Page 1

MC34064, MC33064,

NCV33064

Undervoltage Sensing

Circuit

The MC34064 is an undervoltage sensing circuit specifically

designed for use as a reset controller in microprocessor−based

systems. It offers the designer an economical solution for low voltage

detection with a single external resistor. The MC34064 features a

trimmed−in−package bandgap reference, and a comparator with

precise thresholds and built-in hysteresis to prevent erratic reset

operation. The open collector reset output is capable of sinking in

excess of 10 mA, and operation is guaranteed down to 1.0 V input with

low standby current. The MC devices are packaged in 3−pin TO-92,

micro size TSOP−5, 8−pin SOIC−8 and Micro8t surface mount

packages. The NCV device is packaged in SOIC−8 and TO−92.

Applications include direct monitoring of the 5.0 V MPU/logic

power supply used in appliance, automotive, consumer and industrial

equipment.

Features

• Trimmed−In−Package Temperature Compensated Reference

• Comparator Threshold of 4.6 V at 25°C

• Precise Comparator Thresholds Guaranteed Over Temperature

• Comparator Hysteresis Prevents Erratic Reset

• Reset Output Capable of Sinking in Excess of 10 mA

• Internal Clamp Diode for Discharging Delay Capacitor

• Guaranteed Reset Operation with 1.0 V Input

• Low Standby Current

• Economical TO−92, TSOP−5, SOIC−8 and Micro8 Surface Mount

Packages

• Pb−Free Packages are Available

• NCV Prefix for Automotive and Other Applications Requiring Site

and Control Changes

Input

Reset

http://onsemi.com

8

1

8

1

5

1

Pin 1. Ground

Pin 1. Reset

1

2

3

PIN CONNECTIONS

1

Reset

2

Input

3

N.C.

4

Ground

(Top View)

SOIC−8

D SUFFIX

CASE 751

Micro8

DM SUFFIX

CASE 846A

TSOP−5

SN SUFFIX

CASE 483

2. Input

3. Reset

4. NC

5. NC

TO−92

P SUFFIX

CASE 29

2. Input

3. Ground

8

N.C.

7

N.C.

6

N.C.

5

N.C.

1.2 V

ref

GND

This device contains 21 active transistors.

Figure 1. Representative Block Diagram

© Semiconductor Components Industries, LLC, 2005

October, 2005 − Rev. 16

Sink Only

=

Positive True Logic

1 Publication Order Number:

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 6 of this data sheet.

DEVICE MARKING INFORMATION

See general marking information in the device marking

section on page 7 of this data sheet.

MC34064/D

Page 2

MC34064, MC33064, NCV33064

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Input Supply Voltage V

Reset Output Voltage V

Reset Output Sink Current (Note 2) I

Clamp Diode Forward Current, Reset to Input Pin (Note 2) I

in

O

Sink

F

Power Dissipation and Thermal Characteristics

P Suffix, Plastic Package

Maximum Power Dissipation @ TA = 25°C

Thermal Resistance, Junction−to−Air

D Suffix, Plastic Package

Maximum Power Dissipation @ TA = 25°C

Thermal Resistance, Junction−to−Air

DM Suffix, Plastic Package

Maximum Power Dissipation @ TA = 25°C

Thermal Resistance, Junction−to−Air

Operating Junction Temperature T

Operating Ambient Temperature

P

D

R

q

JA

P

D

R

q

JA

P

D

R

q

JA

J

T

A

MC34064

MC33064

NCV33064

Storage Temperature Range T

stg

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously. If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

1. ESD data available upon request.

−1.0 to 10 V

10 V

Internally

mA

Limited

100 mA

625

200

625

200

520

240

mW

°C/W

mW

°C/W

mW

°C/W

+150 °C

°C

0 to +70

−40 to +85

−40 to +125

−65 to +150 °C

ELECTRICAL CHARACTERISTICS (For typical values T

= 25°C, for min/max values TA is the operating ambient temperature range

A

that applies [Notes 3 and 4] unless otherwise noted.)

Characteristics Symbol Min Typ Max Unit

COMPARATOR

Threshold Voltage

High State Output (Vin Increasing)

Low State Output (Vin Decreasing)

Hysteresis

V

IH

V

IL

V

H

4.5

4.5

0.01

4.61

4.59

0.02

0.05

RESET OUTPUT

Output Sink Saturation

(Vin = 4.0 V, I

(Vin = 4.0 V, I

(Vin = 1.0 V, I

= 8.0 mA)

Sink

= 2.0 mA)

Sink

= 0.1 mA)

Sink

Output Sink Current (Vin, Reset = 4.0 V) I

Output Off-State Leakage (Vin, Reset = 5.0 V) I

Clamp Diode Forward Voltage, Reset to Input Pin (IF = 10 mA) V

V

Sink

OH

OL

−

−

−

0.46

0.15

−

10 27 60 mA

− 0.02 0.5

F

0.6 0.9 1.2 V

TOTAL DEVICE

Operating Input Voltage Range V

Quiescent Input Current (Vin = 5.0 V) I

in

in

1.0 to 6.5 − − V

− 390 500

2. Maximum package power dissipation limits must be observed.

3. Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient as possible.

4. T

=0°C for MC34064 T

low

−40°C for MC33064 +85°C for MC33064

= +70°C for MC34064

high

−40°C for NCV33064 +125°C for NCV33064

5. NCV prefix is for automotive and other applications requiring site and change control.

4.7

V

4.7

V

1.0

0.4

0.1

mA

mA

http://onsemi.com

2

Page 3

MC34064, MC33064, NCV33064

10

RL = 10 k to V

TA = 25°C

in

8.0

6.0

4.0

, OUTPUT VOLTAGE (V)

O

2.0

V

0

0 2.0 4.0 6.0 8.0 10

Vin, INPUT VOLTAGE (V)

Figure 2. Reset Output Voltage versus

Input Voltage

4.630

, THRESHOLD VOLTAGE (V)

V

th

RL = 10 k to V

4.620

4.610

4.600

4.590

4.580

in

Upper Threshold

High State Output

Lower Threshold

Low State Output

5.0

RL = 10 k to V

TA = 25°C

in

4.0

3.0

2.0

, OUTPUT VOLTAGE (V)

O

1.0

V

0

4.560 4.580 4.600 4.620 4.640

Vin, INPUT VOLTAGE (V)

Figure 3. Reset Output Voltage versus

Input Voltage

1.0

TA = +25°C

−40°C

+85°C

−40°C

, INPUT CURRENT (mA)

in

I

0.8

0.6

0.4

0.2

TA = +25°C

+85°C

4.570

−55 −25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

Figure 4. Comparator Threshold Voltage

versus Temperature

2.0

1.5

Vin = 4.0 V

TA = 85°C

TA = 25°C

TA = −40°C

1.0

, OUTPUT SATURATION (V)

0.5

OL

V

0

0102030 40

I

, SINK CURRENT (mA)

Sink

Figure 6. Reset

Output Saturation versus

Sink Current

0

0 2.0 4.0 6.0 8.0 10

Vin, INPUT VOLTAGE (V)

Figure 5. Input Current versus Input Voltage

90%

5.0 V −

4.0 V −

10%

5.0V

4.0V

V

in

Reset

V

in

REF

10k

Reset

200 ns/DIV

Vin = 5.0 V to 4.0 V

RL = 10 k

TA = 25°C

Figure 7. Reset Delay Time

http://onsemi.com

3

Page 4

MC34064, MC33064, NCV33064

80

Vin = 0 V

TA = 25°C

60

40

20

, FORWARD CURRENT (mA)

F

I

0

0 0.4 0.8 1.2 1.6

VF, FORWARD VOLTAGE (V)

Figure 8. Clamp Diode Forward Current versus Voltage

+

Power

Supply

−

+

Power

Supply

−

I

in

R

H

Input

1.2V

Input

−

1.2 V

+

ref

A time delayed reset can be accomplished with the

addition of C

power supply rise times (<500 ns) it is recommended

that the RC

V

GND

Figure 9. Low Voltage Microprocessor Reset

R

L

Reset

−

+

ref

GND

4.6 R

R

th(lower)

H

+ 0.02

L

≈ 340 RH x 10

VH ≈

DV

Where:RH ≤ 150 W

Where:RL ≥ 1.5 W, ≤ 10 kW

R

Reset

Microprocessor

Circuit

C

DLY

. For systems with extremely fast

DLY

time constant be greater than 5.0 ms.

DLY

is the microprocessor reset input threshold.

th(MPU)

1

t

= RC

DLY

In

DLY

1 −

V

th(MPU)

V

(mV)

Microprocessor

Circuit

112

100

164

−6

190

327

276

480

20

51

40

81

71

V

in

H

TEST DATA

10

10

16

16

34

34

51

51

R

th

(W)

0

10

20

20

30

30

47

47

100

100

150

150

DV

(mV)

3.4

6.8

6.8

R

H

L

(kW)

0

0

1.5

4.7

1.5

2.7

1.5

2.7

1.5

2.7

1.5

2.7

1.5

Comparator hysteresis can be increased with the addition of resistor RH. The hysteresis equation has been

simplified and does not account for the change of input current Iin as VCC crosses the comparator threshold

(Figure 4). An increase of the lower threshold DV

4.59V. The equations are accurate to ±10% with RH less than 150 W and RL between 1.5 kW and 10 kW.

will be observed due to Iin which is typically 340 mA at

th(lower)

Figure 10. Low Voltage Microprocessor Reset with Additional Hysteresis

http://onsemi.com

4

Page 5

MC34064, MC33064, NCV33064

+

Power

Supply

−

Vin = 11.5

to 14.5V

+

−

Input

Reset

−

+

1.2V

ref

GND

Input

1.2V

1.0k

Reset

−

+

ref

GND

Figure 11. Voltage Monitor Figure 12. Solar Powered Battery Charger

25mH

4.7k

470

Input

+

1.2V

MPSW51A

470

1N5819

1.2k

1N756

330

68022

+

Line Regulation Vin = 11.5 V to 14.5 V, IO = 50 mA 35 mV

Reset

−

+

ref

Load Regulation Vin = 12.6 V, IO = 0 mA to 50 mA 12 mV

Output Ripple Vin = 12.6 V, IO = 50 mA 60 mVpp

Efficiency Vin = 12.6 V, IO = 50 mA 77%

VO = 5.0 V

IO = 50 mA

+

Test Conditions Results

Solar

Cells

GND

Figure 13. Low Power Switching Regulator

V

CC

R

L

MTP3055EL

4.6V

270

Input

Reset

−

+

1.2V

ref

GND

Overheating of the logic level power MOSFET due to insufficient gate voltage can be prevented with the above

circuit. When the input signal is below the 4.6 V threshold of the MC34064, its output grounds the gate of the L

MOSFET.

Figure 14. MOSFET Low Voltage Gate Drive Protection

2

http://onsemi.com

5

Page 6

MC34064, MC33064, NCV33064

ORDERING INFORMATION

Device Operating Temperature Range Package Shipping

MC34064D−005

MC34064D−005G SOIC−8

MC34064D−5R2 SOIC−8

MC34064D−5R2G SOIC−8

MC34064DM−5R2 Micro8

MC34064DM−5R2G Micro8

MC34064P−005 TO−92

MC34064P−005G TO−92

MC34064P−5RA TO−92

MC34064P−5RAG TO−92

MC34064P−5RP TO−92

MC34064P−5RPG TO−92

MC34064P−5RM TO−92

MC34064P−5RMG TO−92

MC34064SN−5T1 TSOP−5

MC34064SN−5T1G TSOP−5

MC33064D−005

MC33064D−005G SOIC−8

MC33064D−5R2 SOIC−8

MC33064D−5R2G SOIC−8

MC33064DM−5R2 Micro8

MC33064DM−5R2G Micro8

MC33064P−005 TO−92

MC33064P−005G TO−92

MC33064P−5RA TO−92

MC33064P−5RAG TO−92

MC33064P−5RP TO−92

MC33064P−5RPG TO−92

MC33064SN−5T1 TSOP−5

MC33064SN−5T1G TSOP−5

†For information on tape and reel specifications, including part orientation and tape sizes, pleaserefer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

*NCV33064: T

change control.

= −40°C, T

low

= +125°C. Guaranteed by design. NCV prefix is for automotive and other applications requiring site and

high

TA = 0°C to +70°C

TJ = −40°C to +85°C

SOIC−8

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

SOIC−8

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

98 Units / Rail

2500 Units/ Tape & Reel

4000 Units / Tape & Reel

2000 Units / Bag

2000 Units / Tape & Reel

2000 Units / Ammo Pack

3000 Units / Tape & Reel

98 Units / Rail

2500 Units / Tape & Reel

4000 Units / Tape & Reel

2000 Units / Bag

2000 Units / Tape & Reel

2000 Units / Ammo Pack

3000 Units / Tape & Reel

†

http://onsemi.com

6

Page 7

MC34064, MC33064, NCV33064

ORDERING INFORMATION

Device Shipping

NCV33064D−5R2*

NCV33064D−5R2G* SOIC−8

NCV33064P−5RA* TO−92

NCV33064P−5RAG* TO−92

NCV33064P−5RP* TO−92

NCV33064P−5RPG* TO−92

NCV33064DM−5R2* Micro8

NCV33064DM−5R2G* Micro8

†For information on tape and reel specifications, including part orientation and tape sizes, pleaserefer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

*NCV33064: T

change control.

= −40°C, T

low

high

TA = −40°C to +125°C

= +125°C. Guaranteed by design. NCV prefix is for automotive and other applications requiring site and

PackageOperating Temperature Range

SOIC−8

(Pb−Free)

(Pb−Free)

(Pb−Free)

(Pb−Free)

2500 Units / Tape & Reel

2000 Units / Tape & Reel

2000 Units / Ammo Pack

4000 Units / Tape & Reel

MARKING DIAGRAMS

†

8

1

3x064

ALYW5

G

SOIC−8

D SUFFIX

CASE 751

8

1

V3064

ALYW5

G

Micro8

DM SUFFIX

CASE 846A

8

Ly50

AYW G

G

1

SN SUFFIX

CASE 483

5

SRB AYWG

G

1

MC34064 MC33064

x = 3 or 4

y = C or I

A = Assembly Location

L = Wafer Lot

Y = Year

W, WW = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

8

VI50

AYW G

G

1

TSOP−5

5

SSN AYWG

G

1

MC3x0

64P−5

ALYWW G

G

123

TO−92

P SUFFIX

CASE 29

NCV30

64P−5

ALYWW G

G

123

http://onsemi.com

7

Page 8

−Y−

−Z−

MC34064, MC33064, NCV33064

PACKAGE DIMENSIONS

SOIC−8

D SUFFIX

PLASTIC PACKAGE

CASE 751−07

ISSUE AG

NOTES:

−X−

A

58

B

1

S

0.25 (0.010)

4

M

M

Y

K

G

C

SEATING

PLANE

0.10 (0.004)

H

D

0.25 (0.010) Z

M

SXS

Y

N

X 45

_

M

J

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

____

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

SOLDERING FOOTPRINT*

1.52

0.060

7.0

0.275

0.6

0.024

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

4.0

0.155

1.270

0.050

SCALE 6:1

ǒ

inches

mm

Ǔ

http://onsemi.com

8

Page 9

MC34064, MC33064, NCV33064

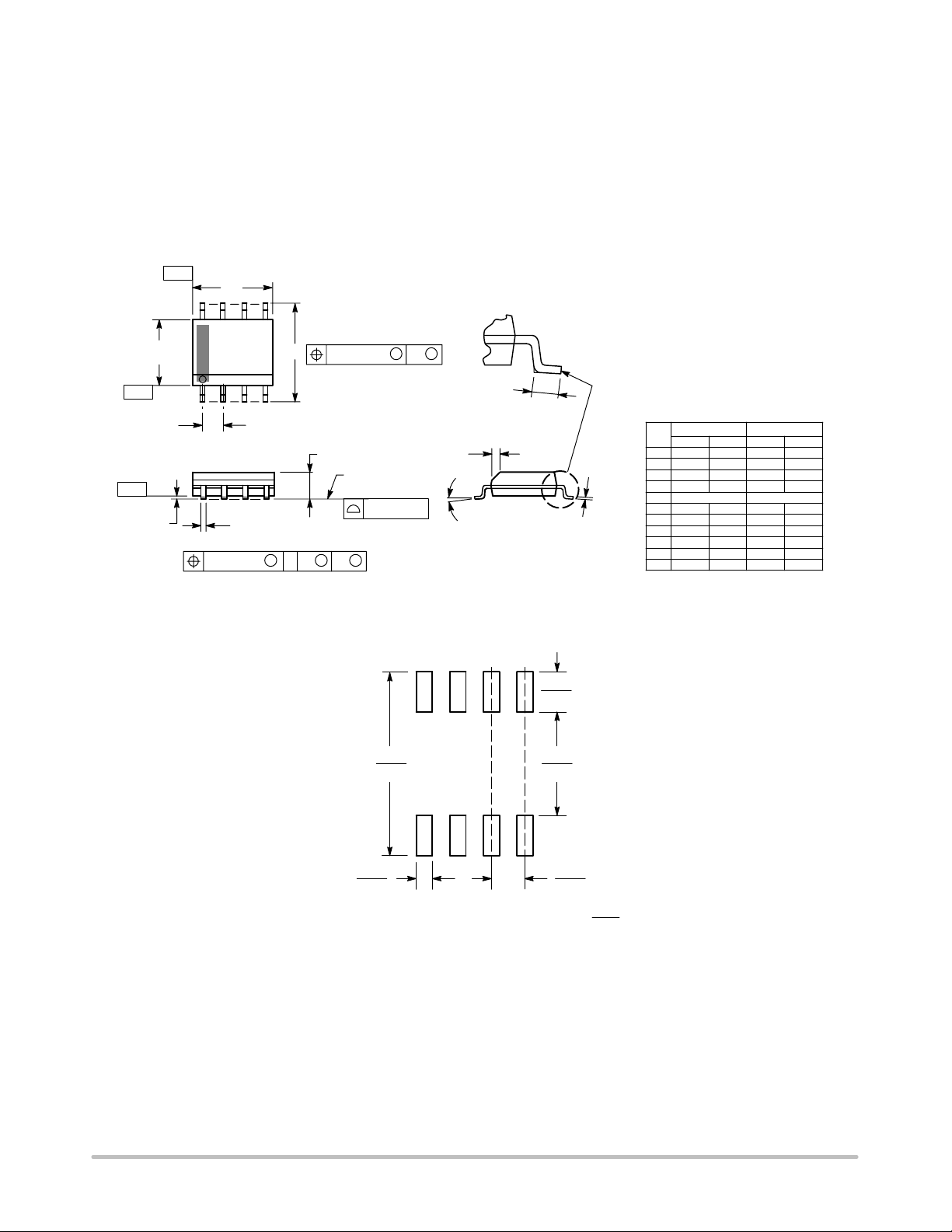

Micro8

PACKAGE DIMENSIONS

DM SUFFIX

PLASTIC PACKAGE

CASE 846A−02

ISSUE F

SEATING

PLANE

−T−

0.038 (0.0015)

PIN 1 ID

−A−

K

G

−B−

D

8 PL

0.08 (0.003) A

M

T

S

B

S

C

H

J

L

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD FLASH,

PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT

EXCEED 0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH OR

PROTRUSION SHALL NOT EXCEED 0.25 (0.010)

PER SIDE.

5. 846A−01 OBSOLETE, NEW STANDARD 846A−02.

DIM MIN MAX MIN MAX

A 2.90 3.10 0.114 0.122

B 2.90 3.10 0.114 0.122

C −−− 1.10 −−− 0.043

D 0.25 0.40 0.010 0.016

G 0.65 BSC 0.026 BSC

H 0.05 0.15 0.002 0.006

J 0.13 0.23 0.005 0.009

K 4.75 5.05 0.187 0.199

L 0.40 0.70 0.016 0.028

INCHESMILLIMETERS

SOLDERING FOOTPRINT*

8X

1.04

0.041

0.38

0.015

8X

6X

0.0256

3.20

0.126

0.65

0.167

4.24

SCALE 8:1

5.28

0.208

ǒ

inches

mm

Ǔ

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

http://onsemi.com

9

Page 10

0.05 (0.002)

S

H

D

54

123

L

G

A

MC34064, MC33064, NCV33064

PACKAGE DIMENSIONS

TSOP−5

SN SUFFIX

PLASTIC PACKAGE

CASE 483−02

ISSUE E

NOTES:

1. DIMENSIONING AND TOLERANCING PER

2. CONTROLLING DIMENSION: MILLIMETER.

3. MAXIMUM LEAD THICKNESS INCLUDES

B

J

C

K

M

4. A AND B DIMENSIONS DO NOT INCLUDE

ANSI Y14.5M, 1982.

LEAD FINISH THICKNESS. MINIMUM LEAD

THICKNESS IS THE MINIMUM THICKNESS

OF BASE MATERIAL.

MOLD FLASH, PROTRUSIONS, OR GATE

BURRS.

DIM MIN MAX MIN MAX

A 2.90 3.10 0.1142 0.1220

B 1.30 1.70 0.0512 0.0669

C 0.90 1.10 0.0354 0.0433

D 0.25 0.50 0.0098 0.0197

G 0.85 1.05 0.0335 0.0413

H 0.013 0.100 0.0005 0.0040

J 0.10 0.26 0.0040 0.0102

K 0.20 0.60 0.0079 0.0236

L 1.25 1.55 0.0493 0.0610

M 0 10 0 10

____

S 2.50 3.00 0.0985 0.1181

INCHESMILLIMETERS

SOLDERING FOOTPRINT*

1.9

0.95

0.037

1.0

0.039

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

0.074

0.028

0.7

2.4

0.094

SCALE 10:1

ǒ

inches

mm

Ǔ

http://onsemi.com

10

Page 11

MC34064, MC33064, NCV33064

PACKAGE DIMENSIONS

TO−92

P SUFFIX

PLASTIC PACKAGE

CASE 29−11

ISSUE AL

SEATING

PLANE

A

B

R

P

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. CONTOUR OF PACKAGE BEYOND DIMENSION R

IS UNCONTROLLED.

4. LEAD DIMENSION IS UNCONTROLLED IN P AND

BEYOND DIMENSION K MINIMUM.

L

MILLIMETERSINCHES

XX

V

1

K

D

G

H

J

C

SECTION X−X

N

DIM MIN MAX MIN MAX

A 0.175 0.205 4.45 5.20

B 0.170 0.210 4.32 5.33

C 0.125 0.165 3.18 4.19

D 0.016 0.021 0.407 0.533

G 0.045 0.055 1.15 1.39

H 0.095 0.105 2.42 2.66

J 0.015 0.020 0.39 0.50

K 0.500 −−− 12.70 −−−

L 0.250 −−− 6.35 −−−

N 0.080 0.105 2.04 2.66

P −−− 0.100 −−− 2.54

R 0.115 −−− 2.93 −−−

V 0.135 −−− 3.43 −−−

N

Micro8 is a trademark of International Rectifier.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

MC34064/D

11

Loading...

Loading...