Page 1

查询MC34270供应商

MC34271

Liquid Crystal Display and

Backlight Integrated

Controller

The MC34271 is a low power dual switching voltage regulator,

specifically designed for handheld and laptop applications, to provide

several regulated output voltages using a minimum of external parts.

Two uncommitted switching regulators feature a very low standby

bias current of 5.0 µA, and an operating current of 7.0 mA capable of

supplying output currents in excess of 200 mA.

Both devices have three additional features. The first is an ELD

Output that can be used to drive a backlight or a liquid crystal display .

The ELD output frequency is the clock divided by 256. The second

feature allows four additional output bias voltages, in specific

proportions to VB, one of the switching regulated output voltages. It

allows use of mixed logic circuitry and provides a voltage bias for

N–Channel load control MOSFETst. The third feature is an Enable

input that allows a logic level signal to turn–“off” or turn–“on” both

switching regulators.

Due to the low bias current specifications, this device is ideally

suited for battery powered computer, consumer, and industrial

equipment where an extension of useful battery life is desirable.

MC34271 Features:

• Low Standby Bias Current of 5.0 µA

• Uncommitted Switching Regulators Allow Both Positive and

Negative Supply Voltages

• Logic Enable Allows Microprocessor Control of All Outputs

• Synchronizable to External Clock

• Mode Commandable for ELD and LCD Interface

• Frequency Synchronizable

• Auxiliary Output Bias Voltages Enable Load Control via N–Channel

FETs

MAXIMUM RATINGS (T

Rating

Input Voltage

Power Dissipation and

Thermal Characteristics

Maximum Power Dissipation – Case 873 P

Thermal Resistance, Junction–to–Ambient R

Thermal Resistance, Junction–to–Case R

Output #1 and #2 Switch Current

Output #1 and #2 “Off”–State V oltage

Feedback Enable MOSFETs

“Off”–State Voltage

Operating Junction Temperature

Operating Ambient Temperature

Storage Temperature Range

= 25°C, unless otherwise noted.)

A

Symbol Value Unit

V

DD

D

θJA

θJC

ISL & I

SB

V

SL

V

LF

T

J

T

A

T

stg

16

1.43 W

100 °C/W

60 °C/W

500

60

20

125

0 to +70

–55 to +150

Vdc

mA

Vdc

Vdc

°C

°C

°C

http://onsemi.com

32

1

QFP–32

FB SUFFIX

CASE 873

PIN CONNECTIONS AND

MARKING DIAGRAM

32

31 30 29 2728 26 25

1

T

SW

124

DS

1

2

Ref

1

3

FB

1

4

Comp

1

5

SS

1

6

S

1

7

D

1

8

Drv

1

ELD

9101112 1413 15 16

R

Sync

Mode

V

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

Gnd

AWLYYWW

DD

4

V

(Top View)

A

V

MC34271

3

V

1

ref

V

EN

DS

Ref

Comp

SS

V2V1V

FB

V

EN

S

D

0

2

2

23

2

22

2

21

2

20

2

19

2

18

2

17

B

ORDERING INFORMATION

Device Package Shipping

MC34271FB QFP–32 250 Units / Tray

Semiconductor Components Industries, LLC, 2000

April, 2000 – Rev. 0

1 Publication Order Number:

MC34271/D

Page 2

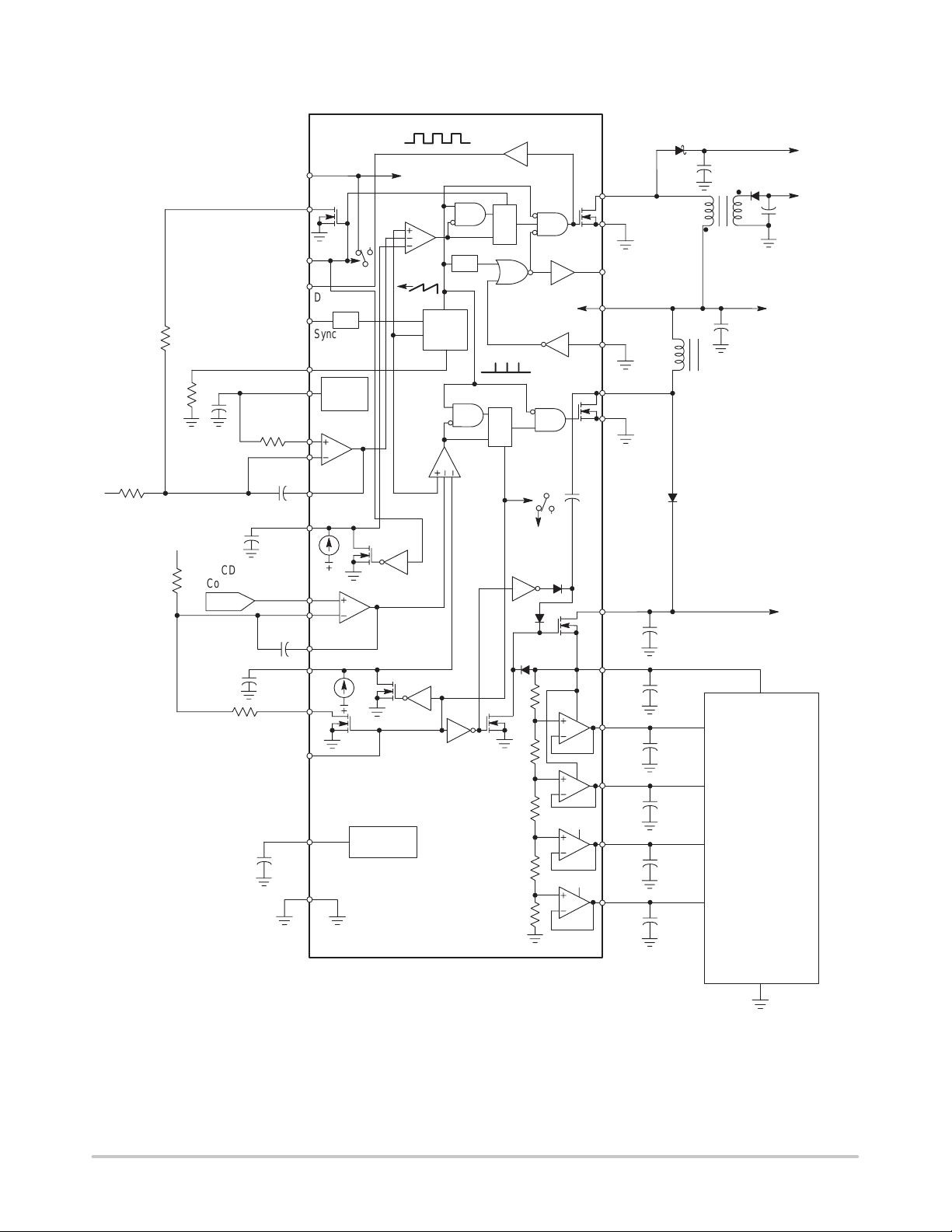

EL

Panel

From DAC

EL

Control

µP Control

V

B

V

in

On/Off

Comp

Comp

VA = 5.0 V

MC34271

Representative Block Diagram

SW

EN

Drv

Sync

R

V

Ref

Ref

FB

EN

Ref

FB

1

32

1

26

1

8

31

30

T

V

27

1.25 V

1

2

1

3

1

4

2

25

2

23

2

22

2

21

28

÷ 2

ref

V

DD

BIAS

OSC

Circuit #1

PWM

Circuit #2

ELD

EN

PWM

BIAS Output

Buffers

D

1

7

S

1

6

ELD

9

V

V

DD

DD

11

Mode

10

D

2

18

S

2

19

V

B

17

V

0

16

V

1

15

V

2

14

V

3

13

V

in

V

B

V

0

V

1

V

2

V

3

Gnd

29

This device contains 350 active transistors.

http://onsemi.com

2

V

4

12

V

4

Page 3

MC34271

ELECTRICAL CHARACTERISTICS (V

the operating ambient temperature range that applies, unless otherwise noted.)

Characteristic

REFERENCE SECTION

Reference Voltage (TJ = 25°C) V

Line Regulation (VDD = 5.0 V to 12.5 V) Reg

Load Regulation (IO = 0 to 120 µA) Reg

Total Variation (Line, Load and Temperature) V

ERROR AMPLIFIERS

Input Offset Voltage (VCM = 1.25 V) V

Input Bias Current (VCM = 1.25 V) I

Open Loop Voltage Gain (VCM = 1.25 V, V

Output Voltage Swing V

High State (IOH = –100 µA) Ve

Low State (IOL = 100 µA) Ve

BIAS VOLTAGE

Voltage (VDD = 5.0 V to 12.5 V, IO = 0) V

OSCILLATOR AND PWM SECTIONS

Total Frequency Variation Over Line and Temperature f

VDD = 5.0 V to 10 V, TA = 0° to 70°C, RT = 169 k 90 115 140

Duty Cycle at Each Output %

Maximum DC

Minimum DC

Sync Input

Input Resistance (V

Minimum Sync Pulse Width T

OUTPUT MOSFETs

Output Voltage – “On”–State (I

Output Current – “Off”–State (VOH = 40 V) I

Rise and Fall Times tr, t

EL DISCHARGE OUTPUT (ELD) AND DRV

Output Voltage – “On”–State (I

Output Voltage – “On”–State (I

Output Voltage – “Off”–State (I

Output Voltage – “Off”–State (I

FEEDBACK ENABLE SWITCHES (DS1, DS2)

Output Voltage – “Low”–State (I

Output Current – “Off”–State (VOH = 12.5 V) Ife

SWITCHED VDD OUTPUT (SW1)

Output Voltage V

Switch “On” (EN1 = 1, I

Switch “Off” (EN1 = 0, I

AUXILIARY VOLTAGE OUTPUTS

V0 Enable Switch

“On”–Resistance: VB to V

“Off”–State Leakage Current (VB = 10 V) I

V0 Voltage (VB = 30 V, I

V0 Resistance (I

NOTE: 1. Low duty pulse techniques are used during test to maintain junction temperature as close to ambient as possible.

= 3.5 V) R

sync

= 200 mA) V

sink

= 100 µA) V

sink

= 50 mA) V

sink

= –100 µA) V

source

= –50 mA) V

source

= 1.0 mA) Vfe

sink

= 100 µA) Vsw

source

= 100 µA) Vsw

sink

0

= 0 mA) V

source

= 4.0 mA) R

source

= 6.0 V, for typical values TA = Low to High [Note 1], for min/max values TA is

DD

Symbol Min Typ Max Unit

1.225 1.250 1.275 V

– 2.0 10 mV

– 2.0 10 mV

1.215 – 1.285 V

– 1.0 10 mV

– 120 600 nA

80 100 – dB

VA–1.5 4.0 5.5

0 – 1.0

4.6 5.0 5.4 V

92 95 –

– – 0

25 50 100 kΩ

– 1.0 – µs

– 150 250 mV

– 0.1 1.0 µA

– 50 – ns

– 30 100 mV

– 2.0 2.5 V

VDD–0.5 5.9 – V

VDD–3.5 3.3 – V

– 10 100 mV

– 0.6 1.0 µA

5.5 5.9 6.0

0 0.1 0.2

0 0.1 2.0 µA

29.5 29.9 30 V

20 40 60 Ω

= 2.0 V) A

COMP

1

ref

line

load

ref

IO

IB

VOL

OH

OL

A

OSC

max

min

sync

p

OL

OH

f

OL

OL

OH

OH

OL

OH

OH

OL

Rds 0 2.0 10 Ω

lkg

0

0

kHz

http://onsemi.com

3

Page 4

MC34271

100

1.0

DC

SWITC

O

T

T

D

T

C

CLE

0

ELECTRICAL CHARACTERISTICS (continued) (V

the operating ambient temperature range that applies, unless otherwise noted.)

Characteristic UnitMaxTypMinSymbol

AUXILIARY VOLTAGE OUTPUTS

V1, V2, V3, V4 Outputs

1–V1/V0 Ratio 0.0500 0.0520 0.0535

1–V2/V0 Ratio 0.1010 0.1035 0.1065

V3/V0 Ratio 0.1010 0.1035 0.1065

V4/V0 Ratio 0.0500 0.0520 0.0535

Output Resistance (I

Output Short Circuit Current I

LOGIC INPUTS (EN1, EN2, MODE)

Input Low State V

Input High State V

Input Impedance R

SOFT START CONTROL (SS1,SS2)

Charge Current (Capacitor Voltage = 1.0 V to 4.0 V)

Discharge Current (Capacitor Voltage = 1.0 V) I

TOTAL SUPPLY CURRENT

VDD Current VDD = 6.0 V I

Standby Mode (EN1 = EN2 = 0) VDD = 16 V – 3.0 15

VDD Current I

Backlight “On” (EN1 = 1; EN2 = 0)

VDD Current I

LCD “On” (No Inductor) (EN1 = 0; EN2 = 1)

VB Current (V0 = 35 V) I

NOTE: 1. Low duty pulse techniques are used during test to maintain junction temperature as close to ambient as possible.

= 4.0 mA) R

source

= 6.0 V , for typical values TA = Low to High [Note 1], for min/max values TA is

DD

o

ss

IL

IH

in

I

chg

dschg

CC

CC

CC

O

20 40 60 Ω

5.0 10 20 mA

0 – 0.8 V

2.0 – 6.0 V

25 50 100 kΩ

0.5 1.0 2.5 µA

250 650 – µA

– 2.0 5.0 µA

– 0.7 3.0 mA

– 0.9 2.0 mA

– 1.2 3.0 mA

Y

Y

U

PU

U

H

,

0.8

0.6

0.4

0.2

0

1.5

2.0 2.5 3.0 3.5 4.0 4.5 100 1.0 k 10 k 100 k 1000 k

V

, COMPENSATION VOLTAGE (V)

Comp

Figure 1. Switch Output Duty Cycle versus

Compensation V oltage

VDD = 6.0 V

TA = 25°C

80

60

40

20

, OPEN LOOP VOLTAGE GAIN (dB)

0

VOL

A

–20

10

Figure 2. Error Amp Open Loop Gain and

Gain

Phase

f, FREQUENCY (Hz)

Phase versus Frequency

VDD = 6.0 V

V

Comp

RL = Open

TA = 25°C

= 2.5 V

30

60

90

120

150

180

http://onsemi.com

4

Page 5

MC34271

FET

DRAIN

OLTAGE

(

)

O

T

T

OLTAGE

DRO

(m

)

SWITC O T T SIN SAT RATION( )

8.0

OLTAGE

ARIATION

(

)

V

P

V

PU

U

– 5.0

–10

–15

–20

–25

–30

0

VDD = 6.0 V

TA = 25°C

0

1.0 2.0 3.0 4.0 5.0 4.0 6.0 8.0 10 12 16 18

V

ref

I, CURRENT DRAW (mA)

Figure 3. Reference V oltage Change versus

Reference Current

0.16

V

0.12

0.08

V

2.5

2.0

V

A

1.5

1.0

0.5

QUIESCENT CURRENT (mA)

0

2.0

EN1 = 1 and EN2 = 0

Standby Current

EN1 and EN2 = 0

VDD, SUPPLY VOLTAGE (V)

EN1 and EN2 = 1

RT = 169 k

No Loading

TA = 25°C

14

2.2

1.8

1.4

1.0

0.6

0.2

Figure 4. Quiescent Current versus Supply V oltage

–1.0

– 2.0

0

V

DD

Sink Saturation

VDD = 6.0 V

TA = 25°C

2.0

1.5

1.0

0.04

VDD = 6.0 V

TA = 25°C

0 – 4.0 0

0

ID, DRAIN CURRENT (mA)

– 3.0

, SWITCH OUTPUT SOURCE SATURATION (V)

sat

V

0

Source Saturation

30 6015 4550 150100 200

I

, SWITCH OUTPUT CURRENT (mA)

Source

Figure 5. FET Drain Voltage versus Sink Current Figure 6. ELD and DRV1 Switch Output Source

and Sink Saturation versus Current

0.30

0.25

V

0.20

0.15

0.10

V

0.05

V

– 0.05

– 0.10

VDD = 6.0 V

V

A

V

ref

0

10 20 30 40 50 60 70 10 20 30 40 50 60 70

0

TA, AMBIENT TEMPERATURE (°C)

Figure 7. V

and VA Variation

ref

versus T emperature

6.0

4.0

2.0

0

– 2.0

– 4.0

– 6.0

OSCILLATOR FREQUENCY CHANGE (kHz)

– 8.0

0

Figure 8. Oscillator Frequency Variation

TA, AMBIENT TEMPERATURE (°C)

versus T emperature

VDD = 6.0 V

RT = 169 k

0.5

http://onsemi.com

5

Page 6

MC34271

1000

VDD = 6.0 V

TA = 25°C

100

FREQUENCY (kHz)

10

TIMING RESISTANCE (kΩ, s)

Figure 9. Frequency versus Timing

100 1000 1.0 2.0 3.0 4.0 5.0 6.0

OPERATING DESCRIPTION

The MC34271 is a monolithic, fixed frequency power

switching regulator specifically designed for dc to dc

converter and battery powered applications. This device

operates as a fixed frequency, voltage mode regulator

containing all the active functions required to directly

implement step–up, step–down and voltage inverting

converters with a minimum number of external components.

Potential markets include battery powered, handheld,

automotive, computer, industrial and cost sensitive

consumer products. A description of each section is given

below with the representative block diagram shown in

Figure 11.

Oscillator

The oscillator frequency is programmed by resistor RT.

The charge to discharge ratio is controlled to yield a 95%

maximum duty cycle at the switch outputs. During the fall

time of the internal sawtooth waveform, the oscillator

generates an internal blanking pulse that holds the inverting

input of the AND gates high, disabling the output switching

MOSFET s. The internal sawtooth waveform has a nominal

peak voltage of 3.3 V and a valley voltage of 1.7 V.

Pulse Width Modulators

Both pulse width modulators consist of a comparator with

the oscillator ramp voltage applied to the noninverting input,

while the error amplifier output is applied to the inverting

input. A third input to the comparator has a 0.5 mA typical

current source that can be used to implement soft start.

Output switch conduction is initiated when the ramp

waveform is discharged to the valley voltage. As the ramp

voltage increases to a voltage that exceeds the error

amplifier output, the latch resets, terminating output

MOSFET conduction for the duration of the oscillator ramp.

This PWM/latch combination prevents multiple output

pulses during a given oscillator cycle.

Each PWM circuit is enabled by a logic input. When

disabled, the entire block is turned off, drawing only leakage

current from the power source. Shared circuits, like the

5.0

REFERENCE VOLTAGE (V)

4.0

3.0

2.0

1.0

RT = 169 k

TA = 25°C

0

00

VDD LEVEL (V)

Figure 10. VA, V

versus V

ref

DD

V

A

V

ref

reference and oscillator, can be activated by either EN

or EN2.

Circuit #1 has an ELD output which may be used to drive

an LCD or backlight. Its output frequency is the oscillator

frequency divided by 1024.

Error Amplifiers and Reference

Each error amplifier is provided with access to both

inverting and noninverting inputs, and the output. The Error

Amplifiers’ Common Mode Input Range is 0 to 2.5 V. The

amplifiers have a minimum dc voltage gain of 60 dB. The

1.25 V reference has an accuracy of ±4.0% at room

temperature.

External loop compensation is required for converter

stability. A simple low–pass filter is formed by connecting

a resistive divider from the output to the error amplifier

inverting input, and a series resistor–capacitor from the error

amplifier output also to the to the inverting input. The step

down converter is easiest to compensate for stability. The

step–up and voltage inverting configurations, when

operated as continuous conduction boost or flyback

converters, are more difficult to compensate, and may

require a lower loop design bandwidth.

MOSFET Switch Outputs

The output MOSFET s are designed to switch a maximum

of 60 V, with a peak drain current capability of 500 mA. In

circuit #1 an additional DRV1 output is provided for

interfacing with an external MOSFET.The gates of the

MOSFETs are held low when the circuit is disabled.

Auxiliary Output Voltages

Output voltages V0 through V4 are provided for use as

references or bias voltages. V0 is the circuit #2 output

voltage, when an internal FET switch is activated. The other

auxiliary output voltages are proportional to VB. The

amplifiers for V1 and V2 are powered from V0, while the

amplifiers for V3 and V4 are powered from VDD.

1

http://onsemi.com

6

Page 7

EL

Panel

MC34271

Figure 11. Representative Block Diagram Electroluminescent Backlight Configuration

SW

V

B

169 k

Brightness

DAC

1

32

DS

1

1

EN

1

26

31

30

27

23

22

21

20

24

8

2

3

4

5

Drv

Sync

R

T

Ref

FB

1

Comp

SS

1

Ref

FB

2

Comp

SS

2

DS

1

÷ 2

V

ref

1.25 V

1

1

2

2

2

V

DD

Circuit #1 Bias Supply

÷ N

OSC

S

R

En

S

Q

R

Q

En

V

DD

V

DD2

Circuit #2

Bias Supply

D

1

7

S

6

1

ELD

9

V

DD

Mode

D

S

V

V

V

11

10

2

18

19

2

B

17

V

0

16

1

15

0

V

1

“On/Off”

V

DD

V

B

6.0 V to 30 V

V

2

V

3

V

4

LCD

Display

V

V

DD2

DD2

V

2

14

V

3

13

V

4

12

25

EN

2

V

A

28

Gnd

29

BIAS

http://onsemi.com

7

Page 8

MC34271

Figure 12. Auxiliary Supply Configuration

12 V

V

169 k

B

LCD

Contrast

DAC

SW

1

32

DS

1

1

EN

1

26

31

30

27

23

22

21

20

24

8

2

3

4

5

Drv

Sync

R

T

Ref

FB

1

Comp

SS

1

Ref

FB

2

Comp

SS

2

DS

2

V

1

÷ 2

V

ref

1.25 V

1

1

2

2

DD

Circuit #1 Bias Supply

÷ N

OSC

S

R

En

En

S

Q

R

Q

Circuit #2

Bias Supply

V

V

DD

DD2

D

1

7

S

6

1

ELD

9

V

DD

Mode

D

S

V

V

V

11

10

2

18

19

2

B

17

V

0

16

1

15

0

V

1

12 V

–27 V

V

DD

5.0 V to 16 V

V

B

6.0 V to 30 V

25

EN

2

V

A

28

Gnd

29

BIAS

V

V

DD2

DD2

V

2

14

V

3

13

V

4

12

V

2

V

3

V

4

LCD

Display

http://onsemi.com

8

Page 9

2.2 M

160 k

8.25 k

9.1 k

MC34271

Figure 13. EL PANEL Drive Circuit

Vin 6.0 V

+

MC34271

SW

1

32

EN

1

26

31

30

V

ref

27

0.1

µF

V

DD

Drv

8

1

÷ 2

Sync

R

T

V

ref

1.25 V

Ref

2

1

Circuit #1 Bias Supply

÷ N

OSC

S

R

D

En

S

Q

R

Q

1

7

S

6

1

ELD

V

DD

Mode

400 Hz

9

0.1

µF

11

10

D

2

18

S

19

2

10 µF

34

4T

#364T#36

65

10

2.2 k

MR856

8

1

7

MPSA44

120T

#36

2

MR856

MTP3055EL

120T

#36

0.22 µF

200 V

15 k

EL

PANEL

1.0 k

1.0 k

8.2 k

22 k

1.0 k

10 k

V

B

4.3 M

DAC

15 pF

0.1 µF

MMBT2907

FB

3

1

Comp

4

1

SS

1

5

DS

1

1

Ref

2

23

22

FB

2

Comp

2

21

SS

2

20

DS

2

24

25

EN

2

V

A

28

Gnd

29

BIAS

V

DD

V

DD2

Circuit #2

Bias Supply

V

V

DD2

DD2

V

B

17

V

0

16

V

1

15

V

2

14

V

3

13

V

4

12

V

0

V

1

V

2

V

3

V

4

LCD

Display

V

B

NOTES::1. Transformer information TDK Core # PC40EEM12.7/13.7–Z

Bobbin # BEPC–10–118G 2 mil gap. LP = 1.6 µhy.

2.EL PANEL: DUREL 3/SL ORANGE

http://onsemi.com

9

Page 10

L

24 17

25

MC34271

P ACKAGE DIMENSIONS

QFP–32

FB SUFFIX

CASE 873–01

ISSUE A

16

L

–C–

SEATING

PLANE

–A–

C

S S

S S

–B–

B

V

M

M

B

0.20 (0.008) C A–B D

DETAIL A

32

9

81

0.05 (0.002) A–B

–D–

A

0.20 (0.008) A–B D

0.05 (0.002)

M

A–B

S S

C

S

0.20 (0.008) A–B D

M

E

H

G

S S

H

–H–

DETAIL C

DATUM

PLANE

0.01 (0.004)

M

M

0.20 (0.008) H A–B D

BASE METAL

B

P

–A–,–B–,–D–

DETAIL A

F

J

N

D

0.20 (0.008) A–B D

M

S S

C

SECTION B–B

VIEW ROTATED 90° CLOCKWISE

–H–

DATUM

PLANE

DETAIL C

NOTES:

U

T

R

K

Q

X

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DATUM PLANE –H– IS LOCATED AT BOTTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD WHERE

THE LEAD EXITS THE PLASTIC BODY AT THE

BOTTOM OF THE PARTING LINE.

4. DATUMS –A–, –B– AND –D– TO BE DETERMINED AT

DATUM PLANE –H–.

5. DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE –C–.

6. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS 0.25

(0.010) PER SIDE. DIMENSIONS A AND B DO

INCLUDE MOLD MISMATCH AND ARE DETERMINED

AT DATUM PLANE –H–.

7. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR PROTRUSION

SHALL BE 0.08 (0.003) TOTAL IN EXCESS OF THE D

DIMENSION AT MAXIMUM MATERIAL CONDITION.

DAMBAR CANNOT BE LOCATED ON THE LOWER

RADIUS OR THE FOOT.

MILLIMETERS INCHES

MIN MINMAX MAX

DIM

A

6.95

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

R

S

T

U

V

X

7.10

6.95

7.10

1.40

1.60

0.273

0.373

1.30

1.50

0.273

0.80 BSC

–

0.20

0.119

0.197

0.33

0.57

5.6 REF

6°

8°

0.119

0.135

0.40 BSC

5°

10°

0.15

0.25

8.85

9.15

0.15

0.25

5°

11°

8.85

9.15

1.0 REF 0.039 REF

0.280

0.274

0.280

0.274

0.063

0.055

0.015

0.010

0.059

0.051

–

0.010

–

0.031 BSC

0.008

–

0.008

0.005

0.022

0.013

0.220 REF

8°

6°

0.005

0.005

0.016 BSC

10°

5°

0.010

0.006

0.360

0.348

0.010

0.006

11°

5°

0.360

0.348

http://onsemi.com

10

Page 11

Notes

MC34271

http://onsemi.com

11

Page 12

MC34271

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich Time)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse T ime)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

12

MC34271/D

Loading...

Loading...