Page 1

Order this document by MC33340/D

The MC33340 is a monolithic control IC that is specifically designed as a

fast charge controller for Nickel Cadmium (NiCd) and Nickel Metal Hydride

(NiMH) batteries. This device features negative slope voltage detection as

the primary means for fast charge termination. Accurate detection is ensured

by an output that momentarily interrupts the charge current for precise

voltage sampling. An additional secondary backup termination method can

be selected that consists of either a programmable time or temperature limit.

Protective features include battery over and undervoltage detection, latched

over temperature detection, and power supply input undervoltage lockout

with hysteresis. Provisions for entering a rapid test mode are available to

enhance end product testing. This device is available in an economical

8–lead surface mount package.

• Negative Slope Voltage Detection with 4.0 mV Sensitivity

• Accurate Zero Current Battery Voltage Sensing

• High Noise Immunity with Synchronous VFC/Logic

• Programmable 1 to 4 Hour Fast Charge Time Limit

• Programmable Over/Under Temperature Detection

• Battery Over and Undervoltage Fast Charge Protection

• Rapid System Test Mode

• Power Supply Input Undervoltage Lockout with Hysteresis

• Operating Voltage Range of 3.0 V to 18 V

Simplified Block Diagram

BATTERY FAST CHARGE

CONTROLLER

SEMICONDUCTOR

TECHNICAL DATA

P SUFFIX

PLASTIC PACKAGE

8

1

8

1

CASE 626

D SUFFIX

PLASTIC PACKAGE

CASE 751

(SO–8)

DC

Input

∆

V Detect

Counter

Timer

Undervoltage

Lockout

Over

Under

t1

t2

t3

t/T

Time/

Temp

Select

4

R

Q

S

Regulator

Internal Bias

V

sen

1

V

sen

Gate

2

3

Fast/

Trickle

This device contains 2,512 active transistors.

This document contains information on a new product. Specifications and information herein

are subject to change without notice.

MOTOROLA ANALOG IC DEVICE DATA

Voltage to

Frequency

Converter

Ck F/V R

High

Battery

Detect

Low

V

Gate

F/T

–

sen

Gnd

V

Over

Temp

Latch

Temp

Detect

CC

8

V

CC

Battery

Pack

t1/T

High

ref

7

t2/T

sen

6

t3/T

Low

ref

5

V

CC

PIN CONNECTIONS

V

Input

sen

V

Gate Output

sen

Fast/Trickle Output

Gnd

1

2

3

4

(Top View)

8V

CC

t1/T

High

7

ref

6

t2/T

sen

5

t3/T

Low

ref

ORDERING INFORMATION

Operating

Device

MC33340D

MC33340P Plastic DIP

Motorola, Inc. 1996 Rev 0

Temperature Range

TA = –25° to +85°C

Package

SO–8

1

Page 2

MC33340

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage (Pin 8) V

CC

Input Voltage Range V

Time/Temperature Select (Pins 5, 6, 7) V

Battery Sense, Note 1 (Pin 1) V

V

Gate Output (Pin 2)

sen

Voltage

Current

IR(t/T)

IR(sen)

V

O(gate)

I

O(gate)

Fast/Trickle Output (Pin 3)

Voltage

Current

Thermal Resistance, Junction–to–Air R

V

O(F/T)

I

O(F/T)

θJA

P Suffix, DIP Plastic Package, Case 626 100

D Suffix, SO–8 Plastic Package, Case 751 178

Operating Junction Temperature T

Operating Ambient Temperature (Note 2) T

Storage Temperature T

NOTE: ESD data available upon request.

J

A

stg

18 V

–1.0 to V

CC

–1.0 to VCC + 0.6

or

–1.0 to 10

20

50

20

50

+150 °C

–25 to +85 °C

–55 to +150 °C

V

mA

V

mA

°C/W

ELECTRICAL CHARACTERISTICS (V

= 6.0 V, for typical values TA = 25°C, for min/max values TA is the operating

CC

ambient temperature range that applies (Note 2), unless otherwise noted.)

Characteristic

BATTERY SENSE INPUT (Pin 1)

Input Sensitivity for –∆V Detection

Overvoltage Threshold

БББББББББББББББББ

Undervoltage Threshold

Input Bias Current

Input Resistance

TIME/TEMPERA TURE INPUTS (Pins 5, 6, 7)

Programing Inputs (Vin = 1.5 V)

БББББББББББББББББ

Input Current

Input Current Matching

БББББББББББББББББ

Input Offset Voltage, Over and Under Temperature Comparators

Under Temperature Comparator Hysteresis (Pin 5)

Temperature Select Threshold

INTERNAL TIMING

Internal Clock Oscillator Frequency

V

Gate Output (Pin 2)

sen

Gate Time

БББББББББББББББББ

Gate Repetition Rate

Fast Charge Holdoff from –∆V Detection

V

GATE OUTPUT (Pin 2)

sen

Off–State Leakage Current (VO = 20 V)

Low State Saturation Voltage (I

sink

= 10 mA)

FAST/TRICKLE OUTPUT (Pin 3)

Off–State Leakage Current (VO = 20 V)

Low State Saturation Voltage (I

NOTES: 1. Whichever voltage is lower.

2.Tested junction temperature range for the MC33340:

T

= –25°C T

low

high

= 10 mA)

sink

= +85°C

Symbol Min Typ Max Unit

–∆V

th

V

th(OV)

ÁÁÁ

V

th(UV)

I

IB

R

in

I

in

ÁÁÁ

∆I

in

ÁÁÁ

V

IO

V

H(T)

V

th(t/T)

f

OSC

t

gate

ÁÁÁ

t

hold

I

off

V

OL

I

off

V

OL

–

1.9

Á

0.95

–

–

Á

–24

–

Á

–

–

–

–

–

Á

–

–

–

–

–

–

–4.0

2.0

ÁÁÁ

1.0

10

6.0

ÁÁÁ

–30

1.0

ÁÁÁ

5.0

44

VCC –0.7

760

33

ÁÁÁ

1.38

177

10

1.2

10

1.0

2.1

Á

1.05

Á

–36

2.0

Á

Á

–

–

–

–

–

–

–

–

–

–

–

–

–

–

ÁÁ

ÁÁ

ÁÁ

ÁÁ

mV

V

mV

nA

MΩ

µA

%

mV

mV

mV

kHz

ms

s

s

nA

V

nA

V

2

MOTOROLA ANALOG IC DEVICE DATA

Page 3

MC33340

Á

Á

Á

Á

Á

Á

ELECTRICAL CHARACTERISTICS (continued) (V

= 6.0 V, for typical values TA = 25°C, for min/max values TA is the operating

CC

ambient temperature range that applies (Note 2), unless otherwise noted.)

Characteristic UnitMaxTypMinSymbol

UNDERVOLTAGE LOCKOUT (Pin 8)

Start–Up Threshold (VCC Increasing, TA = 25°C)

Turn–Off Threshold (VCC Decreasing, TA = 25°C)

TOTAL DEVICE (Pin 8)

Power Supply Current (Pins 5, 6, 7 Open)

Start–Up (VCC = 2.9 V)

БББББББББББББББББ

Operating (VCC = 6.0 V)

NOTES: 1. Whichever voltage is lower.

2.Tested junction temperature range for the MC33340:

T

= –25°C T

low

high

= +85°C

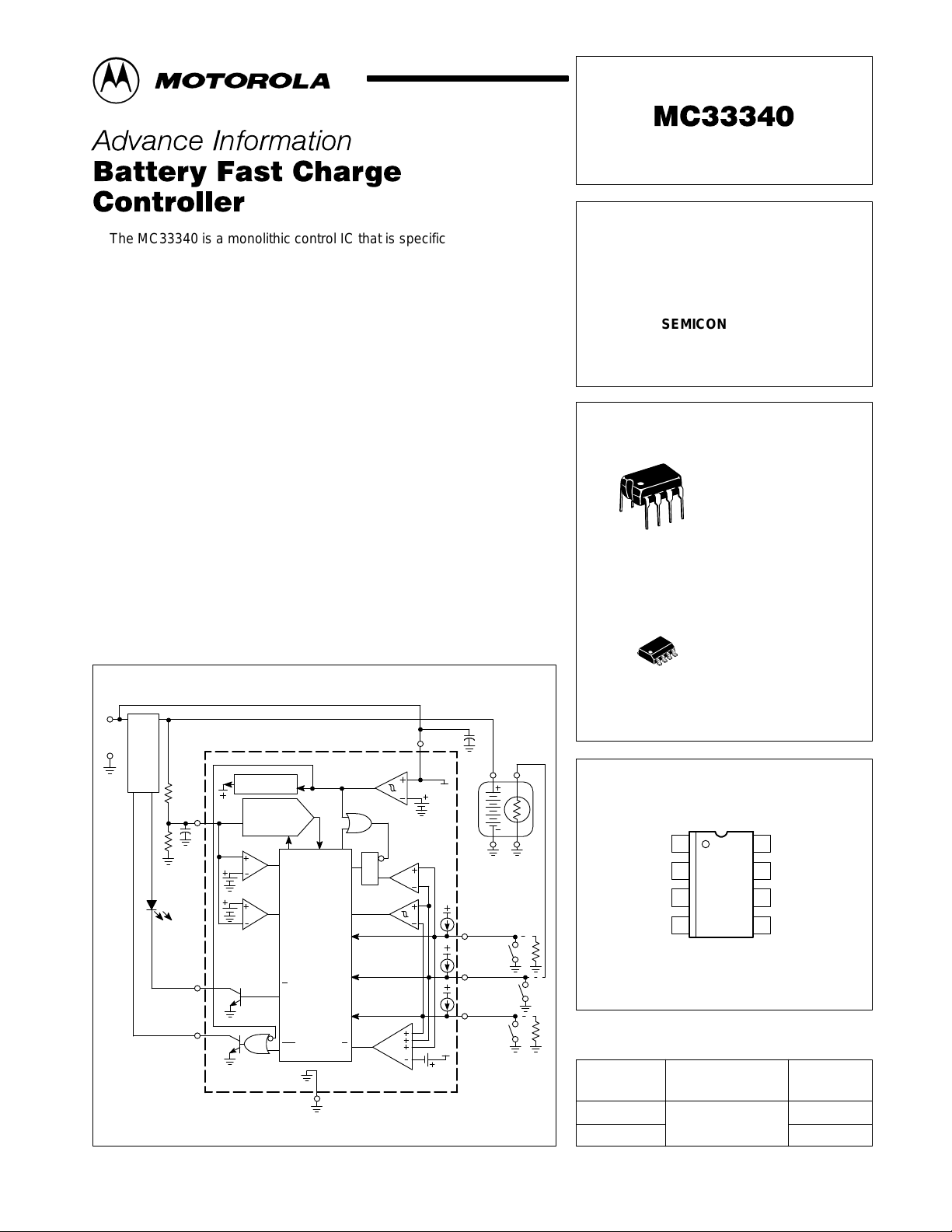

Figure 1. Battery Sense Input Thresholds

versus T emperature

2.10

VCC = 6.0 V

2.00

1.90

V

th(on)

V

th(off)

I

CC

ÁÁÁ

16

8.0

–

2.75

–

Á

–

3.0

2.85

0.65

ÁÁÁ

0.61

3.1

2.0

Á

2.0

–

Figure 2. Oscillator Frequency

versus T emperature

VCC = 6.0 V

V

V

mA

ÁÁ

1.02

1.00

, OVER/UNDERVOL TAGE THRESHOLDS (V)

th

0.98

V

–50 –25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

0

–8.0

, OSCILLAT OR FREQUENCY CHANGE (%)

–16

OSC

f

∆

–50 –25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

MOTOROLA ANALOG IC DEVICE DATA

3

Page 4

MC33340

V

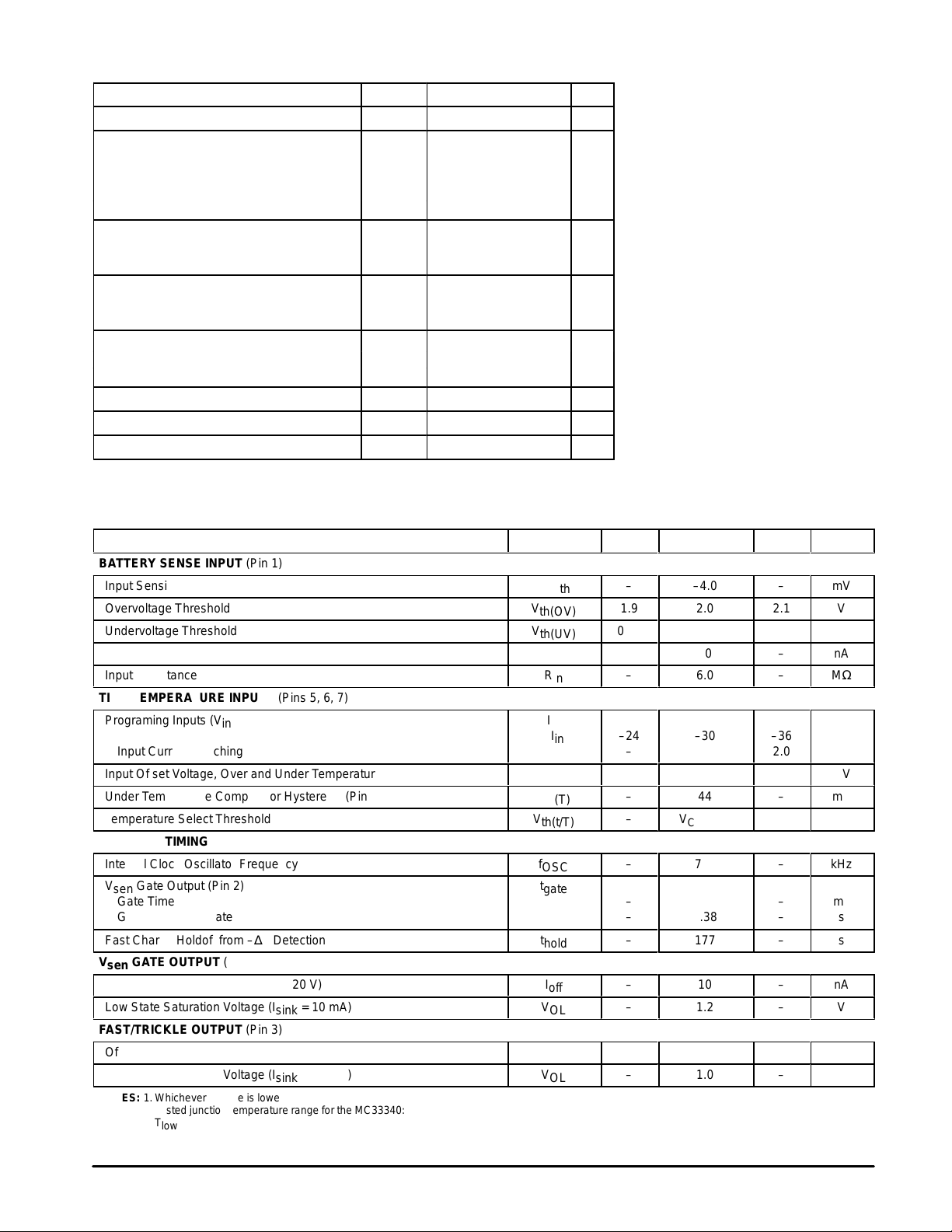

Figure 3. T emperature Select Threshold Voltage

versus T emperature

0

V

CC

–0.2

0.4

–

–0.6

–0.8

, TEMPERATURE SELECT THRESHOLD VOLTAGE (

–1.0

th(t/T)

V

Threshold voltage is measured with respect to V

Time mode is selected if any of

the three inputs are above the

threshold.

Temperature mode is selected

when all three inputs are below

the threshold.

–50 –25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

VCC = 6.0 V

CC

Figure 5. Undervoltage Lockout Thresholds

versus T emperature

3.1

Startup Threshold

3.0

2.9

, SUPPLY VOLTAGE (V)

2.8

CC

V

(VCC Increasing)

Minimum Operating Threshold

(VCC Decreasing)

Figure 4. Saturation V oltage versus Sink Current

V

Gate and Fast/Trickle Outputs

3.2

.

2.4

1.6

0.8

, SINK SATURATION VOLTAGE (V)

OL

V

0

0 8.0 16 24 32 40

sen

VCC = 6.0 V

°

C

TA = 25

V

Gate

sen

Pin 2

I

, SINK SATURATION (mA)

sink

Fast/Trickle

Pin 3

Figure 6. Supply Current

versus Supply V oltage

1.0

TA = 25°C

0.8

0.6

0.4

, SUPPLY CURRENT (mA)

0.2

CC

I

2.7

–50

–25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

0

0 4.0 8.0 12 16

VCC, SUPPLY VOLTAGE (V)

INTRODUCTION

Nickel Cadmium and Nickel Metal Hydride batteries

require precise charge termination control to maximize cell

capacity and operating time while preventing overcharging.

Overcharging can result in a reduction of battery life as well

as physical harm to the end user. Since most portable

applications require the batteries to be charged rapidly, a

primary and usually a secondary or redundant charge

sensing technique is employed into the charging system. It is

also desirable to disable rapid charging if the battery voltage

or temperature is either too high or too low. In order to

address these issues, an economical and flexible fast charge

controller was developed.

The MC33340 contains many of the building blocks and

protection features that are employed in modern high

performance battery charger controllers that are specifically

designed for Nickel Cadmium and Nickel Metal Hydride

batteries. The device is designed to interface with either

primary or secondary side regulators for easy implementation

of a complete charging system. A representative block

diagram in a typical charging application is shown in Figure 7.

The battery voltage is monitored by the V

input that

sen

internally connects to a voltage to frequency converter and

counter for detection of a negative slope in battery voltage. A

timer with three programming inputs is available to provide

backup charge termination. Alternatively , these inputs can be

used to monitor the battery pack temperature and to set the

over and under temperature limits also for backup charge

termination.

Two active low open collector outputs are provided to

interface this controller with the external charging circuit. The

first output furnishes a gating pulse that momentarily

interrupts the charge current. This allows an accurate

method of sampling the battery voltage by eliminating voltage

drops that are associated with high charge currents and

wiring resistances. Also, any noise voltages generated by the

charging circuitry are eliminated. The second output is

designed to switch the charging source between fast and

trickle modes based upon the results of voltage, time, or

temperature. These outputs normally connect directly to a

linear or switching regulator control circuit in non–isolated

primary or secondary side applications. Both outputs can be

used to drive optoisolators in primary side applications that

require galvanic isolation. Figure 8 shows the typical charge

characteristics for NiCd and NiMh batteries.

4

MOTOROLA ANALOG IC DEVICE DATA

Page 5

DC

Input

Charge

Status

Regulator

Reg Control

R2

R1

MC33340

Figure 7. T ypical Battery Charging Application

MC33340

Undervoltage

Over

Under

4

Lockout

Q

t1

t2

t3

t/T

Time/

Temp

Select

V

sen

1

V

sen

Gate

2

3

Fast/

Trickle

2.0 V

1.0 V

Internal Bias

Voltage to

Frequency

Converter

Battery

Detect

Ck F/V R

High

Low

∆

V Detect

–

Counter

Timer

V

sen

Gate

F/T

Gnd

R

S

Detect

Over

Temp

Latch

Temp

V

8

CC

V

CC

0.7 V

2.9 V

V

CC

30

µ

µ

30

30 µA

Battery

Pack

A

t1/T

High

ref

7

A

t2/T

sen

6

t3/T

Low

ref

5

T

SW1

SW3

R

SW2

NTC

R3

R4

R2+R1

ǒ

V

sen

–1

Ǔ

V

Batt

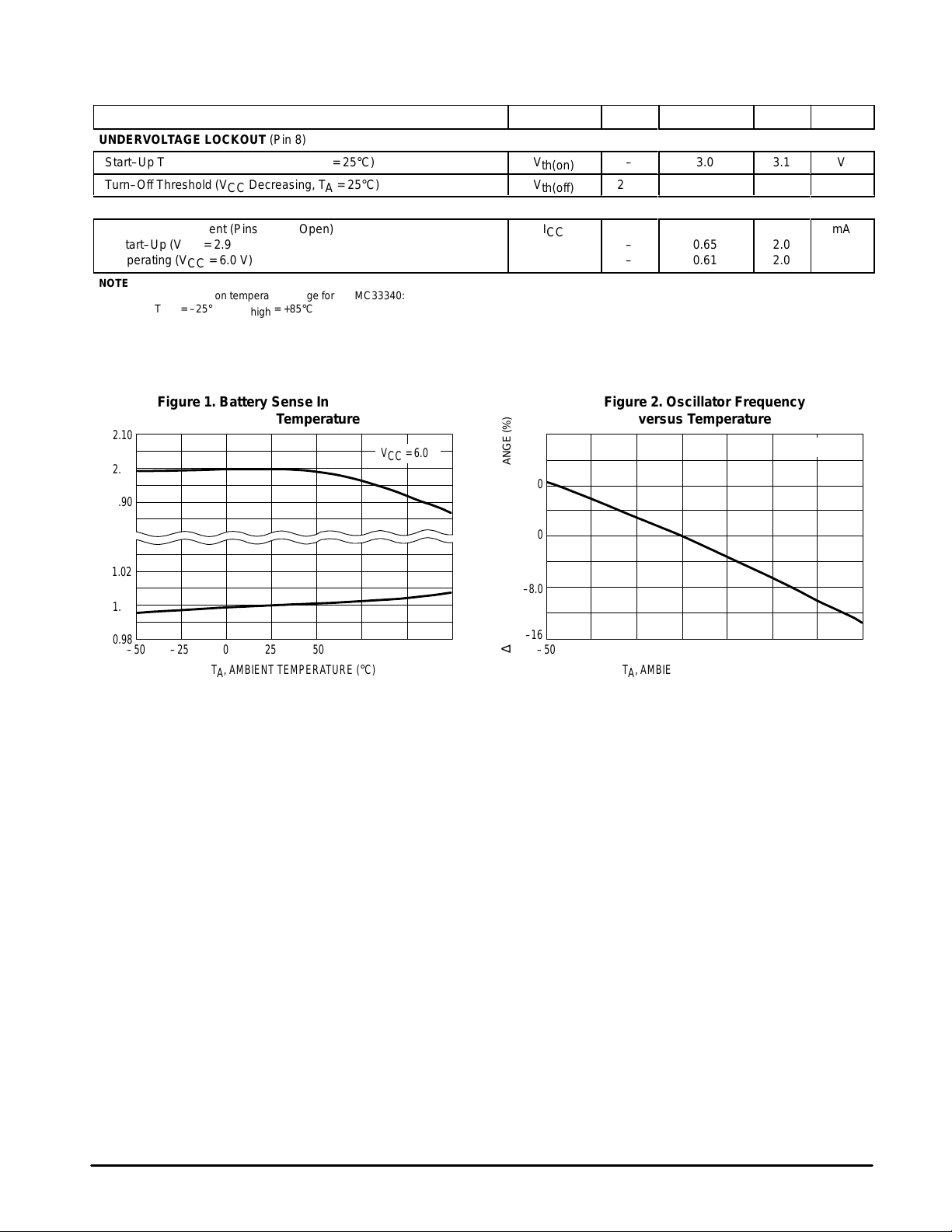

Figure 8. T ypical Charge Characteristics for NiCd and NiMh Batteries

1.6

1.5

1.4

1.3

CELL VOLTAGE (V)

1.2

1.1

1.0

0 40 80 120 160

Voltage

Temperature

Relative Pressure

CHARGE INPUT PERCENT OF CAP ACITY

V

max

T

max

–∆V

dV

dt

70

60

50

40

30

20

10

°

CELL TEMPERATURE ( C)

MOTOROLA ANALOG IC DEVICE DATA

5

Page 6

MC33340

OPERA TING DESCRIPTION

The MC33340 starts up in the fast charge mode when

power is applied to VCC. A change to the trickle mode can

occur as a result of three possible conditions. The first is if the

V

input voltage is above 2.0 V or below 1.0 V . Above 2.0 V

sen

indicates that the battery pack is open or disconnected, while

below 1.0 V indicates the possibility of a shorted or defective

cell. The second condition is if a negative slope in battery

voltage is detected after a minimum of 177 seconds of fast

charging. This indicates that the battery pack is fully charged.

The third condition is either due to the battery pack being out

of a programmed temperature range, or that the preset timer

period has been exceeded.

There are three conditions that will cause the controller to

return from trickle to fast charge mode. The first is if the V

sen

input voltage moved to within the 1.0 to 2.0 V range from

initially being either too high or too low. The second is if the

battery pack temperature moved to within the programmed

temperature range, but only from initially being too cold. Third

is by cycling VCC off and then back on causing the internal

logic to reset. A concise description of the major circuit blocks

is given below.

Negative Slope V oltage Detection

A representative block diagram of the negative slope

voltage detector is shown in Figure 9. It includes a

Synchronous Voltage to Frequency Converter, a Sample

Timer , and a Ratchet Counter. The V

pin is the input for the

sen

Voltage to Frequency Converter (VFC), and it connects to the

rechargeable battery pack terminals through a resistive

voltage divider. The input has an impedance of

approximately 6.0 MΩ and a maximum voltage range of

–1.0 V to VCC + 0.6 V or 0 V to 10 V , whichever is lower. The

10 V upper limit is set by an internal zener clamp that

provides protection in the event of an electrostatic discharge.

The VFC is a charge–balanced synchronous type which

generates output pulses at a rate of FV = V

(24 kHz).

sen

The Sample Timer circuit provides a 95 kHz system clock

signal (SCK) to the VFC. This signal synchronizes the F

output to the other Sample Timer outputs used within the

detector. At 1.38 second intervals the V

Gate output goes

sen

low for a 33 ms period. This output is used to momentarily

interrupt the external charging power source so that a precise

voltage measurement can be taken. As the V

Gate goes

sen

low, the internal Preset control line is driven high for 11 ms.

During this time, the battery voltage at the V

sen

input is

allowed to stabilize and the previous FV count is preloaded.

At the Preset high–to–low transition, the Convert line goes

high for 22 ms. This gates the FV pulses into the ratchet

counter for a comparison to the preloaded count. Since the

Convert time is derived from the same clock that controls the

VFC, the number of FV pulses is independent of the clock

frequency. If the new sample has more counts than were

preloaded, it becomes the new peak count and the cycle is

repeated 1.38 seconds later. If the new sample has two fewer

counts, a less than peak voltage event has occurred, and a

register is initialized. If two successive less than peak voltage

events occur, the –∆V ‘AND’ gate output goes high and the

Fast/Trickle output is latched in a low state, signifying that the

battery pack has reached full charge status. Negative slope

voltage detection can only occur after 177 seconds have

elapsed in the fast charge mode. The trickle mode holdoff

time is implemented to ignore any initial drop in voltage that

may occur when charging batteries that have been stored for

an extended time period. The negative slope voltage detector

has a maximum resolution of 2.0 V divided by 1023, or 1.955

mV per count with an uncertainty of ±1.0 count. This yields a

detection range of 1.955 mV to 5.865 mV. In order to obtain

maximum sensing accuracy, the R2/R1 voltage divider must

be adjusted so that the V

input voltage is slightly less than

sen

2.0 V when the battery pack is fully charged. Voltage

variations due to temperature and cell manufacturing must

be considered.

V

V

sen

Input

Synchronous

Voltage to

Frequency

Converter

V

Gate

sen

Preset

Convert

SCK

95 kHz

Figure 9. Negative Slope V oltage Detector

FV = V

11 ms

(24 kHz)

sen

Ck

Convert

Sample

22 ms

Rachet Counter Convert

0 to 1023 FV Pulses

Preset

Timer

Rachet

Counter

Trickle Mode

Holdoff 160s

1.38 s

Battery Detect

∆

V

–

Over Under

V

Gate

sen

Logic

Temperature

UVLOHighLow

Charge

Timer

F/T

6

MOTOROLA ANALOG IC DEVICE DATA

Page 7

MC33340

Backup

Time Limit

Fast Charge Timer

A programmable backup charge timer is available for fast

charge termination. The timer is activated by the Time/Temp

Select comparator, and is programmed from the t1/T

t2/T

, and t3/T

sen

Low inputs. If one or more of these inputs

ref

is allowed to go above VCC – 0.7 V or is left open, the

comparator output will switch high, indicating that the timer

feature is desired. The three inputs allow one of seven

possible fast charge time limits to be selected. The

programmable time limits, rounded to the nearest whole

minute, are shown in Figure 10.

Over/Under Temperature Detection

A backup over/under temperature detector is available

and can be used in place of the timer for fast charge

termination. The timer is disabled by the Time/Temp Select

comparator when each of the three programming inputs are

held below VCC – 0.7 V.

Temperature sensing is accomplished by placing a

negative temperature coefficient (NTC) thermistor in thermal

contact with the battery pack. The thermistor connects to the

t2/T

input which has a 30 µA current source pull–up for

sen

developing a temperature dependent voltage. The

temperature limits are set by a resistor that connects from the

t1/T

High and the t3/T

ref

Low inputs to ground. Since all

ref

three inputs contain matched 30 µA current source pull–ups,

the required programming resistor values are identical to that

of the thermistor at the desired over and under trip

temperature. The temperature window detector is composed

of two comparators with a common input that connects to the

t2/T

input.

sen

The lower comparator senses the presence of an under

temperature condition. When the lower temperature limit is

exceeded, the charger is switched to the trickle mode. The

comparator has 44 mV of hysteresis to prevent erratic

switching between the fast and trickle modes as the lower

temperature limit is crossed. The amount of temperature rise

to overcome the hysteresis is determined by the thermistor’s

rate of resistance change or sensitivity at the under

temperature trip point. The required resistance change is:

D

R(T

Low

³

T

High

H(T)

)

+

I

in

+

44 mV

30mA

V

The resistance change approximates a thermal hysteresis

of 2°C with a 10 kΩ thermistor operating at 0°C. The under

temperature fast charge inhibit feature can be disabled by

biasing the t3/T

Low input to a voltage that is greater than

ref

Figure 10. Fast Charge Backup T ermination Time/Temperature Limit

Backu

Termination

Mode

Time Open Open Open 283

Time Open Open Gnd 247

Time Open Gnd Open 212

Time Open Gnd Gnd 177

Time Gnd Open Open 141

Time Gnd Open Gnd 106

Time Gnd Gnd Open 71

Temperature 0 V to VCC – 0.7 V 0 V to VCC – 0.7 V 0 V to VCC – 0.7 V Timer Disabled

t3/T

Low

ref

(Pin 5)

High,

ref

+

1.46 k

Programming Inputs

that present at t2/T

, and less than VCC – 0.7 V. Under

sen

extremely cold conditions, it is possible that the thermistor

resistance can become too high, allowing the t2/T

go above VCC – 0.7 V , and activate the timer . This condition

can be prevented by placing a resistor in parallel with the

thermistor. Note that the time/temperature threshold of V

– 0.7 V is a typical value at room temperature. Refer to the

Electrical Characteristics table and to Figure 3 for additional

information.

The upper comparator senses the presence of an over

temperature condition. When the upper temperature limit is

exceeded, the comparator output sets the Over Temperature

Latch and the charger is switched to trickle mode. Once the

latch is set, the charger cannot be returned to fast charge,

even after the temperature falls below the limit. This feature

prevents the battery pack from being continuously

temperature cycled and overcharged. The latch can be reset

by removing and reconnecting the battery pack or by cycling

the power supply voltage.

If the charger does not require either the time or

temperature backup features, they can both be easily

disabled. This is accomplished by biasing the t3/T

input to a voltage greater than t2/T

t1/T

High input. Under these conditions, the Time/Temp

ref

, and by grounding the

sen

Select comparator output is low, indicating that the

temperature mode is selected, and that the t2/T

biased within the limits of an artificial temperature window.

Charging of battery packs that are used in portable power

tool applications typically use temperature as the only means

for fast charge termination. The MC33340 can be configured

in this manner by constantly resetting the –∆V detection

logic. This is accomplished by biasing the V

≈1.5 V from a two resistor divider that is connected between

the positive battery pack terminal and ground. The V

output is also connected to the V

that the Sample Timer causes the V

V

input will be pulled below the undervoltage threshold of

sen

input. Now, each time

sen

output to go low, the

sen

1.0 V. This causes a reset of the –∆V logic every 1.38

seconds, thus disabling detection.

Operating Logic

The order of events in the charging process is controlled

by the logic circuitry . Each event is dependent upon the input

conditions and the chosen method of charge termination. A

table summary containing all of the possible operating modes

is shown in Figure 1 1.

t2/T

sen

(Pin 6)

t1/T

High

ref

(Pin 7)

Time Limit

Fast Charge

(Minutes)

sen

sen

sen

input to

CC

Low

ref

input is

input to

Gate

sen

MOTOROLA ANALOG IC DEVICE DATA

7

Page 8

MC33340

Figure 11. Controller Operating Mode Table

Input Condition Controller Operation

V

Input Voltage:

sen

>1.0 V and <2.0 V

>1.0 V and <2.0 V with

two consecutive –∆V

events detected after 160 s

<1.0 V or >2.0 V The divided down battery pack voltage is outside of the fast charge voltage range. The charger switches

Timer Backup:

Within time limit

Beyond time limit The timer has exceeded the programmed limit. The charger switches from fast to a latched trickle mode.

T emperature Backup:

Within limits

Below lower limit The battery pack temperature is below the programmed lower limit. The charger will stay in trickle mode

Above upper limit The battery pack temperature has exceeded the programmed upper limit. The charger switches from fast

Power Supply Voltage:

VCC >3.0 V and <18 V

VCC >0.6 V and <2.8 V The undervoltage lockout comparator will be activated and the charger will be in trickle mode. A reset

The divided down battery pack voltage is within the fast charge voltage range. The charger switches from

trickle to fast charge mode as V

timer and the over temperature latch.

The battery pack has reached full charge and the charger switches from fast to a latched trickle mode.

A reset pulse must be applied for the charger to switch back to the fast mode. The reset pulse occurs

when entering the 1.0 V to 2.0 V window for V

from fast to trickle mode.

The timer has not exceeded the programmed limit. The charger will be in fast charge mode if V

VCC are within their respective operating limits.

The battery pack temperature is within the programmed limits. The charger will be in fast charge mode if

V

and VCC are within their respective operating limits.

sen

until the lower temperature limit is exceeded. When exceeded, the charger will switch from trickle to fast

charge mode.

to a latched trickle mode. A reset signal must be applied and then released for the charger to switch back

to the fast charge mode. The reset pulse occurs when entering the 1.0 V to 2.0 V window for V

when VCC rises above 3.0 V.

This is the nominal power supply operating voltage range. The charger will be in fast charge mode if

V

, and temperature backup or timer backup are within their respective operating limits.

sen

signal is applied to the timer and over temperature latch.

enters this voltage range, and a reset pulse is then applied to the

sen

or when VCC rises above 3.0 V.

sen

sen

sen

and

or

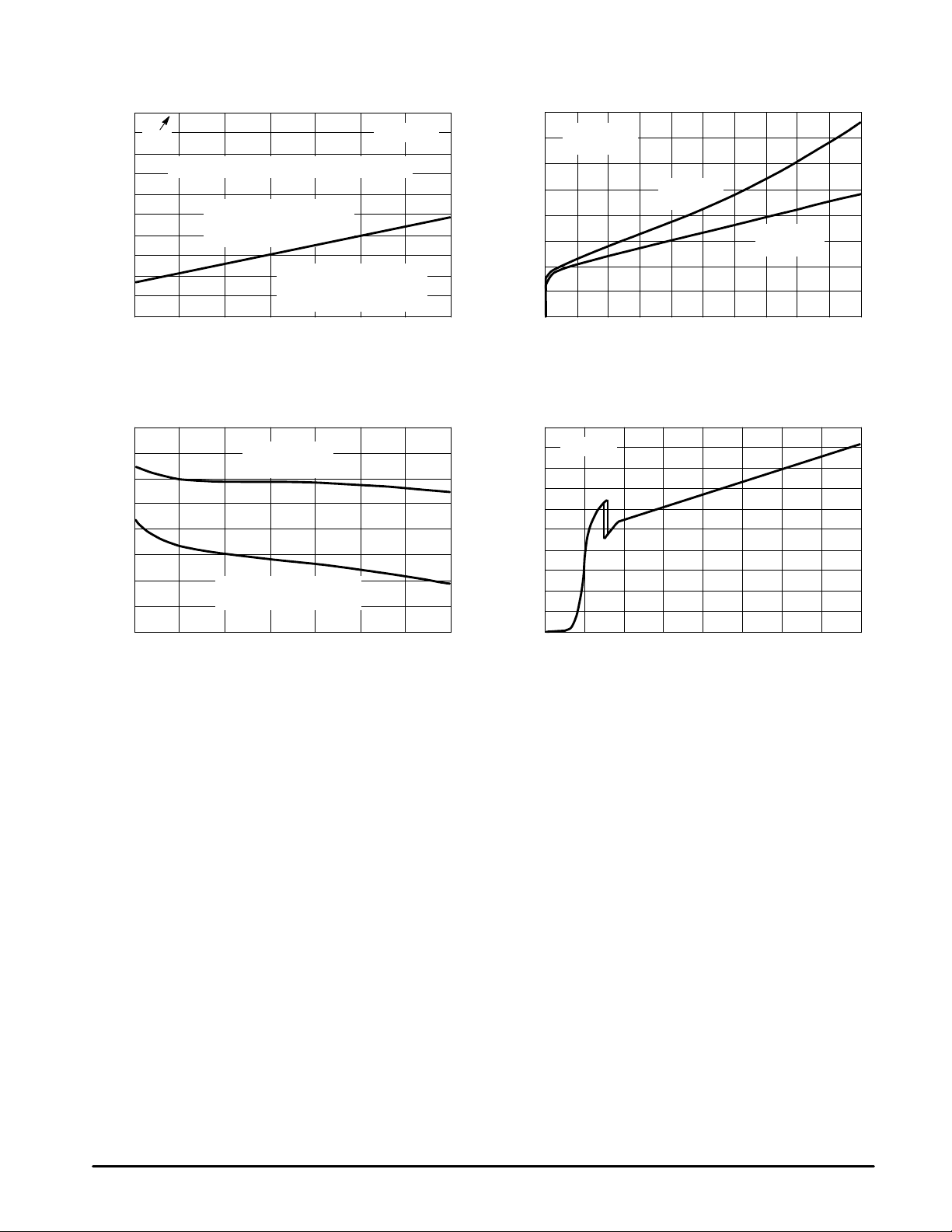

T esting

Under normal operating conditions, it would take 283

minutes to verify the operation of the 34 stage ripple counter

used in the timer. In order to significantly reduce the test time,

three digital switches were added to the circuitry and are

used to bypass selected divider stages. Entering each of the

test modes without requiring additional package pins or

affecting normal device operation proved to be challenging.

Refer to the timer functional block diagram in Figure 12.

Switch 1 bypasses 19 divider stages to provide a 524,288

times speedup of the clock. This switch is enabled when the

V

input falls below 1.0 V. Verification of the programmed

sen

fast charge time limit is accomplished by measuring the

propagation delay from when the V

input falls below 1.0 V ,

sen

to when the F/T output changes from a high–to–low state.

The 71, 106, 141, 177, 212, 247 and 283 will now correspond

to 8.1, 12.1, 16.2, 20.2, 24.3, 28.3 and 32.3 ms delays. It is

possible to enter this test mode during operation if the

equivalent battery pack voltage was to fall below 1.0 V. This

will not present a problem since the device would normally

switch from fast to trickle mode under these conditions, and

the relatively short variable time delay would be transparent

to the user.

Switch 2 bypasses 11 divider stages to provide a 2048

times speedup of the clock. This switch is necessary for

testing the 19 stages that were bypassed when switch 1 was

enabled. Switch 2 is enabled when the V

1.0 V and the t1/T

High input is biased at –100 mV.

ref

input falls below

sen

Verification of the 19 stages is accomplished by measuring a

nominal propagation delay of 338.8 ms from when the V

sen

input falls below 1.0 V, to when the F/T output changes from

a high–to–low state.

Switch 3 is a dual switch consisting of sections “A” and “B”.

Section “A” bypasses 5 divider stages to provide a 32 times

speedup of the V

gate signal that is used in sampling the

sen

battery voltage. This speedup allows faster test verification of

two successive –∆V events. Section “B” bypasses 11 divider

stages to provide a 2048 speedup of the trickle mode holdoff

timer. Switches 3A and 3B are both activated when the t1/T

ref

High input is biased at –100 mV with respect to Pin 4.

Activation results in a reduction of the V

gate sample rate

sen

from 1.38 s to 43 ms, and a trickle mode holdoff time of 177 s

to 86 ms.

8

MOTOROLA ANALOG IC DEVICE DATA

Page 9

Switch 2

11

2

MC33340

Figure 12. Timer Functional Block Diagram

Switch 1

19

Switch 3A

5

2

2

Oscillator

760 kHz

Each test mode bypass switch is shown

in the proper position for normal charger operation.

3

÷

2

95 kHz

SCK

Voltage to

Frequency

Converter

8

÷

2

Decoder

to

11 ms

Preset

Figure 13. Line Isolated Linear Regulator Charger

R5

1.0 k

D3

AC

Line

Input

DC

Input

R6

1.8 k

D1

Charge

Status

R2

I

chg(fast)

I

chg(trickle)

+

LM317

IC2

I

Adj

R1

+

D4

V

Batt

ǒ

V

sen

V

+

1N4002

D2

R7

2.4

R8

220

–1

)

(I

ref

R7

Vin–V

4

÷

2

22 ms

Convert

R2

R1

Ǔ

R8)

Adj

f(D3)–VBatt

R5

1

÷

2

V

sen

C1

0.01

V

sen

Gate

Fast/

Trickle

4

÷

2

V

Switch 3B

86 ms 177 s

Internal Bias

1

2.0 V

1.0 V

2

3

1.38 s

Gate

sen

11

2

Trickle

Handoff

Voltage to

Frequency

Converter

Battery

Detect

7

÷

2

Ck F/V R

High

Low

∆

–

V

sen

Gate

F/T

Gnd

3

÷

2

23.5 47.1 94.2

IC1 MC33340

Undervoltage

Over

Under

t1

V Detect

Counter

Timer

t2

t3

t/T

4

÷2÷2÷2÷

Time Period Minutes

Time and Test

Decoder

Timer Output

V

CC

Lockout

Over

Temp

Latch

R

Q

S

Temp

Detect

Time/Temp

Select

188.4

8

0.6 V

V

CC

2.9 V

V

CC

30

30

30

2

376.8

µ

A

µ

A

µ

A

C2

0.1

t1/T

7

t2/T

6

t3/T

5

t1/T

t2/T

t3/T

Battery

High

ref

sen

Low

ref

ref

sen

ref

Pack

SW1

SW3

High

Low

R

10 k

SW2

NTC

R3

R4

This application combines the MC33340 with an adjustable three terminal regulator to form an isolated secondary side battery charger. Regulator IC2 operates as

a constant current source with R7 setting the fast charge level. The trickle charge level is set by R5. The R2/R1 divider should be adjusted so that the V

less than 2.0 V when the batteries are fully charged. The printed circuit board shown below will accept the several TO–220 style heatsinks for IC2 and are all

manufactured by AAVID Engineering Inc.

AAVID # θSA °C/W

592502B03400 24.0

593002B03400 14.0

590302B03600 9.2

MOTOROLA ANALOG IC DEVICE DATA

sen

input is

9

Page 10

Input

Return

Input

Positive

Input

R5

MC33340

Figure 14. Printed Circuit Board and Component Layout

(Circuit of Figure 13)

Charge Mode

R

C2

R7

NTC

Output

D2

D1

R6

IC2

D4

D3

R4

R1

C1

321

R3

IC1

R2

R8

(Top View) (Bottom View)

Figure 15. Line Isolated Switch Mode Charger

V

CC

R2

R1

OC2

Voltage

Feedback

Input

2

1

Output/

Compensation

V

Battery

Battery

Negative

R

NTC

R

NTC

Battery

Positive

Error

Amplifier

Primary Circuitry

Isolation Boundary

UC3842 Series

1.0 mA

2R

1.70

″

R

1.0 V

Current Sense

Gnd 5

Secondary Circuitry

Comparator

2.25

″

MC33340

MC33340

V

sen

Gate

R3

OC1

V

sen

Gate

2

3

Fast/

Trickle

F/T

Gnd 4

The MC33340 can be combined with any of the devices in the UC3842 family of current mode controllers to form a switch mode battery charger. In this example,

optocouplers OC1 and OC2 are used to provide isolated control signals to the UC3842. During battery voltage sensing, OC2 momentarily grounds the

Output/Compensation pin, effectively turning off the charger . When fast charge termination is reached, OC1 turns on, and grounds the lower side of R3. This reduces

the peak switch current threshold of the Current Sense Comparator to a programmed trickle current level. For additional converter design information, refer to the

UC3842 and UC3844 device family data sheets.

10

MOTOROLA ANALOG IC DEVICE DATA

Page 11

MC33340

Figure 16. Switch Mode Fast Charger

MC34166 or MC34167

I

Limit

Osc

PWM

Thermal

Gnd 3 Compensation 5

S

Q

R

UVLO

Ref

EA

C1 R3

V

sen

Gate

2

3

Fast/

Trickle

V

CC

+

4

Switch

Output

2

Voltage

Feedback

Input

1

R1

MC33340

R2

Battery

Pack

V

sen

Gate

F/T

AC

Line

Input

R4

Gnd 4

The MC33340 can be used to control the MC34166 or MC34167 power switching regulators to produce an economical and efficient fast charger. These devices are

capable of operating continuously in current limit with an input voltage range of 7.5 to 40 V . The typical charging current for the MC34166 and MC34167 is 4.3 A and

6.5 A respectively. Resistors R2 and R1 are used to set the battery pack fast charge float voltage. If precise float voltage control is not required, components R1, R2,

R3 and C1 can be deleted, and Pin 1 must be grounded. The trickle current level is set by resistor R4. It is recommended that a redundant charge termination method

be employed for end user protection. This is especially true for fast charger systems. For additional converter design information, refer to the MC34166 and MC34167

data sheets.

MOTOROLA ANALOG IC DEVICE DATA

11

Page 12

NOTE 2

A

B

C

A1

–T–

SEATING

PLANE

H

E

58

14

F

–A–

N

D

G

0.13 (0.005) B

D

58

1

H

4

e

A

B

SS

A0.25MCB

–B–

C

K

M

T

0.25MB

SEATING

PLANE

0.10

MC33340

OUTLINE DIMENSIONS

P SUFFIX

PLASTIC PACKAGE

CASE 626–05

ISSUE K

L

J

M

M

A

M

D SUFFIX

PLASTIC PACKAGE

CASE 751–05

(SO–8)

ISSUE R

M

h

X 45

_

q

C

L

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

DIM MIN MAX MIN MAX

A 9.40 10.16 0.370 0.400

B 6.10 6.60 0.240 0.260

C 3.94 4.45 0.155 0.175

D 0.38 0.51 0.015 0.020

F 1.02 1.78 0.040 0.070

G 2.54 BSC 0.100 BSC

H 0.76 1.27 0.030 0.050

J 0.20 0.30 0.008 0.012

K 2.92 3.43 0.115 0.135

L 7.62 BSC 0.300 BSC

M ––– 10 ––– 10

N 0.76 1.01 0.030 0.040

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. DIMENSIONS ARE IN MILLIMETERS.

3. DIMENSION D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 1.35 1.75

A1 0.10 0.25

B 0.35 0.49

C 0.18 0.25

D 4.80 5.00

E

3.80 4.00

1.27 BSCe

H 5.80 6.20

h

0.25 0.50

L 0.40 1.25

0 7

q

INCHESMILLIMETERS

__

__

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

Mfax is a trademark of Motorola, Inc.

How to reach us:

USA/EUROPE/ Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 5405, Denver, Colorado 80217. 303–675–2140 or 1–800–441–2447 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 81–3–3521–8315

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

12

◊

MOTOROLA ANALOG IC DEVICE DATA

MC33340/D

Loading...

Loading...