Page 1

Order this document by MC33368/D

T

25° to +125°C

The MC33368 is an active power factor controller that functions as a

boost preconverter in off–line power supply applications. MC33368 is

optimized for low power, high density power supplies requiring a minimum

board area, reduced component count and low power dissipation. The

narrow body SOIC package provides a small footprint. Integration of the high

voltage startup saves approximately 0.7 W of power compared to resistor

bootstrapped circuits.

The MC33368 features a watchdog timer to initiate output switching, a

one quadrant multiplier to force the line current to follow the instantaneous

line voltage a zero current detector to ensure critical conduction operation, a

transconductance error amplifier, a current sensing comparator, a 5.0 V

reference, an undervoltage lockout (UVLO) circuit which monitors the V

supply voltage and a CMOS driver for driving MOSFET s. The MC33368 also

includes a programmable output switching frequency clamp. Protection

features include an output overvoltage comparator to minimize overshoot, a

restart delay timer and cycle–by–cycle current limiting.

• Lossless Off–Line Startup

• Output Overvoltage Comparator

• Leading Edge Blanking (LEB) for Noise Immunity

• Watchdog T imer to Initiate Switching

CC

HIGH VOLTAGE

GREENLINE POWER

FACTOR CONTROLLER

SEMICONDUCTOR

TECHNICAL DATA

16

1

P SUFFIX

PLASTIC PACKAGE

CASE 648

(DIP–16)

16

1

D SUFFIX

PLASTIC PACKAGE

CASE 751K

(SO–16)

• Restart Delay Timer

GreenLine is a trademark of Motorola, Inc.

ORDERING INFORMATION

Operating

Device

MC33368D

MC33368P

Temperature Range

–

= –

J

PIN CONNECTIONS

5.0 V

Restart Delay

Voltage FB

Package

°

°

SO–16

DIP–16

Current Sense

Zero Current

5.0 V

Restart Delay

Voltage FB

Current Sense

Zero Current

116

ref

2

3

Comp

4

Mult

5

6

7

AGnd

8

(Top View)

116

ref

2

3

Comp

4

Mult

5

6

7

AGnd

8

(Top View)

Line

N/C

15

N/C

14

13

Frequency Clamp

12

V

11

Gate

10

PGnd

9

LEB

Line

13

Frequency Clamp

12

V

SO–16 DIP–16

11

Gate

10

PGnd

9

LEB

CC

CC

This document contains information on a new product. Specifications and information herein

are subject to change without notice.

MOTOROLA ANALOG IC DEVICE DATA

Motorola, Inc. 1997 Rev 2

1

Page 2

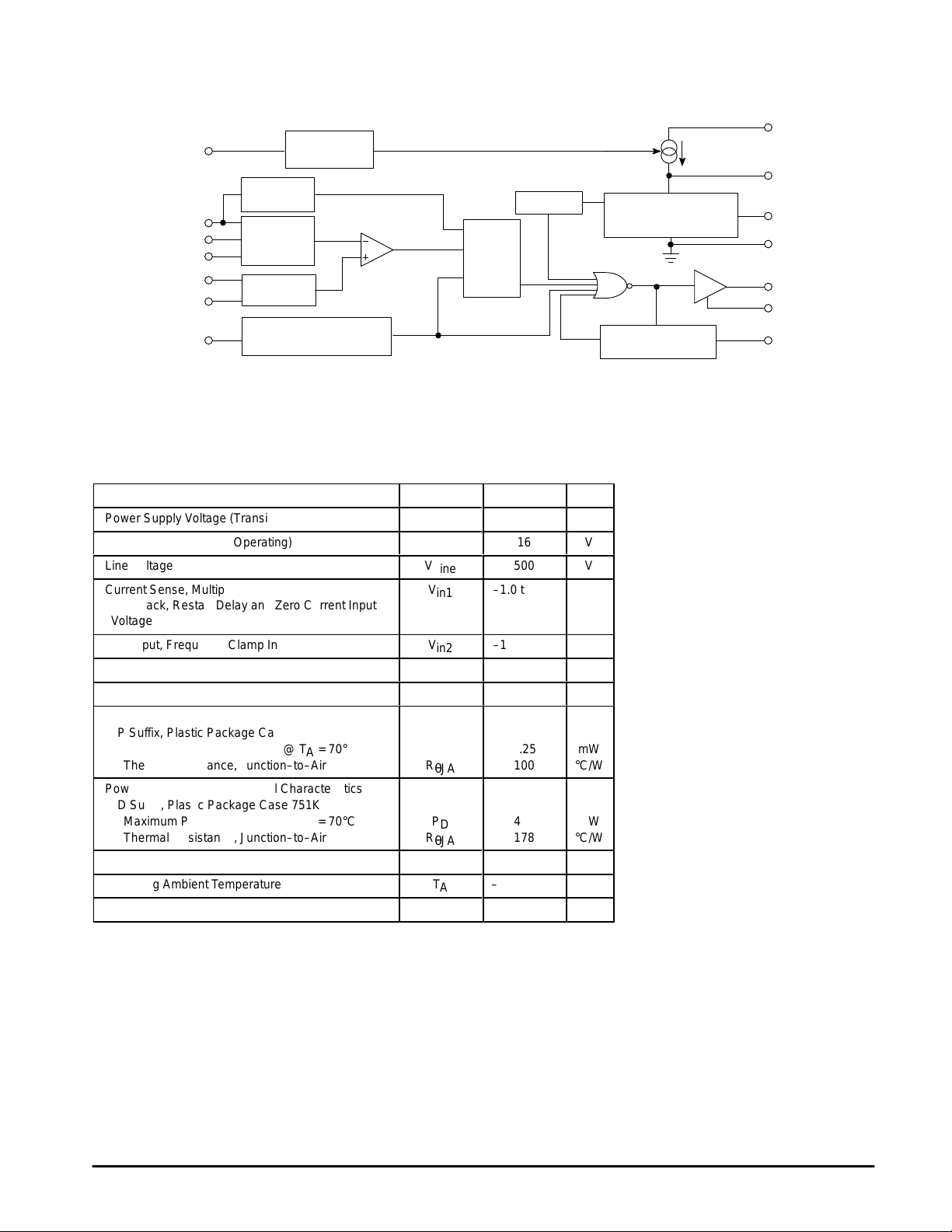

Restart Delay

FB

Comp

Mult

LEB

Current Sense

ZC Det

Restart Delay

Output

Overvoltage

Multiplier/

Error

Amplifier

Current

Sense

WatchdogTimer/

Zero Current Detector

MC33368

Representative Block Diagram

UVLO

PWM

This device contains 240 active transistors.

S

S

R

Q

Internal Bias

Generator

Frequency

Clamp

Line

V

CC

V

ref

AGnd

Gate

PGnd

Frequency

Clamp

MAXIMUM RATINGS (T

Power Supply Voltage (Transient)

Power Supply Voltage (Operating)

Line Voltage

Current Sense, Multiplier, Compensation, V oltage

Feedback, Restart Delay and Zero Current Input

Voltage

LEB Input, Frequency Clamp Input

Zero Current Detect Input

Restart Diode Current

Power Dissipation and Thermal Characteristics

P Suffix, Plastic Package Case 648

Maximum Power Dissipation @ TA = 70°C P

Thermal Resistance, Junction–to–Air R

Power Dissipation and Thermal Characteristics

D Suffix, Plastic Package Case 751K

Maximum Power Dissipation @ TA = 70°C P

Thermal Resistance, Junction–to–Air R

Operating Junction Temperature

Operating Ambient Temperature

Storage Temperature Range

NOTE: ESD data available upon request.

= 25°C, unless otherwise noted.)

A

Rating

Symbol Value Unit

V

V

V

V

V

T

CC

CC

Line

in1

in2

I

in

I

in

D

θJA

D

θJA

T

J

T

A

stg

20

16

500

–1.0 to +10 V

–1.0 to +20

±5.0

5.0

1.25 mW

100 °C/W

450 mW

178 °C/W

150

–25 to +125

–55 to +150

V

V

V

V

mA

mA

°C

°C

°C

2

MOTOROLA ANALOG IC DEVICE DATA

Page 3

MC33368

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

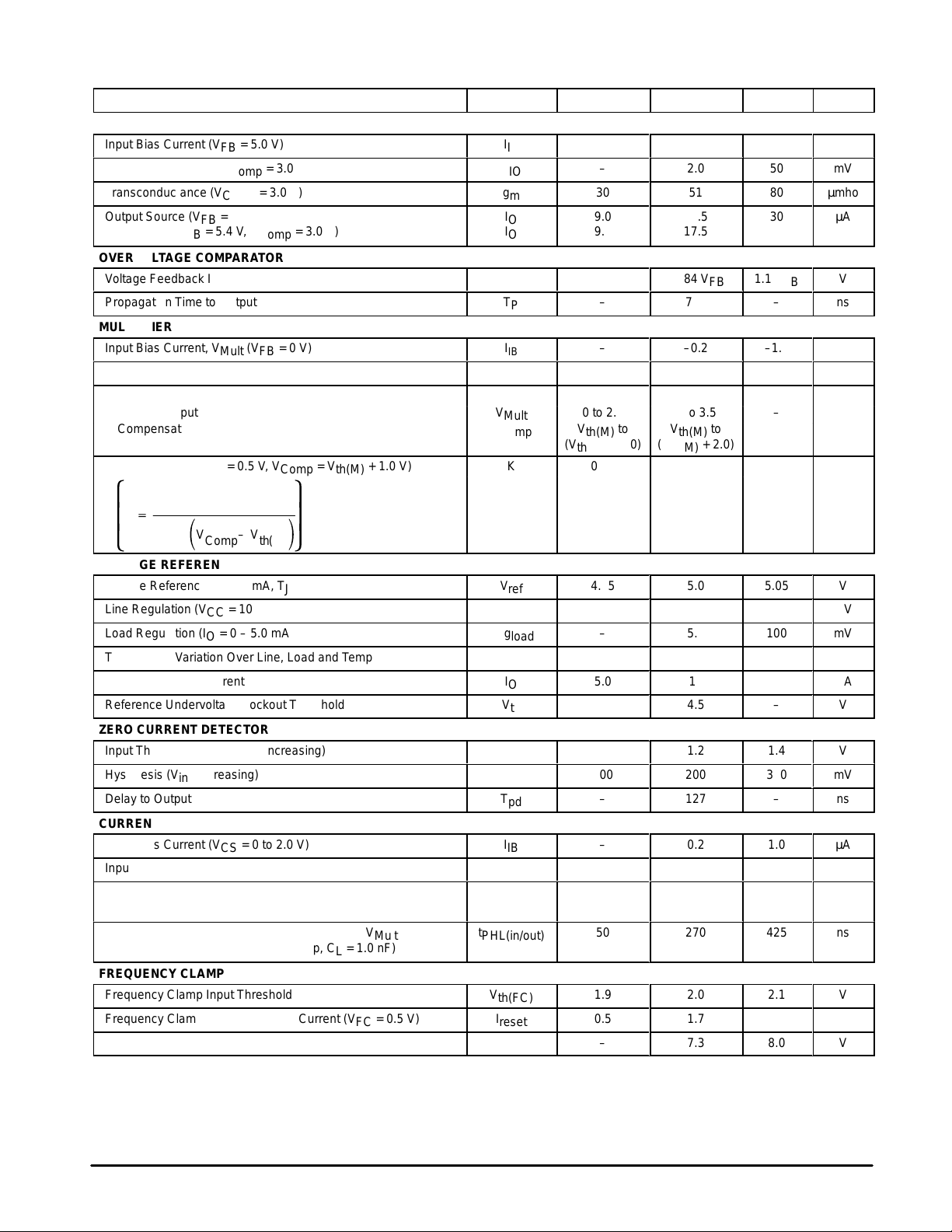

ELECTRICAL CHARACTERISTICS (V

= 14.5 V, for typical values TA = 25°C, for min/max values TJ = –25 to +125°C)

CC

Characteristic

ERROR AMPLIFIER

Input Bias Current (VFB = 5.0 V)

Input Offset Voltage (V

Transconductance (V

Output Source (VFB = 4.6 V, V

Output Sink (VFB = 5.4 V, V

БББББББББББББББ

Comp

Comp

= 3.0 V)

= 3.0 V)

Comp

Comp

= 3.0 V)

= 3.0 V)

OVERVOLTAGE COMPARATOR

Voltage Feedback Input Threshold

Propagation Time to Output

MULTIPLIER

Input Bias Current, V

Input Threshold, V

Mult

Comp

(VFB = 0 V)

Dynamic Input Voltage Range

Multiplier Input V

Compensation V

Multiplier Gain (V

ȡ

K

+

ȧ

V

Ȣ

Mult

= 0.5 V, V

Mult

VCSThreshold

ǒ

V

–V

Comp

th(M)

Comp

ȣ

ȧ

Ǔ

Ȥ

= V

+ 1.0 V) K 0.25 0.51 0.75 1/V

th(M)

VOLTAGE REFERENCE

Voltage Reference (IO = 0 mA, TJ = 25°C)

Line Regulation (VCC = 10 V to 16 V)

Load Regulation (IO = 0 – 5.0 mA)

Total Output Variation Over Line, Load and Temperature

Maximum Output Current

Reference Undervoltage Lockout Threshold

ZERO CURRENT DETECTOR

Input Threshold Voltage (Vin Increasing)

БББББББББББББББ

Hysteresis (Vin Decreasing)

БББББББББББББББ

Delay to Output

БББББББББББББББ

CURRENT SENSE COMPARATOR

Input Bias Current (VCS = 0 to 2.0 V)

Input Offset Voltage (V

Maximum Current Sense Input Threshold (V

БББББББББББББББ

V

= 5.0 V)

Mult

Delay to Output (V

БББББББББББББББ

(VCS = 0 to 5.0 V Step, CL = 1.0 nF)

LEB

= –0.2 V)

Mult

= 12 V, V

Comp

Comp

= 5.0 V, V

= 5.0 V,

= 5.0 V)

Mult

FREQUENCY CLAMP

Frequency Clamp Input Threshold

Frequency Clamp Capacitor Reset Current (VFC = 0.5 V)

Frequency Clamp Disable Voltage

Symbol Min Typ Max Unit

I

IB

V

IO

g

m

I

O

I

ÁÁÁ

O

V

FB(OV)

T

P

I

IB

V

th(M)

Mult

Comp

ÁÁÁ

ÁÁÁ

ÁÁÁ

V

ref

Reg

line

Reg

load

V

ref

I

O

V

th

V

th

ÁÁÁ

V

H

ÁÁÁ

T

pd

ÁÁÁ

I

IB

V

IO

V

th(max)

ÁÁÁ

t

PHL(in/out)

ÁÁÁ

V

th(FC)

I

reset

V

DFC

–

–

30

9.0

9.0

ÁÁÁ

1.07 V

FB

–

–

1.8

0

2.0

51

17.5

17.5

ÁÁÁ

1.084 V

FB

705

–0.2

2.1

0 to 2.5 0 to 3.5 –

V

to

th(M)

(V

+ 1.0)

th(M)

ÁÁÁ

ÁÁÁ

ÁÁÁ

4.95

–

–

4.8

5.0

–

1.0

ÁÁÁ

100

ÁÁÁ

–

ÁÁÁ

–

–

1.3

ÁÁÁ

50

ÁÁÁ

1.9

0.5

–

V

th(M)

(V

+ 2.0)

th(M)

ÁÁÁ

ÁÁÁ

ÁÁÁ

5.0

5.0

5.0

–

10

4.5

1.2

ÁÁÁ

200

ÁÁÁ

127

ÁÁÁ

0.2

4.0

1.5

ÁÁÁ

270

ÁÁÁ

2.0

1.7

7.3

to

1.0

50

80

30

30

ÁÁ

1.1 V

–

–1.0

2.4

–

ÁÁ

ÁÁ

ÁÁ

5.05

100

100

5.2

–

–

1.4

ÁÁ

300

ÁÁ

–

ÁÁ

1.0

50

1.8

ÁÁ

425

ÁÁ

2.1

4.0

8.0

ÁÁ

FB

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

µA

mV

µmho

µA

V

ns

µA

V

V

V

mV

mV

V

mA

V

V

mV

ns

µA

mV

V

ns

V

mA

V

MOTOROLA ANALOG IC DEVICE DATA

3

Page 4

MC33368

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

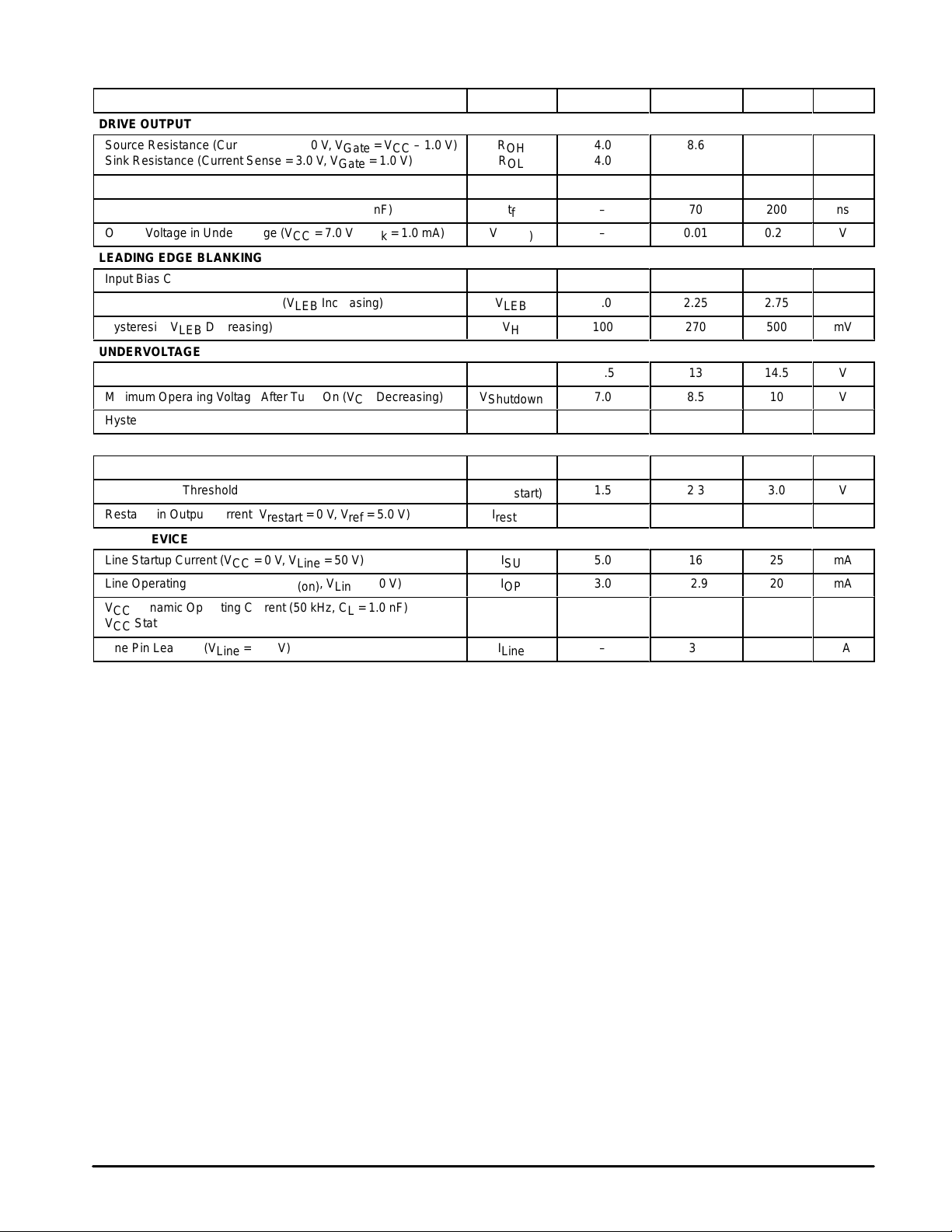

ELECTRICAL CHARACTERISTICS

(continued) (VCC = 14.5 V, for typical values TA = 25°C, for min/max values TJ = –25 to +125°C)

Characteristic UnitMaxTypMinSymbol

DRIVE OUTPUT

Source Resistance (Current Sense = 0 V, V

Sink Resistance (Current Sense = 3.0 V, V

БББББББББББББББ

= VCC – 1.0 V)

Gate

= 1.0 V)

Gate

Output Voltage Rise T ime (25% – 75%) (CL = 1.0 nF)

Output Voltage Fall Time (75% – 25%) (CL = 1.0 nF)

Output Voltage in Undervoltage (VCC = 7.0 V, I

Sink

= 1.0 mA)

LEADING EDGE BLANKING

Input Bias Current

Threshold (as Offset from VCC) (V

Hysteresis (V

Decreasing)

LEB

Increasing)

LEB

UNDERVOLTAGE LOCKOUT

Startup Threshold (VCC Increasing)

Minimum Operating Voltage After Turn–On (VCC Decreasing)

Hysteresis

TIMER

Watchdog Timer

Restart Timer Threshold

Restart Pin Output Current (V

restart

= 0 V, V

= 5.0 V)

ref

TOTAL DEVICE

Line Startup Current (VCC = 0 V, V

БББББББББББББББ

Line Operating Current (VCC = V

VCC Dynamic Operating Current (50 kHz, CL = 1.0 nF)

БББББББББББББББ

VCC Static Operating Current (IO = 0)

Line Pin Leakage (V

Line

= 500 V)

Line

th(on)

= 50 V)

, V

= 50 V) I

Line

R

OH

R

ÁÁÁ

OL

t

r

t

f

V

O(UV)

I

bias

V

LEB

V

H

V

th(on)

V

Shutdown

V

H

t

DLY

V

th(restart)

I

restart

I

SU

ÁÁÁ

OP

I

CC

ÁÁÁ

I

Line

4.0

4.0

ÁÁÁ

–

–

–

–

1.0

100

11.5

7.0

–

180

1.5

3.1

5.0

ÁÁÁ

8.6

7.2

ÁÁÁ

55

70

0.01

0.1

2.25

270

13

8.5

4.5

385

2.3

5.2

16

ÁÁÁ

20

20

ÁÁ

200

200

0.25

0.5

2.75

500

14.5

10

–

800

3.0

7.1

25

ÁÁ

3.0 12.9 20 mA

–

ÁÁÁ

–

–

5.3

ÁÁÁ

3.0

30

8.5

ÁÁ

–

80

Ω

ÁÁ

ns

ns

V

µA

V

mV

V

V

V

µs

V

mA

mA

ÁÁ

mA

ÁÁ

µA

4

MOTOROLA ANALOG IC DEVICE DATA

Page 5

MC33368

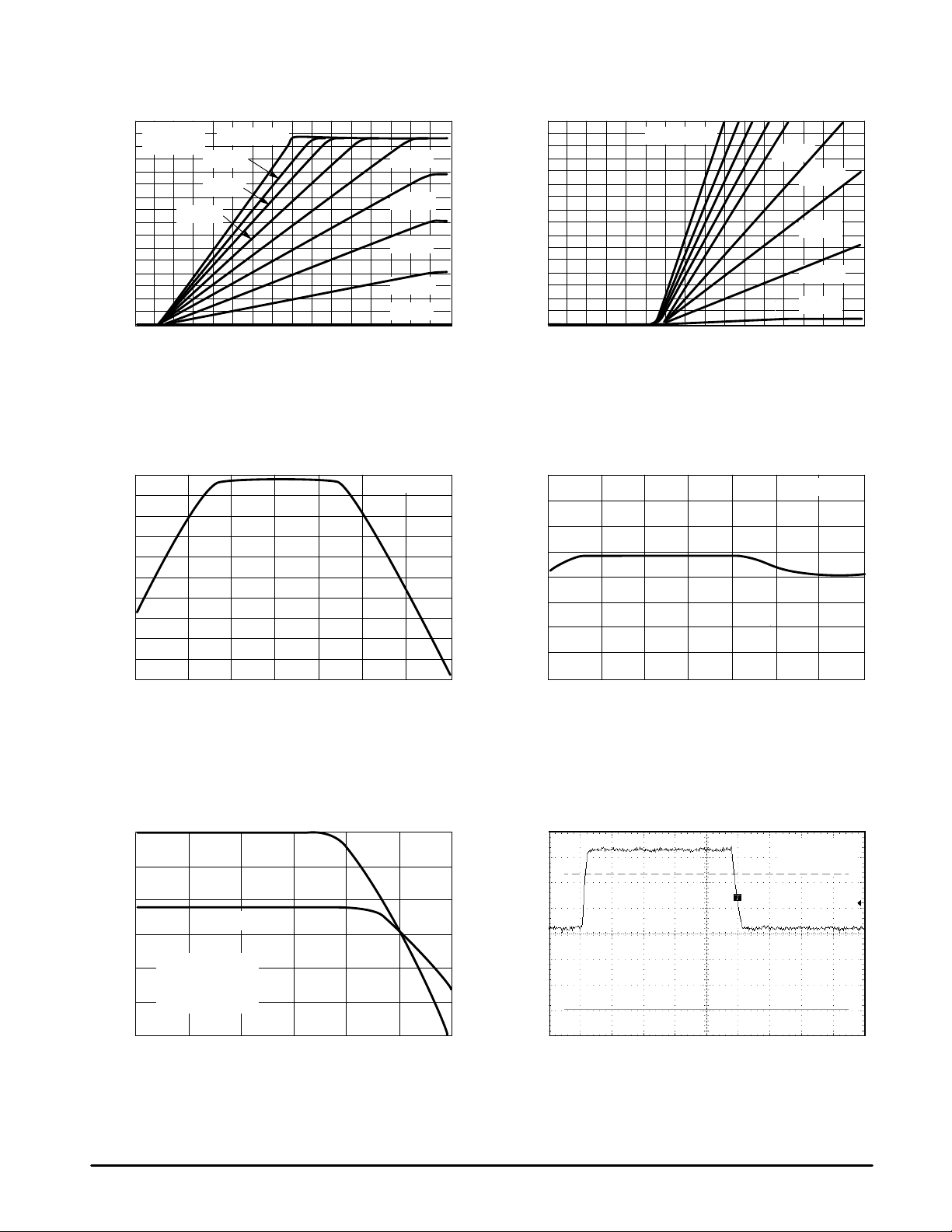

Figure 1. Current Sense Input Threshold

versus Multiplier Input

1.6

, CURRENT SENSE PIN 6 THRESHOLD (V)

V

CS

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

–0.2

VCC = 14 V

TA = 25

V

= 4.0 V

Pin 4

°

C

= 3.75 V

= 3.5 V

= 3.25 V

0.6 1.4 2.2 3.0 –0.06 0 0.06 0.12 0.20

VM, MULTIPLIER PIN 5 INPUT VOLTAGE (V)

Figure 3. Reference V oltage versus Temperature

16

12

= 3.0 V

= 2.75 V

= 2.5 V

= 2.25 V

= 2.0 V

VCC = 14 V

, CURRENT SENSE PIN 6 THRESHOLD (V)

0.08

0.07

0.06

0.05

0.04

0.03

0.02

0.01

CS

FB

Figure 2. Current Sense Input Threshold

versus Multiplier Input, Expanded View

V

= 4.0 V

Pin 4

0

–0.12

VM, MULTIPLIER PIN 5 INPUT VOLTAGE (V)

Figure 4. Overvoltage Comparator Input

Threshold versus T emperature

110

109

= 3.0 V

= 2.75 V

= 2.5 V

= 2.25 V

= 2.0 V

VCC = 14 V

8.0

4.0

CHANGE (mV)

0

, VOLTAGE FEEDBACK THRESHOLD

FB

V

∆

–4.0

–55

–25 0 25 50 75 125100 –25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

Figure 5. Error Amplifier Transconductance

and Phase versus Frequency

100

80

µ

60

40

20

, TRANSCONDUCTANCE ( mho)

0

m

g

–20

10

Transconductance

VCC = 14 V

VO = 2.0 to 4.0 V

Ω

RL = 10 k

TA = 25°C

100 1.0 k 10 k 100 k 1.0 M 10 M

f, FREQUENCY (Hz)

Phase

108

107

, OVERVOL TAGE INPUT THRESHOLD (% V ) V

106

–55

FB(OV)

V

Figure 6. Error Amplifier Transient Response

0

30

60

90

120

150

180

6.0 V

4.0 V

2.0 V

0 V

, EXCESS PHASE (DEGREES)

θ

–1.0 V

TA, AMBIENT TEMPERATURE (

5.0 µs/DIV

°

C)

VCC = 14 V

TA = 25

°

C

MOTOROLA ANALOG IC DEVICE DATA

5

Page 6

MC33368

1.80

1.76

1.72

1.68

, QUICKSTAR T CHARGE VOLTAGE (V)

chg

V

1.64

–55

20

15

10

Figure 7. Quickstart Charge Current

versus T emperature

VCC = 14 V

Voltage

Current

–25 0 25 50 75 100 125 –25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

1.50

1.30

1.10

0.90

0.70

µ

, WATCHDOG TIME DELAY ( s)

t

, QUICKSTAR T CHARGE CURRENT (mA)

chg

I

500

460

420

380

DLY

340

–55

Figure 8. Watchdog Timer Delay

versus T emperature

VCC = 14 V

TA, AMBIENT TEMPERATURE (°C)

Figure 10. Supply Current versus

Figure 9. Drive Output Waveform

VCC = 14 V

CL = 1000 pF

TA = 25

6.0

Pulse tested with a 4.0 V peak, 50 kHz square

°

C

wave through a 22 k resistance into Pin 7.

4.0

Supply V oltage

5.0

OUTPUT VOLTAGE (V)

–5.0

1000

°

100

, THERMAL RESISTANCE

JA(t)

JUNCTION–TO–AIR ( C/W)

θ

R

0

5.0 µs/DIV

Figure 11. Transient Thermal Resistance

10

0.01

0.1 1.0 10 100

t, TIME (s)

CO = 1000 pF

Pin 3, 6, 8= Gnd

2.0

, SUPPLY CURRENT (mA)

Pin 5 = 1.0 k to Gnd

CC

TA = 25

I

0

2.0

400

200

0

OUTPUT VOLTAGE (V)

°

C

4.0 6.0 8.0 10 12 14

VCC, SUPPLY VOLTAGE (V)

Figure 12. Low Load Detection

Response Waveform

Output

Voltage

Load

Current

200 ms/DIV

3.0

2.0

1.0

OUTPUT CURRENT (A)

0

6

MOTOROLA ANALOG IC DEVICE DATA

Page 7

MC33368

FUNCTIONAL DESCRIPTION

INTRODUCTION

With the goal of exceeding the requirements of legislation

on line current harmonic content, there is an ever increasing

demand for an economical method of obtaining a unity power

factor. This data sheet describes a monolithic control IC that

was specifically designed for power factor control with

minimal external components. It offers the designer a simple

cost effective solution to obtain the benefits of active power

factor correction.

Most electronic ballasts and switching power supplies use

a bridge rectifier and a bulk storage capacitor to derive raw dc

voltage from the utility ac line, Figure 13.

Figure 13. Uncorrected Power Factor Circuit

Converter

Load

AC

Line

Rectifiers

Bulk

Storage

Capacitor

This simple rectifying circuit draws power from the line

when the instantaneous ac voltage exceeds the capacitor

voltage. This occurs near the line voltage peak and results in

a high charge current spike, Figure 14. Since power is only

taken near the line voltage peaks, the resulting spikes of

current are extremely nonsinusoidal with a high content of

harmonics. This results in a poor power factor condition

where the apparent input power is much higher than the real

power. Power factor ratios of 0.5 to 0.7 are common.

Figure 14. Uncorrected Power Factor Input Waveforms

V

pk

Rectified

DC

0

AC Line

Voltage

0

AC Line

Current

Line Sag

Power factor correction can be achieved with the use of

either a passive or active input circuit. Passive circuits

usually contain a combination of large capacitors, inductors,

and rectifiers that operate at the ac line frequency. Active

circuits incorporate some form of a high frequency switching

converter for the power processing with the boost converter

being the most popular topology. Since active input circuits

operate at a frequency much higher than that of the ac line,

they are smaller, lighter in weight, and more efficient than a

passive circuit that yields similar results. With proper control

of the preconverter, almost any complex load can be made to

appear resistive to the ac line, thus significantly reducing the

harmonic current content.

Operating Description

The MC33368 contains many of the building blocks and

protection features that are employed in modern high

performance current mode power supply controllers.

Referring to the block diagram in Figure 15, note that a

multiplier has been added to the current sense loop and that

this device does not contain an oscillator. A description of

each of the functional blocks is given below.

Error Amplifier

An Error Amplifier with access to the inverting input and

output is provided. The amplifier is a transconductance type,

meaning that it has high output impedance with controlled

voltage–to–current gain (gm 50 µmhos). The noninverting

input is internally biased at 5.0 V ±2.0%. The output voltage

of the power factor converter is typically divided down and

monitored by the inverting input. The maximum input bias

current is –1.0 µA which can cause an output voltage error

that is equal to the product of the input bias current and the

value of the upper divider resistor R2. The Error Amplifier

output is internally connected to the Multiplier and is pinned

out (Pin 4) for external loop compensation. Typically, the

bandwidth is set below 20 Hz so that the amplifier’s output

voltage is relatively constant over a given ac line cycle. In

effect, the error amplifier monitors the average output voltage

of the converter over several line cycles resulting in a fixed

Drive Output on–time. The amplifier output stage can sink

and source 11.5 µA of current and is capable of swinging

from 1.7 to 5.0 V, assuring that the Multiplier can be driven

over its entire dynamic range.

Note that by using a transconductance type amplifier, the

input is allowed to move independently with respect to the

output, since the compensation capacitor is connected to

ground. This allows dual usage of the Voltage Feedback pin

by the Error Amplifier and Overvoltage Comparator.

Overvoltage Comparator

An Overvoltage Comparator is incorporated to eliminate

the possibility of runaway output voltage. This condition can

occur during initial startup, sudden load removal, or during

output arcing and is the result of the low bandwidth that must

be used in the Error Amplifier control loop. The Overvoltage

Comparator monitors the peak output voltage of the

converter, and when exceeded, immediately terminates

MOSFET switching. The comparator threshold is internally

set to 1.08 V

. In order to prevent false tripping during

ref

normal operation, the value of the output filter capacitor C3

must be large enough to keep the peak–to–peak ripple less

than 16% of the average dc output.

MOTOROLA ANALOG IC DEVICE DATA

7

Page 8

MC33368

Multiplier

A single quadrant, two input multiplier is the critical

element that enables this device to control power factor. The

ac haversines are monitored at Pin 5 with respect to ground

while the Error Amplifier output at Pin 4 is monitored with

respect to the Voltage Feedback Input threshold. A graph of

the Multiplier transfer curve is shown in Figure 1. Note that

both inputs are extremely linear over a wide dynamic range,

0 to 3.2 V for Pin 5 and 2.5 to 4.0 V for Pin 4. The Multiplier

output controls the Current Sense Comparator threshold as

the ac voltage traverses sinusoidally from zero to peak line.

This has the effect of forcing the MOSFET on–time to track

the input line voltage, thus making the preconverter load

appear to be resistive.

Pin 6 Threshold[0.55

Zero Current Detector

The MC33368 operates as a critical conduction current

mode controller, whereby output switch conduction is

initiated by the Zero Current Detector and terminated when

the peak inductor current reaches the threshold level

established by the Multiplier output. The Zero Current

Detector initiates the next on–time by setting the RS Latch at

the instant the inductor current reaches zero. This critical

conduction mode of operation has two significant benefits.

First, since the MOSFET cannot turn–on until the inductor

current reaches zero, the output rectifier’s reverse recovery

time becomes less critical allowing the use of an inexpensive

rectifier. Second, since there are no deadtime gaps between

cycles, the ac line current is continuous thus limiting the peak

switch to twice the average input current

The Zero Current Detector indirectly senses the inductor

current by monitoring when the auxiliary winding voltage falls

below 1.2 V . To prevent false tripping, 200 mV of hysteresis is

provided. The Zero Current Detector input is internally

protected by two clamps. The upper 10 V clamp prevents

input overvoltage breakdown while the lower –0.7 V clamp

prevents substrate injection. An external resistor must be

used in series with the auxiliary winding to limit the current

through the clamps to 5.0 mA or less.

Current Sense Comparator and RS Latch

The Current Sense Comparator RS Latch configuration

used ensures that only a single pulse appears at the Drive

Output during a given cycle. The inductor current is

converted to a voltage by inserting a ground–referenced

sense resistor R7 in series with the source of output switch.

This voltage is monitored by the Current Sense Input and

compared to a level derived from the Multiplier output. The

peak inductor current under normal operating conditions is

controlled by the threshold voltage of Pin 6 where:

Ipk+

Abnormal operating conditions occur when the

preconverter is running at extremely low line or if output

voltage sensing is lost. Under these conditions, the Current

Sense Comparator threshold will be internally clamped to

1.5 V. Therefore, the maximum peak switch current is:

I

pk(max)

ǒ

V

Pin 4–VPin 3

Pin 6 Threshold

R7

1.5 V

+

R7

Ǔ

V

Pin 5

With the component values shown in Figure 15, the

Current Sense Comparator threshold, at the peak of the

haversine, varies from 110 mV at 90 Vac to 100 mV at

268 Vac. The Current Sense Input to Drive Output

propagation delay is typically 200 ns.

Timer

A watchdog timer function was added to the IC to

eliminate the need for an external oscillator when used in

stand alone applications. The Timer provides a means to

automatically start or restart the preconverter if the Drive

Output has been off for more than 385 µs after the inductor

current reaches zero.

Undervoltage Lockout and Quickstart

The MC33368 has a 5.0 V internal reference brought out

to Pin 1 and capable of sourcing 10 mA typically. It also

contains an Undervoltage Lockout (UVLO) circuit which

suppresses the Gate output at Pin 11 if the VCC supply

voltage drops below 8.5 V typical.

A Quickstart circuit has been incorporated to optimize

converter startup. During initial startup, compensation

capacitor C1 will be discharged, holding the Error Amplifier

output below the Multiplier’s threshold. This will prevent Drive

Output switching and delay bootstraping of capacitor C4 by

diode D6. If Pin 4 does not reach the multiplier threshold

before C4 discharges below the lower SMPS UVLO

threshold, the converter will hiccup and experience a

significant startup delay . The Quickstart circuit is designed to

precharge C1 to 1.7 V. This level is slightly below the Pin 4

Multiplier threshold, allowing immediate Drive Output

switching.

Restart Delay

A restart delay pin is provided to allow hiccup mode fault

protection in case of a short circuit condition and to prevent

the SMPS from repeatedly trying to restart after the input line

voltage has been removed. When power is first applied, there

is no startup delay , but subsequent cycling of the VCC voltage

will result in delay times that are programmed by an external

resistor and capacitor. The Restart Delay, Pin 2, is a high

impedance, so that an external capacitor can provide delay

times as long as several seconds.

If the SMPS output is short circuited, the transformer

winding, which provides the VCC voltage to the control IC and

the MC33368, will be unable to sustain VCC to the control

circuits. The restart delay capacitor at Pin 2 of the MC33368

prevents the high voltage startup transistor within the IC from

maintaining the voltage on C4. After VCC drops below the

UVLO threshold in the SMPS, the SMPS switching

transistors are held off for the time programmed by the values

of the restart capacitor (C9) and resistor (R8). In this manner,

the SMPS switching transistors are operated at very low duty

cyles, preventing their destruction. If the short circuit fault is

removed, the power supply system will turn on by itself in a

normal startup mode after the restart delay has timed out.

8

MOTOROLA ANALOG IC DEVICE DATA

Page 9

MC33368

Output Switching Frequency Clamp

In normal operation, the MC33368 operates the boost

inductor in the critical mode. That is, the inductor current

ramps to a peak value, ramps down to zero, then immediately

begins ramping positive again. The peak current is

programmed by the multiplier output within the IC. As the

input voltage haversine declines to near zero, the output

switch on–time becomes constant, rather than going to zero

because of the small integrated dc voltage at Pin 5 caused by

C2, R3 and R5. Because of this, the average line current

does not exactly follow the line voltage near the zero

crossings. The Output Switching Frequency Clamp remedies

this situation to improve power factor and minimize EMI

generated in this operating region. The values of R10 and

C7, as shown in Figure 15, program a minimum off–time in

the frequency clamp which overrides the zero current detect

signal, forcing a minimum off–time. This allows discontinuous

conduction operation of the boost inductor in the zero

crossing region, and the average line current more nearly

follows the voltage. The Output Switching Frequency Clamp

function can be disabled by connecting the FC input, Pin 13,

to the VCC supply Pin 12.

For best results, the minimum off–time, determined by

the values of R10 and C7, should be chosen so that

t

= t

s(min)

voltage at the frequency clamp input is less than 2.0 V . When

the output drive is high, C7 is discharged through an internal

100 µA current source. When the output drive switches low,

C7 is charged through R10. The drive output is inhibited until

the voltage across C7 reaches 2.0 V, establishing a minimim

off–time where:

t

Output

The IC contains a CMOS output driver that was

specifically designed for direct drive of power MOSFET s. The

Gate Output is capable of up to ±1500 mA peak current with

a typical rise and fall time of 50 ns with a 1.0 nF load.

Additional internal circuitry has been added to keep the Gate

Output in a sinking mode whenever the Undervoltage

Lockout is active. This characteristic eliminates the need for

an external gate pull–down resistor. The totem–pole output

has been optimized to minimize cross–conduction current

during high speed operation.

(on)

(off)fc

+ t

(off)fc

+*

. Output drive is inhibited when the

R10 C7 log

1

ƪ

e

*

2

ǒ

Ǔ

ƫ

V

CC

MOTOROLA ANALOG IC DEVICE DATA

9

Page 10

MC33368

T able 1. Design Equations

Calculation Formula Notes

Converter Output Power

Peak Indicator Current

Inductance

LP+

Switch On–Time

Switch Off–Time

Minimum Switch

Off–Time

Delay Time

Switching Frequency

Peak Switch Current

Multiplier Input Voltage

Converter Output

Voltage

Converter Output

Peak–to–Peak

Ripple Voltage

Error Amplifier

Bandwidth

NOTE:The following converter characteristics must be chosen:

VO = Desired output voltage. Vac

IO = Desired output current. ∆VO = Converter output peak–to–peak ripple voltage.

Vac = AC RMS operating line voltage.

D

V

O(pp)

t

td+

VO+

PO+

I

L(pk)

V

O

ǒ

t

Ǹ

2

t

(on)

+

(off)

Ǹ

t

(off)

min

–R10C7ln

f

+

VM+

V

ref

+

I

L(pk)

BW

VOI

O

Ǹ

P

22

O

h

Vac

(LL)

Vac

–1

Ǔ

(LL)

Ǔ

2

)

2

ESR

Ǔ

h

(LL)

2

VOP

O

2POL

P

2

h

Vac

t

(on)

O

Ť

q

LPI

L(pk)

V

O

VCC–2

ǒ

V

CC

1

)

t

(off)

V

CS

I

L(pk)

Ǹ

Vac 2

R5

Ǔ

)

1

R3

Ǔ

–IIBR1

)

1

1

2pfacC3

g

m

2pC1

= AC RMS minimum required operating line voltage for output regulation.

–Vac

+

2

t

R7

Ǹ

+

Ǹ

V

VacŤSin

+

(on)

+

ǒ

R2

ǒ

R1

ǒ

+

(LL)

Calculate the maximum required output power.

Calculated at the minimum required ac line voltage for

output regulation. Let the efficiency η = 0.92 for low line

operation.

Let the switching cycle t = 40 µs for universal input (85 to

265 Vac) operation and 20 µs for fixed input (92 to

138 Vac, or 184 to 276 Vac) operation.

In theory, the on–time t

tends to increase at the ac line zero crossings due to the

charge on capacitor C5. Let Vac = Vac

and t

The off–time t

voltage and approaches zero at the ac line zero crossings.

Theta (θ) represents the angle of the ac line voltage.

The off–time is at a minimum at ac line crossings. This

equation is used to calculate t

zero.

The delay time is used to override the minimum off–time at

the ac line zero crossings by programming the Frequency

Clamp with C7 and R10.

The minimum switching frequency occurs at the peak of

the ac line voltage. As the ac line voltage traverses from

peak to zero, t

in switching frequency.

Set the current sense threshold VCS to 1.0 V for universal

input (85 to 265 Vac) operation and to 0.5 V for fixed input

(92 to 138 Vac, or 184 to 276 Vac) operation. Note that V

must be less than 1.4 V.

Set the mulltiplier input voltage VM to 3.0 V at high line.

Empirically adjust VM for the lowest distortion over the ac

line voltage range while guaranteeing startup at minimum

line.

The IIB R1 error term can be minimized with a divider

current in excess of 100 µA.

The calculated peak–to–peak ripple must be less than 16%

of the average dc output voltage to prevent false tripping of

2

the Overvoltage Comparator. Refer to the Overvoltage

Comparator Text. ESR is the equivalent series resistance

of C3.

The bandwidth is typically set to 20 Hz. When operating at

high ac line, the value of C1 may need to be increased.

calculations.

(off)

(off)

(off)

is constant. In practice, t

(on)

for initial t

(LL)

is greatest at the peak of the ac line

as Theta approaches

(off)

approaches zero producing an increase

(on)

(on)

CS

10

MOTOROLA ANALOG IC DEVICE DATA

Page 11

MC33368

Figure 15. 80 W Power Factor Controller

92 to

270 Vrms

330

R5

1.3 M

R3

20 k

R8

10 k

C9

µ

1N4006

D2 D4

V

F

EMI

Filter

ref

D1 D3

V

ref

RD

2

AGnd

8

1.5 V

Load Detect

Mult

5

Multiplier

C2

0.01

T: Coilcraft N2881–A

Primary = 62 turns of #22 AWG

Secondary = 5 turns of #22 AWG

Core = Coilcraft PT2510, EE25

Gap = 0.072

″

total for a primary inductance (Lp) of 320

C5

1.0

MC33368

15 V

Q

Timer R

RS Latch

R

R

S

S

Q

S

Set Dominant

Overvoltage

Comparator

Low

1.08 x V

ref

Quickstart

Reference

Comp FB

C1

0.68

V

ref

C6

0.1

Zero

Current

Detect

Leading Edge

5.0 V

V

µ

H

UVLO

1.2/1.0

Frequency

Clamp

Blanking

ref

16

Line

V

CC

12

13/8.0

7

ZCD

Gate

11

PGnd

10

13

FC

9

LEB

6

CS

314

Not Used: D7, C8, R6, R9

1N4744

15 V

D8

R4

22 k

To V

Pin 12

R13

C4

100

51

R11

10

CC

R10

10

C7

10 pF

D6

1N4934

Q1

T

320

µ

H

MUR130

D5

C3

220

MTP8N50E

R7

0.1

0.25 W

V

O

R2

470 k

R1

10 k

AC Line Input

V

Pin PF I

rms

90 79.7 0.999 0.89 0.5 0.15 0.09 0.06 0.09 3.0 244.4 0.31 76.01 95.4

100 79.3 0.998 0.79 0.5 0.14 0.09 0.08 0.10 3.0 242.9 0.31 75.54 95.3

110 78.9 0.997 0.72 0.5 0.16 0.13 0.08 0.10 3.0 242.9 0.31 75.30 95.4

120 78.5 0.996 0.66 0.5 0.15 0.12 0.08 0.13 3.0 243.0 0.31 75.57 96.3

130 78.1 0.994 0.60 0.5 0.14 0.12 0.07 0.14 3.0 243.0 0.31 75.57 96.7

138 77.8 0.991 0.57 0.5 0.15 0.14 0.08 0.14 3.0 243.0 0.31 75.57 97.1

Heatsink = AAVID Engineering Inc., 590302B03600, or 593002B03400

fund

MOTOROLA ANALOG IC DEVICE DATA

Power Factor Controller Test Data

Current Harmonic Distortion (% I

THD2357V

)

fund

O(pp)VOIOPO

DC Output

n(%)

11

Page 12

MC33368

Figure 16. 175 W Universal Input Power Factor Controller

92 to

270 Vrms

1.0 M

R5

1.3 M

R3

10 k

R8

C9

2.2

EMI

Filter

V

ref

D2 D4

RD

2

AGnd

8

Mult

5

C2

0.01

1N5406

D1 D3

V

ref

1.5 V

Multiplier

C5

1.0

MC33368

15 V

Timer R

Q

RS Latch

R

R

S

S

Q

S

Set Dominant

Overvoltage

Comparator

Low

Load Detect

Not Used: D7, C7, C8, R6, R9, R10

1.08 x V

ref

Quickstart

Reference

Comp FB

C1

2.2

V

ref

C6

0.1

Zero

Current

Detect

Leading Edge

5.0 V

V

ref

UVLO

Frequency

Clamp

Blanking

16

1.2/1.0

Line

13/8.0

314

6.9 V

R13

D8

V

1N4744

CC

12

7

15 V

ZCD

Gate

11

PGnd

10

13

FC

LEB

CS

R4

22 k

To V

Pin 12

9

6

T: Coilcraft N2880–A

L = 870 µHy

Primary: 78 turns of #16 AWG

Secondary: 6 turns of #18 AWG

Core: Coilcraft PT4215, EE42–15

Gap: 0.104

″

51

C4

100

CC

total

R11

10

D6

1N4934

Q1

T

MUR460

D5

MTW20N50E

R7

0.1

C3

330

V

O

R2

820 k

R1

10 k

12

Power Factor Controller Test Data

AC Line Input

Current Harmonic Distortion (% I

V

Pin PF I

rms

90 190.4 0.995 2.11 5.8 0.16 0.32 0.24 0.80 3.6 398.0 0.44 175.9 92.4

120 192.1 0.997 1.60 3.2 0.08 0.17 0.07 0.30 3.6 398.9 0.44 177.1 92.2

138 192.7 0.997 1.40 0.9 0.08 0.24 0.03 0.15 3.6 402.3 0.45 179.0 92.9

180 194.3 0.995 1.08 0.9 0.04 0.18 0.04 0.08 3.6 409.1 0.45 182.9 94.1

240 189.3 0.983 0.80 0.7 0.08 0.21 0.08 0.06 3.6 407.0 0.45 181.1 95.7

268 186.3 0.972 0.71 0.6 0.11 0.32 0.10 0.10 3.6 406.2 0.44 180.4 96.8

Heatsink = AAVID Engineering Inc., 590302B03600

THD2357V

fund

)

fund

O(pp)VOIOPO

DC Output

MOTOROLA ANALOG IC DEVICE DATA

n(%)

Page 13

MC33368

Figure 17. Power Factor Test Setup

2X Step–up

Isolation

Autoformer

Line

115 Vrms

Input

Neutral

An RFI filter is required for best performance when connecting the preconverter directly to the ac line. The filter attenuates the level of high

frequency switching that appears on the ac line current waveform. Figures 15 and 16 work well with commercially available two stage filters such

as the Delta Electronics 03DPCG6. Shown above is a single stage test filter that can easily be constructed with four ac line rated capacitors and

a common–mode transformer. Coilcraft CMT3–28–2 was used to test Figures 15 and 16. It has a minimum inductance of 28 mH and a maximum

current rating of 2.0 A. Coilcraft CMT4–17–9 was used to test Figure 19. It has a minimum inductance of 17 mH and a maximum current rating of

9.0 A. Circuit conversion efficiency η (%) was calculated without the power loss of the RFI filter.

Transformer

AC Power

Analyzer

PM 1000

10

WVAPFV

VDAcf Ainst Freq HARM

HI HI

rmsArms

A V

L.O. L.O.

Voltech

Figure 18. On/Off Control

EMI Filter

T

0.1 1.0

0 to 270 Vac

Output to

Power Factor

Correction

Circuit

270 Vrms

1N4148

On/Off

Input

5.0 V Off

0 V On

92 to

10 k

330

R5

1.3 M

R3

10 k

EMI

Filter

R8

C9

µ

F

V

ref

AGnd

C2

0.01

D2 D4

D1 D3

V

ref

RD

2

8

1.5 V

Mult

5

Multiplier

C5

1.0

MC33368

15 V

Timer R

Q

RS Latch

R

R

S

S

Q

S

Set Dominant

Overvoltage

Comparator

Low

Load Detect

1.08 x V

ref

Quickstart

Reference

Comp FB

C1

22

1.0 k

V

ref

C6

0.1

1.0 k

Zero

Current

Detect

Leading Edge

5.0 V

V

ref

UVLO

Frequency

Clamp

Blanking

2N3904

V

CC

16

1.2/1.0

10 k

Line

13/8.0

314

6.9 V

V

CC

12

7

ZCD

Gate

11

PGnd

10

13

FC

9

LEB

6

CS

D8

15 V

R4

22 k

R13

C4

100

51

R11

10

D6

T

Q1

D5

C3

330

MTW14N50E

R2

820 k

R7

0.1

R1

10 k

DC

Out

MOTOROLA ANALOG IC DEVICE DATA

13

Page 14

MC33368

Figure 19. 400 W Power Factor Controller

92 to

270 Vac

R5

1.3 M

R3

10.5 k

1.0 M

330

EMI

Filter

V

R8

C9

µ

F

D2 D4

D1 D3

ref

RD

AGnd

Mult

C2

0.01

2

8

5

1N5406

V

ref

1.5 V

Multiplier

C5

1.0

MC33368

15 V

Timer R

Q

RS Latch

R

R

S

S

Q

S

Set Dominant

Overvoltage

Comparator

Low

Load Detect

1.08 x V

ref

Quickstart

Reference

Comp FB

C1

1.0

V

ref

C6

0.1

Zero

Current

Detect

Leading Edge

5.0 V

V

ref

UVLO

Frequency

Clamp

Blanking

16

1.2/1.0

Line

13/8.0

314

1.5 V

1N4744

V

CC

12

7

ZCD

Gate

11

PGnd

10

13

FC

9

LEB

6

CS

D8

15 V

C4

100

R4

22 k

V

ref

C8

0.001

R13

51

R11

10

R10

10 k

C7

470 pF

R9

10

D6

1N4934

T

Q1

MUR460

D5

C3

330

MTW20N50E

R2

820 k

R7

0.1

R1

10 k

400 V

14

MOTOROLA ANALOG IC DEVICE DATA

Page 15

MC33368

Figure 20. Printed Circuit Board and Component Layout

(Circuits of Figures 15 and 16)

DC Output

R2

C9

C7

R10

J = Jumper

D7

R1

D3

C6

R3

C2

R5

C1

R8

J

IC1

R4

R11

C8

J

R13

J

R9

C3

R6

D6

D1

D2 D4

R7

J

Q1

DGS

D5

(Top View)

4.5

AC Input

C5

C4

Transformer

D8

″

3.0

MC33368

″

(Bottom View)

MOTOROLA ANALOG IC DEVICE DATA

15

Page 16

–A–

916

B

18

F

C

S

–T–

H

G

D

16 PL

0.25 (0.010) T

K

M

-A-

16

9

SM

B

-B-

P

0.25 (0.010)

18

G

C

-T-

K

D 14 PL

0.25 (0.010)

T

AB

SM S

MC33368

OUTLINE DIMENSIONS

P SUFFIX

PLASTIC PACKAGE

CASE 648–08

(DIP–16)

ISSUE R

L

SEATING

PLANE

J

M

A

D SUFFIX

PLASTIC PACKAGE

CASE 751K–01

(SO–16)

ISSUE O

_

R X 45

SEATING

PLANE

J

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. ROUNDED CORNERS OPTIONAL.

DIM MIN MAX MIN MAX

A 0.740 0.770 18.80 19.55

B 0.250 0.270 6.35 6.85

C 0.145 0.175 3.69 4.44

D 0.015 0.021 0.39 0.53

F 0.040 0.70 1.02 1.77

M

_

M

F

G 0.100 BSC 2.54 BSC

H 0.050 BSC 1.27 BSC

J 0.008 0.015 0.21 0.38

K 0.110 0.130 2.80 3.30

L 0.295 0.305 7.50 7.74

M 0 10 0 10

S 0.020 0.040 0.51 1.01

NOTES:

1 DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2 CONTROLLING DIMENSION: MILLIMETER.

3 DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4 MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5 DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL IN

EXCESS OF THE D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

DIMAMIN MAX MIN MAX

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

MILLIMETERSINCHES

____

MILLIMETERS

9.80 10.00 0.368 0.393

____

INCHES

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

Mfax is a trademark of Motorola, Inc.

How to reach us:

USA/EUROPE/ Locations Not Listed: Motorola Literature Distribution; JAP AN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 5405, Denver, Colorado 80217. 303–675–2140 or 1–800–441–2447 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 81–3–3521–8315

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://www.mot.com/SPS/ 51 Ting Kok Road, Tai Po, N.T ., Hong Kong. 852–26629298

16

◊

MOTOROLA ANALOG IC DEVICE DATA

MC33368/D

Loading...

Loading...