Page 1

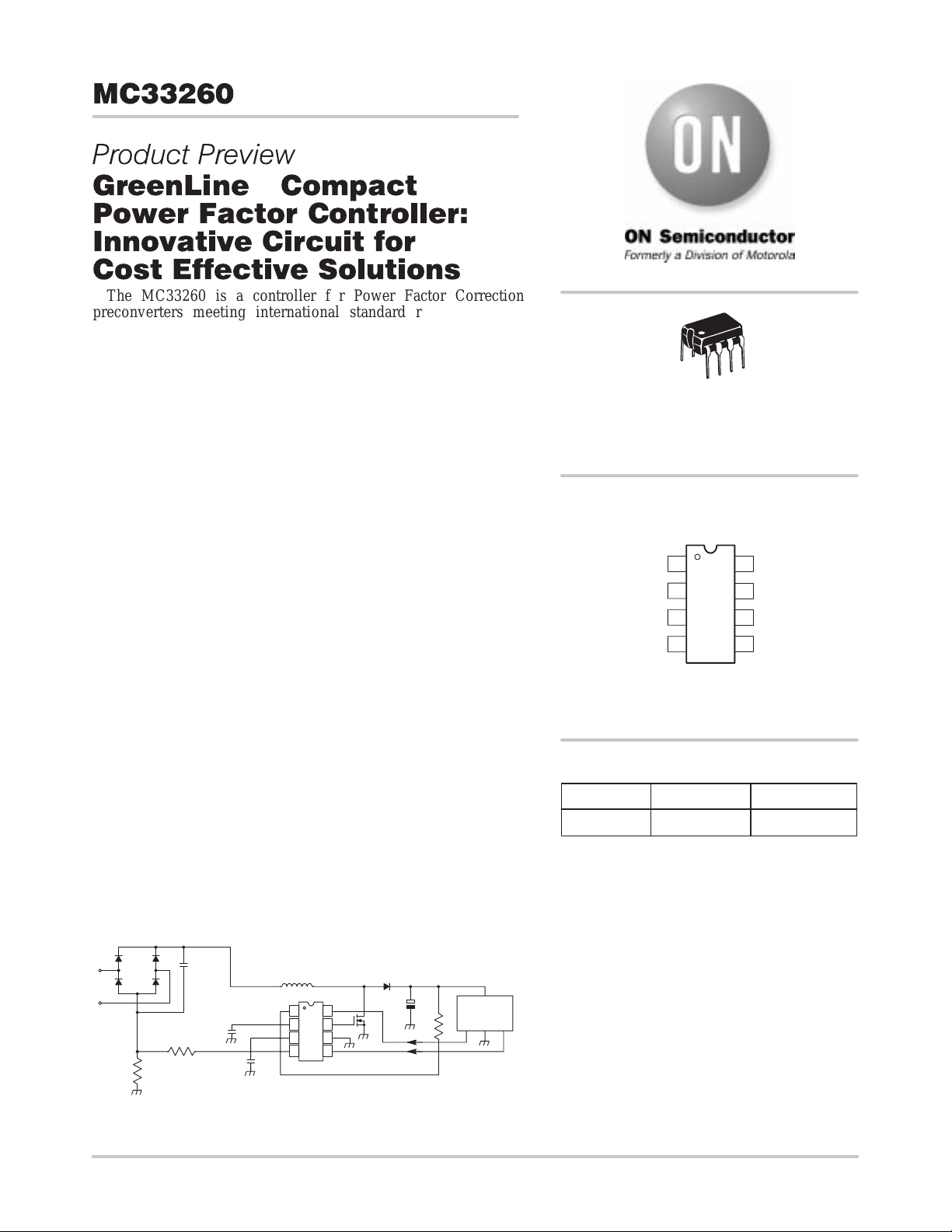

MC33260

Product Preview

GreenLine

Compact

Power Factor Controller:

Innovative Circuit for

Cost Effective Solutions

The MC33260 is a controller for Power Factor Correction

preconverters meeting international standard requirements in

electronic ballast and off–line power conversion applications.

Designed to drive a free frequency discontinuous mode, it can also be

synchronized and in any case, it features very effective protections that

ensure a safe and reliable operation.

This circuit is also optimized to offer extremely compact and cost

effective PFC solutions. While it requires a minimum number of

external components, the MC33260 can control the follower boost

operation that is an innovative mode allowing a drastic size reduction

of both the inductor and the power switch. Ultimately, the solution

system cost is significantly lowered.

Also able to function in a traditional way (constant output voltage

regulation level), any intermediary solutions can be easily

implemented. This flexibility makes it ideal to optimally cope with a

wide range of applications.

General Features

• Standard Constant Output Voltage or “Follower Boost” Mode

• Switch Mode Operation: Voltage Mode

• Latching PWM for Cycle–by–Cycle On–Time Control

• Constant On–Time Operation That Saves the Use of an Extra Multiplier

• Totem Pole Output Gate Drive

• Undervoltage Lockout with Hysteresis

• Low Start–Up and Operating Current

• Improved Regulation Block Dynamic Behavior

• Synchronization Capability

• Internally Trimmed Reference Current Source

Safety Features

• Overvoltage Protection: Output Overvoltage Detection

• Undervoltage Protection: Protection Against Open Loop

• Effective Zero Current Detection

• Accurate and Adjustable Maximum On–Time Limitation

• Overcurrent Protection

• ESD Protection on Each Pin

http://onsemi.com

8

1

DIP–8

P SUFFIX

CASE 626

PIN CONNECTIONS AND

MARKING DIAGRAM

AWL

YYWW

V

CC

Gate Drive

7

Gnd

6

Synchronization

5

Input

Feedback Input

V

control

Oscillator

Capacitor (CT)

Current Sense

Input

AWL = Manufacturing Code

18

2

3

MC33260

4

YYWW = Date Code

(Top View)

ORDERING INFORMATION

Device Package Shipping

MC33260P Plastic DIP–8 50 Units / Rail

TYPICAL APPLICATION

D1...D4

R

cs

This document contains information on a product under development. ON Semiconductor

reserves the right to change or discontinue this product without notice.

Semiconductor Components Industries, LLC, 1999

November, 1999 – Rev. 1

Filtering

Capacitor

V

control

R

OCP

L1

8

1

2

7

3

6

MC33260

4

CT

5

V

Sync

D1

C1

CC

+

M1

LOAD

(SMPS, Lamp

Ballast,...)

R

o

1 Publication Order Number:

MC33260/D

Page 2

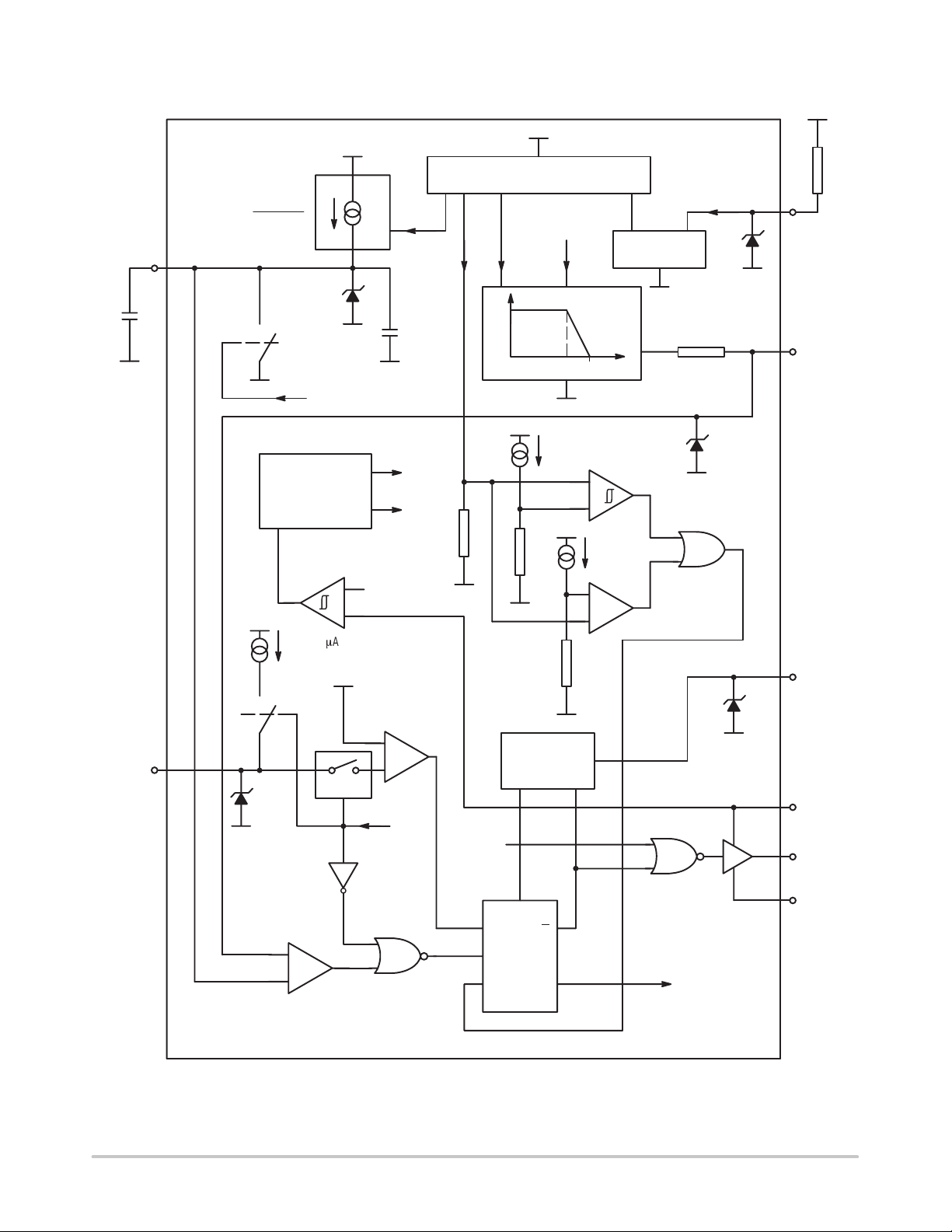

CT

MC33260

BLOCK DIAGRAM

V

o

Current Mirror

2 x IO x I

I

– ch =

OSC

3

O

I

ref

11 V

I

o

I

oIo

I

ref

V

ref

1.5 V

Current

Mirror

I

o

FB

1

Current

Sense

01

Output_Ctrl

REGULATOR

Enable

–

+

Ics (205 mA)

–60 mV

01

4

11 V

LEB

15 pF

V

ref

I

ref

11 V/8.5 V

+

–

Output_Ctrl

300 k

V

reg

I

o

97%I

r

r

Synchro

Arrangement

I

ref

ref

I

ovpH/IovpL

r

I

+

–

uvp

+

–

11 V

OVP

UVP

11 V

V

control

2

Synchro

5

V

CC

8

+

–

PWM Comparator

ThStdwn

S

R

PWM

R

Latch

RQ

http://onsemi.com

2

Drive

7

Gnd

6

Q

Output_Ctrl

MC33260

Page 3

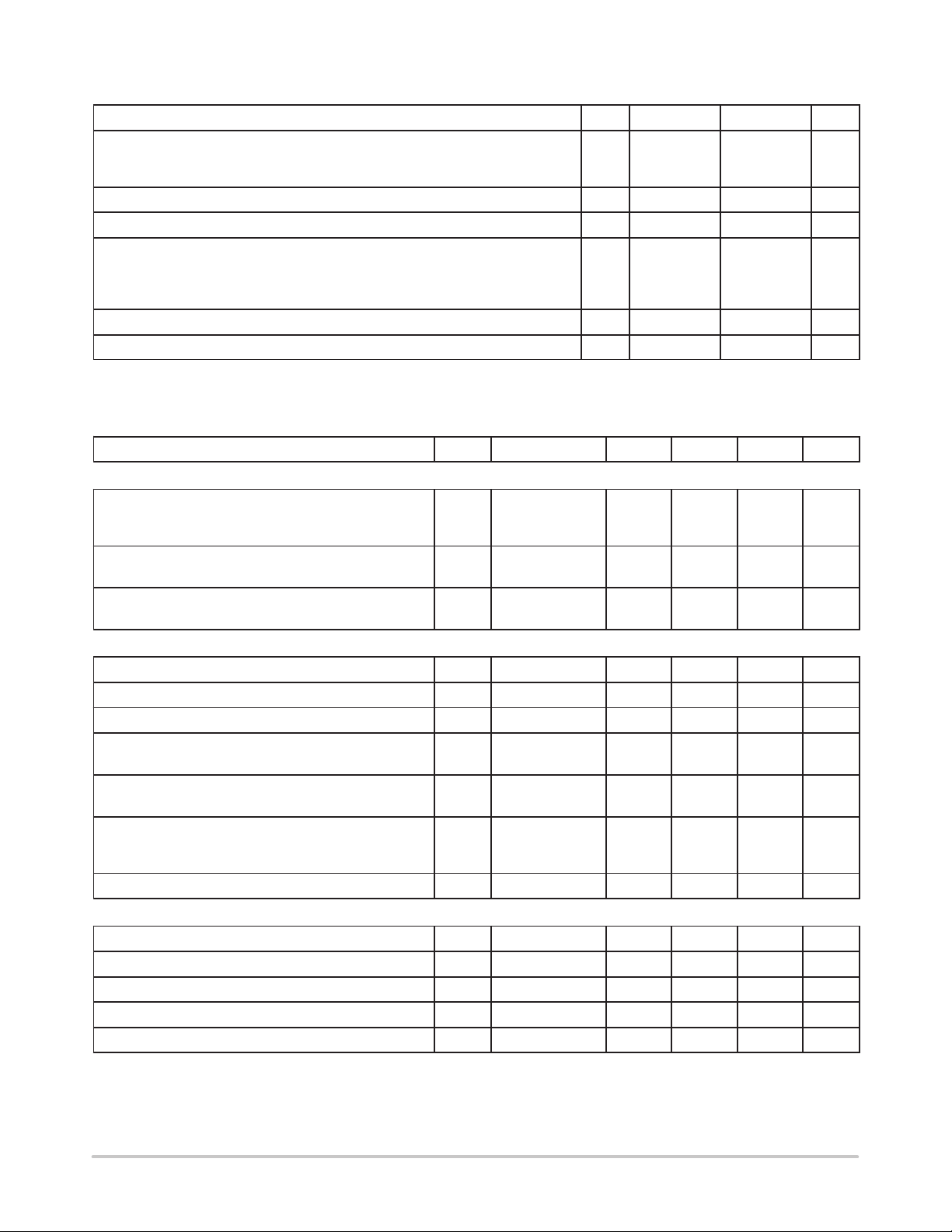

MC33260

MAXIMUM RATINGS

Rating Pin # Symbol Value Unit

Gate Drive Current (Pin 7)*

Source

Sink

VCC (Pin 8) Maximum Voltage 8 (Vcc)

Input Voltage V

Power Dissipation and Thermal Characteristics

P Suffix, DIP Package

Maximum Power Dissipation @ TA = 85°C

Thermal Resistance Junction to Air

Operating Junction Temperature T

Operating Ambient Temperature T

*The maximum package power dissipation must be observed.

7

I

O(Source)

I

O(Sink)

max

in

P

D

R

θJA

J

A

–500

500

16 V

–0.3 to +10 V

600

100

150 °C

–40 to +105 °C

mA

mW

°C/W

ELECTRICAL CHARACTERISTICS (V

unless otherwise noted.)

Characteristic

GATE DRIVE SECTION

Gate Drive Resistor

Source Resistor @ I

Sink Resistor @ I

Gate Drive Voltage Rise Time (From 3 V Up to 9 V)

(Note 1)

Output Voltage Falling Time (From 9 V Down to 3 V)

(Note 1)

OSCILLATOR SECTION

Maximum Oscillator Swing 3 ∆V

Charge Current @ I

Charge Current @ I

Ratio Multiplier Gain Over Maximum Swing

@ I

=100 µA

pin1

Ratio Multiplier Gain Over Maximum Swing

@ I

=200 µA

pin1

Average Internal Pin 3 Capacitance Over Oscillator

Maximum Swing (V

(Note 2)

Discharge Time (CT = 1 nF) 3 T

REGULATION SECTION

Regulation High Current Reference 1 I

Ratio (Regulation Low Current Reference)/I

Pin 2 Impedance 1 Z

Pin 1 Clamp Voltage @ I

Pin 1 Clamp Voltage @ I

pin1

pin1

= 100 mA

pin7

= 100 mA

pin7

= 100 µA 3 I

= 200 µA 3 I

Varying From 0 Up to 1.5 V)

pin3

= 100 µA 1 V

pin1

= 200 µA 1 V

pin1

= 13 V, TJ = 25°C for typical values, TJ = –40 to 105°C for min/max values

CC

Pin # Symbol Min Typ Max Unit

7

7 t

7 t

3 K

3 K

3 C

reg–H

1 I

reg–L/Ireg–H

R

OL

R

OH

r

f

T

charge

charge

osc

osc

int

disch

reg–H

pin3

pin1–100

pin1–200

10

5

— 50 — ns

— 50 — ns

1.4 1.5 1.6 V

87.5 100 112.5 µA

350 400 450 µA

5600 6400 7200 1/(V.A)

5600 6400 7200 1/(V.A)

10 15 20 pF

— 0.5 1 µs

192 200 208 µA

0.965 0.97 0.98 —

— 300 — kΩ

1.5 2.1 2.5 V

2 2.6 3 V

20

10

35

25

Ω

http://onsemi.com

3

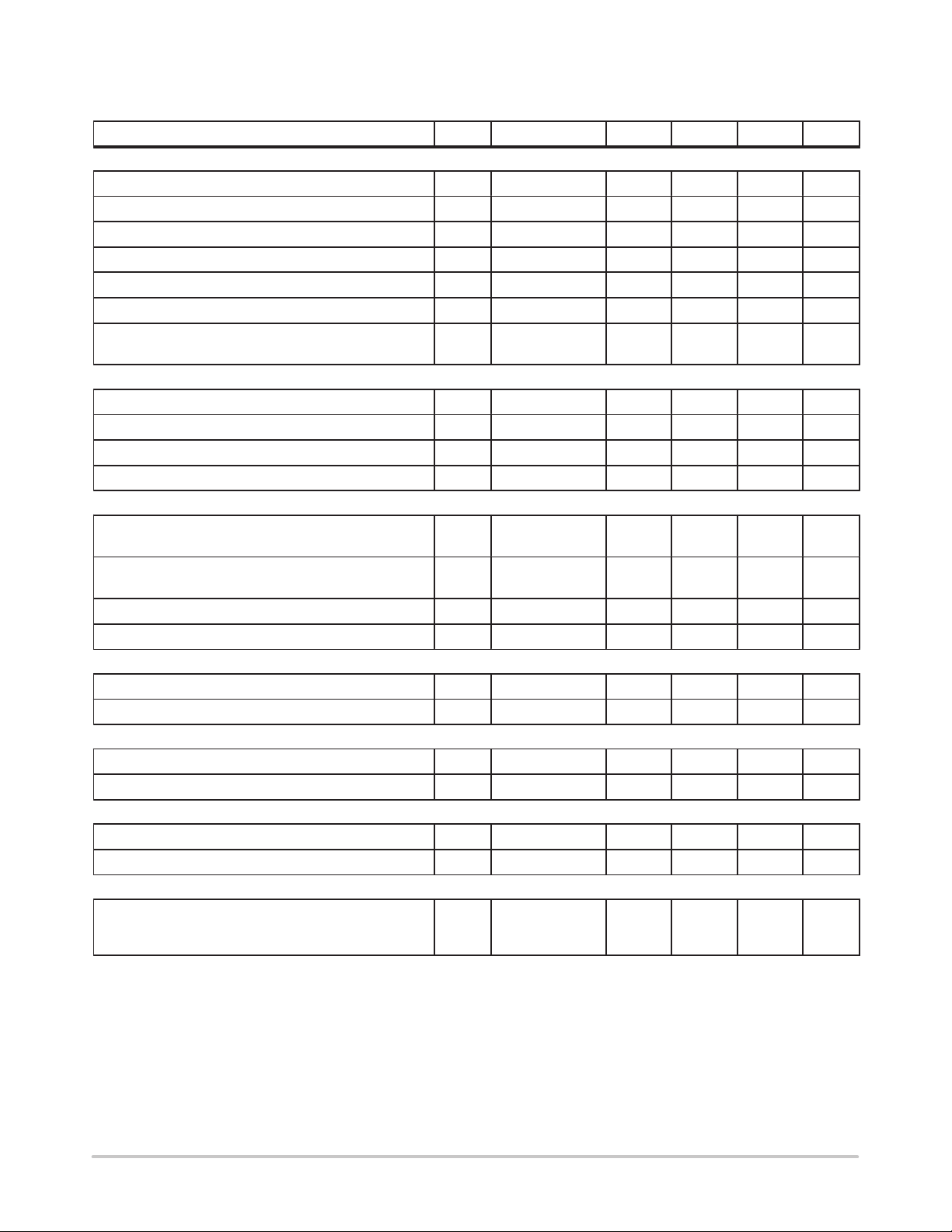

Page 4

MC33260

ELECTRICAL CHARACTERISTICS (V

unless otherwise noted.)

Characteristic UnitMaxTypMinSymbolPin #

CURRENT SENSE SECTION

Zero Current Detection Comparator Threshold 4 V

Negative Clamp Level (I

Bias Current @ V

Propagation Delay (V

Pin 4 Internal Current Source 4 I

Leading Edge Blanking Duration τ

OverCurrent Protection Propagation Delay

(Pin 4 < V

SYNCHRONIZATION SECTION

Synchronization Threshold 5 V

Negative Clamp Level (I

Minimum Off–Time 7 T

Minimum Required Synchronization Pulse Duration 5 T

OVERVOLTAGE PROTECTION SECTION

OverVoltage Protection High Current Threshold

and I

reg–H

OverVoltage Protection Low Current Threshold

and I

reg–H

Ratio (I

OVP–H/IOVP–L

Propagation Delay (I

UNDERVOLTAGE PROTECTION SECTION

Ratio (UnderVoltage Protection Current Threshold)/I

Propagation Delay (I

THERMAL SHUTDOWN SECTION

Thermal Shutdown Threshold 7 T

Hysteresis 7 ∆T

VCC UNDERVOLTAGE LOCKOUT SECTION

Start–Up Threshold 8 V

Disable Voltage After Threshold T urn–On 8 V

TOTAL DEVICE

Power Supply Current

Start–Up (VCC = 5 V with VCC Increasing)

Operating @ I

NOTES:

(1) 1 nF being connected between the pin 7 and ground.

(2) Guaranteed by design.

(3) No load is connected to the gate drive which is kept high during the test.

pin4

ZCD–th

Difference

Difference

pin1

= –1 mA) 4 Cl–neg — –0.7 — V

pin2

= V

ZCD–th

> V

pin4

ZCD–th

to Gate Drive Low)

= –1 mA) 5 Cl–neg — –0.7 — V

pin5

) 1 I

pin1

pin1

= 200 µA

> 110% I

< 12% I

to Gate Drive Low) 7 T

ref

to Gate Drive Low) 7 T

ref

= 13 V, TJ = 25°C for typical values, TJ = –40 to 105°C for min/max values

CC

4 I

) to Gate Drive High 7 T

7 T

reg–H

1 I

1 I

1 I

8 I

OVP–H–Ireg–H

OVP–L–Ireg–H

OVP–H/IOVP–L

ZCD–th

b–cs

ZCD

OCP

LEB

OCP

sync–th

off

sync

OVP

UVP/Ireg–H

UVP

stdwn

stdwn

stup–th

disable

CC

–90 –60 –30 mV

–0.2 — — µA

— 500 — ns

192 205 218 µA

— 400 — ns

100 160 240 ns

0.8 1 1.2 V

1.5 2.1 2.7 µs

— — 0.5 µs

8 13 18 µA

0 — — —

1.02 — — —

— 500 — ns

12 14 16 %

— 500 — ns

— 150 — °C

— 30 — °C

9.7 11 12.3 V

7.4 8.5 9.6 V

—

—

0.1

4

0.25

8

mA

http://onsemi.com

4

Page 5

MC33260

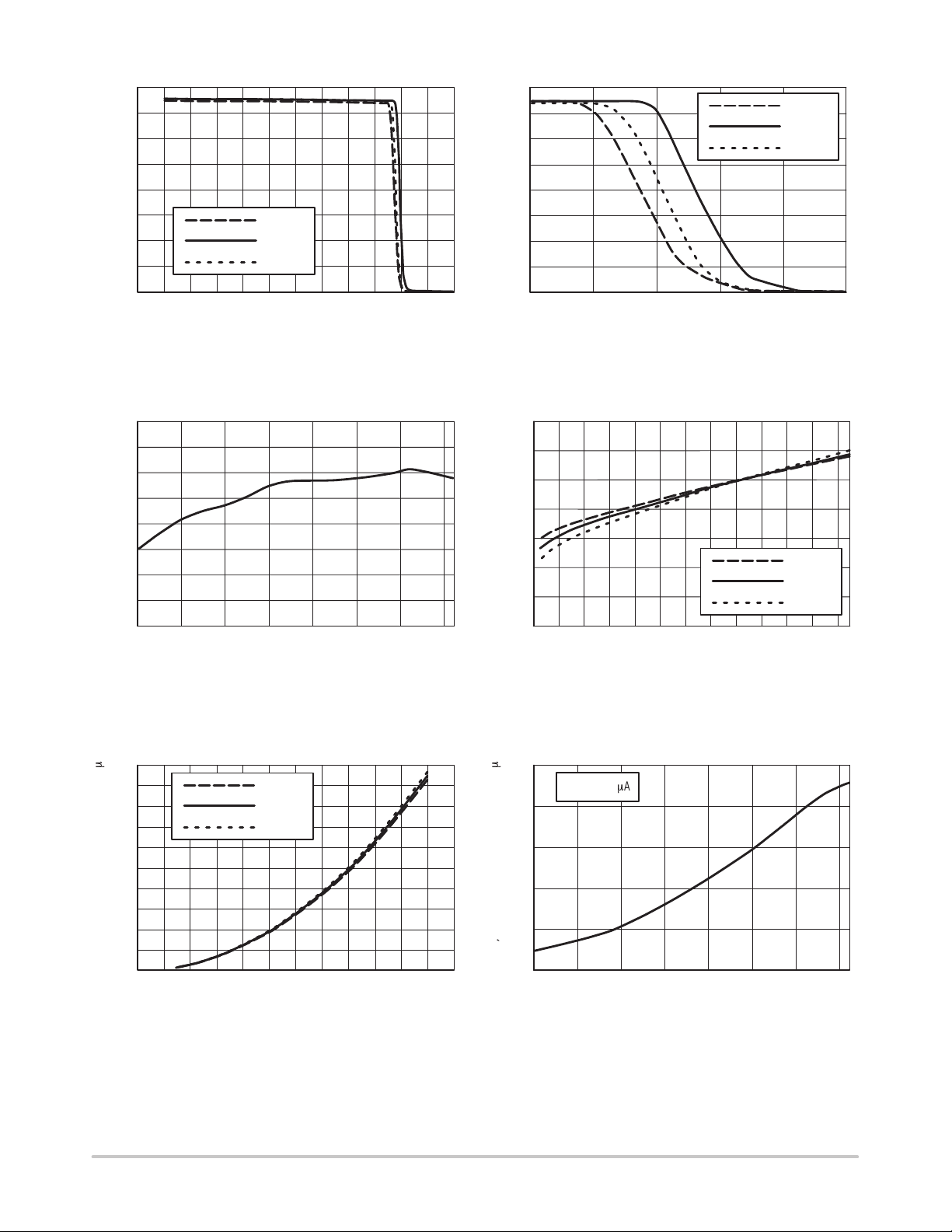

1.6

1.4

1.2

1.0

0.8

control

V : REGULATION BLOCK OUTPUT (V)

0.6

0.4

0.2

0

20

0

60

40

I

pin1

–40°C

25°C

105°C

100

80

: FEEDBACK CURRENT (µA)

120

140

Figure 1. Regulation Block Output versus

Feedback Current

1.340

1.335

1.330

1.325

1.320

1.315

1.310

MAXIMUM OSCILLAT OR SWING (V)I , OSCILLATOR CHARGE CURRENT ( A)

1.305

1.300

–40

–20 0

20

40 60

JUNCTION TEMPERATURE (°C)

160

180

200

80

220

100

240

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

control

V : REGULATION BLOCK OUTPUT (V)

0

185

190 195 200 205 210

I

: FEEDBACK CURRENT (µA)

pin1

Figure 2. Regulation Block Output versus

Feedback Current

3.5

3.0

2.5

2.0

1.5

1.0

FEEDBACK INPUT VOLTAGE (V)

0.5

0

0

20 40 60 80 100 120 140 160 180 200 220 240

I

: FEEDBACK CURRENT (µA)

pin1

–40°C

25°C

105°C

–40°C

25°C

105°C

Figure 3. Maximum Oscillator Swing versus

Temperature

m

500

450

400

350

300

250

200

150

100

50

osc–ch

0

0

20 40 60 80 100 120 140 160 180 200 220 240

I

pin1

–40°C

25°C

105°C

: FEEDBACK CURRENT (µA)

Figure 5. Oscillator Charge Current versus

Feedback Current

Figure 4. Feedback Input Voltage versus

Feedback Current

m

410

I

= 200 mA

pin1

405

400

395

390

385

osc–ch

I , OSCILLATOR CHARGE CURRENT ( A)

–40

–20 0

20

40 60

JUNCTION TEMPERATURE (°C)

Figure 6. Oscillator Charge Current versus

Temperature

80

100

http://onsemi.com

5

Page 6

MC33260

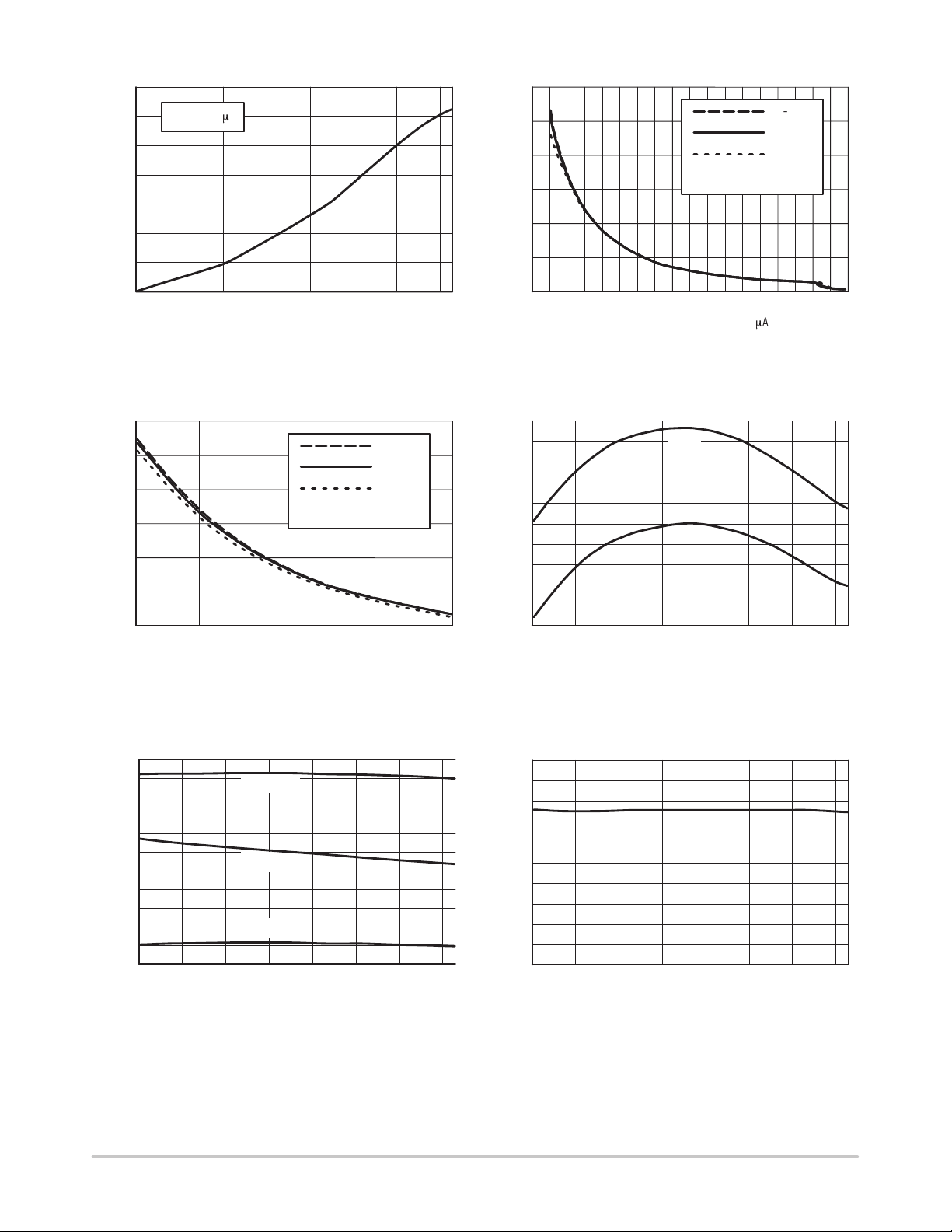

104

103

102

101

100

99

98

OSCILLATOR CHARGE CURRENT ( A)µ

97

I

= 100 mA

pin1

–40

–20 0 20 40 60 80 100

TJ, JUNCTION TEMPERATURE (°C)

Figure 7. Oscillator Charge Current versus

T emperature

75

65

55

45

ON–TIME ( s)µ

35

25

15

50

60 70 80 90 100

I

: FEEDBACK CURRENT (µA)

pin1

1 nF Connected to Pin 3

–40°C

25°C

105°C

120

100

80

60

ON–TIME ( s)µ

40

20

0

30

50 70 90 110 130 150 170 190 210

I

: FEEDBACK CURRENT (mA)

pin1

1 nF Connected to Pin 3

Figure 8. On–Time versus Feedback Current

207

I

206

205

204

203

202

201

200

199

198

197

REGULATION AND CS CURRENT SOURCE ( A)µ

–20 0 20 40 60 80 100

–40

TJ, JUNCTION TEMPERATURE (°C)

OCP

I

regH

–40°C

25°C

105°C

Figure 9. On–Time versus Feedback Current Figure 10. Internal Current Sources versus

T emperature

1.07

)

1.06

ref

/I

1.05

regL

1.04

), (I

1.03

ref

/I

1.02

1.01

ovpL

1.00

), (I

ref

0.99

/I

0.98

ovpH

(I

0.97

0.96

–40

Figure 11. (I

(I

(I

–20 0 20 40 60 80 100

TJ, JUNCTION TEMPERATURE (°C)

ovpH/Iref

ovpH/Iref

ovpL/Iref

(I

regL/Iref

)

)

)

), (I

ovpL/Iref

), (I

regL/Iref

)

versus T emperature

0.150

0.148

ref

/I )

0.146

uvp

0.144

0.142

0.140

0.138

0.136

0.134

UNDERVOLTAGE RATIO (I

0.132

0.130

–20 0 20 40 60 80 100

–40

TJ, JUNCTION TEMPERATURE (°C)

Figure 12. Undervoltage Ratio versus

T emperature

http://onsemi.com

6

Page 7

MC33260

–54.8

–55

–55.2

–55.4

–55.6

–55.8

–56

–56.2

–56.4

–56.6

–20 0 20 40 60 80 100

–40

TJ, JUNCTION TEMPERATURE (°C)

Figure 13. Current Sense Threshold versus

T emperature

20

15

10

–40°C

25°C

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

, CIRCUIT CONSUMPTION (mA)I

CC

0.5

0

2 4 6 8 10 12 14 16

0

–40°C

25°C

105°C

VCC: SUPPLY VOLTAGE (V)

Figure 14. Circuit Consumption versus

Supply V oltage

Vgate

1

25°C

VCC = 12 V

C

I

cross–cond

= 1 nF

gate

(50 mA/div)

105°C

Ch1

10.0 V Ch2210.0 mVWM 1.00ms Ch1 600 mV

OSCILLATOR PIN INTERNAL CAPACITANCE (pF) CURRENT SENSE THRESHOLD (mV)

5

0

0

0.2 0.4 0.6 0.8 1.0 1.2 1.4

V

: PIN 2 VOLTAGE (V)

control

Figure 15. Oscillator Pin Internal Capacitance Figure 16. Gate Drive Cross Conduction

Vgate

–40°C

VCC = 12 V

C

= 1 nF

gate

I

cross–cond

Ch1110.0 V Ch2210.0 mVWM 1.00ms Ch1 600 mV Ch1110.0 V Ch2210.0 mVWM 1.00ms Ch1 600 mV

(50 mA/div)

Vgate

105°C

VCC = 12 V

C

I

cross–cond

gate

= 1 nF

(50 mA/div)

Figure 17. Gate Drive Cross Conduction Figure 18. Gate Drive Cross Conduction

http://onsemi.com

7

Page 8

MC33260

PIN FUNCTION DESCRIPTION

Pin No.

1 Feedback Input This pin is designed to receive a current that is proportional to the preconverter output voltage. This

2 V

3 Oscillator Capacitor

4 Zero Current

5 Synchronization

6 Ground This pin must be connected to the preregulator ground.

7 Gate Drive The gate drive current capability is suited to drive an IGBT or a power MOSFET.

8 V

Function Description

information is used for both the regulation and the overvoltage and undervoltage protections. The

current drawn by this pin is internally squared to be used as oscillator capacitor charge current.

control

(CT)

Detection Input

Input

CC

This pin makes available the regulation block output. The capacitor connected between this pin and

ground, adjusts the control bandwidth. It is typically set below 20 Hz to obtain a nondistorted input

current.

The circuit uses an on–time control mode. This on–time is controlled by comparing the CT voltage to

the V

This pin is designed to receive a negative voltage signal proportional to the current flowing through

the inductor. This information is generally built using a sense resistor. The Zero Current Detection

prevents any restart as long as the pin 4 voltage is below (–60 mV). This pin is also used to perform

the peak current limitation. The overcurrent threshold is programmed by the resistor connected

between the pin and the external current sense resistor.

This pin is designed to receive a synchronization signal. For instance, it enables to synchronize the

PFC preconverter to the associated SMPS. If not used, this pin must be grounded.

This pin is the positive supply of the IC. The circuit turns on when VCC becomes higher than 11 V, the

operating range after start–up being 8.5 V up to 16 V.

voltage. CT is charged by the squared feedback current.

control

R

cs

D1...D4

R

OCP

V

control

CT

APPLICATION SCHEMATIC

Filtering

Capacitor

18

2

3

MC33260

4

L1

D1

C1

+

V

CC

7

6

5

Sync

M1

R

o

Load

(SMPS, Lamp

Ballast,...)

http://onsemi.com

8

Page 9

MC33260

ConverterRectifiers

Load

PFC Preconverter

FUNCTIONAL DESCRIPTION

INTRODUCTION

The need of meeting the requirements of legislation on

line current harmonic content, results in an increasing

demand for cost effective solutions to comply with the

Power Factor regulations. This data sheet describes a

monolithic controller specially designed for this purpose.

Most off–line appliances use a bridge rectifier associated

to a huge bulk capacitor to derive raw dc voltage from the

utility ac line.

ConverterRectifiers

AC

Line

Figure 19. T ypical Circuit Without PFC

+

Bulk

Storage

Capacitor

Load

This technique results in a high harmonic content and in

poor power factor ratios. In effect, the simple rectification

technique draws power from the mains when the

instantaneous ac voltage exceeds the capacitor voltage. This

occurs near the line voltage peak and results in a high charge

current spike. Consequently, a poor power factor (in the

range of 0.5 – 0.7) is generated, resulting in an apparent input

power that is much higher than the real power.

V

pk

Rectified DC

0

Line Sag

AC Line Voltage

AC Line Current

Figure 20. Line Waveforms Without PFC

0

Active solutions are the most popular way to meet the

legislation requirements. They consist of inserting a PFC

pre–regulator between the rectifier bridge and the bulk

capacitor. This interface is, in fact, a step–up SMPS that

outputs a constant voltage while drawing a sinusoidal

current from the line.

OPERATION DESCRIPTION

The MC33260 is optimized to just as well drive a free

running as a synchronized discontinuous voltage mode.

It also features valuable protections (overvoltage and

undervoltage protection, overcurrent limitation, ...) that

make the PFC preregulator very safe and reliable while

requiring very few external components. In particular, it is

able to safely face any uncontrolled direct charges of the

output capacitor from the mains which occur when the

output voltage is lower than the input voltage (start–up,

overload, ...).

In addition to the low count of elements, the circuit can

control an innovative mode named “Follower Boost” that

permits to significantly reduce the size of the preconverter

inductor and power MOSFET. With this technique, the

output regulation level is not forced to a constant value, but

can vary according to the a.c. line amplitude and to the

power. The gap between the output voltage and the ac line

is then lowered, what allows the preconverter inductor and

power MOSFET size reduction. Finally, this method brings

a significant cost reduction.

A description of the functional blocks is given below.

REGULATION SECTION

Connecting a resistor between the output voltage to be

regulated and the pin 1, a feedback current is obtained.

Typically, this current is built by connecting a resistor

between the output voltage and the pin 1. Its value is then

given by the following equation:

Vo*

V

I

pin1

+

pin1

R

o

where:

Ro is the feedback resistor,

Vo is the output voltage,

V

is the pin 1 clamp value.

pin1

The feedback current is compared to the reference current

so that the regulation block outputs a signal following the

characteristic depicted in Figure 22. According to the power

and the input voltage, the output voltage regulation level

varies between two values (Vo)

corresponding to the I

Regulation Block Output

1.5 V

regL

and I

regH

and (Vo)

regL

levels.

regH

AC

Line

High Frequency

Bypass Capacitor

Figure 21. PFC Preconverter

The MC33260 was developed to control an active solution

MC33260

+

Capacitor

Bulk Storage

with the goal of increasing its robustness while lowering its

global cost.

http://onsemi.com

I

reg–L

(97%I

)

ref

Figure 22. Regulation Characteristic

I

reg–H

(I

ref

)

The feedback resistor must be chosen so that the feedback

current should equal the internal current source I

9

regH

I

o

when

Page 10

MC33260

the output voltage exceeds the chosen upper regulation

voltage [(Vo)

In practice, V

equation can be simplified as follows (I

]. Consequently:

regH

ǒ

Ǔ

V

o

Ro+

is small compared to (Vo)

pin1

regH

I

*

regH

V

pin1

regH

regH

and this

being also

replaced by its typical value 200 µA):

Ǔ

<

Ro[5 ǒV

o

regH

>

k

W

The regulation block output is connected to the pin 2

through a 300 kΩ resistor. The pin 2 voltage (V

control

) is

compared to the oscillator sawtooth for PWM control.

An external capacitor must be connected between pin 2

and ground, for external loop compensation. The bandwidth

is typically set below 20 Hz so that the regulation block

output should be relatively constant over a given ac line

cycle. This integration that results in a constant on–time over

the ac line period, prevents the mains frequency output

ripple from distorting the ac line current.

OSCILLATOR SECTION

The oscillator consists of three phases:

• Charge Phase: The oscillator capacitor voltage grows

up linearly from its bottom value (ground) until it

exceeds V

(regulation block output voltage). At

control

that moment, the PWM latch output gets low and the

oscillator discharge sequence is set.

• Discharge Phase: The oscillator capacitor is abruptly

discharged down to its valley value (0 V).

• Waiting Phase: At the end of the discharge sequence,

the oscillator voltage is maintained in a low state until

the PWM latch is set again.

I

= 2 Io Io / I

charge

01

CT

3

15 pF

Figure 23. Oscillator

ref

Output_Ctrl

01

The oscillator charge current is dependent on the feedback

current (Io). In effect

2

I

I

charge

+2

o

I

ref

where:

I

is the oscillator charge current,

charge

Io is the feedback current (drawn by pin 1),

I

is the internal reference current (200 µA).

ref

So, the oscillator charge current is linked to the output

voltage level as follows:

2

I

charge

+

ǂ

Vo*

2

2

R

o

I

V

ref

pin1

ǃ

where:

Vo is the output voltage,

Ro is the feedback resistor,

V

is the pin 1 clamp voltage.

pin1

In practice, V

that is in the range of 2.5 V , is very small

pin1

compared to Vo. The equation can then be simplified by

neglecting V

pin1

:

I

charge

[

2 V

2

R

o

2

o

I

ref

It must be noticed that the oscillator terminal (pin 3) has

an internal capacitance (C

) that varies versus the pin 3

int

voltage. Over the oscillator swing, its average value

typically equals 15 pF (min 10 pF, max 20 pF).

The total oscillator capacitor is then the sum of the internal

and external capacitors.

C

+

CT)

pin3

PWM LATCH SECTION

C

int

The MC33260 operates in voltage mode: the regulation

block output (V

– pin 2 voltage) is compared to the

control

oscillator sawtooth so that the gate drive signal (pin 7) is

high until the oscillator ramp exceeds V

control

.

The on–time is then given by the following equation:

C

V

ton+

pin3

I

ch

control

where:

ton is the on–time,

C

is the total oscillator capacitor (sum of the

pin3

internal and external capacitor),

I

is the oscillator charge current (pin 3 current),

charge

V

Consequently, replacing I

is the pin 2 voltage (regulation block output).

control

by the expression given in

charge

the Oscillator Section:

2

R

I

C

V

control

2

o

ton+

o

ref

pin3

2 V

One can notice that the on–time depends on V

(preconverter output voltage) and that the on–time is

maximum when Vcontrol is maximum (1.5 V typically).

At a given Vo, the maximum on–time is then expressed by

the following equation:

2

R

o

C

ǂ

ǃ

t

max

on

+

pin3

I

ref

2 V

2

o

ǂ

V

control

ǃ

max

This equation can be simplified replacing

NJ

2 / [(V

control)max

* I

ref

]Nj by K

osc

Refer to Electrical Characteristics, Oscillator Section.

Then:

o

http://onsemi.com

10

Page 11

MC33260

2

R

o

2

V

o

C

ǂ

ǃ

t

max

on

+

K

pin3

osc

This equation shows that the maximum on–time is

inversely proportional to the squared output voltage. This

property is used for follower boost operation (refer to

Follower Boost section).

CURRENT SENSE BLOCK

The inductor current is converted into a voltage by

inserting a ground referenced resistor (Rcs) in series with the

input diodes bridge (and the input filtering capacitor).

Therefore a negative voltage proportional to the inductor

current is built:

Vcs+*ǂRcs

ǃ

I

L

where:

IL is the inductor current,

Rcs is the current sense resistor,

Vcs is the measured Rcs voltage.

V

OCP

–60 mV

Time

Power Switch DriveInductor CurrentRcs VoltagePin 4 Voltage

V

An overcurrent is detected if V

OCP

during the Power Switch on state

Figure 24. Current Sensing

Zero Current Detection

= R

I

OCP

OCP

crosses the threshold (–60 mV)

pin4

The negative signal Vcs is applied to the current sense

through a resistor R

. The pin is internally protected by a

OCP

negative clamp (–0.7 V) that prevents substrate injection.

As long as the pin 4 voltage is lower than (–60 mV), the

Current Sense comparator resets the PWM latch to force the

gate drive signal low state. In that condition, the power

MOSFET cannot be on.

During the on–time, the pin 4 information is used for the

overcurrent limitation while it serves the zero current

detection during the off time.

Zero Current Detection

The Zero Current Detection function guarantees that the

MOSFET cannot turn on as long as the inductor current

hasn’t reached zero (discontinuous mode).

The pin 4 voltage is simply compared to the (–60 mV)

threshold so that as long as Vcs is lower than this threshold,

the circuit gate drive signal is kept in low state.

Consequently, no power MOSFET turn on is possible until

the inductor current is measured as smaller than (60 mV/Rcs)

that is, the inductor current nearly equals zero.

I

(205 mA)

D1...D4

R

OCP

4

V

OCP

R

cs

Figure 25. Current Sense Block

Overcurrent Protection

ocp

Output_Ctrl

1 0

(Output_Ctrl Low <=> Gate Drive in Low State)

–60 mV

LEB

T o Output Buffer

S

R

+

R

–

PWM

Latch

Output_Ctrl

Q

During the power switch conduction (i.e. when the Gate

Drive pin voltage is high), a current source is applied to the

pin 4. A voltage drop V

resistor R

that is connected between the sense resistor

OCP

is then generated across the

OCP

and the Current Sense pin (refer to Figure 25). So, instead of

Vcs, the sum (Vcs + V

) is compared to (–60 mV) and the

OCP

maximum permissible current is the solution of the

following equation:

*ǂRcs

Ipk

max

ǃ

)

V

+*

OCP

60 mV

where:

Ipk

is maximum allowed current,

max

Rcs is the sensing resistor.

The overcurrent threshold is then:

*

10

3

Ipk

max

+

ǂ

R

OCP

I

OCP

ǃ

R

cs

)60

where:

R

is the resistor connected between the pin and the

OCP

sensing resistor (Rcs),

I

is the current supplied by the Current Sense pin

OCP

when the gate drive signal is high (power switch

conduction phase). I

Practically, the V

offset is high compared to 60 mV

OCP

equals 205 µA typically.

OCP

and the precedent equation can be simplified. The maximum

current is then given by the following equation:

<

Ipk

max

[

Consequently, the R

R

OCP

R

OCP

>

k

cs

<W>

W

0.205<A

>

resistor can program the OCP

level whatever the Rcs value is. This gives a high freedom in

the choice of Rcs. In particular, the inrush resistor can be

utilized.

http://onsemi.com

11

Page 12

MC33260

Synchronization

–

+

Arrangement

ZCD & OCP

OVP, UVP

&

PWM Latch

Comparator

–

+

Figure 26. PWM Latch

5

Current Sense

Comparator

–60 mV

Oscillator Sawtooth

A LEB (Leading Edge Blanking) has been implemented.

This circuitry disconnects the Current Sense comparator

from pin 4 and disables it during the 400 first ns of the power

switch conduction. This prevents the block from reacting on

the current spikes that generally occur at power switch turn

on. Consequently, proper operation does not require any

filtering capacitor on pin 4.

PROTECTIONS

OCP (Overcurrent Protection)

Refer to Current Sense Block.

OVP (Overvoltage Protection)

The feedback current (Io) is compared to a threshold

current (I

). If it exceeds this value, the gate drive signal

ovpH

is maintained low until this current gets lower than a second

level (I

Drive

Enable

V

control

).

ovpL

Gate

I

uvp

Figure 27. Internal Current Thresholds

I

regL

I

regH

I

ovpL

I

ovpH

I

o

So, the OVP upper threshold is:

V

Output

Buffer

CC

7

PWM

Latch

RSQ

Output_Ctrl

V

(V

control

pin2

Practically, V

Th–Stdwn

Q

– Regulation Output)

that is in the range of 2.5 V, can be

pin1

neglected. The equation can then be simplified:

V

ovpH

+

<

R

M

W>

o

I

ovpH

<

m

A><V

>

On the other hand, the OVP low threshold is:

V

ovpL

where I

is the internal low OVP current threshold.

ovp–L

Consequently, V

V

ovpL

+

V

pin1

being neglected:

pin1

<

+

R

M

W>

o

)ǒRo

I

ovpL

I

<

m

ovpL

A><V

Ǔ

>

The OVP hysteresis prevents erratic behavior.

I

is guaranteed to be higher than IregH (refer to

ovpL

parameters specification). This ensures that the OVP

function doesn’t interfere with the regulation one.

UVP (Undervoltage Protection)

This function detects when the feedback current is lower

than 14% of I

. In this case, the PWM latch is reset and the

ref

power switch is kept off.

This protection is useful to:

• Protect the preregulator from working in too low

mains conditions.

• To detect the feedback current absence (in case of a

nonproper connection for instance).

The UVP threshold is:

V

[

uvp

Practically (V

V

V

)ǒR

pin1

being neglected),

pin1

+

R

uvp

o

<

M

<

M

o

W>

W>

I

uvp

<

I

uvp

m

A><V

Ǔ

<

>

(V)

m

A

>

V

ovpH

+

V

pin1

)ǒRo

I

ovpH

Ǔ

where:

Ro is the feedback resistor that is connected between

pin 1 and the output voltage,

I

V

is the internal upper OVP current threshold,

ovp–H

is the pin 1 clamp voltage.

pin1

Maximum On–Time Limitation

As explained in PWM Latch, the maximum on–time is

accurately controlled.

Pin Protection

All the pins are ESD protected.

http://onsemi.com

12

Page 13

MC33260

In particular, a 11 V zener diode is internally connected

between the terminal and ground on the following pins:

R

sync

1 V

SYNCHRONIZATION BLOCK

Sync

5

+

–

1 V

2 ms

Figure 28. Synchronization Arrangement

The MC33260 features two modes of operation:

• Free Running Discontinuous Mode: The power switch

is turned on as soon as there is no current left in the

inductor (Zero Current Detection). This mode is

simply obtained by grounding the synchronization

terminal (pin 5).

• Synchronization Mode: This mode is set as soon as a

signal crossing the 1 V threshold, is applied to the pin

5. In this case, operation in free running can only be

recovered after a new circuit start–up. In this mode, the

power switch cannot turn on before the two following

conditions are fulfilled.

— Still, the zero current must have been detected.

— The precedent turn on must have been followed by

(at least) one synchronization raising edge

crossing the 1 V threshold.

In other words, the synchronization acts to prolong the

power switch off time.

Consequently, a proper synchronized operation requires

that the current cycle (on–time + inductor demagnetization)

is shorter than the synchronization period. Practically, the

inductor must be chosen accordingly. Otherwise, the system

will keep working in free running discontinuous mode.

Figure 33 illustrates this behavior.

It must be noticed that whatever the mode is, a 2 µs

minimum off–time is forced. This delay limits the switching

frequency in light load conditions.

OUTPUT SECTION

The output stage contains a totem pole optimized to

minimize the cross conduction current during high speed

operation. The gate drive is kept in a sinking mode whenever

the Undervoltage Lockout is active. The rise and fall times

Feedback, V

, Oscillator, Current Sense, and

control

Synchronization.

UVLO

S1

Q1

R2

S2

Q2

R2

Q1 High <=>

Synchronization Mode

&

Output_Ctrl

PWM

Latch

Set

have been controlled to typically equal 50 ns while loaded

by 1 nF.

REFERENCE SECTION

An internal reference current source (I

) is trimmed to be

ref

±4% accurate over the temperature range (the typical value

is 200 µA). I

= I

).

ref

UNDERVOLTAGE LOCKOUT SECTION

is the reference used for the regulation (I

ref

regH

An Undervoltage Lockout comparator has been

implemented to guarantee that the integrated circuit is

operating only if its supply voltage (VCC) is high enough to

enable a proper working. The UVLO comparator monitors

the pin 8 voltage and when it exceeds 11 V, the device gets

active. To prevent erratic operation as the threshold is

crossed, 2.5 V of hysteresis is provided.

The circuit off state consumption is very low: in the range

of 100 µA @ VCC = 5 V. This consumption varies versus

VCC as the circuit presents a resistive load in this mode.

THERMAL SHUTDOWN

An internal thermal circuitry is provided to disable the

circuit gate drive and then to prevent it from oscillating, if

the junction temperature exceeds 150°C typically .

The output stage is again enabled when the temperature

drops below 120°C typically (30°C hysteresis).

FOLLOWER BOOST

Traditional PFC preconverters provide the load with a fixed

and regulated voltage that generally equals 230 V or 400 V

according to the mains type (U.S., European, or universal).

In the “Follower Boost” operation, the preconverter

output regulation level is not fixed but varies linearly versus

the ac line amplitude at a given input power.

http://onsemi.com

13

Page 14

MC33260

Traditional Output

Vo (Follower Boost)

V

ac

Load

Figure 29. Follower Boost Characteristics

This technique aims at reducing the gap between the

output and the input voltages to minimize the boost

efficiency degradation.

Follower Boost Benefits

The boost presents two phases:

• The on–time during which the power switch is on. The

inductor current grows up linearly according to a slope

(Vin/Lp), where Vin is the instantaneous input voltage

and Lp the inductor value.

• The off–time during which the power switch is off.

The inductor current decreases linearly according the

slope (Vo – Vin)/Lp, where Vo is the output voltage.

This sequence that terminates when the current equals

zero, has a duration that is inversely proportional to the

gap between the output and input voltages.

Consequently, the off–time duration becomes longer

in follower boost.

Consequently, for a given peak inductor current, the

longer the off time, the smaller power switch duty cycle and

then its conduction dissipation. This is the first benefit of this

technique: the MOSFET on–time losses are reduced.

The increase of the off time duration also results in a

switching frequency diminution (for a given inductor

value). Given that in practise, the boost inductor is selected

big enough to limit the switching frequency down to an

acceptable level, one can immediately see the second benefit

of the follower boost: it allows the use of smaller, lighter and

cheaper inductors compared to traditional systems.

Finally, this technique utilization brings a drastic system

cost reduction by lowering the size and then the cost of both

the inductor and the power switch.

traditional preconverter

IL

Vin

the power switch is on

Follower Boost Implementation

Ipk

Vin

IL

Figure 30. Off–Time Duration Increase

follower boost preconverter

Vin

Vin

the power switch is off

IL

time

Vout

In the MC33260, the on–time is differently controlled

according to the feedback current level. Two areas can be

defined:

• When the feedback current is higher than I

regL

(refer

to regulation section), the regulation block output

(V

) is modulated to force the output voltage to a

control

desired value.

• On the other hand, when the feedback current is lower

than I

, the regulation block output and therefore,

regL

the on–time are maximum. As explained in PWM

Latch Section, the on–time is then inversely

proportional to the output voltage square. The

Follower Boost is active in these conditions in which

the on–time is simply limited by the output voltage

level. Note: In this equation, the feedback pin voltage

(V

) is neglected compared to the output voltage

pin1

(refer to the PWM Latch Section).

ton+ǂt

on

ǃ

max

+

C

pin3

K

osc

2

R

o

2

V

o

where:

C

is the total oscillator capacitor (sum of the

pin3

internal and external capacitors – C

K

is the ratio (oscillator swing over oscillator gain),

osc

int

+ CT),

Vo is the output voltage,

Ro is the feedback resistor.

http://onsemi.com

14

Page 15

MC33260

On the other hand, the boost topology has its own rule that

dictates the on–time necessary to deliver the required power:

4 Lp

ton+

P

in

2

V

pk

where:

Vpk is the peak ac line voltage,

Lp is the inductor value,

Pin is the input power.

Combining the two equations, one can obtain the

Follower Boost equation:

C

pin3

K

Lp

osc

V

P

pk

in

Vo+

R

o

Ǹ

2

Consequently, a linear dependency links the output

voltage to the ac line amplitude at a given input power.

The Regulation Block is Active

(Vac)max

Output Voltage

Input Power

P

in

V

o

Figure 31. Follower Boost Characteristics

V

ac

(Vac)min

t

on

Output Voltage

Input Power

ton = k/V

on–time

2

o

The behavior of the output voltage is depicted in Figures

31 and 32. In particular, Figure 31 illustrates how the output

voltage converges to a stable equilibrium level. First, at a

given ac line voltage, the on–time is dictated by the power

demand. Then, the follower boost characteristic makes

correspond one output voltage level to this on–time.

Combining these two laws, it appears that the power level

forces the output voltage.

One can notice that the system is fully stable:

• If an output voltage increase makes it move away from

its equilibrium value, the on–time will immediately

diminish according to the follower boost law . This will

result in a delivered power decrease. Consequently,

the supplied power being too low, the output voltage

will decrease back,

• In the same way, if the output voltage decreases, more

power will be transferred and then the output voltage

will increase back.

V

o

(Pin)min

Figure 32. Follower Boost Output Voltage

Mode Selection

Regulation Block is Active Vo = V

P

in

(Pin)max

V

acLL

V

ac

non usable area

V

acHL

pk

V

ac

The operation mode is simply selected by adjusting the

oscillator capacitor value. As shown in Figure 32, the output

voltage first has an increasing linear characteristic versus the

ac line magnitude and then is clamped down to the

regulation value. In the traditional mode, the linear area

must be rejected. This is achieved by dimensioning the

oscillator capacitor so that the boost can deliver the

maximum power while the output voltage equals its

regulation level and this, whatever the given input voltage.

Practically, that means that whatever the power and input

voltage conditions are, the follower boost would generate

output voltages values higher than the regulation level, if

there was no regulation block.

In other words, if (Vo)

is the low output regulation

regL

level:

CT)

Lp

C

int

ǂ

P

V

ǃ

max

in

pk

R

ǂ

ǃ

V

o

regL

v

o

Ǹ

2

K

osc

Consequently,

2

ǂV

o

ǃ

regL

CTw*

Using I

ǂ

ǃ

P

4 K

C

)

int

(regulation block current reference), this

regL

osc

Lp

R

max

in

2

2

V

o

pk

equation can be simplified as follows:

2

regL

CTw*

4 K

C

)

int

osc

Lp ǂP

ǃ

max I

in

2

V

pk

In the Follower Boost case, the oscillator capacitor must

be chosen so that the wished characteristics are obtained.

Consequently, the simple choice of the oscillator

capacitor enables the mode selection.

http://onsemi.com

15

Page 16

Synchronization

Signal

Zero Current

Detection

2 ms

Delay

MC33260

Oscillator

Circuit

Output

I

2 ms

cs

2 ms 2 ms

205 mA

V

control

2 ms

Inductor

Current

3 41 2

case no. 1: the turn on is delayed by the Zero Current Detection

cases no. 2 and no. 3: the turn on is delayed by the synchronization signal

case no. 4: the turn on is delayed by the minimum off–time (2 ms)

Figure 33. T ypical Waveforms

http://onsemi.com

16

Page 17

MC33260

MAIN DESIGN EQUATIONS (Note 1)

rms Input Current (Iac)

Iac+

Maximum Inductor Peak Current ((Ipk)max):

(Ipk)max

Output Voltage Peak to Peak 100Hz (120Hz) Ripple ((∆Vo)pk–pk):

(DVo)

pk–pk

Inductor Value (Lp):

Maximum Power MOSFET Conduction Losses ((pon)max):

(Pon)max

Maximum Average Diode Current (Id):

Current Sense Resistor Losses (pRcs):

Over Current Protection Resistor (R

Oscillator External Capacitor Value (CT):

–Traditional Operation

CTw*

– Follower Boost:

Feedback Resistor (Ro):

Note 1. The preconverter design requires the following characteristics specification:

– (Vo)

– (∆Vo)

– Po: desired output power

– Vac: ac rms operating line voltage

– V

: desired output voltage regulation level

reg

: admissible output peak to peak ripple voltage

pk–pk

: minimum ac rms operating line voltage

acLL

2 t

Lp+

1

[

(Rds)on (Ipk)max

3

(Id)max

pRcs+

R

OCP

C

)

int

R

o

Vo+

Ro+

2

(Vo)

Vo

1

6

OCP

2 K

Ǹ

reg

I

P

o

h V

ac

Ǹ

h V

fac

*

V

(Po)max

(Vo)min

0.205

CT)

pin1

(Po)max

acLL

P

o

Co

Ǔ

acLL

(Ipk)max

2

ƪ

(Ipk)max

Lp

V

C

int

Lp

V

o

[

200

2

ac

P

2 2

+

+

2p

V

o

ǒ

Ǹ

2

V

acLL

+

(Rds)on (Ipk)2max

):

Rcs

[

osc

K

osc

*

V

regH

V

o

V

1

acLL

1.2 V

*

V

pk

2

(Pin)max I

in

V

2

regL

acLL

o

ƫ

(kW)

(MW)

η (preconverter efficiency) is generally in the

range of 90 – 95%.

(Ipk)max is the maximum inductor current.

fac is the ac line frequency (50 or 60Hz)

t is the maximum switching period.

(t=40µs) for universal mains operation and

(t=20µs) for narrow range are generally used.

(Rds)on is the MOSFET drain source on–time

resistor.

In Follower Boost, the ratio (V

higher. The on–time MOSFET losses are then

reduced

The Average Diode Current depends on the

power and on the output voltage.

This formula indicates the required dissipation

capability for Rcs (current sense resistor).

The overcurrent threshold is adjusted by R

at a given Rcs.

Rcs can be a preconverter inrush resistor

The Follower Boost characteristic is adjusted

by the CT choice.

The Traditional Mode is also selected by CT.

C

is the oscillator pin internal capacitor.

int

The output voltage regulation level is adjusted

by Ro.

acLL/Vo

) is

OCP

http://onsemi.com

17

Page 18

90 to

270 Vac

680 nF

C3

V

control

EMI

Filter

R4

15 kW/0.25 W

Feedback

1

2

300 k

1N4007

Block

MC33260

L1

320 mH

D1

D2

Q1

MTP4N50E

D4D3

C1

330 nF

500 Vdc

R3

1 W/2 W

I

I

o

o

I

ref

Regulation

Block

I

ref

I

o

I

V

reg

V

reg

1.5 V

97%.I

ref

o

I

uvp

V

prot

(– – –)

I

ovpLIovpH

D5

I

UVP, OVP

MUR460E

ref

I

o

R1

1 M

0.25 W

R2

1 M

0.25 W

22 W/0.25 W

V

ref

REGULATOR

V

prot

ThStdwn

W

W

R5

Enable

80 W Load

(SMPS, Lamp

+

C2

Ballast,...)

47 mF

450 V

I

ref

MC33260

11 V/8.5 V

–

+

V

CC

8

Output

Buffer

Drive

7

PWM Comp

C4

330 pF

CT

Oscillator

2x|0x|0

I

+

osc–ch

I

ref

3

15 pF

Output

+

–

I

ocp

(205 mA)

Current

Sense

PWM

Latch

SRQ

Q

Output

Block

0110

–60 mV

+

Synchronization

Block

LEB

–

4

L1: Coilcraft N2881 – A (primary: 62 turns of # 22 AWG – Secondary: 5 turns of # 22 AWG Core: Coilcraft PT2510, EE 25

L1: Gap: 0.072″ total for a primary inductance (Lp) of 320 mH)

Figure 34. 80 W Wide Mains Power Factor Corrector

POWER FACTOR CONTROLLER TEST DATA*

AC Line Input

V

rms

(V)

P

(W)

Current Harmonic Distortion (% I

PF

(–)

I

fund

(mA)

THD H2 H3 H5 H7 H9

in

fund

)

V

o

(V)

90 88.2 0.991 990 8.1 0.07 5.9 4.3 1.5 1.7 181 31.2 440 79.6 90.2

110 86.3 0.996 782 7.0 0.05 2.7 5.7 1.1 0.8 222 26.4 360 79.9 92.6

135 85.2 0.995 642 8.2 0.03 1.5 6.8 1.1 1.5 265 20.8 300 79.5 93.3

180 87.0 0.994 480 9.5 0.16 4.0 6.5 3.1 4.0 360 16.0 225 81.0 93.1

220 84.7 0.982 385 15 0.5 8.4 7.8 5.3 1.9 379 14.0 210 79.6 94.4

240 85.3 0.975 359 16.5 0.7 9.0 7.8 7.4 3.8 384 14.0 210 80.6 94.5

260 84.0 0.967 330 18.8 0.7 11.0 7.0 9.0 4.0 392 13.2 205 80.4 95.7

*Measurements performed using Voltech PM1200 ac power analysis.

∆V

(V)

o

DC Output

I

o

(mA)

P

o

(W)η(%)

Gnd

6

Synchro

5

http://onsemi.com

18

Page 19

D1...D4

MC33260

15 V

V

18

CC

R

stup

r

+

C

pin8

+

2

3

4

7

6

MC33260

5

Figure 35. Circuit Supply V oltage

MC33260 VCC SUPPLY VOLTAGE

In some applications, the arrangement shown in Figure 35

must be implemented to supply the circuit. A start–up

resistor is connected between the rectified voltage (or

one–half wave) to charge the MC33260 VCC up to its

start–up threshold (11 V typically). The MC33260 turns on

and the VCC capacitor (C

) starts to be charged by the PFC

pin8

transformer auxiliary winding. A resistor, r (in the range of

22 Ω) and a 15 V zener should be added to protect the circuit

from excessive voltages.

Preconverter Output

When the PFC preconverter is loaded by an SMPS, the

MC33260 should preferably be supplied by the SMPS itself.

In this configuration, the SMPS starts first and the PFC gets

active when the MC33260 VCC supplied by the power

supply, exceeds the device start–up level. With this

configuration, the PFC preconverter doesn’t require any

auxiliary winding and finally a simple coil can be used.

PCB LAYOUT

The connections of the oscillator and V

control

capacitors

should be as short as possible.

++

18

2

3

4

7

6

MC33260

5

Figure 36. Preconverter loaded by a Flyback SMPS: MC33260 VCC Supply

V

CC

+

+

SMPS Driver

++

+

http://onsemi.com

19

Page 20

NOTE 2

–T–

SEATING

PLANE

H

58

–B–

14

F

–A–

C

N

D

G

0.13 (0.005) B

MC33260

P ACKAGE DIMENSIONS

DIP–8

P SUFFIX

PLASTIC P ACKAGE

CASE 626–05

ISSUE K

L

J

K

M

A

T

M

M

M

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

DIM MIN MAX MIN MAX

A 9.40 10.16 0.370 0.400

B 6.10 6.60 0.240 0.260

C 3.94 4.45 0.155 0.175

D 0.38 0.51 0.015 0.020

F 1.02 1.78 0.040 0.070

G 2.54 BSC 0.100 BSC

H 0.76 1.27 0.030 0.050

J 0.20 0.30 0.008 0.012

K 2.92 3.43 0.115 0.135

L 7.62 BSC 0.300 BSC

M ––– 10 ––– 10

N 0.76 1.01 0.030 0.040

STYLE 1:

PIN 1. AC IN

2. DC + IN

3. DC – IN

4. AC IN

5. GROUND

6. OUTPUT

7. AUXILIARY

8. V

CC

INCHESMILLIMETERS

__

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

USA/EUROPE Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line*: 303–675–2167

800–344–3810 Toll Free USA/Canada

*To receive a Fax of our publications

N. America Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5487–8345

Email: r14153@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local Sales Representative.

MC33260/D

20

Loading...

Loading...