Page 1

MC34280

Power Supply &

Management IC for Handheld

Electronic Products

The MC34280 is a power supply integrated circuit which provides

two boost regulated outputs and some power management supervisory

functions. Both regulators apply Pulse–Frequency–Modulation

(PFM). The main step–up regulator output can be externally adjusted

from 2.7V to 5V. An internal synchronous rectifier is used to ensure

high efficiency (achieve 87%). The auxiliary regulator with a built–in

power transistor can be configured to produce a wide range of positive

voltage (can be used for LCD contrast voltage). This voltage can be

adjusted from +5V to +25V by an external potentiometer; or by a

microprocessor, digitally through a 6–bit internal DAC.

The MC34280 has been designed for battery powered hand–held

products. With the low start–up voltage from 1V and the low quiescent

current (typical 35 µA); the MC34280 is best suited to operate from 1

to 2 AA/ AAA cell. Moreover, supervisory functions such as low

battery detection, CPU power–on reset, and back–up battery control,

are also included in the chip. It makes the MC34280 the best one–chip

power management solution for applications such as electronic

organizers and PDAs.

FEATURES:

• Low Input Voltage, 1V up

• Low Quiescent Current in Standby Mode: 35µA typical

• PFM and Synchronous Rectification to ensure high efficiency

(87% @200mA Load)

• Adjustable Main Output: nominal 3.3V @ 200mA max, with 1.8V

input

• Auxiliary Output Voltage can be digitally controlled by

microprocessor

• Auxiliary Output Voltage:

+5V @ 25mA max, with 1.8V input

+25V @ 15mA max, with 1.8V input

• Current Limit Protection

• Power–ON Reset Signal with Programmable Delay

• Battery Low Detection

• Lithium Battery Back–up

• 32–Pin LQFP Package

32

1

VMAINFB

VBAT

ENABLE

VDD

PDELAY

VREF

AGND

IREF

http://onsemi.com

32–LEAD LQFP

FTB SUFFIX

CASE 873A

MARKING DIAGRAM

MC34280F

TB

AWLYYWW

PIN CONNECTIONS

VMAIN

VMAINSW

VMAINGND

32

1

MC34280

PROB

DGND

LOWBATSEN

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

LIBAOUTNCLIBATIN

VAUXEMR

VAUXSW

NC

VAUXBASE

VAUXCHG

VAUXBDV

VAUXFBN

VAUXREF

VAUXFBP

VAUXEN

LIBATCL

LIBATON

LOWBATB

VAUXADJ

VAUXCON

APPLICATIONS:

• Digital Organizer and Dictionary

• Personal Digital Assistance (PDA)

• Dual Output Power Supply (For MPU, Logic, Memory, LCD)

• Handheld Battery Powered Device (1–2 AA/AAA cell)

Semiconductor Components Industries, LLC, 1999

February , 2000 – Rev. 2

1 Publication Order Number:

ORDERING INFORMATION

Device Package Shipping

MC34280FTB LQFP 250 Units/Tray

MC34280FTBR2 LQFP 1800 Tape & Reel

MC34280/D

Page 2

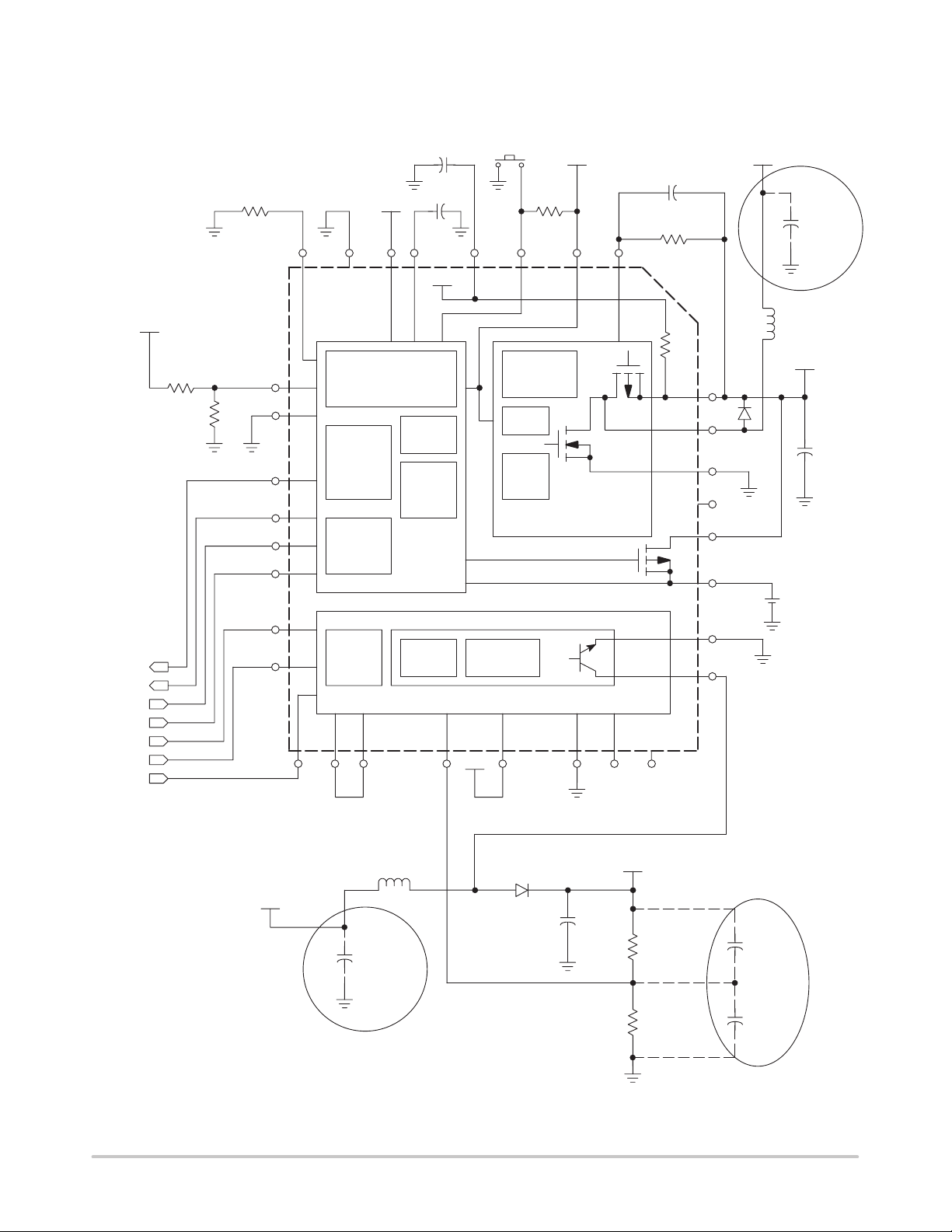

GND

Riref

r = 480 k

I

REF

MC34280

Figure 1. T ypical Application Block Diagram

Battery

4

Lock

Switch

GND

DD

VBAT

Ren

r = 1000 k

ENABLE

321

GND

AGND

V

REF

87

GND

V

REF

65

CVDD

c = 20u

Cpor

c = 80n

GND

PDELAY V

V

DD

VMAINFBVBAT

CMAINb

c = 100p

RMAINb

r = 1000 k

VBAT

Optional

CMAINbp

c = 100u

10 V SMT

tantalum

GND

PORB

LOWBAT

LIBATON

LIBATCL

VAUXADJ

VAUXCON

VAUXEN

VBAT

RLBa

r = 300 k

RLBb

r = 900 k

LOWBATSEN

DGND

GNDGND

PORB

LOWBATB

LIBATON

LIBATCL

VAUXADJ

VAUXCON

VAUXEN

9

10

11

12

13

14

15

16

17

VAUXFBP

R123

Power

ON

Reset

Current

Voltage

Reference

Lithium

Battery

Backup

Level

Control

Auxiliary Regulator

18 20 2119 22 23 24

VAUXREF

(1.1 V to 2.2 V)

Bias

Low

Battery

Detect

Current

Limit

VAUXFBN

VBAT

Control and

Gate Drive

Startup

Current

Limit

Main Regulator with

Synchronous Rectifier

Control and

Base Drive

VAUXBDV

s

M2

d

M1

s

Q1

VAUXBASE

VAUXCHG

r = 5

d

d

s

N/C

32

31

30

29

28

M3

27

26

25

VMAIN

1N5817

VMAINSW

VMAINGND

N/C

LIBATOUT

LIBATIN

VAUXEMR

VAUXSW

LMAIN

L = 33u

(Rs < 60 mOhm)

VMAIN

GND

GND

GND

CMAIN

c = 100u

10 V SMT

tantalum

GND

VBAT

Optional

LAUX

L = 22u

(Rs < 60 mOhm)

CAUXbp

c = 100u

10 V SMT

tantalum

GND

1N5818

30 V SMT

tantalum

http://onsemi.com

2

Caux

c = 30u

GND

VAUX

Rauxb

r = 2.2 M

Rauxa

r = 200 k

GND

Optional

CAUXb

c = 2n

CAUXa

c = 33n

Page 3

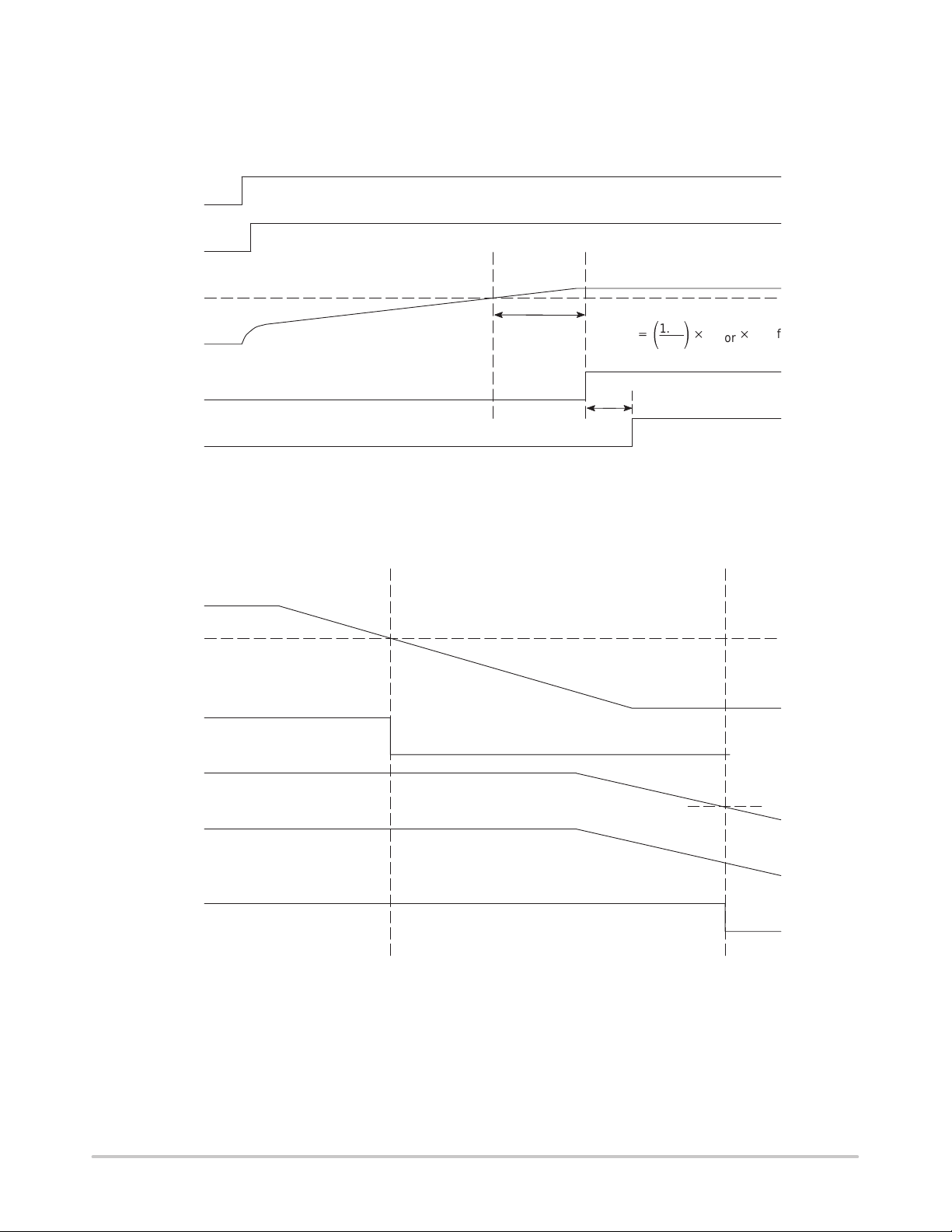

VBAT

ENABLE

VMAIN

PORB

VAUXEN

V

MAINreg

– 0.15 V

MC34280

TIMING DIAGRAMS

Figure 2. Startup Timing

T

POR

t

PORC

+

V

MAINreg

1.22

ǒ

0.5

Ǔ

C

RIref

por

VBAT

LOWBATB

VMAIN

ENABLE

PORB

LOWBAT Threshold

Figure 3. Power Down Timing

V

MAINreg

– 0.5 V

http://onsemi.com

3

Page 4

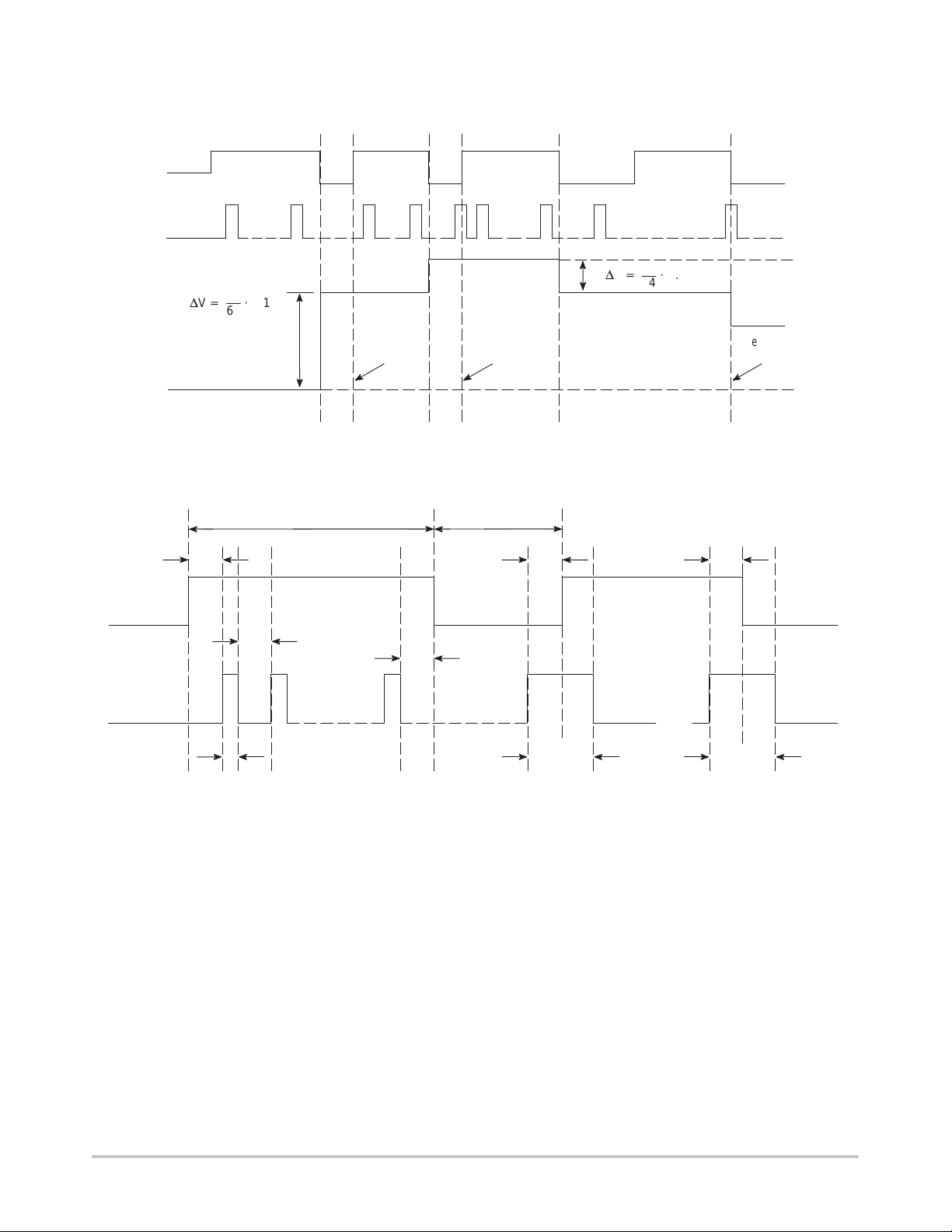

MC34280

TIMING DIAGRAMS (Con’t)

VAUXCON

VAUXADJ

VAUXREF

1.1 V

T otal N Pulses Total M Pulses

N

DV+

64

@

1.1 V

“Countup”

Flag is HIGH

Figure 4. Auxiliary Regulator Voltage Control

t

CW

t

CL

“Countup”

Flag is LOW

t

CC

M

@

64

1.1 V

t

RJL

Reset

VAUXREF

DV+

t

DL

2.2 V

1.65 V

VAUXCON

VAUXADJ

t

JC

t

JW

t

JL

t

DW

t

RW

Figure 5. Auxiliary Regulator Voltage Control Timing

http://onsemi.com

4

Page 5

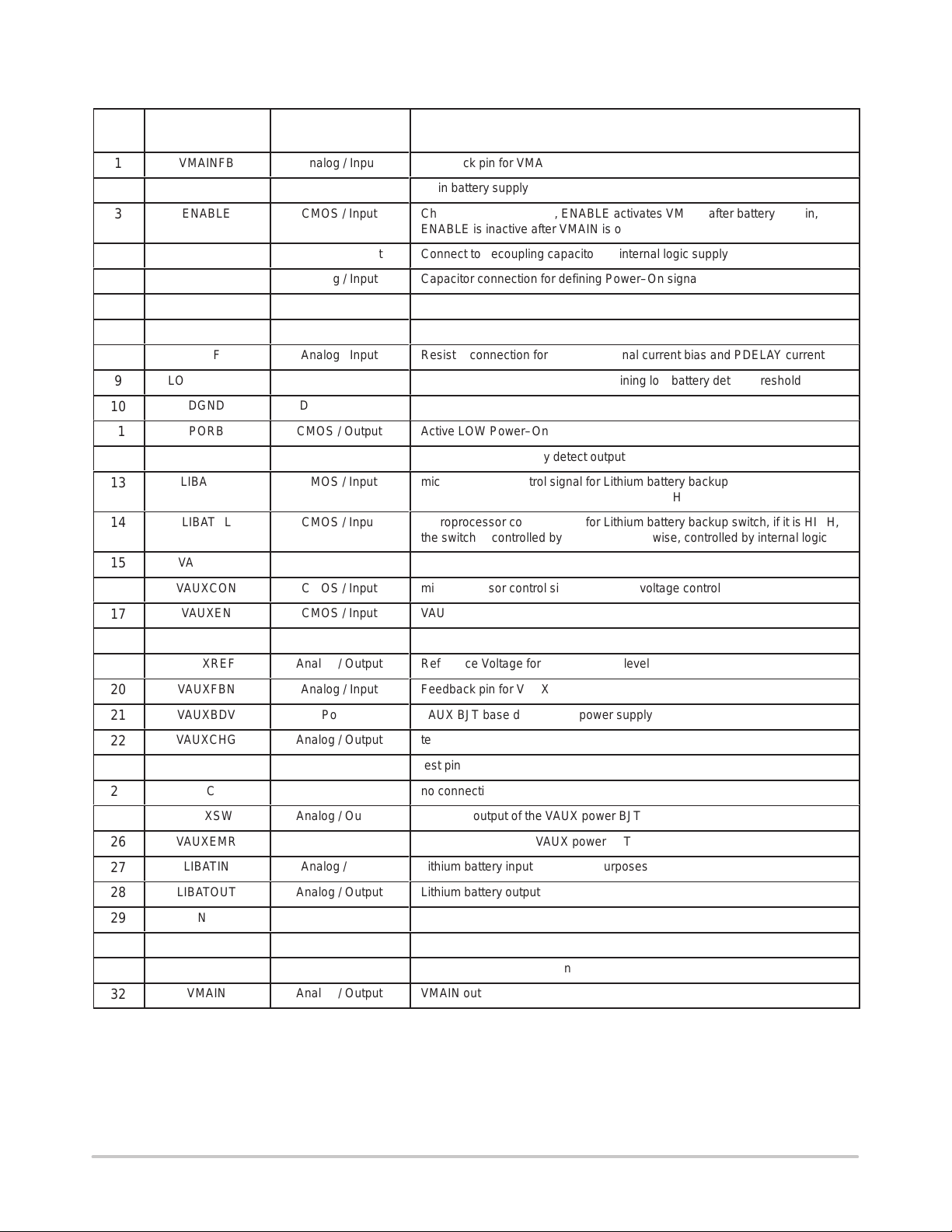

Pin

ББББББ

ББББББ

Á

ББББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

No.

1

2

3

ÁÁ

4

5

6

7

8

9

10

11

12

13

ÁÁ

14

ÁÁ

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

ÁÁ

30

31

32

MC34280

PIN FUNCTION DESCRIPTION

Function Type/Direction Description

VMAINFB

VBAT

ENABLE

ÁÁÁÁ

VDD

PDELAY

VREF

AGND

IREF

LOWBATSEN

DGND

PORB

LOWBATB

LIBATON

ÁÁÁÁ

LIBATCL

ÁÁÁÁ

VAUXADJ

VAUXCON

VAUXEN

VAUXFBP

VAUXREF

VAUXFBN

VAUXBDV

VAUXCHG

VAUXBASE

NC

VAUXSW

VAUXEMR

LIBATIN

LIBATOUT

NC

ÁÁÁÁ

VMAINGND

VMAINSW

VMAIN

Analog / Input

Power

CMOS / Input

БББББ

Analog / Output

Analog / Input

Analog / Output

Feedback pin for VMAIN

Main battery supply

Chip enable, Active high, ENABLE activates VMAIN after battery plug in,

ENABLE is inactive after VMAIN is on

БББББББББББББББББ

Connect to decoupling capacitor for internal logic supply

Capacitor connection for defining Power–On signal delay

Bandgap Reference output voltage. Nominal voltage is 1.25V

Analog Ground

Analog / Input

Analog / Input

Resistor connection for defining internal current bias and PDELAY current

Resistive network connection for defining low battery detect threshold

Digital Ground

CMOS / Output

CMOS / Output

CMOS / Input

БББББ

CMOS / Input

БББББ

CMOS / Input

CMOS / Input

CMOS / Input

Analog / Input

Analog / Output

Analog / Input

Power

Analog / Output

Analog / Output

Active LOW Power–On reset signal

Active LOW low battery detect output

microprocessor control signal for Lithium battery backup switch, the switch is

БББББББББББББББББ

ON when LIBATON=HIGH and LIBATCL=HIGH

microprocessor control signal for Lithium battery backup switch, if it is HIGH,

the switch is controlled by LIBATON, otherwise, controlled by internal logic

БББББББББББББББББ

microprocessor control signal for VAUX voltage control

microprocessor control signal for VAUX voltage control

VAUX enable, Active high

Feedback pin for VAUX

Reference Voltage for VAUX voltage level

Feedback pin for VAUX

VAUX BJT base drive circuit power supply

test pin

test pin

no connection

Analog / Output

Analog / Output

Analog / Input

Analog / Output

БББББÁБББББББББББББББББ

Power Ground

Analog / Input

Analog / Output

Collector output of the VAUX power BJT

Emitter output of the VAUX power BJT

Lithium battery input for backup purposes

Lithium battery output

no connection

Ground for VMAIN low side switch

VMAIN inductor connection

VMAIN output

http://onsemi.com

5

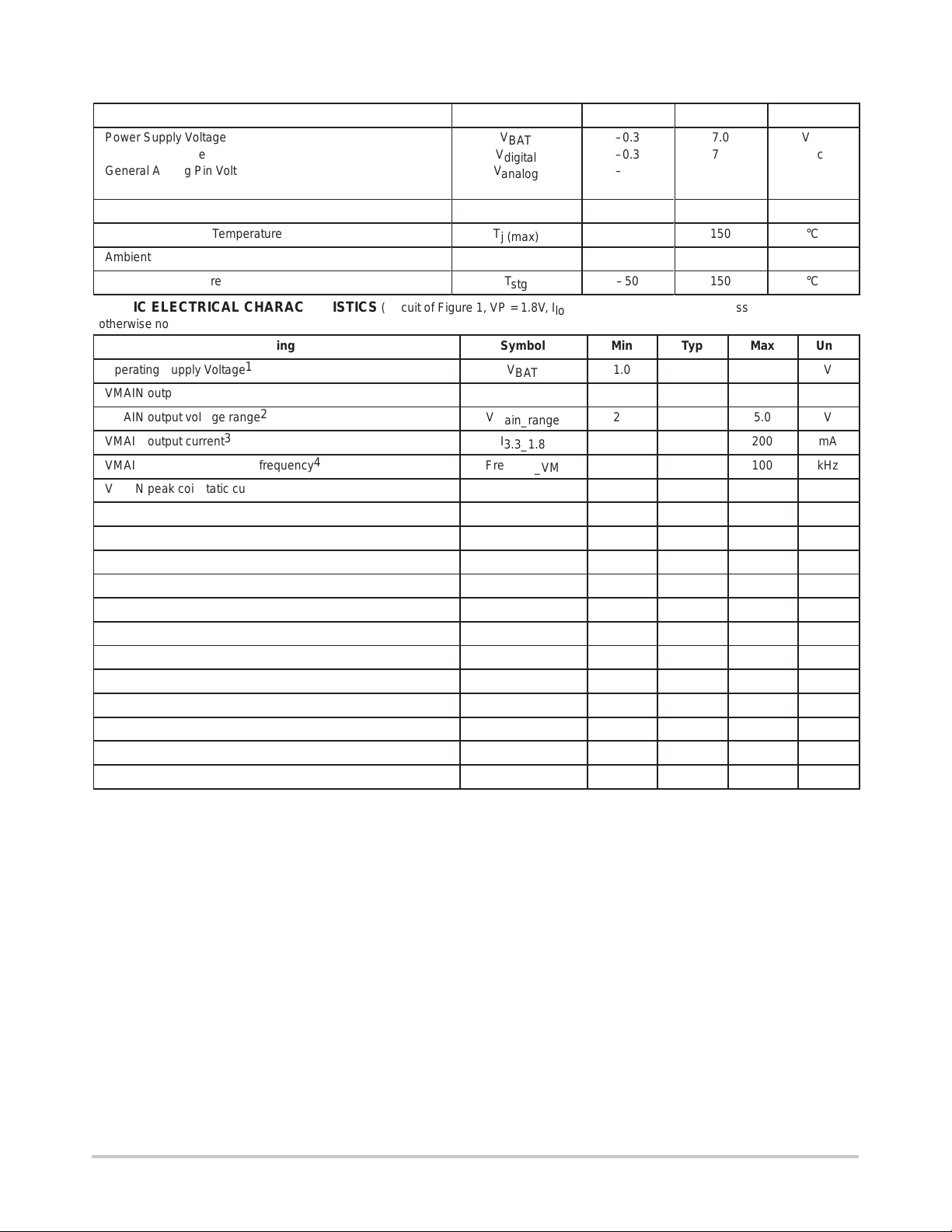

Page 6

MC34280

ABSOLUTE MAXIMUM RATINGS (T

Parameter

Power Supply Voltage

Digital Pin Voltage V

General Analog Pin Voltage V

Pin VAUXSW to Pin VAUXEMR Voltage (Continuous) V

Pin VMAINSW to Pin VMAIN Voltage (Continuous)

Operating Junction Temperature

Ambient Operating Temperature

Storage Temperature

STATIC ELECTRICAL CHARACTERISTICS (Circuit of Figure 1, VP = 1.8V, I

= 25°C, unless otherwise noted.)

A

Symbol Min Max Unit

V

BAT

digital

analog

AUXCE

V

syn

Tj

(max)

T

a

T

stg

load

–0.3

7.0

–0.3 7.0 Vdc

–0.3 7.0 Vdc

–0.3 30 Vdc

0.3

150

0

–50

70

150

= 0 mA, TA = 0 to 70°C unless

Vdc

Vdc

°C

°C

°C

otherwise noted.)

Rating

Operating Supply Voltage

1

VMAIN output voltage V

VMAIN output voltage range

VMAIN output current

VMAIN maximum switching frequency

2

3

4

VMAIN peak coil static current limit I

Symbol Min Typ Max Unit

V

BAT

main

V

main_range

I

3.3_1.8

Freq

max_VM

LIM_VM

1.0 V

3.13 3.3 3.47 V

2.7 5.0 V

200 mA

100 kHz

0.85 1.0 1.15 A

VAUX output voltage range VAUX_range 5.0 25 V

VAUXREF lower level voltage VAUX

VAUXREF upper level voltage VAUX

VAUXREF step size VAUX

VAUX maximum switching frequency Freq

VAUX peak coil static current limit I

Quiescent Supply Current at Standby Mode

5

Reference Voltage @ no load Vref

Battery Low Detect lower hysteresis threshold

6

Battery Low Detect upper hysteresis threshold V

PDELAY Pin output charging current Ichg

PDELAY Pin voltage threshold Vth

NOTE: 1. Output current capability is reduced with supply voltage due to decreased energy transfer. The supply voltage must not be higher than

NOTE: 2. Output voltage can be adjusted by external resistor to the VMAINFB pin.

NOTE: 3. At VBAT = 1.8V, output current capability increases with VBAT .

NOTE: 4. Only when current limit is not reached.

NOTE: 5. This is average current consumed by the IC from VDD, which is low–pass filtered from VMAIN, when only VMAIN is enabled and at no loading.

NOTE: 6. This is the minimum of ”LOWBATB” threshold for battery voltage, the threshold can be increased by external resistor divider from ”VBA T” to

VMAIN+0.6V to ensure boost operation. Max Start–up loading is typically 1V at 400 µA, 1.8V at 4.4 mA, and 2.2V at 88 mA.

”LOWBATSEN”.

REF_L

REF_H

REF_S

max_VL

LIM_VL

Iq

standby

no_load

V

LOBAT_L

LOBAT_H

PDELAY

PDELAY

1.0 1.1 1.2 V

2.0 2.2 2.4 V

17 mV

120 kHz

1.0 A

35 60 µA

1.19 1.22 1.25 V

0.8 0.85 0.9 V

1.05 1.1 1.15 V

0.8 1.0 1.2 µA

1.19 1.22 1.25 V

http://onsemi.com

6

Page 7

MC34280

IN

Eff

,

EFFICIENCY

OF

VAUX

%

OUT_AUX

Eff

,

EFFICIENCY

OF

VMAIN

%

DYNAMIC ELECTRICAL CHARACTERISTICS (Refer to TIMING DIAGRAMS, T

Rating

Minimum PORB to Control delay t

Minimum VAUXCON pulse HIGH width t

Minimum V AUXCON pulse LOW width t

Minimum VAUXADJ to VAUXCON delay t

Minimum VAUXADJ pulse HIGH width t

Minimum V AUXADJ pulse LOW width t

Minimum VAUXCON LOW to VAUXADJ pulse delay

Minimum hold time of VAUXADJ for Reset VAUXREF t

Minimum VAUXADJ pulse HIGH width for Reset VAUXREF t

Minimum hold time of VAUXADJ for Decrement VAUXREF t

Minimum V AUXADJ pulse HIGH width for Decrement VAUXREF t

NOTE: 1. For not resetting VAUXREF.

1

Symbol Min Typ Max Unit

PORC

CW

CC

CL

JW

JC

t

JL

RJL

RW

DL

DW

TYPICAL ELECTRICAL CHARACTERISTICS

Figure 6. Efficiency of VMAIN versus Output

Current (VMAIN = 3.3 V, L = 33 uH, Various VIN)

90%

)

(

85%

80%

75%

VMAIN

70%

0

50 100 150 200 250 300

I

OUT_MAIN

, MAIN OUTPUT CURRENT (mA)

Vin = 3V

Vin = 1.8V

Vin = 1.5V

Vin = 1V

, EFFICIENCY OF VMAIN (%)

Eff

Figure 7. Efficiency of VMAIN versus Input

V oltage (VMAIN = 3.3 V, L1 = 33 uH, Various I

90%

85%

80%

75%

VMAIN

70%

1

= 0 to 70°C unless otherwise noted.)

A

500 nS

5.0 µS

8.0 µS

1.0 µS

1.0 µS

1.0 µS

1.0 µS

500 nS

1.0 µS

500 nS

1.0 µS

X

X

X

1.5 2 3

VIN, INPUT VOLTAGE (V)

2.5

I

out

I

out

I

out

I

out

I

out

OUT

= 10mA

= 60mA

= 100mA

= 150mA

= 200mA

)

X

Figure 8. Efficiency of VAUX versus Output

Current (VAUX = 25 V, L2 = 33 uH, Various VIN)

80%

)

(

75%

70%

65%

60%

55%

VAUX

50%

1

357 111315

I

, AUX OUTPUT CURRENT (mA)

9

Vin = 3V

Vin = 1.8V

Vin = 1.5V

Vin = 1V

http://onsemi.com

Figure 9. Efficiency of V AUX versus Input

Voltage (VAUX = 25 V, L2 = 33 uH, Various I

80%

75%

70%

65%

60%

, EFFICIENCY OF VAUX (%)

55%

VAUX

Eff

50%

1

7

1.5 2 2.5 3

, INPUT VOLTAGE (V)

V

I

out

I

out

I

out

I

out

= 1mA

= 5mA

= 10mA

= 15mA

OUT

)

Page 8

MC34280

Eff

,

EFFICIENCY

OF

VAUX

%

IN

OUT_AUX

TYPICAL ELECTRICAL CHARACTERISTICS (Cont’d)

Figure 10. Efficiency of VAUX versus Output

Current (VAUX = 20 V, L2 = 33 uH, Various VIN)

80%

)

(

75%

70%

65%

VAUX

60%

55%

50%

1

Vin = 3V

Vin = 1.8V

Vin = 1.5V

Vin = 1V

3 5 7 11 13 15

I

OUT_AUX

, AUX OUTPUT CURRENT (mA)

9

Figure 12. Efficiency of VAUX versus Output

Current (VAUX = 5 V, L2 = 82 uH, Various VIN)

85%

80%

75%

70%

65%

, EFFICIENCY OF VAUX (%)

Eff

60%

55%

50%

VAUX

45%

40%

5 1015 3035

1

I

, AUX OUTPUT CURRENT (mA)

Vin = 3V

Vin = 2.4V

Vin = 1.8V

Vin = 1.5V

Vin = 1V

Figure 11. Efficiency of VAUX versus Input

Voltage (VAUX = 20 V, L2 = 33 uH, Various I

80%

75%

70%

65%

60%

, EFFICIENCY OF VAUX (%)

55%

VAUX

Eff

50%

1

1.5 2 2.5 3

VIN, INPUT VOLTAGE (V)

Figure 13. Efficiency of V AUX versus Input

Voltage (VAUX = 5 V, L2 = 82 uH, Various I

85%

80%

75%

70%

, EFFICIENCY OF VAUX (%)

65%

VAUX

Eff

50%

1

1.5

V

2 2.5 320 25

, INPUT VOLTAGE (V)

I

out

I

out

I

out

I

out

= 1mA

= 5mA

= 10mA

= 15mA

I

= 1V

out

I

= 5V

out

I

= 10V

out

I

= 15V

out

I

= 25V

out

OUT

OUT

)

)

http://onsemi.com

8

Page 9

MC34280

Figure 14. VMAIN Output Ripple (Medium Load) Figure 15. VMAIN Output Ripple (Heavy Load)

20 uS / div

1: VMAIN = 3.3 V (50 mV/div, AC COUPLED)

2: Voltage at VMAINSW (1 V/div)

1: VMAIN = 3.3 V (50 mV/div, AC COUPLED)

2: Voltage at VMAINSW (1 V/div)

10 uS / div

Figure 16. VAUX Output Ripple (Medium Load) Figure 17. VAUX Output Ripple (Heavy Load)

20 uS / div

1: VAUX = 20 V (50 mV/div, AC COUPLED)

2: Voltage at VAUXSW (10 V/div)

Figure 18. VMAIN Startup and Power–On Reset

1: VAUX = 20 V (50 mV/div, AC COUPLED)

2: Voltage at VAUXSW (10 V/div)

Figure 19. V AUX Startup

10 uS / div

50 mS / div

1: VMAIN from 1 V to 3.3 V (1 V/div)

2: Voltage of PORB (2 V/div)

3: Voltage of ENABLE (2 V/div)

5 mS / div

1: VAUX from 1.8 V to 20 V (5 V/div)

2: VAUXEN (2 V/div)

http://onsemi.com

9

Page 10

MC34280

DET AILED OPERATING DESCRIPTION

General

The MC34280 is a power supply integrated circuit which

provides two boost regulated outputs and some power

management supervisory functions. Both regulators apply

Pulse–Frequency–Modulation (PFM). The main boost

regulator output can be externally adjusted from 2.7V to 5V .

An internal synchronous rectifier is used to ensure high

efficiency (achieve 87%). The auxiliary regulator with a

built–in power transistor can be configured to produce a

wide range of positive voltage (can be used to supply a LCD

contrast voltage). This voltage can be adjusted from +5V to

+25V by an external potentiometer; or by a microprocessor,

digitally through a 6–bit internal DAC.

The MC34280 has been designed for battery powered

hand–held products. With the low start–up voltage from 1V

and the low quiescent current (typical 35 µA); the MC34280

is best suited to operate from 1 to 2 AA/ AAA cell.

Moreover, supervisory functions such as low battery

detection, CPU power–on reset, and back–up battery

control, are also included in the chip. It makes the MC34280

the best one–chip power management solution for

applications such as electronic organizers and PDAs.

Pulse Frequency Modulation (PFM)

Both regulators apply PFM. With this switching scheme,

every cycle is started as the feedback voltage is lower than

the internal reference. This is normally performed by

internal comparator. As cycle starts, Low–Side switch (i.e.

M1 in Figure 1) is turned ON for a fixed ON time duration

(namely, Ton) unless current limit comparator senses coil

current reaches its preset limit. In the latter case, M1 is OFF

instantly . So Ton is defined as the maximum ON time of M1.

When M1 is ON, coil current ramps up so energy is being

stored inside the coil. At the moment just after M1 is OFF,

the Synchronous Rectifier (i.e. M2 in Figure 1) or any

rectification device (such as Schottky Diode of Auxiliary

Regulator) is turned ON to direct coil current to charge up

the output bulk capacitor. Provided that coil current is not

reached, every switching cycle delivers fixed amount of

energy to the bulk capacitor. So for higher loading, larger

amount of energy (Charge) is withdrawn from the bulk

capacitor, and as output voltage is needed to regulated, larger

amount of Charge is needed to be supplied to the bulk

capacitor, that means switching frequency is needed to be

increased; and vice–versa.

Main Regulator

Figure 20 shows the simplified block diagram of Main

Regulator. Notice that precise bias current Iref is generated

by a VI converter and external resistor RIref, where

+

0.5

RIref

(A)

Iref

This bias current is used for all internal current bias as well

as setting VMAIN value. For the latter application, Iref is

doubled and fed as current sink at Pin 1. With external

resistor RMAINb tied from Pin1 to Pin32, a constant level

shift is generated in between the two pins. In close–loop

operation, voltage at Pin 1 (i.e. Output feedback voltage) is

needed to be regulated at the internal reference voltage level,

1.22V. Therefore, the delta voltage across Pin 1 and Pin 32

which can be adjusted by RMAINb determines the Main

Output voltage. If the feedback voltage drops below 1.22V,

internal comparator sets switching cycle to start. So, VMAIN

can be calculated as follows.

VMAIN

+

1.22

RMAINb

)

RIref

(V)

From the above equation, although VMAIN can be

adjusted by RMAINb and RIref ratio, for setting VMAIN, it

is suggested, by changing RMAINb value with RIref kept at

480K. Since changing RIref will alter internal bias current

which will affect timing functions of Max ON time (T

and Min OFF time (T

). Their relationships are as

OFF1

ON1

follows;

+

1

1

1.7 10

+

6.4 10

T

ON

T

OFF

Continuous Conduction Mode and Discontinuous

Conduction Mode

–11

–12

RIref

RIref

(S)

(S)

In Figure 21, regulator is operating at Continuous

Conduction Mode. A switching cycle is started as the output

feedback voltage drops below internal voltage reference

VREF . At that instant, the coil current does not drop to zero

yet, and it starts to ramp up for the next cycle. As the coil

current ramps up, loading makes the output voltage to

decrease as the energy supply path to the output bulk

capacitor is disconnected. And after Ton elapsed, M1 is OFF ,

M2 becomes ON, energy is dumped to the bulk capacitor.

Output voltage is increased as excessive charge is pumped

in, then it is decreased after the coil current drops below the

loading. Notice the abrupt spike of output voltage is due to

ESR of the bulk capacitor. Feedback voltage can be

resistor–divided down or level–shift down from the output

voltage. As this feedback voltage drops below VREF, next

switching cycle starts.

)

http://onsemi.com

10

Page 11

VBAT

D

Iref

IREF

RIref

480 kOhm

8

x2

Voltage

Reference

0.5 V

1.22 V

MC34280

DETAILED OPERATING DESCRIPTION (Cont’d)

CMAINb

100 pF

2 x Iref

VMAINFB

+ve Edge Delay

for Max. ON Time

VCOMP

COMP1

1–SHOT

for Min. OFF Time

RSQ

Qb

RMAINb

1000 kOhm

ZLC

V

DD

DGND

RSQ

COMP3

311

L1

33uH

VMAINSW

M1

senseFET

V

DD

M2

VMAIN

32

CMAIN

100 uF

VMAINGN

30

+

AGND

Voltage Reference

& Current Bias

Main Regulator

with Synchronous Rectifier

Figure 20. Simplified Block Diagram of Main Regulator

In Figure 22, regulator is operating at Discontinuous

Conduction Mode, waveforms are similar to those of Figure

21. However, coil current drops to zero before next

switching cycle starts.

To estimate conduction mode, below equation can be

used.

Iroom

where,

if I

room

T

h

+

η

ON

L Vout

2

is efficiency, refer to Figure 6

> 0, the regulator is at Discontinuous Conduction

Vin

2

*

I

LOAD

mode

if I

= 0, the regulator is at Critical Conduction mode

room

where coil current just drops to zero and next cycle starts.

if I

< 0, the regulator is at Continuous Conduction

room

mode

2

COMP2

AGND

DGND

ON

L

(A)

T

SW

I

pk

+

+

1*h

1

*

T

ON

I

LOAD

T

ǒ

T

ǒ

ON

SW

Vin

Vout

Ǔ

ILIM

(S);

Ǔ

Vin T

)

For Discontinuous Conduction mode, provided that

current limit is not reached,

2

T

Vin

@

(A)

@

ON

ǒ

Vout

h

@

Vin

*

(S);

Ǔ

1

T

SW

+

2

@L@

I

LOAD

Vin

I

+

@

pk

T

ON

L

For Continuous Conduction mode, provided that current

limit is not reached,

http://onsemi.com

11

Page 12

VREF

Feedback Voltage

MC34280

Cycle Starts

t

dl

Loading Current, I

Coil Current

VMAIN Zoom–In

LOAD

VMAIN

V@SW

Feedback Voltage

VREF

M1 ON

M2 OFF

I

pk

VMAIN + 1 V

M1 OFF

t

dh

M2 ON

0 V

M1 ON

M2 OFF

T

ON

T

SW

Figure 21. Waveforms of Continuous Conduction Mode

Cycle Starts

t

dl

M1 OFF

M2 ON

M1 ON

M2 OFF

M1 OFF

M2 ON

Loading Current, I

Coil Current

VMAIN Zoom–In

LOAD

VMAIN

V@SW

M1 ON

M2 OFF

I

pk

VMAIN + 1 V

M1 OFF M1 OFF M1 OFF

t

dh

0 V

M1 ON

M2 OFF

T

ON

V

IN

M2 OFF

T

SW

Figure 22. Waveforms of Discontinuous Conduction Mode

http://onsemi.com

12

M1 ON

Page 13

MC34280

X

F

VBAT

DETAILED OPERATING DESCRIPTION (Cont’d)

Synchronous Rectification

A Synchronous Rectifier is used in the main regulator to

enhance efficiency. Synchronous rectifier is normally

realized by powerFET with gate control circuitry which,

however, involved relative complicated timing concerns. In

Figure 20, as main switch M1 is being turned OFF, if the

synchronous switch M2 is just turned ON with M1 not being

completed turned OFF , current will be shunt from the output

bulk capacitor through M2 and M1 to ground. This power

loss lowers overall efficiency. So a certain amount of dead

time is introduced to make sure M1 is completely OFF

before M2 is being turned ON, this timing is indicated as t

dh

in Figure 21.

When the main regulator is operating in continuous mode,

as M2 is being turned OFF, and M1 is just turned ON with

M2 not being completed OFF , the above mentioned situation

will occur. So dead time is introduced to make sure M2 is

completed OFF before M1 is being turned ON, this is

indicated as tdl in Figure 21.

When the main regulator is operating in discontinuous

mode, as coil current is dropped to zero, M2 is supposed to

be OFF. Fail to do so, reverse current will flow from the

output bulk capacitor through M2 and then the inductor to

the battery input. It causes damage to the battery. So

M2–voltage–drop sensing comparator (COMP3 of Figure

20) comes with fixed offset voltage to switch M2 OFF

before any reverse current builds up. However, if M2 is

switch OFF too early, large residue coil current flows

through the body diode of M2 and increases conduction loss.

Therefore, determination on the offset voltage is essential

for optimum performance.

Auxiliary Regulator

The Auxiliary Regulator is a boost regulator, applies PFM

scheme to enhance high efficiency and reduce quiescent

current. An internal voltage comparator (COMP1 of Figure

23) detects when the voltage of Pin V AUXFBN drops below

that of Pin VAUXFBP. The internal power BJT is then

switched ON for a fixed–ON–time (or until the internal

current limit is reached), and coil current is allowed to build

up. As the BJT is switched OFF, coil current will flow

through the external Schottky diode to charge up the bulk

capacitor. After a fixed–mimimum–OFF time elapses, next

switching cycle will start if the output of the voltage

comparator is HIGH. Refer to Figure 23, the VAUX

regulation level is determined by the equation as follows,

R

AUXb

AUXa

Ǔ

(V)

V

AUX

+

VAUXFBP

@ǒ1

)

R

Where Max ON Time, TON2, and Min OFF T ime, TOFF2

can be determined by the following equations.

T

ON

T

OFF

2

2

+

1.7 10

+

2.1 10

–11

–12

RIref

RIref

(S)

(S)

VAUXADJ

VAUXCON

VAUXEN

VAUXREF

19

2.2 V

6–Bit

Counter

15

Input

Logic

16

17

Auxiliary Level Control Auxiliary Regulator

6–Bit

6

1.1 V

Figure 23. Simplified Block Diagram of Auxiliary Regulator

2018

COMP1

RAUXa

200 kOhm

VAUXFBN VAUXSWVAUXBDVVAUXFBP

VCOMP

RAUXb

2200 kOhm

+ve Edge Delay

for Max. ON Time

RSQ

1–SHOT

for Min. OFF Time

Qb

VBAT

ILIM

2521

Q1

COMP2

AGND

L2

33uH

senseBJT

+

CAU

33 u

VAUXEMR

26

http://onsemi.com

13

Page 14

MC34280

DETAILED OPERATING DESCRIPTION (Cont’d)

Auxiliary Regulator (Cont’d)

As the Auxiliary Regulator control scheme is the same as

the Main Regulator, equations for conduction mode, Tsw

and Ipk can also be applied, However, h to be used for

caculation is refered to Figure 8, 10, or 12.

If external potentiometer is used for voltage level

adjustment, internal 1.22V reference voltage can be used as

shown in the application diagram of Figure 24.

Cpor

c = 80n

GND

GND

RLBa

r = 300 k

GND

GND

GND

Riref

r = 480 k

10

11

12

13

14

15

16

87654321

9

MC34280

17 18 19 20 21 22 23 24

VBAT

GND

GND

Vref

RLBb

r = 900 k

PORB

LOWBAT

LIBATON

LIBATCL

VAUXEN

Current Limit for Both regulators

From Figure 20 and Figure 23, sense devices (senseFET

or senseBJT) are applied to sample coil current as the

low–side switch is ON. With that sample current flowing

through a sense resistor, sense–voltage is developed.

Threshold detector (COMP2 in both figures) detects

whether the sense–voltage is higher than preset level. If it

happens, detector output reset the flip–flop to switch OFF

low–side switch, and the switch can only be ON as next

cycle starts.

CVDD

c = 20u

GND

VBAT

Ren

r = 1000 k

32

31

30

29

28

27

26

25

GND

GND

GND

VBAT

CMAINb

c = 100p

RMAINb

r = 1000 k

1N5817

L = 33uH

LAUX

L = 33uH

LMAIN

GND

VBAT

1N5818

Caux

c = 30u

CMAIN

c = 100u

GND

VAUX

GND

Rauxb

r = 2.2 M

Figure 24. Application Diagram with External Potentiometer for V AUX Adjustment

http://onsemi.com

14

Rauxa

r = 200 k

GND

Page 15

MC34280

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

Á

Á

ББББББ

Á

Á

Á

DETAILED OPERATING DESCRIPTION (Cont’d)

Auxiliary voltage adjustment

The V AUX voltage can be adjusted by the microprocessor

control signals, namely, VAUXCON and VAUXADJ. The

control signal pattern is shown in Figure 4. The input truth

table is shown in Figure 25.

When VAUXEN is LOW, the Auxiliary Regulator is shut

down, only the counter content is retained. The initial

counter content is mid–range of 6–bit.

At the rising edge of VAUXCON, if V AUXADJ is LOW

(/ HIGH), each following V AUXADJ pulse enclosed by the

VAUXCON pulse packet increments (/ decrements) the

6–bit counter. At the falling edge of VAUXCON, the counter

content is then latched to a 6–bit DAC and is converted to a

voltage level of VAUXREF between 1.1V and 2.2V.

At the falling edge of V AUXCON, if V AUXADJ is HIGH,

the counter content will be reset to mid–range (1.65V). This

is also the default setting just after power–ON reset is

removed.

The 6–bit DAC converts the counter content to voltage

level ranging from 1.1 to 2.2V, so there are altogether 64

levels, and each voltage step is 17mV. When the counter

content reaches its maximum or minimum, further pulse of

VAUXADJ will be disregarded, until counting direction is

changed.

auxiliary regulator. Meanwhile, the startup circuitry will be

shut down. The Power–ON Reset block also starts to charge

up the external capacitor tied from Pin PDELAY to ground

with precise constant current. As the Pin PDELA Y’s voltage

reaches an internal set threshold, Pin PORB will go HIGH

to awake the microprocessor. And,

1.22

ǒ

T

POR

+

0.5

Ǔ

C

RIref

por

(S)

From Figure 3, if, by any chance, VMAIN is dropped

below the user–defined VMAIN output level minus 0.5V,

PORB will go LOW to indicate the OUTPUT LOW

situation. And, the IC will continue to function until the

VMAIN is dropped below 2V.

Low–Battery–Detect

The Low–Battery–Detect block is actually a voltage

comparator. Pin LOWBAT is LOW , if the voltage of external

Pin LOWBATSEN is lower than 0.85V internal reference.

The IC will neglect this warning signal. Pin LOWBAT will

become HIGH, if the voltage of external Pin LOWBA TSEN

is recovered to more than 1.1V . From Figure 1, with external

resistors RLBa and RLBb, thresholds of

Low–Battery–Detect can be adjusted based on the equations

below .

Power–ON Reset

The Power–ON Reset block accepts external active HIGH

ENABLE signal to activate the IC after battery is plugged in.

During the startup period (see Figure 2), the internal startup

circuitry is enabled to pump up VMAIN to a certain voltage

level, which is the user–defined VMAIN output level minus

an offset of 0.15V . The internal power–on reset signal is then

disabled to activate the main regulator and conditionally the

VAUXEN

0

1

1

1

1

1

1

ÁÁÁÁ

VAUXCON VAUXADJ RESULT

X

0

1

БББББ

X

X

0

1

0

1

ÁÁÁÁ

Figure 25. Auxiliary Voltage Control Input Truth Table

R

LBa

V

LOBAThigh

V

LOBATlow

Hold the counter content

Hold the counter content

Set ”countup” flag HIGH

Set ”countup” flag LOW

Increment (/ Decrement) the counter if ”countup” flag is HIGH (/ LOW)

DAC the counter content to VAUXREF voltage level (1.1 – 2.2 V)

Reset the counter to mid–range, then convert the counter content to

VAUXREF voltage level (1.65V)

ББББББББББББББББ

+

+

1.1

0.85

ǒ1

ǒ1

)

)

R

R

R

LBb

LBa

LBb

Ǔ

(V)

Ǔ

(V)

http://onsemi.com

15

Page 16

MC34280

Á

Á

Á

DETAILED OPERATING DESCRIPTION (Cont’d)

Lithium–Battery backup

The backup conduction path which is provided by an

internal power switch (typ. 13 Ohm) can be controlled by

internal logic or microprocessor.

If LIBA TCL is LOW, the switch, which is then controlled

by internal logic, is ON when the battery is removed and

VMAIN is dropped below LIBATIN by more than 100mV ,

feedback response, destabilizing the regulator and creating

a larger ripple at the output. From Figure 1, ripple of Main

and AUX regulator can be reduced by CMAINb, CAUXa

and CAUXb ranging from 100pF to 100nF respectively.

Reducing the ripple is also with improving efficiency,

system designers are recommended to do experiments on

capacitance values based on the PCB design.

and returns OFF when the battery is plugged back in.

If LIBATCL is HIGH, the switch is controlled by

microprocessor through LIBA TON. The truth table is shown

in Figure 26.

Efficiency and Output Ripple

For both regulators, when large values are used for

feedback resistors (> 50kOhm), stray capacitance of pin 1

(VMAINFB) and pin 20 (VAUXFBN) can add ”lag” to the

LIBATCL LIBATON Action

0

БББББ

1

1

БББББ

X

0

1

The switch is ON when the battery is removed and VMAIN is dropped below LIBATIN

by more than 100mV; The switch is OFF when the battery is plugged in.

ББББББББББББББББББББ

The switch is OFF

The switch is ON

Figure 26. Lithium Battery Backup Control Truth Table

Bypass Capacitors

If the metal leads from battery to coils are long, its stray

resistance can put additional power loss to the system as AC

current is being conducted. In that case, bypass capacitors

(CMAINbp and CAUXbp of Figure 1) are recommended to

remove AC components of coil currents to minimize that

power loss to optimize efficiency.

http://onsemi.com

16

Page 17

SEATING

PLANE

9

C

–T–

B1

–AB–

–AC–

E

MC34280

P ACKAGE DIMENSIONS

32–LEAD LQFP

FTB SUFFIX

CASE 873A–02

A

A1

32

1

4X

25

T–U0.20 (0.008) ZAB

BASE

METAL

N

–U–

VB

DETAIL Y

8

9

–Z–

S1

V1

17

4X

T–U0.20 (0.008) Z

AC

SECTION AE–AE

DF

J

S

G

DETAIL AD

0.10 (0.004) AC

AE

_

8X

M

R

P

AE

DETAIL Y

H

W

_

Q

K

X

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DATUM PLANE –AB– IS LOCATED AT BOTTOM

T–U

M

0.20 (0.008) ZAC

OF LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY AT

THE BOTTOM OF THE PARTING LINE.

4. DATUMS –T–, –U–, AND –Z– TO BE

DETERMINED AT DATUM PLANE –AB–.

5. DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE –AC–.

6. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION. ALLOWABLE PROTRUSION

IS 0.250 (0.010) PER SIDE. DIMENSIONS A AND B

DO INCLUDE MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE –AB–.

7. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

NOT CAUSE THE D DIMENSION TO EXCEED

0.520 (0.020).

8. MINIMUM SOLDER PLATE THICKNESS SHALL

BE 0.0076 (0.0003).

9. EXACT SHAPE OF EACH CORNER MAY VARY

FROM DEPICTION.

–T–, –U–, –Z–

MILLIMETERS

DIMAMIN MAX MIN MAX

7.000 BSC 0.276 BSC

A1 3.500 BSC 0.138 BSC

B 7.000 BSC 0.276 BSC

B1 3.500 BSC 0.138 BSC

C 1.400 1.600 0.055 0.063

D 0.300 0.450 0.012 0.018

E 1.350 1.450 0.053 0.057

F 0.300 0.400 0.012 0.016

G 0.800 BSC 0.031 BSC

H 0.050 0.150 0.002 0.006

J 0.090 0.200 0.004 0.008

K 0.500 0.700 0.020 0.028

__

M 12 REF 12 REF

N 0.090 0.160 0.004 0.006

P 0.400 BSC 0.016 BSC

Q 1 5 1 5

____

R 0.150 0.250 0.006 0.010

S 9.000 BSC 0.354 BSC

S1 4.500 BSC 0.177 BSC

V 9.000 BSC 0.354 BSC

V1 4.500 BSC 0.177 BSC

W 0.200 REF 0.008 REF

X 1.000 REF 0.039 REF

INCHES

DETAIL AD

0.250 (0.010)

GAUGE PLANE

http://onsemi.com

17

Page 18

Notes

MC34280

http://onsemi.com

18

Page 19

Notes

MC34280

http://onsemi.com

19

Page 20

MC34280

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich Time)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse T ime)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

20

MC34280/D

Loading...

Loading...