced to 75%

of its original value (bit VDI) to make possible the display of a

16:9 picture on a 4:3 screen.

The reference ramp is squared to provide a pin-cushion

correction parabola, developed across an external resistor at

Pin 8. The parabola itself is squared, giving an independent

fourth order term (Corner Correction) whose level can also

be varied; this is then added as a further modifying term to

the E-W output. This latter correction is used for obtaining

good corner geometry with flat-square tubes. A variable dc

current is added to the parabola to effect a width control.

Using a suitable power amplifier and a diode-modulator in the

line output stage, the parabola may be used for E-W

correction and dynamic width control. A further control is

provided to shift the center point of the parabola up and down

the screen (Parabola Tilt).

All of the vertical and horizontal signals are adjustable via

6-bit words from the MCU, and stored in latches. The

adjustment controls available are:

Vertical Amplitude/Linearity/Breathing Correction/Position

Parabola (E-W) Amplitude/Horizontal Amplitude/

Corner Correction, and Parabola Tilt

The Anode Current Sense at Pin 9 is also used as a beam

current monitor. Two thresholds may be set, by the

manufacturer, using external components. The first threshold

sets a flag to the processor if beam current becomes

excessive. The MCU could, e.g., reduce brightness and/or

contrast to alleviate the condition. The second threshold sets

a flag warning of an overload condition where the CRT

phosphor could be damaged. If such a condition were to

arise, the processor would be programmed to shut down

the PSU.

The vertical blanking lines may be selected by means of a

bit from the MCU for either the 525 or 625 standard. The

interlace may also be suppressed again under the control of

the processor (bits ICI, IFI).

Page 22

MC44002 MC44007

22

MOTOROLA ANALOG IC DEVICE DATA

Phase

Detector

15

Flyback In

Drive Out

(MPU)

Flyback

Detector

(MPU)

Offset

Phase

Detector

Phase Shifter

Enable/Start (MPU)

x2 Frequency

(MPU)

÷

2 or 1

2Fh

14

13

12

Horizontal Out of Lock

(MPU)

Coincidence

Detector

HGAIN2

HGAIN1

Fh

Divide by 64

1.0 MHz

VCO

DC Bias

I

ref

CalKill

A

D

Up/Down Counter

Norm (MPU)

Frequency

Comparator

Frequency

Divider

Fh

4.43/

3.58 MHz

Figure 14. Horizontal Timebase

Figure 15. Vertical Timebase

Horizontal Sync

H–Phase

Flyback

Present

Vertical

Drive

DAC DAC DAC DAC

Vertical

Amplitude

(MCU)

Vertical

Linearity

(MCU)

Vertical Breathing

Correction

(MCU)

Vertical

Position

(MCU)

2Fh

Clock

Line Counter

Decoder16Fh

Clock

Composite

Sync

Horizontal

Amplitude

(MCU)

Vert Sync

Separator

Coincidence Counter

and Control

Vertical

Ramp

VDI

(MCU)

Reset

Parabola Tilt (MCU)

DAC

Anode Current

Sense

97

E–W Drive

8

6

DAC

DAC

Corner

Correction

(MCU)

Parabola

Amplitude

(MCU)

X

4

X

2

DAC

Vert Modes

(MCU)

V Countdown

Engaged (MCU)

<576 Lines

(MCU)

x1.2

x0.75

448 525 576 625 740

Overload and

Excess Average

Beam Current

(MCU)

Page 23

MC44002 MC44007

23

MOTOROLA ANALOG IC DEVICE DATA

Figure 16. Auto Gray Scale Control Loops

R Intensity

(MCU)

Latch 3

Latch 2

Latch 1

DAC3

DAC2

DAC1

Cathode

Current

Feedback

R

2.5 V

Comp2Comp1

Buffer

V

ref2

V

ref1

G2 Down

Request

G2 Up

Request

To MPU

B DC

G DC

R DC

Down

Up

G2 Up/Down

Request

Clock Debounce

Up/Down

Counter

Offset

Compensation

Timing

Signals

Output

Output

Output

B DC

DAC

B GAIN

DAC

G DC

DAC

G GAIN

DAC

R DC

DAC

R GAIN

DAC

DAC4

Latch 10

Latch 9

Latch 8

Latch 7

Latch 6

Latch 5

Latch 4

Dark

Bright

Load

Backload

BLUE Line

GREEN Line

RED Line

Vertical

Vertical

Clock

Selector

x10 Amplifier

Load/Backload Sequencer

R Signal

G Signal

B Signal

20

17

18

19

B

out

G

out

R

out

Latch

Excess Peak

Beam Current

(MCU)

EPBC Reset

(MCU)

G Intensity

(MCU)

B Intensity

(MCU)

PIN FUNCTION AND EXTERNAL CIRCUIT REQUIREMENTS

The following section describes the purpose and function

of each of the 40 pins on the MC44002/7. There is also an

explanation of the external circuit component requirements

for a practical application; a diagram of the small signal circuit

will be found in Figure 17. One of the primary design aims for

the MC44002/7 was to use the minimum number of external

components, and where these are necessary, to employ low

cost and easily obtainable standard types. Thus for example,

as all the video signal filtering is carried out on the IC, there

are no coils required whatsoever. The most common

requirement is for ac coupling capacitors which are far too big

to be integrated onto the chip. The time constants on certain

pins are deliberately determined by external components to

facilitate testing and for fine tuning the performance.

Page 24

MC44002 MC44007

24

MOTOROLA ANALOG IC DEVICE DATA

PIN FUNCTION DESCRIPTION

Pin Equivalent Internal Circuit Description

1

0.1

V

CC

Gnd

ACC

External Filter used by ACC section. A single capacitor, that does not

have a critical value, typically 0.01 µF, filters the feedback loop of the

chroma automatic gain control amplifier.

2

40

100 nF

Gnd

1.0 k

20 k

20 k

14 k

Video Input 1 (Pin 40) and 2 (Pin 2)

Video inputs (Pin 2 = Video 2; Pin 40 = Video1); Intended for a

nominal 1.0 Vpp input level of composite video. Separate luma and

chroma components may also be used with these input pins for

S–VHS. The external circuit requirement is for a coupling capacitor of

0.01 µF and a series resistance not exceeding 1.0 kΩ. The input

selection and adaptation for Y and C is carried out in software.

3

Set

I

ref

V

CC

Gnd

8.0 k

20 k

V

Supply

0.01 2.2

µ

F

Reference Current

Master reference current used throughout the IC. This is programmed

by means of an external pull–up resistor, as on–board resistors are

not sufficiently accurate. The designated current is 70 µA. This pin

should be very well de–coupled to ground to avoid picking up

interference from the nearby I2C bus inputs. Nominal voltage at the

pin is 1.3 V .

4

Gnd

To MCU

150 k

70 k

I2C Clock

I2C bus clock input. This input can be taken straight into the IC, but in

a real TV application it may be prudent to fit a series current limiting

resistor near the pin in case of flash–over. A single pull–up resistor to

5.0 V is required. Although its value is associated with the µP, taking

into account system capacitance at high data rates, a value of 4.7 kΩ,

giving optimal performance, is recommended.

5

Gnd

To MCU

180 k

70 k

I2C Data

I2C data input. Comments above for Pin 4 also apply to this pin.

6

0.082 µF

V

CC

Gnd

Vertical Ramp

A current is used to charge an external capacitor connected to this

pin, developing a voltage sawtooth with a field period. The capacitor