Page 1

SEMICONDUCTOR TECHNICAL DATA

1

REV 1

Motorola, Inc. 1997

1/97

The MC1658 is a voltage–controlled multivibrator which provides

appropriate level shifting to produce an output compatible with MECL III

and MECL 10,000 logic levels. Frequency control is accomplished

through the use of voltage–variable current sources which control the

slew rate of a single external capacitor.

The bias filter may be used to help eliminate ripple on the output

voltage levels at high frequencies and the input filter may be used to

decouple noise from the analog input signal.

Pinout: 16–Lead Package (Top View)

1516 14 13 12 11 10

21 34567

NC

9

8

NC CX2 INF BIAS CX1 NC NC

V

CC1VCX

NC Q

V

CC2

QNCV

EE

VCX 2

CX1 11

Bias Filter

Input Filter

CX2 14

Q

Q

6

4

V

CC1

= Pin 1

V

CC2

= Pin 5

VEE = Pin 8

LOGIC DIAGRAM

Pin Conversion Table

16 PIN DIP 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

20 PIN PLCC 2 3 4 5 7 8 9 10 12 13 14 15 17 18 19 20

FN SUFFIX

20–LEAD PLCC PACKAGE

CASE 775–02

L SUFFIX

16–LEAD CERAMIC PACKAGE

CASE 620–10

Not Recommended for New Designs

VOLTAGE

CONTROLLED

MULTIVIBRATOR

P SUFFIX

16–LEAD PLASTIC PACKAGE

CASE 648–08

D SUFFIX

PLASTIC SOIC PACKAGE

CASE 751B–05

Page 2

MC1658

MOTOROLA HIPERCOMM

BR1334 — Rev 4

2

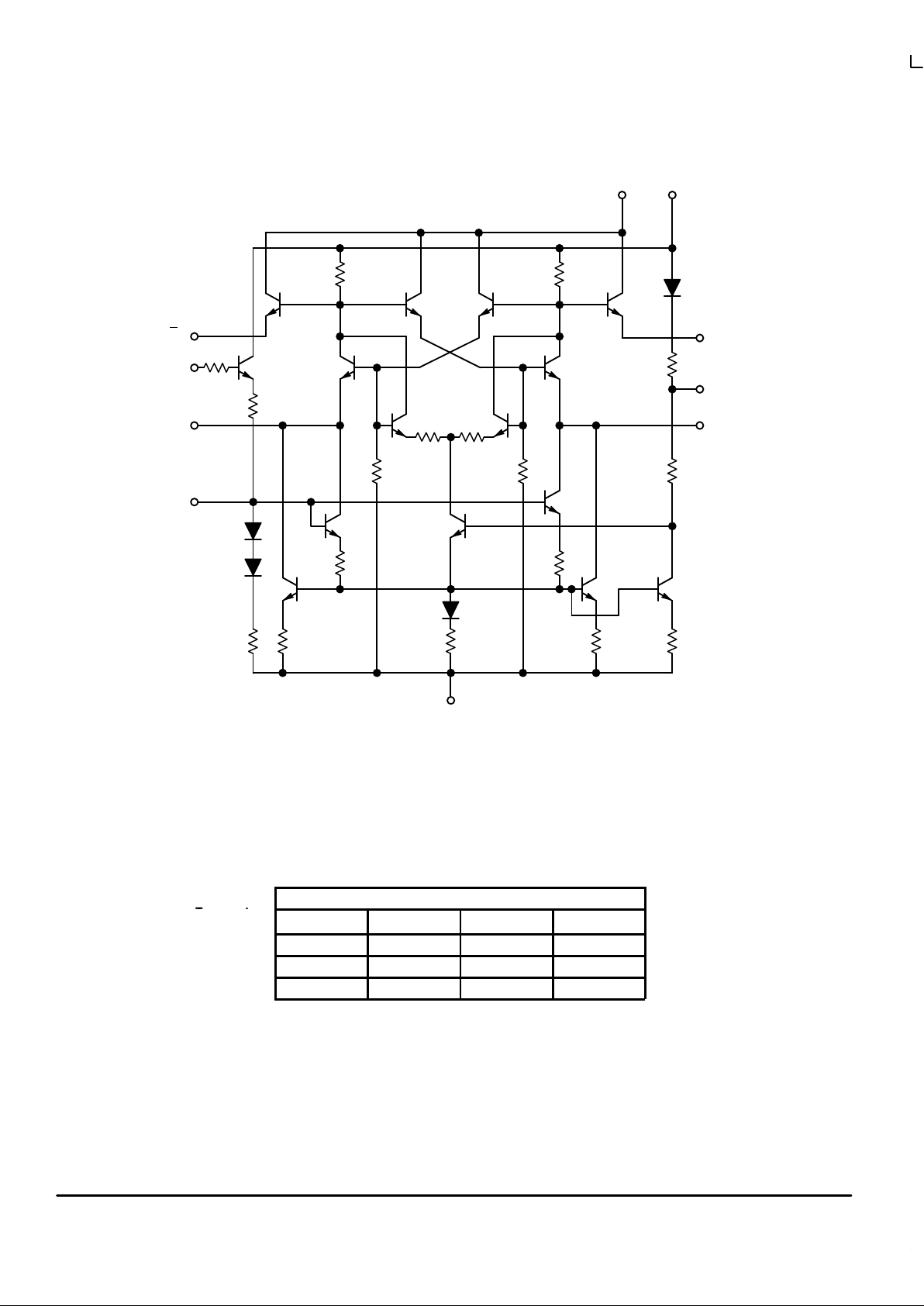

Figure 1. Circuit Schematic

8

V

EE

V

CC2

5

14 CX2

V

CC1

1

12 Bias Filter

6 Q

CX1 11

VCX 2

Q

4

Input Filter 13

500 500 62 500 250

125125

1k1k 250

1000

100100

1k

1k

80 80

TEST VOLTAGE VALUES

@ Test

Vdc ±1%

Temperature

V

IH

V

IL

V

3

I

IHA

–30°C0 –2.0 –1.0 +2.0

+25°C0 –2.0 –1.0 +2.0

+85°C0 –2.0 –1.0 +2.0

Note: SOIC “D” package guaranteed –30°C to +70°C only

Page 3

MC1658

HIPERCOMM

BR1334 — Rev 4

3 MOTOROLA

ELECTRICAL CHARACTERISTICS (VEE = –5.2V, VCC = 0V [GND] )

–30°C +25°C +85°C

Symbol Characteristic Min Max Min Max Min Max Unit Condition

I

E

Power Supply Drain Current – – – 32 – – mAdc VIH to VCX Limit Applies for

1 or 2

I

inH

Input Current – – – 350 – – µAdc VIH to V

CX

1

V

OH

Output Voltage “Q” HIGH –1.045 –0.875 –0.96 –0.81 –0.89 –0.7 Vdc

V3 to VCX. Limits Apply for 1

V

OL

Output Voltage “Q” LOW –1.89 –1.65 –1.85 –1.62 –1.83 –1.575 Vdc

or 2

AC CHARACTERISTICS (VEE = –3.2V, VCC = +2.0V )

–30°C +25°C +85°C Condition

Symbol Characteristic Min Max Min Typ Max Min Max Unit (See Figure 2)

t

+

Rise Time (10% to 90%) – 2.7 – 1.6 2.7 – 3.0 ns

V

IHA

to VCX, CX14 from Pin

t

–

Fall Time (10% to 90%) – 2.7 – 1.4 2.7 – 3.0 ns

11 to Pin 14

f

osc1

Oscillator Frequency 130 – 130 155 175 110 – MHz

f

osc2

– – 78 100 120 – – V

IHA

to VCX, CX25 from

Pin 11 to Pin 14

TR

3

Tuning Ratio Test – – 3.1 4.5 – – – – CX25 from Pin 11 to Pin 14

1 Germanium diode (0.4 drop) forward biased from 11 to 14 (11 14).

2 Germanium diode (0.4 drop) forward biased from 14 to 11 (11

14).

3 TR =

Output frequency at VCX+

GND

Output frequency at VCX+*

2.0V

4 CX1 = 5.0pF connected from pin 11 to pin 14.

5 CX2 = 10pF connected from pin 11 to pin 14.

10%

90%

Figure 2. AC Test Circuit and Waveforms

12

0.01

µ

F

13

0.001

µ

F

2

11

14

Bias Filter

Input Filter

V

CX

CX

CX

C

X

0.1

µ

F

V

CC1

1 5V

CC2

+2.0Vdc

V

CC

0.1µF

6

Channel “A”

Input 2

Coax

Q

4

Channel “B”

Input 2

Q

Coaxial Cables

(Equal lengths, 50

Ω

)

To Scope

V

EE

0.1

µ

F

–3.2Vdc

8

50 ohm termination to ground located in each scope channel input.

All input and output cables to the scope are equal lengths of 50 ohm

coaxial cable. Wire length should be < 1/4 inch from TP

in

to input pin

and TP

out

to output pin.

Note: All power supply and logic levels are shown shifted 2.0V positive.

50%Q

Coax

50%

10%

90%

t

–

50%

Q

50%

t

+

t

–

t

+

Page 4

MC1658

MOTOROLA HIPERCOMM

BR1334 — Rev 4

4

Figure 3. Output Frequency versus Capacitance

for Various Values of Input Voltage

Figure 4. RMS Noise Deviation versus

Operating Frequency

Figure 5. Frequency Capacitance Product versus Control Voltage (VCX)

1000

1

cx (pF)

100

10

1

0.1

10 100 1000 10,000

10,000

0.1

f, OPERATING FREQUENCY (MHz)

f, FREQUENCY DEVIA TION, RMS (Hz)

∆

1000

100

10

1 10 100

1600

–2

VCX, INPUT VOLTAGE (Vdc)

–1.8

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

–1.6 –1.4 –1.2 –1 –0.8 –0.6 –0.4 –0.2 0

cx (pF) = FREQUENCY–CAPACITANCE PRODUCT AT

cx (pF) = DESIRED VCX DESIRED FREQUENCY (MHz)

f

o

•

C

x

; FREQUENCY -CAPACITANCE PRODUCT (MHz-pF)

DC CONTROL INPUT = 4 Vdc

VCX = 0 Vdc

150 MHz @ 5 pF

75 MHz @ 5 pF

35 MHz @ 5 pF

VCX = –2 Vdc

VCX = –1 Vdc

VCC = +5.2 Vdc

VEE = 0 Vdc

VEE = –5.2V, VCC = 0V.

For Use at VEE = 0V, VCC = +5V (V

CXP

= +5V – VCX)

V

CXP

= Positive Input Voltage

Page 5

MC1658

HIPERCOMM

BR1334 — Rev 4

5 MOTOROLA

OUTLINE DIMENSIONS

P SUFFIX

PLASTIC PACKAGE

CASE 648–08

ISSUE R

L SUFFIX

CERAMIC PACKAGE

CASE 620–10

ISSUE V

D SUFFIX

PLASTIC SOIC PACKAGE

CASE 751B–05

ISSUE J

0.25 (0.010) T B A

M

S S

MIN MINMAX MAX

MILLIMETERS INCHES

DIM

A

B

C

D

F

G

J

K

M

P

R

9.80

3.80

1.35

0.35

0.40

0.19

0.10

0

°

5.80

0.25

10.00

4.00

1.75

0.49

1.25

0.25

0.25

7

°

6.20

0.50

0.386

0.150

0.054

0.014

0.016

0.008

0.004

0

°

0.229

0.010

0.393

0.157

0.068

0.019

0.049

0.009

0.009

7

°

0.244

0.019

1.27 BSC 0.050 BSC

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

1

8

916

–A

–

–B

–

D

16 PL

K

C

G

–T

–

SEATING

PLANE

R X 45°

M

J

F

P 8 PL

0.25 (0.010) B

M M

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

A

B

C

D

F

G

H

J

K

L

M

S

18.80

6.35

3.69

0.39

1.02

0.21

2.80

7.50

0

°

0.51

19.55

6.85

4.44

0.53

1.77

0.38

3.30

7.74

10

°

1.01

0.740

0.250

0.145

0.015

0.040

0.008

0.110

0.295

0

°

0.020

0.770

0.270

0.175

0.021

0.070

0.015

0.130

0.305

10

°

0.040

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. ROUNDED CORNERS OPTIONAL.

2.54 BSC

1.27 BSC

0.100 BSC

0.050 BSC

-A-

B

18

916

F

H

G

D

16 PL

S

C

-T-

SEATING

PLANE

K

J

M

L

TA0.25 (0.010)

M M

19.05

6.10

—

0.39

1.40

0.21

3.18

19.93

7.49

5.08

0.50

1.65

0.38

4.31

0

°

0.51

15

°

1.01

1.27 BSC

2.54 BSC

7.62 BSC

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

0.750

0.240

—

0.015

0.055

0.008

0.125

0.785

0.295

0.200

0.020

0.065

0.015

0.170

0.050 BSC

0.100 BSC

0.300 BSC

A

B

C

D

E

F

G

J

K

L

M

N

0

°

0.020

15

°

0.040

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

4. DIMENSION F MAY NARROW TO 0.76 (0.030)

WHERE THE LEAD ENTERS THE CERAMIC

BODY.

18

916

-A-

-B-

C

KN

G

E

F

D 16 PL

-T-

SEATING

PLANE

M

L

J

16 PL

0.25 (0.010) T A

M

S

0.25 (0.010) T B

M

S

Page 6

MC1658

MOTOROLA HIPERCOMM

BR1334 — Rev 4

6

OUTLINE DIMENSIONS

FN SUFFIX

PLASTIC PLCC PACKAGE

CASE 775–02

ISSUE C

A

B

C

E

F

G

H

J

K

R

U

V

W

X

Y

Z

G1

K1

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

9.78

9.78

4.20

2.29

0.33

0.66

0.51

0.64

8.89

8.89

1.07

1.07

1.07

—

2

°

7.88

1.02

10.03

10.03

4.57

2.79

0.48

0.81

—

—

9.04

9.04

1.21

1.21

1.42

0.50

10

°

8.38

—

0.385

0.385

0.165

0.090

0.013

0.026

0.020

0.025

0.350

0.350

0.042

0.042

0.042

—

2

°

0.310

0.040

0.395

0.395

0.180

0.110

0.019

0.032

—

—

0.356

0.356

0.048

0.048

0.056

0.020

10

°

0.330

—

1.27 BSC0.050 BSC

NOTES:

1. DATUMS -L-, -M-, AND -N- DETERMINED WHERE

TOP OF LEAD SHOULDER EXITS PLASTIC BODY

AT MOLD PARTING LINE.

2. DIM G1, TRUE POSITION TO BE MEASURED AT

DATUM -T-, SEATING PLANE.

3. DIM R AND U DO NOT INCLUDE MOLD FLASH.

ALLOWABLE MOLD FLASH IS 0.010 (0.250) PER

SIDE.

4. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

5. CONTROLLING DIMENSION: INCH.

6. THE PACKAGE TOP MAY BE SMALLER THAN THE

PACKAGE BOTTOM BY UP TO 0.012 (0.300).

DIMENSIONS R AND U ARE DETERMINED AT THE

OUTERMOST EXTREMES OF THE PLASTIC BODY

EXCLUSIVE OF MOLD FLASH, TIE BAR BURRS,

GATE BURRS AND INTERLEAD FLASH, BUT

INCLUDING ANY MISMATCH BETWEEN THE TOP

AND BOTTOM OF THE PLASTIC BODY.

7. DIMENSION H DOES NOT INCLUDE DAMBAR

PROTRUSION OR INTRUSION. THE DAMBAR

PROTRUSION(S) SHALL NOT CAUSE THE H

DIMENSION TO BE GREATER THAN 0.037 (0.940).

THE DAMBAR INTRUSION(S) SHALL NOT CAUSE

THE H DIMENSION TO BE SMALLER THAN 0.025

(0.635).

-N-

Y BRK

-M-

-L-

W

V

D

D

20

1

A

R

Z

C

G

G1

E

J

VIEW S

B

U

Z

G1

X

H

F

VIEW S

K

K1

VIEW D-D

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

SEATING

PLANE

-T-

0.010 (0.250) T L

–M

SNSS

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

0.010 (0.250) T L

–M

SNSS

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

0.004 (0.100)

Loading...

Loading...