Page 1

SEMICONDUCTOR

TECHNICAL DATA

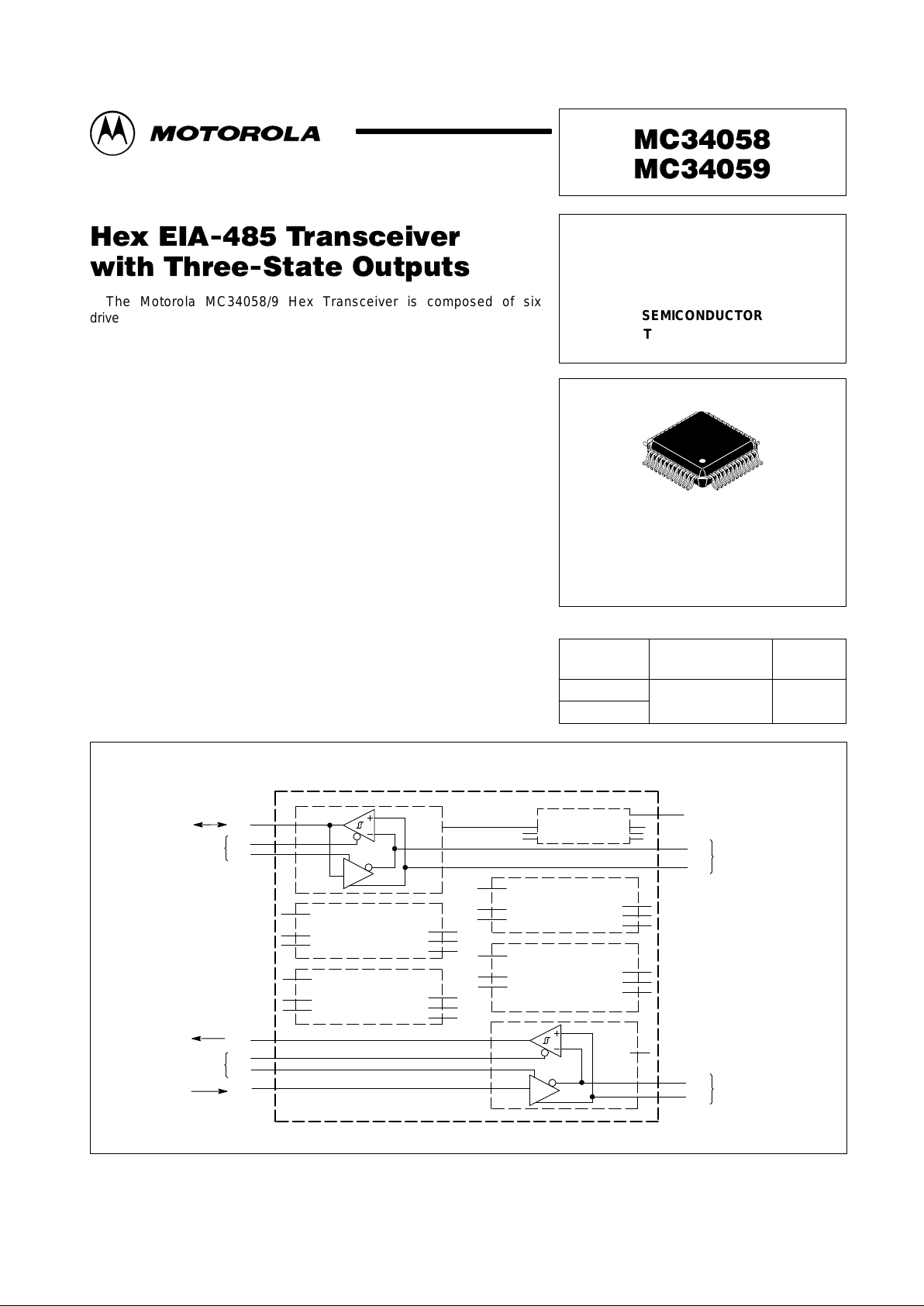

HEX EIA–485 TRANSCEIVER

with THREE–STATE OUTPUTS

Order this document by MC34058/D

FTA SUFFIX

PLASTIC PACKAGE

CASE 932

(Thin QFP)

148

Device

Operating

Temperature Range

Package

ORDERING INFORMATION

MC34058FTA

MC34059FTA

TA = 0° to +70°C TQFP–48

1

MOTOROLA ANALOG IC DEVICE DATA

The Motorola MC34058/9 Hex Transceiver is composed of six

driver/receiver combinations designed to comply with the EIA–485 standard.

Features include three–state outputs, thermal shutdown for each driver, and

current limiting in both directions. This device also complies with EIA–422

and CCITT Recommendations V.11 and X.27.

The devices are optimized for balanced multipoint bus transmission at

rates to 20 MBPS (MC34059). The driver outputs/receiver inputs feature a

wide common mode voltage range, allowing for their use in noisy

environments. The current limit and thermal shutdown features protect the

devices from line fault conditions.

The MC34058/9 is available in a space saving 7.0 mm 48 lead surface

mount quad package designed for optimal heat dissipation.

• Meets EIA–485 Standard for Party Line Operation

• Meets EIA–422A and CCITT Recommendations V.11 and X.27

• Operating Ambient Temperature: 0°C to +70°C

• Common Mode Driver Output/Receiver Input Range: –7.0 to +12 V

• Positive and Negative Current Limiting

• Transmission Rates to 14 MBPS (MC34058) and 20 MBPS (MC34059)

• Driver Thermal Shutdown at 150°C Junction Temperature

• Thermal Shutdown Active Low Output

• Single +5.0 V Supply, ±10%

• Low Supply Current

• Compact 7.0 mm 48 Lead TQFP Plastic Package

Representative Block Diagram

This device contains 1,399 active transistors.

TTL/CMOS Data DR

Direction

Control

RE

DE

Thermal

Shutdown

OB

OA

To Cable

Thermal

Shutdown

(Same as #1)

(Same as #1)

(Same as #1)

(Same as #1)

#3

#5

#4

#2

#1

TSD

#6

TSD

OB

OA

To Cable

TTL/CMOS Data RO

Direction

Control

RE

DE

TTL/CMOS Data DI

D

D

Motorola, Inc. 1996 Rev 1

Page 2

MC34058 MC34059

2

MOTOROLA ANALOG IC DEVICE DATA

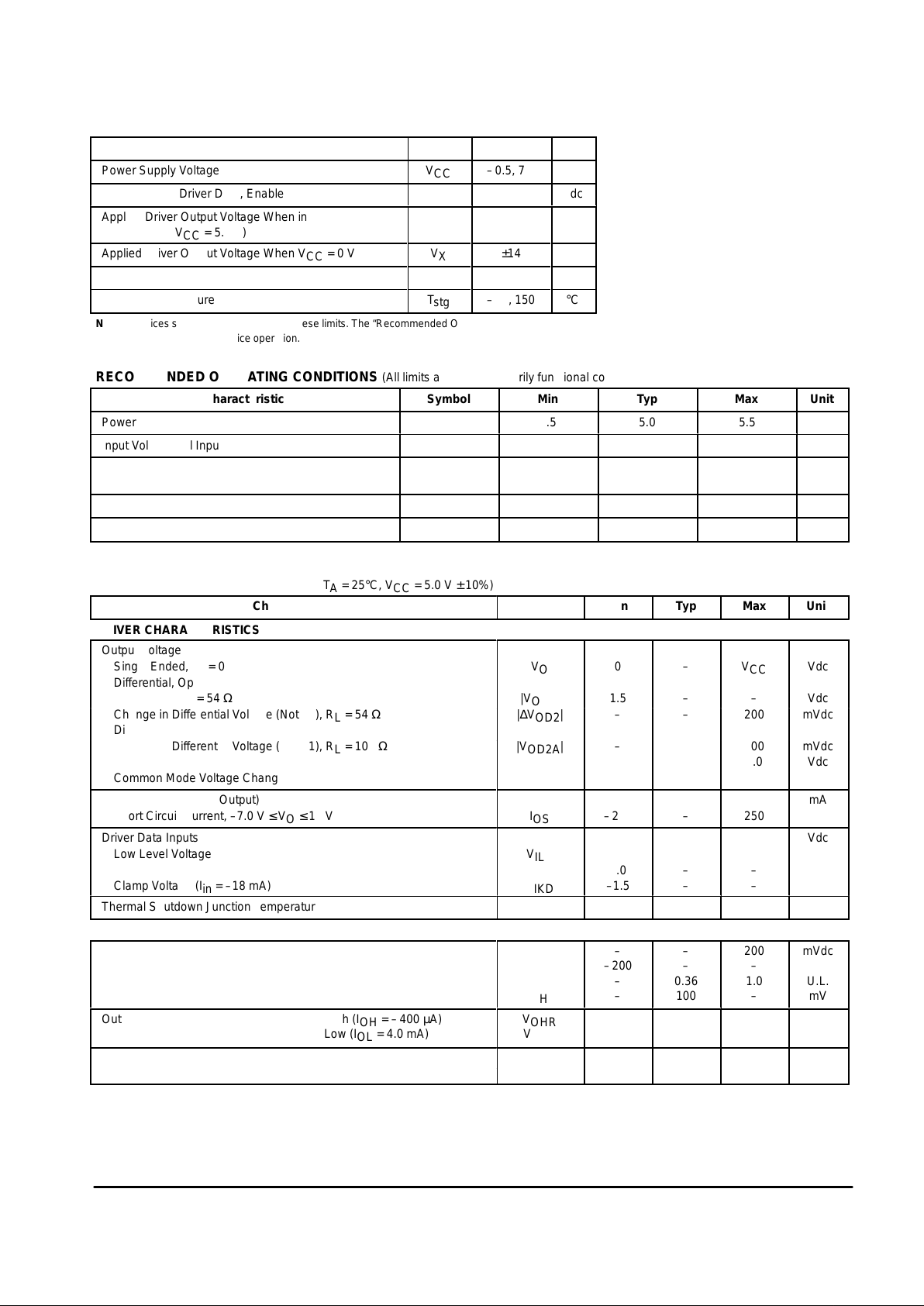

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage

V

CC

–0.5, 7.0

Vdc

Input Voltage (Driver Data, Enables)

V

in

7.0

Vdc

Applied Driver Output Voltage When in Three–State

V

Z

–10, 14

Vdc

Condition (VCC = 5.0 V)

Applied Driver Output Voltage When VCC = 0 V

V

X

±14

Vdc

Output Current

I

O

Self Limiting

–

Storage Temperature

T

stg

–65, 150

°C

NOTE: Devices should not be operated at these limits. The “Recommended Operating Conditions”

provides for actual device operation.

RECOMMENDED OPERATING CONDITIONS (All limits are not necessarily functional concurrently.)

Characteristic

Symbol Min Typ Max Unit

Power Supply Voltage

V

CC

4.5

5.0

5.5

Vdc

Input Voltage (All Inputs Except Receiver Inputs)

V

in

0

–

V

CC

Vdc

Driver Output Voltage in Three–State Condition,

V

CM

–7.0

–

12

Vdc

Receiver Inputs, or When VCC = 0 V

БББББББББББББ

Driver Output Current (Normal Data Transmission)

ÁÁÁ

I

O

ÁÁÁ

–60

ÁÁÁÁ–ÁÁÁ60Á

mA

БББББББББББББ

Á

Operating Ambient Temperature

ÁÁÁ

Á

T

A

ÁÁÁ

Á

0

ÁÁÁÁ

Á

–

ÁÁÁ

Á

70

Á

Á

°C

ELECTRICAL CHARACTERISTICS (T

A

= 25°C, VCC = 5.0 V ± 10%)

Characteristic

Symbol Min Typ Max Unit

DRIVER CHARACTERISTICS

Output Voltage

ÁÁÁ

Single Ended, IO = 0 V

O

0 – V

CC

Vdc

Differential, Open Circuit (IO = 0) |V

OD1

| 1.5 – – Vdc

Differential, RL = 54 Ω |V

OD2

| 1.5 – – Vdc

Change in Differential V oltage (Note 1), RL = 54 Ω |∆V

OD2

| – – 200 mVdc

Differential, RL = 100 Ω |∆V

OD2A

| 2.0 – – Vdc

Change in Differential V oltage (Note 1), RL = 100 Ω |V

OD2A

| – – 200 mVdc

Common Mode Voltage, RL = 54 Ω V

OCM

– – 3.0 Vdc

Common Mode Voltage Change, RL = 54 Ω |∆V

OCM

| – – 200 mVdc

Output Current (Each Output)

ÁÁÁ

mA

Short Circuit Current, –7.0 V ≤ VO ≤ 12 V I

OS

–250 – 250

Driver Data Inputs

ÁÁÁ

Vdc

Low Level Voltage V

ILD

– – 0.8

High Level Voltage V

IHD

2.0 – –

Clamp Voltage (Iin = –18 mA) V

IKD

–1.5 – –

Thermal Shutdown Junction Temperature

T

JTS

–

150

–

ÁÁÁ

°C

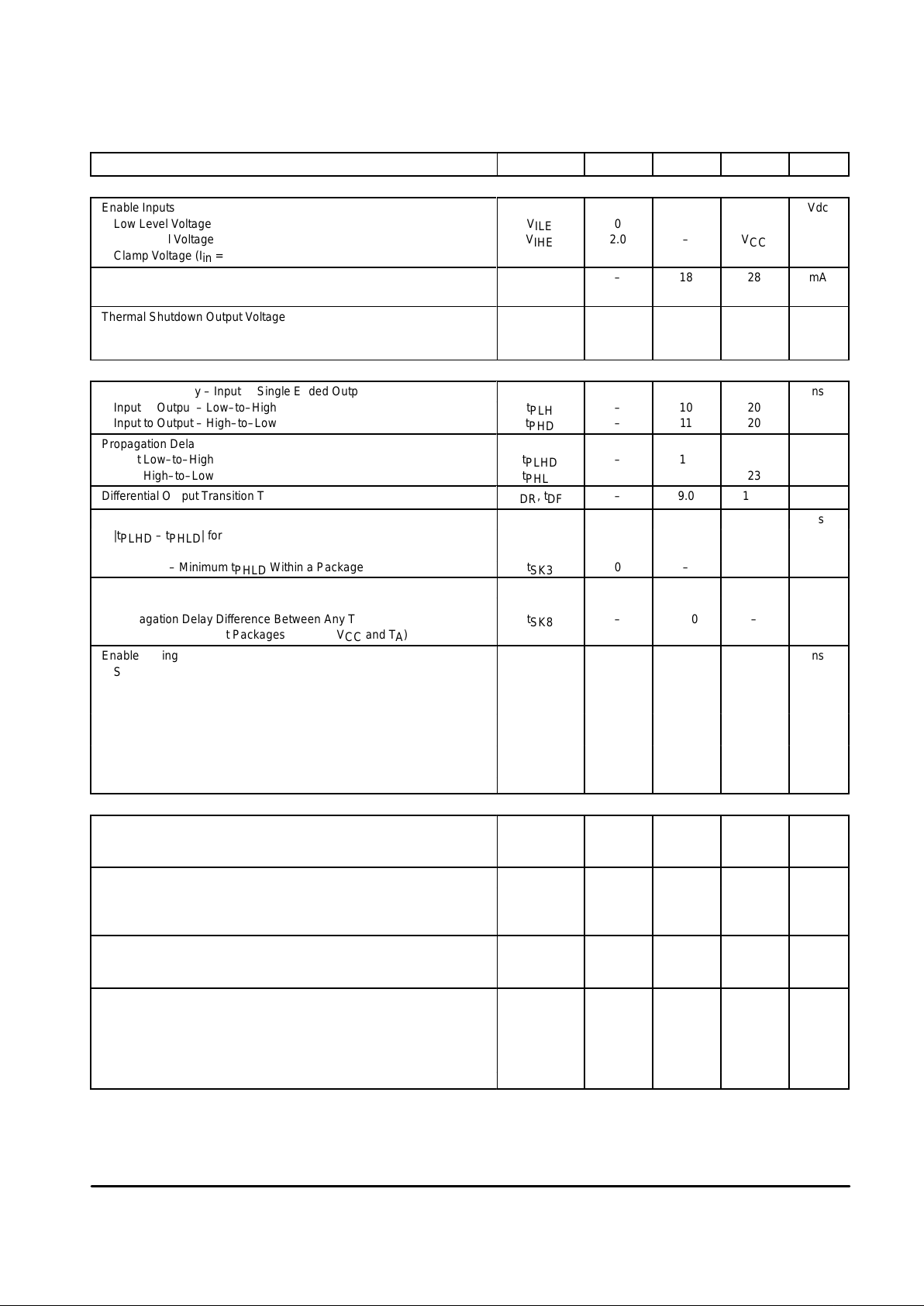

RECEIVER CHARACTERISTICS

БББББББББББББББББ

Á

БББББББББББББББББ

Á

Input Threshold RO = High

RO = Low

Input Loading (Driver Disabled)

Hysteresis

ÁÁÁ

Á

ÁÁÁ

Á

V

th

V

H

ÁÁ

Á

ÁÁ

Á

–

–200

–

–

ÁÁ

Á

ÁÁ

Á

–

–

0.36

100

ÁÁ

Á

ÁÁ

Á

200

–

1.0

–

ÁÁÁ

ÁÁ

Á

ÁÁ

Á

mVdc

U.L.

mV

Output Voltage High (IOH = –400 µA)

Low (IOL = 4.0 mA)

V

OHR

V

OLR

2.4

–

–

–

–

0.4

ÁÁÁ

Vdc

Output Short Circuit Current

I

OSR

–

45

85

ÁÁÁ

mA

Output Leakage Current When in Three–State Mode I

OLKR

– – 20 µA

NOTE: 1. Input switched from low to high.

Page 3

MC34058 MC34059

3

MOTOROLA ANALOG IC DEVICE DATA

ELECTRICAL CHARACTERISTICS (continued) (T

A

= 25°C, VCC = 5.0 V ± 10%)

Characteristic UnitMaxTypMinSymbol

MISCELLANEOUS

Enable Inputs

ÁÁÁ

Vdc

Low Level Voltage V

ILE

0 – 0.8

High Level Voltage V

IHE

2.0 – V

CC

Clamp Voltage (Iin = –18 mA) V

IKE

–1.5 – –

Power Supply Current (Total Package, All Outputs Open, Enabled

or Disabled)

I

CC

–

18

28

ÁÁÁ

mA

БББББББББББББББББ

Á

БББББББББББББББББ

Á

Thermal Shutdown Output Voltage

High

Low

ÁÁÁ

Á

ÁÁÁ

Á

V

OHT

V

OLT

ÁÁ

Á

ÁÁ

Á

2.4

0

ÁÁ

Á

ÁÁ

Á

–

–

ÁÁ

Á

ÁÁ

Á

–

0.8

ÁÁÁ

ÁÁ

Á

ÁÁ

Á

Vdc

TIMING CHARACTERISTICS – DRIVER

Propagation Delay – Input to Single Ended Output

ns

Input to Output – Low–to–High t

PLH

– 10 20

Input to Output – High–to–Low t

PHD

– 11 20

Propagation Delay – Input to Differential Output

ÁÁÁ

ns

Input Low–to–High t

PLHD

– 15 23

Input High–to–Low t

PHLD

– 15 23

Differential Output Transition T ime

tDR, t

DF

–

9.0

10.7

ÁÁÁ

ns

Skew Timing MC34058 ns

|t

PLHD

– t

PHLD

| for Each Driver t

SK1

0 0.1 –

Maximum – Minimum t

PLHD

Within a Package t

SK2

0 – 8.0

Maximum – Minimum t

PHLD

Within a Package t

SK3

0 – 6.0

Skew Timing MC34059 ns

|t

PLHD

– t

PHLD

| for Each Driver t

SK7

0 0.1 –

Propagation Delay Difference Between Any Two Drivers (Same

Package or Different Packages at Same VCC and TA)

t

SK8

– <4.0 –

Enable Timing ns

Single Ended Outputs

Enable to Active High Output t

PZH

– 15 40

Enable to Active Low Output t

PZL

– 25 40

Active High to Disable t

PHZ

– 12 25

Active Low to Disable t

PLZ

– 10 25

Differential Outputs

Enable to Active Output t

PZD

– – 40

Enable to Three–State Output t

PDZ

– – 25

TIMING CHARACTERISTICS – RECEIVER

Propagation Delay ns

Input to Output – Low–to–High t

PLHR

– 16 23

Input to Output – High–to–Low t

PHLR

– 16 23

Skew Timing ns

|t

PLHR

– t

PHLR

| for Each Receiver t

SK4

0 1.0 –

Maximum – Minimum t

PLHR

Within a Package t

SK5

0 – 3.0

Maximum – Minimum t

PHLR

Within a Package t

SK6

0 – 3.0

Skew Timing t

SK9

– <5.0 – ns

Propagation Delay Difference Between Any Two Receivers in Different

Packages at Same VCC and TA (MC34059 Only)

Enable Timing ns

Single Ended Outputs

Enable to Active High Output t

PZHR

– 15 22

Enable to Active Low Output t

PZLR

– 25 30

Active High to Disable t

PHZR

– 12 25

Active Low to Disable t

PLZR

– 10 25

Page 4

MC34058 MC34059

4

MOTOROLA ANALOG IC DEVICE DATA

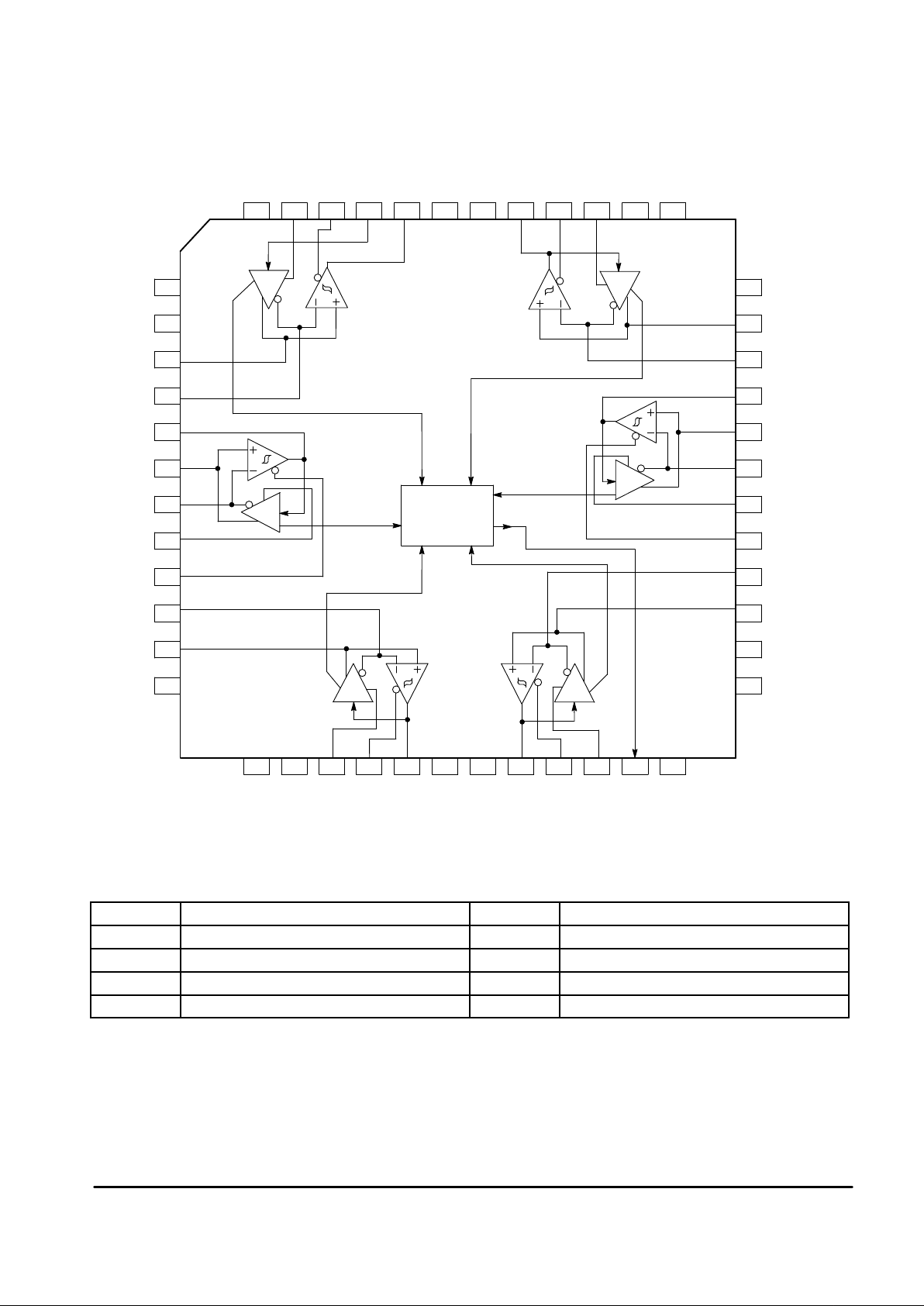

Block Diagram and Pinout

MC34058/9

Thermal

Shutdown

Indicator

Gnd

1

Gnd Gnd Gnd

GndDE5RE5DR5V

CC

V

CC

RO6DI6RE6DE6

DE2 RE2 DR2 VCCVCCDR3 RE3 DE3 TSD

Gnd

OA5

OB5

DR4

OA4

OB4

DE4

RE4

OB3

OA3

Gnd

Gnd

#4

#5

#6

#3

#2

#1

Gnd

Gnd

OA6

OB6

DR1

OA1

OB1

DE1

RE1

OB2

OA2

Gnd

2

3

4

5

6

7

8

9

10

11

12

36

35

34

33

32

31

30

29

28

27

26

18 19 20 21 22 23 24

25

1716151413

43 42 41 40 39 38 374445464748

Gnd

D

D

D

D

D

D

PINOUT SUMMARY

OA NonInverting Output/Input DE Driver Enable, Active High (TTL)

OB Inverting Output/Input RE Receiver Enable, Active Low (TTL)

DR Driver Input/Receiver Output (TTL) TSD Thermal Shutdown Indicator

DI6 #6 Driver Input (TTL) V

CC

Connect 4 Pins to 5.0 V , ±10%

RO6 #6 Receiver Output (TTL) Gnd Connect 12 Pins to Circuit Ground

Page 5

MC34058 MC34059

5

MOTOROLA ANALOG IC DEVICE DATA

V

CC

27

15 pF

2.3 V

Output

S.G.

3.0 V

3.0 V

3.0 V

3.0 V

3.0 V

1.5 V

1.5 V

0 V

V

OL

V

OH

Figure 1. VOD and VOS Test Circuit

Figure 2. VOD and VCM Test Circuit

Figure 3. VOD AC Test Conditions

Figure 4. VOH and VOL AC Test Conditions

V

CC

R

L/2

R

L/2

V

OS

V

OD2, A

V

in

(0.8 or 2.0 V)

375

375

58

V

CM

(+12 to

±

7.0 V)

50 pF

S.G.

V

OD

V

in

t

PLHD

t

PHLD

50%

50%

3.0 V

1.5 V

1.5 V

OAX

0 V

V

OD

t

dr

t

dr

V

CC

V

OD2, A

V

in

(0.8 or 2.0 V)

54

V

CC

V

in

OAX

OBX

t

PLH

t

PLH

t

PHL

t

PHL

Page 6

MC34058 MC34059

6

MOTOROLA ANALOG IC DEVICE DATA

Figure 5. VOH versus I

OH

–10

0.4

0

1.1

–100

4.0

–80

4.6

INPUT CURRENT (mA)

INPUT VOLTAGE (V)

IOL (mA)

IOD (mA)

V

ODH

V

OH

(V)

IOH (mA)

Figure 6. VOL versus I

OL

Figure 7. VOD versus I

OL

Figure 8. Input Characteristics of

OAX and OAB

V

OL

(V)

V

OD

(V)

– 60 – 40 – 20 0 20 10 20 30 40 50 60 70 80

– 5.0 0 5.0 10 15– 50 0 50 100

4.4

4.2

4.0

3.8

0.9

1.0

0.8

0.6

0.7

0.5

0.3

0.1

– 0.1

– 0.3

– 0.4

– 0.2

0

0.2

2.0

0

– 2.0

– 4.0

3.6

V

ODL

OAX_lin(mA)

OBX_lin(mA)

Description

The MC34058/9 is a differential line driver designed to

comply with EIA–485 Standard for use in balanced digital

multipoint systems containing multiple drivers. The drivers

also comply with EIA–422–A and CCITT Recommendations

V.11 and X.27. Positive and negative current limiting of the

drivers meet the EIA–485 requirement for protection from

damage in the event that two or more drivers try to transmit

simultaneously on the same cable. Data rates in excess of

10 MBPS are possible, depending on the cable length and

cable characteristics. Only a single power supply, 5.0 V

±ā10% is required.

Driver Inputs

The driver inputs and enable logic determine the state of

the outputs in accordance with T able 1. The driver inputs have

a nominal threshold of 1.2 V, and the voltage must be kept

within the range of 0 V to VCC for proper operation. If the

voltage is taken more than 0.5 V below ground or above VCC,

excessive currents will flow and proper operation of the

drivers will be affected. An open Pin is equivalent to a logic

high, but good design practices dictate that inputs should

never be left open. The inputs are TTL type and their

characteristics are unchanged by the state of the enable pins.

Driver Outputs

Each output (when active) will be a low or a high voltage,

depending on the input state and the load current (see

Tables 1, 2 and Figures 2 and 3). The graphs apply to each

driver, regardless of how many other drivers within the

package are supplying load current.

Page 7

MC34058 MC34059

7

MOTOROLA ANALOG IC DEVICE DATA

Table 1. Driver Truth Table

Enables Outputs

Driver Data Inputs DEX REX OAX OBX

H H H H L

L H H L H

X L H Z Z

X H L Not Defined Not Defined

The outputs will be in a high impedance state when:

a) The Enable inputs are set according to T able 1;

b) The junction temperature exceeds the trip point of the thermal shutdown circuit. When in this condition, the output’s source and sink capability are shut off, and a

leakage current of less than 20 µA will flow. Disabled outputs may be taken to any voltage between –7.0 V and 12 V without damage to internal circuitry.

The drivers are protected from short circuits by two methods:

a) Current limiting is provided at each output, in both the source and sink direction, for shorts to any voltage within the 12 V to –7.0 V range, with respect to circuit

ground. The short circuit current will flow until the fault is removed, or until the thermal shutdown activates. The current limiting circuit has a negative temperature

coefficient and requires no resetting upon removal of the fault condition.

b) A thermal shutdown circuit disables the outputs when the junction temperature reaches +150°C, ± 20°C. The thermal shutdown circuit has a hysteresis of ∼ 12°C

to prevent oscillations. When this circuit activates, the output stage of each driver is put into the high impedance mode, thereby shutting off the output currents.

However, the remainder of the internal circuitry remains biased and the outputs will become active once again as the IC cools down.

Receiver Inputs

The receiver inputs and enable logic determine the state of

the receiver outputs in accordance with Table 2. Each

receiver input pair has a nominal differential threshold of at

most 200 mV (Pin OAX with respect to OBX) and a common

mode voltage range of –7.0 V and 12 V must be maintained

for proper operation. A nominal hysteresis of 100 mV is

typical. The receiver input characteristics are shown in

Figure 8. When the inputs are in the high impedance state,

they remain capable of the common mode voltage range of

–7.0 V to 12 V.

Receiver Outputs

The receiver outputs are TTL type outputs and act in

accordance with Table 2.

Enable Logic

Each driver output is active when the Driver Enable input

is true according to Table 1. Each receiver output is active

when the Receiver Enable input is true according to Table 2.

The Enable inputs have a nominal threshold of 1.2 V and

their voltage must be kept within the range of 0 V and VCC for

proper operation. If the voltage is taken more than 0.5 V

below ground or above VCC, excessive currents will flow and

proper operation of the drivers will be affected. An open pin is

equivalent to a logic high, but good design practices dictate

that inputs should never be left open. The enable inputs are

TTL compatible. Since the same pins are used for driver input

and receiver output, care must be taken to make sure that

DEX and REX

are not both enabled. This may result in

corruption of both the transmitted and received data.

Table 2. Receiver Truth Table

Receiver Data Inputs

Enables Outputs

OAX–OBX DEX REX DRX

≥ +200 mV L L H

≤ –200 mV L L L

X L H Z

X H L Not Defined

APPLICA TIONS

The MC34058/9 was designed to meet EIA/TIA–422 and

EIA/TIA–485 standards. EIA/TIA–422 specifies balanced

point–to–point transmission with the provision for multiple

receivers on the line. EIA/TIA–485 specifies balanced

point–to–point transmission and allows for multiple drivers

and receivers on the line. Refer to EIA/TIA documents for

more details. Figure 9 shows a typical EIA/TIA–422 example.

Figure 10 shows a typical EIA/TIA–485 example.

Figure 9. Typical EIA/TIA–422 Application

R

T

100

Ω

Page 8

MC34058 MC34059

8

MOTOROLA ANALOG IC DEVICE DATA

Figure 10. Typical EIA/TIA–485 Application

R

T

120

Ω

R

T

120

Ω

EIA/TIA–422 specifications require the ability to drive at

least 10 receivers of input impedance of greater than or equal

to 4.0 KΩ plus the 100 Ω termination resistor. This protocol

was intended for unidirectional transmission. EIA/TIA–485 is

capable of bidirectional transmission by allowing multiple

drivers and receivers on the same twisted pair segment. The

loading of the twisted pair segment can be up to 32 Unit

Loads (U.L.) plus the two 120 Ω terminating resistors. The

U.L. definition is shown in Figure 11.

Figure 11. TIA/EIA–485 Unit Load Definition

I

i

V

i

+1.0 mA

+12 V

+5.0 V

–0.8 mA

–7.0 V –3.0 V

Calculating Power Dissipation for the

MC34058/9 Hex–Transceiver.

The operational temperature range is listed as 0°C to 70°C

to satisfy both EIA/TIA–485 and EIA/TIA–422 specifications.

However, a lower ambient temperature may be required

depending on the specific board layout and/or application.

Using a first order approximation for heat transfer, the

maximum power which may be dissipated by the package is

determined by (see Appendix A for more details);

P

Dmax

+

T

Jmax

–T

A

θja

[1]

where:

θja = package thermal resistance (see Appendix A)

T

Jmax

= Maximum Junction Temperature. Since the

thermal shutdown feature has a trip point of 150°C ± 20°,

T

Jmax

is selected to be +130°C.

TA = Ambient Operating Temperature.

The power generated within the package is then;

PD

+

NJ

ƪ

ǒ

VCC–V

OH

1

Ǔ

·I

OH

1

ƫ

)

V

OL

1

·I

OL

1

Nj

)

..

[2]

(each_driver)..

)

NJ

ƪ

ǒ

VCC–V

OH

6

Ǔ

·I

OH

6

ƫ

)

V

OL

6

·I

OL

6

Nj

)

VCC·I

CCQ

As indicated in the equation, the part of Equation 2

consisting of IOH , VOH , IOL and VOL must be calculated for

each of the drivers and summed for the total power

dissipation estimate. The last term can be considered the

quiescent power required to keep the IC operational and is

measured with the drivers idle and unloaded. The VOH and

VOL terms can be determined from the output current

versus output voltage curves which provide driver output

characteristics.

Example 1 estimates thermal performance based on

current requirements.

Page 9

MC34058 MC34059

9

MOTOROLA ANALOG IC DEVICE DATA

θja = j, j = 40, 60, .. 100°C/W.

Example 1. Balanced and Unbalanced Operation

IOL = 50 mA and IOH = ±50 mA for each driver. VCC = 5.0 V.

How many drivers can be used? (Typical power supply current I

CCQ

= 18 mA.)

Solution:

I

CCQ

= 0.018 A

The quiescent power is given by:

Balanced Operation:

To determine the amount of power dissipated by each

output stage we need to know the differential output voltage

for the output current required. Figure 7 shows that for I

OH

and IOL differential of 50 mA, V

ODH

and V

ODL

are:

Unbalanced Operation:

To determine the amount of power dissipated by each

output stage we need to know the single–ended output

voltage for the output current required. Figures 5 and 6

shows that for an IOH and IOL of ±50 mA,

(For this example, balanced operation is assumed.)

Summing the quiescent and driver power for 6 transceivers operating in a package produces;

produces a set curves that can be used to determine a Safe Operating Area for the specific application. P

DT otal

is graphed with

P

Dmax

to provide a reference.

P

Dmax

ǒ

q

ja

Ǔ

,TA+

T

Jmax–TA

q

ja

For the MC34058/9, the thermal resistance is capable of a wide range. The ability of the package to dissipate power depends

on board type and temperature, layout and ambient temperature (see Appendix A). For the purposes of this example the

thermal resistance can range from 40°C/W to 100°C/W;

Varying the ambient operating temperature TA = 25, 30, .. 85°C; specifying a maximum junction temperature to avoid

thermal shutdown T

Jmax

= 130°C; and using the first order approximation for maximum power dissipation;

VOD+|3.0|, and IOL+

|IOH|+I

Out

+

0.050 A.

And the power dissipated by each driver is given by;

P

DrvB

+

I

Out

·

ǒ

VCC–V

OD

Ǔ

and equal to

P

DrvB

+

0.10 W.

VOH+

3.9 V VOL+

0.895 V

And the power dissipated by each driver is calcu-

lated by;

P

DrvU

+

ǒ

VCC–V

OH

Ǔ

·|IOH|)VOL·I

OL

P

DrvU

+

0.10 W.

and equal to

20

3.0

WATTS

TA (°C)

30 40 60 80 90

2.5

1.5

0.5

0

1.0

2.0

* Safe Operating Area (SOA), is an operating power, P

DT otal

, less than P

Dmax.

So all the drivers in the package can be used if the thermal resistance and/or the ambient temperature is low enough.

Graph of Maximum Power Dissipation Possible

for a Particular θja and Ambient Temperature

7050

P

DTotal

P

Dmax (

θ

ja

), T

A

PQ+I

CCQ

·VCC, and is equal to PQ+0.09 W.

P

DTotal

= PQ + 6 ⋅ P

DrvB

, and equal to P

DTotal

= 0.69 W.

*SOA

40

P

Dmax (θja

), T

A

60

P

Dmax (θja

), T

A

80

P

Dmax (θja

), T

A

100

Page 10

MC34058 MC34059

10

MOTOROLA ANALOG IC DEVICE DATA

Appendix A. Optimizing the Thermal Performance of the MC34058/9

Figure 12. Electrical Model of Package Heat Transfer

Device Junction

Ambient Temperature

RCA

RJCU

RJCD

RCDB

RLB

RJL

IPD

5.0 A

Board Temperature

An equivalent electrical circuit for the thermal model for the

MC34058/9 package is shown in Figure 12. It is a simplified

model that shows the dominant means of heat transfer from

the thermally enhanced 48–ld package used for the

MC34058/9. The model is a first order approximation and is

intended to emphasize the need to consider thermal issues

when designing the IC into any system. It is however

customary to use similar models and Equation 1 to estimate

device junction temperatures.

Equation 1 is the common means of using the thermal

resistance of a package to estimate junction temperature in a

particular system.

T

J

+

ǒ

PD·qjxǓ)

T

A

[1]

The term θjx in Equation 1 is usually quoted as a øja value

in °C/Watt. However, since the 48–ld package for the

MC34058/9 has been thermally enhanced to take advantage

of other heat sinking potentials, it must be modified. θjx must

actually be considered a composite of all the heat transfer

paths from the chip. That is, the three dominant and parallel

paths shown in Figure 12. Of those three paths, potentially

the most effective is the corner package leads. This is

because these corner leads have been attached to the flag

on which the silicon die is situated. These pins can be

connected to circuit board ground to provide a more efficient

conduction path for internal package heat. This path is

modeled as the Rjl (junction–to–leads) and Rlb

(leads–to–board) combination in Figure 12. This path

provides the most effective way of removing heat from the

device provided that there is a viable temperature potential

(i.e. heat sinking source) to conduct towards. However, if it is

not properly considered in the system design, the other

paths, (Rjcd + Rcdb) and (Rjcu + Rca) attain greater

importance and must be more carefully considered.

So Equation 1, modified to reflect a more complete heat

transfer model becomes;

[2]

TJ+

T

A·

ȧ

ȡ

Ȣ

1

1

Rjcd

)

1

Rjlb

ȧ

ȣ

Ȥ

ȧ

ȡ

Ȣ

1

1

Rjcd

)

1

Rjlb

ȧ

ȣ

Ȥ

)

Rjca

)AAA

AAA

TB·

Rjca

ȧ

ȡ

Ȣ

1

1

Rjcd

)

1

Rjlb

ȧ

ȣ

Ȥ

)

Rjca

)

PDISS ·qja

where;

TJ= Junction Temperature

TA = Ambient Temperature

TB = Board Temperature

P

DISS

= Device Power

and θja = Total Thermal Resistance and is composed the

parallel combination of all the heat transfer paths from

the package.

While Equation 2 is still only a first order approximation of

the heat transfer paths of the MC34058/9, at least now it

includes consideration for the most effective heat transfer

path for the MC34058/9; the board to which the device is

soldered. The modified equation also better serves to

explain how external variables, namely the board and

ambient temperatures, affect the thermal performance of

the MC34058/9.

Methods of removing heat via the flag connected pins can

be classified into two means; conduction and convection.

Radiation is omitted as the contribution is small compared to

the other means. Conduction is by far the best method to

draw heat away from the MC34058/9 package. This is best

accomplished by using a multilayer board with generous

ground plane. In this case, the flag connected pins can be

connected directly to the ground plane to maximize the heat

transfer from the package. Figure 13 shows the results of

thermal measurements of a board with an external ground

plane (the actual ground area was approximately 6 1/4 in2).

The thermal leads are connected to the board ground plane

per the recommended strategy.

Page 11

MC34058 MC34059

11

MOTOROLA ANALOG IC DEVICE DATA

θjc for the package on this board is 25 ±20% depending on the location of

the package on the board.

Figure 13. Thermal Resistance (θja) for Board

with Large External Ground Plane

55

θ

ja ( C/W)

AIR SPEED (LINEAR FT/MIN)

0 100 200 300 500

50

45

40

35

30

°

400 600

θ

ja ( C/W)

°

* Masked radiators were covered by a solder mask. Exposed radiators

were bare copper.

Figure 14A. Thermal Resistance (θja) for

Board Without Ground Plane

120

AIR SPEED (LINEAR FT/MIN)

0 200 400 600 1000

100

80

60

50

110

90

70

800 1200

Exposed Radiators*

Masked Radiators*

No Radiators

Figure 14B. Layout Used for Thermal Resistance

Measurements in Figure 14A

8 (mm)

8 (mm)

Copper

Radiators

l (mm)

w (mm)

Copper

Radiators

l (mm)

w (mm)

Figure 15. Placement of Thermal Vias to Enhance

Heat Transfer to Ground Plane

Figure 14A on the other hand shows the result of a single

layer board without an internal ground plane. The graphs

show that even though there are radiators of substantial area

surrounding the package, substantial degredation of thermal

performance is evident (Figure 14B shows the layout used

for the measurements in Figure 14A). Comparing Figures 13

and 14A shows almost a 2:1 improvement for the strategy

involving the external ground plane.

It is clear from Figures 13, 14A and Example 1, that if an

application is to use all the device drivers, preparations to

assure adequate thermal performance of the system must

be taken.

If an extensive external ground plane is unavailable, and

only an internal ground plane is available, the thermal

performance of the device can still be improved by providing

thermal vias to connect the radiators to the internal ground

plane. Figure 15 shows a proposed scheme for thermal vias

(contact board manufactures for specifics about the thermal

performance of their products and possible enhancements).

The thermal resistance for this structure on 1.0 oz. Copper

connecting each of the four radiators to an internal ground

plane and provide an estimated thermal resistance of

approximately 5.0°C/W. The vias used in the estimate had

80 mil diameters, on 100 mil centers and a 1.0 mil copper

thickness.

Page 12

MC34058 MC34059

12

MOTOROLA ANALOG IC DEVICE DATA

FTA SUFFIX

PLASTIC PACKAGE

CASE 932–02

(Thin QFP)

ISSUE D

DIMAMIN MAX MIN MAX

INCHES

7.000 BSC 0.276 BSC

MILLIMETERS

A1 3.500 BSC 0.138 BSC

B 7.000 BSC 0.276 BSC

B1 3.500 BSC 0.138 BSC

C 1.400 1.600 0.055 0.063

D 0.170 0.270 0.007 0.011

E 1.350 1.450 0.053 0.057

F 0.170 0.230 0.007 0.009

G 0.500 BASIC 0.020 BASIC

H 0.050 0.150 0.002 0.006

J 0.090 0.200 0.004 0.008

K 0.500 0.700 0.020 0.028

M 12 REF 12 REF

N 0.090 0.160 0.004 0.006

P 0.250 BASIC 0.010 BASIC

Q 1 5 1 5

R 0.150 0.250 0.006 0.010

S 9.000 BSC 0.354 BSC

S1 4.500 BSC 0.177 BSC

V 9.000 BSC 0.354 BSC

V1 4.500 BSC 0.177 BSC

W 0.200 REF 0.008 REF

X 1.000 REF 0.039 REF

NOTES:

1 DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2 CONTROLLING DIMENSION: MILLIMETER.

3 DATUM PLANE –AB– IS LOCATED AT BOTTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY AT

THE BOTTOM OF THE PARTING LINE.

4 DATUMS –T–, –U–, AND –Z– TO BE DETERMINED

AT DATUM PLANE –AB–.

5 DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE –AC–.

6 DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS

0.250 (0.010) PER SIDE. DIMENSIONS A AND B DO

INCLUDE MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE –AB–.

7 DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

NOT CAUSE THE D DIMENSION TO EXCEED

0.350 (0.014).

8 MINIMUM SOLDER PLATE THICKNESS SHALL BE

0.0076 (0.0003).

9 EXACT SHAPE OF EACH CORNER IS OPTIONAL.

__

____

A

A1

–T–

Z0.200 (0.008) AB T–U

–U–

4X

Z0.200 (0.008) AC T–U

4X

B

B1

1

12

13

24

25

36

37

48

–Z–

S1

S

V

V1

P

AE AE

–T–, –U–, –Z–

DETAIL Y

DETAIL Y

BASE METAL

N

J

F

D

S

T–U

M

0.080 (0.003) Z

S

AC

SECTION AE–AE

–AB–

–AC–

AD

G

0.080 (0.003) AC

M

_

TOP & BOTTOM

Q

_

W

K

X

E

C

H

0.250 (0.010)

GAUGE PLANE

R

9

DETAIL AD

OUTLINE DIMENSIONS

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAP AN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 or 602–303–5454 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–81–3521–8315

MFAX: RMF AX0@email.sps.mot.com – TOUCHT ONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET .com 51 Ting Ko k Road, Tai Po, N.T., Hong Kong. 852–26629298

MC34058/D

*MC34058/D*

◊

Loading...

Loading...