Page 1

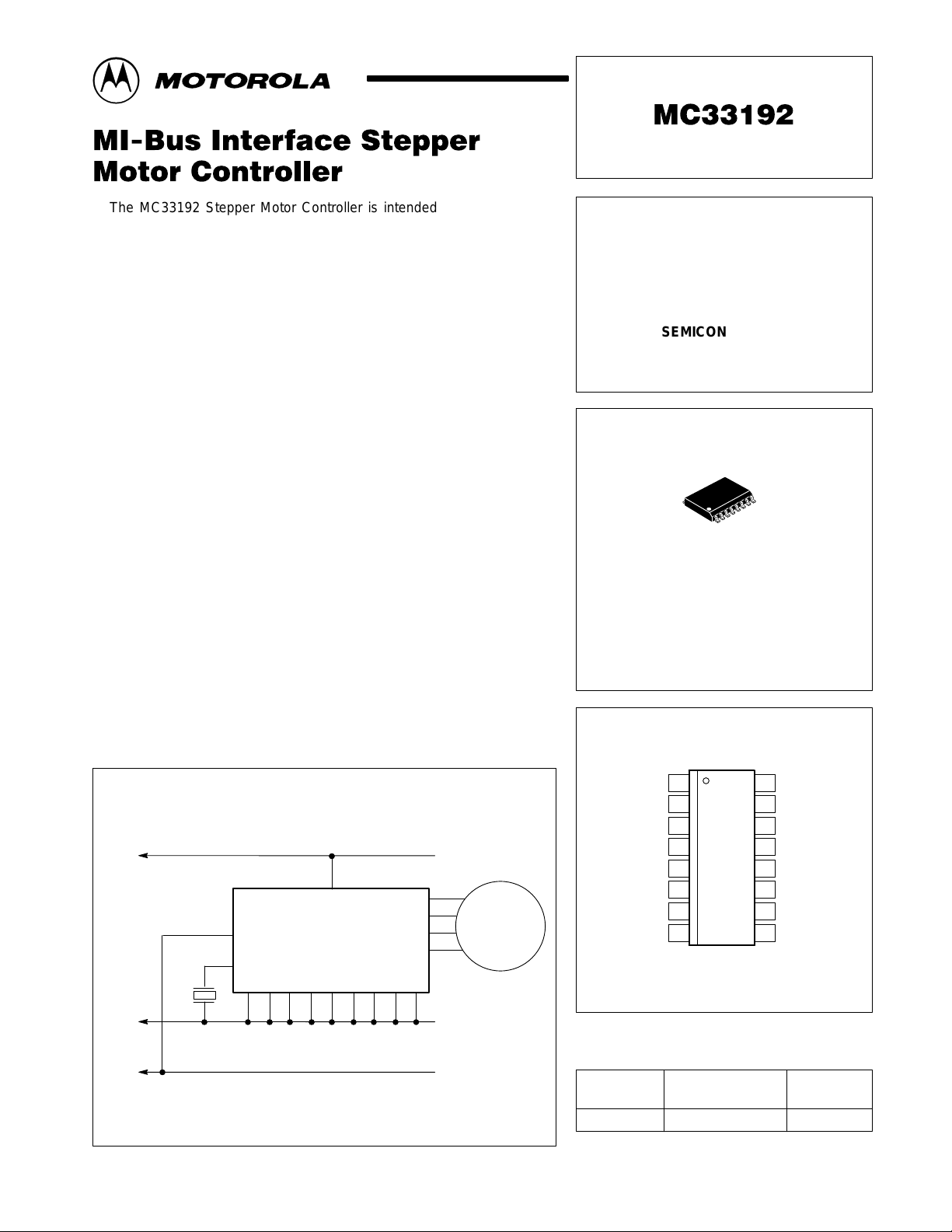

The MC33192 Stepper Motor Controller is intended to control loads in

harsh automotive environments using a serial communication bus. The

MI–Bus can provide satisfactory real time control of up to eight stepper

motors. MI–Bus technology offers a noise immune system solution for

difficult control applications involving relay drivers, motor controllers, etc.

The MC33192 stepper motor controller provides four phase signals to

drive two phase motors in either half or full step modes. When used with an

appropriate Motorola HCMOS microprocessor it provides an economical

solution for applications requiring a minimum amount of wiring and optimized

system versatility.

The MC33192 is packaged in an economical 16 pin surface mount

package and specified at an operating voltage 12 V for – 40°C ≤ TA ≤ 100°C.

• Single Wire Open Bus Capability Up to 10 Meters in Length

• Programmable Address Bus System

• Fault Detection of Half–Bridge Drivers and Motor Windings

• Ceramic Resonator For Accurate and Reliable Transmission of Data

• Sub–Multiple of Oscillator End–of–Frame Signal

• MI–Bus Signal Slew Rate Limited to 1.0 V/µs for Minimum RFI

• MI–Bus Error Diagnostics

• Non–Functioning Device Diagnotics

• Over Temperature Detection

• Address Programming Sequence Status

• Load and Double Battery (Jump Start) Protection

Order this document by MC33192/D

MI–BUS INTERFACE

STEPPER MOTOR

CONTROLLER

SEMICONDUCTOR

TECHNICAL DATA

16

1

DW SUFFIX

PLASTIC PACKAGE

CASE 751G

(SO–16L)

Simplified Application

7

V

CC

1

To

Other

Devices

MI–Bus

MI

8

Xtal

16 15 14 13 12 1 1 10 9 2

Ceramic

Resonator

This device contains 1,528 active transistors.

MC33192DW

MOTOROLA ANALOG IC DEVICE DATA

A1

A2

B1

B2

Gnd

+V

batt

3

4

5

6

Ground

From MCU

MI–Bus

Stepper

Motor

PIN CONNECTIONS

15

14

13

12

11

10

Gnd

Gnd

Gnd

Gnd

Gnd

Gnd

Gnd

Gnd

9

MI–Bus

Gnd

A1

A2

B1

B2

V

CC

Xtal

116

2

3

4

5

6

7

8

(Top View)

ORDERING INFORMATION

Operating

Device

MC33192DW TA = – 40° to +100°C

Motorola, Inc. 1996 Rev 0

Temperature Range

Package

SO–16L

1

Page 2

MC33192

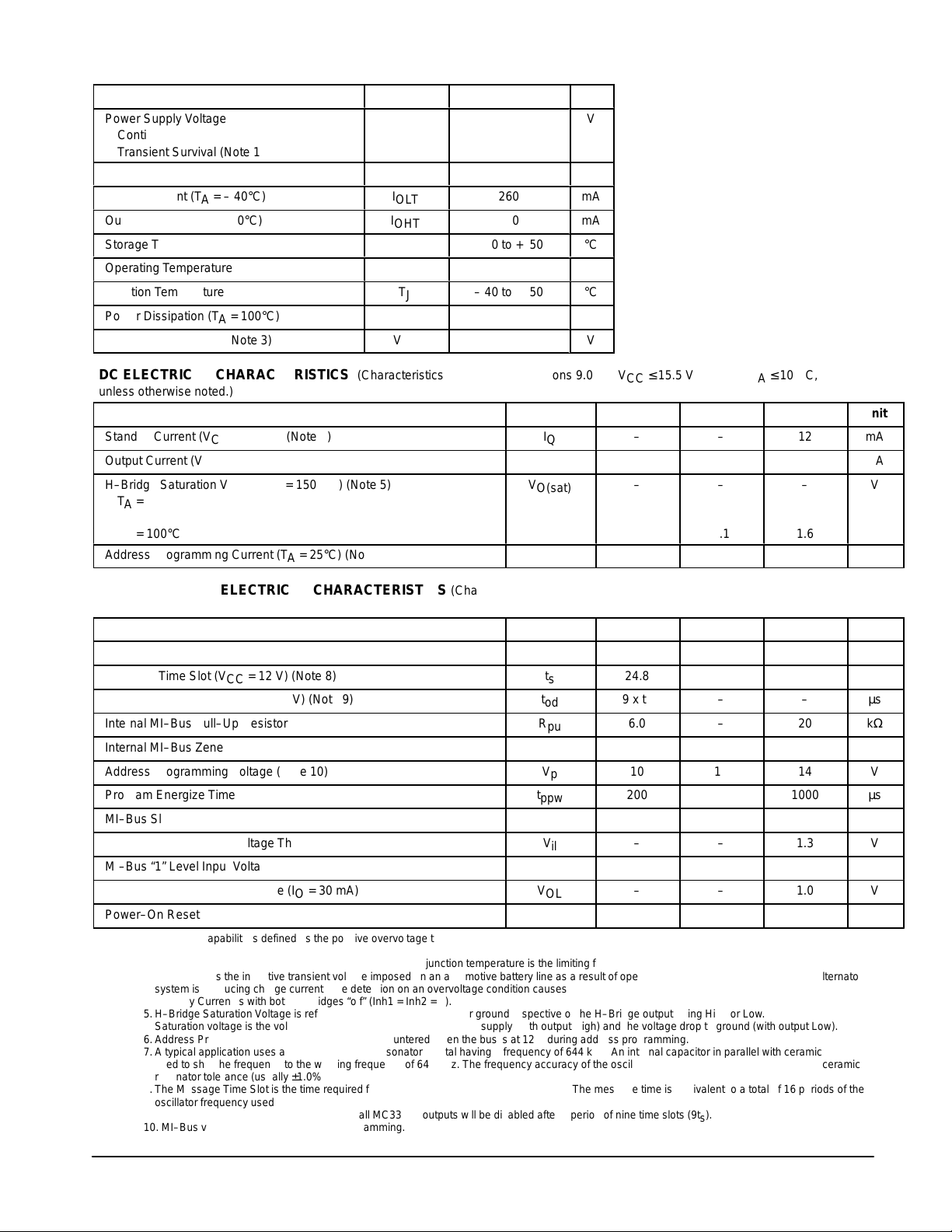

MAXIMUM RATINGS

(All voltages are with respect to ground, unless otherwise noted.)

Rating Symbol Value Limit

Power Supply Voltage

Continuous Operation V

Transient Survival (Note 1) V

Digital Input Voltage

Output Current (TA = – 40°C)

Output Current (TA = 100°C)

Storage Temperature

Operating Temperature (Note 2)

Junction Temperature

Power Dissipation (TA = 100°C)

Load Dump Transient (Note 3)

CC

V

I

OLT

I

OHT

T

stg

T

T

P

V

LD

i

A

J

D

LD

25

40

0.3 to VCC + 0.3

260

150

– 40 to +150

– 40 to +125

– 40 to +150

0.5

40

DC ELECTRICAL CHARACTERISTICS (Characteristics noted under conditions 9.0 V ≤ V

V

V

mA

mA

°C

°C

°C

W

V

≤ 15.5 V, – 40°C ≤ TA ≤ 100°C,

CC

unless otherwise noted.)

Characteristic

Standby Current (VCC = 15.5 V) (Note 4)

Output Current (VCC = 15.5 V)

H–Bridge Saturation Voltage (IO = 150 mA) (Note 5)

Symbol Min Typ Max Unit

V

O(sat)

I

Q

I

O

–

–

–

–

120

–

TA = – 40°C – 1.3 1.6

TA = 25°C – 1.2 1.6

TA = 100°C – 1.1 1.6

Address Programming Current (TA = 25°C) (Note 6)

I

pc

–

1.2

12

mA

–

–

–

mA

V

A

CONTROL LOGIC ELECTRICAL CHARACTERISTICS (Characteristics noted under conditions 9.0 V ≤ V

≤ 15.5 V, – 40°C ≤ TA ≤

CC

100°C, unless otherwise noted.)

Characteristic

Oscillator (Note 7)

Message Time Slot (VCC = 12 V) (Note 8)

Urgent Output Disable (VCC = 12 V) (Note 9)

Internal MI–Bus Pull–Up Resistor

Internal MI–Bus Zener Diode Clamp Voltage

Address Programming Voltage (Note 10)

Program Energize Time

MI–Bus Slew Rate

MI–Bus “0” Level Input Voltage Threshold

MI–Bus “1” Level Input Voltage Threshold

MI–Bus “0” Level Output Voltage (IO = 30 mA)

Power–On Reset Time (VCC ≥ 7.5 V)

NOTES: 1. Transient capability is defined as the positive overvoltage transient with 250 ms decay time constant. The detection on an overvoltage condition causes all

H–Bridges to be latched “off”.

2.Ambient temperature is given as a convience; Maximum junction temperature is the limiting factor.

3.Load Dump is the inductive transient voltage imposed on an automotive battery line as a result of opening the battery connection while the alternator

system is producing charge current. The detection on an overvoltage condition causes all H–Bridges to be latched “off”.

4.Standby Current is with both H–Bridges “off” (Inh1 = Inh2 = 0).

5.H–Bridge Saturation V oltage is referenced to the positive supply or ground respective of the H–Bridge output being High or Low.

Saturation voltage is the voltage drop from the output to the positive supply (with output High) and the voltage drop to ground (with output Low).

6.Address Programming Current is the current encountered when the bus is at 12 V during address programming.

7.A typical application uses an external ceramic resonator crystal having a frequency of 644 kHz. An internal capacitor in parallel with ceramic resonator is

used to shift the frequency to the working frequency of 640 kHz. The frequency accuracy of the oscillator is dependant on the capacitor and ceramic

resonator tolerance (usually ±1.0%).

8.The Message Time Slot is the time required for one complete device message transfer. The message time is equivalent to a total of 16 periods of the

oscillator frequency used.

9.If the MI–Bus becomes shorted to ground, all MC33192 outputs will be disabled after a period of nine time slots (9ts).

10. MI–Bus voltage required for address programming.

Symbol Min Typ Max Unit

f

cl

t

s

t

od

R

pu

V

cl

V

p

t

ppw

∆V/∆t

V

il

V

ih

V

OL

t

por

24.8

9 x t

6.0

–

10

200

1.0

–

2.4

–

–

s

640

25

–

–

18

12

1.5

–

–

–

250

–

25.2

–

20

–

14

1000

2.0

1.3

–

1.0

–

kHz

µs

µs

kΩ

V

V

µs

V/µs

V

V

V

µs

2

MOTOROLA ANALOG IC DEVICE DATA

Page 3

MC33192

GENERAL DESCRIPTION

The MC33192 is a serial stepper motor controller for use in

harsh automotive applications using multiplex wiring. The

MC33192 provides all the necessary four phase drive signals

to control two phase bipolar stepper motors operated in either

half or full step modes. Multiple stepper motor controllers can

be operated on a real time basis at step frequencies up to

200 Hz using a single microcontroller (MCU). A primary

attribute of operation is the utilization of the MI–Bus message

media to provide high noise immunity communication

ensuring very high operating reliability of motor stepping.

The MC33192 is designed to drive bipolar stepper motors

having a winding resistance of 80 Ω at 20°C with a supply

voltage of 12 V. It is supplied in a SO–16L plastic package

having eight pins, on one side, connected directly to the lead

frame thus enhancing the thermal performance to allow a

power dissipation of 0.5 W at 120°C ambient temperature.

Multiple Simultaneous Motor Operation

Several motors can be controlled in a serial fashion, one

after the other, using the same software time base. The time

base determines the step frequency of the motors. A single

motor can be operated at a maximum speed of 200 Hz

pull–in with a duration of 5.0 ms per step. Three motors can

be operated simultaneously using a 68HC05B6 MCU at the

same time base (200 Hz) with about 1.7 ms per step. A

68HC11 MCU can control 4 stepper motors with adequate

program step time. The step frequency must be decreased to

control additional motors. To control eight motors

simultaneously would require the motor speed to be

decreased to 100 Hz producing about 2.0 ms time duration

per step with adequate program time.

MI–Bus General Description

The Motorola Interconnect Bus (MI–Bus) is a serial

push–pull communications protocol which efficiently

supports distributed real time control while exhibiting a high

level of noise immunity .

Under the SAE Vehicle Network categories, the MI–Bus is

a Class A bus with a data stream transfer bit rate in excess of

20 kHz and thus inaudible to the human ear. It requires a

single wire to carry the control data between the master MCU

and its slave devices. The bus can be operated at lengths up

to 15 meters.

At 20 kHz the time slot used to construct the message

(25 µs) can be handled by software using many MCUs

available on the market.

The MI–Bus is suitable for medium speed networks

requiring very low cost multiplex wiring. Aside from ground,

the MI–Bus requires only one signal wire connecting the

MCU to multiple slave MC33192 devices with individual

control.

A single MI–Bus can accomplish simultaneous automotive

system control of Air Conditioning, Head Lamp Levellers,

Window Lifts, Sensors, Intelligent Coil Drivers, etc. The

MI–Bus has been found to be cost effective in vehicle body

electronics by replacing the conventional wiring harness.

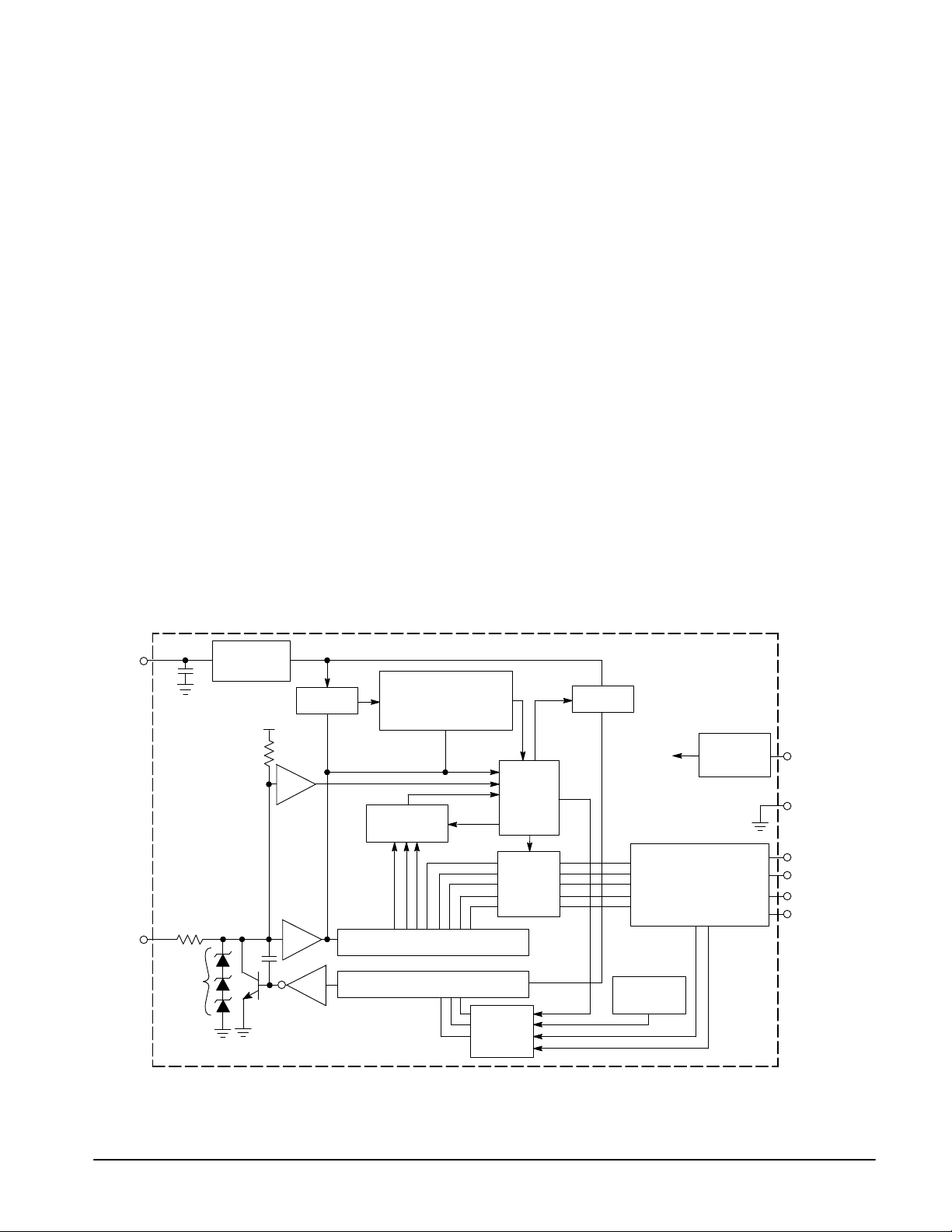

Figure 1 shows the internal block diagram of the MC33192

Stepper Motor Controller.

Xtal (8)

MI (1)

Oscillator

(640 kHz)

10 k

Programming

Level Detection

Ω

20

18 V

Figure 1. MC33192 Stepper Motor Conroller Block Diagram

5.0 V

Divider

Noise Detector

Bi–Phase

Bi–Phase Program

Programmed

Address

Serial to Parallel Register

Parallel to Serial Register

Status

Encoder

Control

Logic

Latch

Divider

20 kHz

5.0 V

Dual Bridge Driver and

Motor Diagnostics

Thermal

Shutdown

Regulator

5.0 V

+VCC (7)

Gnd (*)

A11 (3)

A12 (4)

B11 (5)

B12 (6)

NOTE: (*) Pins 2, 9, 10, 11, 12, 13, 14, 15 and 16 are common electrical and heatsink ground pins for the device.

MOTOROLA ANALOG IC DEVICE DATA

3

Page 4

MC33192

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

Á

Á

ББББББББ

Á

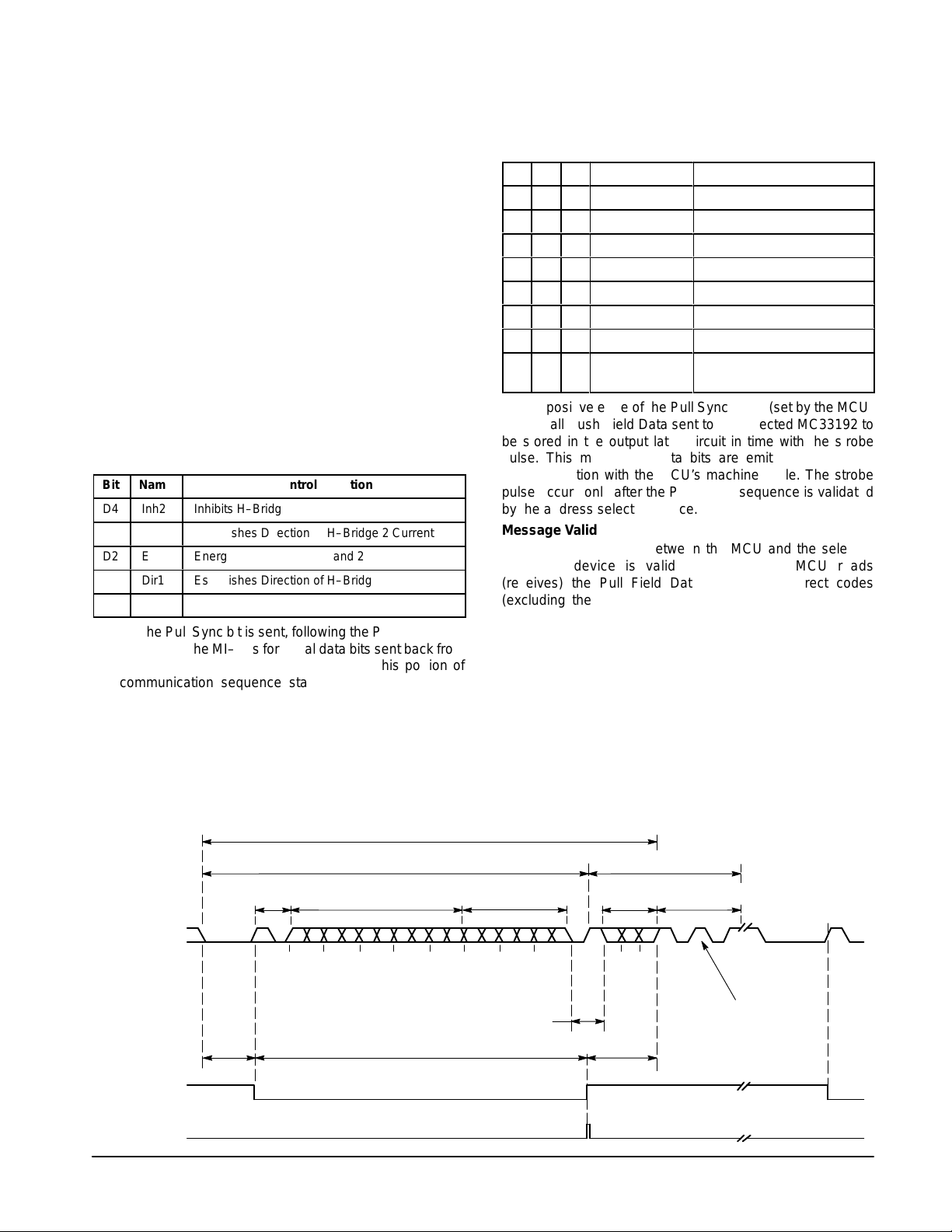

MI–Bus Access Method

The information on the MI–Bus is sent in a fixed message

frame format (See Figure 4). The system MCU can take

control of the MI–Bus at any time with a start bit which

violates the law of Manchester Bi–Phase code by having

three consecutive Time Slots (3ts) held constantly at a Logic

“0” state.

Push–Pull Communication Sequence

Communication between the system MCU and slave

MC33192 devices always use the same message frame

organization. The MCU first sends eight serial data bits over

the MI–Bus comprised of five control bits followed by three

address bits. This communication sequence is called a “Push

Field” since it represents command information sent from the

MCU. The sequence of the five control data bits follow the

order D0, D1, D2, D3 and D4. The three address bits are sent

in sequential order A0, A1 and A2 defining a binary address

code. The condition of MI–Bus during any of the control bit

time windows defines a specific control function as shown in

Figure 2. A “Pull Sync” bit is sent at the end of the Push Field,

the positive edge of which causes all data sent to the

selected device to be latched into the output circuit.

Figure 2. Push Field Data Bits

Bit

D4

D3

D2

D1

D0

Name

Inh2

Dir2

E

Dir1

Inh1

Inhibits H–Bridge 2

Establishes Direction of H–Bridge 2 Current

Energizes Bridge Coils 1 and 2

Establishes Direction of H–Bridge 1 Current

Inhibits H–Bridge 1

Control Function

After the Pull Sync bit is sent, following the Push Field, the

MCU listens on the MI–Bus for serial data bits sent back from

the previously addressed MC33192 device. This portion of

the communication sequence starts the “Pull Field Data”

since it represents information pulled from the addressed

MC33192 and received by the MCU.

The address selected MC33192 device sends data, in

the form of status bits, back to the MCU reporting the

devices condition. At the end of the Push Field the MCU

outputs a Pull Sync bit which signals the start of the Pull

Field. In the Pull Field are three bits (S2, S1 and S0) which

report the status of the previously addressed MC33192

according to Figure 3.

Figure 3. Pull Field Status Bits

S2

S1

Á

S0

0

0

0

0

0

1

0

1

0

0

1

1

1

0

0

1

0

1

1

1

0

1

1

1

Status

Not used

Free

No Back EMF

Free

Normal/OK

Thermal

Programming

Selection failed

ÁÁÁÁ

Comments

Drivers and/or coils failed

Chip temperature > 150°C

PROM energized

Noise on MI–Bus, failed or

БББББББ

disconnected module

The positive edge of the Pull Sync pulse (set by the MCU)

causes all Push Field Data sent to the selected MC33192 to

be stored in the output latch circuit in time with the strobe

pulse. This means the data bits are emitted in real time

synchronization with the MCU’s machine cycle. The strobe

pulse occurs only after the Push Field sequence is validated

by the address selected device.

Message Validation

The communication between the MCU and the selected

MC33192 device is valid only when the MCU reads

(receives) the Pull Field Data having the correct codes

(excluding the code “1–1–1” and “0–0–0”) followed by an

End–of–Frame signal. The frequency of the End–of–Frame

signal may be a sub–multiple of the selected devices local

oscillator or related to an internal or external analog

parameter using a Voltage to Frequency Converter.

Error Detection

An error is detected when the Pull Field contains the code

“1–1–1” followed by the End–of–Frame permanently tied to a

logic “1” state (internally from 5.0 V through a pull–up

resistor). This means the communication between the MCU

and the selected device was not obtained.

MI–Bus Wire

Push/Pull Function

Strobe

4

Figure 4. MI–Bus Timing Diagram

Frame

Push Field

AddressDataPush Sync Data End–of–Frame

3t

s

234567891 1 32

“0” S1

“1”D3

S2 S0

NRZ

Bi–Phase Coded

Pull Sync

Coded

75 µs 475 µs 100 µs

Push

Strobe Pulse

MOTOROLA ANALOG IC DEVICE DATA

Pull Field

4

÷

32 = 20 kHz

Pull

Oscillator

Frequency

3t

s

StartStart “1” “0” D0 D1 D2 D4 A0 A1 A2

Page 5

MC33192

There are four types of system error detections which are

not mutually exclusive; These are:

1) Noise Detection

The system MC33192 slave devices receive the Push

Field message from the MCU twice for each Time Slot (ts)

of the Bi–Phase Code. A receive error occurs when the two

message samples fail to “logic wise” match. Noise and

Bi–Phase detection are discussed further under Message

Coding.

2) Bi–Phase Detection

The system slave devices receiving the Push Field

message from the MCU detect the Bi–Phase Code. A

detector error occurs when the two time slots of the Bi–Phase

Code do not contain an Exclusive–OR logic function.

3) Field Check

A field error is detected when a fixed–form bit field

contains an improper number of bits. A bit error can also be

detected by the MCU during the Push Field. The MCU can

simultaneously monitor the MI–Bus at the time it is sending

data. A bit error is detected if the sent bit value does not

match the value which was monitored.

4) Urgent Output Disable

If the MI–Bus becomes shorted to ground, the slave

device outputs will be disabled after a period of 9ts. The MCU

itself can take advantage of this feature to “globally” disable

the outputs of all system slave devices by keeping the

MI–Bus at a logic “0” level for a duration of 9ts or more.

Normal operation is resumed when the MCU sends a

“standard” instruction over the MI–Bus.

Basic Stepper Motor Construction and Operation

Stepper motors are constructed with a permanent magnet

rotor magnetized with the same number of pole pairs as

contained in one stator coil section. Operationally, stepper

motors rotate at constant incremental angles by stepping one

step every time the current switches discretely in one stator

field coil causing the North–South stator field to rotate either

clockwise or counter–clockwise causing the permanent

magnet rotor to follow (see Figure 5). For simplicity, assume

the starting condition of the A1 to A2 stator field to be top to

bottom polarized N to S and the B1 to B2 stator field to be left

to right polarized N to S. The resulting stator field will produce

a vector which points in the direction of position 3. The rotor

will, in this case, be in the position shown in Figure 5 (pointing

to position 1). This initial condition corresponds to that of

step 1 in Figure 6. As the direction of current flow in the B1 to

B2 stator field is reversed, the field polarity of the B1 to B2

also reverses and is left to right polarized S to N. This causes

the resulting stator field vector to point in the direction of

position 4. This in turn causes the N–S rotor to follow and

rotate 90° in a clockwise direction and point in the direction of

position 2. This condition corresponds to step 2 of Figure 6.

Continued clockwise rotor steps will be experienced as the

stator field continues to be incrementally rotated as shown in

steps 3, 4, 5, etc. of Figure 6. The 90° steps in this simplistic

example constitute “full steps”. It is to be noticed that both

coils, in the foregoing full step example, were simultaneously

energized in one of two directions. It is possible to increment

the rotor in 45° “intermediate steps” or “half steps” by

alternately energizing only one stator coil at a time in the

appropriate direction while turning the other stator coil off.

The drive signals for Half Step operation are shown in

Figure 7. The Power output stages of the MC33192 consist

of two H–Bridges capable of driving two–phase bi–polar

permanent magnet motors in either half or full step

increment.

Figure 5. Permanent Magnet Stepper Motor

A1

3

B1 B2

2

A2

4

1

Figure 6. 4–Step “Full Step” Operation

Step

Coil A

(A1 to A2)

Coil B

(B1 to B2)

Stator

Field

Rotor

Position

Rotor

Direction

1234 56

+

–

+

–

CWCCW

Figure 7. 8–Step “Half Step” Operation

Step

Coil A

(A1 to A2)

Coil B

(B1 to B2)

Stator

Field

Rotor

Position

Rotor

Direction

123456

+

–

+

–

781

CWCCW

MOTOROLA ANALOG IC DEVICE DATA

5

Page 6

MC33192

Permanent magnetic stepping motors exhibit the

characteristic ability to hold a shaft rotor position with or

without a stator coil being energized. Normally the shaft

holding ability of the motor with a stator coil energized is

referred to as “Holding Torque” while “Residual Torque” or

“Detent Torque” refers to the shaft holding ability when a

stator coil is not energized. The Holding Torque value is

dependent on the interactive magnetic force created by the

resulting energized stator fields with that of the permanent

magnet rotor. The Residual Torque is a function of the

physical size and composition of the permanent magnet rotor

material coupled with its intrinsic magnetic attraction for the

un–energized stator core material and as a result, the weaker

of the two torques.

It is to be noted when using half step operation, only one

coil is energized during alternate step periods which

produces a somewhat weaker Holding Torque. Holding

Torque is maximized when both coils are simultaneously

Figure 8. Truth Table and Serial Push Field Data Bits For Sequential Stepping

Push Field Bits

Step

Full Half

D0 D1

Inh1

DIR1

D2ED3

DIR2D4Inh2 A1 A2 B1 B2

energized. In addition, since each winding and resulting flux

conditions are not perfectly matched for each half step,

incremental accuracy is not as good as when full stepping.

T wo Phase Drive Signals

The DIR1 and DIR2 bits in the Data Frame of the Push

Field determine the direction of H–Bridge current flow, and

thus the magnetic field polarization of the stator coils, for

H–Bridge outputs “A” and “B” respectively. The directional

signals DIR1 and DIR2, generated by the MCU,

communicate over the MI–Bus to control the two H–Bridge

power output stages of the MC33192 to drive two phase

bipolar permanent magnet motors. Figure 8 shows the

MC33192 truth table to accomplish incremental stepping of

the motor in a clockwise or counter–clockwise direction in

either half or full step modes. The stator field polarization and

rotor position are also shown for reference relative to the

basic stepper motor of Figure 5.

H–Bridge Outputs

Stator

Field

(Note 2)

Rotor

Position

(Note 2)

Direction

of Shaft

Rotation

1

1

101011010

–

2

101X010ZZ

2

3

101111001

–

4

0X 1 1 1 ZZ01

3

5

111110101

–

6

111X00100

7

4

–

NOTES: 1. X = Don’t care; Z = High impedance; 1 = High (active “on”) state; 0 = Low (inactive “off”) state.

111010110

8

0X 1 0 1 ZZ10

0XXX0ZZZZ

11011Z1Z1

100011Z1Z

11000Z1ZZ

00011ZZZ1

2.The stator field direction and position of the rotor are shown for explanation purposes and relative to the basic

stepper motor shown in Figure 3.

3.DIR1 establishes the direction of current flow in H–Bridge “A”.

4.DIR2 establishes the direction of current flow in H–Bridge “B”.

CCW

CW

6

MOTOROLA ANALOG IC DEVICE DATA

Page 7

MC33192

MI–Bus Interface Description

The MI–Bus Interface shown in Figure 9 is made up of a

single NPN transistor (Q1). The two main functions of this

NPN transistor are:

1) To drive the MI–Bus during the Push Field with

approximately 20 mA of current while also exhibiting low

saturation characteristics (V

CE(sat)

).

2) To protect the Input/Output (I/O) pin of the MCU against

any Electro–Magnetic Interference (EMI) captured on the

bus wire.

Without the NPN transistor, the MCU could be destroyed

as a result of receiving excessive EMI energy present on the

bus. In addition, the transistor blocks the MCU from receiving

EMI signals which could erroneously change the data

direction register of the MCU I/O.

The MCU input pin (Pin), used to read the Pull Field of the

MI–Bus, is protected by two diodes (D2 and D3) and two

resistors (R5 and R6). Any transient EMI generated voltage

present on the bus is clamped by the two diodes to a

windowed voltage value not to be greater than the VDD or

less than the VSS supply voltages of the MCU.

MI–Bus Levels

The MI–Bus can have one of two valid logic states,

recessive or dominant. The recessive state corresponds to a

Logic “1” and is obtained through use of a 10 kΩ pull–up

resistor (R9) to 5.0 V. The dominant state corresponds to a

Logic “0” which represents a voltage less than 0.3 V and

created by the V

CE(sat) of Q1.

MI–Bus Overvoltage Protection

An external zener diode (Z1) is incorporated in the

interface circuit so as to protect the MCU output pin (P

out

from overvoltages commonly encountered in automotive

applications as a result of “Load Dump” and “Jump Start”

conditions. Load Dump is defined as the inductive transient

generated on the battery line as a result of opening the

battery connection while the alternator system is producing

charge current. Jump Start overvoltages are the result of

paralleling the installed automotive battery, through the use

of “jumper cables”, to an external voltage source in excess

of the vehicles nominal system voltage. For 12 V

automotive systems, it is common for 24 V “jump start”

voltages to be used.

When an overvoltage situation (>18 V) exists, due to a

load dump or jump start condition, the zener diode (Z1) is

activated and supplies base current to turn on the NPN

transistor Q1 causing the bus to be pulled to less than 0.3 V

producing a Logic “0” on the MI–Bus. After a duration

corresponding to 8ts (200 µs) of continuous Logic “0” on the

bus all MC33192 devices will disable their outputs. Normal

operation is resumed, following the overvoltage, by the MCU

sending out a “standard” message instruction.

MI–Bus T ermination Network

The MI–Bus is resistively loaded according to the number

of MC33192 devices installed on the bus. Each MC33192

has an internal 10 kΩ pull–up resistor to 5.0 V. An external

pull–up resistor (R7) is recommended to be used to optimally

adjust termination of the bus for a load resistance of 600 Ω.

)

5.0 V

V

DD

MCU

V

SS

Figure 9. MI–Bus MCU Interface

Program

Run

Z1

R1

(4.7 K)

P

out

D1

R5

P

(10 k)

in

(18 V)

R3

(3.9 k)

V

DD

D2

D3

R2

(1.2 k)

MI–Bus

Q1

R4

(10 k)

R6

(22 k)

5.0 V

Z

in

R7

(1.2 k)

#2

#3

#4

#5

#6

#7

#8

R8

Ω

)

(20

1

Z2

(18 V)

Additional MC33192 Devices

5.0 V

MC33192

6.5 V

R9

(10 k)

Q2

Data

Out

7

V

Gnd

2

CC

12 V

Programming

Data In

0 V

MOTOROLA ANALOG IC DEVICE DATA

7

Page 8

MC33192

MESSAGE CODING

Bi–Phase Coding and Detection

The Manchester Bi–Phase code shown in Figure 10

requires two time slots (2ts) to encode a single data bit. This

allows detection of a single error at the time slot level. The

logic levels “1” or “0” are determined by the organization of

the two time slots. These always have complementary logic

levels of either zero volts or plus five volts, which are

detected using an Exclusive OR detection circuit during the

Push Field sequence. A “1” bit is detected when the first time

slot is set to a zero logic state (0 V) followed by the second

time slot set to a logic state one (5.0 V). Conversely , a “0” bit

is detected when the first time slot is set to the logic state

“one” (5.0 V) followed by a second time slot set to a “zero”

logic state (0 V). For these two bits are Exclusive–ORs of

each other.

The addressed devices receiving the Push Field detect

the Bi–Phase code. Bi–Phase detection involves the

sampling of the Push Field Bi–Phase code twice (a and b) for

each time slot. A code error occurs when the two time slots of

the Bi–Phase do not follow a logical Exclusive–OR function

(see Figure 10).

Noise monitoring is accomplished by sampling the Push

Field Bi–Phase code twice (a and a’) and (b and b’) during

each time slot. A noise error is detected if the two sample

values do not have the same logical level.

Figure 10. Noise/Bi–Phase Detection

2 t

s

5.0 V

Push Field

Bi–Phase

Coded Bits

t

s

(Logic “0”)

001234567 12345670

abab

ababa’ b’ a’

t

s

(Logic “1”)

b’

t

Bi–Phase

Detection

Noise

Detection

Each message frame consists of two fields: The Push

Field, in which data and addresses are transferred by the

MCU to the slave device; and the Pull Field, in which serial

data is transferred back to the MCU from the address

selected slave device. The message frame is broken down

into seven individual field segments as indicated in Figure 4

(Start, Push Field Sync, Push Field Data, Push Field

Address, Pull Field Sync, Pull Field Data, and

End–of–Frame). The following lists the bit size and function

of each of these segments:

1) Start is the start of message and consists of three time

slots (3ts) having the dominant Logic “0” state of less than

0.3 V . Holding the MI–Bus at ground for three time slots (3ts)

marks the beginning of the message frame by violating the

law of the Manchester Code.

2) Push Field Sync is a single bit which establishes initial

timing for the Push Field Data to follow.

3) Push Field Data is comprised of five serial data bit

fields (D0, D1, D2, D3 and D4) which comprise the instruction

set defining the configuration and condition of the two

H–Bridge output stages.

4) Push Field Address is comprised of three serial data

bit fields (A0, A1 and A2) which define the address or name

of a MC33192 on the MI–Bus.

5) Pull Field Sync is a single bit which establishes the end

of the Push Field and the initial start timing for the Pull Field

Data to follow.

6) Pull Field Data is made up of three serial data bit fields

(S2, S1 and S0) which contain the existing status information

of an addressed MC33192.

7) End–of–Frame field is a signal which communicates

to the MCU that the status information sent by the MC33192

is complete.

The Push Field Sync bit, Push Field Data bits, Push Field

Address bits, Pull Field Sync bit are all coded by the

Manchester Bi–Phase L Code. The Pull Field Data bits are

Non–Return to Zero (NRZ) coded. The End–of Frame field is

a square wave signal with a frequency of 20 kHz or higher so

as to avoid a condition which causes a bus violation.

The Manchester Bi–Phase L code requires two time slots

(2ts) to encode a single bit. This allows a single error to be

detected during the time slot.

Address Programming involves the use of three

instructions. Refer to Figure10.

First Instruction Set the MI–Bus continuously at 12 V.

This places the MC33192 in the programming mode.

Programming is possible only when the MI–Bus is at 12 V.

Next, the MCU serially enters ”Logic Zeros” in all five Push

Field Data bit positions (D0, D1, D2, D3 and D4) followed by

the designated address value in the Push Field Address

positions (A0, A1, & A2).

The MCU now waits 275 µs before starting the second

instruction. The total of the Pull time, Delay time, and Bus

Violation time (V) of the second instruction (150 µs, 275 µs

and 75 µs respectively) will cause the memory cell to be

energized for 500 µs. During the first 150 µs of this time, the

MCU is checking the Pull Field Data Bits S2, S1 and S0

looking for the programming code “110” to indicate

complete activation of the memory cell.

Second Instruction (MI–Bus voltage remaining at 12 V)

The MCU repeats the same Push Field instruction as

previously sent in the First Instruction; entering all “Logic

Zeros” in the Push Field Data positions followed by the

designated Push Field Address value in the address

positions.

Again, the MCU waits for the Pull, Delay, and Bus violation

time while checking the Pull Field Data bits looking for the

programming code “110” code. The MCU must repeat the

initial Push Field Address instruction until a “110” code is

received before advancing to the Third Instruction.

Third Instruction The MI–Bus voltage is lowered to 5.0 V .

The MCU serially loads “Logic Zeros” in all five Push Field

Data bit positions followed by the programmed address in the

Push Field Address positions. The MCU then checks the Pull

Field Address status bits looking this time for the

8

MOTOROLA ANALOG IC DEVICE DATA

Page 9

MC33192

programming OK code “100” indicating the address

programming to be executed.

The First and Second Instructions must be repeated until

the MCU successfully receives the programming code

“100”. Address programming is not complete until a “100”

OK status is received by the MCU with the MI–Bus voltage

at 5.0 V.

Overwrite–Bit Programming involves the use of two

instructions. See Figure 1 1.

First Instruction Have the MI–Bus continuously set at

12 V so as to have the MC33192 in the programming mode.

Programming can only be accomplished with the MI–Bus at

12 V.

The MCU serially enters “Logic Zeros” for the Push Field

Data bits D0, D1, D2 and D3 and a Logic “1” for D4 bit

followed by the programmed address bits A0, A1 and A2.

The MCU now waits 275 µs before starting the second

instruction. The total of the Pull time, Delay time, and Bus

Violation time (V) of the second instruction (150 µs, 275 µs

and 75 µs respectively) will cause the memory cell to be

energized for 500 µs. During the first 150 µs of this time, the

MCU is checking the Pull Field Data Bits for the status of bits

S2, S1 and S0 looking for the programming code “110” to

indicate complete activation of the memory cell.

Second Instruction (MI–Bus remaining at 12 V)

The MCU repeats the first instruction outlined above until

the programming OK code “100” is sent back to the MCU

from the selected MC33192 indicating the overwrite–bit

protection to be programmed. If after eight repeat

instructions, the programming code “110” or the OK code

“100” is not generated four times in succession,

programming of the MC33192 has failed. If this occurs, the

Overwrite–Bit Programming sequence should be reviewed

and re–started from the beginning.

H–Bridge Output

The H–Bridge output drive circuit and associated

diagnostic encoder are shown in Figure 12. The H–Bridge

output uses internal diode clamps (D1, D2, D3, D4) to provide

transient protection of the output transistors necessary when

switching inductive loads associated with stepper motors.

Back EMF Detection

Three different Back EMF currents can occur depending

on whether the motor is running or manner in which it is being

stopped. Referring to Figure 12; When the Dir1 bit is set to

logic 0, the direction of current flow will be from VCC through

transistor Q2, Coil A (A1 to A2), and transistor Q4 to ground.

1) Fast Decay (when transistors Q1, Q2, Q3 and Q4 are

switched off).

When the current flowing in the coil is stopped by setting

the Inh1

bit to logic 0, the back EMF current will circulate

through the voltage supply (VCC) and diodes D1 and D3. At

that time, the voltage developed across the diode D1 is

detected by transistor Q6. The generated voltage pulse of Q6

is then encoded and sent, in the Pull–Field, to the

microprocessor.

2) Slow Decay (Q3 and Q4 are switched off)

When the current flowing in the coil is stopped by setting

the E bit to logic 0, the back EMF current will circulate through

the diode D1 and transistor Q2 which is already switched on.

3) When Motor is Running

The rotational direction of the motor changes whenever

the Dir bit state is changed. When the Dir bit is changed from

a logic 0 to a logic 1, transistors Q2 and Q4 are switched off

and transistors Q1 and Q3 are switched on. At this time, the

back EMF current will circulate from ground through diodes

D1 and D3 to the voltage supply (VCC). In all cases, the back

EMF currents will be detected by transistors Q5 and Q6.

Programming

MI–Bus Voltage

Instruction Number

MI–Bus Field

Status Code

Overwrite–Bit

Status Code

Strobe Pulse

Memory Cell

Figure 11. Address Programming Diagram

Active

Finished Finished

12V

5.0 V

Address

Energy in

1

Push Pull DelayV V Pull Delay VPush Push Pull

µ

s 150 µs 275 µs 75 µs 550 µs

550

“110” “110”

500

µ

s

2

150 µs 275 µs 75 µs

“100”“110”

500 µs475 µs

12 V

5.0 V

3

“100”

“100”

OK

t

MOTOROLA ANALOG IC DEVICE DATA

9

Page 10

Inh1

MC33192

Figure 12. H–Bridge Output Drive Circuit and Diagnostic Encoder

V

CC

Dir 1

EE

BF1

BF2

ST

Programming

Thermal

Q2

Q3

D2

D3

DQ

C

Q5 Q6

D1

D4

Q1

Q4

A1

Coil 1

A2

Ground

S0

S1

S2

B1

Coil 2

B2

S2 S1 S0 Status

000

001

010

011

100

101

110

111

Second

H–Bridge

Not Used

Free

No Back EMF

Free

Normal/OK

Thermal

Programming

Selection Failed

Inh2

Dir2

E

10

MOTOROLA ANALOG IC DEVICE DATA

Page 11

MC33192

Figure 13. Single Wire MI–Bus Control of 8 Stepper Motors

12 V

5.0 V

Regulator

Micorcontroller

MC68HC05B6

MC68HC11KA

Gnd

Program

Run

R2

R1

P

out

D1

P

R5

in

Z1

D2

D3

R3

Q1

R4

R6

Mi–Bus

MC33192DW

MC33192DW

MC33192DW

MC33192DW

MC33192DW

MC33192DW

Stepper

Motor

1

Stepper

Motor

2

Stepper

Motor

3

Stepper

Motor

4

Stepper

Motor

5

Stepper

Motor

6

MC33192DW

MC33192DW

Stepper

Motor

7

Stepper

Motor

8

MOTOROLA ANALOG IC DEVICE DATA

11

Page 12

–A–

16 9

D16X

M

0.010 (0.25) B

A

T

G14X

–B– P8X

81

S

S

C

K

MC33192

OUTLINE DIMENSIONS

DW SUFFIX

PLASTIC PACKAGE

CASE 751G–02

(SO–16L)

ISSUE A

M

0.010 (0.25)

–T–

SEATING

PLANE

J

B

F

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

M

R

X 45

_

3. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 (0.005) TOTAL IN

EXCESS OF D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 10.15 10.45 0.400 0.411

B 7.40 7.60 0.292 0.299

C 2.35 2.65 0.093 0.104

D 0.35 0.49 0.014 0.019

F 0.50 0.90 0.020 0.035

G 1.27 BSC 0.050 BSC

J 0.25 0.32 0.010 0.012

K 0.10 0.25 0.004 0.009

M 0 7 0 7

____

P 10.05 10.55 0.395 0.415

R 0.25 0.75 0.010 0.029

INCHESMILLIMETERS

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE /Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 or 602–303–5454 3–14–2 T atsumi Koto–Ku, Tokyo 135, Japan. 03–81–3521–8315

MFAX: RMF AX0@email.sps.mot.com – TOUCHT ONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

12

◊

MOTOROLA ANALOG IC DEVICE DATA

M33192/D

*MC33192/D*

Loading...

Loading...