Page 1

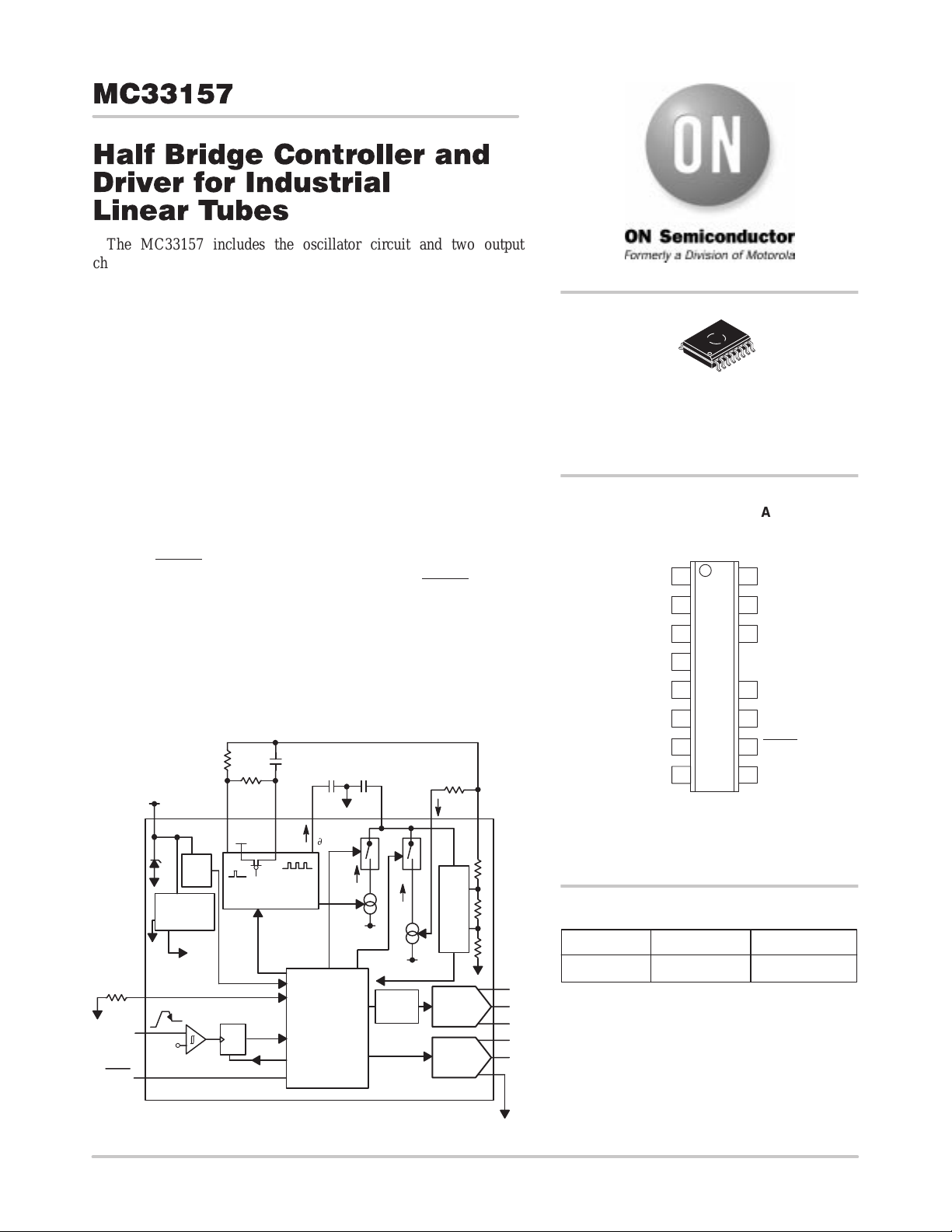

MC33157

Half Bridge Controller and

Driver for Industrial

Linear Tubes

The MC33157 includes the oscillator circuit and two output

channels to control a half–bridge power stage.

One of the channels is ground–referenced. The second one is

floating to provide a bootstrap operation for the high side switch.

Dedicated Driver for Industrial Linear T ubes

• Main oscillator is current controlled, making it easy to set up by a

single external resistor . On top of that, such a feature is useful to

implement a dimming function by frequency shift.

• Filament pre–heating time control built–in.

• The strike sequence is controllable by external passive components,

the resonnant frequency being independently adjustable. This

frequency can be made different from the pre–heating and the steady

state values. A frequency sweep between two defined values makes

this IC suitable for any series resonnant topologies.

• Dedicated internal comparator provides an easy lamp strike detection

implementation.

• Digital RESET pin provides a fast reset of the system (less than 10µs).

Both output MOSFET are set to “OFF” state when RESET is zero.

• Adjustable dead time makes the product suitable for any snubber

capacitor and size of MOSFET used as power switches.

• Designed to be used with standard setting capacitors ≤ 470nF.

• A voltage reference, derived from the internal bandgap, is provided

for external usage. This voltage is 100% trimmed at probe level

yielding a 2% tolerance over the temperature range.

C

PH

SWEEP

C

PH

Iph

ē

Iph

Ifstrike

ENABLE

Dead Time

CONTROL LOGIC

Strike Detection

Clear

INHIBIT

+Vref

C

OP

SHIFTER

Iop

LEVEL

+Vref

R

OP

ICO

COMPARATOR

HIGH SIDE

BUFFER

LOW SIDE

BUFFER

+Vref

2

R

R

R

16

VHS

15

VHO

14

VOUT

13

NC

12

VLO

11

GND

DT adjust

Strike

Detection

RESET

R

ENDSWP

U

VLO

+Vref

(+7 V)

R

+Vref

PREHEAT

& STRIKE CONTROL

Latch

Q

C

V

DD

145367

15 V

BAND GAP

REFERENCE

8

9

Vth

10

http://onsemi.com

16

1

SO–16L

DW SUFFIX

CASE 751G

PIN CONNECTIONS AND

MARKING DIAGRAM

116

V

DD

2

+V

ref

C

3

PH

R

4

PH

C

SWEEP

512

MC33157DW

6

C

OP

ICO

7

DTA SD

AWL = Manufacturing Code

YYWW = Date Code

(Top View)

15

14

AWLYYWW

11

10

98

V

HS

V

HO

V

OUT

V

LO

GND

RESET

ORDERING INFORMATION

Device Package Shipping

MC33157DW Plastic SO–16L 47 Units / Rail

Semiconductor Components Industries, LLC, 1999

November, 1999 – Rev. 1

1 Publication Order Number:

MC33157/D

Page 2

MC33157

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

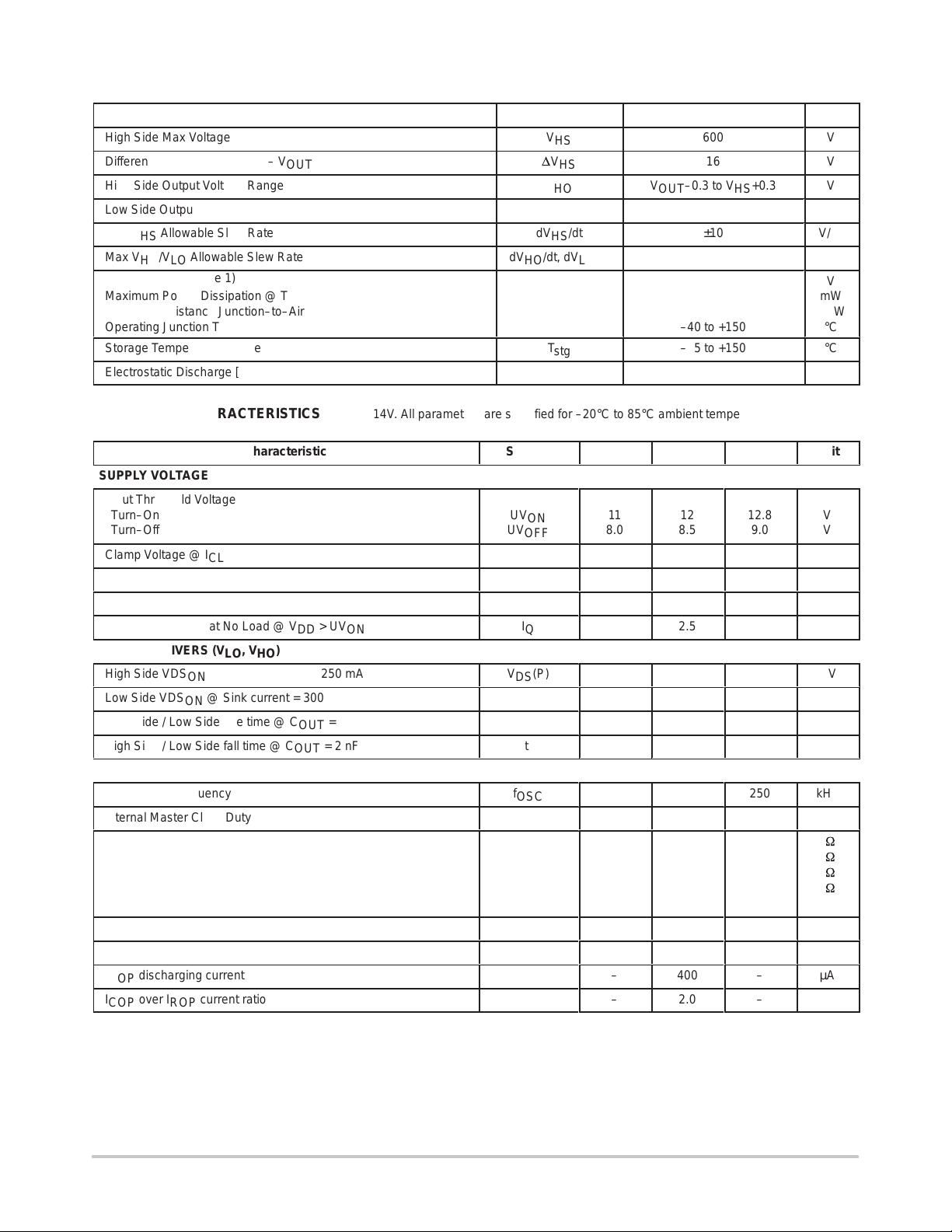

MAXIMUM RATINGS

Rating Symbol Value Unit

High Side Max Voltage

Differential Max Voltage VHS – V

High Side Output Voltage Range

Low Side Output Voltage Range

Max VHS Allowable Slew Rate

Max VHO/VLO Allowable Slew Rate

Supply Voltage

Maximum Power Dissipation @ TA = 50°C

ББББББББББББББББ

Thermal Resistance Junction–to–Air

Operating Junction Temperature

ББББББББББББББББ

(Note 1)

Storage Temperature Range

Electrostatic Discharge [HBMI]

OUT

V

HS

D

V

HS

V

HO

V

LO

dVHS/dt

dVHO/dt, dVLO/dt

V

DD

P

БББББ

БББББ

D

R

θJA

T

J

T

stg

ESD

600

16

V

–0.3 to VHS+0.3

OUT

–0.3 to +16

±10

±10

16

ББББББ

ББББББ

600

140

–40 to +150

–65 to +150

2.0

V/ns

V/ns

mW

Á

°C/W

Á

V

V

V

V

V

°C

°C

kV

ELECTRICAL CHARACTERISTICS (V

= 14V . All parameters are specified for –20 °C to 85°C ambient temperature

DD

unless otherwise noted.)

Characteristic

SUPPLY VOLTAGE

Input Threshold Voltage

Turn–On

ББББББББББББББББ

Turn–Off

Clamp Voltage @ I

Supply Current

(Note 2)

Standby Current at No Load @ VDD < UV

Quiescent Current at No Load @ VDD > UV

CLAMP

= 10 mA

OFF

ON

OUTPUT DRIVERS (VLO, VHO)

High Side VDSON @ Source current = 250 mA

Low Side VDSON @ Sink current = 300 mA

High Side / Low Side rise time @ C

High Side / Low Side fall time @ C

OUT

OUT

= 2 nF

= 2 nF

OSCILLATOR

Output Max Frequency

Internal Master Clock Duty Cycle

System operation programming recommended values

ББББББББББББББББ

ББББББББББББББББ

ББББББББББББББББ

V

High threshold

COP

V

Low threshold

COP

I

discharging current

COP

I

COP

over I

current ratio

ROP

Symbol Min Typ Max Unit

UV

ON

ÁÁÁ

UV

OFF

V

CLAMP

I

S

I

STDBY

I

Q

VDS(P)

VDS(N)

t

r

t

f

f

OSC

DC

R

OP

ÁÁÁ

R

PH

R

ENDSWEEP

ÁÁÁ

R

DTA

ÁÁÁ

C

OP

11

ÁÁ

8.0

15

–

–

–

68

ÁÁ

68

68

ÁÁ

10

ÁÁ

100

–

–

–

–

12

ÁÁ

8.5

16

12

1.5

2.5

880

880

40

35

50

ÁÁ

ÁÁ

ÁÁ

4.2

2.8

400

2.0

12.8

ÁÁ

9.0

16.5

1500

1500

250

–

560

ÁÁ

560

2200

ÁÁ

250

ÁÁ

560

–

–

–

–

Á

mA

mA

mA

mV

mV

ns

ns

kHz

%

k

Á

k

k

Á

k

Á

pF

µA

V

V

V

W

W

W

W

V

V

http://onsemi.com

2

Page 3

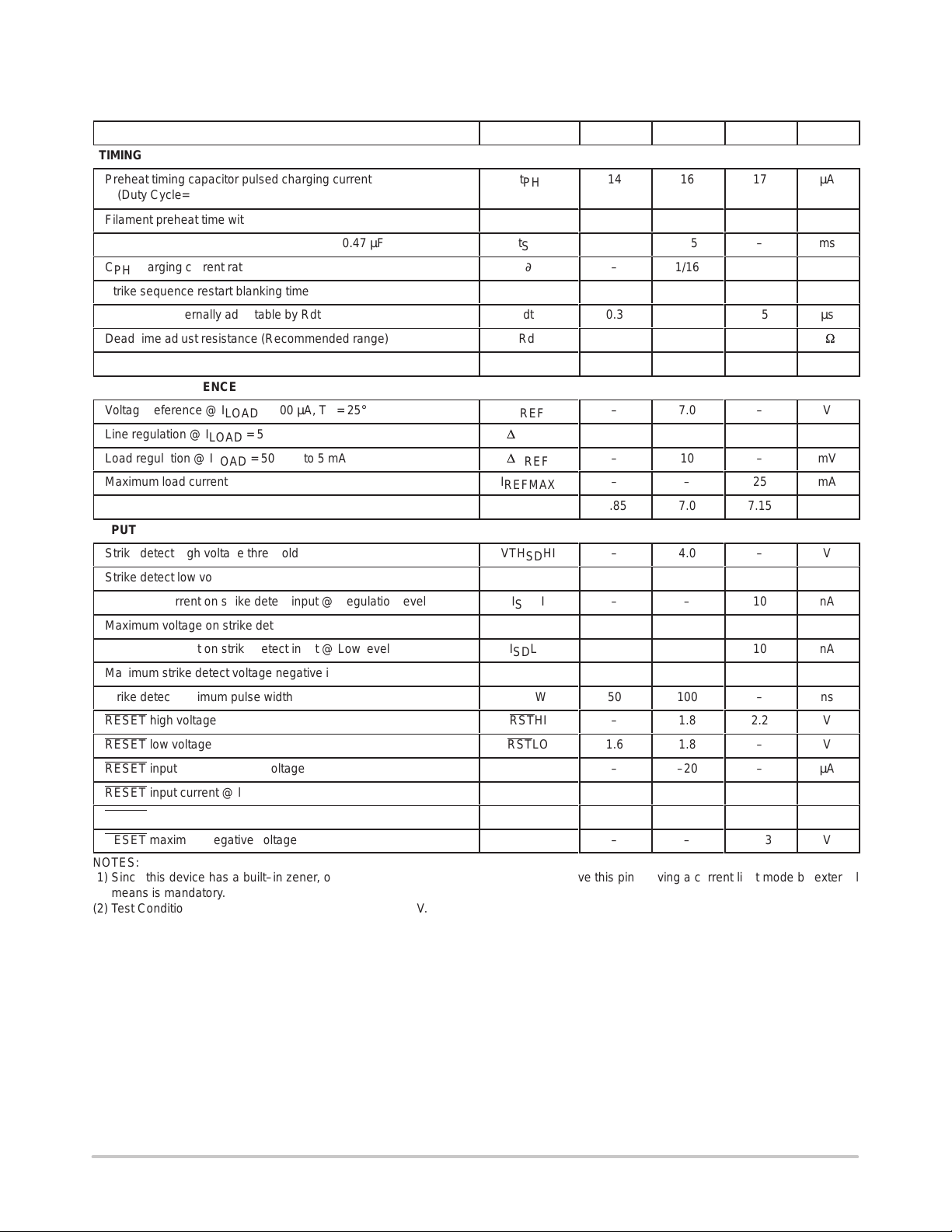

MC33157

ELECTRICAL CHARACTERISTICS (continued) (V

unless otherwise noted.)

Characteristic UnitMaxTypMinSymbol

TIMING

Preheat timing capacitor pulsed charging current

(Duty Cycle=1/16)

Filament preheat time with CPH = 0.47 µF

Strike sequence recycling time with CPH = 0.47 µF

CPH charging current ratio

Strike sequence restart blanking time with CPH = 470nF

Dead time: externally adjustable by Rdt

Dead time adjust resistance (Recommended range)

Dead time tolerance

VOLTAGE REFERENCE

Voltage reference @ I

Line regulation @ I

Load regulation @ I

Maximum load current

Total V

REF

INPUT

Strike detect high voltage threshold

Strike detect low voltage threshold

Maximum current on strike detect input @ Regulation level ISDHI – – 10 nA

Maximum voltage on strike detect @ Regulation level VSDHI – – 7.0 V

Maximum current on strike detect input @ Low level ISDLO – – 10 nA

Maximum strike detect voltage negative input VSDNEG – – –0.3 V

Strike detect minimum pulse width

RESET high voltage

RESET low voltage

RESET input current @ high voltage

RESET input current @ low voltage

RESET maximum voltage

RESET maximum negative voltage

NOTES:

(1) Since this device has a built–in zener, one cannot use a low impedance supply to drive this pin. Having a current limit mode by external

means is mandatory.

(2) Test Conditions: C

LOAD

variation over Line, Temperature, Load

OUT

= 500 µA, TJ = 25°C

LOAD

= 500 µA, TJ = 25°C

= 500 µA to 5 mA

LOAD

= 2.2 nF, f = 100 kHz, VDD = 15V.

= 14V . All parameters are specified for –20 °C to 85°C ambient temperature

DD

It

PH

t

PH

t

SK

∂

t

bk

dt

Rdt

dt

Tol

V

REF

D

V

REF

D

V

REF

I

REFMAX

V

REF

VTHSDHI

VTHSDLO

SDPW

RSTHI

RSTLO

14

–

–

–

–

0.3

10

–

–

–

–

6.85

–

–

50

–

1.6

–

–

–

–

16

2.0

125

1/16

10

–

–

±10

7.0

10

10

–

7.0

4.0

3.75

100

1.8

1.8

–20

–20

–

–

17

–

–

–

–

2.5

220

–

–

–

25

7.15

–

–

–

2.2

–

–

–

7.0

–0.3

µA

s

ms

ms

µs

k

%

V

mV

mV

mA

V

V

V

ns

V

V

µA

µA

V

V

W

http://onsemi.com

3

Page 4

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

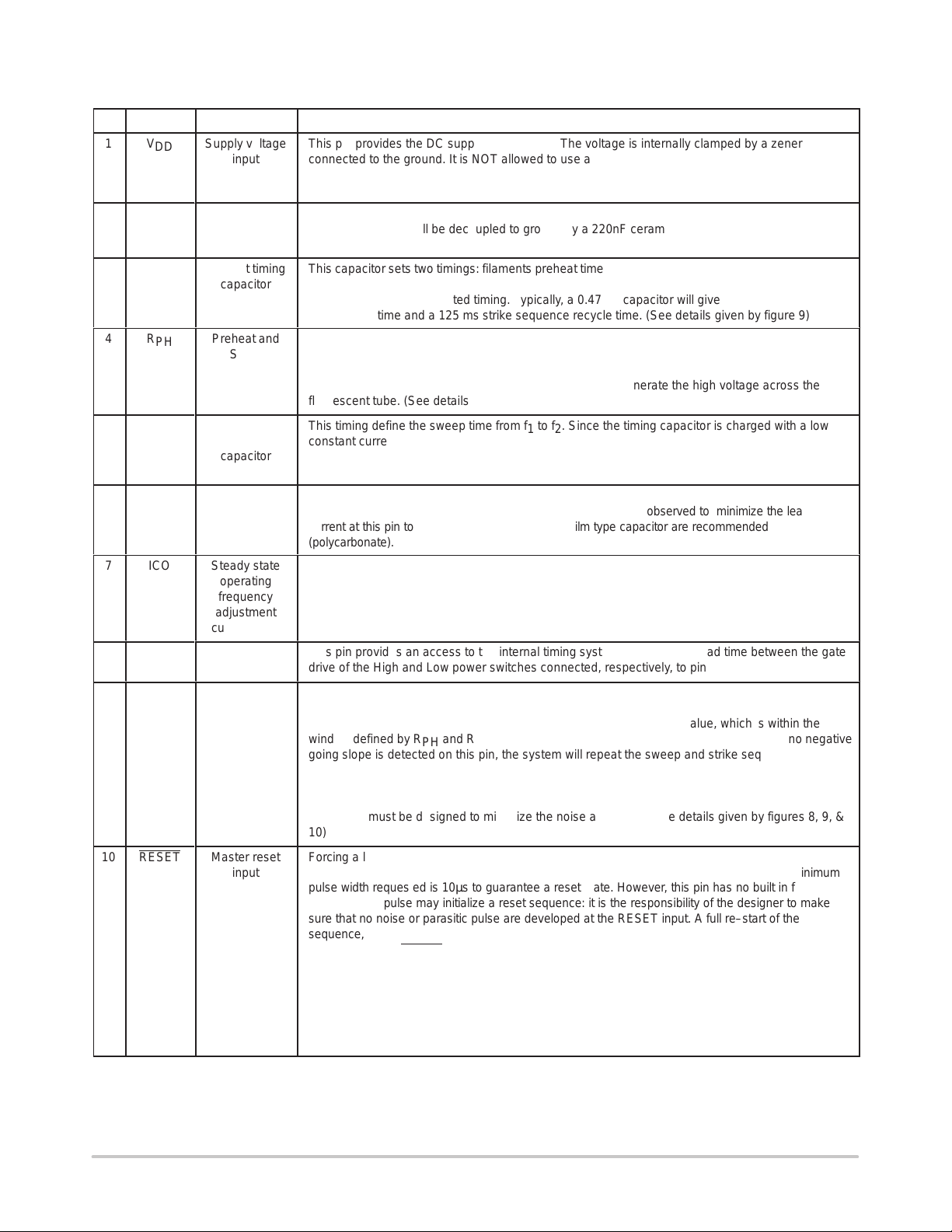

MC33157

PIN FUNCTION DESCRIPTION

Pin Symbol Function Description

1

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

10

Á

Á

Á

Á

Á

Á

Á

Á

V

DD

ÁÁ

ÁÁ

2

+V

ÁÁ

3

C

PH

ÁÁ

ÁÁ

4

R

PH

ÁÁ

ÁÁ

ÁÁ

5

C

SWEEP

ÁÁ

ÁÁ

6

C

OP

ÁÁ

ÁÁ

7

ICO

ÁÁ

ÁÁ

8

DTA

ÁÁ

9

SD

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

RESET

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ref

Supply voltage

input

ÁÁÁ

ÁÁÁ

Voltage

reference

ÁÁÁ

output

Preheat timing

ÁÁÁ

capacitor

ÁÁÁ

Preheat and

ÁÁÁ

Strike

frequencies

ÁÁÁ

adjustment

resistors

ÁÁÁ

Frequency

sweep timing

ÁÁÁ

capacitor

ÁÁÁ

Oscillator

capacitor

ÁÁÁ

ÁÁÁ

Steady state

operating

ÁÁÁ

frequency

adjustment

ÁÁÁ

current input

Dead Time

ÁÁÁ

Adjust

Strike detection

input

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Master reset

input

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

This pin provides the DC supply to the circuit. The voltage is internally clamped by a zener

connected to the ground. It is NOT allowed to use a DC low impedance power supply to feed this

ББББББББББББББББББББББ

pin, but limiting the current by an external resistor is mandatory. It is recommended to damp this pin

ББББББББББББББББББББББ

to ground by an electrolytic capacitor connected close to pin 1.

This pin provides a +7V voltage reference derived from the internal bandgap. The +Vref can supply

up to 25 mA and shall be decoupled to ground by a 220nF ceramic capacitor

ББББББББББББББББББББББ

This capacitor sets two timings: filaments preheat time (tPH) and strike sequence recycle time (tSK).

ББББББББББББББББББББББ

It is charged with a constant current and cares must be observed to minimize the leakage current

at this pin to get the expected timing. Typically, a 0.47 µF capacitor will give a 2 seconds

ББББББББББББББББББББББ

pre–heating time and a 125 ms strike sequence recycle time. (See details given by figure 9)

The RPH resistor together with R

ББББББББББББББББББББББ

filaments (fPH = f1). R

timing, the frequency will sweep from the high pre–heating f1 to the low strike f2 values. Normally,

ББББББББББББББББББББББ

f1 is far from the LC resonance but f2 is close enough to generate the high voltage across the

fluorescent tube. (See details given by figure 9)

ББББББББББББББББББББББ

ENDSWEEP

ENDSWEEP

defines the strike frequency (f

This timing define the sweep time from f1 to f2. Since the timing capacitor is charged with a low

constant current, cares must be observed to minimize the leakage current at this pin to get the

ББББББББББББББББББББББ

expected timing. Since this capacitor is charged through resistor RPH, the voltage rises according

to an exponential and the frequency shifts with the same law.

ББББББББББББББББББББББ

This pin defines the steady state operation frequency (f3 = fOP) of the controller. Since this timing

capacitor is charged with a low constant current, cares must be observed to minimize the leakage

ББББББББББББББББББББББ

current at this pin to get the expected frequency. Film type capacitor are recommended

(polycarbonate).

ББББББББББББББББББББББ

Since the circuit uses a Current Controlled Oscillator (ICO), the current forced into this pin will

control the operating frequency. The allowable current range is from 1 µA to 500 µA. The +Vref

ББББББББББББББББББББББ

output can be used to provide the voltage across ROP. An auxiliary voltage source can be used to

implement a dimming function.

ББББББББББББББББББББББ

This pin provides an access to the internal timing system to adjust the dead time between the gate

ББББББББББББББББББББББ

drive of the High and Low power switches connected, respectively, to pin VHO and VLO.

This pin drives a comparator, with an internal fixed reference, and acknowledges the tube strike.

When a negative going slope (across the internal reference) is detected, the system considers the

ББББББББББББББББББББББ

lamp has struck and the oscillator jumps from the present frequency value, which is within the

ББББББББББББББББББББББ

window defined by RPH and R

going slope is detected on this pin, the system will repeat the sweep and strike sequence four

ББББББББББББББББББББББ

times, then stops. The circuit will re–start from either a RESET, or by pulling +VDD to ground. The

ББББББББББББББББББББББ

input signal can be either a logic level or an analog voltage ramping up from zero to +Vref followed

by a negative going slope to zero. In any case, the positive pulse width must be 1 µs minimum. The

ББББББББББББББББББББББ

pcb layout must be designed to minimize the noise at this pin. (See details given by figures 8, 9, &

ББББББББББББББББББББББ

10)

ENDSWEEP

Forcing a logic zero to this pin (HCMOS low level) will reset the circuit, initializing a frequency sweep

and lamp strike sequence. The master reset does not include the pre–heating timing. The minimum

ББББББББББББББББББББББ

pulse width requested is 10µs to guarantee a reset state. However, this pin has no built in filtering

ББББББББББББББББББББББ

and a shorter pulse may initialize a reset sequence: it is the responsibility of the designer to make

sure that no noise or parasitic pulse are developed at the RESET input. A full re–start of the

ББББББББББББББББББББББ

sequence, including the pre–heating time, can be initialized by pulling the +VDD pin to ground. In this

case, +VDD and RESET

ББББББББББББББББББББББ

low (active) both outputs MOS are biased in the off condition. An internal 20µA pull up current forces

ББББББББББББББББББББББ

the pin to logic one, allowing the designer to left this pin open if the RESET function is not used. In

order to avoid any uncontrolled state of the output drivers, it is recommended to set up a 10ms low

ББББББББББББББББББББББ

level at pin 10. The reset is activated in less than 10 microsecond, but releasing this pin while the Vcc

ББББББББББББББББББББББ

supply is high (above 300V) can generate a random operation, depending upon the dv/dt coming

from the power supply.

ББББББББББББББББББББББ

must be simultaneously released to a high state. When RESET is asserted

http://onsemi.com

4

and COP defines the frequency used to preheat the

ENDSWEEP

= f2). During the sweep

to the steady state value defined by ROP. If no negative

Page 5

Pin DescriptionFunctionSymbol

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

11

GND

Á

Á

Á

Á

Á

12

13

14

15

16

ÁÁ

V

LO

ÁÁ

NC

V

OUT

ÁÁ

ÁÁ

V

HO

ÁÁ

V

HS

Ground

(zero voltage

ÁÁÁ

reference)

Low side driver

ÁÁÁ

output

Not Connected

High side

common point /

ÁÁÁ

Half bridge

ÁÁÁ

output

High side driver

output

ÁÁÁ

High voltage

boost supply

MC33157

PIN FUNCTION DESCRIPTION (continued)

Since high and fast currents circulate in the circuit, it is mandatory to build a single ground point in

the system.

ББББББББББББББББББББББ

This pin provides the VGS to drive the Low side power MOSFET.

ББББББББББББББББББББББ

This pin is connected to the output of the half bridge and is referenced for the High side switch.

ББББББББББББББББББББББ

ББББББББББББББББББББББ

This pin provides the VGS to drive the High side power MOSFET.

ББББББББББББББББББББББ

The gate drive of the High side switch is derived from this voltage.

http://onsemi.com

5

Page 6

+Vref

C

OP

External

MC33157

Internal

6

10 V

ESD

2K

10 V

ESD

Figure 1. PIN 6 COP INPUT

+Vref

I

I

PH

SWP

(8 UA)

Circuits

CAN’T READ

0V

ph/swp Switch

I

blanking

(200 uA)

10 V

ESD

2K

10 V

ESD

3

C

PH

(external)

Figure 2. PIN 3 CPH INPUT

+Vref

Internal

Circuits

5V

10

10 V

ESD

2K

10 V

ESD

Figure 3. PIN 10 RESET

4 V

+Vref

0.0 V

10 V

ESD

2K

10 V

ESD

9

Internal

Circuits

Hysteresis Switch

Figure 4. PIN 9 SD

http://onsemi.com

6

Page 7

MC33157

+Vref

81

2

R

OP

(external)

7

ph/swp switch

2K

10 V

ESD

R

DTA

(external)

I

8

10 V

ESD

10 V

ESD

(external)

(external)

I I/8

10 V

ESD

Internal

Circuits

10 V

ESD

2K

Figure 5. PIN 8 DTA

+Vref

10 V

ESD

2K

10 V

ESD

1 k

W

(internal)

1 k

W

(internal)

6

2I

C

OP

(external)

Figure 6. PIN ICO

+Vref

10 V

ESD

10 V

ESD

I

2K

10 V

ESD

6

2I

C

SWP

5

R

PH

2

R

4

ENDSWEEP

(external)

SD max

1 k

W

(internal)

Figure 7. PIN 2, 4 & 5 V

V

T 1 stw

ref

m

SDHIVth

4 V typ

Internal Hysterisis

The Strike Detect is acknowledged as soon as the input

voltage drops below SDLOVth. It is not necessary to pull

the input voltage to zero volt or to a negative bias

Figure 8. STRIKE DETECTION

http://onsemi.com

7

, RPH & C

SDNEG max

1 k

(internal)

SWP

W

SDLOVth

3.75 V typ

C

OP

(external)

Page 8

MC33157

Rise time

V

DD

U

VON

9.2 V typ

U

VLO

3.8 V typ

V

V

CPH

(PREHEAT)

Frequency

SWEEP

STRIKE

DETECTION

RESET

Output

Frequency

status

w

lms

ref

1

0

OFF STATE

f1 = fPH, preheating frequency adjusted by RPH and R

f2 = f

ENDSWEEP

f3 = fOP, operating frequency controlled by the ICO current (pin 7) and capacitor C

tPH = (CPH * 2/3 * Vref) / (ē * I

“OFF” state: High side switch OFF, Low side switch ON

tph

t 1 swm

STRIKE

F1 F2 F3 F1 F2 F3

, end of sweep frequency, adjusted by R

tPH

FSwp

ENDSWEEP

ENDSWEEP (

)

U RESET

VLO

7.0 V typ

OFF STATE

pin 2). In any case f1 w f

OP

FSwp

time

2

RESET

+V

ref

V

CSWP

STRIKE

DETECTION

Output Frequency

status

Figure 9. TIMING DIAGRAM (Normal startup sequence and U

10 swm

1

0

SD

HIGH

F3

Previous On state

When RESET

then executes a frequency sweep down to f

detection signal is applied to pin 9. There is no preheating timing performed after a reset coming from pin 10.

RESET

Note: Strike detection lever can be either digital – CMOS or analog as depicted here above, as long as the

signal fulfills the SD

OFF STATE: both output MOSFET are biased in the off condition.

pin is released to a logic one, the system jumps to the preheat frequency as defined by RPH,

logic level is CMOS compatible.

HIGH

OFF STATE

and SD

ENDSWEEP

values and timing.

LOW

FSweep

, as defined by R

SD

ENDSWEEP

LOW

, and waits until a strike

VLO

F3

reset)

V repeats indefinitely

CSWP

No further logic action activated

time

Figure 10. TIMING DIAGRAM (External reset)

http://onsemi.com

8

Page 9

RESET

+V

ref

V

CSWP

+VV

w

ref

STRIKE

DETECTION

MC33157

1

0

End of preheating sequence

Blanking 10 ms typ

@ C = 470 nF

PH

t

F

t

FEND

t

SK

SD

Blanking

HIGH

SD

Last restrike valid cycle

LOW

Frequency status

The controller repeats the f

Following a non strike situation, the controller goes in a full STOP and can be reinitialized by either pulling the VDD pin 1 to ground or by forcing a low to the RESET

pin 9. The controller assumes the lamp has struck when a negative going transient is applied on the STRIKE detection pin 10. On the other hand, in order to avoid false

strike information, the controller force a blank time between the end of t

Output

FSweep FSweep FSweep

tSF: Sweep Frequency time. This time is given by the RC network built with C

tSK: Sweep sequence recycle time. This time is derived by integrating a constant DC current in capacitor

C

There is a fixed ratio (ē ) between the preheating time tPH and strike sequence recycle time tSK.

PH.

t

fEND

and the strike sequence until there is a STRIKE signal coming from the external circuit, or until FOUR sequences have been counted.

SWEEP

FSweep

F2

F1

: Time during which f = (f

F2 F1 F2 F1 F2 F3

). This time is equal to tSK – tSF.

ENDSWP

and the start of the next sequence.

SWEEP

SWEEP

time

and RPH.

Figure 11. TIMING DIAGRAM (no strike conditions)

5

4.5

I = V/√ [(R2 + (Lw – 1/Cw)2]

4

3.5

I = V/√ [(R2 + (Lw)2]

Z @ RLCF

Z = Lw

3

2.5

2

Current (A)

1.5

1

0.5

0

5000

9000

13000

17000

21000

25000

29000

33000

37000

41000

45000

49000

53000

57000

61000

Frequency (F)

Figure 12. OUTPUT = f (freq) @ Lc = 1.5 mH, Cs = 6.8 nF

http://onsemi.com

9

65000

69000

73000

77000

93000

81000

85000

89000

97000

Page 10

C3

10 F/25 V

m

MC33157

+400 V

R3

C4

R4

72116

I

C2

C1

R2

R1

C6

R5

Typical Values for FPH = 70 kHz, FOP = 45 kHz, tPH = 2 s, t

T1 Np = R1 390 k

Ns = R2 62 k

Lp = 150 mH R3 100 kW – 0.5 W C3 10 mF/25 V/Electrolytic

Q1 MTP6N60E R4 100 k

Q2 MTP6N60E R5 82 K

D1 MUR160RL R6 1 M

D2 MUR120RL R7 68 K

D3 1N4148 R8 68 k

U1 MC33157 R9 22

C

6

0

C

OP

3

C

PH

4

R

PH

5

C

SWP

8

D

TA

RESET GND SD

W

W

W

W

W

W

W

W

+V

REF

MC33157

10 11 9

D1 MUR160

V

DD

U1

= 125 ms

SWEEP

C1 470 nF/25 V/Polyester

C2 470 pF/2%/50 ppm

C4 220 nF/Polyester

C5 100 nF/63 V/Polyester

C6 220 nF/25 V/Polyester

C7 6.8 nF/5%/1000 V

C8 100 nF/400 V/Polyester

C9 100 nF/400 V/Polyester

C10 22 mF/450 V/Electrolytic

C11 100 nF/25 V/Polyester

C12 330 pF/500 V/Polyester

R9

100 nF/400 V

C9

V

HS

V

HO

V

OUT

V

LO

MTP6N60E

15

14

MTP6N60E

12

Q1

Q2

C5 100 nF

330 pF

C12

Ns

Np

C11

C7

T1

D3 1N4148

R8

100 nF

100 nF/400 V

C8

R6

R7

m

22 F/450 V

C10

TO SEE: AN1682 (Using the MC33157 Electronic Ballast Controller)

Figure 13. T ypical Application Schematic Diagram

http://onsemi.com

10

Page 11

MC33157

P ACKAGE DIMENSIONS

SO–16L

DW SUFFIX

PLASTIC P ACKAGE

CASE 751G–03

ISSUE B

16 9

M

B

H8X

M

0.25

0.25 B

14X

D

B16X

M

S

A

T

e

A

q

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS.

2. INTERPRET DIMENSIONS AND TOLERANCES

PER ASME Y14.5M, 1994.

E

_

h X 45

81

B

S

A

L

A1

T

SEATING

PLANE

C

3. DIMENSIONS D AND E DO NOT INLCUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 2.35 2.65

A1 0.10 0.25

B 0.35 0.49

C 0.23 0.32

D 10.15 10.45

E 7.40 7.60

e 1.27 BSC

H 10.05 10.55

h 0.25 0.75

L 0.50 0.90

q

0 7

__

http://onsemi.com

11

Page 12

MC33157

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

USA/EUROPE Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line*: 303–675–2167

800–344–3810 Toll Free USA/Canada

*To receive a Fax of our publications

N. America Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5487–8345

Email: r14153@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local Sales Representative.

MC33157/D

12

Loading...

Loading...