Page 1

MOTOROLA

SEMICONDUCTOR TECHNICAL

Standalone Tag Reader Circuit

Order this document

by MC33690/D

MC33690

STANDALONE

STARC

The Standalone Tag Reader Circuit (STARC) is an integrated

circuit dedicated to the automotive immobilizer applications. It

combines on the same chip all the circuitry to interface with a

transponder : antenna drivers and demodulator.

A low dropout voltage regulator and a physical interface fully

compatible with the ISO 9141 norm are also available.

The Standalone Tag Reader Circuit is fabricated with the

SMARTMOS

metal, 1.4µm, 45V technology, combining CMOS and bipolar

devices.

• Contactless 125kHz tag reader module :

- Self synchronous sample & hold demodulator

- Amplitude or phase modulation detection

- High sensitivity

- Fast “read after write“ demodulator settling time

- Low resistance and high current antenna drivers :

2Ω @ 150mA (typ.)

- Bidirectionnal data transmission

- Multi tag, multi scheme operation.

• Low dropout voltage regulator :

- Wide input supply voltage range :

from 5.5V up to 40V

- Output current capability up to 150mA DC with an

external power transistor

- 5V output voltage with a ± 5% accuracy

- Low voltage reset function

- Low current consumption in standby mode :

300µA (typ.).

• ISO 9141 transmitter and receiver module :

- Input voltage thresholds ratiometric to the supply

voltage

- Current limitation

- Ouput slew rate control

- No external protection device required.

TM

3.5 technology. This process is a double layer

TAG READER

CIRCUIT

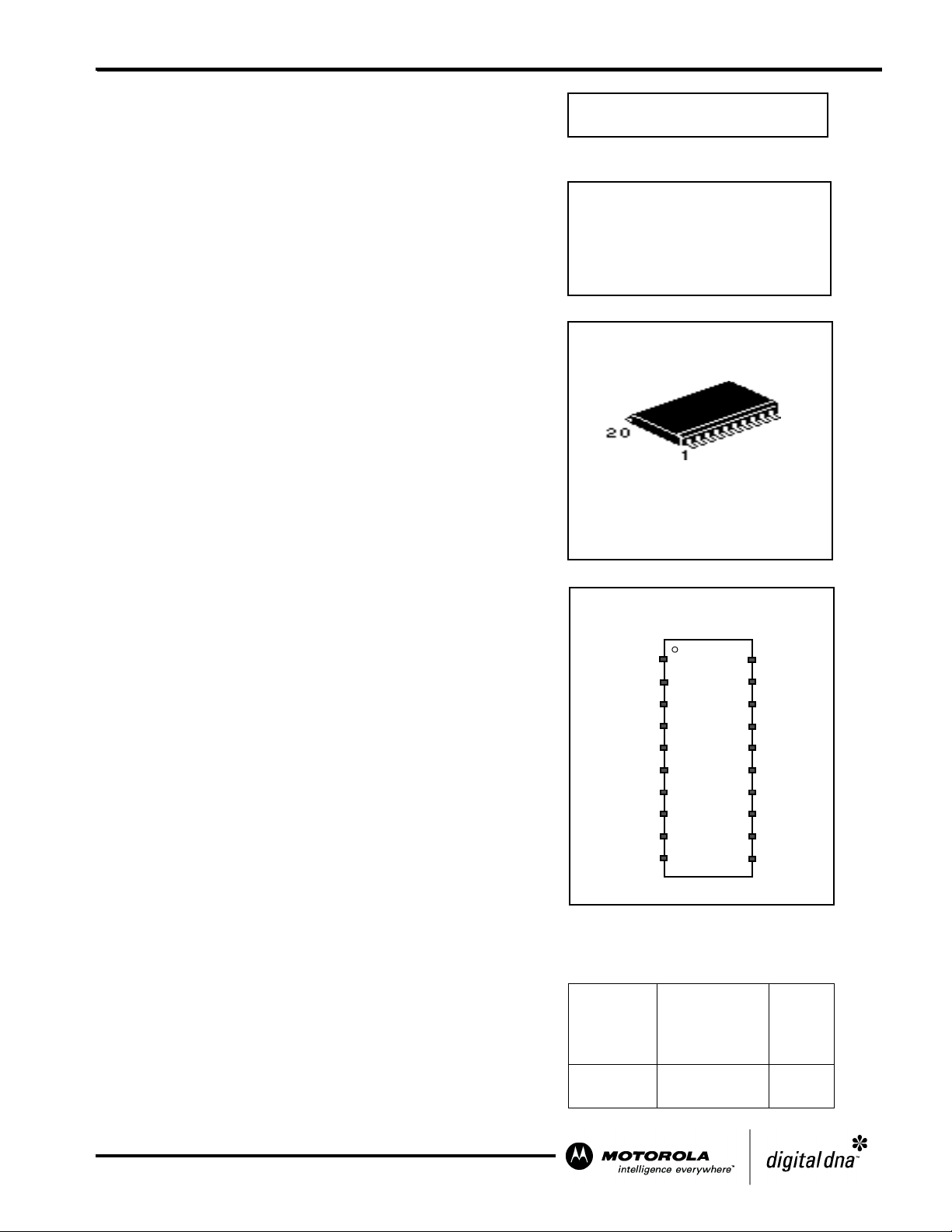

DW SUFFIX

Plastic Package

CASE 751D

SO - 20

Pin Connections

VSUP

SOURCE

GATE

TD1

VSS

VDD

TD2

MODE1

MODE2

1

2

3

4

5

6

7

8

9

RD

ORDERING INFORMATION

Tx

20

19

Rx

18

K

17

AM

XTAL1

16

XTAL2

15

14

LVR

13

DOUT

12

CEXT

1110

AGND

This document contains information on a new product under development. Motorola

reserves the right to change or discontinue this product without notice.

REV 4.8

© Motorola, Inc., 2002.

Device

MC33690DW

Operating

Junction

Tem p e r a t ure

Range

= -40°C to

T

J

125°C

Package

SOIC 20

Page 2

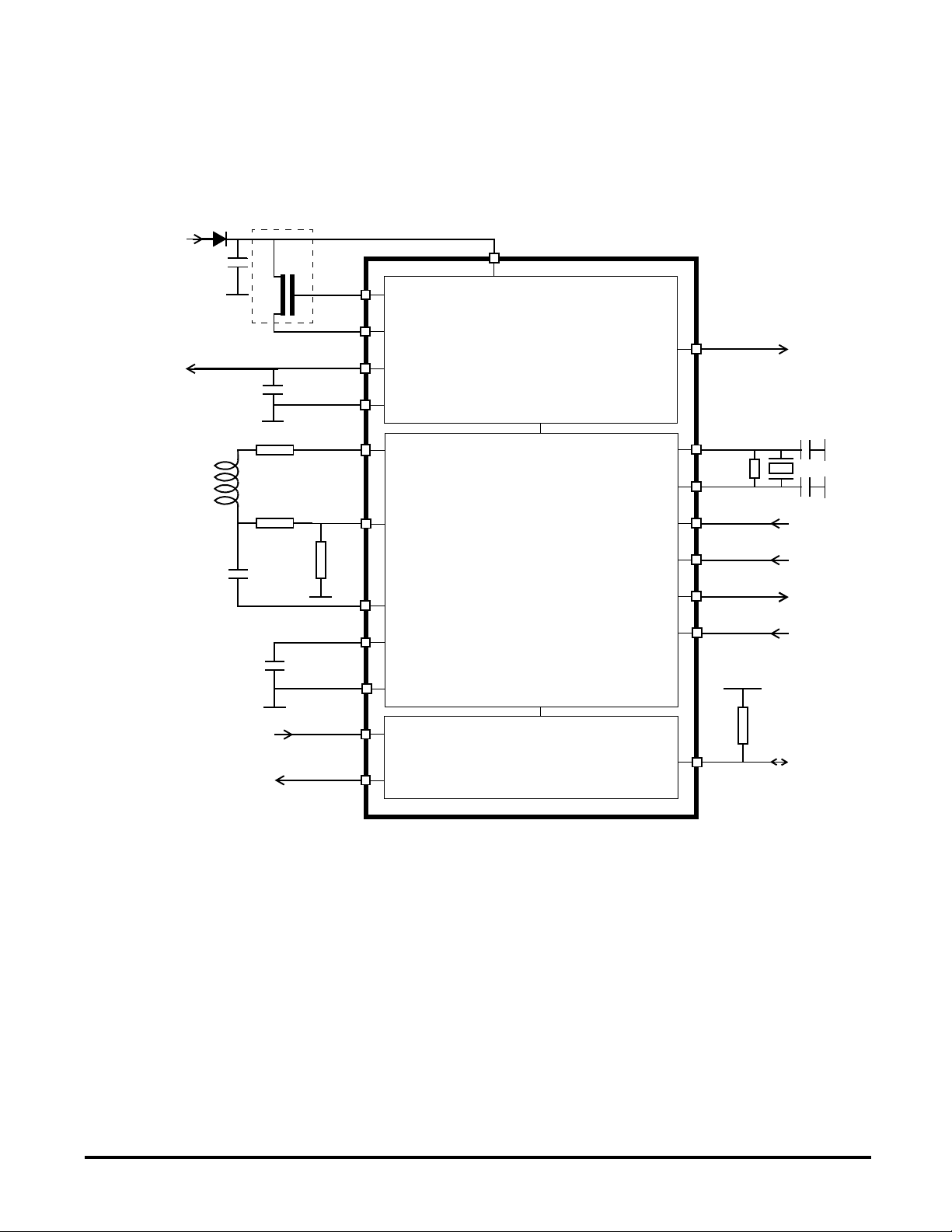

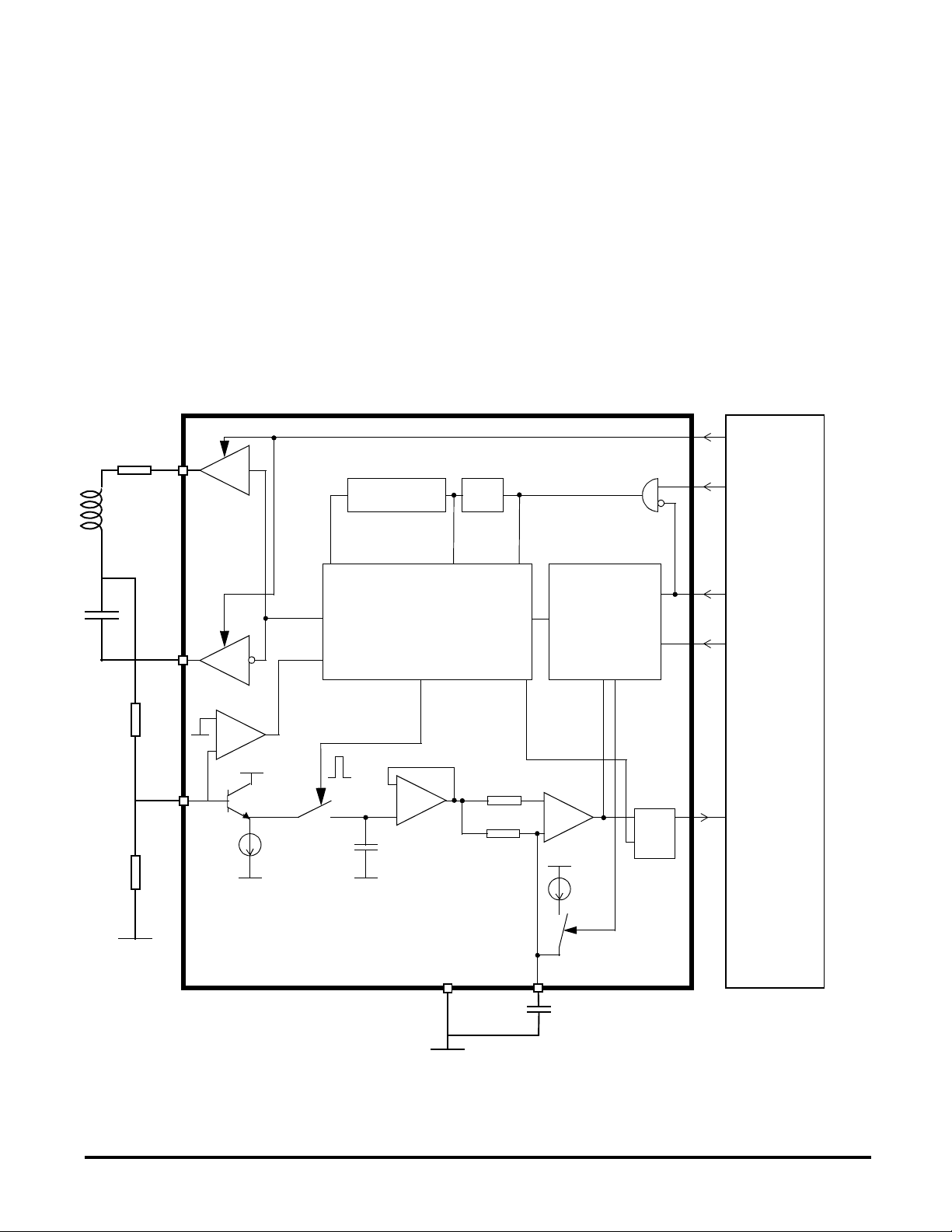

BLOCK DIAGRAM

Optional : external N channel MOS required for sourced current > 50mA.

A recommended reference is MMFT 3055VL from Motorola.

MC33690

Figure 1 : Standalone Tag Reader Circuit

VBAT

VDD

VSUP

C

1

GATE

SOURCE

VDD

10µF

VSS

R

A

L

A

R

1

C

A

C

EXT

10nF

TD1

RD

R

2

TD2

CEXT

AGND

Tx

Voltage Regulator

Tag Reader

LVR

8MHz

XTAL1

XTAL2

MODE1

MODE2

DOUT

AM

VBAT

510Ω

ISO 9141 Interface

Rx

K

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

2

revision 4.8, 5 February 2002

Page 3

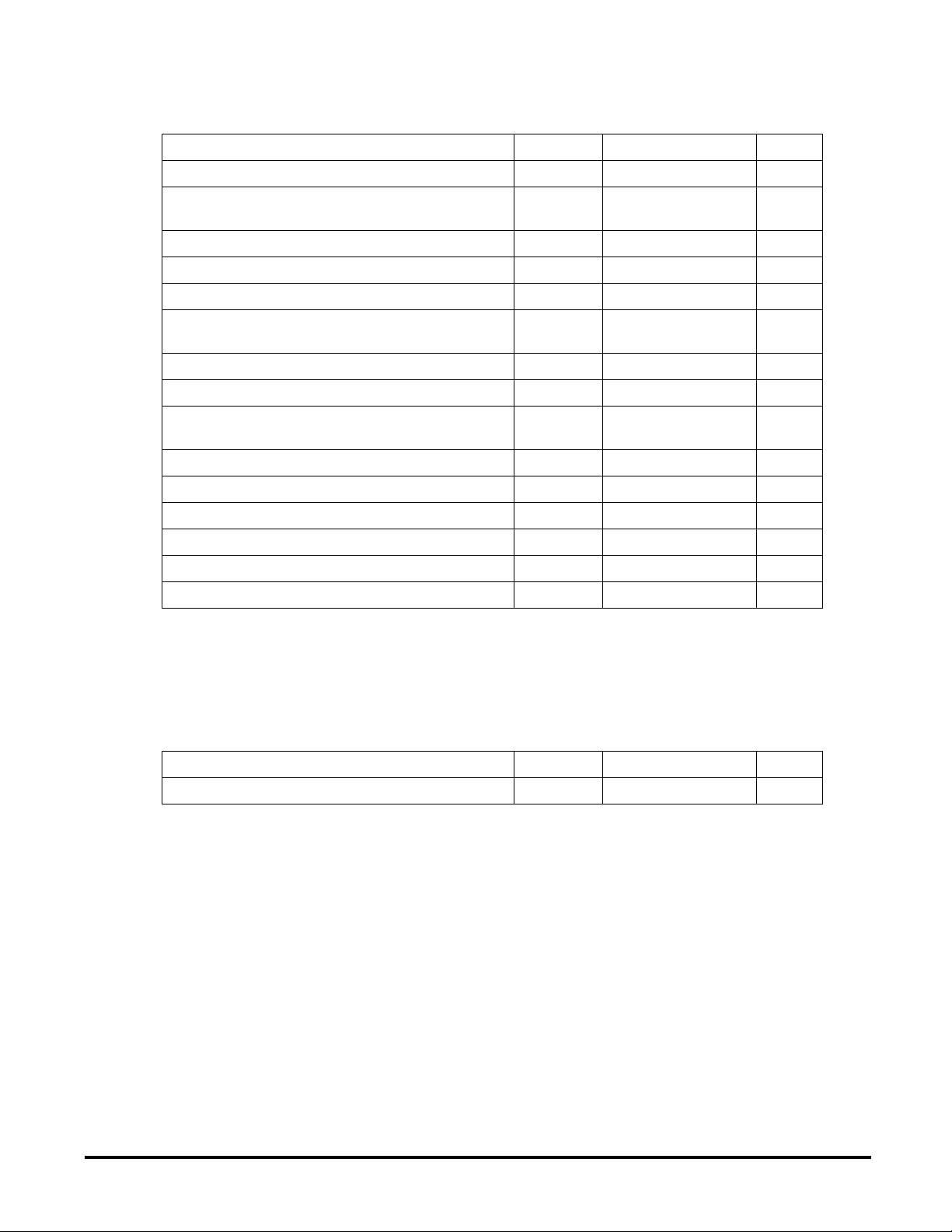

MAXIMUM RATINGS

Supply voltage V

Supply voltage without using the voltage regulator

(V

= VDD)

SUP

Voltage on SOURCE V

Current into/from GATE 0 mA

MC33690

Rating Symbol Value Unit

VSS-0.3 to +40 V

VSS-0.3 to +7 V

-0.3 to +40 V

SS

V

SUP

DD

Voltage on GATE V

Voltage on pins :

MODE1/2, CEXT, DOUT, LVR, XTAL1/2, Rx, Tx

Voltage on RD ±10 V

Voltage on K and AM V

Current on TD1 & TD2

(Drivers on & off)

Voltage on AGND VSS±0.3 V

ESD voltage capability (HBM, see note 1) ±2000 V

ESD voltage capability (MM, see note 1) ±200 V

Solder heat resistance test (10s) 260 °C

Junction temperature T

Storage temperature T

Note 1 :

Human Body model, AEC-Q100-002 Rev. C.

Machine Model, AEC-Q100-003 Rev. E.

THERMAL CHARACTERISTIC

-0.3 V

SS

V

SS

-0.3 to V

-3 to 40 V

SS

+0.3 V

DD

±300 mA

J

s

170 °C

-65 to +150 °C

Junction to ambiant thermal resistance (SOIC20) R

© Motorola, Inc., 2002.

Characteristic Symbol Value Unit

th

MOTOROLA SEMICONDUCTORS PRODUCTS

80 °C/W

revision 4.8, 5 February 2002

3

Page 4

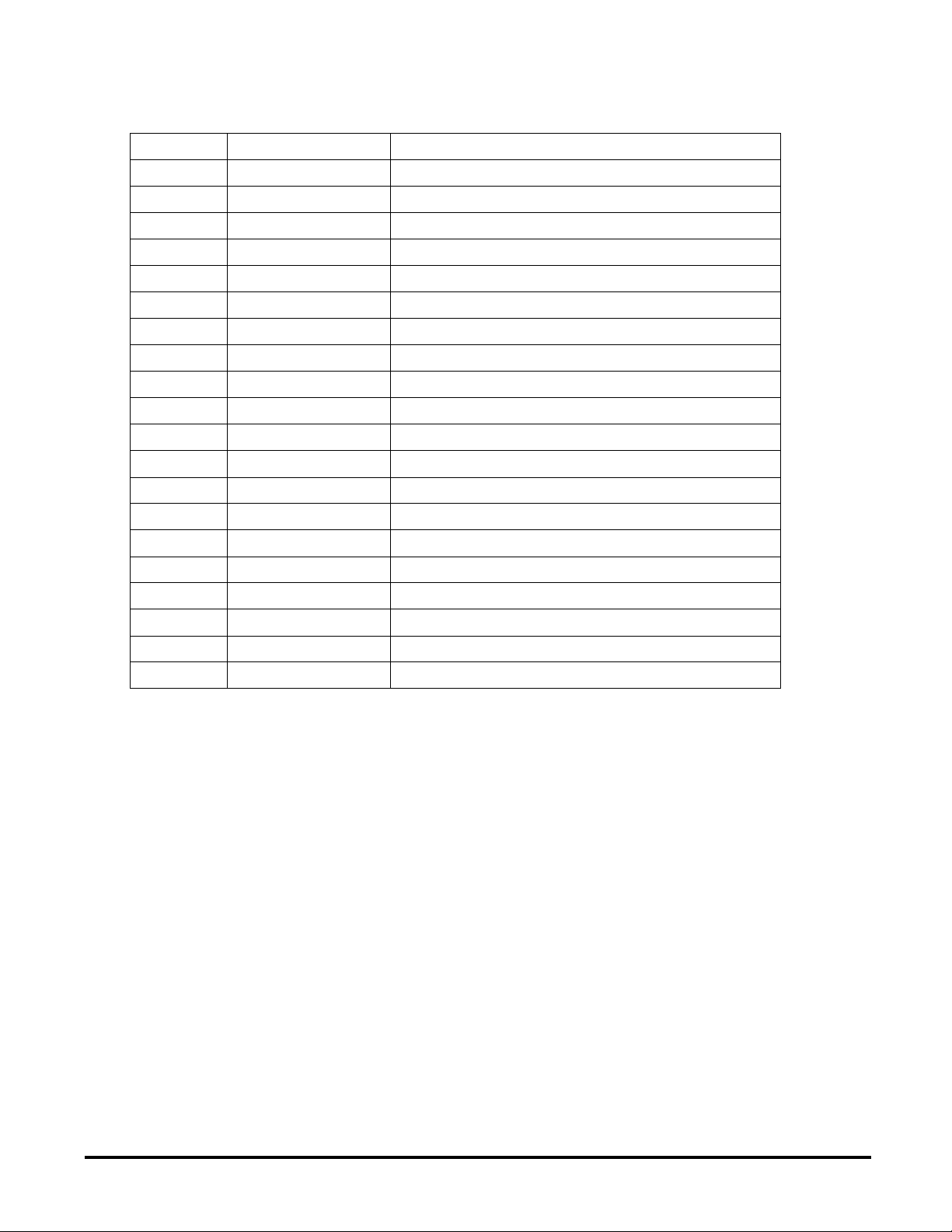

PIN FUNCTION DESCRIPTION

Pin Function Description

1 VSUP Power supply

2 SOURCE External N channel transistor source

3 GATE External N channel transistor gate

4 TD1 Antenna driver 1 output

5 VSS Power and digital ground

6 VDD Voltage regulator output

7 TD2 Antenna driver 2 output

8 MODE1 Mode selection input 1

9 MODE2 Mode selection input 2

10 RD Demodulator input

11 AGND Demodulator ground

12 CEXT Comparator reference input

MC33690

13 DOUT Demodulator output (5V)

14 LVR Low Voltage Reset input/output

15 XTAL2 Oscillator output

16 XTAL1 Oscillator input

17 AM Amplitude modulation input

18 K ISO 9141 transmitter output and receiver input

19 Rx ISO 9141 receiver monitor output

20 Tx ISO 9141 transmitter input

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

4

revision 4.8, 5 February 2002

Page 5

DESCRIPTION

TAG READER MODULE

MC33690

The Tag Reader module is dedicated for

automotive or industrial applications where

information has to be transmitted contactless.

The tag reader module is a write/read (challenge/

response) controller for applications which

demand high security level.

The tag reader module is connected to a serial

tuned LC circuit which generates a magnetic field

power supplying the tag.

Figure 2 : Tag Reader block diagram

R

A

TD1

L

A

125kHz

C

A

1/32 counter 1/2

125kHz

Self synchronous

sample & hold

The use of a synchronous sample & hold

technique allows communication with all

avalaible tags using admittance switching

producing absorption of the RF field.

Load amplitude or phase shift modulation can be

detected at high bit rates up to 8kHz.

125kHz is the typical operational carrier

frequency of the tag reader module with a 8MHz

clock.

AM Data

Clock 8MHz

4MHz

8MHz

Shutdown

Setup & Preload

LVR

TD2

R

1

R

2

-

+

VDD

RD

11.25° , 22.5° , 33.75° , 45° , 56.25° , 67.5° , 78.75° , 90°

+ 0°, -11.25°, -22.5°, -33.75°, -45°, -56.25°, -67.5°, -78.75°

Buffer

500ns

S/H Buffer

+

-

AGND

100K

C

EXT

Comparator

+

Ω

-

VDD

CEXT

10nF

DCQ

500µA

Interface

Data out

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

5

revision 4.8, 5 February 2002

Page 6

MC33690

Read function

When answering to the base station, a

transponder generates an absorption modulation

of the magnetic field. It results in an amplitude/

phase modulation of the current across the

antenna. This information is picked up at the

antenna tap point between the coil and the

capacitor. An external resistive ladder down

scales this voltage to a level compatible with the

demodulator input voltage range (see parameter

V

page 16).

INRD

The demodulator (see figure 2) consists of :

- an input stage (emitter follower),

- a sample & hold circuit,

- a voltage follower,

- a low offset voltage comparator.

The sampling time is automatically set to take

into account a phase shift due to the tolerances

of the antenna components (L and C) and of the

oscillator. The allowed phase shift measured at

the input RD ranges from -45° to +45°. Assuming

that the phase reference is the falling edge of the

driving signal TD1, this leads to a sampling time

phase ranging from -78.75° to 90° with discrete

steps of 11.25°. After reset condition, the

sampling time phase is +11.25°.

The antenna phase shift evaluation is only

done :

- after each wake-up command (see pages

10 to 12),

- or after reset (see page 7).

This is necessary to obtain the best demodulator

performances.

In order to ensure a fast demodulator settling

time after wake up, reset or a write sequence, the

external capacitor C

is preloaded at its

EXT

working voltage.

This preset occurs 256µs after switching the

antenna drivers on and its duration is 128µs.

After wake up or reset, the preset has the same

duration but begins 518µs after clock settling.

After power on reset, VSUP must meet the

minimum specified value, enabling the nominal

operation of VDD, before the start of the preset.

Otherwise the preset must be done by the user

through a standby/wake-up sequence.

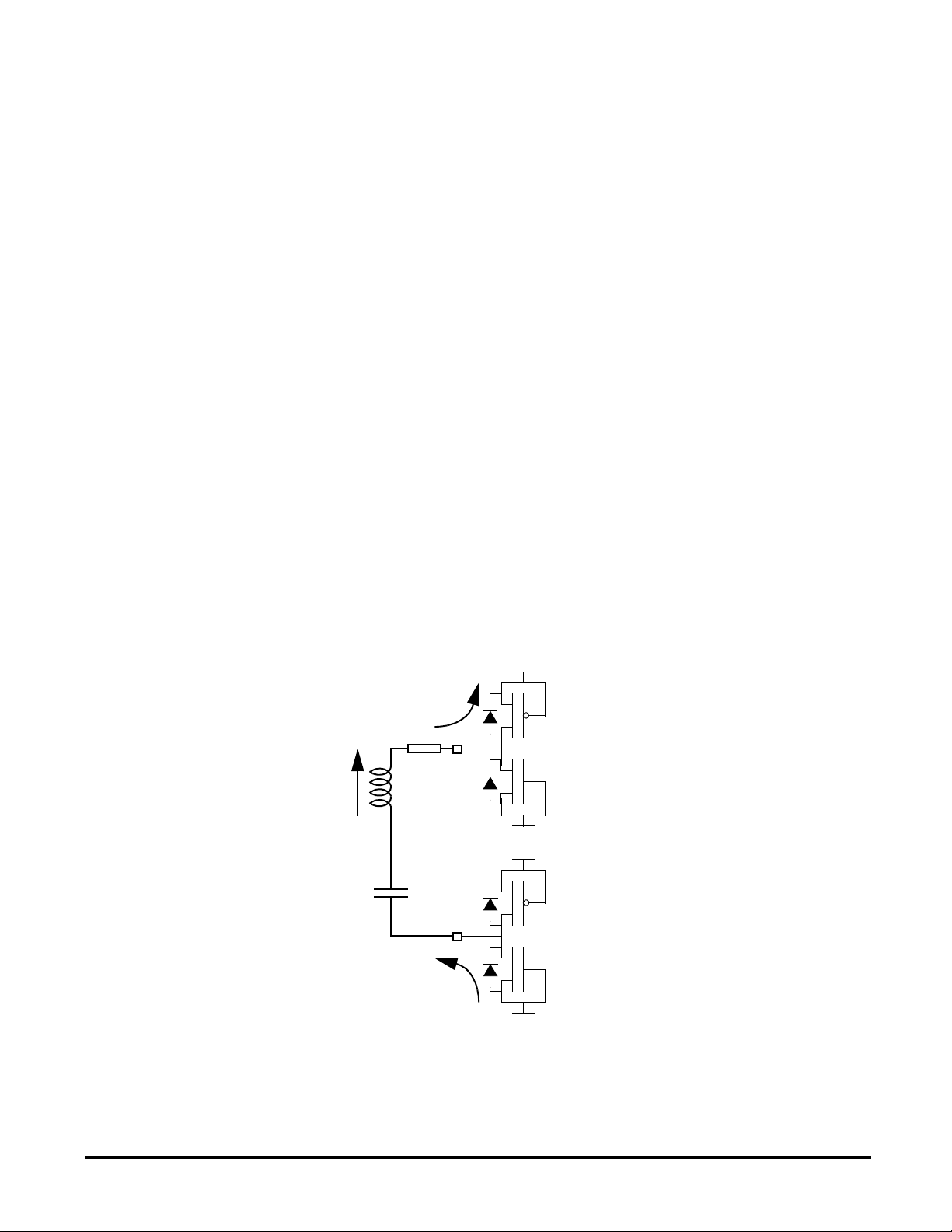

Write function

Whatever the selected configuration (see

page 9), the write function is achieved by

switching on/off the output drivers TD1/2.

Once the drivers have been set in high

impedance, the load current flows alternatively

Figure 3 : Current flow when the buffers are switched off

VDD

R

A

TD1

I

LOAD

L

A

R

1

C

A

TD2

VDD

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

6

revision 4.8, 5 February 2002

Page 7

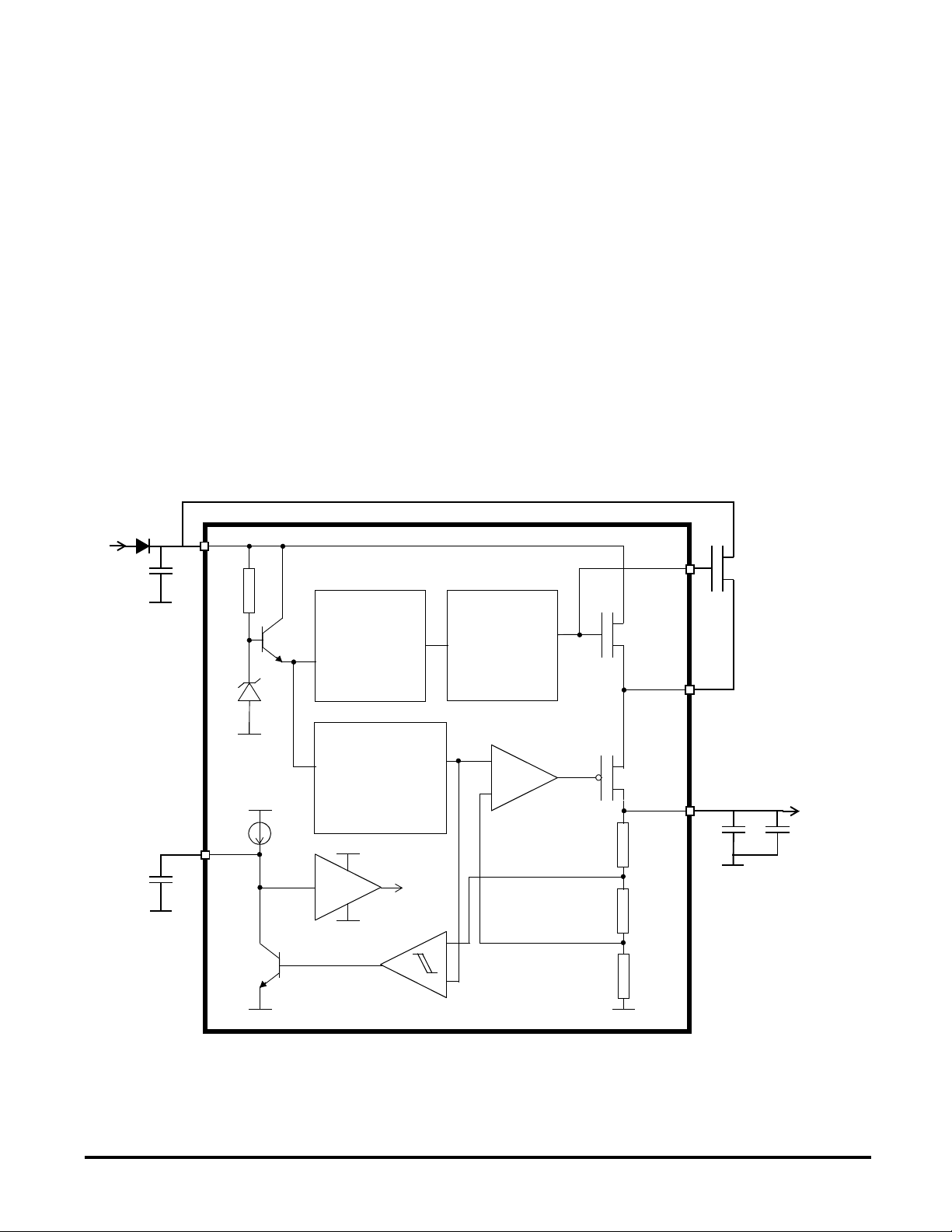

VOLTAGE REGULATOR

MC33690

The low dropout voltage regulator provides a

regulated 5V supply for the internal circuitry. It

can also supply external peripherals or sensors.

The input supply voltage ranges from 5.5V to

over 40V.

This voltage regulator uses a series combination

of high voltage LDMOS and low voltage PMOS

transistors to provide regulation. An external low

ESR capacitor is required for the regulator

stability.

The maximum average current is limited by the

power dissipation capability of the SO 20

package.

This limitation can be overcome by connecting

an external N channel MOS in parallel with the

Figure 4 : Voltage regulator block diagram

VBAT

C

1

VSUP

internal LDMOS. The threshold voltage of this

transistor must be lower than the one of the

internal LDMOS (1.95V typ.) in order to prevent

the current from flowing into the LDMOS. Its

breakdown voltage must be higher than the

maximum supply voltage.

A low voltage reset function monitors the VDD

output. An internal 10µA pull-up current source

allows, when an external capacitor is connected

between LVR and GND, to generate delays at

power up (5ms typ. with C

Reset

=22nF) .

The LVR pin is also the input generating the

internal reset signal. Applying a logic low level on

this pin resets the circuit :

- all the internal flip flops are reset,

- the drivers TD1/2 are switched on.

GATE

C

Reset

LVR

VDD

10µA

1MHz oscillator

Voltage reference

and biasing

generator

VDD

reset

Comparator

Charge pump

-

+

N channel

LDMOS

SOURCE

-

+

P channel

MOS

VDD

C

2

10µF

C

3

100nF

VDD

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

7

revision 4.8, 5 February 2002

Page 8

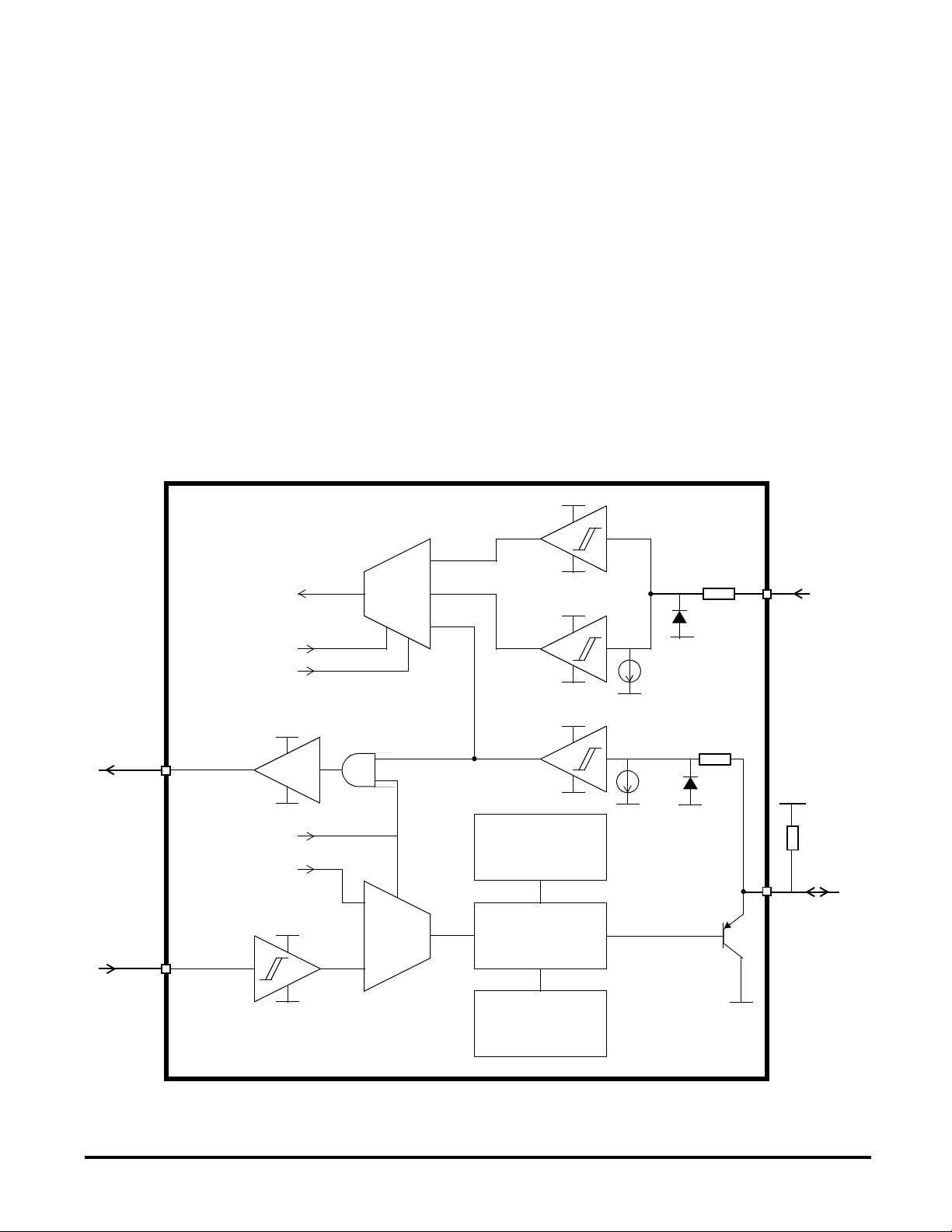

ISO 9141 PHYSICAL INTERFACE

MC33690

This interface module is fully compatible with

the ISO 9141 norm describing the diagnosis line.

It includes one transmitter (pin K) and 2 receivers

(pins K and AM).

The input stages consist of high voltage CMOS

triggers. The thresholds are ratiometric to VSUP.

A ground referenced current source (2.5µA typ.)

pulls down the input when unconnected.

When a negative voltage is applied on the K or

AM lines, the input current is internally limited by

a 2k

Ω resistor (typ.) in series with a diode.

A current limitation allows the transmitter to drive

Figure 5 : ISO 9141interface

AM data

any capacitive load and protects against short

circuit to the battery voltage. An overtemperature

protection shuts the driver down when the

junction temperature exceeds 150°C (typ). Once

shut down by the overtemperature protection,

the driver can be switched on again :

- if the junction temperature has decreased

below the threshold,

- and by applying an off/on command, coming

either from the demodulator in configurations A

and B or directly applied on the input Tx in

configuration C (see pin K status in table 1 page

9).

The electromagnetic emission is reduced thanks

to the voltage slew rate control (5V/µs typ.).

VDD

2kΩ

VSUP

L line

AM

From configuration controller

VDD

Rx

From configuration controller

Tag Reader module output

VDD

Tx

VSUP

Over temperature

detector

Command

Current limitation

GND

GND

2.5µA

2.5µA

GND

2kΩ

VBAT

GND

K line

K

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

8

revision 4.8, 5 February 2002

Page 9

MC33690

COMMUNICATION MODES DESCRIPTION

The STARC offers 3 different communication

modes. Therefore it can be used as a standalone

circuit connected to an Electronic Control Unit

Table 1. Communication modes description

Configuration

Configuration

pins

Type Bus type Name Mode1 Mode2

Standalone

Direct

connection

to a MCU

1 wire

(VBAT)

2 wires

(VBAT)

2 wires

(VDD)

A00

B01

C1

(ECU) through a bus line or it can be directly

connected to a microcontroller in case of a single

board architecture.

Pin status

& function description

K output/input :

- demodulator output,

- amplitude modulation input

- shutdown/wake-up

AM must be connected to VSUP

DOUT forces a low level

K output :

- demodulator output

AM input :

- amplitude modulation input,

- shutdown/wake-up

DOUT forces a low level

DOUT output :

- demodulator output

AM input :

x

- amplitude modulation input

MODE2 input :

- shutdown/wake-up

K output/input (standalone ISO 9141 inter-

1

face) :

- driven by Tx and monitored by Rx

K input (standalone ISO 9141 interface) :

0

- monitored by Rx

-Tx disabled

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

9

revision 4.8, 5 February 2002

Page 10

MC33690

STANDALONE CONFIGURATION WITH ONE WIRE BUS

When a low level is applied on pins MODE1

and MODE2, the circuit is in configuration A

(standalone single wire bus configuration, see

figure 13 page 18).

After power on, the circuit is set into read mode.

The demodulator output is directly routed to the

ISO 9141 interface output K.

The circuit can be set into write mode at anytime

by violation of all possible patterns on the single

wire bus during more than 1ms. Then the K line

achieves the amplitude modulation by switching

on/off both antenna drivers.

After 1ms of inactivity at the end of the challenge

phase (bus in idle recessive one state), the circuit

is set back into read mode.

Figure 6 : Mode access description in one wire bus configuration

Read to write mode :

K line

read mode

Write to read mode :

K line

write mode

Write to standby mode :

K line

write mode

Standby mode to read mode :

T0 ≤ t < T0’+T1’ 1 0 0 01 1

t ≥T

0

t ≥ T

1

The circuit can be put into standby mode by

forcing the K line at zero during more than 2 ms

after entering the write mode. Once the K line is

released, the circuit sends an acknowledge pulse

before entering into standby mode.

In standby mode, the oscillator and most of the

internal biasing currents are switched off.

Therefore, the functions (tag reader, ISO 9141

driver) are inactive except the voltage regulator

and the ISO 9141 receiver on pin K. The driver

output TD1 forces a low level and TD2 a high

level. A rising edge on K wakes up the circuit.

After completion of the wake-up sequence, the

circuit is automatically set in read mode.

In configuration A, DOUT and Rx outputs always

force a low level, Tx is disabled.

write mode

read mode

T

2

acknowledge

T

2

standby mode

K line

reset

standby mode read mode

wake-up sequence

Figure 7 : Configuration A state diagram

T0 ≤ K line low

write

read

T0 ≤ K line high

TD1/2 off

K line low

T1 ≤ K line low

K line high < T

write

TD1/2

switching

’

0

wake up

K

standby

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

10

revision 4.8, 5 February 2002

Page 11

Timing definitions for a 8MHz crystal:

- T

is crystal oscillator period (125 ns typ.)

ref

- T

=8064.T

0

= 1.008ms typ.

ref

MC33690

’=7932.T

- T

0

- T

=16256.T

1

- T

’=16128.T

1

=4096.T

- T

2

T

is the minimum time required to guarantee

0

= 0.992ms typ.

ref

= 2.032ms typ.

ref

= 2.016ms typ.

ref

, = 512µs typ.

ref

that the device toggles from read to write (or from

write to read). But indeed, the STARC may toggle

from read to write (or from write to read) between

T

and T0’.

0

is the minimum time required to guarantee

T

1

that the device toggles from write to standby. But

indeed, the STARC may toggle in standby

between T

and T1’.

1

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

11

revision 4.8, 5 February 2002

Page 12

MC33690

STANDALONE CONFIGURATION WITH TWO WIRES BUS

When a low level is applied on MODE1 and a

high level on MODE2, the circuit is in

configuration B (standalone 2 wires bus

configuration, see figure 14 page 19).

The K pin is set as an output sending the

demodulated data.

The AM pin is set as a VSUP referenced input pin

receiving the amplitude modulation and the

shutdown/wake-up commands. Forcing high and

low levels on AM achieves the amplitude

modulation by switching on/off both antenna

drivers. Meanwhile, this amplitude modulation

can be monitored on the K output. This allows

antenna short and open circuit diagnosis.

The circuit can be put into standby mode by

Figure 8 : Modes access description in two wires bus configuration

Read & write sequences :

AM line

K line

Entering into st

AM line

K line

andby mode :

t ≥ T1

data read

T1

drivers on

acknowledge

T2 T2

forcing the AM line at zero during more than 2

ms. The circuit sends an acknowledge pulse

before entering into standby mode

In standby mode, the oscillator and most of the

internal biasing currents are switched off.

Therefore, the functions (tag reader, ISO 9141

driver) are inactive except the voltage regulator

and the ISO 9141 receiver on pin AM. The driver

output TD1 forces a low level and TD2 a high

level. A rising edge on AM wakes up the circuit.

After completion of the wake-up sequence, the

circuit is automatically set in read mode.

In configuration B, DOUT and Rx outputs always

force a low level, Tx is disabled.

drivers off

data write modulation

1 0 0 01 1

data write

1 0 0 01 1

AM line monitoring

standby mode

Coming out of standby mode :

AM line

standby mode

K line

wake-up sequence

Figure 9 : Configuration B state diagram

reset

AM line high

wake up

AM

TD1/2

switching

AM line high

AM line low

AM line low

T1 ≤ AM line low

standby

data read

TD1/2 off

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

12

revision 4.8, 5 February 2002

Page 13

MC33690

DIRECT CONNECTION TO A MICROCONTROLLER CONFIGURATION

When a high level is applied on MODE1, the

circuit is in configuration C (direct connection to

a microcontroller configuration, see figure 15

page 19).

The demodulated data are sent through DOUT.

The AM pin is set as a VDD referenced input pin

receiving the AM command. Forcing high and

low levels on AM achieves the amplitude

modulation by switching on/off both antenna

drivers. Meanwhile, this amplitude modulation

can be monitored on DOUT. This allows antenna

short and open circuit diagnosis.

The circuit can be put into standby mode by

applying a low level on the MODE2 pin.

In standby mode, the oscillator and most of the

internal biasing currents are switched off.

Therefore, the functions (tag reader, ISO 9141

interface) are inactive except the voltage

Figure 10 : Configuration C state diagram

reset

TD1/2

switching

regulator. The driver outputs TD1 and TD2 are

frozen in their state (high or low level) before

entering into standby mode. DOUT forces a low

level.

The ISO 9141 interface K is standalone and can

be directly controlled by the input pin Tx and

monitored by the output Rx.

Applying a logic high level on Tx switches the

output driver K on (dominant zero state when an

external pull-up resistor is connected between K

and VBAT). Applying a logic low level turns the

driver off (one recessive state).

Rx monitors the voltage at the K pin. When the

voltage is below the low threshold voltage, Rx

forces a logic low level. When the voltage is

above the high threshold voltage, Rx forces a

logic high level.

In standby mode, Tx is disabled and Rx output

monitors the voltage at the K pin.

AM low

AM high

wake up

mode2 high

AM high

AM low

mode2 low

standby

TD1/2 off

mode2 low

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

13

revision 4.8, 5 February 2002

Page 14

ELECTRICAL CHARACTERISTICS

MC33690

Typical values reflect average measurements at V

=12V and TJ=25°C.

SUP

SUPPLY CURRENT

6V ≤ V

Pin VSUP

9.1 Standby mode current I

9.2 Operating mode current I

1. Circuit in configuration C, no current sunk from VDD, drivers TD1/2 switched off, Tx forced to low.

≤ 16V, VSS = 0V, TJ = –40°C to +125°C, unless otherwise noted

SUP

Parameter

Symbol

SUP1

SUP2

Test Conditions

& Comments

See note

1

Min Typ Max Unit

- 300 500 µA

-1.52.5mA

VOLTAGE REGULATOR

6V ≤ V

Pins VSUP & VDD

1.1 Output Voltage (5.5V ≤ V

1.3 Total Output Current I

1.5 Load Regulation V

1.9 Output Voltage (5.5V ≤ V

1.11 Total Output Current I

1.6 Load Regulation V

1.4 Line Regulation (6V ≤ V

1. The stability is ensured with a decoupling capacitor between VDD and VSS : C

2. The current capability can be increased up to 150mA by using an external N channel MOS transistor (see figure 1 page 2). The main

characteristics for choosing this component are : VT < 1.8V and BVDSS > 40V.

≤ 16V, VSS = 0V, TJ = –40°C to +125°C, unless otherwise noted

SUP

Parameter

≤ 40V) V

SUP

≤ 40V) V

SUP

≤ 16V) V

SUP

Symbol

VDD1 Without external MOS transistor

VDD1

LoadReg1

VDD2

VDD2

LoadReg2

LineReg

Test Conditions

& Comments

I

≤ 50mA

OUT

Without external MOS transistor

1 to 50mA I

With external MOS transistor,

see notes

I

OUT

With external MOS transistor

1 to 150mA I

I

OUT

change

OUT

1

and

≤ 150mA

change

OUT

= 1mA -15 -1 - mV

≥ 10µF with ESR ≤ 3Ω.

OUT

Min Typ Max Unit

4.75 5.0 5.25 V

--50mA

-2060mV

2

4.7 5.0 5.3 V

--150mA

-65150mV

Typ e

Typ e

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

14

revision 4.8, 5 February 2002

Page 15

LOW VOLTAGE RESET

MC33690

6V ≤ V

Pin LVR

1.6 Low Voltage Reset Low Threshold V

1.7 Low Voltage Reset Hysteresis V

1.12 Pull-up Current I

1.13 Output Resistance in reset condition R

1.14 Input Low Voltage V

1.15 Input High Voltage V

1. As the voltage regulator and the low voltage reset are using the same internal voltage reference, it is ensured that the low voltage reset

will only occur when the voltage regulator is out of regulation.

≤ 16V, VSS = 0V, TJ = –40°C to +125°C, unless otherwise noted

SUP

Parameter

Symbol

LVR ON

LVR H

LVRUP

LVR

ILLVR

IHLVR

Test Conditions

& Comments

See note 1 and figure 11

V

= 2.5V

LVR

V

= 2.5V

LVR

Min Typ Max Unit

4.14.354.6 V

50 100 150 mV

51015µA

200 370 500 Ω

0-

0.7 x

V

DD

0.3 x

V

DD

-VDDV

V

Figure 11 : Low voltage reset waveform

VDD

V

V

LVRON

LVRON

+ V

LVRH

LVR

Typ e

OSCILLATOR

6V ≤ V

Pins XTAL1, XTAL2

8.0 Input Capacitance C

8.1 Voltage gain V

8.3 Clock input level V

1. This level ensures the circuit operation with a 8MHz clock. It is applied through a capacitive coupling. A 1MΩ resistor connected between

XTAL1 and XTAL2 biases the oscillator input.

≤ 16V, VSS = 0V, TJ = –40°C to +125°C, unless otherwise noted

SUP

Characteristic

/ V

XTAL2

XTAL1

Symbol

XTAL1

A

OSC

XTAL1

Test Condition

& Comments

V

= 2.5V - 5 - pF

XTAL1

V

= 2.5V - 25 - -

XTAL1

See note

1

Min Typ Max Unit

1.5 - V

DD

Vpp

Typ e

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

15

revision 4.8, 5 February 2002

Page 16

TAG READER

MC33690

6V ≤ V

≤ 16V, VSS = 0V, TJ = –40°C to +125°C, unless otherwise noted

SUP

Parameter

Symbol

DEMODULATOR (pin RD)

2.0 Input Voltage Range V

2.2 Input Modulation Frequency F

2.3 Demodulator Sensitivity V

2.31 Demodulator Sensitivity V

2.4 Demodulation Delay t

2.5 After Write Pulse Settling Time t

INRD

MOD

SENSE1

SENSE2

Demod

Settling1

See figure 12 and note

See figure 12 and note 1 - 7 30 mV

see note

Recovery Time after wake-up or reset

2.6

from clock stable to demodulator valid

t

Settling2

output

DRIVERS (pins TD1, TD2)

Output Carrier Frequency to Crystal

3.5

Frequency Ratio

3.0 Turn on/off Delay t

3.1 Driver1/2 Low Side Out. Resistance R

3.2 Driver1/2 High Side Out. Resistance R

R

FTD/

FXTAL

on/off

TDL

TDH

1. The sensitivity is measured in the following application conditions : I

modulation F

2. Not including the delay due to the slew rate of the K output.

MOD=FTD1

3. Clock stable condition implies V

/32.

meets the specification (see page 15).

XTAL1

Test Conditions

& Comments

Min Typ Max Unit

345V

0.5 4 8 kHz

6.5V ≤ V

6V ≤ V

SUP

SUP

≤ 16V

< 6.5V

1

-515mV

See figure 12

Configuration C

2

for configurations A

-7.510µs

and B

- 394 400 µs

See note

3

- 646 700 µs

-64--

- - 250 ns

I

= 150mA DC - 2.4 4 Ω

LOAD

I

= -150mA DC - 2.1 4 Ω

LOAD

ANTENNA

= 50mA peak, VRD = 4V peak, C

= 10nF, square wave

EXT

Type

Figure 12 : Demodulator parameters definition

V

RD

Demodulator

output (K or DOUT)

V

SENSE

t

Demod

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

16

revision 4.8, 5 February 2002

Page 17

ISO 9141 INTERFACE

MC33690

6V ≤ V

≤ 16V, VSS = 0V, TJ = –40°C to +125°C, unless otherwise noted

SUP

Parameter

Symbol

Test Conditions

& Comments

Min Typ Max Unit

Receiver (pins K & AM)

4.0 Input Low Voltage V

4.1 Input High Voltage V

4.2 Input Hysteresis Voltage V

4.3 Biasi ng Cur re nt I

4.31 Input C ur rent I

IL

IH

HY1

B

BM

-3 -

0.65 x

V

SUP

0.40.651.3 V

0V ≤ VIN ≤ 16V 1 3 5 µA

-3 ≤ VIN < 0-2-1-mA

0.3 x

V

SUP

-40V

4.4 K to Rx delay tdkrx 2 10 µs

Driver (pin K)

5.0 Output Falling Edge Slew Rate SR

5.1 Output Rising Edge Slew Rate SR

5.2 Rise Fall Slew Rates Symmetry

SR

5.3 Output Low Voltage V

Input Current

5.4

(driver switched on or off)

5.5 Current Limitation Threshold I

5.6 Thermal Shutdown Threshold TH

1. Calculated from 20% to 80% of the output swing.

F

R

SYME-

TRY

OLK

I

IK

L

SDWN

R

= 510Ω,

Pull-up

see note

I

LOAD

1

= 25mA - 1.1 1.4 V

-3V ≤ VIN ≤ 0V -2 - 0 mA

0V ≤ VIN ≤ 40V 35 50 65 mA

3.5 5 6.5 V/µs

3.5 5 6.5 V/µs

-1 0 1 V/µs

130 150 170 °C

Typ e

V

DIGITAL I/O

6V ≤ V

INPUT (pins MODE1, MODE2, AM, TX)

6.0 Input Low Voltage V

6.1 Input High Voltage V

6.2 Input Hysteresis Voltage

OUTPUT (pins DOUT,RX)

7.0 Output Low Voltage V

7.1 Output High Voltage V

7.2 Fall/Rise Time t

1. Calculated from 10% to 90% of the output swing.

≤ 16V, VSS = 0V, TJ = –40°C to +125°C, unless otherwise noted

SUP

Characteristic

Symbol

ILD

IHD

V

HD

OL

OH

F/R

Test Condition

& Comments

I

= 500uA 0 0.5

LOAD

I

= -500uA

LOAD

C

=10pF, see note

LOAD

Min Typ Max Unit

0-

0.7 x

V

DD

.24 .7 1 V

0.8 x

V

1

DD

- - 150 ns

-VDDV

4.6 V

0.3 x

V

DD

0.2 x

V

DD

DD

Typ e

V

V

V

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

17

revision 4.8, 5 February 2002

Page 18

APPLICATION SCHEMES

Figure 13 : Standalone configuration with one wire bus

VBAT

C

1

NC

GATE

NC

SOURCE

MC33690

VSUP

LVR

XTAL1

XTAL2

MODE1

MODE2

NC

DOUT

AM

K

NC

1MΩ

VSUP

8.2pF

8MHz

8.2pF

VBAT

510Ω

VSS

L

C

C

10µF

A

A

R

C

2

1

C

EXT

3

100nF

R

R

2

A

NC

VDD

VSS

TD1

RD

TD2

CEXT

10nF

AGND

STARC

Tx

Rx

If no external MOS transistor is necessary to increase the voltage regulator current capability, the pins GATE

and SOURCE must be left unconnected.

In this configuration, the outputs Rx and DOUT force a low level.

C

is not required for the STARC functionality and only acts as a reservoir of energy.

1

To preserve the demodulator sensitivity,

C

and R2 should be connected to AGND, and VSS connected to

EXT

AGND using a low resistance path.

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

18

revision 4.8, 5 February 2002

Page 19

VBAT

MC33690

Figure 14 : Standalone configuration with two wires bus

C

1

NC

GATE

NC

SOURCE

VSUP

LVR

XTAL1

XTAL2

MODE1

MODE2

NC

1MΩ

8.2pF

8MHz

8.2pF

VDD

VBAT

VSS

L

A

C

A

C

10µF

R

1

C

2

3

VDD

100nF

VSS

R

A

TD1

R

2

RD

STARC

TD2

NC

C

EXT

CEXT

10nF

AGND

Tx

DOUT

K

AM

510Ω

NC

Rx

If no external MOS transistor is necessary to increase the voltage regulator current capability, the pins GATE

and SOURCE must be left unconnected.

C

is not required for the STARC functionality and only acts as a reservoir of energy.

1

To preserve the demodulator sensitivity,

AGND using a low resistance path.

© Motorola, Inc., 2002.

C

and R2 should be connected to AGND, and VSS connected to

EXT

MOTOROLA SEMICONDUCTORS PRODUCTS

19

revision 4.8, 5 February 2002

Page 20

VBAT

To microcontroller

power supply pin

C

VSS

L

C

10uF

A

A

R

MC33690

Figure 15 : Direct connection to a microcontroller

C

1

NC

GATE

NC

SOURCE

C

2

3

VDD

100nF

VSS

R

A

TD1

1

R

RD

2

STARC

VSUP

LVR

XTAL1

XTAL2

MODE1

1MΩ

VDD

To microcontroller

port/reset pin

8.2pF

8MHz

8.2pF

TD2

MODE2

To microcontroller

port

DOUT

AM

K

VBAT

510Ω

To microcontroller

port

C

EXT

CEXT

10nF

AGND

Tx

Rx

If no external MOS transistor is necessary to increase the voltage regulator current capability, the pins GATE

and SOURCE must be left unconnected.

is not required for the STARC functionality and only acts as a reservoir of energy.

C

1

To preserve the demodulator sensitivity,

AGND using a low resistance path.

C

and R2 should be connected to AGND, and VSS connected to

EXT

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

20

revision 4.8, 5 February 2002

Page 21

MC33690

Notes

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

21

revision 4.8, 5 February 2002

Page 22

MC33690

Notes

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

22

revision 4.8, 5 February 2002

Page 23

MC33690

Notes

© Motorola, Inc., 2002.

MOTOROLA SEMICONDUCTORS PRODUCTS

23

revision 4.8, 5 February 2002

Page 24

MC33690

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including

“Typicals” must be validated for each customer application by customer ’s technical experts. Motorola does not convey any license under its patent rights nor the

rights of others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or

other applications int ended to support or sustain life, or for any other application in which the failure of t he Motorola product could create a situation where personal

injury or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold

Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney

fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and the Stylized M Logo are registered in the U.S. Patent and Trademark Office.

Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer. All other product or service names are the property of their respective owners.

© Motorola, Inc. 2002

HOW TO REACH US:

USA/EUROPE/LOCATIONS NOT LISTED: Motorola Literature Distribution: P.O. Box 5405, Denver, Colorado 80217.

1-303-675-2140 or 1-800-441-2447

JAPAN: Motorola Japan Ltd.; SPS, Technical Information Center, 3-20-1 Minami-Azabu. Minato-ku, Tokyo 106-8573 Japan.

81-3-3440-3569

ASIA/PACIFIC:

Motorola Semiconductors H.K. Ltd.; Silicon Harbour Centre, 2 Dai King Street, Tai Po Industrial Estate, Tao Po, N.T.,

Hong Kong. 852-26668334

TECHNICAL INFORMATION CENTER:

HOME PAGE:

http://motorola.com/semiconductors/

1-800-521-6274

MC33690/D

Loading...

Loading...