Page 1

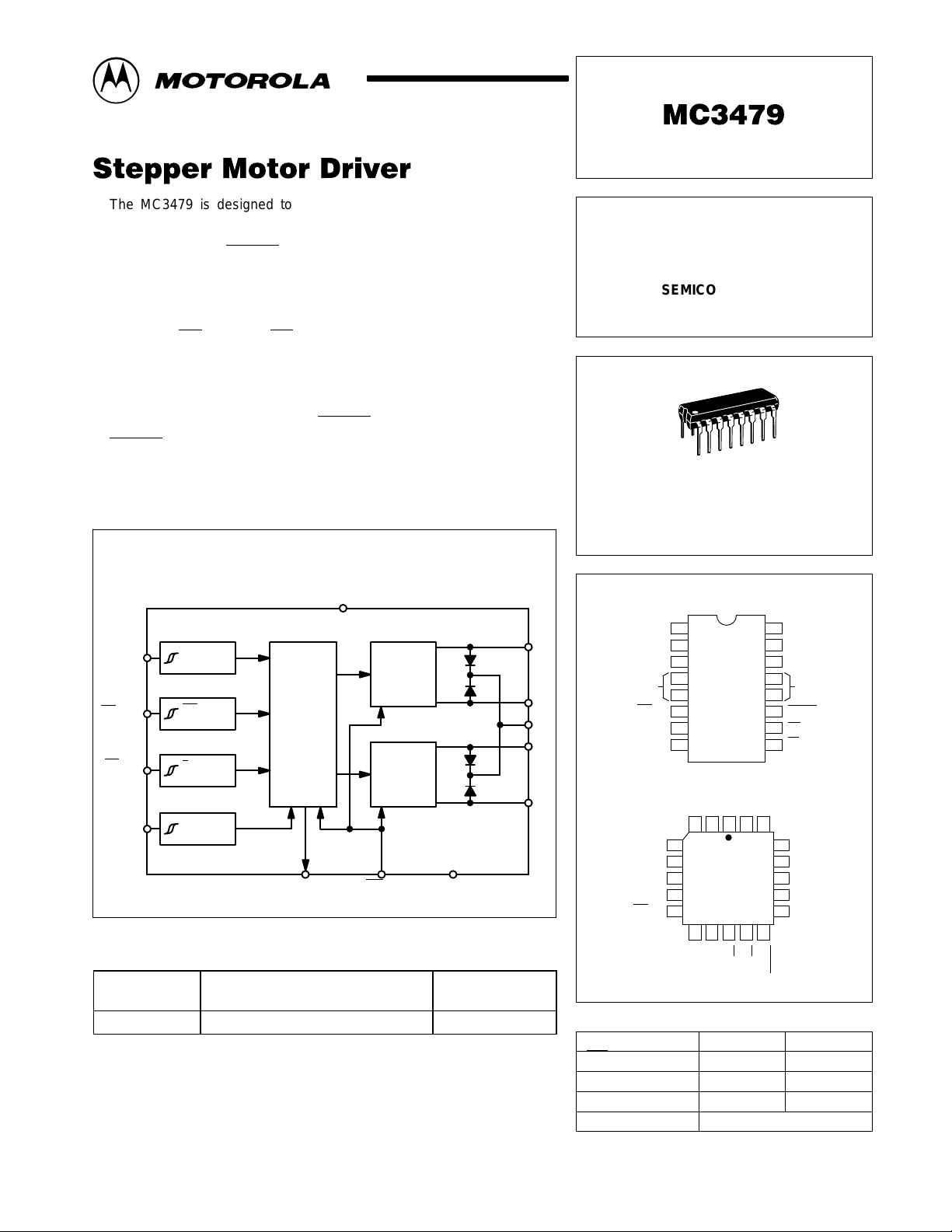

The MC3479 is designed to drive a two–phase stepper motor in the

bipolar mode. The circuit consists of four input sections, a logic

decoding/sequencing section, two driver–stages for the motor coils, and an

output to indicate the Phase A

• Single Supply Operation: 7.2 to 16.5 V

• 350 mA/Coil Drive Capability

• Clamp Diodes Provided for Back–EMF Suppression

• Selectable CW/CCW and Full/Half Step Operation

• Selectable High/Low Output Impedance (Half Step Mode)

• TTL/CMOS Compatible Inputs

• Input Hysteresis: 400 mV Minimum

• Phase Logic Can Be Initialized to Phase A

• Phase A Output Drive State Indication (Open–Collector)

• Available in Standard DIP and Surface Mount

drive state.

Order this document by MC3479/D

STEPPER MOTOR

DRIVER

SEMICONDUCTOR

TECHNICAL DATA

P SUFFIX

PLASTIC PACKAGE

CASE 648C

Figure 1. Representative Block Diagram

V

M

Clock

CW/CCW

/H Step

F

OIC

Logic

/SetPhase A

Driver

Driver

GndBias

CW

Full

Step

Clk

/CCW

/Half

OIC

ORDERING INFORMATION

Operating

Device

MC3479P TA = 0° to +70°C Plastic

Temperature Range

Package

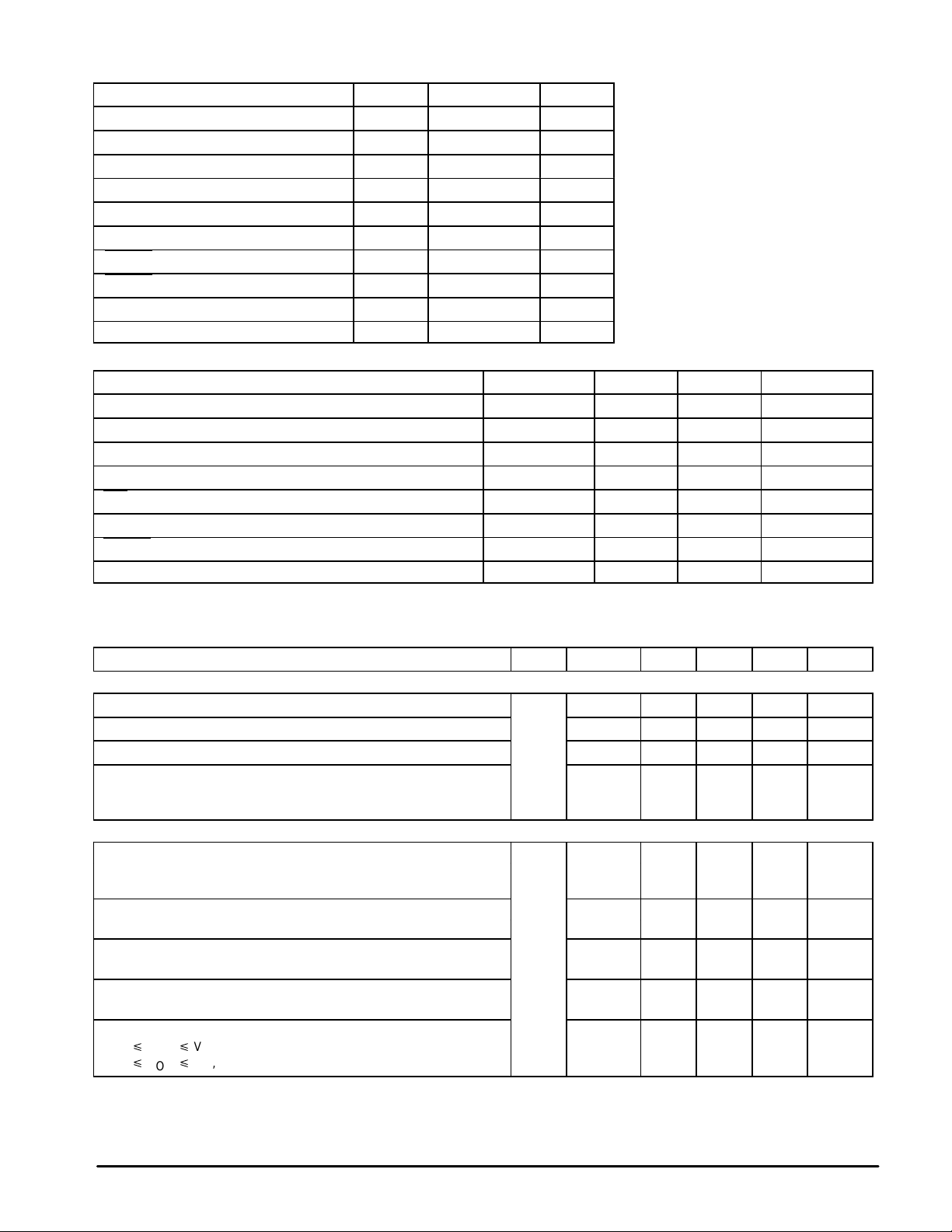

PIN CONNECTIONS

V

V

L3

M

D

20

11 12 13

Full/Half Step

Phase A

CW/CCW

16

15

14

13

12

11

10

9

V

L3

L4

Phase A

CW/CCW

Ful

Step

17

16

15

148

M

Gnd

l/Half

L4

Gnd

Gnd

Gnd

Gnd

1

V

D

2

L1

L2

V

D

L3

L4

L2

3

L1

4

Gnd

5

6

Bias

/Set

Clk

7

8

OIC

(Top View)

L2

L1

21519

3

418

Gnd

Gnd

6

Gnd

7

Gnd

Bias/Set

10

9

Clk

OIC

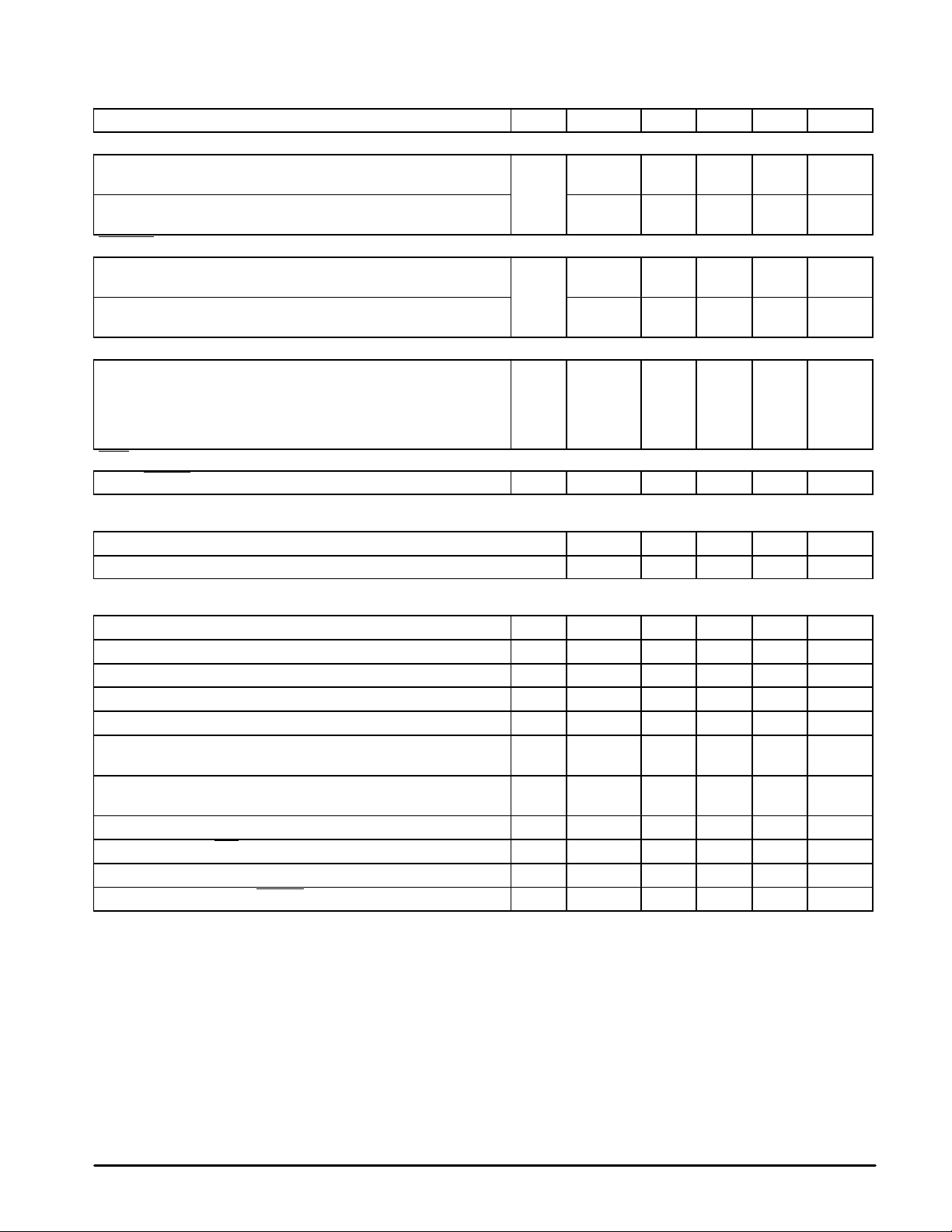

INPUT TRUTH TABLE

Input Low Input High

CW

/CCW

/Half Step

Full

OIC

CW CCW

Full Step Half Step

Hi Z Low Z

Positive Edge TriggeredClk

MOTOROLA ANALOG IC DEVICE DATA

Motorola, Inc. 1996 Rev 1

1

Page 2

MC3479

MAXIMUM RATINGS

Rating Symbol Value Unit

Supply Voltage V

Clamp Diode Cathode Voltage (Pin 1) V

Driver Output Voltage V

Drive Output Current/Coil I

Input Voltage (Logic Controls) V

Bias/Set Current I

Phase A Output Voltage V

Phase A Sink Current I

Junction Temperature T

Storage Temperature Range T

M

D

OD

OD

in

BS

OA

OA

J

stg

RECOMMENDED OPERATING CONDITIONS

Characteristic Symbol Min Max Unit

Supply Voltage V

Clamp Diode Cathode Voltage V

Driver Output Current (Per Coil) (Note 1) I

Input Voltage (Logic Controls) V

Bias/Set Current (Outputs Active) I

Phase A Output Voltage V

Phase A Sink Current I

Operating Ambient Temperature T

NOTE: 1. See section on Power Dissipation in Application Information.

+ 18 Vdc

VM + 5.0 Vdc

VM + 6.0 Vdc

± 500 mA

– 0.5 to + 7.0 Vdc

– 10 mA

+ 18 Vdc

20 mA

+ 150 °C

– 65 to + 150 °C

OD

BS

OA

OA

M

D

+ 7.2 + 16.5 Vdc

V

M

VM + 4.5 Vdc

— 350 mA

in

0 + 5.5 Vdc

– 300 – 75 µA

— V

M

Vdc

0 8.0 mA

A

0 + 70 °C

DC ELECTRICAL CHARACTERISTICS (Specifications apply over the recommended supply voltage and temperature range, [Notes

2, 3] unless otherwise noted.)

Characteristic

INPUT LOGIC LEVELS

Threshold Voltage (Low–to–High)

Threshold Voltage (High–to–Low)

Hysteresis V

Current: (VI = 0.4 V)

Current: (VI = 5.5 V)

Current: (VI = 2.7 V)

DRIVER OUTPUT LEVELS

Output High Voltage 2, 3, V

(IBS = – 300 µA): (IOD = – 350 mA)

(IBS = – 300 µA): (IOD = – 0.1 mA)

Output Low Voltage V

(IBS = – 300 µA, IOD = 350 mA)

Differential Mode Output Voltage Difference (Note 4) DV

(IBS = – 300 µA, IOD = 350 mA)

Common Mode Output Voltage Dif ference (Note 5) CV

(IBS = – 300 µA, IOD = – 0.1 mA)

Output Leakage, Hi Z State µA

(0 p VOD p VM, IBS = – 5.0 µA) I

(0 p VOD p VM, IBS = – 300 µA, F/H = 2.0 V, OIC = 0.8 V) I

NOTES: 2. Algebraic convention rather than absolute values is used to designate limit values.

3.Current into a pin is designated as positive. Current out of a pin is designated as negative.

4.DVOD = V

5.CVOD = V

OD1,2

OHD1

– V

– V

OD3,4

OHD2

where: V

or V

OHD3

OD1,2

V

OD3,4

– V

= (V

OHD4

OHD1

= (V

.

– V

OHD3

OLD2

– V

) or (V

OLD4

Pins Symbol Min Typ Max Unit

7, 8,

9, 10

V

V

TLH

THL

HYS

I

IL

— — 2.0 Vdc

0.8 — — Vdc

0.4 — — Vdc

–100

—

—

—

—

+100

—

+20

OHD

14, 15 VM – 2.0

VM – 1.2——

— — 0.8 Vdc

— — 0.15 Vdc

— — 0.15 Vdc

– 100 — + 100

– 100 — + 100

OHD2

) or (V

– V

OHD4

OLD1

– V

), and

OLD3

OLD

OD

OD

OZ1

OZ2

).

—

µA

Vdc

—

—

2

MOTOROLA ANALOG IC DEVICE DATA

Page 3

MC3479

DC ELECTRICAL CHARACTERISTICS (Specifications apply over the recommended supply voltage and temperature range, [Notes

2, 3] unless otherwise noted.)

Characteristic

CLAMP DIODES

Forward Voltage 1, 2, 3, V

(ID = 350 mA) 14, 15

Leakage Current (Per Diode) I

(Pin 1 = 21 V; Outputs = 0 V; IBS = 0 µA)

PHASE A OUTPUT

Output Low Voltage 11 V

(IOA = 8.0 mA)

Off State Leakage Current I

(V

= 16.5 V)

OHA

POWER SUPPLY

Power Supply Current 16 mA

(IOD = 0 µA, IBS = – 300 µA)

(L1 = V

(L1 = V

(L1 = V

BIAS/SET CURRENT

To Set Phase A 6 I

OHD

OHD

OHD

, L2 = V

, L2 = V

, L2 = V

, L3 = V

OLD

, L3 = Hi Z, L4 = Hi Z) I

OLD

, L3 = V

OLD

OHD

OHD

, L4 = V

, L4 = V

) I

OLD

) I

OHD

Pins Symbol Min Typ Max Unit

DF

DR

OLA

OHA

MW

MZ

MN

BS

— 2.5 3.0 Vdc

— — 100 µA

— — 0.4 Vdc

— — 100 µA

— — 70

— — 40

— — 75

– 5.0 — — µA

PACKAGE THERMAL CHARACTERISTICS

Characteristic Symbol Min Typ Max Unit

Thermal Resistance, Junction–to–Ambient (No Heatsink) R

AC SWITCHING CHARACTERISTICS (T

Characteristic

Clock Frequency 7 f

Clock Pulse Width (High) 7 PW

Clock Pulse Width (Low) 7 PW

Bias/Set Pulse Width 6 PW

Setup Time (CW/CCW and F/HS) 10–7

Hold Time (CW/CCW and F/HS) 10–7

Propagation Delay (Clk–to–Driver Output) t

Propagation Delay (Bias/Set–to–Driver Output) t

Propagation Delay (Clk–to–Phase A Low) 7–11 t

Propagation Delay (Clk–to–Phase A High) 7–11 t

NOTES: 2. Algebraic convention rather than absolute values is used to designate limit values.

3.Current into a pin is designated as positive. Current out of a pin is designated as negative.

= + 25°C, VM = 12 V) (See Figures 2, 3, 4)

A

Pins Symbol Min Typ Max Unit

9–7

9–7

θJA

CK

CKH

CKL

BS

t

su

t

h

PCD

PBSD

PHLA

PLHA

— 45 — °C/W

0 — 50 kHz

10 — — µs

10 — — µs

10 — — µs

5.0 — — µs

10 — — µs

— 8.0 — µs

— 1.0 — µs

— 12 — µs

— 5.0 — µs

MOTOROLA ANALOG IC DEVICE DATA

3

Page 4

MC3479

CW

Bias

F / HS

/ CCW

Figure 2. AC Test Circuit

+ 12 V

/Set

Clk

OIC

56 k

6

MC3479P

7

8

9

10

41213

0.1

µ

F

V

M

16

2

3

14

15

5

1.0 k

L2

1.0 k

L1

1.0 k

1.0 k

L4

1.0 k

L3

1.0 k

11

4.0 k

+ 12 V

Phase A

Bias/Set

Input

L1 – L4

Outputs

V

M

0

Figure 3. Bias/Set Timing

(Refer to Figure 2)

PW

BS

VM – 1.0 VM – 1.0

t

PBSD

(High Impedance)

Note: tr, tf (10% to 90%) for

input signals are

p

25 ns.

t

PBSD

PIN FUNCTION DESCRIPTION

Pin No.

20–Pin 16–Pin

20 16 Power Supply V

4, 5, 6, 7,

14, 15, 16, 17

4, 5,

12, 13

1 1 Clamp Diode

2, 3,

18, 19

2, 3,

14, 15

8 6 Bias/Set B/S This pin is typically 0.7 volts below VM. The current out of this pin

9 7 Clock Clk The positive edge of the clock input switches the outputs to the next

11 9 Full/Half Step F/HS When low (Logic “0”), each clock input pulse will cause the motor to

12 10 Clockwise/

10 8 Output Impedance

13 11 Phase A Ph A This open–collector output indicates (when low) that the driver outputs

Function Symbol Description

M

Power supply pin for both the logic circuit and the motor coil current.

Voltage range is + 7.2 to + 16.5 volts.

Ground Gnd Ground pins for the logic circuit and the motor coil current. The

physical configuration of the pins aids in dissipating heat from within

the IC package.

Voltage

V

D

This pin is used to protect the outputs where large voltage spikes may

occur as the motor coils are switched. Typically a diode is connected

between this pin and Pin 16. See Figure 11.

Driver Outputs L1, L2

L3, L4

High current outputs for the motor coils. L1 and L2 are connected to

one coil, and L3 and L4 to the other coil.

(through a resistor to ground) determines the maximum output sink

current. If the pin is opened (IBS < 5.0 µA) the outputs assume a high

impedance condition, while the internal logic presets to a Phase A

condition.

position. This input has no effect if Pin 6 is open.

rotate one full step. When high, each clock pulse will cause the motor

to rotate one–half step. See Figure 7 for sequence.

CW/CCW This input allows reversing the rotation of the motor. See Figure 7 for

Counterclockwise

sequence.

OIC This input is relevant only in the half step mode (Pin 9 > 2.0 V). When

Control

low (Logic “0”), the two driver outputs of the non–energized coil will be

in a high impedance condition. When high the same driver outputs will

be at a low impedance referenced to VM. See Figure 7.

are in the Phase A

condition (L1 = L3 = V

, L2 = L4 = V

OHD

OLD

).

APPLICATION INFORMATION

General

The MC3479 integrated circuit is designed to drive a

stepper positioning motor in applications such as disk drives

and robotics. The outputs can provide up to 350 mA to each

of two coils of a two–phase motor. The outputs change state

with each low–to–high transition of the clock input, with the

new output state depending on the previous state, as well as

the input conditions at the logic controls.

4

Outputs

The outputs (L1–L4) are high current outputs (see

Figure 5), which when connected to a two–phase motor,

provide two full–bridge configurations (L3 and L4 are not

shown in Figure 5). The polarities applied to the motor coils

depend on which transistor (QH or QL) of each output is on,

which in turn depends on the inputs and the decoding

circuitry.

MOTOROLA ANALOG IC DEVICE DATA

Page 5

MC3479

Figure 4. Clock Timing

(Refer to Figure 2)

Clk

F

/HS,

/CCW

CW

Inputs

Phase A

Output

B

/S

3.0 V

0

L1 – L4

Outputs

0

3.0 V

1.5 V

t

PCD

PW

I

′

BS

CLKH

6.0 V

PW

CLKL

tht

su

1.5 V

t

PHLA

1.5 V

Figure 5. Output Stages

V

M

Q

H

Q

L

L1

t

PLHA

Motor Coil

Note: tr, tf (10% to 90%) for input

p

signals are

V

D

L2

10 ns.

Q

H

Q

L

I

BS

R

B

Current

Drivers

and

Logic

To L3, L4

Transistors

CW

/ CCW

The maximum sink current available at the outputs is a

function of the resistor connected between Pin 6 and ground

(see section on Bias

/Set operation). Whenever the outputs

are to be in a high impedance state, both transistors (QH and

QL of Figure 5) of each output are off.

V

D

This pin allows for provision of a current path for the motor

coil current during switching, in order to suppress back–EMF

voltage spikes. VD is normally connected to VM (Pin 16)

through a diode (zener or regular), a resistor, or directly. The

peaks instantaneous voltage at the outputs must not exceed

VM by more than 6.0 V. The voltage drop across the internal

clamping diodes must be included in this portion of the design

(see Figure 6). Note the parasitic diodes (Figure 5) across

each QL of each output provide for a complete circuit path for

the switched current.

Logic Decoding

Circuit

/HS

Inputs

3.0

2.0

F

V (V)

1.0

Parasitic

Diodes

OIC

ClkF

Figure 6. Clamp Diode Characteristics

0

ID (mA)

300100 2000

MOTOROLA ANALOG IC DEVICE DATA

5

Page 6

MC3479

Full

/Half Step

When this input is at a Logic “0” (<0.8 V), the outputs

change a full step with each clock cycle, with the sequence

direction depending on the CW

steps (Phase A

, B, C, D) for each complete cycle of the

sequencing logic. Current flows through both motor coils

during each step, as shown in Figure 7.

When taken to a Logic “1” (>2.0 V), the outputs change a

half step with each clock cycle, with the sequence direction

depending on the CW

/CCW input. Eight steps (Phase A to H)

result for each complete cycle of the sequenc ing logic. Phas e

A, C, E and G correspond (in polarity) to Phase A, B, C, and

D

, respectively, of the full step sequence. Phase B, D, F and

H

provide current to one motor coil, while de–energizing the

other coil. The condition of the outputs of the de–energized

coil depends on the OIC input, see Figure 7 timing diagram.

/CCW input. There are four

outputs to the de–energized coil are in a high impedance

condition — QL and QH of both outputs (Figure 5) are off.

When this input is at a Logic “1” (>2.0 V), a low impedance

output is provided to the de–energized coil as both outputs

have QH on (QL off). To complete the low impedance path

requires connecting VD to VM as described elsewhere in this

data sheet.

Bias

/Set

This pin can be used for three functions: a) determining

the maximum output sink current; b) setting the internal logic

to a known state; and c) reducing power consumption.

a) The maximum output sink current is determined by the

base drive current supplied to the lower transistors (QLs of

Figure 5) of each output, which in turn, is a function of I

BS.

The appropriate value of IBS is determined by:

OIC

The output impedance control input determines the output

impedance to the de–energized coil when operating in the

half–step mode. When the outputs are in Phase B

, D, F or H

(Figure 7) and this input is at a Logic “0” (<0.8 V), the two

Figure 7. Output Sequence

Clk

Bias

/Set

/CCW

CW

Phase A A

L1

L2

L3

L4

Phase A

Output

A

L1

L2

L3

L4

DBC

A

(a) Full Step Mode

(b) Half Step Mode

IBS = IOD × 0.86

where IBS is in microamps, and IOD is the motor current/coil in

milliamps.

BCDBCB

= High Impedance

F/HS

OIC

/CCW = Logic “0”

CW

/HS = Logic “1”, OIC = Logic “0”

F

= Logic “0”

′

t Care

= Don

A

= High Impedance

CDBHGDBC EF

F

EC

GH B

L1

L2

L3

L4

Phase A

Output

BD

(c) Half Step Mode

6

AA

= Logic “0”

/CCW

CW

F

OIC

/HS

= Logic “1”

= Logic “1”

MOTOROLA ANALOG IC DEVICE DATA

CD

Page 7

MC3479

The value of RB (between this pin and ground) is then

determined by:

VM*

RB+

b) When this pin is opened (raised to VM) such that IBS is

<5.0 µA, the internal logic is set to the Phase A

the four driver outputs are put into a high impedance state.

The Phase A

output (Pin 11) goes active (low), and input

signals at the controls are ignored during this time. Upon

re–establishing IBS, the driver outputs become active, and

will be in the Phase A

V

). The circuit will then respond to the inputs at the

OLD

position (L1 = L3 = V

controls.

The Set function (opening this pin) can be used as a

power–up reset while supply voltages are settling. A CMOS

logic gate (powered by VM) can be used to control this pin as

shown in Figure 1 1.

c) Whenever the motor is not being stepped, power

dissipation in the IC and in the motor may be lowered by

reducing IBS, so as to reduce the output (motor) current.

Setting IBS to 75 µA will reduce the motor current, but will not

reset the internal logic as described above. See Figure 12 for

a suggested circuit.

Power Dissipation

The power dissipated by the MC3479 must be such that

the junction temperature (TJ) does not exceed 150°C. The

power dissipated can be expressed as:

P = (VM IM) + (2 IOD) [(VM – V

where VM = Supply voltage;

IM = Supply current other than IOD;

IOD = Output current to each motor coil;

V

= Driver output high voltage;

OHD

V

= Driver output low voltage.

OLD

The power supply current (IM) is obtained from Figure 8. After

the power dissipation is calculated, the junction temperature

can be calculated using:

TJ = (P R

where R

= Junction–to–ambient thermal resistance

θJA

(52°C/W for the DIP, 72°C/W for the FN Package);

TA = Ambient Temperature.

Figure 8. Power Supply Current

I

BS

θJA

0.7 V

) + T

condition, and

OHD

) + V

OHD

A

, L2 = L4 =

]

OLD

For example, assume an application where VM = 12 V , the

motor requires 200 mA/coil, operating at room temperature

with no heatsink on the IC. IBS is calculated:

IBS = 200 0.86

IBS = 172 µA

RB is calculated:

RB = (12 – 0.7) V/172 µA

RB = 65.7 kΩ

From Figure 8, IM (max) is determined to be 40 mA. From

Figure 9, V

is 0.46 volts, and from Figure 10, (VM – V

OLD

OHD

is 1.4 volts.

P = (12 0.040) + (2 0.2) (1.4 + 0.46)

P = 1.22 W

TJ = (1.22 W 52°C/W) + 25°C

TJ = 88°C

This temperature is well below the maximum limit. If the

calculated TJ had been higher than 150°C, a heatsink such

as the Staver Co. V–7 Series, Aavid #5802, or Thermalloy

#6012 could be used to reduce R

. In extreme cases,

θJA

forced air cooling should be considered.

The above calculation, and R

, assumes that a ground

θJA

plane is provided under the MC3479 (either or both sides of

the PC board) to aid in the heat dissipation. Single nominal

width traces leading from the four ground pins should be

avoided as this will increase TJ, as well as provide potentially

disruptive ground noise and IR drops when switching the

motor current.

Figure 9. Maximum Saturation V oltage —

Driver Output Low

0.8

0.6

(VOLTS)

0.4

OLD

V

0.2

0

0 100 200 300

IOD (mA)

)

70

60

50

40

(mA)

M

I

30

20

10

0

50

IOD = 0

150 200 250 300 350100

µ

A)

IBS (

MOTOROLA ANALOG IC DEVICE DATA

Figure 10. Maximum Saturation V oltage —

2.0

1.5

] (VOLTS)

1.0

OHD

– V

M

[V

0.5

0

0 100 200 300

Driver Output High

IOD (mA)

7

Page 8

Digital Inputs

Phase A

Clock

CW

/CCW

MC3479

Figure 11. Typical Applications Circuit

+V

2.0 k

Typ

+V

Ω

V

11

7

10

M

16

MC3479

1N5221A (3.0 V)

1

V

D

15

L1

3

L2

2

L3

Motor

/Half Step

Full

OIC

Set

Normal

Operation

9

8614

Gnd

MC14049UB

or equivalent

131245

R

B

Bias

L4

/Set

Figure 12. Power Reduction

MC3479

6

/Set

Bias

R

Normal

Operation

Reduced

Power

— Suggested value for RB1 (VM = 12 V) is 150 kΩ.

— RB calculation (see text) must take into account

the current through RB1.

B

MC14049UB

or equivalent

8

R

B1

MOTOROLA ANALOG IC DEVICE DATA

Page 9

MC3479

OUTLINE DIMENSIONS

–T–

SEATING

PLANE

–A–

P SUFFIX

PLASTIC PACKAGE

CASE 648C–03

16 9

ISSUE C

–B–

18

NOTE 5

C

N

F

D

0.13 (0.005) T

E

G

16 PL

M

S

A

K

FN SUFFIX

PLASTIC PACKAGE

D

CASE 775–02

(PLCC 20)

ISSUE C

–L–

–N–

Y BRK

–M–

W

20 1

D

V

A

0.007 (0.180) N

M

L–M

T

Z

M

0.007 (0.180) N

R

C

E

L–M

T

0.004 (0.100)

G

J

–T–

SEATING

PLANE

VIEW S

G1

0.010 (0.250) N

0.007 (0.180) N

B

U

S

M

0.007 (0.180) N

S

L–M

T

L–M

T

M

S

S

S

S

L–M

T

S

Z

L

J 16 PL

0.13 (0.005) T

S

S

M

S

S

K1

K

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. INTERNAL LEAD CONNECTION BETWEEN 4 AND

5, 12 AND 13.

DIM MIN MAX MIN MAX

A 0.740 0.840 18.80 21.34

B 0.240 0.260 6.10 6.60

C 0.145 0.185 3.69 4.69

D 0.015 0.021 0.38 0.53

E 0.050 BSC 1.27 BSC

F 0.040 0.70 1.02 1.78

M

S

B

NOTES:

G 0.100 BSC 2.54 BSC

J 0.008 0.015 0.20 0.38

K 0.115 0.135 2.92 3.43

L 0.300 BSC 7.62 BSC

M 0 10 0 10

N 0.015 0.040 0.39 1.01

1. DATUMS –L–, –M–, AND –N– DETERMINED

WHERE TOP OF LEAD SHOULDER EXITS PLASTIC

BODY AT MOLD PARTING LINE.

2. DIMENSION G1, TRUE POSITION TO BE

MEASURED AT DA TUM –T–, SEATING PLANE.

3. DIMENSIONS R AND U DO NOT INCLUDE MOLD

FLASH. ALLOWABLE MOLD FLASH IS 0.010 (0.250)

PER SIDE.

4. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

5. CONTROLLING DIMENSION: INCH.

6. THE PACKAGE TOP MAY BE SMALLER THAN THE

PACKAGE BOTTOM BY UP TO 0.012 (0.300).

DIMENSIONS R AND U ARE DETERMINED AT THE

OUTERMOST EXTREMES OF THE PLASTIC BODY

EXCLUSIVE OF MOLD FLASH, TIE BAR BURRS,

GATE BURRS AND INTERLEAD FLASH, BUT

INCLUDING ANY MISMATCH BETWEEN THE TOP

AND BOTTOM OF THE PLASTIC BODY.

7. DIMENSION H DOES NOT INCLUDE DAMBAR

PROTRUSION OR INTRUSION. THE DAMBAR

PROTRUSION(S) SHALL NOT CAUSE THE H

DIMENSION TO BE GREATER THAN 0.037 (0.940).

THE DAMBAR INTRUSION(S) SHALL NOT CAUSE

THE H DIMENSION TO BE SMALLER THAN 0.025

(0.635).

DIM MIN MAX MIN MAX

A 0.385 0.395 9.78 10.03

B 0.385 0.395 9.78 10.03

C 0.165 0.180 4.20 4.57

E 0.090 0.110 2.29 2.79

F 0.013 0.019 0.33 0.48

G 0.050 BSC 1.27 BSC

H 0.026 0.032 0.66 0.81

J 0.020 ––– 0.51 –––

K 0.025 ––– 0.64 –––

R 0.350 0.356 8.89 9.04

U 0.350 0.356 8.89 9.04

V 0.042 0.048 1.07 1.21

W 0.042 0.048 1.07 1.21

X 0.042 0.056 1.07 1.42

Y ––– 0.020 ––– 0.50

Z 2 10 2 10

____

G1 0.310 0.330 7.88 8.38

K1 0.040 ––– 1.02 –––

0.007 (0.180) N

H

MILLIMETERSINCHES

____

MILLIMETERSINCHES

M

S

L–M

T

S

0.010 (0.250) N

X

G1

VIEW D–D

MOTOROLA ANALOG IC DEVICE DATA

0.007 (0.180) N

S

S

L–M

T

S

F

M

S

L–M

T

S

VIEW S

9

Page 10

MC3479

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 or 602–303–5454 3–14–2 T atsumi Koto–Ku, Tokyo 135, Japan. 03–81–3521–8315

MFAX: RMF AX0@email.sps.mot.com – TOUCHT ONE 602–244–6609 ASIA/P ACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 T i n g K o k Road, Tai Po, N.T., Hong Kong. 852–26629298

10

◊

MOTOROLA ANALOG IC DEVICE DATA

MC3479/D

*MC3479/D*

Loading...

Loading...