Page 1

Device

Tested Operating

Temperature Range

Package

SEMICONDUCTOR

TECHNICAL DATA

OCTAL SERIAL SWITCH

(SPI Input/Output)

ORDERING INFORMATION

MC33298P

MC33298DW

TC = – 40° to +125°C

DIP

SOP–24L

Order this document by MC33298/D

P SUFFIX

PLASTIC PACKAGE

CASE 738

DIP (16+2+2)

PIN CONNECTIONS

20

1

DW SUFFIX

PLASTIC PACKAGE

CASE 751E

SOP (16+4+4)L

24

1

DIP Function SOP–24L

1

2

3

4

5

6

–

–

7

8

9

10

11

12

13

14

15

16

–

–

17

18

19

20

Output 7

Output 6

SCLK

SI

Ground

Ground

Ground

Ground

SO

CSB

Output 5

Output 4

Output 3

Output 2

SFPD

V

DD

Ground

Ground

Ground

Ground

V

PWR

Reset

Output 1

Output 0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

MOTOROLA ANALOG IC DEVICE DATA

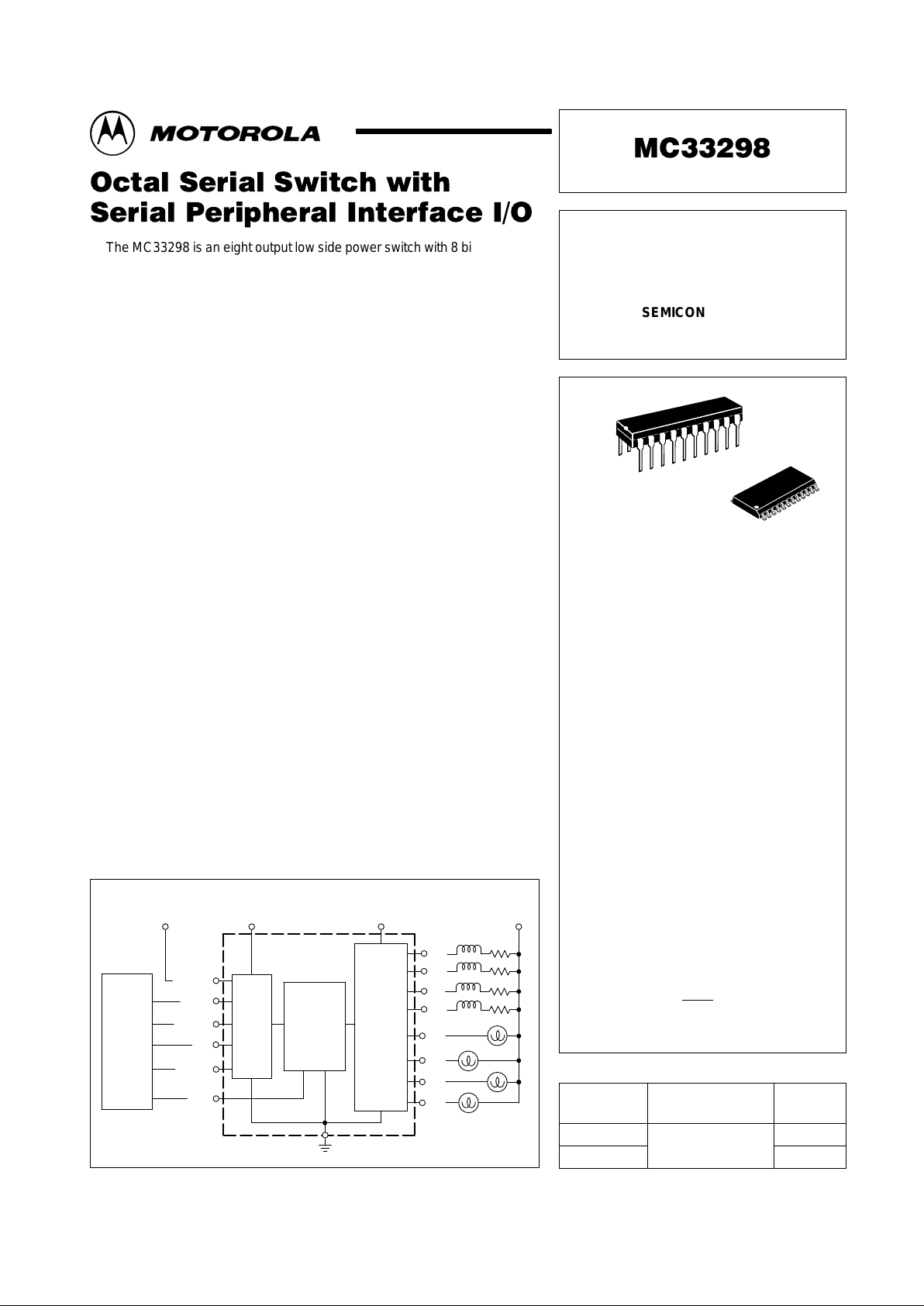

The MC33298 is an eight output low side power switch with 8 bit serial input

control. The MC33298 is a versatile circuit designed for automotive

applications, but is well suited for other environments. The MC33298

incorporates SMARTMOS technology, with CMOS logic, bipolar/MOS

analog circuitry, and DMOS power MOSFETs. The MC33298 interfaces

directly with a microcontroller to control various inductive or incandescent

loads. The circuit’s innovative monitoring and protection features are: very low

standby current, cascadable fault reporting, internal 65 V clamp on each

output, output specific diagnostics, and independent shutdown of outputs. The

MC33298 is parametrically specified over a temperature range of – 40°C ≤ T

A

≤ +125°C ambient temperature and 9.0 V ≤ V

PWR

≤ 16 V supply. The

economical 20 pin DIP and SO–24 wide body surface mount plastic packages

make the MC33298 very cost effective.

• Designed to Operate Over Wide Supply Voltages of 5.5 V to 26.5 V

• Interfaces Directly to Microprocessor Using SPI Protocol

• SPI Communication for Control and Fault Reporting

• 8–Bit Serial I/O is CMOS Compatible

• 3.0 A Peak Current Outputs with Maximum R

DS(on)

of 0.45 Ω at 25°C

• Outputs are Current Limited to 3.0 A to 6.0 A for Driving Incandescent

Lamp Loads

• Output Voltages Clamped to 65 V During Inductive Switching

• Maximum Sleep Current (I

PWR

) of 50 µA with VDD ≤ 2.0 V

• Maximum of 4.0 mA I

DD

During Operation

• Maximum of 2.0 mA I

PWR

During Operation with All Outputs “On”

• Open Load Detection (Outputs “Off”)

• Overvoltage Detection and Shutdown

• Each Output has Independent Over Temperature Detection and Shutdown

• Output Mode Programmable for Sustained Current Limit or Shutdown

• Short Circuit Detect and Shutdown with Automatic Retry for Every

Write Cycle

• Serial Operation Guaranteed to 2.0 MHz

Micro–

controller

with Bus

+V

bat

SCLK

CSB

SFPD

SO

V

PWR

V

DD

CMOS

Serial Shift

Registers

and

Latches

CMOS

Input

Logic

Updrain

DMOS

Output

Switches

and

Sense

Circuits

SI

Reset

SFPD

Y

0

Y

1

Y

2

Y

3

Y

4

Y

5

Y

6

Y

7

Gnd

This device contains 1,200 active transistors.

Simplified Application

Motorola, Inc. 1996 Rev 2

Page 2

MC33298

2

MOTOROLA ANALOG IC DEVICE DATA

I

Limit

Output 0

R

S

Open

Load

Detect

Short

Circuit

Detect

Over

Temperature

Detect

SO

SI

SCLK

CSB

Reset

SFPD

V

DD

Gate

Control

65 V

Outputs

1–7

Grounds

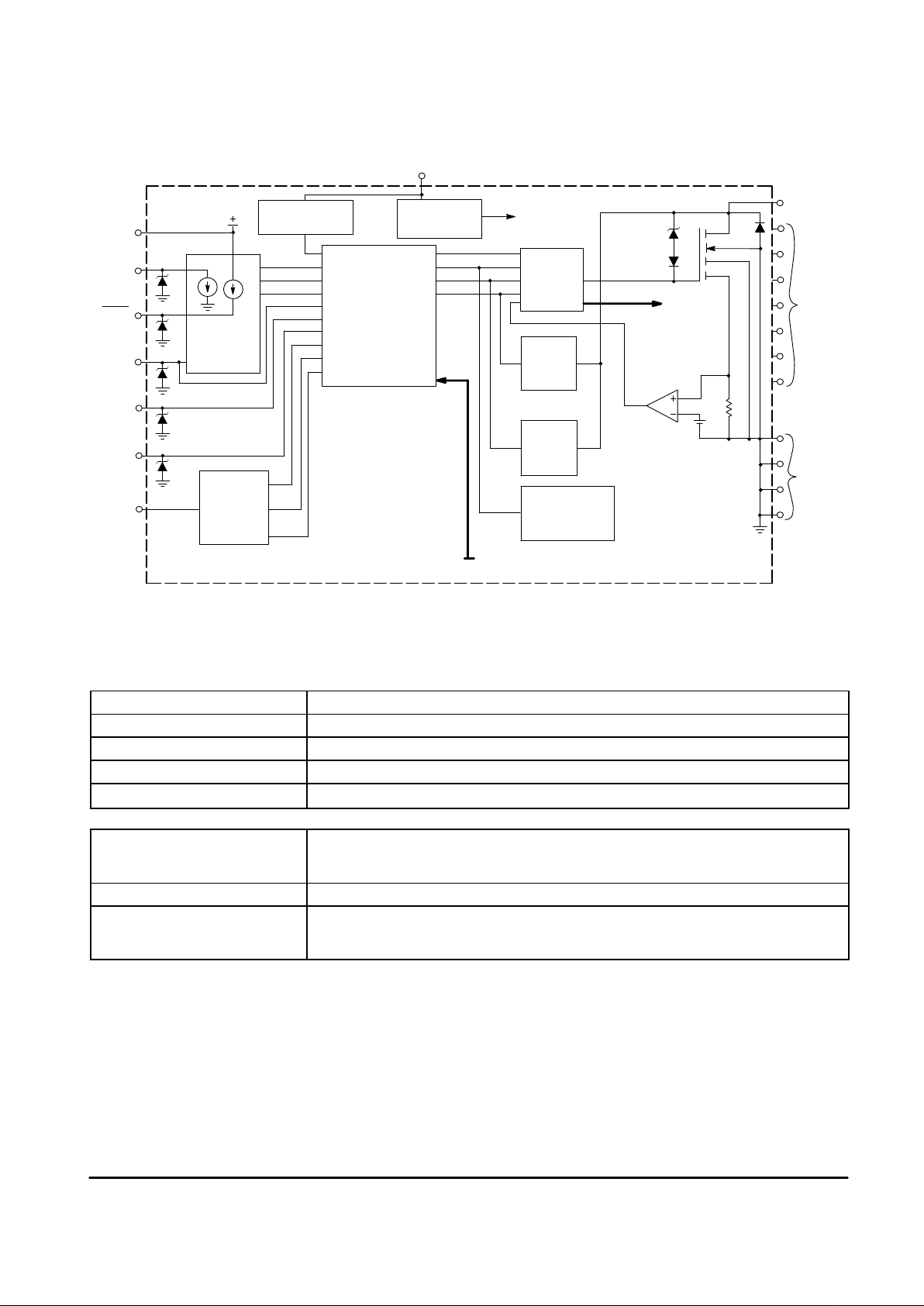

Figure 1. Simplified Block Diagram

Overvoltage

Detect

Voltage

Regulator

Fault

Timers

OVD

RB

SFPDB

SFL

CSB

SCLK

SI

SO

CSI

CSBI

To Gates

1–7

From Detectors 1 to 7

V

PWR

Serial D/O

Line Driver

SPI

Interface

Logic

GE

OT

SF

OF

20

µ

A

20

µ

A

Bias

FAULT OPERATION

SERIAL OUTPUT (SO) PIN REPORTS

Overvoltage

Overvoltage condition reported.

Over Temperature Fault reported by Serial Output (SO) pin.

Over Current SO pin reports short to battery/supply or over current condition.

Output “On,” Open Load Fault Not reported.

Output “Off,” Open Load Fault SO pin reports output “off” open load condition.

DEVICE SHUTDOWNS

Overvoltage Total device shutdown at V

PWR

= 28–36 V. Re–operates when overvoltage is removed with

all outputs assuming an off state upon recovery from overvoltage. All device registers are

automatically reset (cleared) during shutdown.

Over Temperature Only the output experiencing an over temperature shuts down.

Over Current Only the output experiencing an over current condition shuts down at 3.0 A to 6.0 A after a

25 µs to 100 µs delay, with SFPD pin grounded. All outputs will continue to operate in a current

limit mode, with no shutdown, if the SPFD pin is at 5.0 V.

Page 3

MC33298

3

MOTOROLA ANALOG IC DEVICE DATA

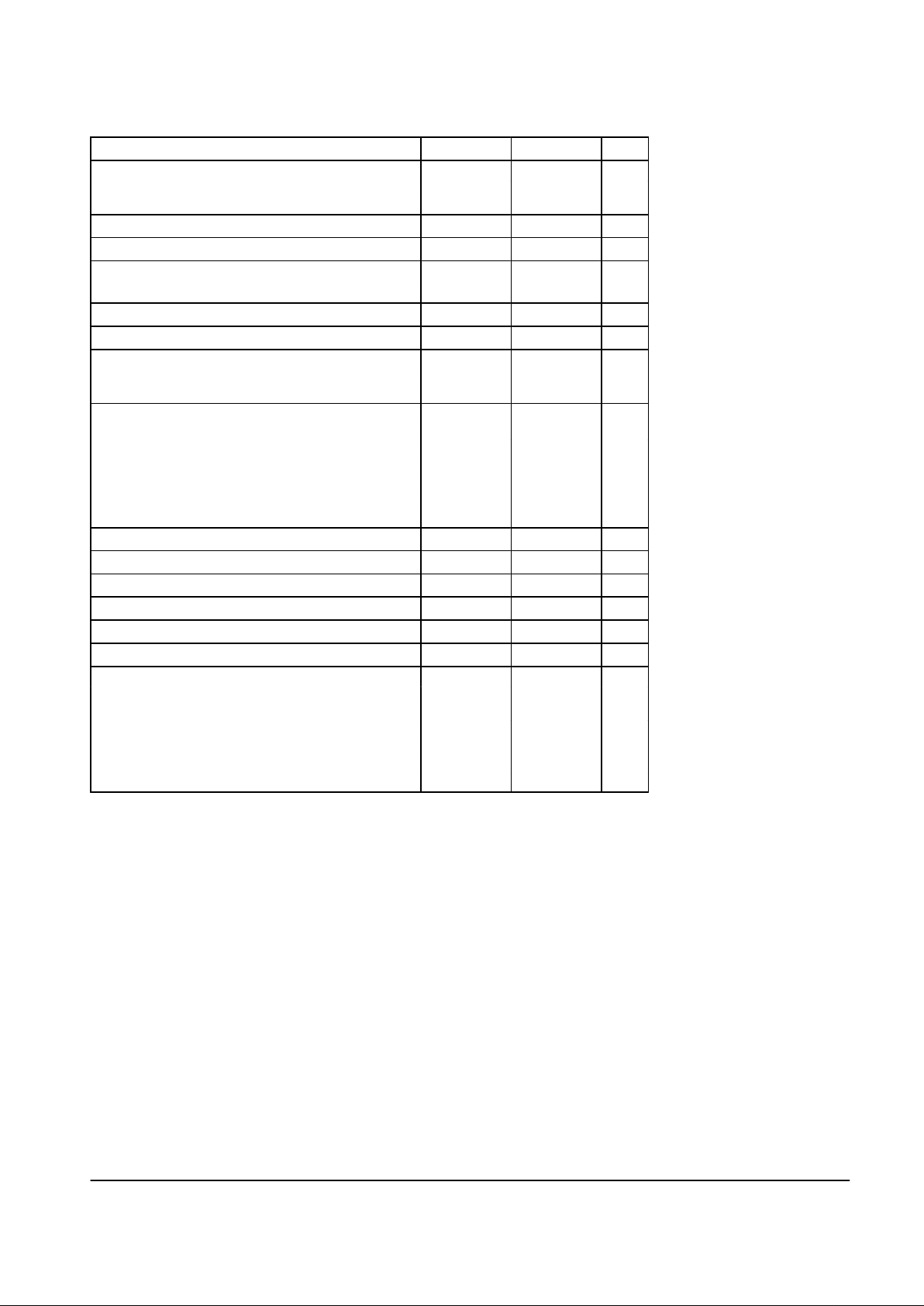

MAXIMUM RATINGS (All voltages are with respect to ground, unless otherwise noted.)

Rating Symbol Value Unit

Power Supply Voltage

Steady–State V

PWR(sus)

–1.5 to 26.5 V

Transient Conditions (Note1) V

PWR(pk)

–13 to 60 V

Logic Supply Voltage (Note 2) V

DD

– 0.3 to 7.0 V

Input Pin Voltage (Note 3) V

IN

– 0.3 to 7.0 V

Output Clamp Voltage (Note 4) V

OUT(off)

V

(2.0 mA ≤ I

out

≤ 0.5 A) 50 to 75

Output Self–Limit Current I

OUT(lim)

3.0 to 6.0 A

Continuous Per Output Current (Note 5) I

OUT(cont)

1.0 A

ESD Voltage

Human Body Model (Note 6) V

ESD1

2000 V

Machine Model (Note 7) V

ESD2

200 V

Output Clamp Energy (Note 8) E

clamp

Repetitive:

TJ =25°C 100 mJ

TJ = 125°C 30 mJ

Non–Repetitive:

TJ =25°C 2.0 J

TJ = 125°C 0.5 J

Recommended Frequency of SPI Operation (Note 9) f

SPI

2.0 MHz

Storage Temperature T

stg

– 55 to +150 °C

Operating Case Temperature T

C

– 40 to +125 °C

Operating Junction Temperature T

J

– 40 to +150 °C

Power Dissipation (TA =25°C) (Note 10) P

D

3.0 W

Soldering Temperature (for 10 seconds) T

solder

260 °C

Thermal Resistance, Junction–to–Ambient (Note 11) R

θJA

°C/W

Plastic Package, Case 738:

All Outputs “On” (Note 12) 31

Single Output “On” (Note 13) 37

SOP–24 Package, Case 751E:

All Outputs “On” (Note 12) 34

Single Output (Note 13) 40

NOTES: 1. Transient capability with external 100 Ω resistor connected in series with V

PWR

pin and supply.

2. Exceeding these limits may cause a malfunction or permanent damage to the device.

3. Exceeding voltage limits on SCLK, SI, CSB, SFPD, or Reset pins may cause permanent damage to

the device.

4. With output “off.”

5. Continuous output rating so long as maximum junction temperature is not exceeded. (See Figure 21 and

22 for more details).

6. ESD1 testing is performed in accordance with the Human Body Model (C

Zap

= 100 pF, R

Zap

= 1500 Ω).

7. ESD2 testing is performed in accordance with the Machine Model (C

Zap

= 100 pF, R

Zap

= 0 Ω).

8. Maximum output clamp energy capability at indicated Junction Temperature using single pulse method.

See Figure 19 for more details.

9. Guaranteed and production tested for 2.0 MHz SPI operation but has been demonstrated to operate to

8.5 MHz @ 25°C.

10. Maximum power dissipation at indicated junction temperature with no heat sink used. See Figures 20,

21, and 22 for more details.

11. See Figure 20 for Thermal Model.

12. Thermal resistance from Junction–to–Ambient with all outputs “on” and dissipating equal power.

13. Thermal resistance from Junction–to–Ambient with a single output “on.”

Page 4

MC33298

4

MOTOROLA ANALOG IC DEVICE DATA

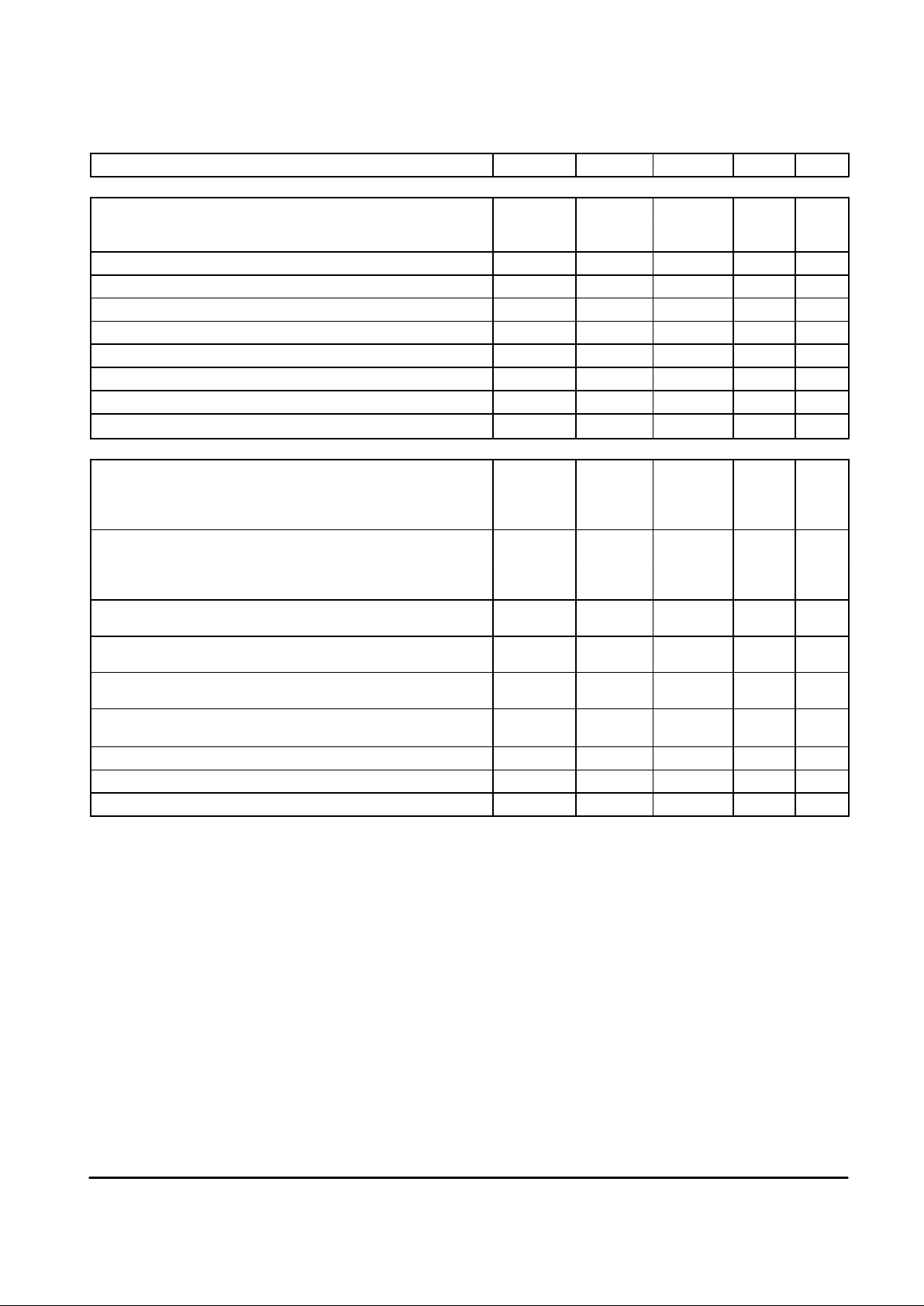

STATIC ELECTRICAL CHARACTERISTICS

(Characteristics noted under conditions of 4.5 V ≤ VDD ≤ 5.5 V, 9.0 V ≤V

PWR

≤ 16 V,

–40°C ≤ TC ≤ 125°C, unless otherwise noted.)

Characteristic

Symbol Min Typ Max Unit

POWER INPUT

Supply Voltage Range V

Quasi–Functional (Note 1) V

PWR(qf)

5.5 – 9.0

Full Operational V

PWR(fo)

9.0 – 26.5

Supply Current (all Outputs “On,” I

out

= 0.5 A) (Note 2) I

PWR(on)

– 1.0 2.0 mA

Sleep State Supply Current (VDD

=0.5 V)

I

PWR(ss)

– 1.0 50 µA

Sleep State Output Leakage Current (per Output, VDD = 0.5 V) I

OUT(ss)

– – 50 µA

Overvoltage Shutdown V

OV

28 – 36 V

Overvoltage Shutdown Hysteresis V

OV(hys)

0.2 – 1.5 V

Logic Supply Voltage V

DD

4.5 – 5.5 V

Logic Supply Current (with any combination of Outputs “On”) I

DD

– – 4.0 mA

Logic Supply Undervoltage Lockout Threshold (Note 3) V

DD(uvlo)

2.0 – 4.5 V

POWER OUTPUT

Drain–to–Source “On” Resistance (I

out

= 0.5 A, TJ =25°C) R

DS(on)

Ω

V

PWR

= 5.5 V – – 1.0

V

PWR

= 9.0 V – 0.4 0.5

V

PWR

= 13 V – 0.35 0.45

Drain–to–Source “On” Resistance (I

out

= 0.5 A, TJ = 150°C) R

DS(on)

Ω

V

PWR

= 5.5 V – – 1.8

V

PWR

= 9.0 V – 0.75 0.9

V

PWR

= 13 V – 0.65 0.8

Output Self–Limiting Current I

OUT(lim)

A

Outputs Programmed “On”, V

out

= 0.6 V

DD

3.0 4.0 6.0

Output Fault Detect Threshold (Note 4) V

OUTth(F)

V

DD

Output Programmed “Off” 0.6 0.7 0.8

Output “Off” Open Load Detect Current (Note 5) I

OCO

µA

Output Programmed “Off,” V

out

= 0.6 V

DD

30 50 100

Output Clamp Voltage V

OK

V

2.0 mA ≤ I

out

≤ 200 mA 50 60 75

Output Leakage Current (VDD ≤ 2.0 V) (Note 6) I

OUT(lkg)

–50 0 50 µA

Over T emperature Shutdown (Outputs “Of f”) (Note 7) T

LIM

155 170 185 °C

Over Temperature Shutdown Hysteresis (Note 7) T

LIM(hys)

– 10 20 °C

NOTES: 1. SPI inputs and outputs operational; Fault reporting may not be fully operational within this voltage range.

2.Value reflects normal operation (no faults) with all outputs “on.” Each “on” output contributes approximately 20 µA to I

PWR

. Each output experiencing

a “soft short” condition contributes approximately 0.5 mA to I

PWR

. A “soft short” is defined as any load current causing the output source current to

self–limit. A “hard” output short is a very low impedance short to supply.

3.For VDD less than the Undervoltage Lockout Threshold voltage, all data registers are reset and all outputs are disabled.

4.Output fault detect threshold with outputs programmed “off.” Output fault detect thresholds are the same for output opens and shorts.

5.Output “Off” Open Load Detect Current is the current required to flow through the load for the purpose of detecting the existence of an open condition

when the specific output is commanded to be “off.”

6.Output leakage current measured with output “off” and at 16 V.

7.This parameter is guaranteed by design but is not production tested.

Page 5

MC33298

5

MOTOROLA ANALOG IC DEVICE DATA

STATIC ELECTRICAL CHARACTERISTICS (Characteristics noted under conditions of 4.5 V ≤ V

DD

≤ 5.5 V, 9.0 V ≤ V

PWR

≤ 16 V ,

–40°C ≤ TC ≤ 125°C, unless otherwise noted.)

Characteristic

Symbol Min Typ Max Unit

DIGITAL INTERFACE

Input Logic High Voltage (Note 1) V

IH

0.7 – 1.0 V

DD

Input Logic Low Voltage (Note 2) V

IL

0.0 – 0.2 V

DD

Input Logic Voltage Hysteresis (Note 3) V

I(hys)

50 100 500 mV

Input Logic Current (Note 4) I

IN

–10 0 10 µA

Reset Pull–Up Current (Reset = 0.7 V

DD)

I

RSTB

10 22 50 µA

SFPD Pull–Down Current (SFPD = 0.2 VDD) I

SFPD

10 22 50 µA

SO High State Output Voltage (IOH = 1.0 mA) V

SOH

V

DD

–1.0 V V

DD

– 0.6 V – V

SO Low State Output Voltage (IOL = –1.6 mA) V

SOL

– 0.2 0.4 V

SO Tri–State Leakage Current (CSB = 0.7 VDD, 0 V ≤ VSO ≤ VDD) I

SOT

–10 0 10 µA

Input Capacitance (0 V ≤ VDD ≤ 5.5 V) (Note 5) C

IN

– – 12 pF

SO Tri–State Capacitance (0 V ≤ VDD ≤ 5.5 V) (Note 6) C

SOT

– – 20 pF

NOTES: 1. Upper logic threshold voltage range applies to SI, CSB, SCLK, Reset, and SFPD input signals.

2.Lower logic threshold voltage range applies to SI, CSB, SCLK, Reset, and SFPD input signals.

3.Only the SFPD and Reset inputs have hysteresis. This parameter is guaranteed by design but is not production tested.

4.Input current of SCLK, SI, and CSB logic control inputs.

5.Input capacitance of SI, CSB, SCLK, Reset, and SFPD for 0 V ≤ VDD ≤ 5.5 V. This parameter is guaranteed by design, but is not production tested.

6.Tri–state capacitance of SO for 0 V ≤ VDD ≤ 5.5 V. This parameter is guaranteed by design but is not production tested.

V

IH

V

IL

Don’t Care

0.2 V

DD

0.7 V

DD

t

lag

t

r

t

f

SI

t

wSCLKL

t

SI(hold)

t

SISU

Valid

t

wSCLKH

0.7 V

DD

0.2 V

DD

t

lead

SCLK

0.2 V

DD

0.2 V

DD

t

wRSTB

RSTB

CSB

Don’t Care Don’t CareValid

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

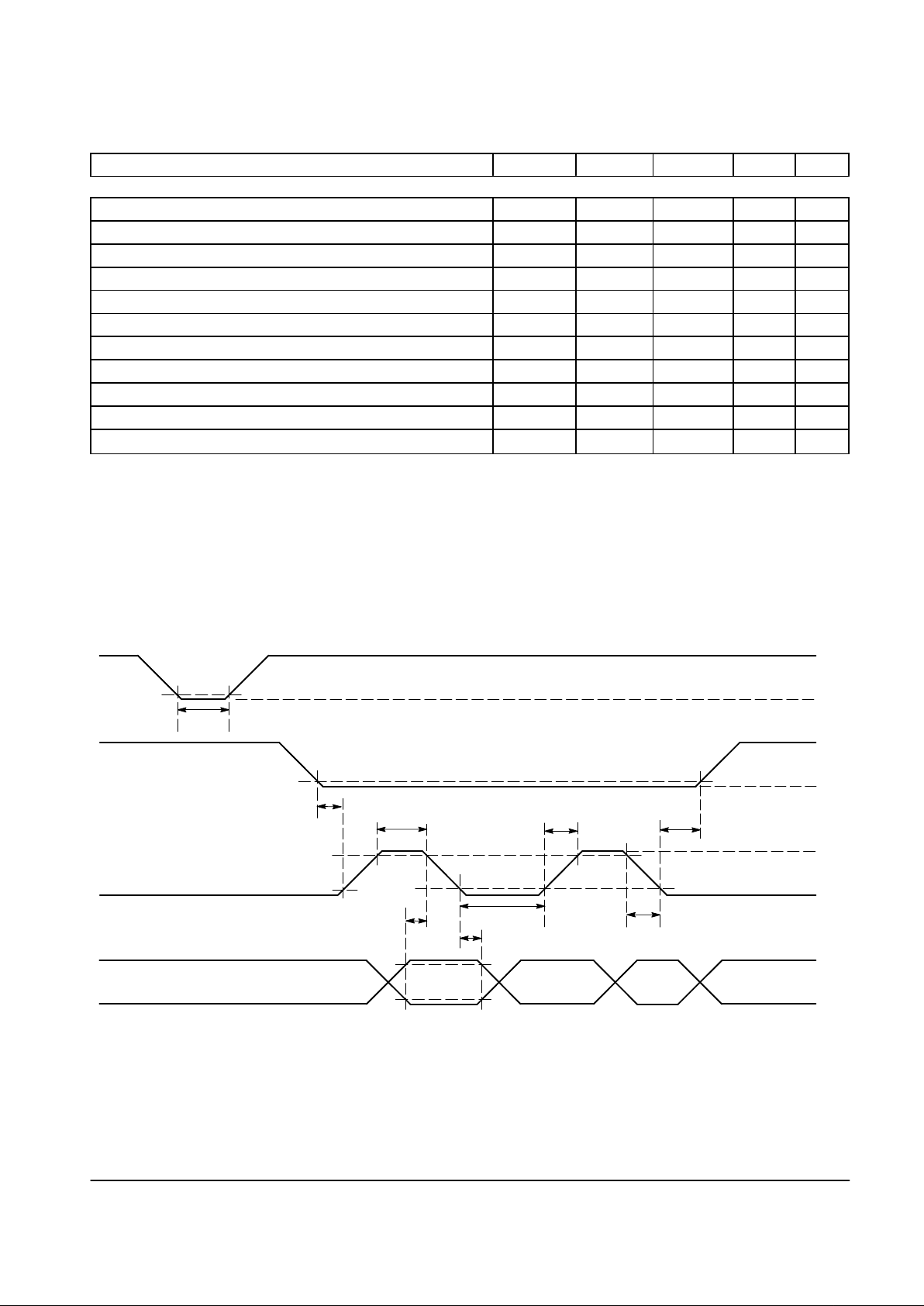

Figure 2. Input Timing Switch Characteristics

Page 6

MC33298

6

MOTOROLA ANALOG IC DEVICE DATA

DYNAMIC ELECTRICAL CHARACTERISTICS

(Characteristics noted under conditions of 4.5 V ≤ VDD ≤ 5.5 V,

9.0 V ≤ V

PWR

≤ 16 V, – 40°C ≤ TC ≤ 125°C, unless otherwise noted.)

Characteristic

Symbol Min Typ Max Unit

POWER OUTPUT TIMING

Output Rise Time (V

PWR

= 13 V, RL = 26 Ω) (Note 1) t

r

0.4 1.5 20 µs

Output Fall Time (V

PWR

= 13 V, RL = 26 Ω) (Note 1) t

f

0.4 2.5 20 µs

Output Turn “On” Delay Time (V

PWR

= 13 V, RL = 26 Ω) (Note 2) t

dly(on)

1.0 5.0 15 µs

Output Turn “Off” Delay Time (V

PWR

= 13 V, RL = 26 Ω) (Note 3) t

dly(off)

1.0 5.0 15 µs

Output Short Fault Disable Report Delay (Note 4) t

dly(sf)

µs

SFPD = 0.2 x V

DD

25 50 100

Output “Off” Fault Report Delay (Note 5) t

dly(off)

µs

SFPD = 0.2 x V

DD

25 50 100

NOTES: 1. Output Rise and Fall time respectively measured across a 26 Ω resistive load at 10% to 90% and 90% to 10% voltage points.

2.Output Turn “On” Delay time measured from rising edge of CSB to 50% of output “off” V

out

voltage with RL = 26 Ω resistive load

(see Figure 7 and 9).

3.Output Turn “Off” Delay time measured from rising edge of CSB to 50% of output “off” V

out

voltage with RL = 26 Ω resistive load

(see Figure 7 and 9).

4.Output Short Fault Disable Report Delay measured from rising edge of CSB to I

out

= 2.0 A point with output “on,” V

out

= 5.0 V,

and SFPD = 0.2 x VDD (see Figure 8 and 10).

5.Output “Off” Fault Report Delay measured from 50% points of rising edge of CSB to rising edge of output (see Figure 9).

DYNAMIC ELECTRICAL CHARACTERISTICS (Characteristics noted under conditions of 4.5 V ≤ V

DD

≤ 5.5 V,

9.0 V ≤ V

PWR

≤ 16 V , –40°C ≤ TC ≤ 125°C, unless otherwise noted.)

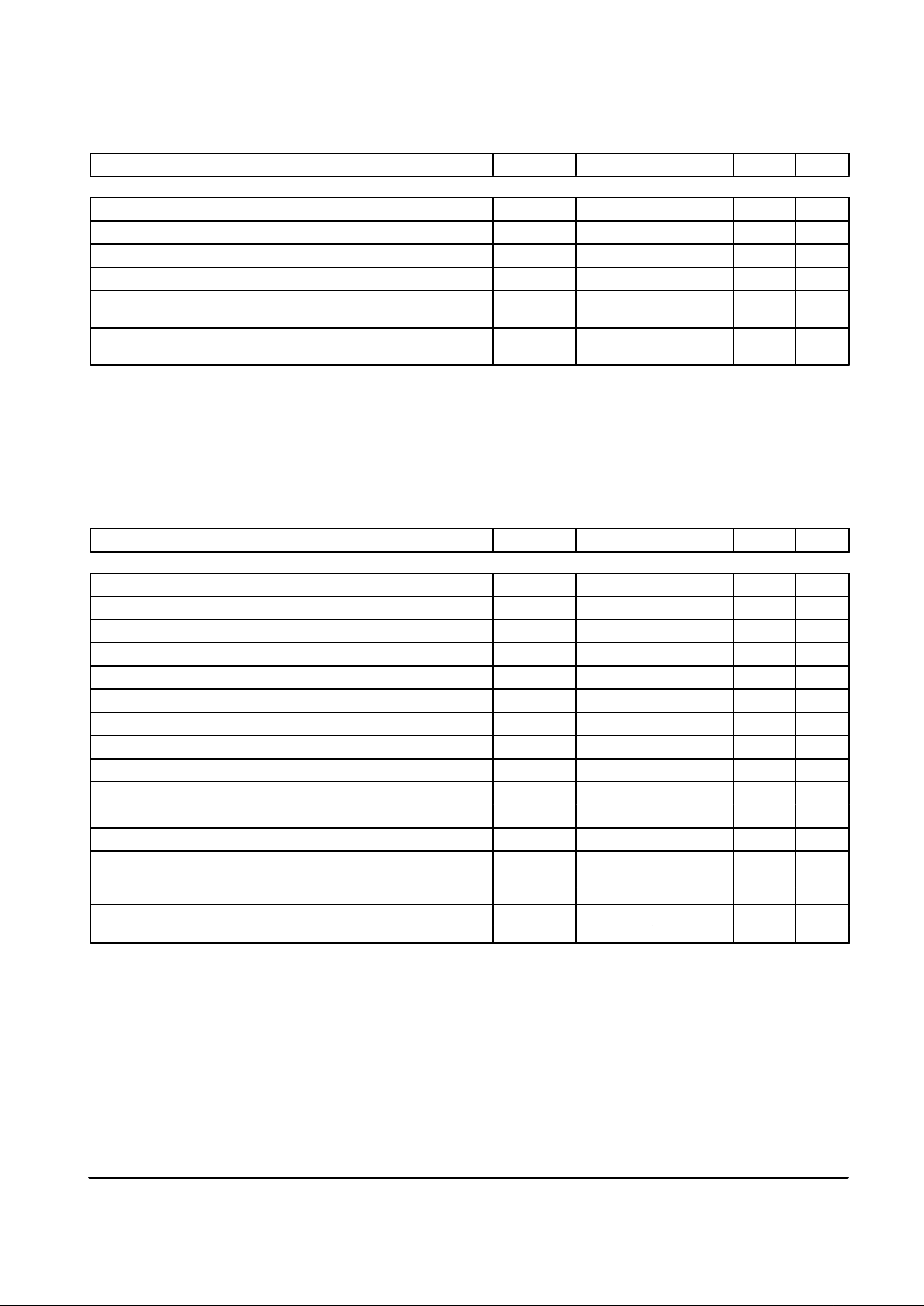

Characteristic Symbol Min Typ Max Unit

DIGITAL INTERFACE TIMING

SCLK Clock Period (Note 6) t

pSCLK

500 – – ns

SCLK Clock High Time t

wSCLKH

175 – – ns

SCLK Clock Low Time t

wSCLKL

175 – – ns

Required Low State Duration for Reset (VIL ≤ 0.2 VDD) (Note 1) t

wRSTB

250 50 – ns

Falling Edge of CSB to Rising Edge of SCLK (Required Setup Time) t

lead

250 50 – ns

Falling Edge of SCLK to Rising Edge of CSB (Required Setup Time) t

lag

250 50 – ns

SI to Falling Edge of SCLK (Required Setup Time) t

SISU

125 25 – ns

Falling Edge of SCLK to SI (Required Hold Time) t

SI(hold)

125 25 – ns

SO Rise Time (CL = 200 pF) t

rSO

– 25 75 ns

SO Fall Time (CL = 200 pF) t

fSO

– 25 75 ns

SI, CSB, SCLK Incoming Signal Rise Time (Note 2) t

rSI

– – 200 ns

SI, CSB, SCLK Incoming Signal Fall TIme (Note 2) t

fSI

– – 200 ns

Time from Falling Edge of CSB to SO ns

Low Impedance (Note 3) t

SO(en)

– – 200

HIgh Impedance (Note 4) t

SO(dis)

– – 200

Time from Rising Edge of SCLK to SO Data Valid (Note 5) t

valid

0.2 VDD ≤ SO ≥ 0.8 VDD, CL = 200 pF – 50 125 ns

NOTES: 1. Reset Low duration measured with outputs enabled and going to “off” or disabled condition.

2. Rise and Fall time of incoming SI, CSB, and SCLK signals suggested for design consideration to prevent the occurrence of double pulsing.

3.Time required for output status data to be available for use at SO.

4.Time required for output status data to be terminated at SO.

5.Time required to obtain valid data out from SO following the rise of SCLK.

6.Clock period includes 75 ns rise plus 75 ns fall transition time in addition to clock high and low time.

Page 7

MC33298

7

MOTOROLA ANALOG IC DEVICE DATA

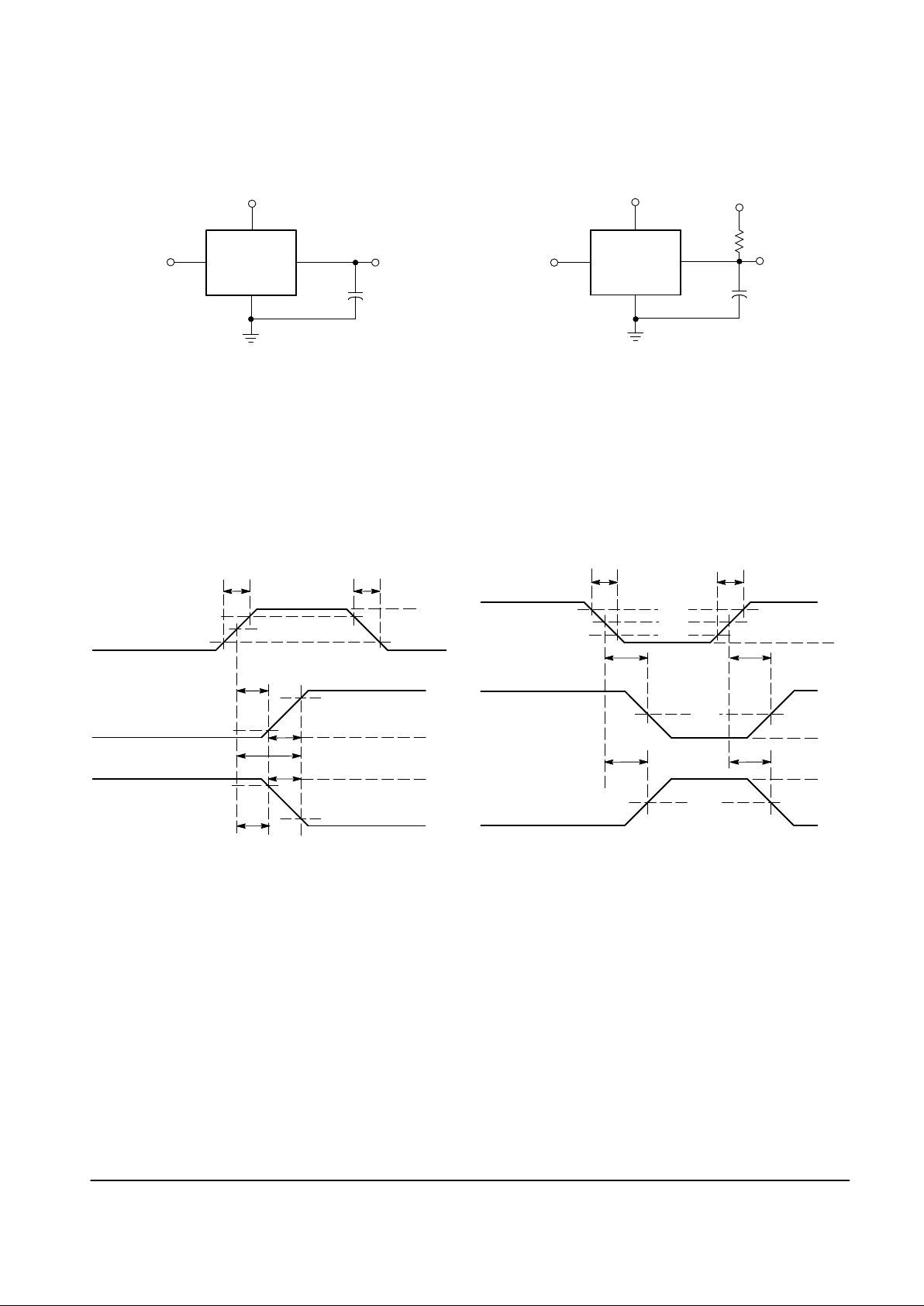

(Low–to–High)

SO

CL = 200 pF

VDD = 5.0 V

SCLK

MC33298

Under

Test

CL represents the total capacitance of the test fixture and probe.

t

fSI

t

rSI

0.2 V

DD

0.7 V

DD

0.2 V

DD

0.7 V

DD

t

fSO

t

valid

t

rSO

V

OL

V

OH

V

OL

V

OH

t

dly(hl)

t

dly(lh)

0.2 V

DD

0.7 VDD (2.5 V)

0

5.0 V

≤

10 ns

50%

≤

10 ns

SO (low–to–high) is for an output with internal conditions such that

the low–to–high transition of CSB causes the SO output to switch

from high–to–low.

SO

CL = 20 pF

RL = 2.0 k

Ω

V

Pull–Up

= 2.5 V

VDD = 5.0 V

CSB

MC33298

Under

Test

CL represents the total capacitance of the test fixture and probe.

t

rSI

t

fSI

V

OL

V

OH

V

OL

V

OH

0

5.0 V

SO

t

SO(dis)

t

SO(en)

t

SO(dis)

t

SO(en)

(High–to–Low)

0.7 V

DD

0.2 VDD (2.5 V)

≤

10 ns

≤

10 ns

CSB

NOTES: 1. SO (high–to–low) waveform is for SO output with internal

conditions such that SO output is low except when an output is

disabled as a result of detecting a circuit fault with CSB in a

High Logic state (e.g., open load).

2.SO (low–to–high) waveform is for SO output with internal

conditions such that SO output is high except when an output

is disabled as a result of detecting a circuit fault with CSB in

a High Logic state (e.g., shorted load).

50%

50%

90%

SO

(Low–to–High)

SO

SCLK

(High–to–Low)

SO

50%

10%

Figure 3. Valid Data Delay Time and

Valid Time Test Circuit

Figure 4. Enable and Disable Time Test Circuit

Figure 5. Vaild Data Delay Time and

Valid Time Waveforms

Figure 6. Enable and Disable Time Waveforms

Page 8

MC33298

8

MOTOROLA ANALOG IC DEVICE DATA

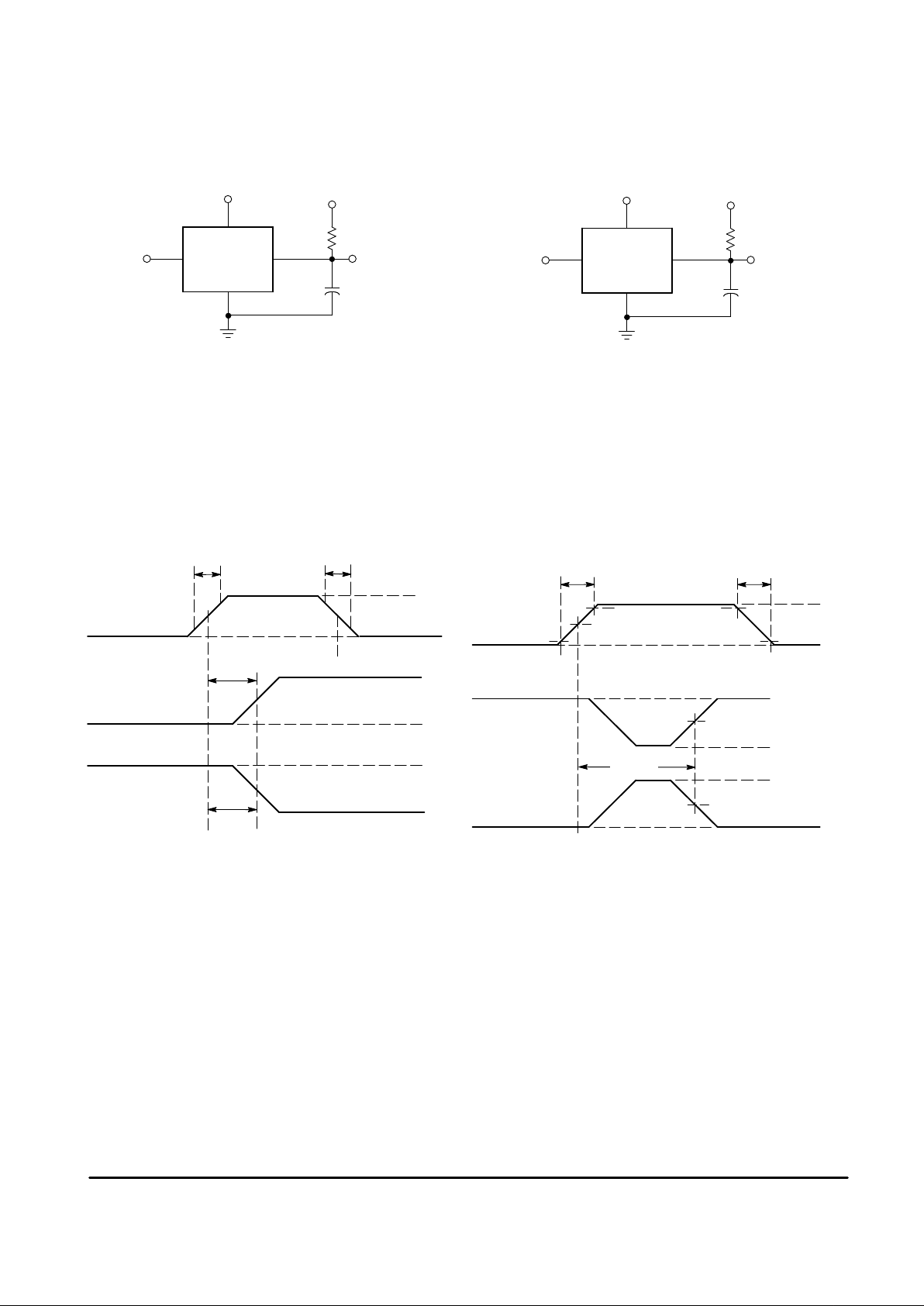

Output

C

L

RL = 26

Ω

V

PWR

= 14 V

VDD = 5.0 V

CSB

MC33298

Under

Test

CL represents the total capacitance of the test fixture and probe.

t

fSI

t

rSI

V

OL

14 V

V

OL

14 V

0

5.0 V

t

dly(on)

50%

Output Voltage

Waveform 2

≤

10 ns

50% 10%

90%

≤

10 ns

90%

50%

10%

CSB

t

dly(off)

50%

Output Voltage

Waveform 1

NOTES: 1. t

dly(on)

and t

dly(off)

are turn–on and turn–off propagation

delay times.

2.Waveform 1 is an output programmed from an “on” to an

“off” state.

3. Waveform 2 is an output programmed from an “off” to an

“on” state.

Output

CL = 20 pF

IL = 2.0 A

(Output “On”)

V

PWR

= 11 V

VDD = 5.0 V

CSB

MC33298

Under

Test

CL represents the total capacitance of the test fixture and probe.

t

fSI

t

rSI

0

5.0 V

0

≤

10 ns

≤

10 ns

10%

90%

50%

I

O(CL)

Von = 5.0 V

V

off

= 11 V

Output Current

Waveform

Output Voltage

Waveform

50%

90%

50%

10%

CSB

NOTES: 1. t

pdly(off)

is the output fault unlatch disable propagation delay

time required to correctly report an output fault after CSB rises.

Represents an output commanded “on” while having an existing

output short (overcurrent) to supply.

2. SFPD pin ≤ 0.2 V.

t

dly(off)

Figure 7. Switching Time Test Circuit Figure 8. Output Fault Unlatch Disable

Delay Test Circuit

Figure 9. Turn–On/Off Waveforms Figure 10. Output Fault Unlatch Disable

Delay Waveforms

Page 9

MC33298

9

MOTOROLA ANALOG IC DEVICE DATA

CIRCUIT DESCRIPTION

Introduction

The MC33298 was conceived, specified, designed, and

developed for automotive applications. It is an eight output

low side power switch having 8–bit serial control. The

MC33298 incorporates SMARTMOS technology having

effective 2.0 µ CMOS logic, bipolar/MOS analog circuitry , and

independent state of the art double diffused MOS (DMOS)

power output transistors. Many benefits are realized as a

direct result of using this mixed technology. A simplified block

diagram of the MC33298 is shown in Figure 1.

Where bipolar devices require considerable control

current for their operation, structured MOS devices, since

they are voltage controlled, require only transient gate

charging current affording a significant decrease in power

consumption. The CMOS capability of the SMARTMOS

process allows significant amounts of logic to be

economically incorporated into the monolithic design. In

addition, bipolar/MOS analog circuits embedded within the

updrain power DMOS output transistors monitor and provide

fast, independent protection control functions for each

individual output. All outputs have internal 65 V at 0.5 A

independent output voltage clamps to provide fast inductive

turn–off and transient protection.

The MC33298 uses high efficiency updrain power DMOS

output transistors exhibiting very low drain to source “on”

resistance values (R

DS(on)

≤ 0.45 Ω) and dense CMOS

control logic. Operational bias currents of less than 4.0 mA

(1.0 mA typical) with any combination of outputs “on” are the

result of using this mixed technology and would not be

possible with bipolar structures. T o accomplish a comparable

functional feature set using a bipolar structure approach

would result in a device requiring hundreds of milliamperes of

internal bias and control current. This would represent a very

large amount of power to be consumed by the device itself

and not available for load use.

In operation the MC33298 functions as an eight output

serial switch serving as a microcontroller (MCU) bus

expander and buffer with fault management and fault

reporting features. In doing so, the device directly relieves

the MCU of the fault management functions. The MC33298

directly interfaces to an MCU and operates at system clock

serial frequencies in excess of 2.0 MHz using a Synchronous

Peripheral Interface (SPI) for control and diagnostic readout.

Figure 11 shows the basic SPI configuration between an

MCU and one MC33298.

To

Logic

MC33298

Shift Register

Parallel

Ports

Receive

Buffer

MC68HCXX

Microcontroller

CSB

Rese

t

SCLK

SO

SI

MISO

MOSI

Shift Register

Figure 11. SPI Interface with Microcontroller

The circuit can also be used in a variety of other

applications in the computer, telecommunications, and

industrial fields. It is parametrically specified over an input

“battery”/supply range of 9.0 V to 16 V but is designed to

operate over a considerably wider range of 5.5 V to 26.5 V.

The design incorporates the use of Logic Level MOSFETs as

output devices. These MOSFETs are sufficiently turned “on”

with a gate voltage of less than 5.0 V thus eliminating the

need for an internal charge pump. Each output is identically

sized and independent in operation. The efficiency of each

output transistor is such that with as little as 9.0 V supply

(V

PWR

), the maximum R

DS(on)

of an output at room

temperature is 0.45 Ω (0.35 Ω typical) and increases to only

1.0 Ω (0.5 Ω typical) as V

PWR

is decreased to 5.5 V.

All inputs are compatible with 5.0 V CMOS logic levels and

incorporate negative or inverted logic. Whenever an input is

programmed to a logic low state (< 1.0 V) the corresponding

low side switched output being controlled will be active low

and turned “on.” Conversely, whenever an input is

programmed to a logic high state (> 3.0 V), the output being

controlled will be high and turned “off.”

8 Outputs

SO SI

CSB SCLK

MC33298

8 Outputs

SO SI

CSB SCLK

MC33298

8 Outputs

SO SI

CSB SCLK

MC33298

8 Outputs

SO SI

CSB SCLK

MC33298

Parallel Port

MISO

IRQ

SCLK

MOSI

MC68XX

Microcontroller

SPI

Figure 12. MC33298 SPI System Daisy Chain

Page 10

MC33298

10

MOTOROLA ANALOG IC DEVICE DATA

One main advantage of the MC33298 is the serial port

which when coupled to an MCU, receives “on”/“off”

commands from the MCU and in return transmits the drain

status of the device’s output switches. Many devices can be

“daisy–chained” together to form a larger system (see

Figure 12). Note in this example that only one dedicated

MCU parallel port (aside from the required SPI) is needed for

chip select to control 32 possible loads.

Multiple MC33298 devices can also be controlled in a

parallel input fashion using SPI (see Figure 13). This figure

shows a possible 24 loads being controlled by only three

dedicated parallel MCU ports used for chip select.

SI

CSB

SCLK

8 Outputs

SI

CSB

SCLK

8 Outputs

SI

CSB

SCLK

MC33298

8 Outputs

Parallel

Ports

SCLK

MOSI

MC68XX

Microconttoller

SPI

MC33298

MC33298

A0

A1

A2

Figure 13. Parallel Input SPI Control

Figure 14 shows a basic method of controlling multiple

MC33298 devices using two MCUs. A system can have only

one master MCU at any given instant of time and one or more

slave MCUs. The master MCU supplies the system clock

signal (top MCU designated the master); the lower MCU

being the slave. It is possible to have a system with more

than one master but not at the same time. Only when the

master is not communicating can a slave communicate. MCU

master control is switched through the use of the slave select

(SS

) pin of the MCUs. A master will become a slave when it

detects a logic low state on its SS

pin.

These basic examples make the MC33298 very attractive

for applications where a large number of loads need be

controlled efficiently. The popular Synchronous Serial

Peripheral Interface (SPI) protocol is incorporated, to this

end, to communicate efficiently with the MCU.

SPI System Attributes

The SPI system is flexible enough to communicate directly

with numerous standard peripherals and MCUs available

from Motorola and other semiconductor manufacturers. SPI

reduces the number of pins necessary for input/output (I/O)

on the MC33298. It also offers an easy means of expanding

the I/O function using few MCU pins. The SPI system of

communication consists of the MCU transmitting, and in

return, receiving one databit of information per clock cycle.

Databits of information are simultaneously transmitted by

one pin, Microcontroller Out Serial In (MOSI), and received

by another pin, Microcontroller In Serial Out (MISO), of

the MCU.

Some features of SPI are:

• Full Duplex, Three–Wire Synchronous Data Transfer

• Each Microcontroller can be a Master or a Slave

• Provides Write Collision Flag Protection

• Provides End of Message Interrupt Flag

• Four I/Os associated with SPI (MOSI, MISO, SCLK, SS)

The only drawbacks to SPI are that an MCU is required for

efficient operational control and, in contrast to parallel input

control, is slower at performing pulse width modulating

(PWM) functions.

8–Bit

MC33298

CSB

SCLK

SO

SI

8 Outputs

8–Bit

CSB

SCLK

SO

SI

8 Outputs

MC33298

8–Bit

MC33298

CSB

SCLK

SO

SI

8 Outputs

SS

8–Bit

MC68XX

Microcontroller

SPI

(Master)

MOSI

MISO

Parallel

Ports

SCLK

A0

A1

A2

Figure 14. Multiple MCU SPI Control

B0

B1

V

DD

SS

8–Bit

MC68XX

Microcontroller

SPI

(Alternate

Master)

MOSI

MISO

Parallel

Ports

SCLK

A0

A1

A2

B0

B1

V

DD

Page 11

MC33298

11

MOTOROLA ANALOG IC DEVICE DATA

PIN FUNCTION DESCRIPTION

CSB Pin

The system MCU selects the MC33298 to be

communicated with through the use of the CSB pin.

Whenever the pin is in a logic low state, data can be

transferred from the MCU to the MC33298 and vise versa.

Clocked–in data from the MCU is transferred from the

MC33298 shift register and latched into the power outputs on

the rising edge of the CSB signal. On the falling edge of the

CSB signal, drain status information is transferred from the

power outputs and loaded into the device’s shift register. The

CSB pin also controls the output driver of the serial output

pin. Whenever the CSB pin goes to a logic low state, the SO

pin output driver is enabled allowing information to be

transferred from the MC33298 to the MCU. To avoid any

spurious data, it is essential that the high–to–low transition of

the CSB signal occur only when SCLK is in a logic low state.

SCLK Pin

The system clock pin (SCLK) clocks the internal shift

registers of the MC33298. The serial input pin (SI) accepts

data into the input shift register on the falling edge of the

SCLK signal while the serial output pin (SO) shifts data

information out of the shift register on the rising edge of the

SCLK signal. False clocking of the shift register must be

avoided to guarantee validity of data. It is essential that the

SCLK pin be in a logic low state whenever chip select bar pin

(CSB) makes any transition. For this reason, it is

recommended though not necessary, that the SCLK pin be

kept in a low logic state as long as the device is not accessed

(CSB in logic high state). When CSB is in a logic high state,

any signal at the SCLK and SI pin is ignored and SO is

tristated (high impedance). See the Data Transfer Timing

diagram of Figure 16.

SI Pin

This pin is for the input of serial instruction data. SI

information is read in on the falling edge of SCLK. A logic high

state present on this pin when the SCLK signal rises will

program a specific output “off,” and in turn, turns “off” the

specific output on the rising edge of the CSB signal.

Conversely, a logic low state present on the SI pin will

program the output “on,” and in turn, turns “on” the specific

output on the rising edge of the CSB signal. To program the

eight outputs of the MC33298 “on” or “off,” an eight bit serial

stream of data is required to be entered into the SI pin

starting with Output 7, followed by Output 6, Output 5, etc., to

Output 0. For each rise of the SCLK signal, with CSB held in

a logic low state, a databit instruction (“on” or “off”) is loaded

into the shift register per the databit SI state. The shift register

is full after eight bits of information have been entered. To

preserve data integrity, care should be taken to not transition

SI as SCLK transitions from a low to high logic state.

SO Pin

The serial output (SO) pin is the tri–stateable output from

the shift register. The SO pin remains in a high impedance

state until the CSB pin goes to a logic low state. The SO data

reports the drain status, either high or low. The SO pin

changes state on the rising edge of SCLK and reads out on

the falling edge of SCLK. When an output is “off” and not

faulted, the corresponding SO databit is a high state. When

an output is “on,” and there is no fault, the corresponding

databit on the SO pin will be a low logic state. The SI/SO

shifting of data follows a first–in–first–out protocol with both

input and output words transferring the Most Significant Bit

(MSB) first. The SO pin is not affected by the status of the

Reset pin.

Reset Pin

The MC33298 Reset pin is active low and used to clear the

SPI shift register and in doing so sets all output switches “off.”

With the device in a system with an MCU; upon initial system

power up, the MCU holds the Reset pin of the device in a

logic low state ensuring all outputs to be “off” until both the

VDD and V

PWR

pin voltages are adequate for predictable

operation. After the MC33298 is reset, the MCU is ready to

assert system control with all output switches initially “off.” If

the V

PWR

pin of the MC33298 experiences a low voltage,

following normal operation, the MCU should pull the Reset

pin low so as to shutdown the outputs and clear the input data

register. The Reset pin is active low and has an internal

pull–up incorporated to ensure operational predictability

should the external pull–up of the MCU open circuit. The

internal pull–up is only 20 µA to afford safe and easy

interfacing to the MCU. The Reset pin of the MC33298

should be pulled to a logic low state for a duration of at least

250 ns to ensure reliable reset.

A simple power “on” reset delay of the system can be

programmed through the use of an RC network comprised of

a shunt capacitor from the Reset pin to Ground and a resistor

to VDD (See Figure 15). Care should be exercised to ensure

proper discharge of the capacitor so as to not adversely

delay the reset nor damage the MCU should the MCU pull the

Reset line low and yet accomplish initialization for turn “on”

delay . It may be easier to incorporate delay into the software

program and use a parallel port pin of the MCU to control the

MC33298 Reset pin.

Reset

MCU

MC33298

Reset

20

µ

A

V

DD

R

DLY

C

DLY

Figure 15. Power “On” Reset

SFPD Pin

The Short Fault Protect Disable (SFPD) pin is used to

disable the over current latch–off. This feature allows control

of incandescent loads where in–rush currents exceed the

device’s analog current limits. Essentially the SFPD pin

determines whether the MC33298 output(s) will instantly shut

down upon sensing an output short or remain “on” in a

current limiting mode of operation until the output short is

removed or thermal shutdown is reached. If the SFPD pin is

tied to VDD = 5.0 V the MC33298 output(s) will remain “on” in

a current limited mode of operation upon encountering a load

short to supply. If the SFPD pin is grounded, a short circuit

will immediately shut down only the output affected. Other

outputs not having a fault condition will operate normally . The

short circuit operation is addressed in more detail later.

Page 12

MC33298

12

MOTOROLA ANALOG IC DEVICE DATA

Figure 16.

SCLK

SI

SO

CSB

Output 7

Output 0

D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 D13 D14 D15

OD* OD* OD* OD* OD* OD* OD* OD* D0* D1* D2* D3* D4* D5* D6* D7*

Old Data

Old Data

New Data DO7

New Data DO0

NOTES: 1. Reset pin is in a logic high state during the above operation.

2. D0, D1, D2, ..., and D15 relate to the ordered entry of program data into the MC33298 with D0/D8 bits (MSB) corresponding to Output 7 and D7/D15 corresponding to Output 0.

3. D0*, D1*, D2*, ..., and D7* relate to the ordered data out of the MC33298 with D0* bit (MSB) corresponding to Output 7.

4. OD* corresponds to Old Databits.

5. For brevity, only DO7 and DO0 are shown which respectively correspond to Output 7 and Output 0.

Data Transfer Timing (General)

CSB High–to–Low

CSB Low–to–High

SO

SI

SO pin is enabled. Output Status information transferred to Output Shift Register.

Data from the Shift Register is transferred to the Output Power Switches.

Will change state on the rising edge of the SCLK pin signal.

Will accept data on the falling edge of the SCLK pin signal.

Figure 16. Data Transfer Timing

Page 13

MC33298

13

MOTOROLA ANALOG IC DEVICE DATA

Power Consumption

The MC33298P has extremely low power consumption in

both the operating and standby modes. In the standby or

“sleep” mode, with VDD ≤ 2.0 V, the current consumed by the

V

PWR

pin is less than 50 µA. In the operating mode, the

current drawn by the VDD pin is less than 4.0 mA (1.0 mA

typical) while the current drawn at the V

PWR

pin is 2.0 mA

maximum (1.0 mA typical). During normal operation, turning

outputs “on” increases I

PWR

by only 20 µA per output. Each

output experiencing a “soft short” (overcurrent conditions just

under the current limit), adds 0.5 mA to the I

PWR

current.

Paralleling of Outputs

Using MOSFET s as output switches allows the connection

of any combination of outputs together. MOSFETs have an

inherent positive temperature coefficient thermal feedback

which modulates R

DS(on)

providing balanced current sharing

between outputs without destructive operation (bipolar

outputs could not be paralleled in this fashion as thermal

run–away would likely occur). The device can even be

operated with all outputs tied together. This mode of

operation may be desirable in the event the application

requires lower power dissipation or the added capability of

switching higher currents. Performance of parallel operation

results in a corresponding decrease in R

DS(on)

while the

Output Off Open Load Detect Currents and the Output

Current Limits increase correspondingly (by a factor of eight

if all outputs are paralleled). Less than 56 mΩ R

DS(on)

with

current limiting of 24 to 48 A will result if all outputs are

paralleled together. There will be no change in the

Overvoltage detect or the “Off” Output Threshold Voltage

Range. The advantage of paralleling outputs within the same

MC33298 affords the existence of minimal R

DS(on)

and

output clamp voltage variation between outputs. Typically,

the variation of R

DS(on)

between outputs of the same device

is less than is 0.5%. The variation in clamp voltages (which

could affect dynamic current sharing) is less than 5%.

Paralleling outputs from two or more devices is possible but

not recommended. This is because there is no guarantee

that the R

DS(on)

and clamp voltage of the two devices will

match. System level thermal design analysis and verification

should be conducted whenever paralleling outputs.

FAULT LOGIC OPERATION

General

The MCU can perform a parity check of the fault logic

operation by comparing the command 8–bit word to the

status 8–bit word. Assume that after system reset, the MCU

first sends an 8–bit command word, Command Word 1, to the

MC33298. Each output that is to be turned “on” will have its

corresponding databit low. Refer to the Data Transfer Timing

diagram of Figure 16. As this word, Command Word 1, is

being written into the shift register of the MC33298, a status

word is being simultaneously written out and received by the

MCU. However, the word being received by the MCU is the

status of the previous write word to the MC33298, Status

Word 0. If the command word of the MCU is written a second

time (Command Word 2 = Command Word 1), the word

received by the MCU, Status Word 2, is the status of

Command Word 1. The timing diagram shown in Figure 16

depicts this operation. Status Word 2 is then compared with

Command Word 1. The MCU will Exclusive OR Status Word

2 with Command Word 1 to determine if the two words are

identical. If the two words are identical, no faults exist. The

timing between the two write words must be greater than

100 µs to receive proper drain status. The system databus

integrity may be tested by writing two like words to the

MC33298 within a few microseconds of each other.

Initial System Setup Timing

The MCU can monitor two kinds of faults:

(1) Communication errors on the data bus and

(2) Actual faults of the output loads.

After initial system start up or reset, the MCU will write one

word to the MC33298. If the word is repeated within a few

microseconds (say 5) of the first word, the word received by

the MCU, at the end of the repeated word, serves as a

confirmation of data bus integrity (1). At startup, the

MC33298 will take 25 to 100 µs before a repeat of the first

word can give the actual status of the outputs. Therefore, the

first word should be repeated at least 100 µs later to verify the

status of the outputs.

The SO of the MC33298 will indicate any one of four faults.

The four possible faults are Over Temperature, Output Off

Open Fault, Short Fault (overcurrent), and V

PWR

Overvoltage Fault. All of these faults, with the exception of

the Overvoltage Fault, are output specific. Over Temperature

Detect, Output Off Open Detect, and Output Short Detect are

dedicated to each output separately such that the outputs are

independent in operation. A V

PWR

Overvoltage Detect is of a

“global” nature causing all outputs to be turned “off.”

Over Temperature Fault

Patent pending Over Temperature Detect and shutdown

circuits are specifically incorporated for each individual

output. The shutdown that follows an Over Temperature

condition is independent of the system clock or any other

logic signal. Each independent output shuts down at 155°C

to 185°C. When an output shuts down due to an Over

Temperature Fault, no other outputs are affected. The MCU

recognizes the fault since the output was commanded to be

“on” and the status word indicates that it is “off.” A maximum

hysteresis of 20°C ensures an adequate time delay between

output turn “off” and recovery. This avoids a very rapid turn

“on” and turn “off” of the device around the Over Temperature

threshold. When the temperature falls below the recovery

level for the Over Temperature Fault, the device will turn “on”

only if the Command Word during the next write cycle

indicates the output should be turned “on.”

Overvoltage Fault

An Overvoltage condition on the V

PWR

pin will cause the

MC33298 to shut down all outputs until the overvoltage

condition is removed and the device is re–programmed by

the SPI. The overvoltage threshold on the V

PWR

pin is

specified as 28 V to 36 V with 1.0 V typical hysteresis.

Following the overvoltage condition, the next write cycle

sends the SO pin the hexadecimal word $FF (all ones)

indicating all outputs are turned “off.” In this way, potentially

dangerous timing problems are avoided and the MCU reset

Page 14

MC33298

14

MOTOROLA ANALOG IC DEVICE DATA

routine ensures an orderly startup of the loads. The

MC33298 does not detect an overvoltage on the VDD pin.

Other external circuitry, such as the Motorola MC33161

Universal Voltage Monitor, is necessary to accomplish this

function.

Output Off Open Load Fault

An Output Off Open Load Fault is the detection and

reporting of an “open” load when the corresponding output is

disabled (input in a logic high state). To understand the

operation of the Open Load Fault detect circuit, see

Figure 17. The Output Off Open Load Fault is detected by

comparing the drain voltage of the specific MOSFET output

to an internally generated reference. Each output has one

dedicated comparator for this purpose.

MC33298

R

L

V

PWR

MOSFET “Off”

Low = Fault

50

µ

A

V

Thres

0.6 to 0.8 x V

DD

Output

Figure 17. Output “Off” Open Load Detect

An Output Off Open Load Fault is indicated when the

output voltage is less than the Output Threshold Voltage

(V

Thres

) of 0.6 to 0.8 x VDD. Since the MC33298 outputs

function as switches, during normal operation, each

MOSFET output should either be completely turned “on” or

“off.” By design the threshold voltage was selected to be

between the “on” and “off” voltage of the MOSFET. During

normal operation, the “on” state VDS voltage of the MOSFET

is less than the threshold voltage and the “off” state V

DS

voltage is greater than the threshold voltage. This design

approach affords using the same threshold comparator for

Output Open Load Detect in the “off” state and Short Circuit

Detect in the “on” state. See Figure 18 for an understanding

of the Short Circuit Detect circuit. With VDD = 5.0 V, an “off”

state output voltage of less than 3.0 V will be detected as an

Output Off Open Load Fault while voltages greater than 4.0 V

will not be detected as a fault.

The MC33298 has an internal pull–down current source of

50 µA, as shown in Figure 17, between the MOSFET drain

and ground. This prevents the output from floating up to

V

PWR

if there is an open load or internal wirebond failure. The

internal comparator compares the drain voltage with a

reference voltage, V

Thres

(0.6 to 0.8 x VDD). If the output

voltage is less than this reference voltage, the MC33298 will

declare the condition to be an open load fault.

During steady–state operation, the minimum load

resistance (RL) needed to prevent false fault reporting during

normal operation can be found as follows:

V

PWR

= 9.0 V (min)

I

LCO

= 50 µA

V

Thres

(max) = (0.8 x 5.5)V = 4.4 V

Therefore, the load resistance necessary to prevent false

open load fault reporting is (using Ohm’s Law) equal to 92 kΩ

or less.

During output switching, especially with capacitive loads,

a false Output Off Open Load Fault may be triggered. To

prevent this false fault from being reported an internal fault

filter of 25 to 100 µs is incorporated. The duration for which a

false fault may be reported is a function of the load

impedance (RL, CL, LL), R

DS(on)

, and C

out

of the MOSFET as

well as the supply voltage, V

PWR

. The rising edge of CSB

triggers a built in fault delay timer which must time out (25

to 100 µs) before the fault comparator is enabled to detect a

faulted threshold. The circuit automatically returns to normal

operation once the condition causing the Open Load Fault

is removed.

Shorted Load Fault

A shorted load (overcurrent) fault can be caused by any

output being shorted directly to supply, or an output

experiencing a current greater than the current limit.

There are three safety circuits progressively in operation

during load short conditions which afford system protection:

1) The device’s output current is monitored in an analog

fashion using a SENSEFET approach and limited; 2) The

device’s output current limit threshold is sensed by

monitoring the MOSFET drain voltage; and 3) The device’s

output thermal limit is sensed and when attained causes only

the specific faulted output to be latched “off,” allowing

remaining outputs to operate normally. All three protection

mechanisms are incorporated in each output affording robust

independent output operation.

The analog current limit circuit is always active and

monitors the output drain current. An overcurrent condition

causes the gate control circuitry to reduce the gate to source

voltage imposed on the output MOSFET which

re–establishes the load current in compliance with current

limit (3.0 to 6.0 A) range. The time required for the current

limit circuitry to act is less than 20 µs. Therefore, currents

higher than 3.0 to 6.0 A will never be seen for more than 20 µs

(a typical duration is 10 µs). If the current of an output

attempts to exceed the predetermined limit of 3.0 to 6.0 A

(4.0 A nominal), the VDS voltage will exceed the V

Thres

voltage and the overcurrent comparator will be tripped as

shown in Figure 18.

Figure 18. Short Circuit Detect and Analog

Current Limiting Circuit

MC33298

R

L

V

PWR

MOSFET “On”

High = Fault

V

Thres

0.6 to 0.8 x V

DD

Output

Analog

Digital

V

ref

Page 15

MC33298

15

MOTOROLA ANALOG IC DEVICE DATA

The status of SFPD will determine whether the MC33298

will shut down or continue to operate in an analog current

limited mode until either the short circuit is removed or

thermal shutdown is reached.

Grounding the SFPD pin will enable the short fault

protection shutdown circuitry. Consider a load short (output

short to supply) occurring on an output before, during, and

after output turn “on.” When the CSB signal rises to the high

logic state, the corresponding output is turned “on” and a

delay timer activated. The duration of the delay timer is

25 to 100 µs. If the short circuit takes place before the output

is turned “on,” the delay experienced is the entire

25 to 100 µs followed by shutdown. If the short occurs

during the delay time, the shutdown still occurs after the

delay time has elapsed. If the short circuit occurs after the

delay time, shut– down is immediate (within 20 µs after

sensing). The purpose of the delay timer is to prevent false

faults from being reported when switching capacitive loads.

If the SFPD pin is at 5.0 V (or V

DD)

, an output will not be

disabled when overcurrent is detected. The specific output

will, within 5.0 to 10 µs of encountering the short circuit, go

into an analog current limited mode. This feature is especially

useful when switching incandescent lamp loads, where high

in–rush currents experienced during startup last for

10 to 20 ms.

Each output of the MC33298 has its own overcurrent

shutdown circuitry. Over temperature faults and the

overvoltage faults are not affected by the SFPD pin.

Both load current sensing and output voltage sensing are

incorporated for Short Fault detection with actual detection

occurring slightly after the onset of current limit. The current

limit circuitry incorporates a SENSEFET approach to

measure the total drain current. This calls for the current

through a small number of cells in the power MOSFET to be

measured and the result multiplied by a constant to give the

total current. Whereas output shutdown circuitry measures

the drain to source voltage and shuts down if a threshold

(V

Thres

) is exceeded.

Short Fault detection is accomplished by sensing the

output voltage and comparing it to V

Thres

. The lowest V

Thres

requires a voltage of 0.6 times 4.5 V (the minimum V

DD

voltage) or 2.7 V to be sensed. For an enabled output, with

VDD = 5.0 ± 0.5 V, an output voltage in excess of 4.4 V will be

detected as a “short” while voltages less than 2.7 V will not be

detected as “shorts.”

Over Current Recovery

If the SFPD pin is in a high logic state, the circuit returns to

normal operation automatically after the short circuit is

removed (unless thermal shutdown has occurred).

If the SFPD pin is grounded and overcurrent shutdown

occurs; removal of the short circuit will result in the output

remaining “off” until the next write cycle. If the short circuit is

not removed, the output will turn “on” for the delay time

(25 to 100 µs) and then turn “off” for every write cycle

commanding a turn “on.”

SFPD Pin Voltage Selection

Since the voltage condition of the SFPD pin controls the

activation of the short fault protection (i.e. shutdown) mode

equally for all eight outputs, the load having the longest

duration of in–rush current determines what voltage (state)

the SFPD pin should be at. Usually if at least one load is, say

an incandescent lamp, the in–rush current on that input will

be milliseconds in duration. Therefore, setting SFPD at 5.0 V

will prevent shutdown of the output due to the in–rush

current. The system relies only on the Over Temperature

Shutdown to protect the outputs and the loads. The

MC33298 was designed to switch GE194 incandescent

lamps with the SFPD pin in a grounded state. Considerably

larger lamps can be switched with the SFPD pin held in a

high logic state.

Sometimes both a delay period greater than 25 to 100 µs

(current limiting of the output) followed by an immediate over

current shutdown is necessary. This can be accomplished by

programming the SFPD pin to 5.0 V for the extended delay

period to afford the outputs to remain “on” in a current limited

mode and then grounding it to accomplish the immediate

shutdown after some period of time. Additional external

circuitry is required to implement this type of function. An

MCU parallel output port can be devoted to controlling the

SFPD voltage during and after the delay period, is often a

much better method. In either case, care should be taken to

execute the SFPD start–up routine every time start–up or

reset occurs.

Undervoltage Shutdown

An undervoltage VDD condition will result in the global

shutdown of all outputs. The undervoltage threshold is

between 2.5 V and 4.5 V. When VDD goes below the

threshold, all outputs are turned “off” and the SO register is

reset to indicate the same.

An undervoltage condition at the V

PWR

pin will not cause

output shutdown and reset. When V

PWR

is between 5.5 V

and 9.0 V, the outputs will operate per the command word.

However, the status as reported by the serial output (SO) pin

may not be accurate. Proper operation at V

PWR

voltages

below 5.5 V cannot be guaranteed.

Deciphering Fault Type

The MC33298 SO pin can be used to understand what

kind of system fault has occurred. With eight outputs having

open load, over current and over temperature faults, a total of

25 different faults are possible. The SO status word received

by the MCU will be compared with the word sent to the

MC33298 during the previous write cycle. If the two words

are not the same, then the MCU should be programmed to

determine which output or outputs are indicating faults. If the

command bit for any of the output switches indicating a fault

is high, the fault is an open load.

The eight open load faults are therefore the ones most

easily detected. Over current and over temperature faults are

often related. Turning the affected output switches “off” and

waiting for some time should make these faults go away.

Over current and over temperature faults can not be

differentiated in normal application usage.

One advantage of the synchronous serial output is that

multiple faults can be detected with only one pin (SO) being

used for fault status indication.

If V

PWR

experiences an overvoltage condition, all outputs

will immediately be turned “off” and remain latched “off.”

A new command word is required to turn the outputs back

“on” following an overvoltage condition.

Page 16

MC33298

16

MOTOROLA ANALOG IC DEVICE DATA

Output Voltage Clamping

Each output of the MC33298 incorporates an internal

voltage clamp to provide fast turn–off and transient protection

of the output. Each clamp independently limits the drain to

source voltage to 65 V at drain currents of 0.5 A and keeps

the output transistors from avalanching by causing the

transient energy to be dissipated in the linear mode (see

Figure 19). The total energy (EJ) can be calculated by

multiplying the current area under the current curve (IA)

during the time the clamp is active and the clamp

voltage (VCL).

Characterization of the output clamps, using a single pulse

repetitive method at 0.5 A, indicate the maximum energy to

be 100 mJ at 25°C and 25 mJ at 125°C per output. Using a

single pulse non–repetitive method at 0.5 A the clamps are

capable of 2.0 Joules at 25°C and 0.5 Joules at 125°C.

Clamp Energy

(EJ = IA x VCL x t)

Drain Voltage

Time

Current

Area (IA)

Gnd

Drain–to–Source “On”

V

PWR

Drain Current

(ID = 0.5 A)

Drain–to–Source Clamp

Voltage (VCL = 65 V)

Figure 19. Output Voltage Clamping

Voltage (V

DS(ON)

)

THERMAL CHARACTERIZA TION

Thermal Model

Logic functions take up a very small area of the die and

generate negligible power. In contrast, the output transistors

take up most of the die area and are the primary contributors

of power generation. The thermal model shown in Figure 20

was developed for the MC33298 mounted on a typical PC

board. The model is accurate for both steady state and

transient thermal conditions. The components Rd0, Rd1,

R

d2,

..., and Rd7 represent the steady state thermal

resistance of the silicon die for transistor outputs 0, 1, 2, ...,

and 7, while Cd0, Cd1, Cd2, ..., and Cd7 represent

the corresponding thermal capacitance of the silicon

die transistor outputs and plastic. The device area and

die thickness determine the values of these specific

components.

The thermal impedance of the package from the internal

mounting flag to the outside environment is represented by

the terms R

pkg

and C

pkg

. The steady state thermal resistance

of leads and the PC board make up the steady state package

thermal resistance, R

pkg

. The thermal capacitance of the

package is made up of the combined capacitance of the flag

and the PC board. The mold compound was not modeled as

a specific component but is factored into the other overall

component values.

The battery voltage in the thermal model represents the

ambient temperature the device and PC board are subjected

to. The I

PWR

current source represents the total power

dissipation and is calculated by adding up the power

dissipation of each individual output transistor. This is easily

done by knowing R

DS(on)

and load current of the

individual outputs.

Very satisfactory steady state and transient results have

been experienced with this thermal model. Tests indicate the

model accuracy to have less than 10% error. Output

interaction with an adjacent output is thought to be the main

contributor to the thermal inaccuracy. Tests indicate little or

no detectable thermal affects caused by distant output

transistors which are isolated by one or more other outputs.

Tests were conducted with the device mounted on a typical

PC board placed horizontally in a 33 cubic inch still air

enclosure. The PC board was made of FR4 material

measuring 2.5″ by 2.5″, having double–sided circuit traces of

1.0 oz. copper soldered to each device pin. The board

temperature was measured with thermal couple soldered to

the board surface one inch away from the center of the

device. The ambient temperature of the enclosure was

measured with a second thermal couple located over the

center and one inch distant from device.

Thermal Performance

Figure 20 shows the worst case thermal component

parameters values for the MC33298 in the 20 pin plastic

power DIP and the SOP–24 wide body surface mount

package. The power DIP package has Pins 5, 6, 15, and 16

connected directly to the lead frame flag. The parameter

values indicated take into account adjacent output cell thermal

pulling effects as well as different output combinations. The

characterization was conducted over power dissipation levels

of 0.7 to 17 W. The junction–to–ambient temperature thermal

resistance was found to be 37°C/W with a single output

active (31°C/W with all outputs dissipating equal power) and

in conjunction with this, the thermal resistance from junction

to PC board (R

junction–board

) was found to be 27°C/W (board

temperature, measured 1″ from device center). In addition,

the thermal resistance from junction–to–heatsink lead was

found to approximate 10°C/W. Devoting additional PC board

metal around the heatsinking pins improved R

pkg

from 30° to

28°C/W.

The SOP–24 package has Pins 5, 6, 7, 8, 17, 18, 19, and

20 of the package connected directly to the lead frame flag.

Characterization was conducted in the same manner as for

the DIP package. The junction–to–ambient temperature

resistance was found to be 40°C/W with a single output

active (34°C/W with all outputs dissipating equal power) and

the thermal resistance from junction–to–PC board

(R

junction–board

) to be 30°C/W (board temperature,

measured 1″ from device center). The junction–to–heatsink

lead resistance was found again to approximate 10°C/W.

Devoting additional PC board metal around the heatsinking

pins for this package improved the R

pkg

from 33° to 31°C/W.

The total power dissipation available is dependent on the

number of outputs enabled at any one time. At 25°C the

R

DS(on)

is 450 mΩ with a coefficient of 6500 ppm/°C. For the

junction temperature to remain below 150°C, the maximum

available power dissipation must decrease as the ambient

temperature increases. Figures 21 and 22 depict the per

output limit of current at ambient temperatures necessary for

the plastic DIP and SOP packages respectively when one,

four, or eight outputs are enabled “on.” Figure 23 depicts how

the R

DS(on)

output value is affected by junction temperature.

Page 17

MC33298

17

MOTOROLA ANALOG IC DEVICE DATA

*Ω = °C/W, F = W s/°C, I

PWR

= W, and VA = °C

0.15

0.2

C

pkg

(F)*

33

30

R

pkg

(Ω)*

0.002

0.002

C

dx

(F)*

7.0

7.0

R

dx

(Ω)*

SOP–24L

20 Pin DIP

Package

Output 7Output 6Output 2Output 1Output 0

I

PWR

(Steady State or Transient)

(1.0 A = 1.0 W of Device Power Dissipation)

Junction Temperature Node

VD = TD (

°

C)

(Volts represent Die Surface Temperature)

Ambient Temperature Node

VA = TA (

°

C)

(1.0 V = 1

°

C Ambient Temperature)

Flag Temperature Node

C

pkg

= C

flag

+ CPC

Board

R

pkg

= R

leads

+ RPC

Board

C

d7

R

d7

C

d6

R

d6

C

d2

R

d2

C

d1

R

d1

C

d0

R

d0

Figure 20. Thermal Model (Electrical Equivalent)

Page 18

MC33298

18

MOTOROLA ANALOG IC DEVICE DATA

1 Output “On” (40°C/W)

1 Output “On” (37°C/W)

8 Outputs “On” (31°C/W)

4 Outputs “On” (32°C/W)

4 Outputs “On” (35°C/W)

I

L(max)

, , MAXIMUM CURRENT PER OUTPUT (A)

I

L(max)

, , MAXIMUM CURRENT PER OUTPUT (A)

Figure 21. Maximum DIP Package Steady State

Output Current versus Ambient Temperature

–50

TA, AMBIENT TEMPERATURE (

°

C)

Figure 22. Maximum SOP Package Steady State

Ouput Current versus Ambient Temperature

3.0

–50

TA, AMBIENT TEMPERATURE (

°

C)

2.5

2.0

1.5

1.0

0.5

0

– 25 0 25 50 75 100 125 150

– 25 0 25 50 75 100 125 150

2.5

2.0

1.5

1.0

0

0.5

8 Outputs “On” (34°C/W)

R

DS(on)

, OUTPUT “ON” RESISTANCE ( )

Ω

–50

0.9

TJ, JUNCTION TEMPERATURE (

°

C)

Figure 23. Maximum Output “On” Resistance

versus Junction Temperature

0.7

0.6

0.5

0.4

0.2

0.3

– 25 0 25 50 75 100 125 150

0.8

R

DS(on)

@ 150°C = 0.8

Ω

TJ = 150°C

R

DS(on)

@ 150°C = 0.8

Ω

TJ = 150°C

V

PWR

= 13 V

VDD = 5.0 V

I

OUT

= 0.5 A

Page 19

MC33298

19

MOTOROLA ANALOG IC DEVICE DATA

Latch–Up Immunity

Device latch–up caused by substrate injection has been

characterized. Latch–up immunity has both a dc and a

transient immunity component. DC latch–up immunity results

indicate the device to be capable of withstanding in excess of

four amps of reverse current out of any of the output

transistors while the control logic continues to function

normally. The logic control current (IDD) was found to

increase by only 0.6 mA with four amps of current being

pulled out of an output. Additionally, the I

PWR

current was

found to increase by only 0.15 mA under the same condition.

These increases are a result of minority carriers being

injected into substrate and subsequently being collected.

The following procedure has been developed to test for

transient latch–up immunity and has been applied to this

automotive circuit design. Results of transient testing indicate

the device to operate properly at output currents greater than

1.5 A. The procedure tests for the device’s immunity to

intermittent load to battery current connection with the device

controlling an inductive load. Appropriately termed “the file

test,” the battery is connected to a shop file while the lead to

the inductive load is dragged across the files surface causing

intermittent load opens producing lots of arcs, sparks, and

smoke, plus severe transients (see Figure 24). It is during

these severe transients that latch–up most likely could occur.

The battery voltage used for this test was 18 V and the

inductive load was 2.0 mH. These values were found to

produce severe transient stresses of the device outputs. All

outputs must maintain operation and input control during

transient generation to pass “the file test.”

The device’s input control currents were found to remain

stable and were not affected by dc or transient latch–up

immunity testing.

Figure 24. Transient Latch–Up Immunity File Test

Battery

0.1 µF

I

limit

Output 0

R

S

Open

Load

Detect

Short

Circuit

Detect

Over

T emperature

Detect

SO

SI

SCLK

CSB

Reset

SFPD

V

DD

Gate

Control

65 V

Outputs

1–7

Grounds

V

PWR

APPLICATIONS INFORMATION

SIOP Communication

Two common communication protocols used in Motorola’s

microprocessors are the Serial Peripheral Interface (SPI) and

Synchronous Input Output Port (SIOP). SIOP is a subset of

the more flexible SPI and the simpler of the two protocols.

SIOP is used on many of the MC68HC05 family of

microcontrollers. Restrictions of the SIOP protocol include:

1) the SCLK frequency is fixed at one–fourth the internal

clock rate and 2) the polarity of the SCLK signal is fixed.

By way of example, the MC68HC05P9 utilizes SIOP

protocol and is not directly compatible with the serial input

requirements of the MC33298. Specifically, the MC33298

accepts data on the falling edge of SCLK whereas its rising

edge triggers data transfer in the SIOP protocol. SCLK is high

during SIOP transmissions, which is the opposite of what the

MC33298 requires.

Though designed specifically for SPI communication

protocol, the MC33298 can easily be adapted to

communicate with SIOP protocol through the use of

software. The amount of code required to implement SPI in

software is relatively small, so the only major drawback is a

slower transfer of data. The software routine shown in

Table 1 completes a transfer in about 100 µs.

Cost

The bottom line relates to cost. The MC33298 is a very

cost effective octal output serial switch for applications

typically encountered in the automotive and industrial market

segments. To accomplish only the most basic serial switch

function the MC33298 offers, using a discrete semiconductor

approach, would require the use of at least eight logic level

power MOSFETs for the outputs and two shift registers for

the I/O plus other miscellaneous “glue” components.

Additional circuitry would have to be incorporated to

accomplish the protection features offered by the MC33298.

Other noteworthy advantages the MC33298 offers are

conservation of power and board space, requirement of

fewer application components, and enhanced application

reliability. The MC33298 is available at a fraction of the cost

required for discrete component implementation and

represents true value.

The MC33298 represents a cost effective device having

advanced performance and features and worthy of

consideration.

Page 20

MC33298

20

MOTOROLA ANALOG IC DEVICE DATA

Table 1. Program to Exercise the MC33298 Using SPI (Having Only SIOP) Protocol

SET LABELS FOR OUTPUT REGISTERS

PORTA

EQU $0000 ;SPI Port

;DO (Data Out), SCLK, CS, RESET, X, FLTOUT, DI (Data In)

PORTB EQU $0001 ;Normally the SIOP Port. SIOP will be disabled

PORTC EQU $0002 ;A–D Converter Port

PORTD EQU $0003 ;Timer Capture Port

DDRA EQU $0004 ;Data Direction Register for SPI Port

DDRB EQU $0005 ;Data Direction Register for SCLK, SDI, SDO, 11111

DDRC EQU $0006 ;Data Direction Register for A–D Converter Port

DDRD EQU $0007 ;Data Direction Register for PORTD, Timer Capture

DTOUT EQU $0080 ;Register for the SPI output data. This register will be used for a Serial–to–Parallel transformation.

DATAIN EQU $0081 ;Input Register for SPI. Also used for a Serial–to–Parallel transformation.

VALUE EQU $0082 ;Register to store the SPI. Also used for a Serial–to–Parallel transformation.

DATA1 EQU $0083 ;Miscellaneous data register

SCR EQU $000A ;Label for SIOP control register, 0 SPE 0 MSTR 0 0 0 0.

SSR EQU $000B ;Label for SIOP status register, SPIF DCOL 0 0 0 0 0 0, Read Only Register.

SDR EQU $000C ;Label for SIOP data register.

ORG $0100 ;Program starts at first byte of User ROM.

INIT RSP ;Reset Stack Pointer to $FF.

INITIALIZE THE DATA REGISTERS AND THEIR DATA DIRECTION BIT REGISTERS

LDA #$FE ;Configuration PortA as the SPI Port.

STA DDRA ;All but Bit 0 will be outputs.

LDA #$FF

STA DDRB ;Configure Register B as an output. SIOP is not used for the MC33298, but is available for

another peripheral.

STA DDRC ;Configure Register C as an output

STA DDRD ;Configure Register D as an output

LDA #%00010000 ;Initialize the SIOP Control Register.

STA SCR ;Disable SIOP by clearing Bit 6.

SELECT THE DESIRED OUTPUTS

TOP LDA

STA

#$55

VALUE

Select outputs of MC33298 to be turned “on.” This instruction is left inside the loop to include

changes while running the program. A set bit will cause the associated MC33298 output to be

“off.” The value register is uncorrupted by the serial–to–parallel conversion.

BSET 4,PORTA ;Reset the MC33298.

BCLR 4,PORT A ;Also establishes a + or – trigger source

BSET 4,PORTA ;The MC33298 is reset with a logic low.

BCLR 5,PORTA ;Enable MC33298 by pulling CSB (chip select bar) low. Within the MC33298 the Fault Status is

transferred to the MC33298 Serial Register at a falling edge of CSB.

LDA VALUE ;Select outputs to be turned “on.”

STA DT OUT ;Save Output Word (Value) to check for fault.

Page 21

MC33298

21

MOTOROLA ANALOG IC DEVICE DATA

SPI TRANSFER LOOP

LDX #$07 ;Set the number of Read/Shift cycles.

LOOP ASL DATAIN ;Shift a Zero into LSB of DATAIN and ASL other bits.

ASL DTOUT ;Test value currently in MSB of DTOUT.

BCS DOONE ;

BCLR 7,PORTA ;MSB was Zero, so clear DA TA OUT bit.