Page 1

Order this document by MC33362/D

The MC33362 is a monolithic high voltage switching regulator that is

specifically designed to operate from a rectified 120 VAC line source. This

integrated circuit features an on–chip 500 V/2.0 A SenseFET power switch,

250 V active off–line startup FET, duty cycle controlled oscillator, current

limiting comparator with a programmable threshold and leading edge

blanking, latching pulse width modulator for double pulse suppression, high

gain error amplifier, and a trimmed internal bandgap reference. Protective

features include cycle–by–cycle current limiting, input undervoltage lockout

with hysteresis, output overvoltage protection, and thermal shutdown. This

device is available in a 16–lead dual–in–line and wide body surface mount

packages.

• On–Chip 500 V, 2.0 A SenseFET Power Switch

• Rectified 120 V AC Line Source Operation

• On–Chip 250 V Active Off–Line Startup FET

• Latching PWM for Double Pulse Suppression

• Cycle–By–Cycle Current Limiting

• Input Undervoltage Lockout with Hysteresis

• Output Overvoltage Protection Comparator

• Trimmed Internal Bandgap Reference

• Internal Thermal Shutdown

Simplified Application

HIGH VOLTAGE

OFF–LINE

SWITCHING REGULATOR

SEMICONDUCTOR

TECHNICAL DATA

16

1

DW SUFFIX

PLASTIC PACKAGE

CASE 751N

(SOP–16L)

16

1

P SUFFIX

PLASTIC PACKAGE

CASE 648E

(DIP–16)

AC Input

Startup Input

Regulator

Output

8

6

R

T

C

7

T

Mirror

Reg

Osc

PWM

Thermal

Gnd 4, 5, 12, 13

This device contains 221 active transistors.

Startup

PWM Latch

S

Q

R

I

pk

Driver

EA

MOTOROLA ANALOG IC DEVICE DATA

LEB

1

UVLO

OVP

V

CC

3

Overvoltage

Protection

Input

11

16

Power Switch

Drain

Compensation

9

10

Voltage

Feedback

Input

DC Output

PIN CONNECTIONS

Startup Input

V

CC

Gnd

R

T

C

T

Regulator Output

116

3

4

5

6

7

8

(Top View)

Power Switch

Drain

13

Gnd

12

Overvoltage

11

Protection Input

Voltage Feedback

10

Input

Compensation

9

ORDERING INFORMATION

Operating

Device

MC33362DW

MC33362P DIP–16

Motorola, Inc. 1999 Rev 3

Temperature Range

TJ = –25° to +125°C

Package

SOP–16L

1

Page 2

MAXIMUM RATINGS

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Rating Symbol Value Unit

Power Switch (Pin 16)

Drain Voltage

ББББББББББББ

Drain Current

Startup Input Voltage (Pin 1, Note 1)

ББББББББББББ

Pin 3 = Gnd

Pin 3 ≤ 1000 µF to ground

ББББББББББББ

Power Supply Voltage (Pin 3)

Input Voltage Range

Voltage Feedback Input (Pin 10)

ББББББББББББ

Compensation (Pin 9)

Overvoltage Protection Input (Pin 11)

ББББББББББББ

RT (Pin 6)

ББББББББББББ

CT (Pin 7)

Thermal Characteristics

P Suffix, Dual–In–Line Case 648E

ББББББББББББ

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case

ББББББББББББ

(Pins 4, 5, 12, 13)

DW Suffix, Surface Mount Case 751N

Thermal Resistance, Junction–to–Air

ББББББББББББ

Thermal Resistance, Junction–to–Case

ББББББББББББ

(Pins 4, 5, 12, 13)

Refer to Figures 15 and 16 for additional thermal

ББББББББББББ

information.

Operating Junction Temperature

Storage Temperature

NOTE: ESD data available upon request.

MC33362

V

DS

ÁÁ

I

DS

V

in

ÁÁ

ÁÁ

V

CC

V

IR

ÁÁ

ÁÁ

ÁÁ

ÁÁ

R

θJA

R

ÁÁ

θJC

R

ÁÁ

θJA

R

θJC

ÁÁ

ÁÁ

T

J

T

stg

500

ÁÁÁ

2.0

ÁÁÁ

250

400

ÁÁÁ

40

–1.0 to V

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

reg

80

15

95

15

– 25 to +150

– 55 to +150

V

Á

A

V

Á

Á

V

V

Á

Á

Á

°C/W

Á

Á

Á

Á

Á

°C

°C

ELECTRICAL CHARACTERISTICS (V

= 20 V, RT = 10 k, CT = 390 pF, C

CC

= 1.0 µF, for typical values TJ = 25°C,

Pin 8

for min/max values TJ is the operating junction temperature range that applies (Note 2), unless otherwise noted.)

Characteristic

Symbol Min Typ Max Unit

REGULAT OR (Pin 8)

Output Voltage (IO = 0 mA, TJ = 25°C)

БББББББББББББББББ

Line Regulation (VCC = 20 V to 40 V)

БББББББББББББББББ

Load Regulation (IO = 0 mA to 10 mA)

БББББББББББББББББ

Total Output Variation over Line, Load, and Temperature

БББББББББББББББББ

OSCILLAT OR (Pin 7)

ББББББББББББББББББББББББББББББББ

Frequency

БББББББББББББББББ

CT = 390 pF

TJ = 25°C (VCC = 20 V)

БББББББББББББББББ

TJ = T

БББББББББББББББББ

CT = 2.0 nF

TJ = 25°C (VCC = 20 V)

БББББББББББББББББ

TJ = T

low

low

to T

to T

(VCC = 20 V to 40 V)

high

(VCC = 20 V to 40 V)

high

Frequency Change with Voltage (VCC = 20 V to 40 V)

V

reg

ÁÁÁ

Reg

line

ÁÁÁ

Reg

load

ÁÁÁ

V

reg

ÁÁÁ

f

OSC

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

∆f

/∆V

OSC

5.5

ÁÁ

–

ÁÁ

–

ÁÁ

5.3

ÁÁ

ÁÁ

260

ÁÁ

255

ÁÁ

60

ÁÁ

59

–

6.5

ÁÁ

30

ÁÁ

44

ÁÁ

–

ÁÁ

ÁÁ

285

ÁÁ

–

ÁÁ

67.5

ÁÁ

–

0.1

7.5

ÁÁ

500

ÁÁ

200

ÁÁ

8.0

ÁÁ

ÁÁ

310

ÁÁ

315

ÁÁ

75

ÁÁ

76

2.0

ERROR AMPLIFIER (Pins 9, 10)

Voltage Feedback Input Threshold

Line Regulation (VCC = 20 V to 40 V, TJ = 25°C)

Input Bias Current (VFB = 2.6 V)

Open Loop Voltage Gain (TJ= 25°C)

Gain Bandwidth Product (f = 100 kHz, TJ= 25°C)

NOTES: 1. Maximum power dissipation limits must be observed.

2.Tested junction temperature range for the MC33362:

T

= –25°CT

low

2

high

= +125°C

V

Reg

A

GBW

FB

line

I

IB

VOL

2.52

–

–

–

–

2.6

0.6

20

82

1.0

2.68

5.0

500

–

–

MOTOROLA ANALOG IC DEVICE DATA

V

ÁÁ

mV

ÁÁ

mV

ÁÁ

V

ÁÁ

kHz

ÁÁ

ÁÁ

ÁÁ

ÁÁ

kHz

V

mV

nA

dB

MHz

Page 3

MC33362

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

ELECTRICAL CHARACTERISTICS (continued) (V

= 20 V, RT = 10 k, CT = 390 pF, C

CC

= 1.0 µF, for typical values TJ = 25°C,

Pin 8

for min/max values TJ is the operating junction temperature range that applies (Note 2), unless otherwise noted.)

Characteristic UnitMaxTypMinSymbol

ERROR AMPLIFIER (Pins 9, 10)

Output Voltage Swing

High State (I

БББББББББББББББББ

Low State (I

= 100 µA, VFB < 2.0 V)

Source

= 100 µA, V

Sink

> 3.0 V)

FB

V

OH

ÁÁÁ

V

OL

4.0

ÁÁ

–

5.3

ÁÁ

0.2

–

ÁÁ

0.35

V

ÁÁ

OVERVOLTAGE DETECTION (Pin 11)

Input Threshold Voltage

Input Bias Current (Vin = 2.6 V)

V

th

I

IB

2.47

–

2.6

100

2.73

500

V

nA

PWM COMPARATOR (Pins 7, 9)

Duty Cycle

Maximum (VFB = 0 V)

БББББББББББББББББ

Minimum (VFB = 2.7 V)

DC

(max)

ÁÁÁ

DC

(min)

48

ÁÁ

–

50

ÁÁ

0

52

ÁÁ

0

%

ÁÁ

POWER SWITCH (Pin 16)

Drain–Source On–State Resistance (ID = 200 mA)

БББББББББББББББББ

TJ = 25°C

TJ = T

БББББББББББББББББ

Drain–Source Off–State Leakage Current (VDS = 500 V)

БББББББББББББББББ

Rise Time

БББББББББББББББББ

Fall Time

БББББББББББББББББ

OVERCURRENT COMPARATOR (Pin 16)

ББББББББББББББББББББББББББББББББ

Current Limit Threshold (RT = 10 k)

БББББББББББББББББ

low

to T

high

R

DS(on)

ÁÁÁ

ÁÁÁ

I

D(off)

ÁÁÁ

t

r

ÁÁÁ

t

f

ÁÁÁ

I

lim

ÁÁÁ

ÁÁ

–

–

ÁÁ

–

ÁÁ

–

ÁÁ

–

ÁÁ

0.7

ÁÁ

ÁÁ

4.4

–

ÁÁ

0.2

ÁÁ

50

ÁÁ

50

ÁÁ

0.9

ÁÁ

ÁÁ

6.0

12

ÁÁ

50

ÁÁ

–

ÁÁ

–

ÁÁ

1.1

ÁÁ

Ω

ÁÁ

ÁÁ

µA

ÁÁ

ns

ÁÁ

ns

ÁÁ

A

ÁÁ

STARTUP CONTROL (Pin 1)

Peak Startup Current (Vin = 200 V)

БББББББББББББББББ

VCC = 0 V

VCC = (V

БББББББББББББББББ

th(on)

– 0.2 V)

Off–State Leakage Current (Vin = 50 V, VCC = 20 V)

I

start

ÁÁÁ

ÁÁÁ

I

D(off)

ÁÁ

–

–

ÁÁ

–

ÁÁ

55

26

ÁÁ

40

ÁÁ

–

–

ÁÁ

200

mA

ÁÁ

ÁÁ

µA

UNDERVOLTAGE LOCKOUT (Pin 3)

Startup Threshold (VCC Increasing)

Minimum Operating Voltage After Turn–On

V

th(on)

V

CC(min)

11

7.5

14.5

9.5

18

11.5

V

V

TOTAL DEVICE (Pin 3)

Power Supply Current

БББББББББББББББББ

Startup (V

Operating

БББББББББББББББББ

= 10 V, Pin 1 Open)

CC

I

CC

ÁÁÁ

ÁÁÁ

ÁÁ

–

–

ÁÁ

ÁÁ

0.3

3.6

ÁÁ

ÁÁ

0.5

5.0

ÁÁ

mA

ÁÁ

ÁÁ

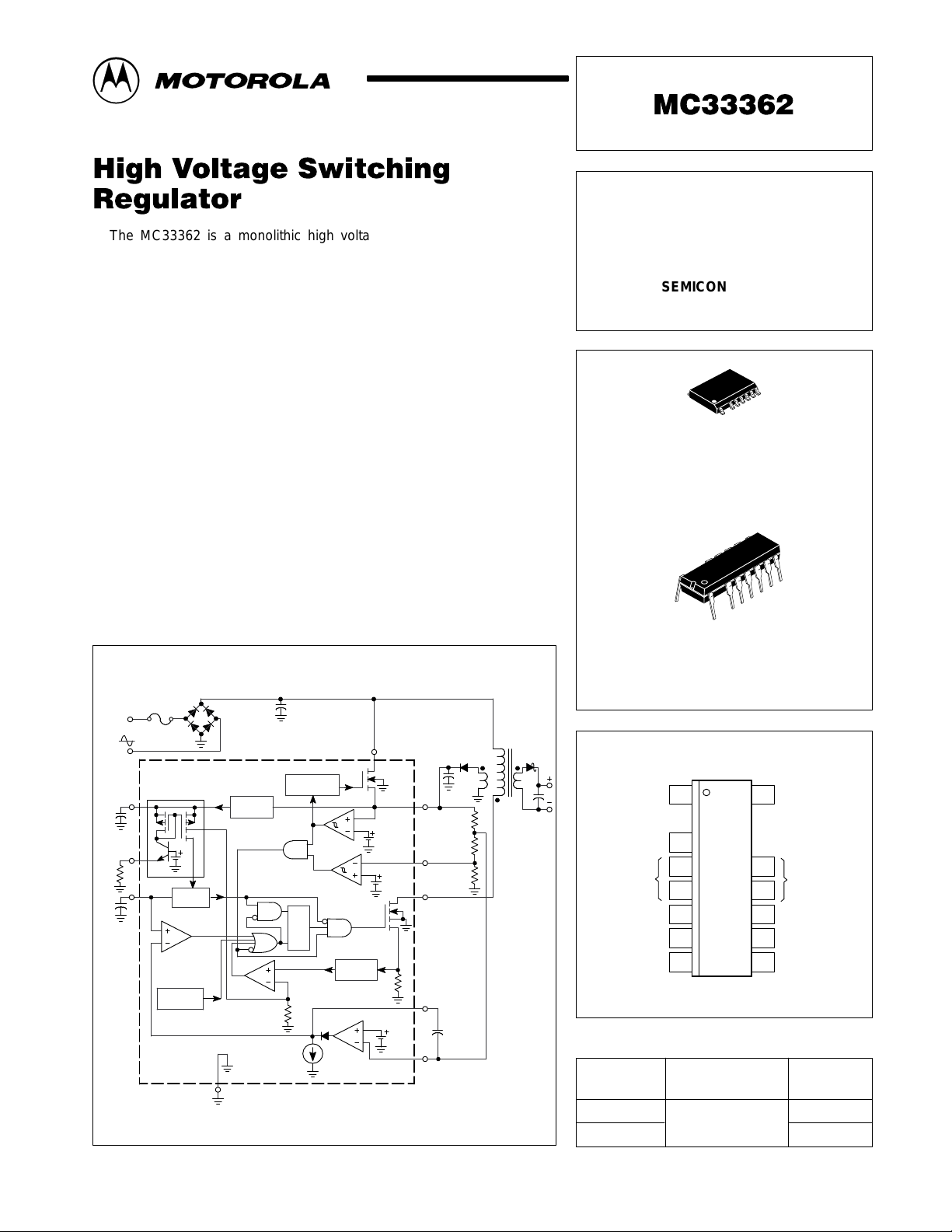

Figure 1. Oscillator Frequency

versus Timing Resistor

1.0 M

CT = 200 pF

500 k

CT = 500 pF

200 k

CT = 1.0 nF

100 k

CT = 2.0 nF

50 k

CT = 5.0 nF

, OSCILLAT OR FREQUENCY (Hz)

20 k

OSC

CT = 10 nF

f

10 k

5.0

10 15 20 30 50 7.0 10 15 20 30 40 50

RT, TIMING RESISTOR (kΩ)

MOTOROLA ANALOG IC DEVICE DATA

CT = 100 pF

VCC = 20 V

°

C

TA = 25

Figure 2. Power Switch Peak Drain Current

versus Timing Resistor

2.0

1.5

1.0

0.8

0.6

0.4

Inductor supply voltage and inductance value are

adjusted so that Ipk turn–off is achieved at 5.0

, POWER SWITCH PEAK DRAIN CURRENT (A)

0.2

PK

5.0

I

RT, TIMING RESISTOR (kΩ)

µ

s.

VCC = 20 V

µ

CT = 1.0

°

C

TA = 25

3

F

Page 4

MC33362

, OSCILLAT OR

dscg

/I

chg

I

1.0

0.7

0.5

0.3

0.2

0.15

CHARGE/DISCHARGE CURRENT (mA)

0.1

100

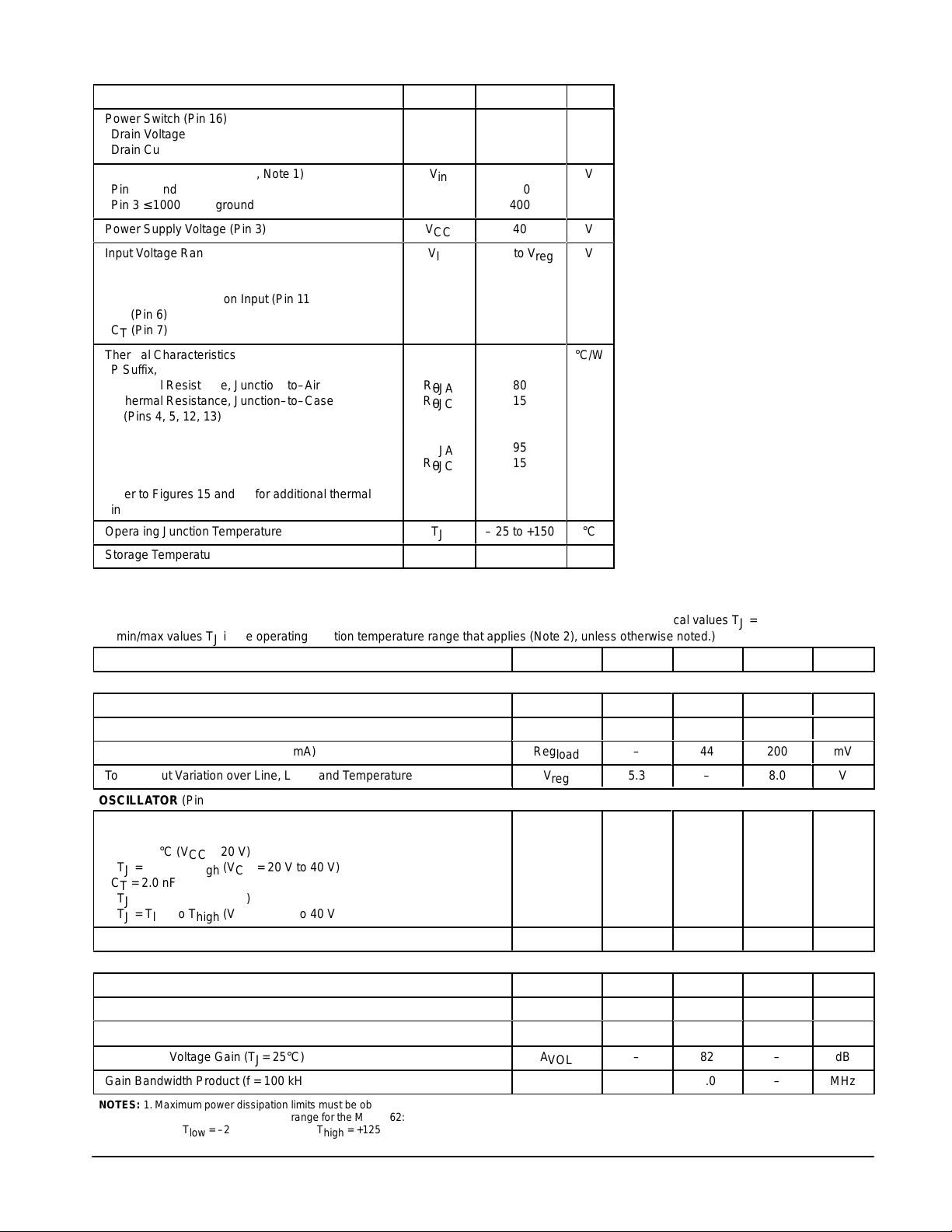

Figure 3. Oscillator Charge/Discharge

Current versus Timing Resistor

5.0

10 15 20 30 50 2.0 3.0 5.0 7.0 10

RT, TIMING RESISTOR (kΩ)

Figure 5. Error Amp Open Loop Gain and

Phase versus Frequency

80

Gain

60

Phase

40

VCC = 20 V

°

C

TA = 25

VCC = 20 V

VO = 1.0 to 4.0 V

RL = 5.0 M

CL = 2.0 pF

TA = 25

Ω

°

C

0

30

60

90

70

60

50

40

, MAXIMUM OUTPUT DUTY CYCLE (%)

max

D

30

1.0

0

–1.0

– 2.0

Figure 4. Maximum Output Duty Cycle

versus Timing Resistor Ratio

RD/RT Ratio

Discharge Resistor

Pin 6 to Gnd

TIMING RESISTOR RA TIO

VCC = 20 V

CT = 2.0 nF

TA = 25

RC/RT Ratio

Charge Resistor

Pin 6 to V

Figure 6. Error Amp Output Saturation

V oltage versus Load Current

Source Saturation)

(Load to Ground)

V

ref

reg

°

C

20

, OPEN LOOP VOL TAGE GAIN (dB)

0

VOL

A

–20

10

Figure 7. Error Amplifier Small Signal

1.80 V

1.75 V

1.70 V

, OUTPUT SA TURATION VOLTAGE (V)

V

sat

2.0

1.0

Sink Saturation

(Load to V

0

0

IO, OUTPUT LOAD CURRENT (mA)

ref

)

Gnd

VCC = 20 V

°

C

TA = 25

120

, EXCESS PHASE (DEGREES)

θ

150

100 1.0 k 10 k 100 k 1.0 M 10 M 0.2 0.4 0.6 0.8 1.0

f, FREQUENCY (Hz)

180

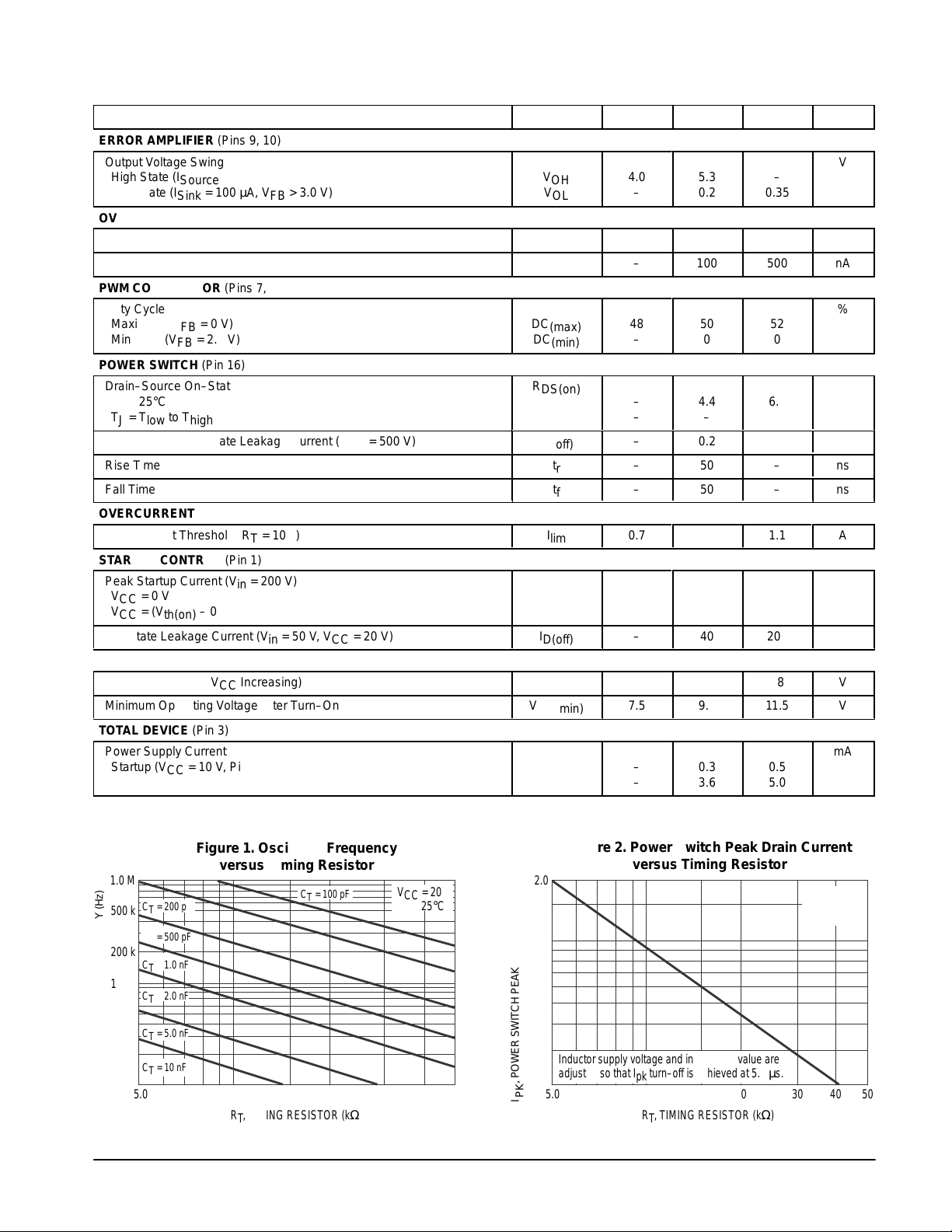

Figure 8. Error Amplifier Large Signal

Transient Response

1.0 µs/DIV

VCC = 20 V

AV = –1.0

CL = 10 pF

°

C

TA = 25

3.00 V

1.75 V

20 mV/DIV

0.50 V

Transient Response

1.0 µs/DIV

VCC = 20 V

AV = –1.0

CL = 10 pF

°

C

TA = 25

0.5 V/DIV

4

MOTOROLA ANALOG IC DEVICE DATA

Page 5

MC33362

Figure 9. Regulator Output Voltage

Change versus Source Current

0

–20

–40

–60

, REGULAT OR VOLTAGE CHANGE (mV)

reg

V

–80

∆

0

4.0 8.0 12 16 20 2.0 4.0 6.0 8.0 10 12 14

I

reg

Figure 11. Power Switch Drain–Source

Ω

10

8.0

On–Resistance versus T emperature

ID = 200 mA

VCC = 20 V

RT = 10 k

C

= 1.0

PIN 8

°

C

TA = 25

, REGULAT OR SOURCE CURRENT (mA)

Figure 10. Peak Startup Current

versus Power Supply V oltage

60

µ

F

40

20

Pulse tested with an on–time of 20 µs to 300 µs

, PEAK STARTUP CURRENT (mA)

at < 1.0% duty cycle. The on–time is adjusted at

pk

Pin 1 for a maximum peak current out of Pin 3.

I

0

0

VCC, POWER SUPPLY VOLTAGE (V)

V

Pin 1

TA = 25

= 200 V

°

C

Figure 12. Power Switch

Drain–Source Capacitance versus V oltage

200

150

VCC = 20 V

°

C

TA = 25

6.0

4.0

2.0

, DRAIN–SOURCE ON–RESISTANCE ( )

0

DS(on)

R

–50

–25 0 25 50 75 150100 5.0 50 500

Pulse tested at 5.0 ms with < 1.0% duty cycle

so that TJ is as close to TA as possible.

TA, AMBIENT TEMPERATURE (°C)

Figure 13. Supply Current versus Supply V oltage

4.0

CT = 390 pF

3.2

CT = 2.0 nF

2.4

1.6

, SUPPLY CURRENT (mA)

0.8

CC

I

0

0

10 20 30 40

VCC, SUPPLY VOLTAGE (V)

RT = 10 k

Pin 1 = Open

Pin 4, 5, 10, 11,

12, 13 = Gnd

TA = 25

125

°

C

100

50

, DRAIN–SOURCE CAPACITANCE (pF)

OSS

C

0

0.5

100

°

10

, THERMAL RESISTANCE

JA

JUNCTION–TO–AIR ( C/W)

θ

R

1.0

0.01

C

measured at 1.0 MHz with 50 mVpp.

OSS

VDS, DRAIN–SOURCE VOLTAGE (V)

Figure 14. DW and P Suffix Transient

Thermal Resistance

L = 12.7 mm of 2.0 oz.

copper. Refer to Figures

15 and 16.

0.1 1.0 10 100

t, TIME (s)

MOTOROLA ANALOG IC DEVICE DATA

5

Page 6

MC33362

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

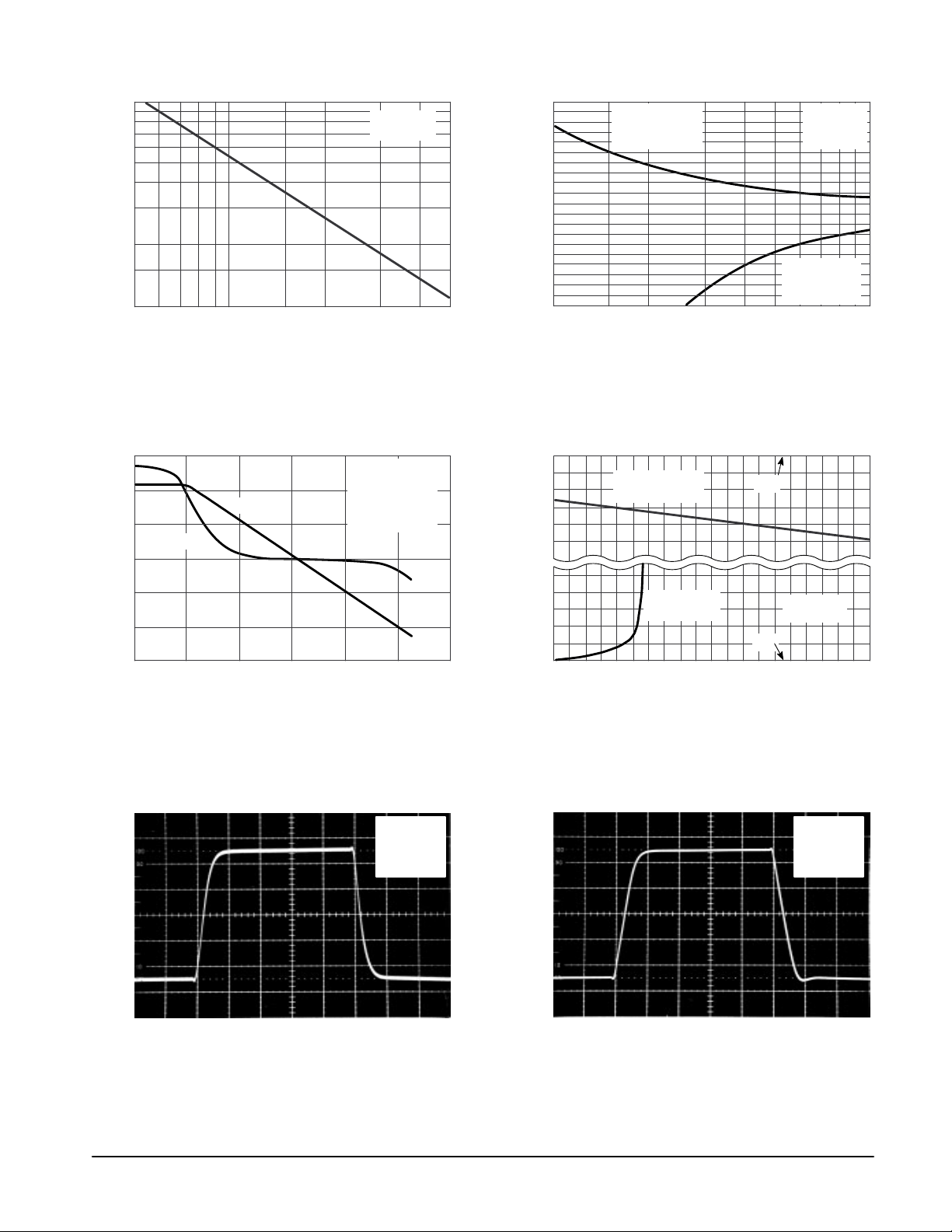

Figure 15. DW Suffix (SOP–16L) Thermal Resistance and

Maximum Power Dissipation versus P.C.B. Copper Length

3.0 mm

2.8

2.4

2.0

1.6

1.2

0.8

0.4

0

100

90

80

°

70

60

, THERMAL RESISTANCE

50

JA

JUNCTION–TO–AIR ( C/W)

θ

R

40

30

0

°

P

D(max)

for TA = 50

C

Printed circuit board heatsink example

2.0 oz

L

Copper

L

Graphs represent symmetrical layout

R

θ

JA

10 20 30 40 50

L, LENGTH OF COPPER (mm)

PIN FUNCTION DESCRIPTION

Pin Function Description

1

ÁÁÁ

ÁÁÁ

2

3

ÁÁÁ

ÁÁÁ

4, 5, 12, 13

6

ÁÁÁ

7

ÁÁÁ

8

9

ÁÁÁ

10

ÁÁÁ

11

ÁÁÁ

ÁÁÁ

14, 15

ÁÁÁ

16

ÁÁÁ

Startup Input

ÁÁÁÁ

ÁÁÁÁ

–

V

CC

ÁÁÁÁ

ÁÁÁÁ

Ground

R

T

ÁÁÁÁ

C

T

ÁÁÁÁ

Regulator Output

Compensation

ÁÁÁÁ

Voltage Feedback

Input

ÁÁÁÁ

Overvoltage

ÁÁÁÁ

Protection Input

ÁÁÁÁ

–

ÁÁÁÁ

Power Switch

Drain

ÁÁÁÁ

This pin connects directly to the rectified ac line voltage source. Internally Pin 1 is tied to the drain

БББББББББББББББББББББББ

of a high voltage startup MOSFET. During startup, the MOSFET supplies internal bias, and charges

an external capacitor that connects from the V

БББББББББББББББББББББББ

This pin has been omitted for increased spacing between the rectified AC line voltage on Pin 1 and

the VCC potential on Pin 3.

This is the positive supply voltage input. During startup, power is supplied to this input from Pin 1.

БББББББББББББББББББББББ

When VCC reaches the UVLO upper threshold, the startup MOSFET turns off and power is supplied

from an auxiliary transformer winding.

БББББББББББББББББББББББ

These pins are the control circuit grounds. They are part of the IC lead frame and provide a thermal

path from the die to the printed circuit board.

Resistor RT connects from this pin to ground. The value selected will program the Current Limit

БББББББББББББББББББББББ

Comparator threshold and affect the Oscillator frequency.

Capacitor C

programs the Oscillator frequency.

БББББББББББББББББББББББ

connects from this pin to ground. The value selected, in conjunction with resistor R

T

This 6.5 V output is available for biasing external circuitry. It requires an external bypass capacitor

of at least 1.0 µF for stability.

This pin is the Error Amplifier output and is made available for loop compensation. It can be used as

БББББББББББББББББББББББ

an input to directly control the PWM Comparator.

This is the inverting input of the Error Amplifier. It has a 2.6 V threshold and normally connects

through a resistor divider to the converter output, or to a voltage that represents the converter

БББББББББББББББББББББББ

output.

This input provides runaway output voltage protection due to an external component or connection

БББББББББББББББББББББББ

failure in the control loop feedback signal path. It has a 2.6 V threshold and normally connects

through a resistor divider to the converter output, or to a voltage that represents the converter

БББББББББББББББББББББББ

output.

These pins have been omitted for increased spacing between the high voltages present on the

БББББББББББББББББББББББ

Power Switch Drain, and the ground potential on Pins 12 and 13.

This pin is designed to directly drive the converter transformer and is capable of switching a

maximum of 500 V and 2.0 A.

БББББББББББББББББББББББ

Figure 16. P Suffix (DIP–16) Thermal Resistance and

Maximum Power Dissipation versus P.C.B. Copper Length

JA

θ

R , THERMAL RESIST ANCE

, MAXIMUM POWER DISSIPATION (W)

D

P

100

80

°

60

40

20

JUNCTION–TO–AIR ( C/W)

0

0

CC

R

θ

JA

P

for TA = 70°C

D(max)

10 20 30 40 50

L, LENGTH OF COPPER (mm)

pin to ground.

Printed circuit board heatsink example

2.0 oz

L

Copper

L

Graphs represent symmetrical layout

3.0 mm

5.0

4.0

3.0

2.0

1.0

0

,

T

, MAXIMUM POWER DISSIPATION (W)

D

P

6

MOTOROLA ANALOG IC DEVICE DATA

Page 7

AC Input

MC33362

Figure 17. Representative Block Diagram

Regulator Output

6.5 V

8

6

R

T

C

7

T

I

Current

Mirror

4 I

Oscillator

PWM

Comparator

Thermal

Shutdown

2.25 I

Band Gap

Regulator

PWM Latch

Current Limit

Comparator

4, 5, 12, 13Gnd

S

Q

R

450

270µA

Startup Input

Startup

Control

UVLO

OVP

Driver

Leading Edge

Blanking

Error

Amplifier

1

14.5 V/

9.5 V

2.6 V

2.6 V

V

CC

3

Overvoltage

Protection

Input

11

16

Power Switch

Drain

9.0

Compensation

9

10

Voltage

Feedback Input

DC Output

Capacitor C

Compensation

Oscillator Output

Power Switch

Leading Edge

Blanking Input

(Power Switch

Drain Current)

T

PWM

Comparator

Output

PWM Latch

Q Output

Gate Drive

Figure 18. Timing Diagram

2.6 V

0.6 V

Current Limit

Propagation

Delay

Current

Limit

Threshold

Normal PWM Operating Range Output Overload

MOTOROLA ANALOG IC DEVICE DATA

7

Page 8

MC33362

OPERA TING DESCRIPTION

Introduction

The MC33362 represents a new higher level of integration

by providing all the active high voltage power, control, and

protection circuitry required for implementation of a flyback or

forward converter on a single monolithic chip. This device is

designed for direct operation from a rectified 120 VAC line

source and requires a minimum number of external

components to implement a complete converter. A

description of each of the functional blocks is given below,

and the representative block and timing diagrams are shown

in Figures 17 and 18.

Oscillator and Current Mirror

The oscillator frequency is controlled by the values

selected for the timing components R

and CT. Resistor R

T

programs the oscillator charge/discharge current via the

Current Mirror 4 I output, Figure 3. Capacitor C

is charged

T

and discharged by an equal magnitude internal current

source and sink. This generates a symmetrical 50 percent

duty cycle waveform at Pin 7, with a peak and valley

threshold of 2.6 V and 0.6 V respectively. During the

discharge of C

, the oscillator generates an internal blanking

T

pulse that holds the inverting input of the AND gate Driver

high. This causes the Power Switch gate drive to be held in a

low state, thus producing a well controlled amount of output

deadtime. The amount of deadtime is relatively constant with

respect to the oscillator frequency when operating below

1.0 MHz. The maximum Power Switch duty cycle at Pin 16

can be modified from the internal 50% limit by providing an

additional charge or discharge current path to C

, Figure 19.

T

In order to increase the maximum duty cycle, a discharge

current resistor R

is connected from Pin 7 to ground. To

D

decrease the maximum duty cycle, a charge current resistor

R

is connected from Pin 7 to the Regulator Output. Figure 4

C

shows an obtainable range of maximum output duty cycle

versus the ratio of either R

or R

C

with respect to RT.

D

Figure 19. Maximum Duty Cycle Modification

Current

Regulator Output

1.0

R

C

R

T

C

R

D

T

8

6

7

Mirror

2.25 I

I

Current

Limit

Reference

4 I

Oscillator

Blanking

Pulse

The formula for the charge/discharge current along with

the oscillator frequency are given below. The frequency

formula is a first order approximation and is accurate for C

values greater than 500 pF. For smaller values of CT, refer to

Figure 1. Note that resistor R

also programs the Current

T

Limit Comparator threshold.

I

chgńdscg

+

5.4

R

T

f

I

[

chgńdscg

PWM Comparator and Latch

The pulse width modulator consists of a comparator with

the oscillator ramp voltage applied to the non–inverting input,

while the error amplifier output is applied into the inverting

T

input. The Oscillator applies a set pulse to the PWM Latch

while C

is discharging, and upon reaching the valley

T

voltage, Power Switch conduction is initiated. When C

charges to a voltage that exceeds the error amplifier output,

the PWM Latch is reset, thus terminating Power Switch

conduction for the duration of the oscillator ramp–up period.

This PWM Comparator/Latch combination prevents multiple

output pulses during a given oscillator clock cycle. The timing

diagram shown in Figure 18 illustrates the Power Switch duty

cycle behavior versus the Compensation voltage.

Current Limit Comparator and Power Switch

The MC33362 uses cycle–by–cycle current limiting as a

means of protecting the output switch transistor from

overstress. Each on–cycle is treated as a separate situation.

Current limiting is implemented by monitoring the output

switch current buildup during conduction, and upon sensing

an overcurrent condition, immediately turning off the switch

for the duration of the oscillator ramp–up period.

The Power Switch is constructed as a SenseFET allowing

a virtually lossless method of monitoring the drain current. It

consists of a total of 3770 cells, of which 50 are connected to

a 9.0 Ω ground–referenced sense resistor. The Current

Sense Comparator detects if the voltage across the sense

resistor exceeds the reference level that is present at the

inverting input. If exceeded, the comparator quickly resets

the PWM Latch, thus protecting the Power Switch. The

current limit reference level is generated by the 2.25 I output

of the Current Mirror. This current causes a reference voltage

to appear across the 450 Ω resistor. This voltage level, as

well as the Oscillator charge/discharge current are both set

by resistor R

. Therefore when selecting the values for R

T

and CT, RT must be chosen first to set the Power Switch peak

drain current, while C

is chosen second to set the desired

T

Oscillator frequency . A graph of the Power Switch peak drain

current versus R

is shown in Figure 2 with the related

T

formula below.

4C

T

T

T

T

R

– 1.1 15

T

ǒ

PWM

Comparator

Ipk+

8

12.3

MOTOROLA ANALOG IC DEVICE DATA

1000

Ǔ

Page 9

MC33362

The Power Switch is designed to directly drive the converter

transformer and is capable of switching a maximum of 500 V

and 2.0 A. Proper device voltage snubbing and heatsinking

are required for reliable operation.

A Leading Edge Blanking circuit was placed in the current

sensing signal path. This circuit prevents a premature reset

of the PWM Latch. The premature reset is generated each

time the Power Switch is driven into conduction. It appears as

a narrow voltage spike across the current sense resistor, and

is due to the MOSFET gate to source capacitance,

transformer interwinding capacitance, and output rectifier

recovery time. The Leading Edge Blanking circuit has a

dynamic behavior in that it masks the current signal until the

Power Switch turn–on transition is completed. The current

limit propagation delay time is typically 233 ns. This time is

measured from when an overcurrent appears at the Power

Switch drain, to the beginning of turn–off.

Error Amplifier

An fully compensated Error Amplifier with access to the

inverting input and output is provided for primary side voltage

sensing, Figure 17. It features a typical dc voltage gain of 82

dB, and a unity gain bandwidth of 1.0 MHz with 78 degrees of

phase margin, Figure 5. The noninverting input is internally

biased at 2.6 V ±3.1% and is not pinned out. The Error

Amplifier output is pinned out for external loop compensation

and as a means for directly driving the PWM Comparator.

The output was designed with a limited sink current capability

of 270 µA, allowing it to be easily overridden with a pull–up

resistor. This is desirable in applications that require

secondary side voltage sensing, Figure 20. In this

application, the Voltage Feedback Input is connected to the

Regulator Output. This disables the Error Amplifier by placing

its output into the sink state, allowing the optocoupler

transistor to directly control the PWM Comparator.

Overvoltage Protection

An Overvoltage Protection Comparator is included to

eliminate the possibility of runaway output voltage. This

condition can occur if the control loop feedback signal path is

broken due to an external component or connection failure.

The comparator is normally used to monitor the primary side

V

voltage. When the 2.6 V threshold is exceeded, it will

CC

immediately turn off the Power Switch, and protect the load

from a severe overvoltage condition. This input can also be

driven from external circuitry to inhibit converter operation.

Undervoltage Lockout

An Undervoltage Lockout comparator has been

incorporated to guarantee that the integrated circuit has

sufficient voltage to be fully functional before the output stage

is enabled. The UVLO comparator monitors the V

CC

voltage

at Pin 3 and when it exceeds 14.5 V, the reset signal is

removed from the PWM Latch allowing operation of the

Power Switch. T o prevent erratic switching as the threshold is

crossed, 5.0 V of hysteresis is provided.

Startup Control

An internal Startup Control circuit with a high voltage

enhancement mode MOSFET is included within the

MC33362. This circuitry allows for increased converter

efficiency by eliminating the external startup resistor, and its

associated power dissipation, commonly used in most

off–line converters that utilize a UC3842 type of controller.

Rectified ac line voltage is applied to the Startup Input, Pin 1.

This causes the MOSFET to enhance and supply internal

bias as well as charge current to the V

that connects from Pin 3 to ground. When V

bypass capacitor

CC

reaches the

CC

UVLO upper threshold of 14.5 V, the IC commences

operation and the startup MOSFET is turned off. Operating

bias is now derived from the auxiliary transformer winding,

and all of the device power is efficiently converted down from

the rectified ac line.

The startup MOSFET will provide an initial peak current of

55 mA, Figure 10, which decreases rapidly as V

and the

CC

die temperature rise. The steady state current will self limit in

the range of 12 mA with VCC shorted to ground. The startup

MOSFET is rated at a maximum of 250 V with V

ground, and 400 V when charging a V

shorted to

CC

capacitor of

CC

1000 µF or less.

Regulator

A low current 6.5 V regulated output is available for

biasing the Error Amplifier and any additional control system

circuitry. It is capable of up to 10 mA and has short–circuit

protection. This output requires an external bypass capacitor

of at least 1.0 µF for stability.

Thermal Shutdown and Package

Internal thermal circuitry is provided to protect the Power

Switch in the event that the maximum junction temperature is

exceeded. When activated, typically at 155°C, the Latch is

forced into a ‘reset’ state, disabling the Power Switch. The

Latch is allowed to ‘set’ when the Power Switch temperature

falls below 145°C. This feature is provided to prevent

catastrophic failures from accidental device overheating. It is

not intended to be used as a substitute for proper

heatsinking.

The MC33362 is contained in a heatsinkable plastic

dual–in–line package in which the die is mounted on a

special heat tab copper alloy lead frame. This tab consists of

the four center ground pins that are specifically designed to

improve thermal conduction from the die to the circuit board.

Figures 15 and 16 show a simple and effective method of

utilizing the printed circuit board medium as a heat dissipater

by soldering these pins to an adequate area of copper foil.

This permits the use of standard layout and mounting

practices while having the ability to halve the junction to air

thermal resistance. The examples are for a symmetrical

layout on a single–sided board with two ounce per square

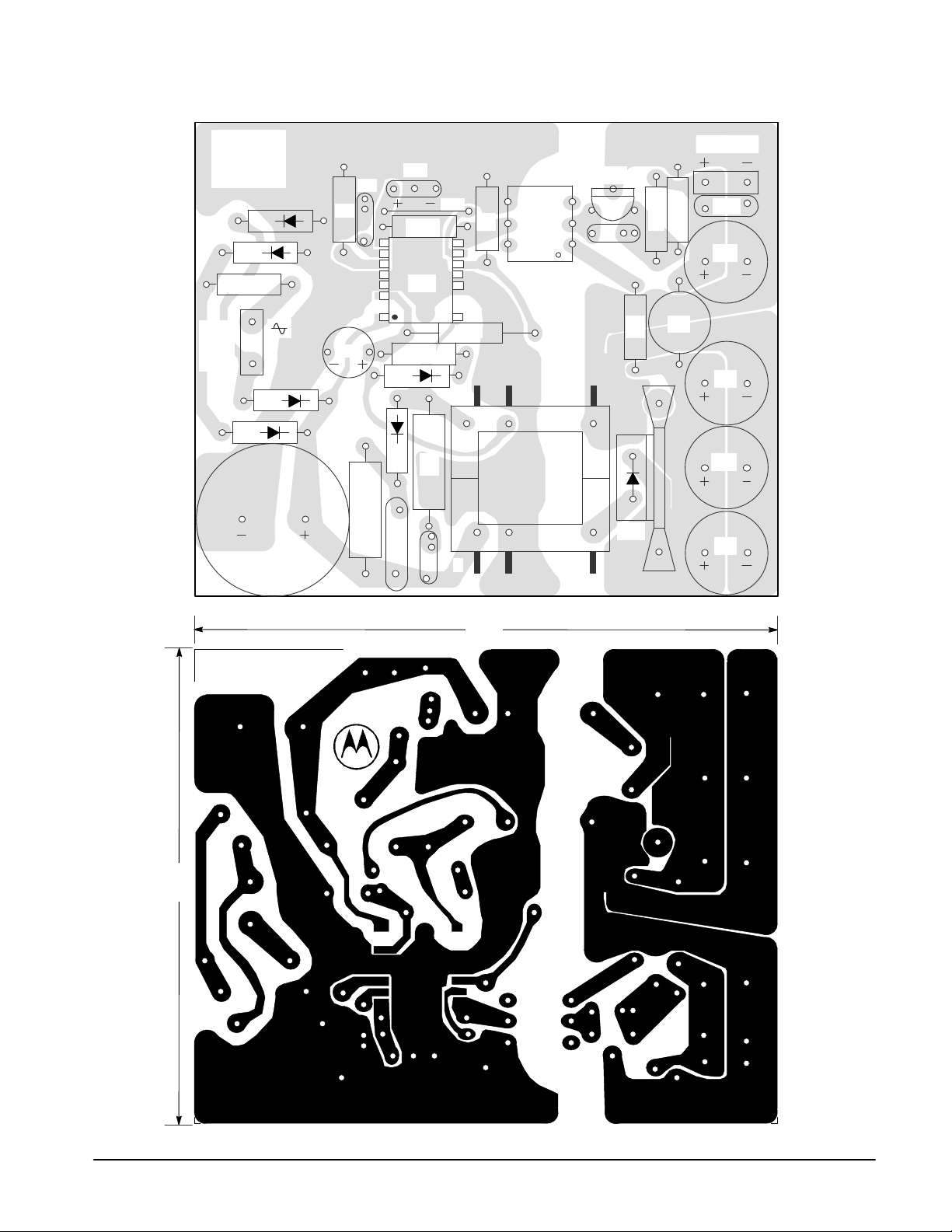

foot of copper. Figure 22 shows a practical example of a

printed circuit board layout that utilizes the copper foil as a

heat dissipater. Note that a jumper was added to the layout

from Pins 8 to 10 in order to enhance the copper area near

the device for improved thermal conductivity. The application

circuit requires two ounce copper foil in order to obtain

20 watts of continuous output power at room temperature.

MOTOROLA ANALOG IC DEVICE DATA

9

Page 10

MC33362

Figure 20. 20 W Off–Line Converter

92 to 138

Vac Input

C4

1.0

R1

8.2 k

C3

1.5 nF

F1

1.0 A

8

6

7

D4

D2

D3

D1

Mirror

Osc

PWM

Thermal

1N4004

Reg

PWM Latch

270µA

C1

47

S

R

Q

I

Limit

Startup

Driver

LEB

EA

1

UVLO

14.5 V/

9.5 V

OVP

2.6 V

2.6 V

C5

4.0 nF

3

11

16

9

10

100 k

1.0 W

MUR

160

C2

10

R4

16 k

R3

2.7 k

5

4

R2

2.7 k

R6

D5

R5

39

C6

47 pF

R7

2.2 k

1.0 W

D6

MUR

120

T1

D7

MBR

2515L

MOC

8103

C8

330

IC2

C9

C10

330

330

IC3

TL431B

1

2

3

2

L1

µ

5.0

R8

220

R9

2.80 k

C7

100 nF

1

R10

2.74 k

H

5.05 V/4.0 A

DC Output

C11

220

C12

1.0

4, 5, 12, 13

IC1 MC33362

Figure 21. Converter T est Data

Test Conditions Results

Line Regulation Vin = 92 Vac to 138 Vac, IO 4.0 A ∆ = 1.0 mV

Load Regulation Vin = 115 Vac, IO = 1.0 A to 4.0 A ∆ = 9.0 mV

Output Ripple Vin = 115 Vac, IO = 4.0 A Triangular = 10 mVpp

Spike = 60 mVpp

Efficiency Vin = 115 Vac, IO = 4.0 A 78.4%

This data was taken with the components listed below mounted on the printed circuit board shown in Figure 22.

For high efficiency and small circuit board size, the Sanyo Os–Con capacitors are recommended for C8, C9, C10 and C11.

C8, C9, C10 = Sanyo Os–Con #6SA330M, 330 µF 6.3 V.

C11 = Sanyo Os–Con #10SA220M, 220 µF 10 V.

D7 = MBR2515L mounted on Aavid #592502B03400 heatsink.

L1 = Coilcraft S5088–A, 5.0 µH, 0.11 Ω.

T1 = Coilcraft S5069–A

Primary: 58 turns of # 26 AWG, Pin 1 = start, Pin 8 = finish.

Two layers 0.002″ Mylar tape.

Secondary: 4 turns of # 18 AWG, 2 strands bifiliar wound, Pin 5 = start, Pin 4 = finish.

Two layers 0.002″ Mylar tape.

Auxiliary: 10 turns of # 26 AWG wound in center of bobbin, Pin 2 = start, Pin 7 = finish.

Two layers 0.002″ Mylar tape.

Gap: 0.014″ total for a primary inductance (LP) of 330 µH.

Core and Bobbin: Coilcraft PT1950, E187, 3F3 material.

10

MOTOROLA ANALOG IC DEVICE DATA

Page 11

MC33362

Figure 22. Printed Circuit Board and Component Layout

(Circuit of Figure 20)

Caution!

High

V oltages

AC

Line

Input

D2

F1

D4

D1

D3

C1

R1

C2

C3

R6

D6

D5

C5

C4

R2

IC1

R5

R7

C6

J1

DC Output

IC3

L1

R10

C12

C11

C10

C9

C8

R3

R3

R4

1

IC2

C7

T1

R9

R8

D7

MC33362

2.25”

(Top View)

2.75”

MOTOROLA ANALOG IC DEVICE DATA

(Bottom View)

11

Page 12

MC33362

OUTLINE DIMENSIONS

–A–

T

16 9

–B–

81

P

0.010 (0.25)

DW SUFFIX

PLASTIC PACKAGE

CASE 751N–01

(SOP–16L)

ISSUE O

M

M

B

J

D13X

0.010 (0.25) B

M

S

A

T

S

F

R

X 45

C

S

–T–

SEATING

PLANE

K

9X

G

M

P SUFFIX

PLASTIC PACKAGE

–A–

R

16 9

–B–

18

P

F

S

H

K

CASE 648E–01

(DIP–16)

ISSUE O

L

C

–T–

SEATING

PLANE

G

D

13 PL

0.25 (0.010) T

M

S

B

S

A

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 (0.005) TOTAL IN

EXCESS OF D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 10.15 10.45 0.400 0.411

B 7.40 7.60 0.292 0.299

C 2.35 2.65 0.093 0.104

D 0.35 0.49 0.014 0.019

_

M

J

F 0.50 0.90 0.020 0.035

G 1.27 BSC 0.050 BSC

J 0.25 0.32 0.010 0.012

K 0.10 0.25 0.004 0.009

M 0 7 0 7

____

P 10.05 10.55 0.395 0.415

R 0.25 0.75 0.010 0.029

S 2.54 BSC 0.100 BSC

T 3.81 BSC 0.150 BSC

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION A AND B DOES NOT INCLUDE MOLD

PROTRUSION.

5. MOLD FLASH OR PROTRUSIONS SHALL NOT

EXCEED 0.25 (0.010).

6. ROUNDED CORNER OPTIONAL.

DIM MIN MAX MIN MAX

A 0.740 0.760 18.80 19.30

B 0.245 0.260 6.23 6.60

C 0.145 0.175 3.69 4.44

D 0.015 0.021 0.39 0.53

F 0.050 0.070 1.27 1.77

G 0.100 BSC 2.54 BSC

H 0.050 BSC 1.27 BSC

J 0.008 0.015 0.21 0.38

K 0.120 0.140 3.05 3.55

L 0.295 0.305 7.50 7.74

M 0 10 0 10

____

P 0.200 BSC 5.08 BSC

R 0.300 BSC 7.62 BSC

S 0.015 0.035 0.39 0.88

INCHESMILLIMETERS

MILLIMETERSINCHES

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

Mfax is a trademark of Motorola, Inc.

How to reach us:

USA/EUROPE/ Locations Not Listed: Motorola Literature Distribution; JAPAN: Motorola Japan Ltd.; SPD, Strategic Planning Office, 141,

P.O. Box 5405, Denver, Colorado 80217. 1–303–675–2140 or 1–800–441–2447 4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan. 81–3–5487–8488

Customer Focus Center: 1–800–521–6274

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 1–602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; Silicon Harbour Centre,

Motorola Fax Back System – US & Canada ONLY 1–800–774–1848 2, Dai King Street, Tai Po Industrial Estate, Tai Po, N.T., Hong Kong.

– http://sps.motorola.com/mfax/ 852–26629298

HOME PAGE: http://motorola.com/sps/

12

◊

MOTOROLA ANALOG IC DEVICE DATA

MC33362/D

Loading...

Loading...